Automatic quantitative adding system

An automatic feeding and automatic technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of low adding precision, easy fatigue of components, and difficult adjustment, so as to meet the production process, ensure the quality of electroplating, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below by specific examples.

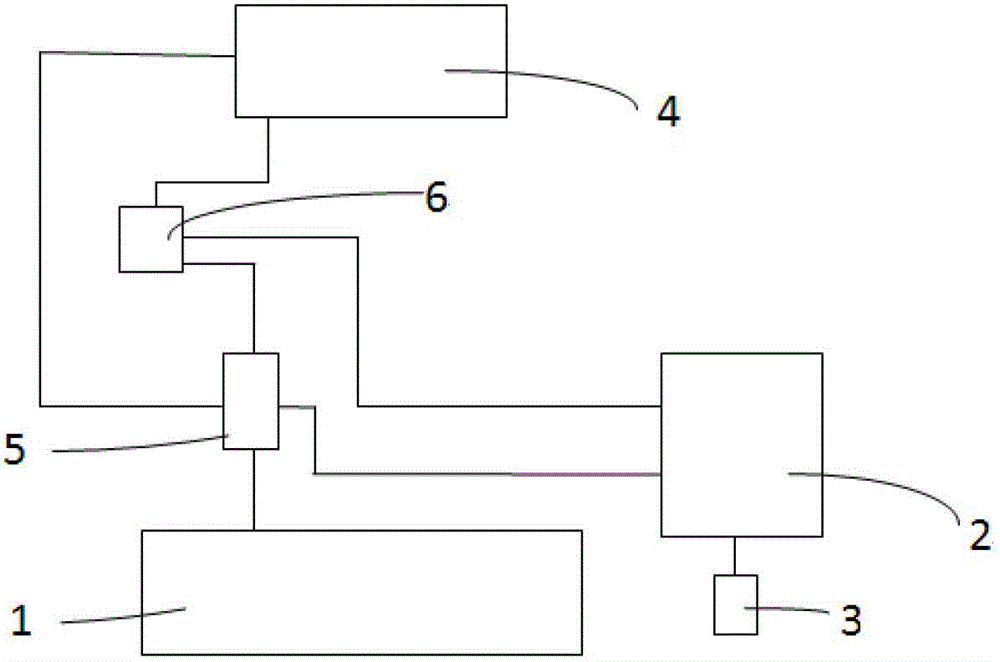

[0021] refer to figure 1 , an automatic quantitative addition system in this embodiment, including an electroplating auxiliary cylinder 1, a PLC controller (programmable controller) 2, a timer 3, an automatic feeding pump 6, a quantitative cup 5 and an additive storage tank 4, the The PLC controller 2 is respectively connected with the automatic feeding pump 6, the timer 3 and the quantitative cup 5 through the lines, and the quantitative cup 5 is respectively connected with the electroplating auxiliary cylinder 1, the auxiliary agent storage tank 4 and the automatic feeding pump 6 through the pipelines, The automatic feeding pump 6 is connected with the auxiliary agent storage tank 4 through pipelines.

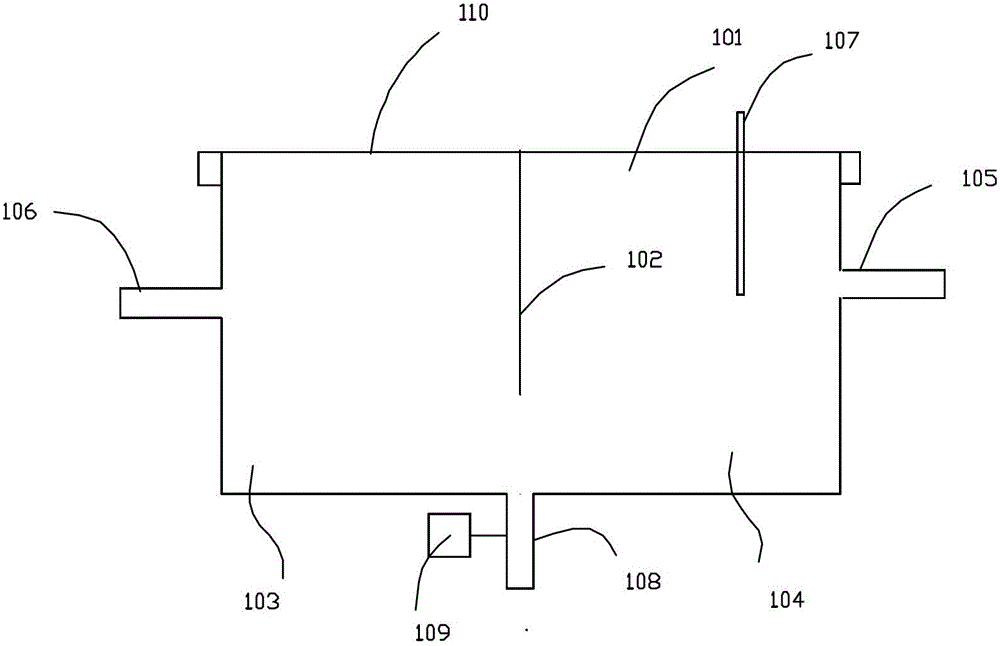

[0022] refer to figure 2 , the quantitative cup includes a cup body 101, and a baffle plate 102 is arranged in the cup body, and the baffle plate 102 divides the cup body into a feed area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com