Electroplating support system for mandrel workpieces

A support system and core rod technology, applied in the field of metallurgy, can solve problems such as difficulty in ensuring the coaxiality of the core rod, affecting the electroplating quality and production efficiency of the mandrel workpiece, and the inability to adjust the height of the mandrel, so as to ensure the quality of electroplating and facilitate adjustment Fast and effective in improving plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; it should be noted that: this embodiment is descriptive, not restrictive, and cannot be used to limit the protection scope of the present invention.

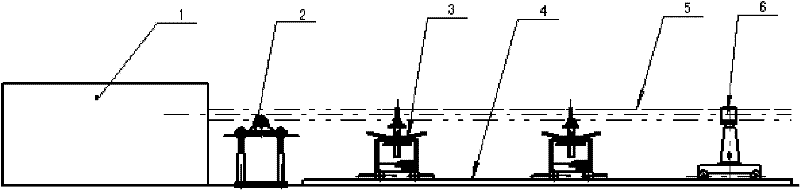

[0024] A mandrel workpiece electroplating support system, consisting of a plating machine 1, a fixed shaft frame 2, a rail trailer 3, and a rail trolley 6, the fixed shaft frame is fixed on the ground foundation in front of the electroplating machine, and the rail trailer and rail trolley are installed on the On the track 4, the fixed axle frame, track trailer and track dolly jointly support the mandrel 5 that will be electroplated in the pull-plating machine in front of the pull-plating machine. The structures of the fixed axle frame, the track trailer and the track dolly are described respectively below.

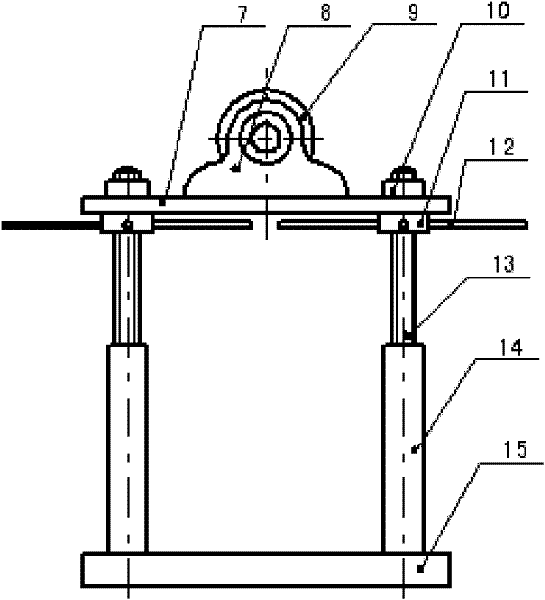

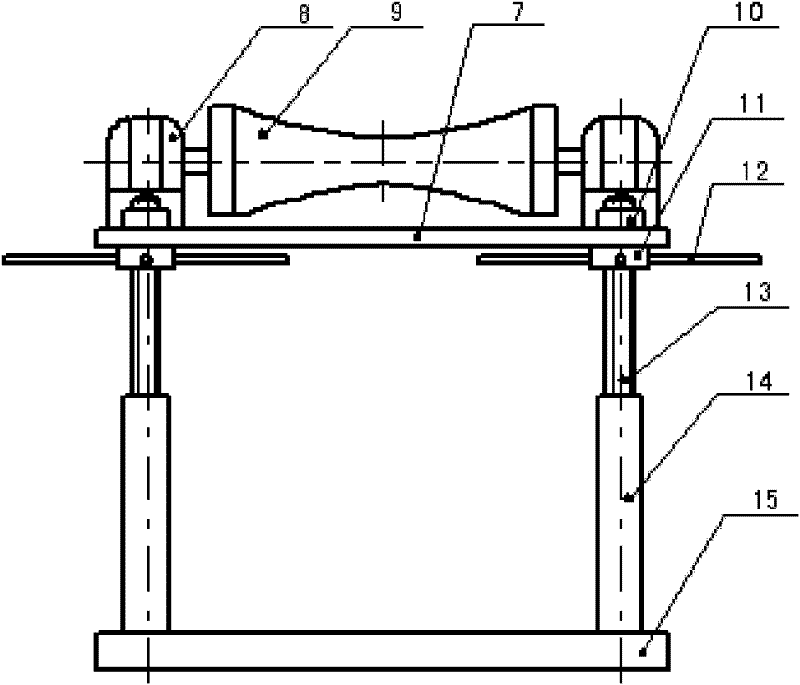

[0025] 1. Fixed shaft frame: it is fixed on the ground foundation in front of the drawing and pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com