Patents

Literature

48results about How to "Guaranteed quality level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

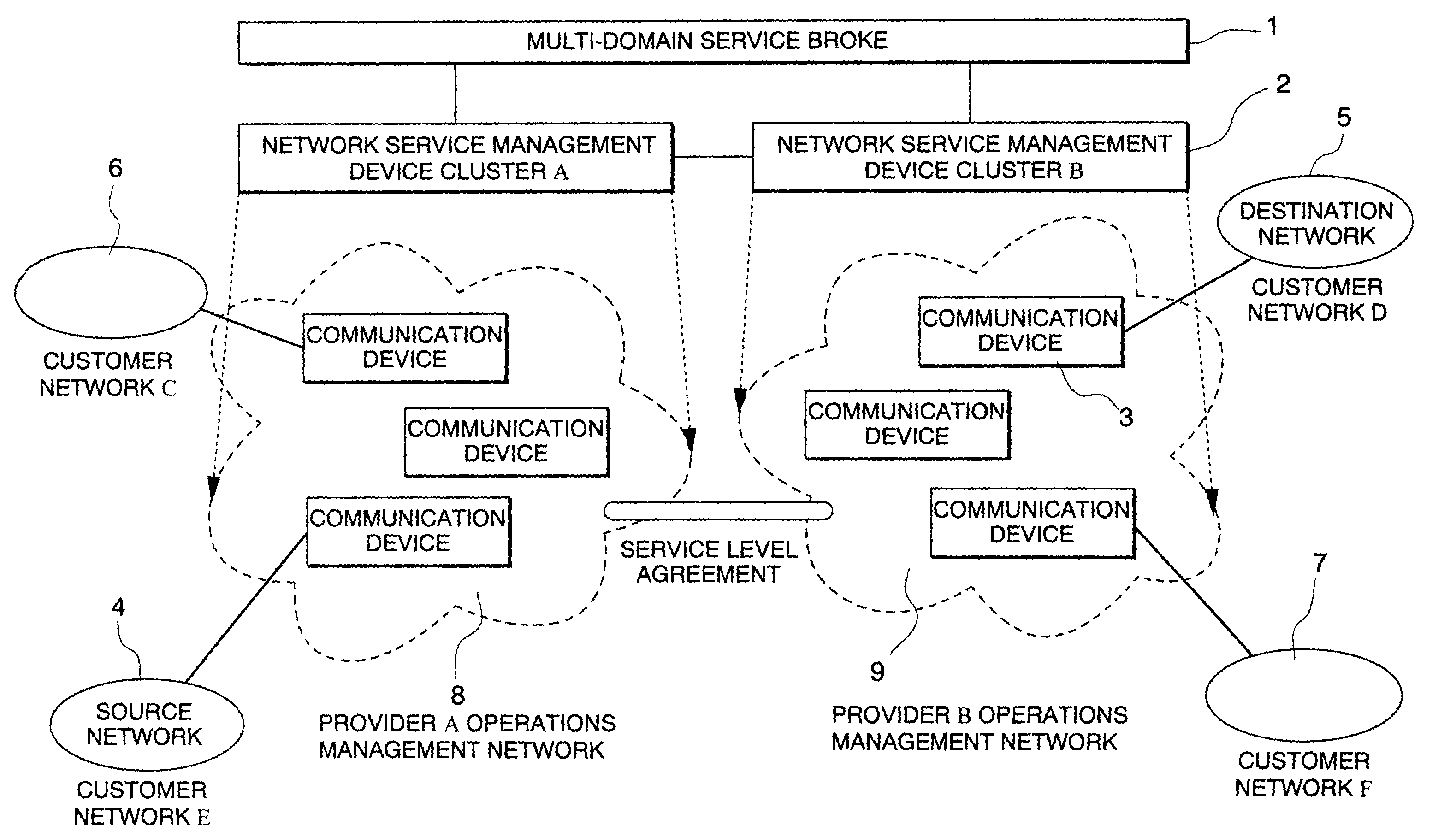

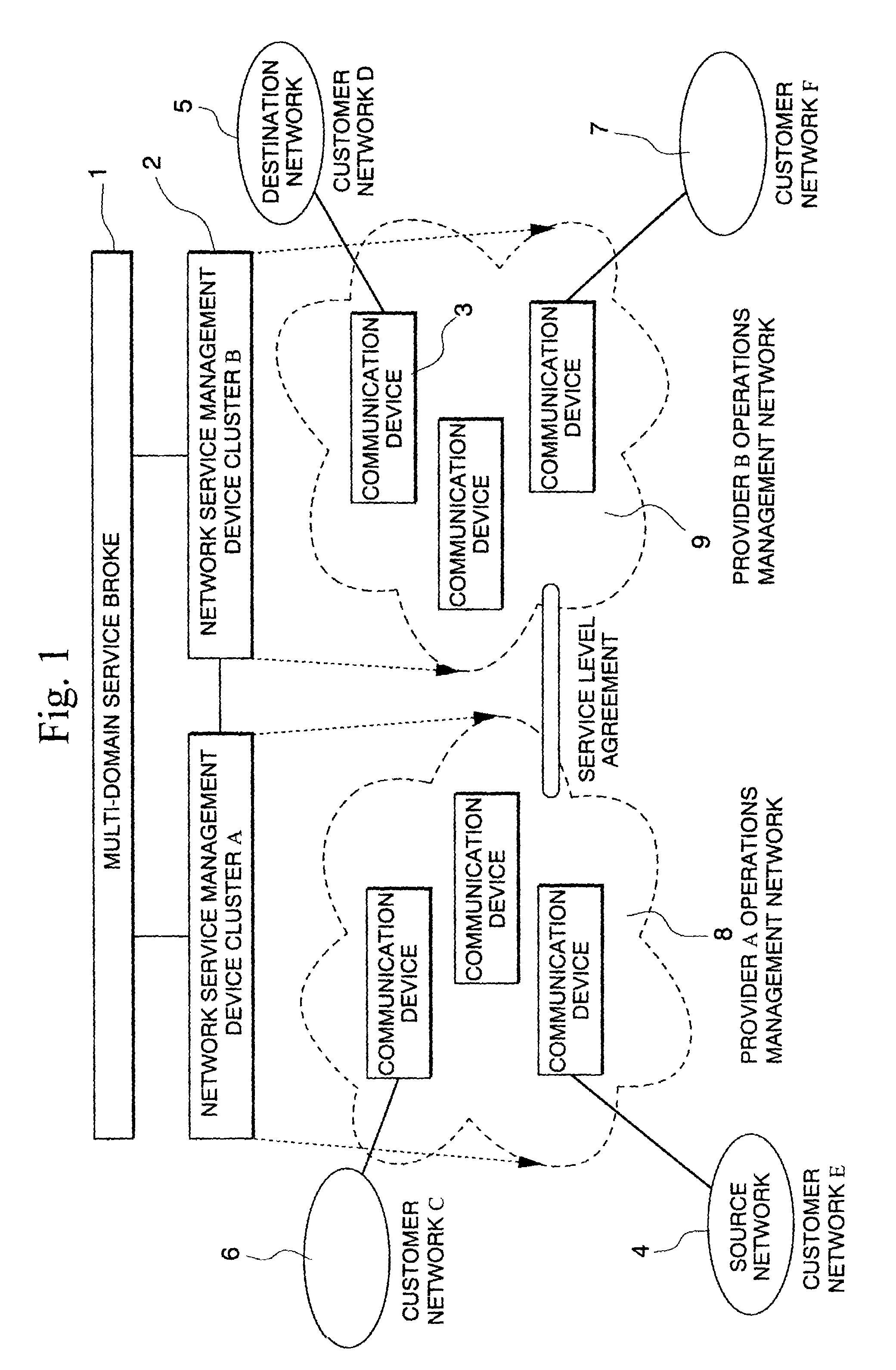

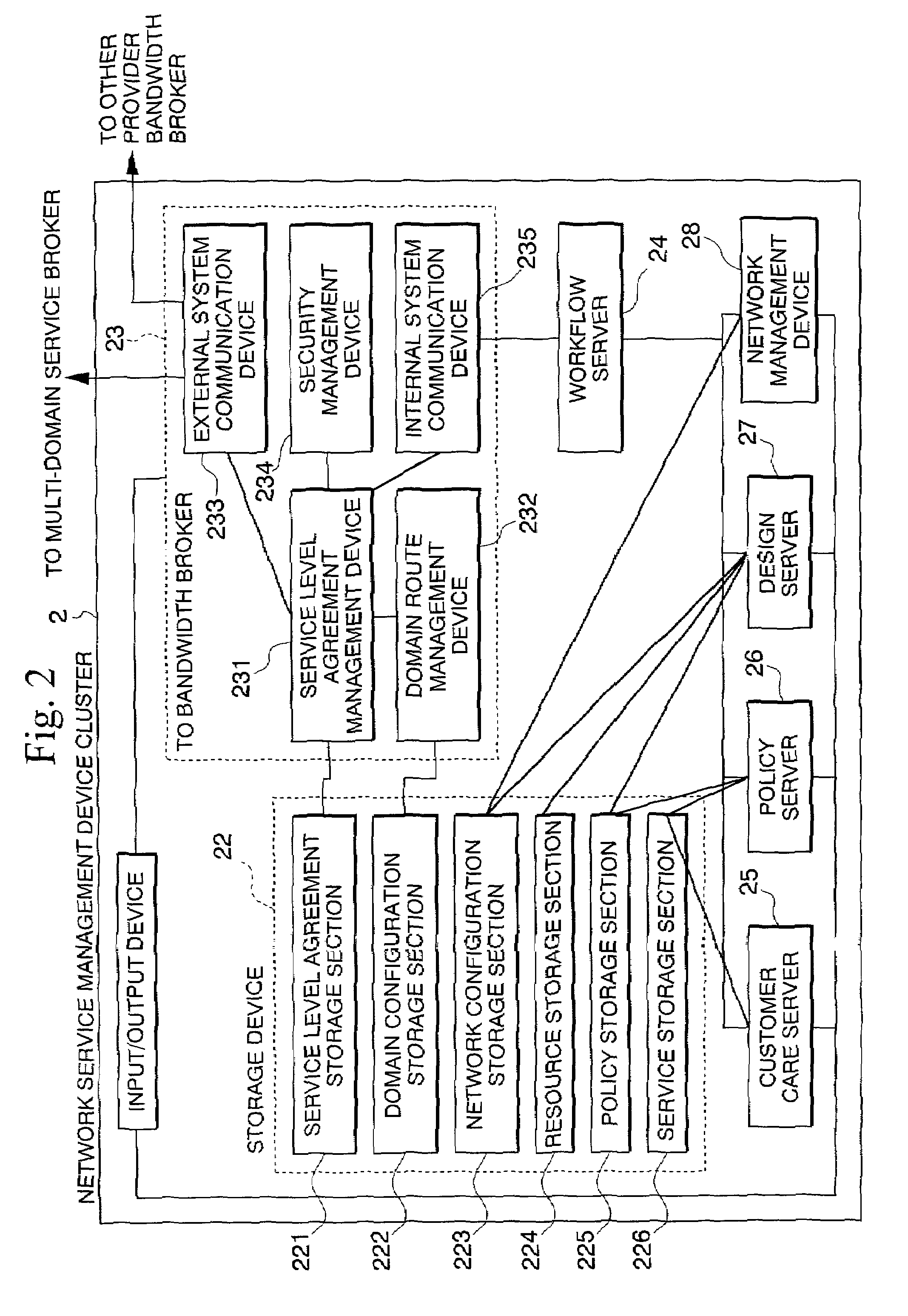

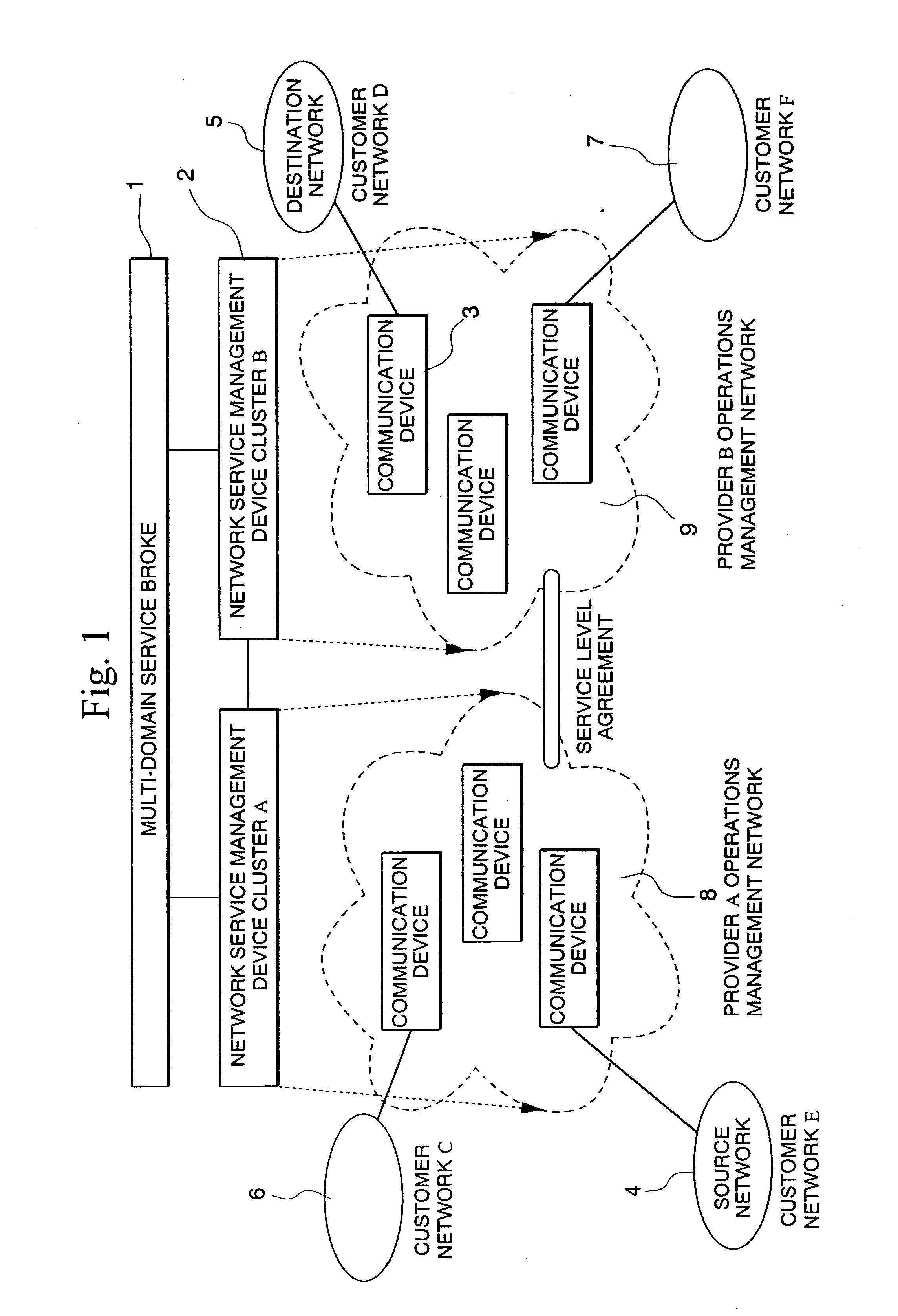

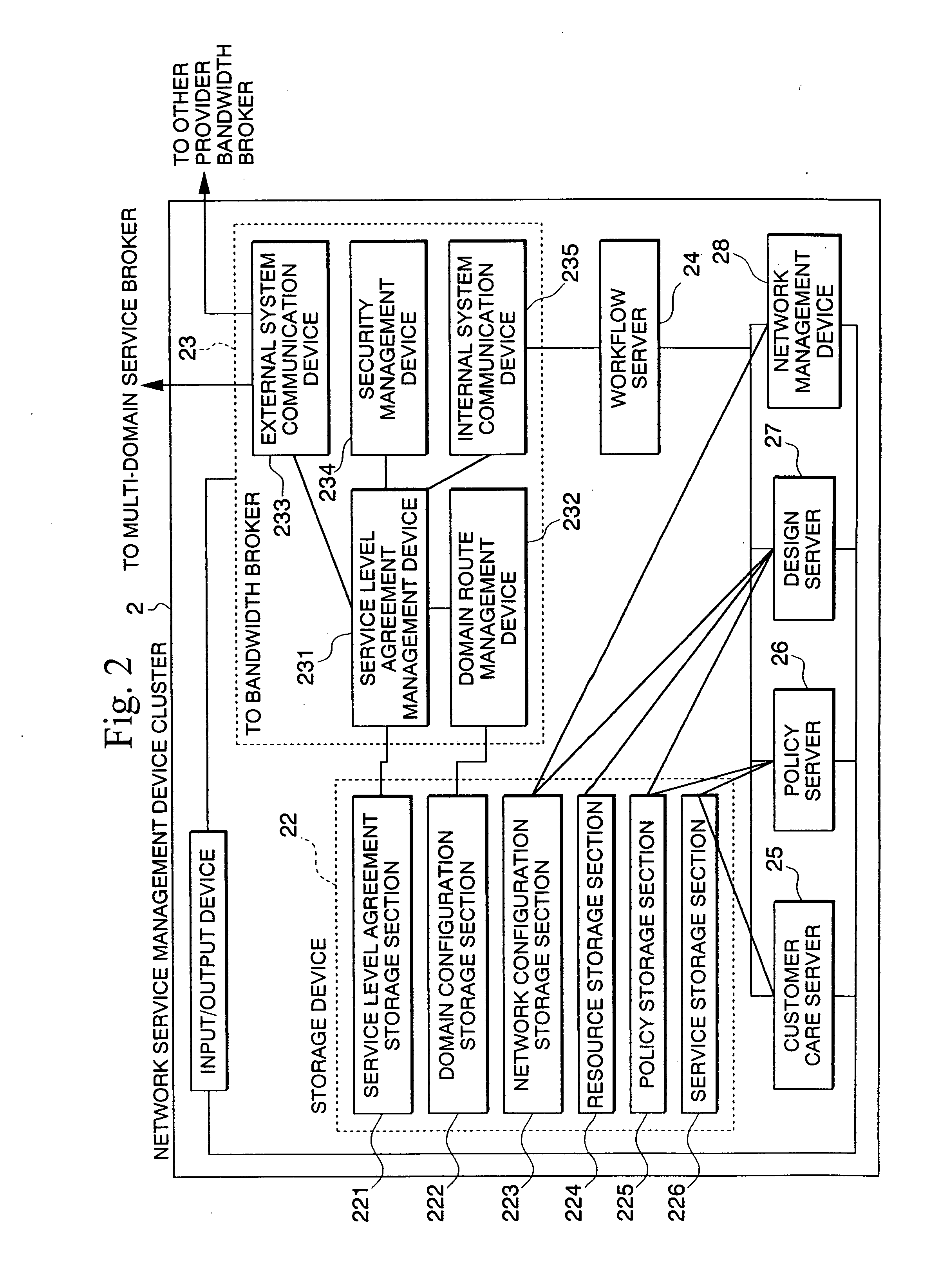

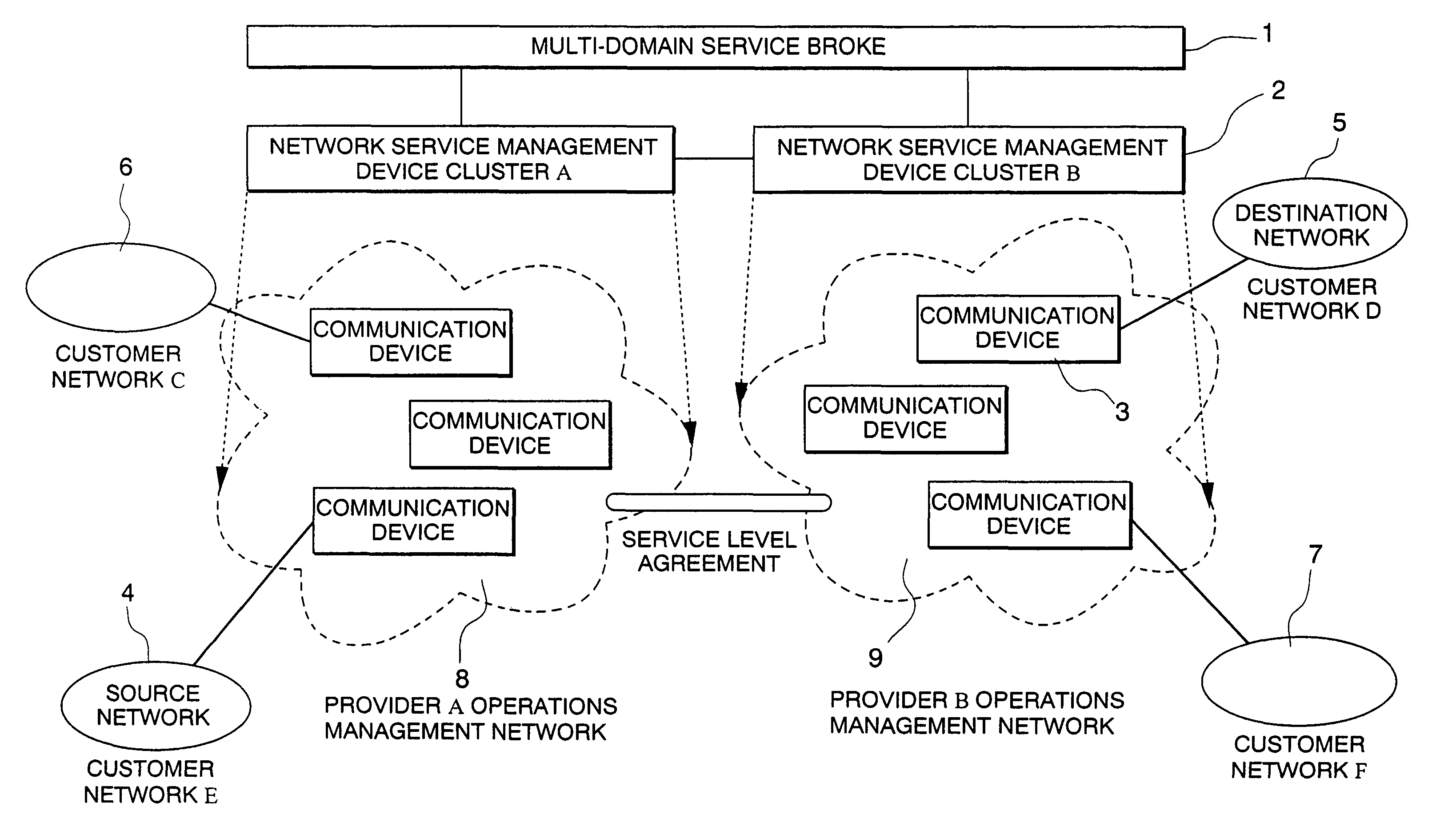

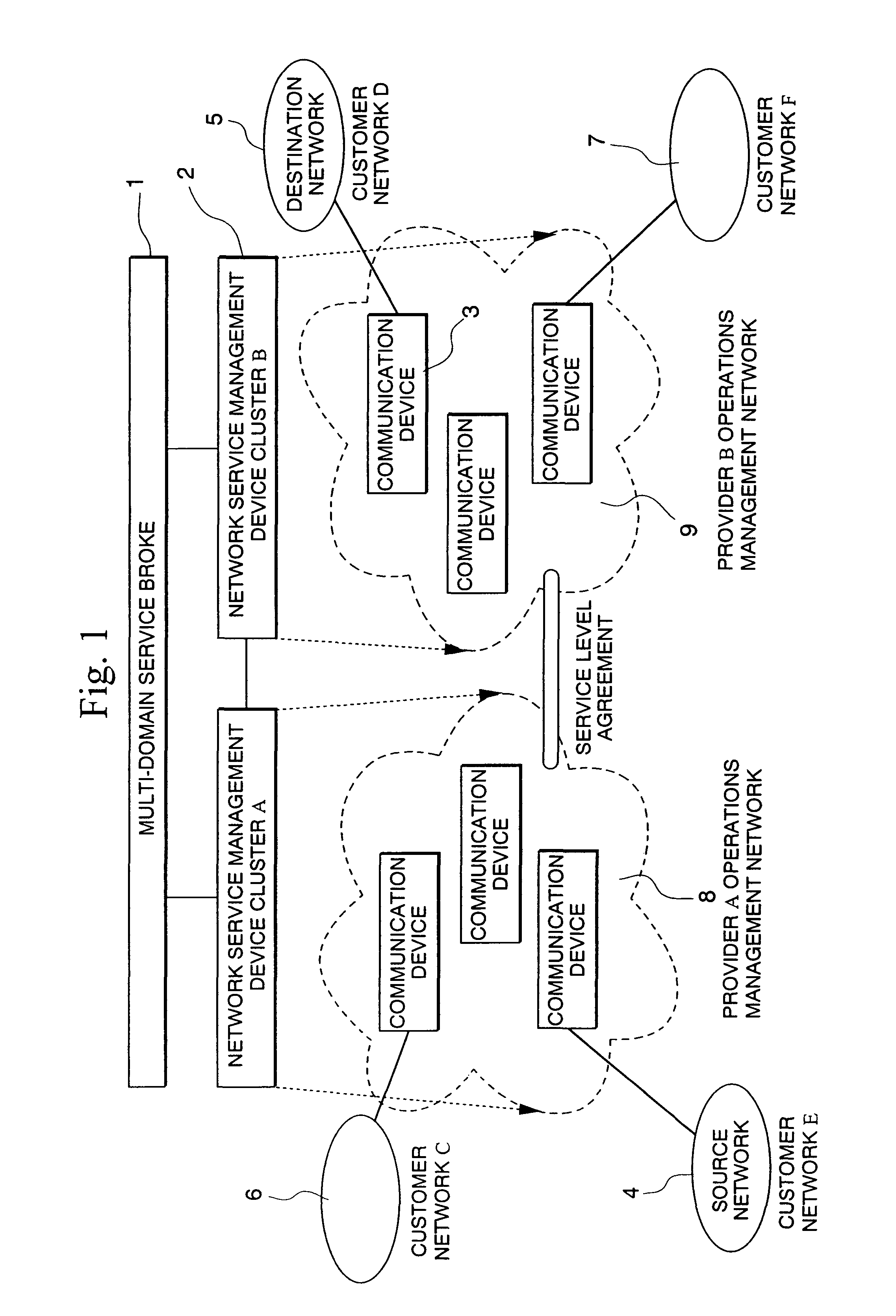

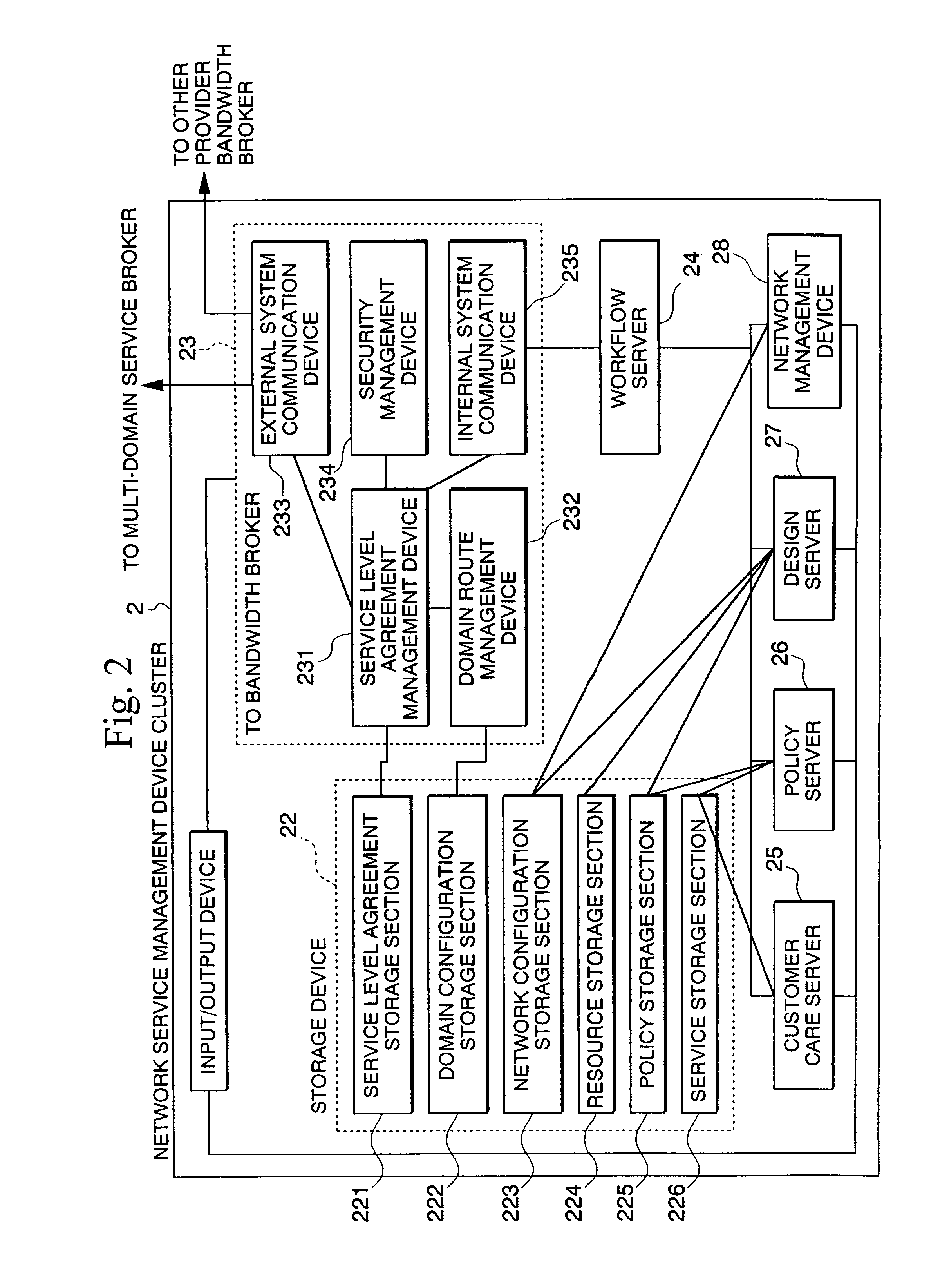

Quality assured network service provision system compatible with a multi-domain network and service provision method and service broker device

InactiveUS7254645B2Guaranteed communication qualityQuality assuranceResource allocationMultiple digital computer combinationsQuality levelService provision

The invention provides quality assured network services in a multi-domain network and comprises a network service management device for managing device clusters incorporated within the operations management network of each provider network and receiving service orders, and a multi-domain service broker for providing a broker function for achieving agreement between a plurality of providers, and the multi-domain service broker further comprises a device for collecting domain information and information relating to the services each provider is able to provide from the network service management devices, and a device which on receipt of a network service request from a customer, extracts the network service management device of the domain which is able to satisfy the required quality level, and then issues instructions for the setting of the required information within the extracted network service management device.

Owner:NEC CORP

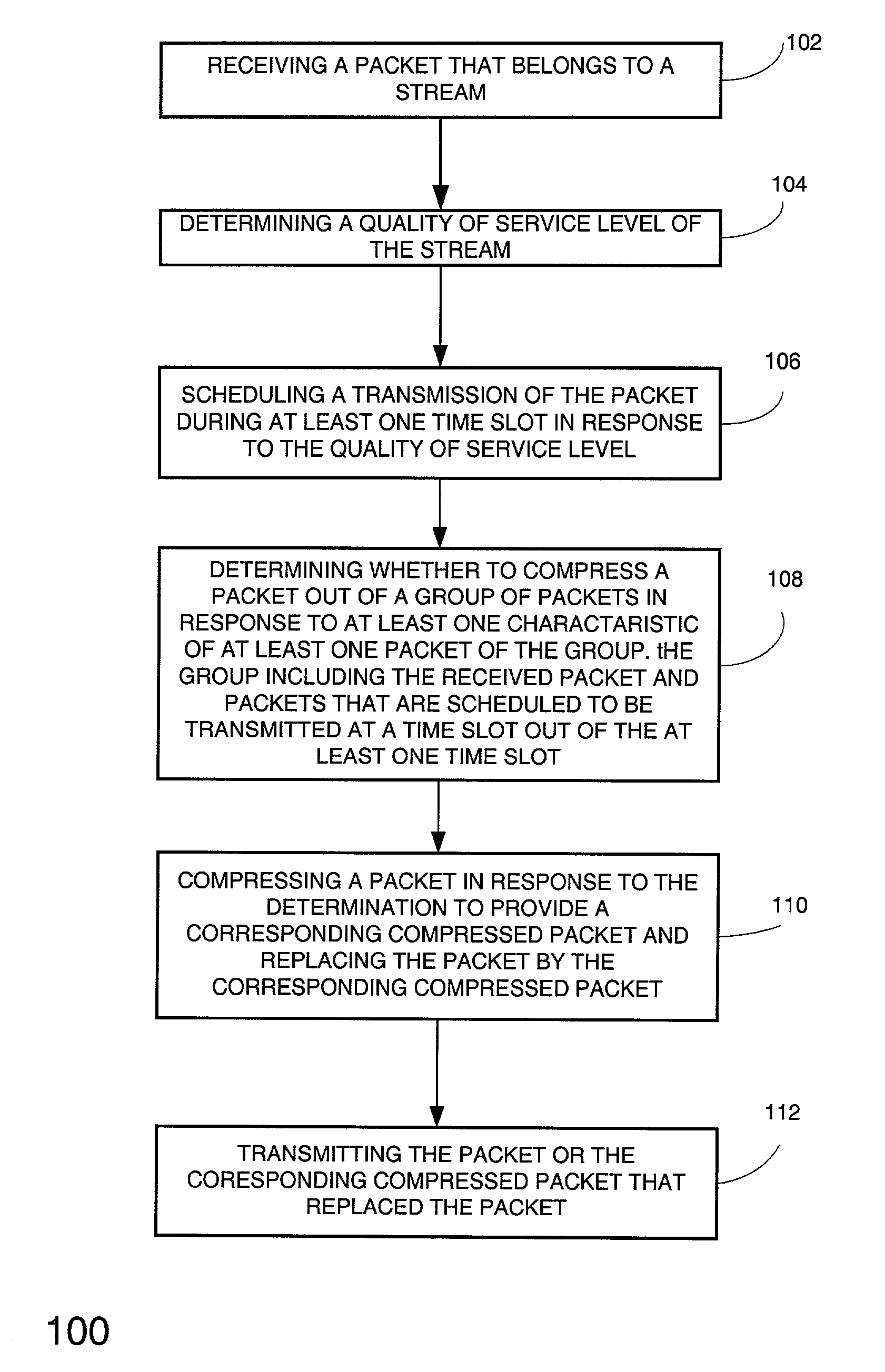

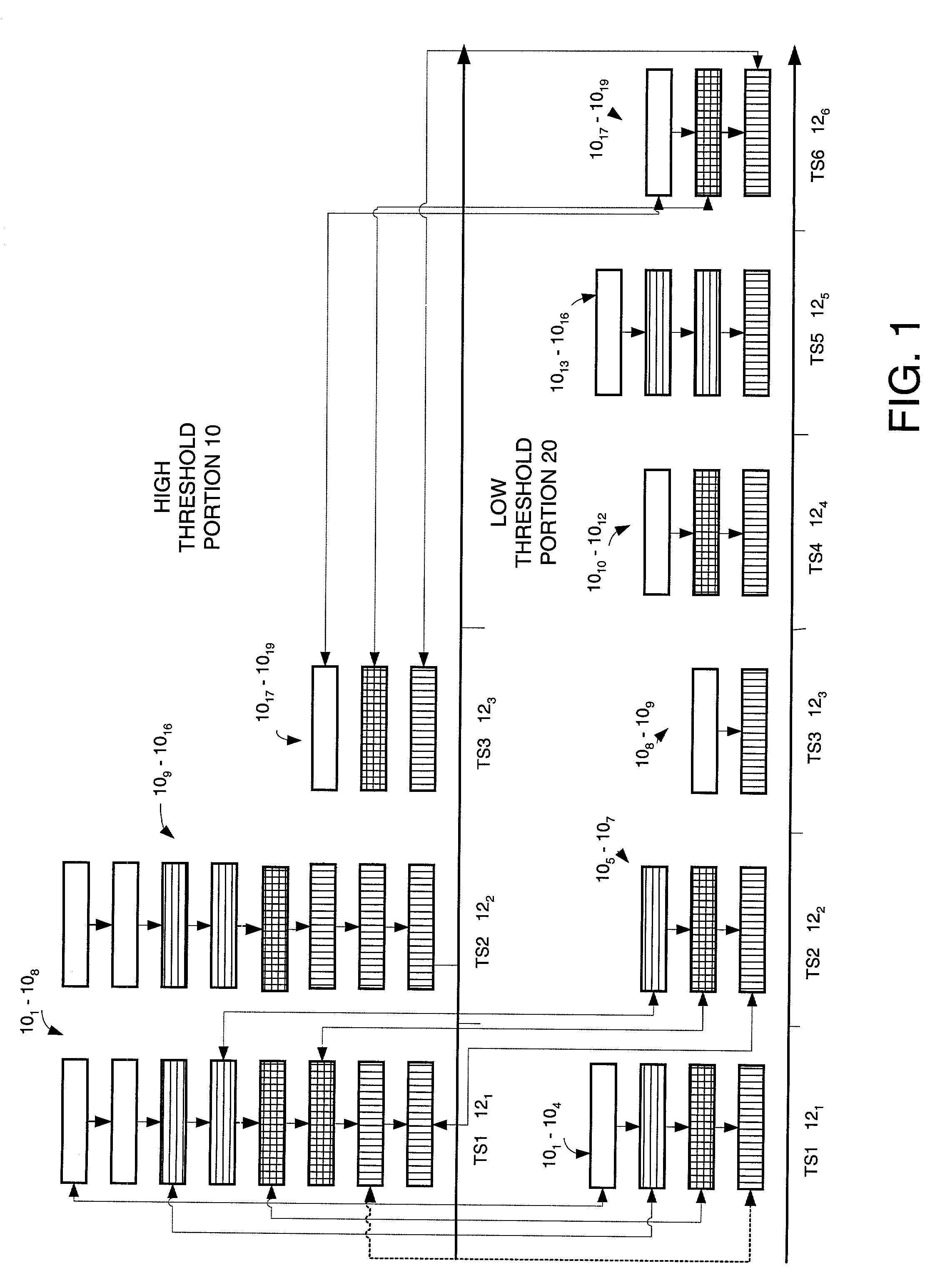

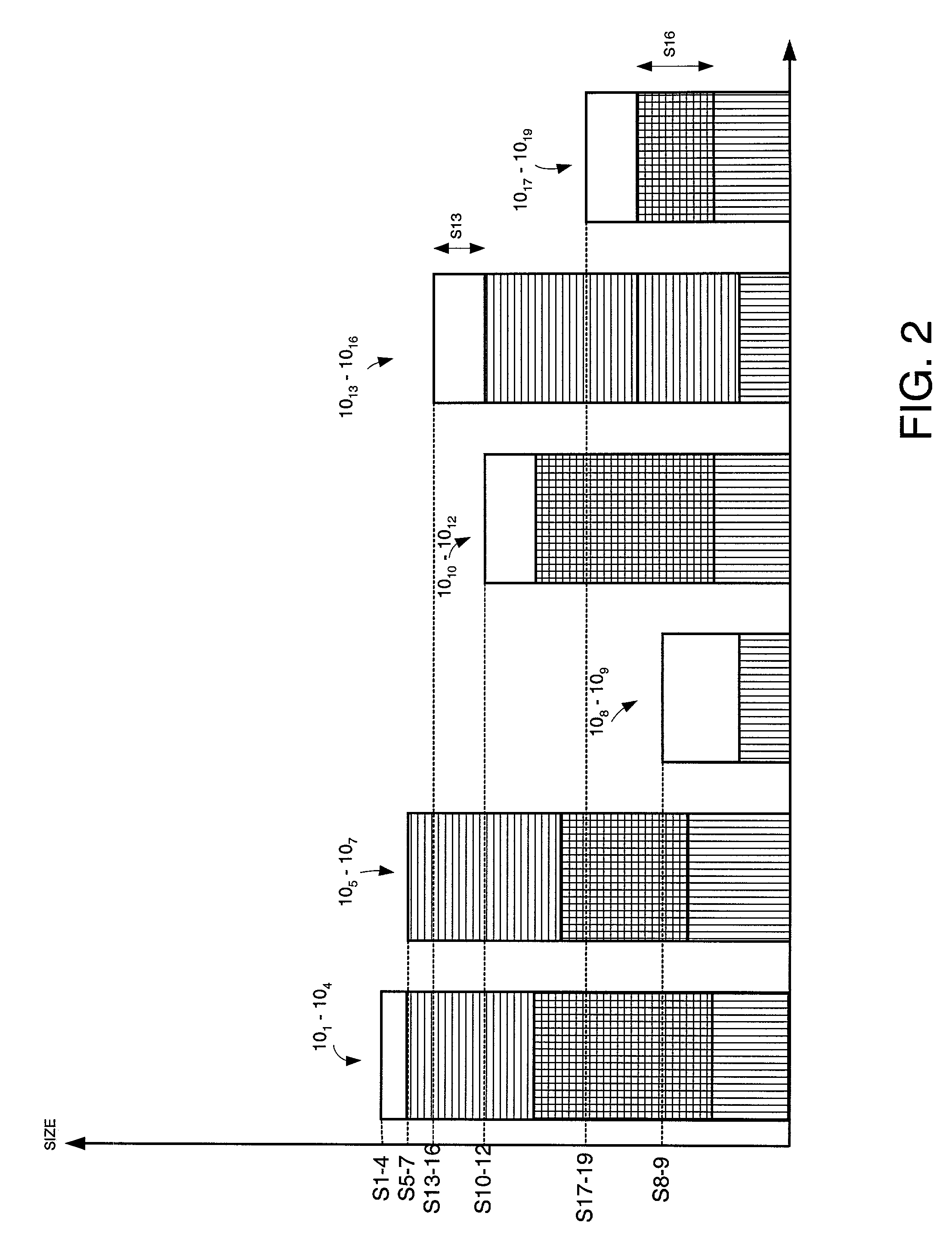

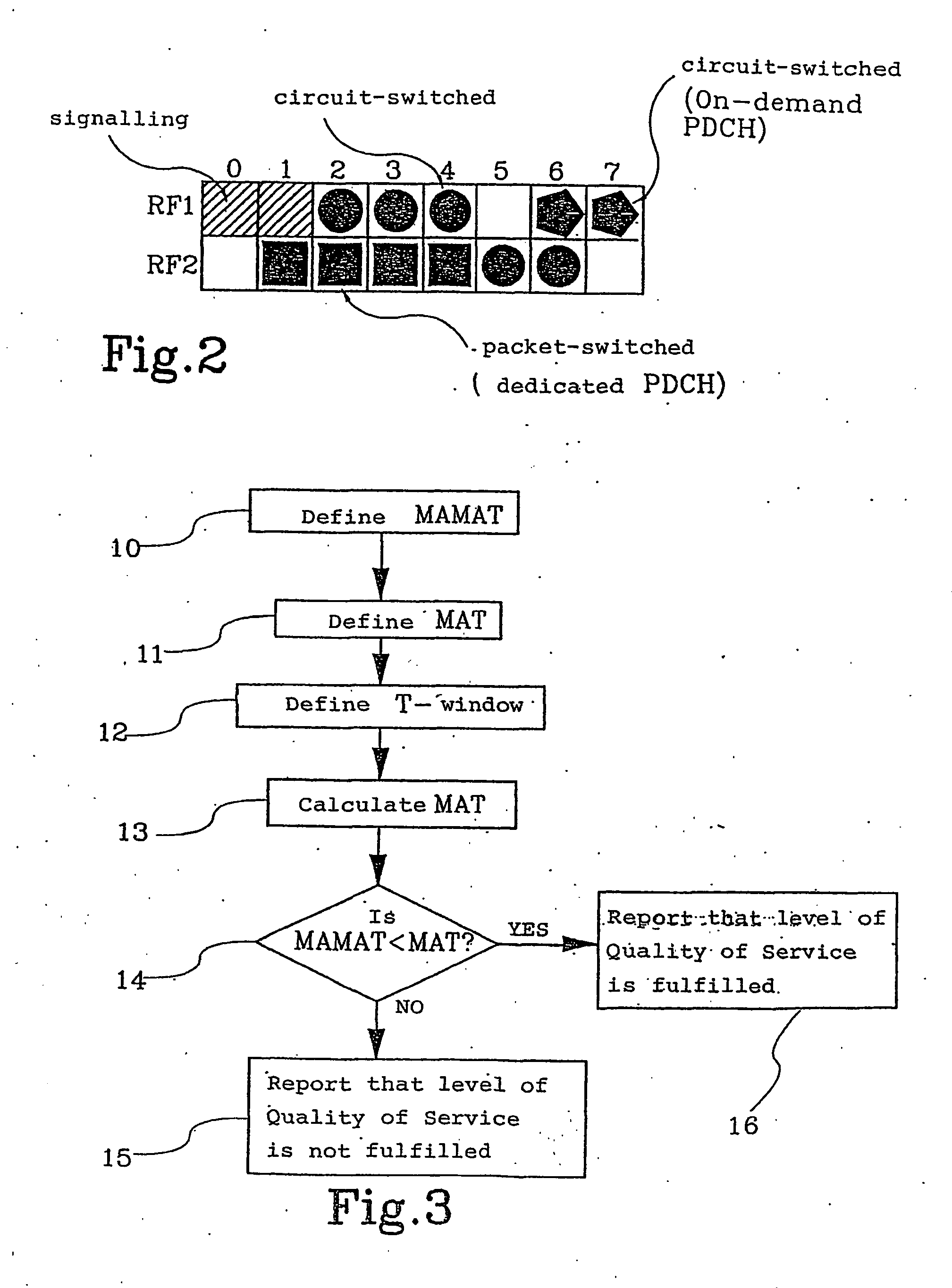

Method and system for scheduling a transmission of compressible and non-compressible packets

InactiveUS7031259B1Guaranteed quality levelError preventionFrequency-division multiplex detailsQuality of servicePacket schedule

A system and method for controlling the transmission of compressible packets, the method including the steps of: (a) receiving a packet that belongs to a stream; (b) determining a quality of service level of the stream; (c) scheduling a transmission of the packet during at least one time slot in response to the quality of service level, and (d) determining whether to compress the packet to provide a corresponding compressed packet, in response to at least one characteristic of at least one packet scheduled to be transmitted during the at least one time slot.

Owner:ARRIS GROUP

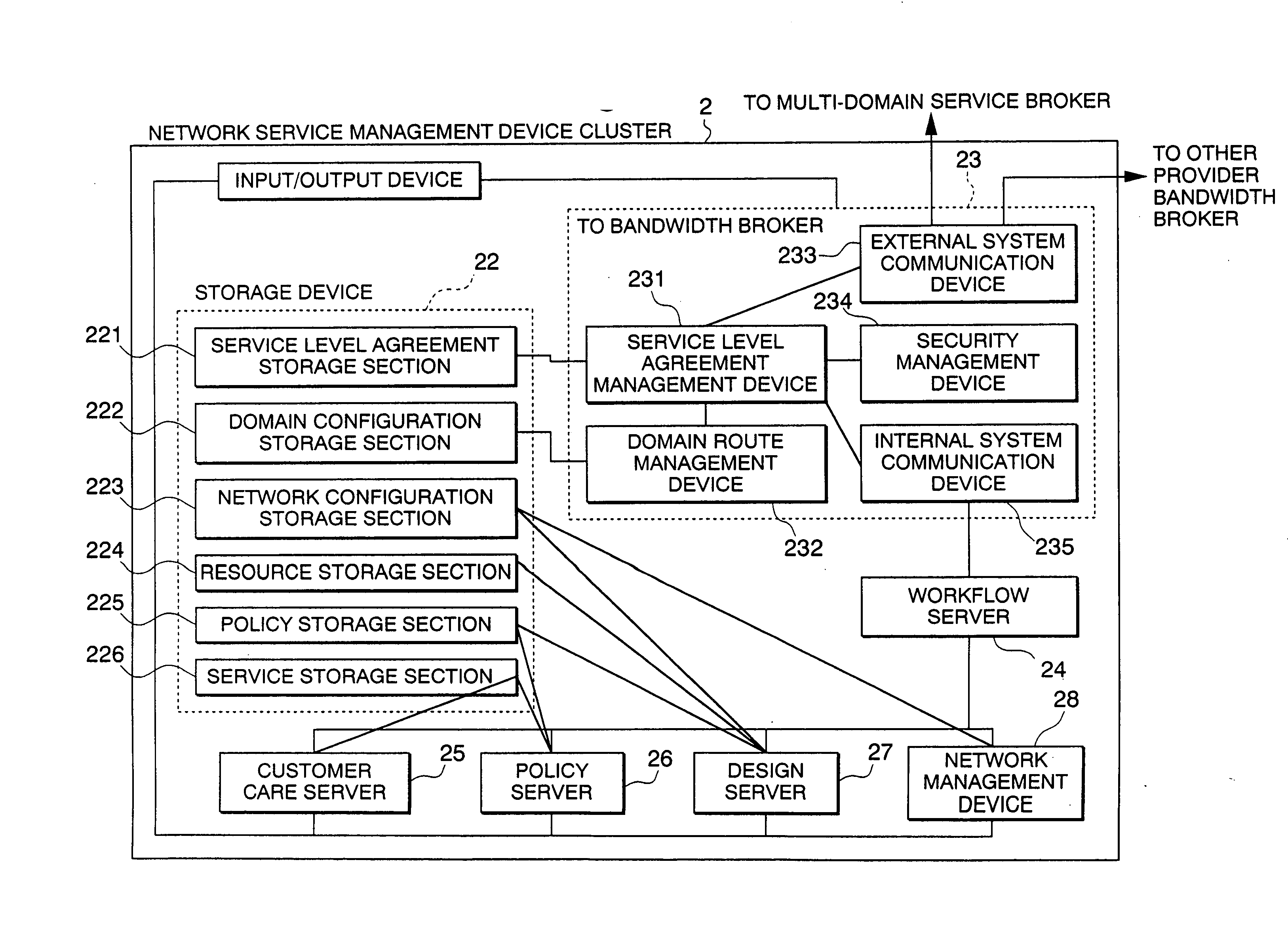

Quality assured network service provision system compatible with a multi-domain network and service provision method and service broker device

InactiveUS20080040469A1Guaranteed quality levelImprove the level ofResource allocationDigital computer detailsQuality levelService provision

The invention provides quality assured network services in a multi-domain network and comprises a network service management device for managing device clusters incorporated within the operations management network of each provider network and receiving service orders, and a multi-domain service broker for providing a broker function for achieving agreement between a plurality of providers, and the multi-domain service broker further comprises a device for collecting domain information and information relating to the services each provider is able to provide from the network service management devices, and a device which on receipt of a network service request from a customer, extracts the network service management device of the domain which is able to satisfy the required quality level, and then issues instructions for the setting of the required information within the extracted network service management device.

Owner:NEC CORP

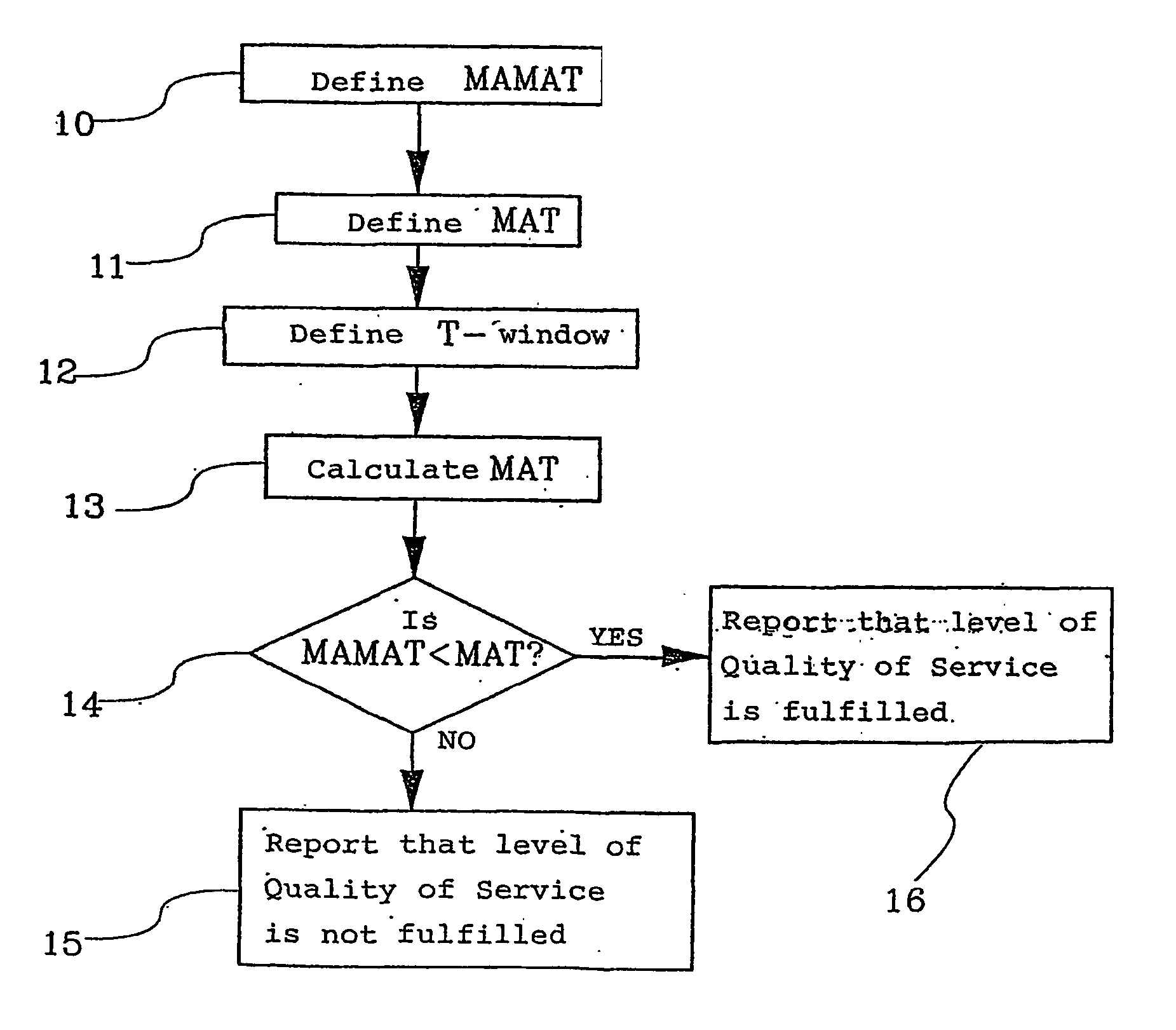

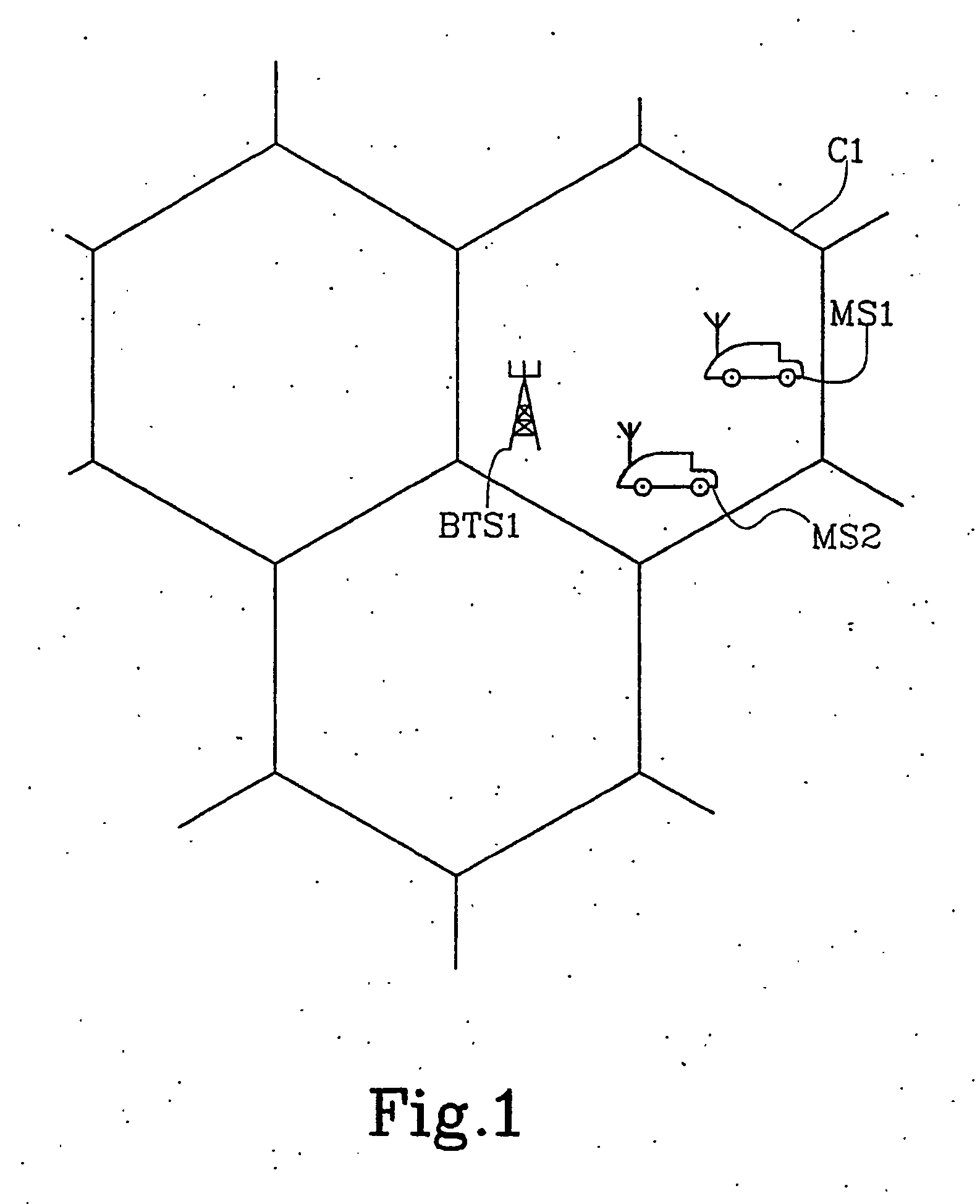

Method in a communication system

InactiveUS20040082324A1Easy to controlGuaranteed quality levelError preventionFrequency-division multiplex detailsQuality of serviceCommunications system

The invention relates to a method for improving the quality of service for data traffic in a mobile communication system, which uses GPRS (General Packet Radio System). The invention may also be used in other types of data networks, using packet switched traffic, e.g. the next generation mobile telecommunication system UMTS. The improvement of the quality of service is attained by defining a number of operator specific parameters, which give better possilibity to monitor and control of the quality of service within an area or for a given user. These parameters are then used by the operator in order to give the user better service. Using this invention the operator may in a better way attain the promised quality of service, both on user and area basis.

Owner:TELEFON AB LM ERICSSON (PUBL)

Quality assured network service provision system compatible with a multi-domain network and service provision method and service broker device

InactiveUS8214533B2Guaranteed quality levelImprove the level ofResource allocationMultiple digital computer combinationsQuality levelService provision

Owner:NEC CORP

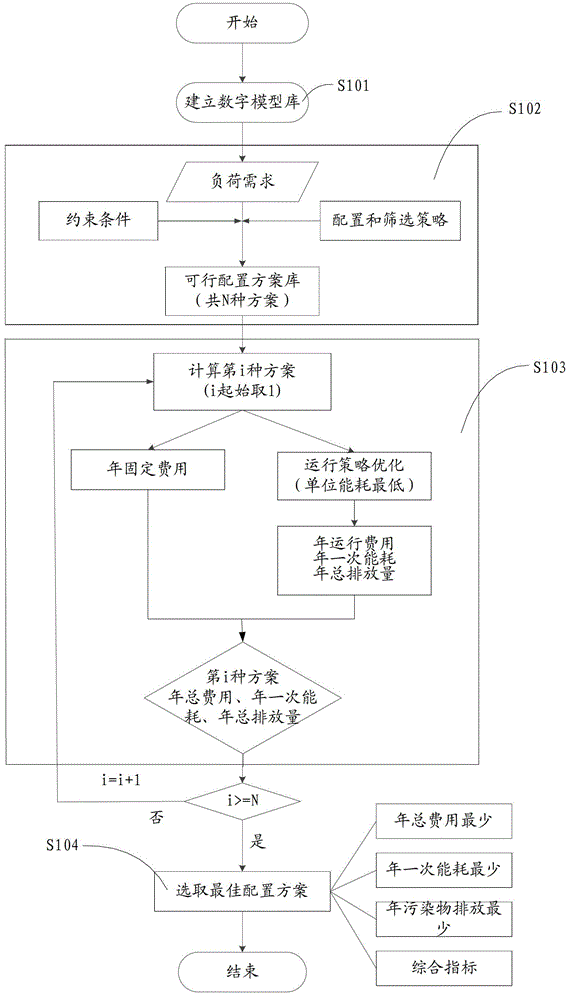

Optimal configuration method of distributed combined cooling heating and power system

InactiveCN103065197AGuaranteed global optimalityOptimized for full time domain coverageSimulator controlEnergy industryPollutant emissionsEngineering

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

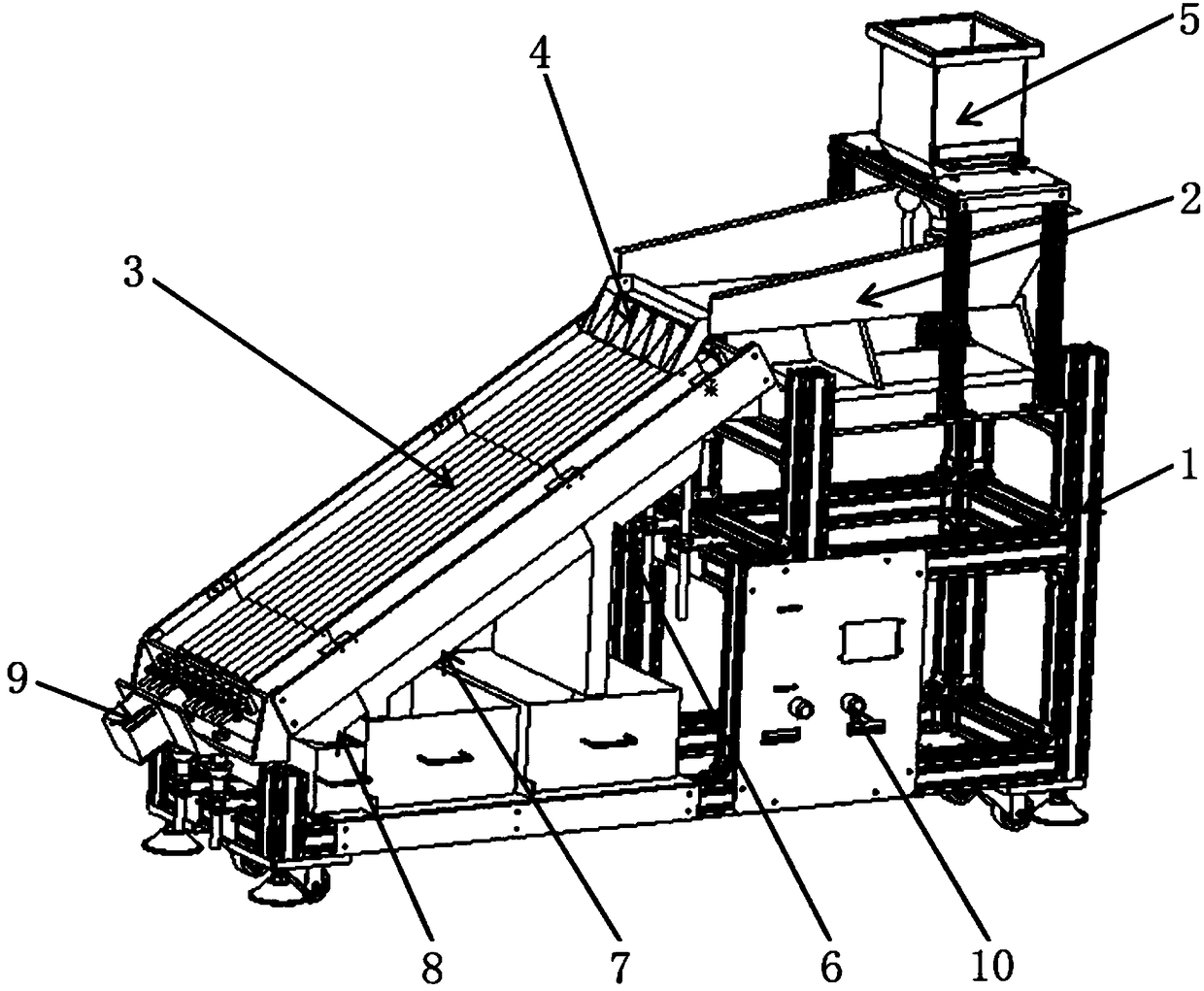

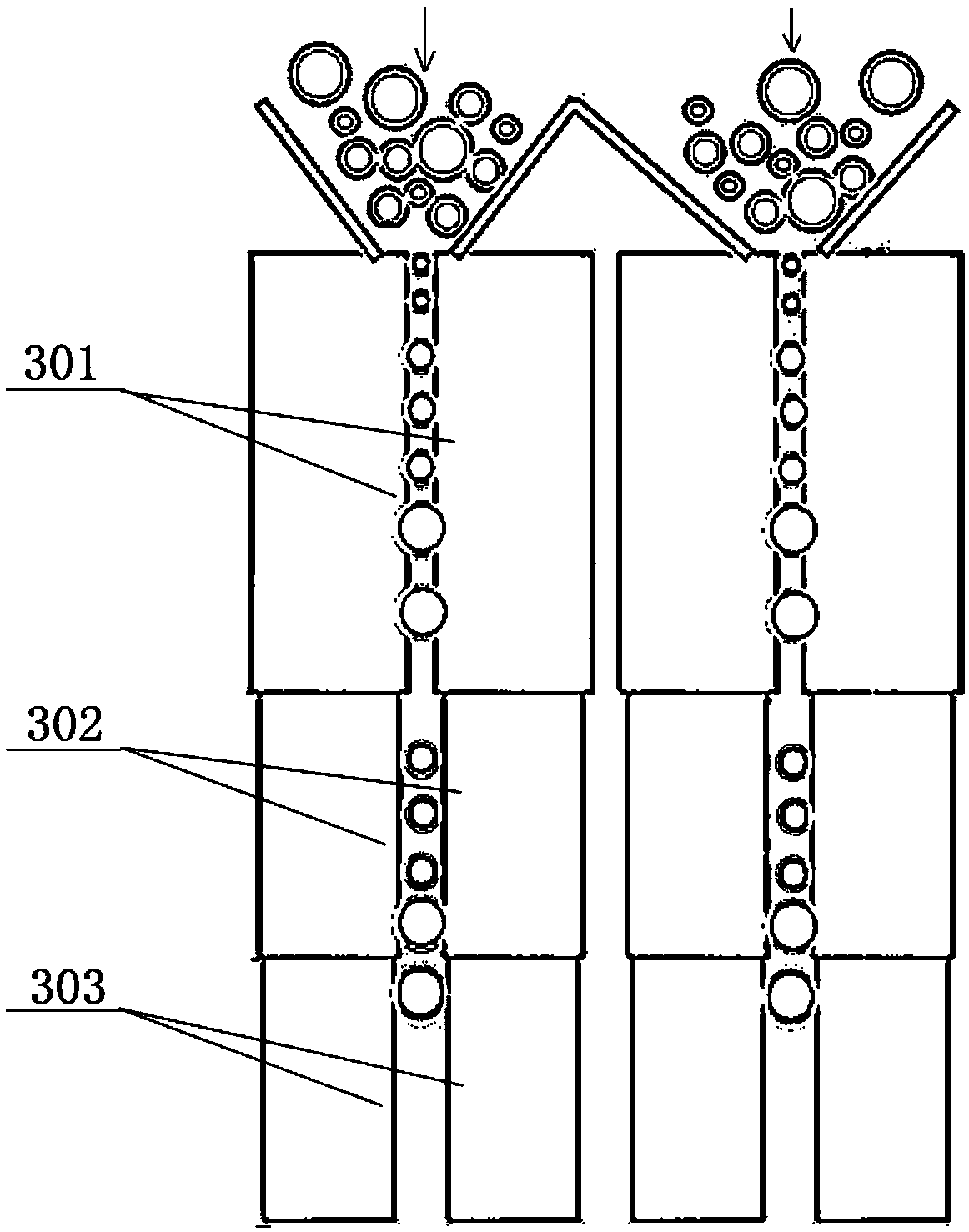

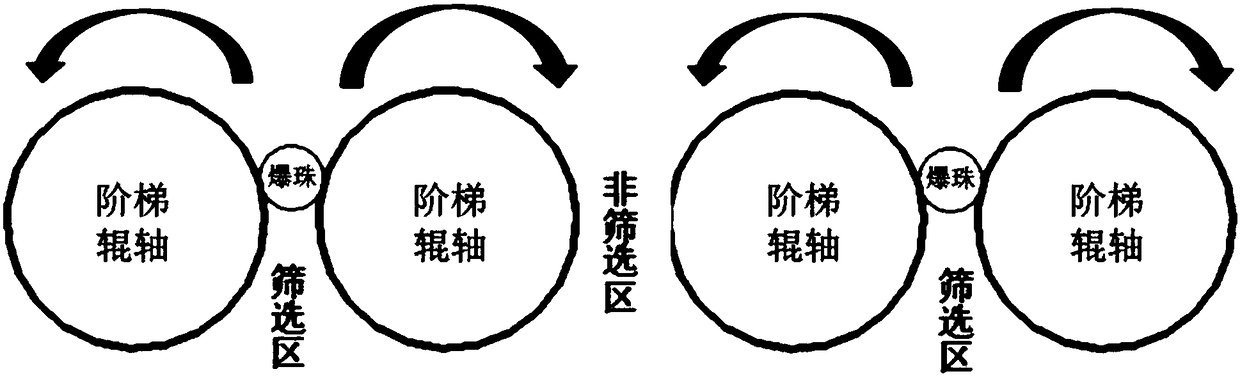

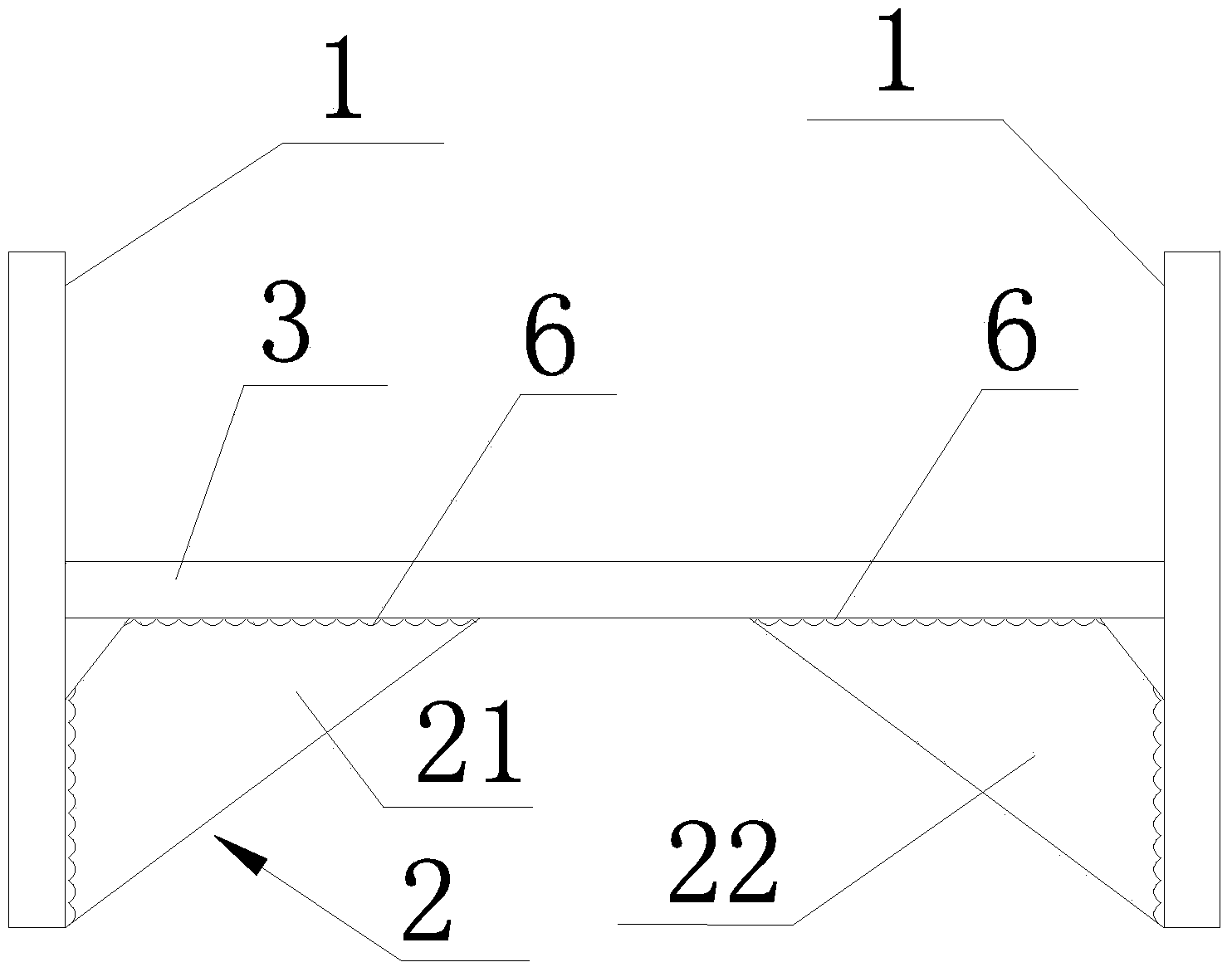

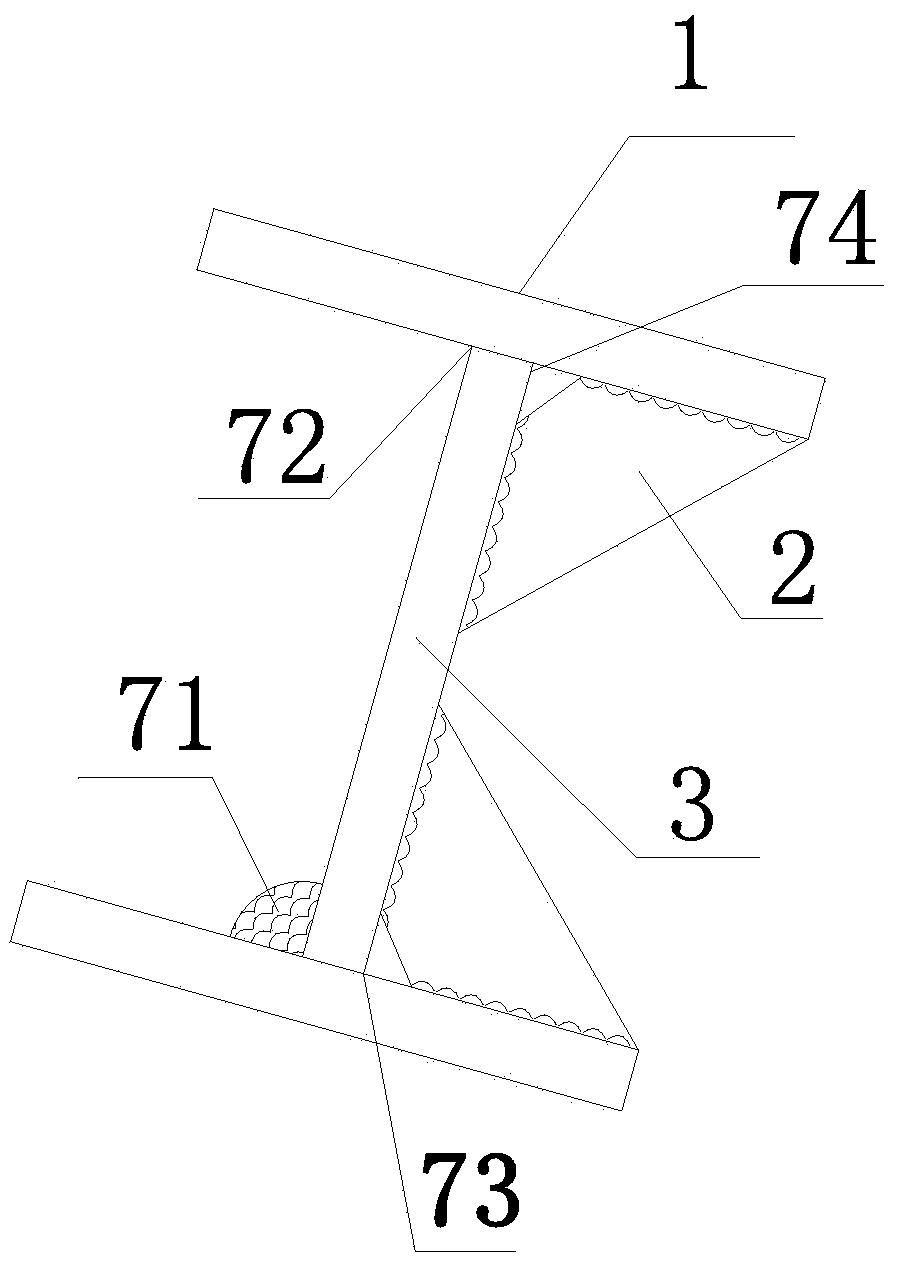

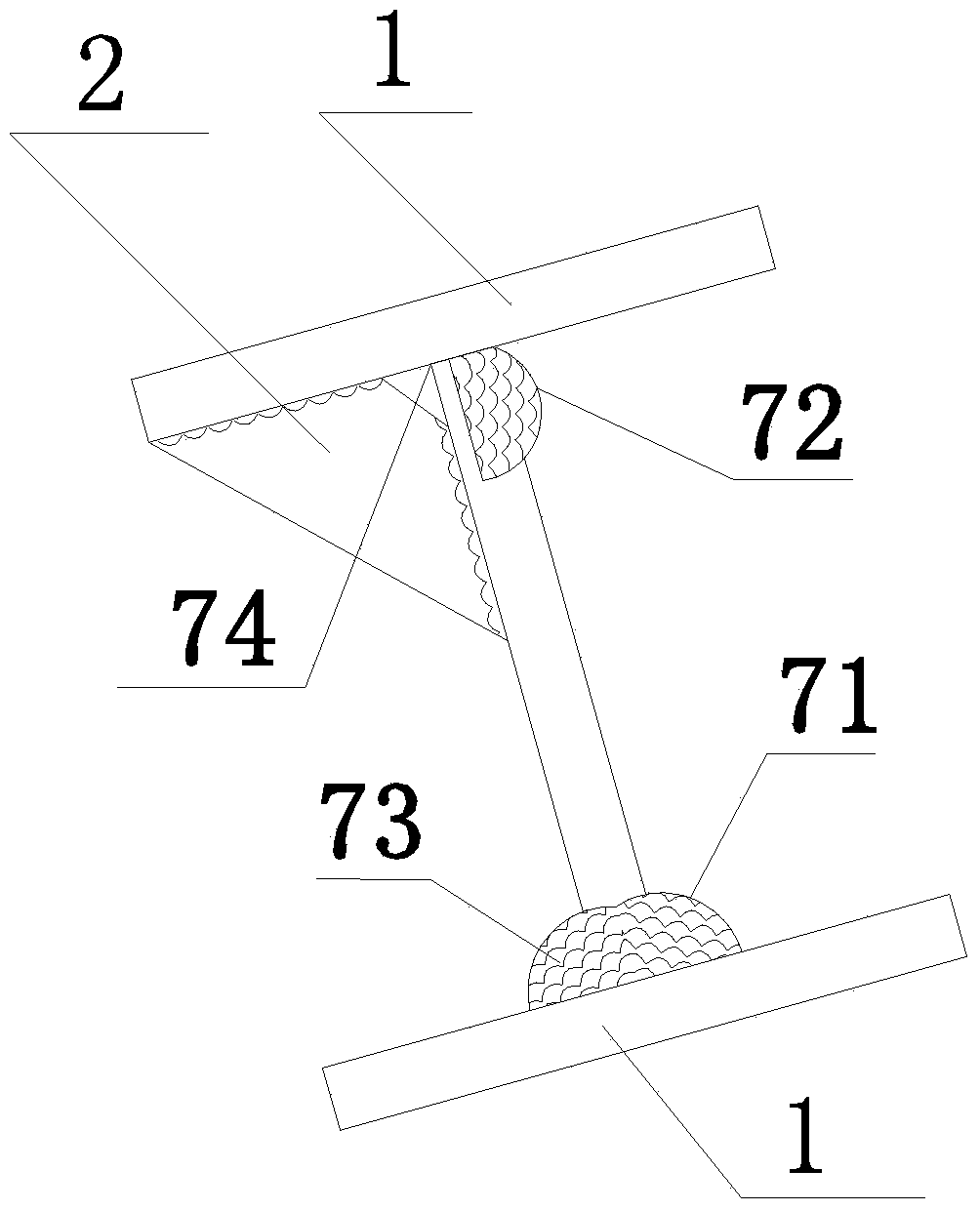

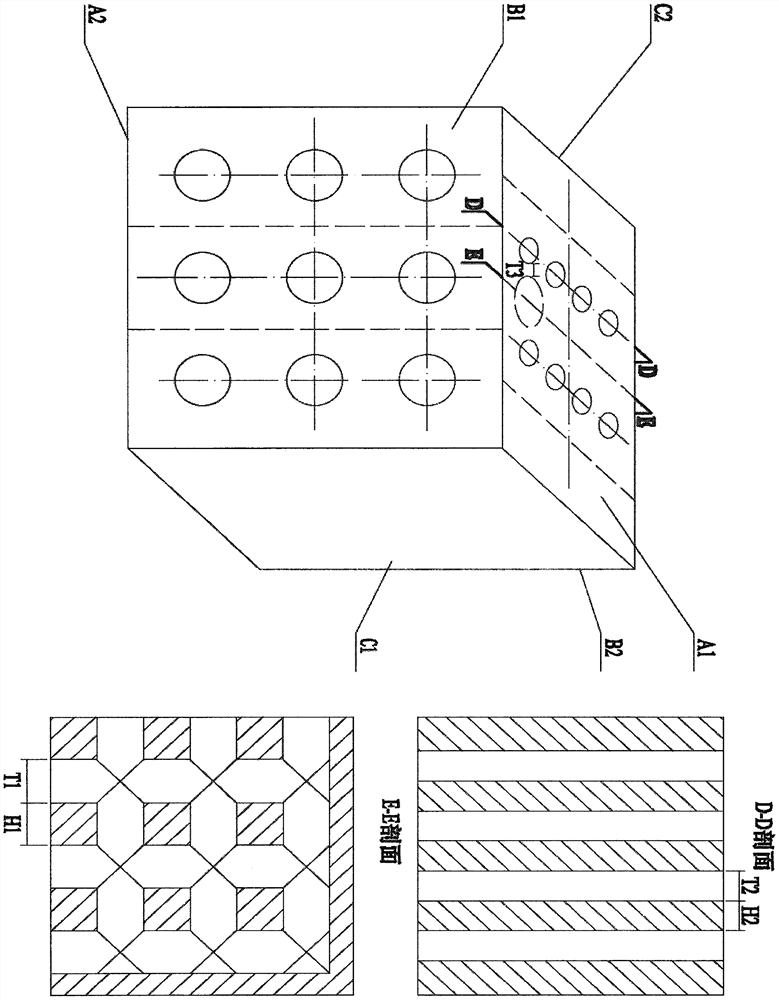

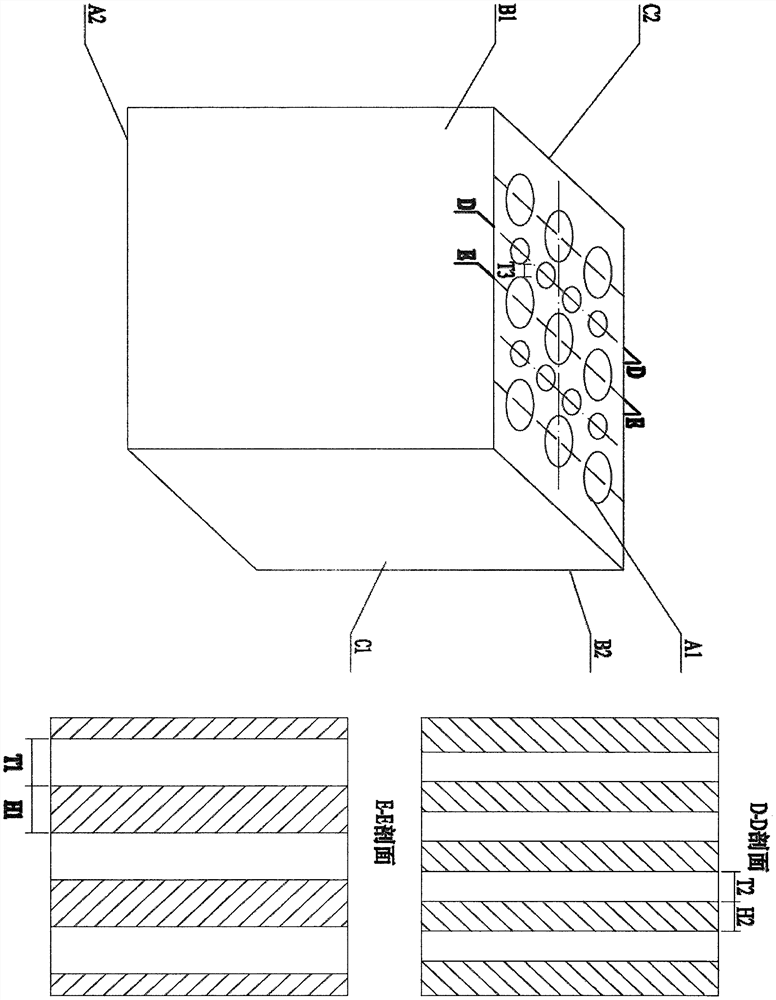

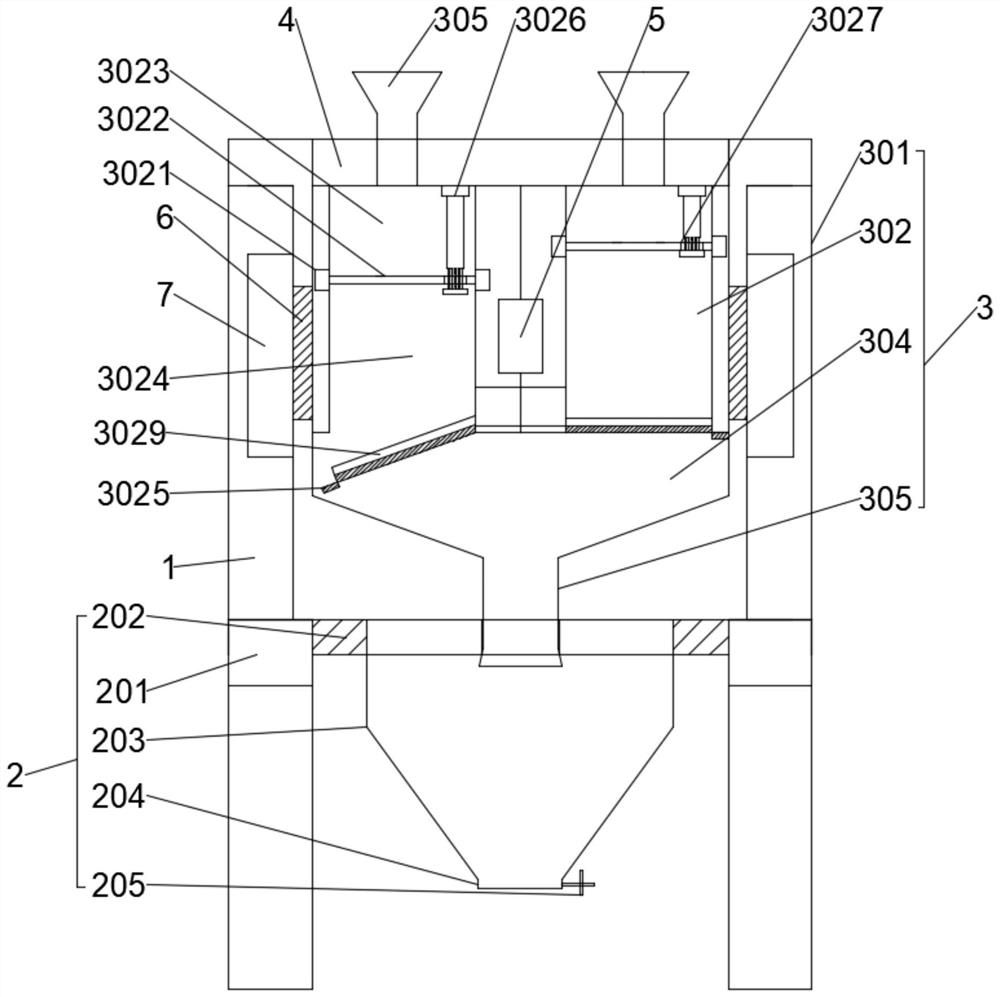

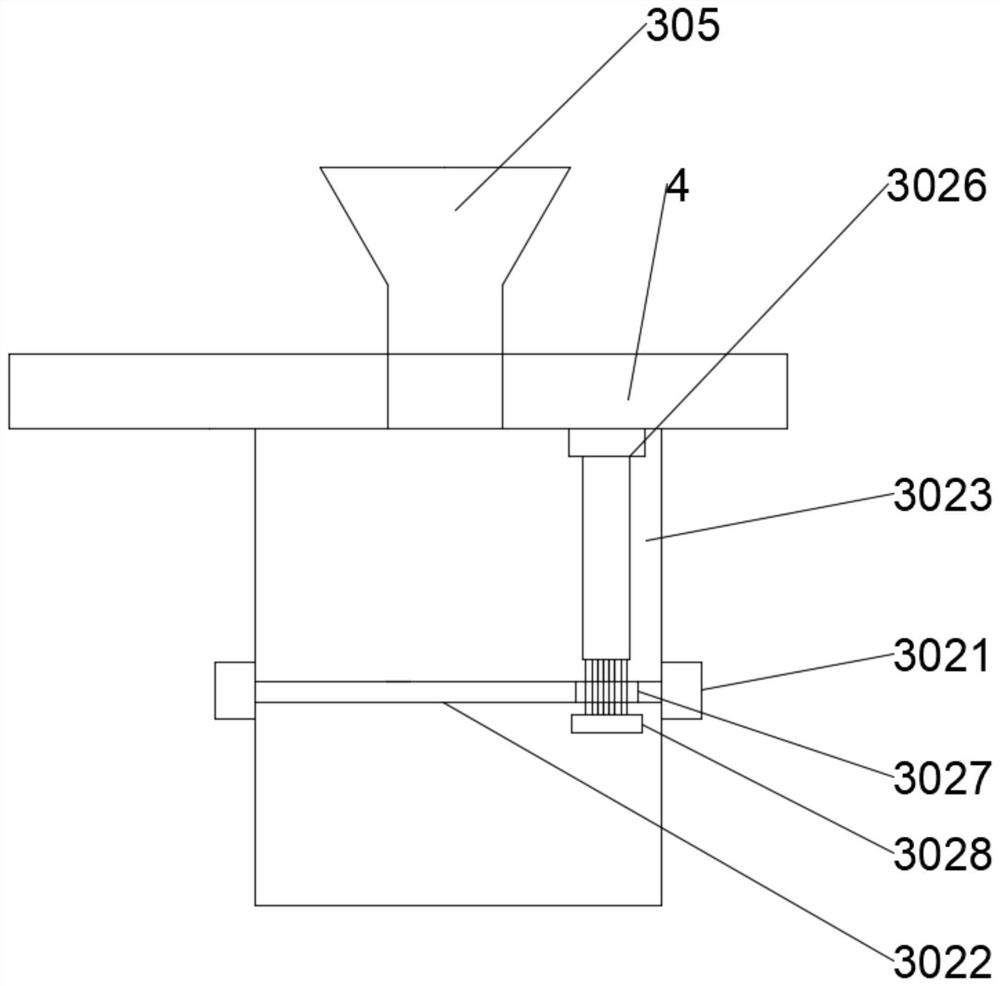

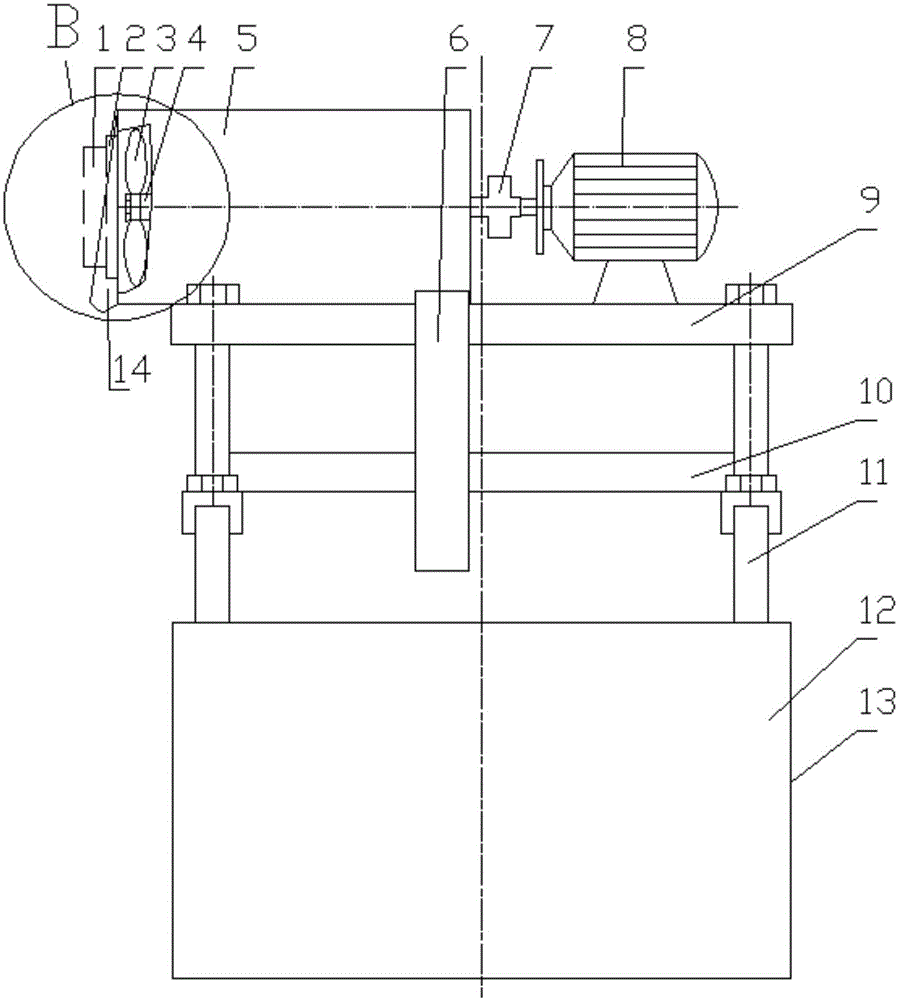

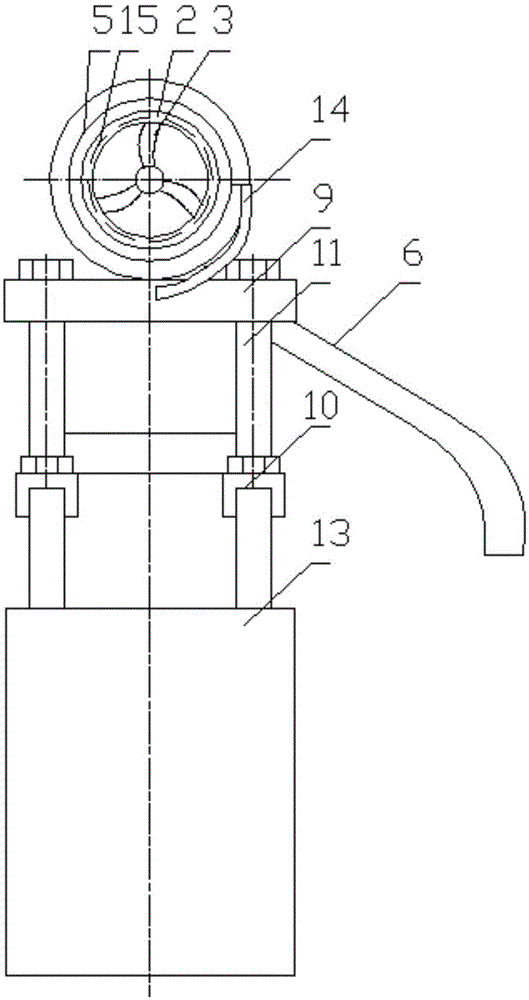

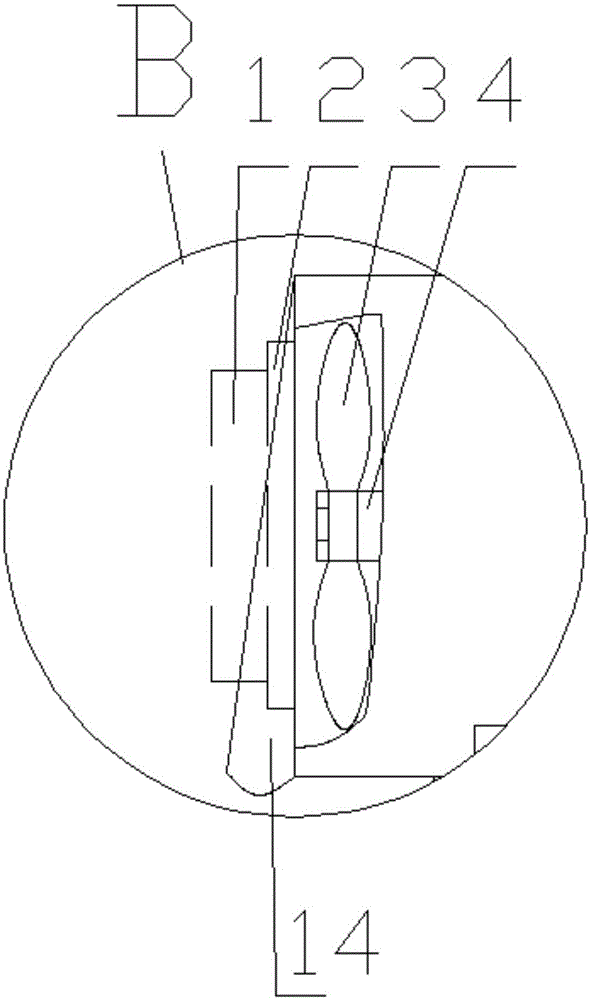

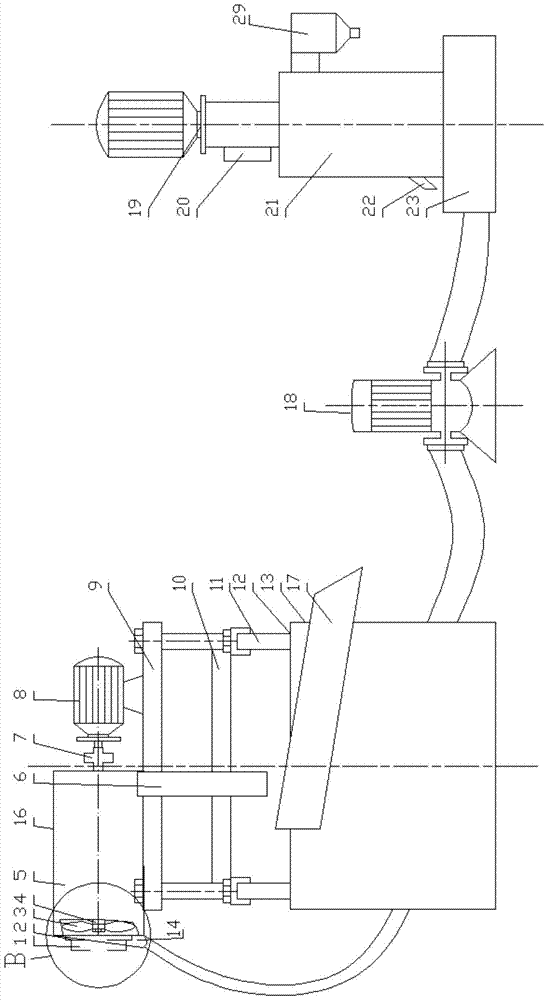

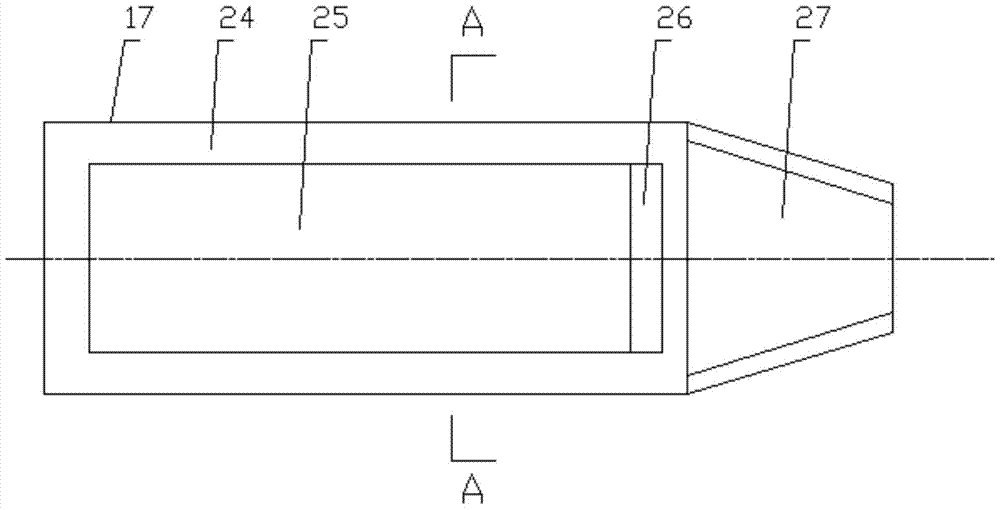

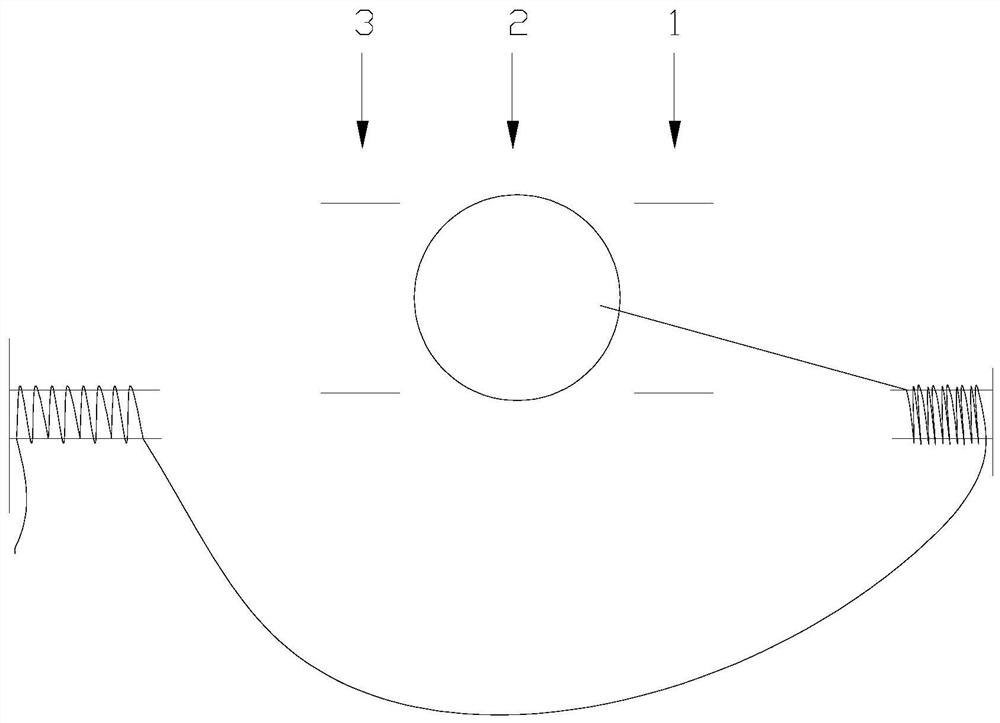

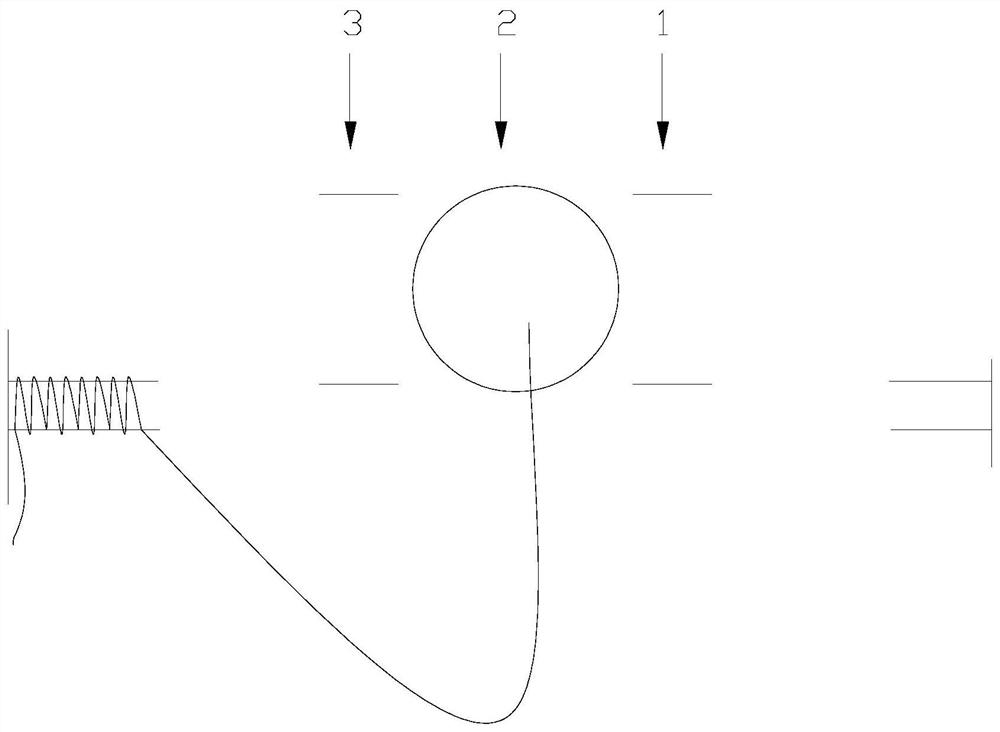

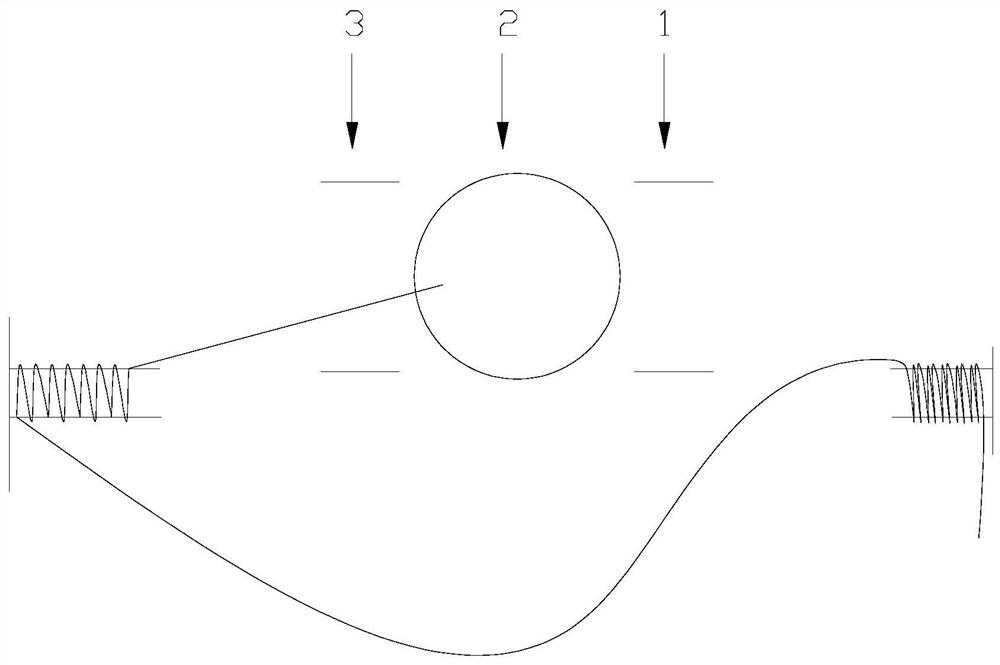

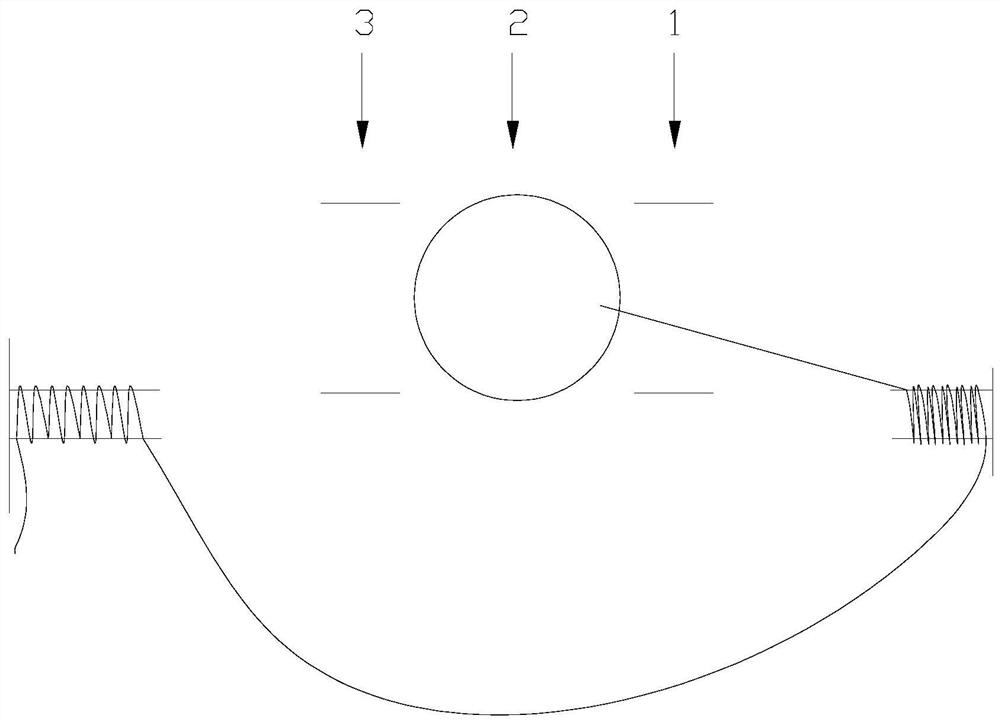

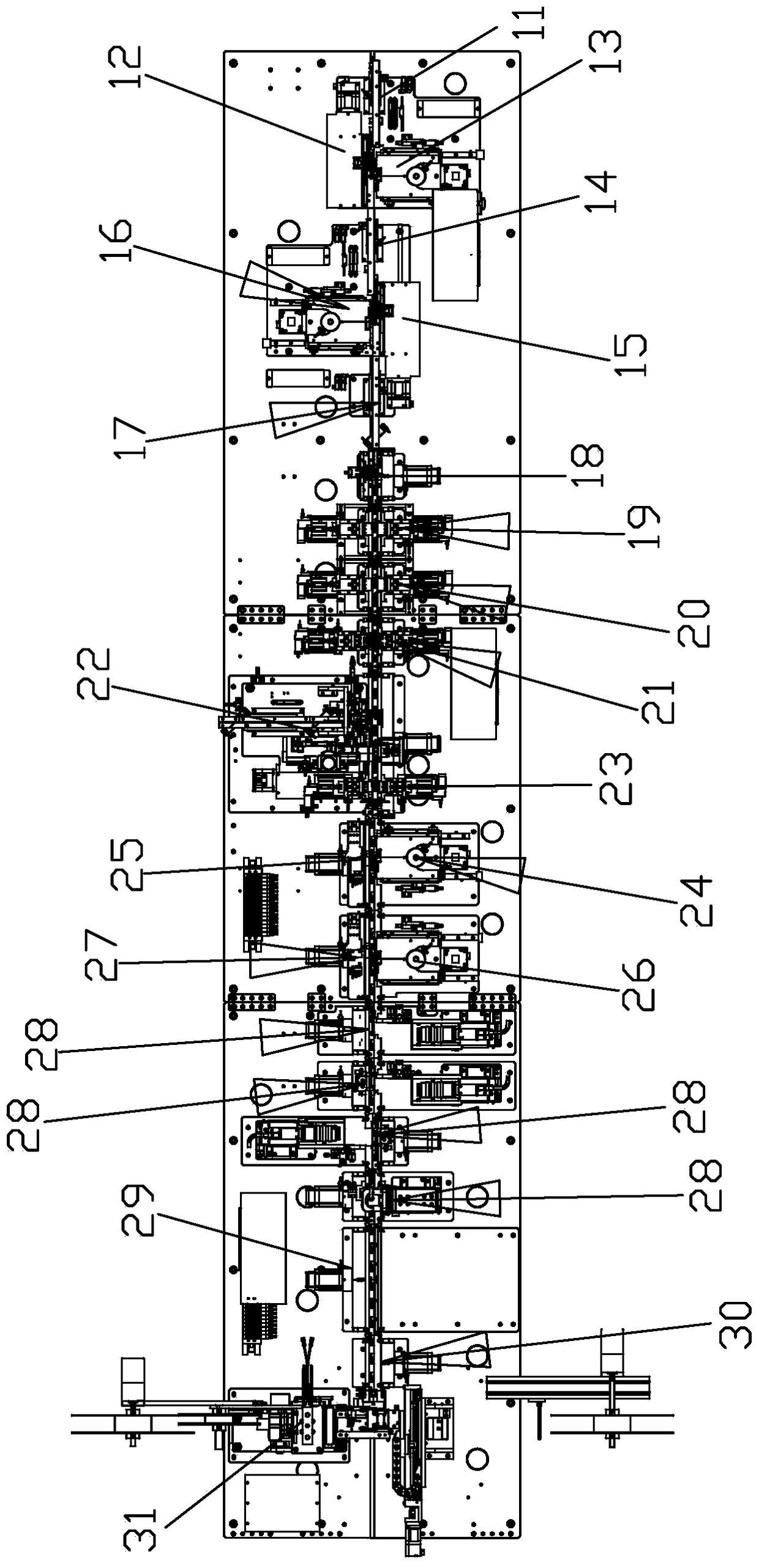

Cigarette blasting bead processing equipment and blasting bead grain size screening device

PendingCN108212797AParticle size screeningGuaranteed quality levelGradingQuality levelAgricultural engineering

The invention discloses a blasting bead grain size screening device of cigarette blasting bead processing equipment. The blasting bead grain size screening device comprises a machine body, a feed chute arranged on the machine body and used for conveying blasting beads to be screened and a plurality of pairs of stepped roll shafts. Each stepped roll shaft is provided with a first step and a secondstep in the axial direction. The gap between every two adjacent first steps communicates with a discharge port of the feed chute, and the size of the gap is equal to the minimum grain size required value of each blasting bead. The gap between every two adjacent second steps is equal to or less than the maximum grain size required value of each blasting bead and is greater than the minimum grain size required value of each blasting bead. The blasting bead grain size screening device can conduct effective grain size screening on cigarette blasting beads through multistage screening of all the pairs of stepped roll shafts. Meanwhile, the problem of material blockage in the screening process is solved, the quality level of blasting bead cigarettes is guaranteed, and user experience is improved. The invention further discloses the cigarette blasting bead processing equipment. The cigarette blasting bead processing equipment has the beneficial effects of conducting effective grain size screening on the cigarette blasting beads through multistage screening of all the pairs of stepped roll shafts, solving the problem of material blockage in the screening process, guaranteeing the quality level of the blasting bead cigarettes and improving user experience.

Owner:CHINA TOBACCO GUIZHOU IND

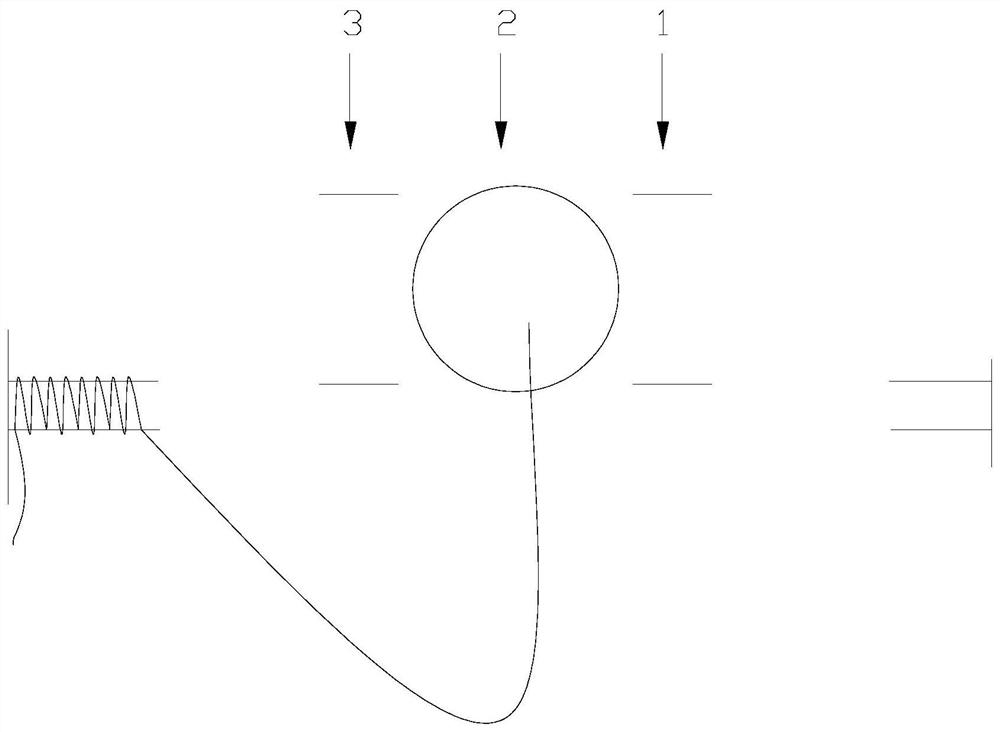

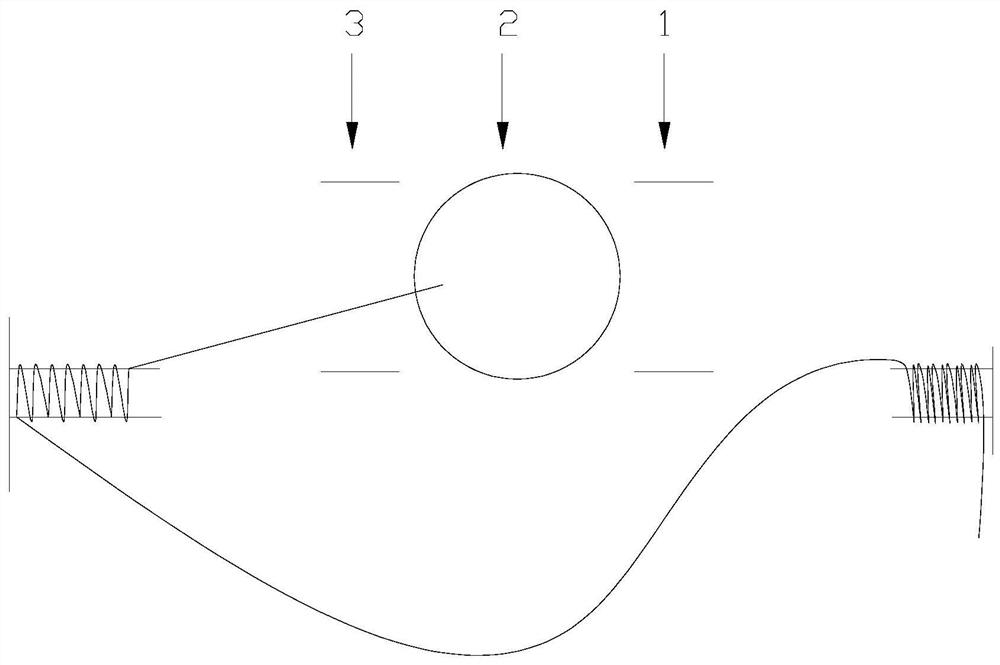

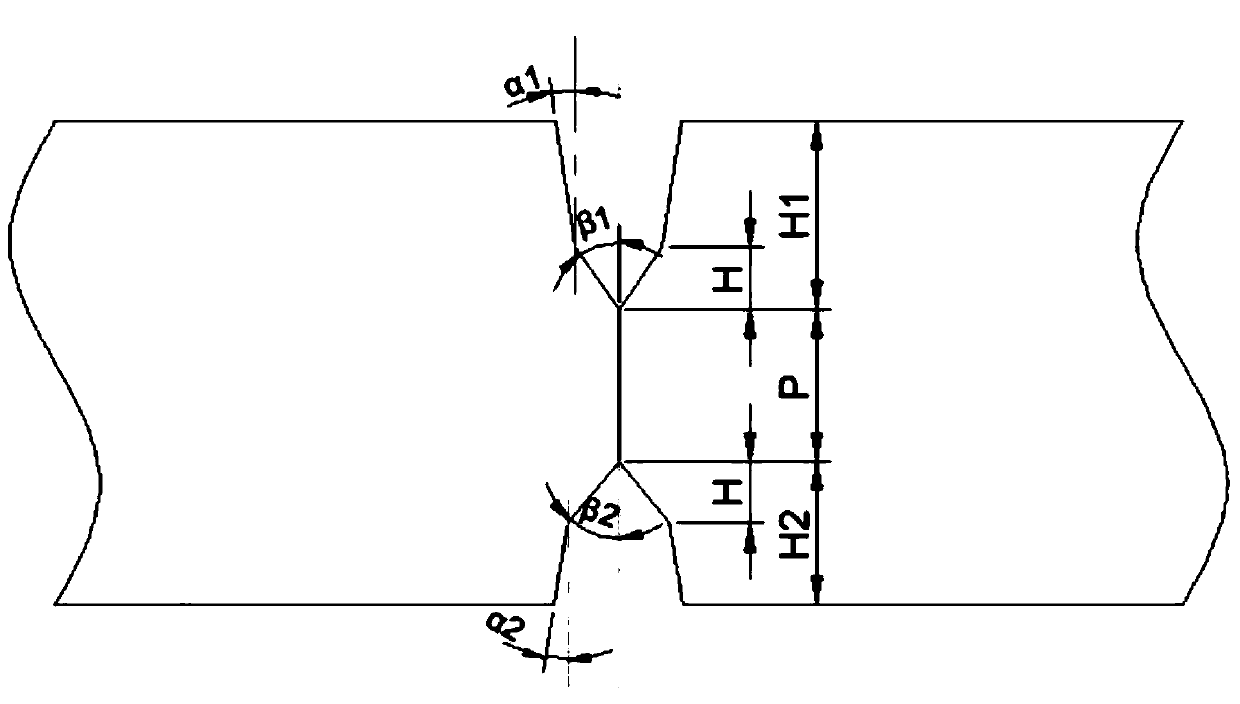

Process for molding I-steel main welding seam non-back chipping full-penetration I-level component

InactiveCN104227182AGuaranteed quality levelReduce production cost inputWelding/cutting auxillary devicesAuxillary welding devicesEngineeringEnergy conservation

The invention discloses a process for molding an I-steel main welding seam non-back chipping full-penetration I-level component and relates to a molding process of light thin-walled I-steel. The process comprises the following steps of preparing a plate, testing welding processing property on the plate, blanking and cutting a flange plate to form a technical beveled edge, cutting or shearing and leveling a technical triangular stiffening plate, positioning and performing full-length welding (single side and singe surface) on the technical triangular stiffening plate, performing submerged-arc door welding on the I-steel, performing ultrasonic (UT) flaw inspection on a main welding seam of an I-steel web, transferring the qualified I-steel component after inspection to the next procedure. When the I-steel is welded, the quality grade of the welding seam can be guaranteed to meet the requirement of full-penetration welding I grade, the deformation of the I-steel is small, back chipping on the opposite surface of a weld bead is not required, backing, filling and surface covering operations which are sequentially performed on the opposite surface of the weld bead are not required, the production cost is relatively low, the production efficiency is relatively high, and the requirements of advanced technology, energy conservation and environment friendliness on construction are met.

Owner:湖北源盛钢构有限公司

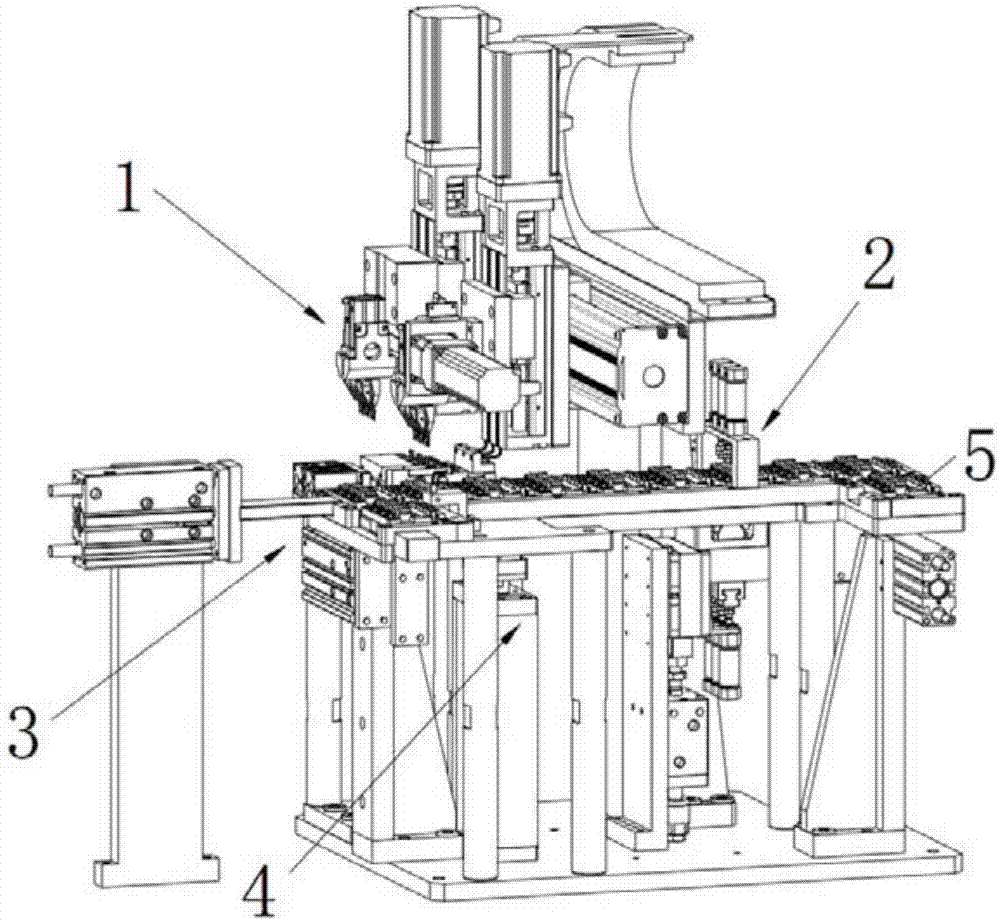

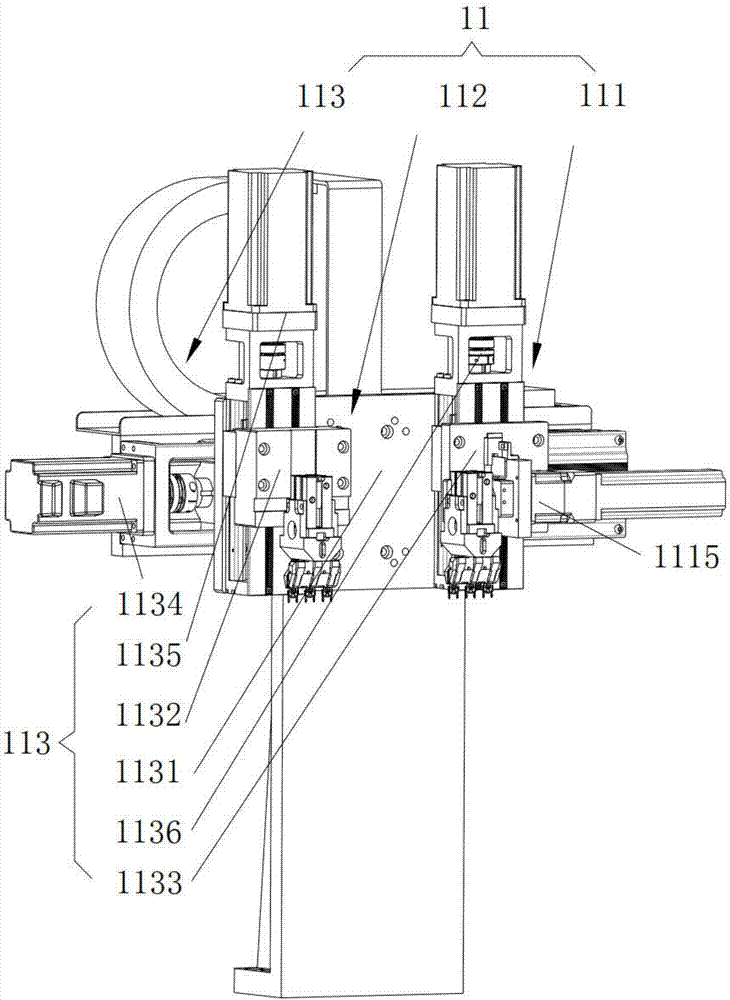

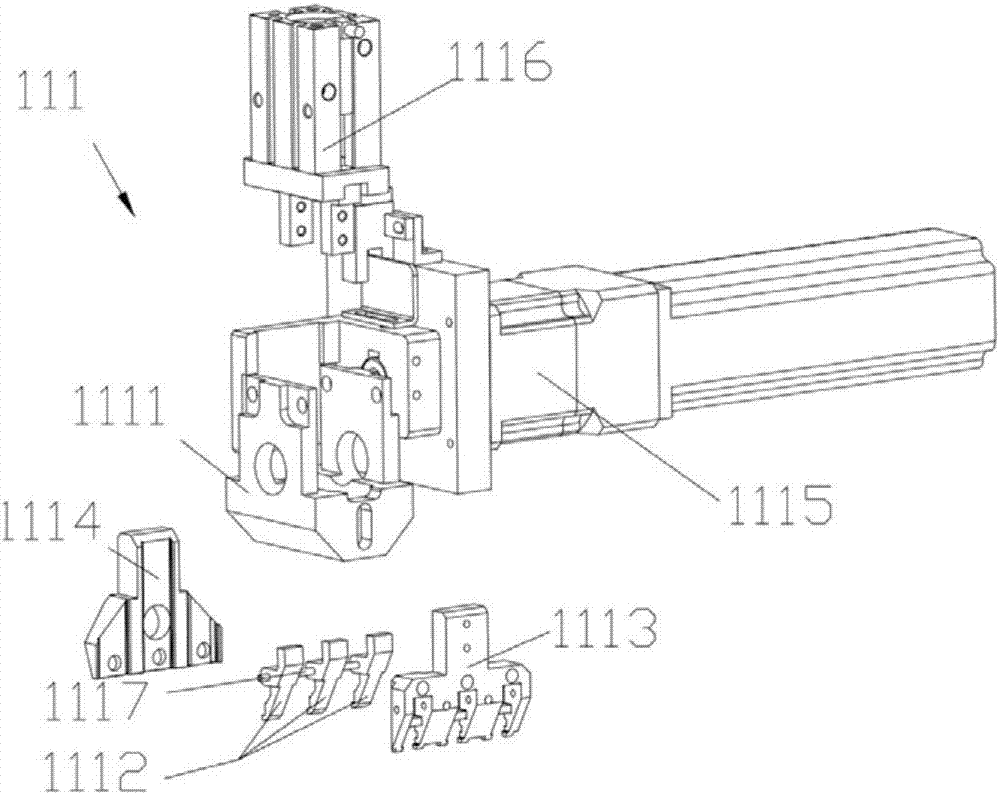

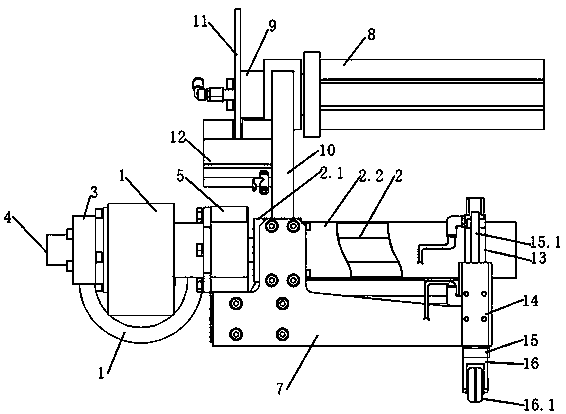

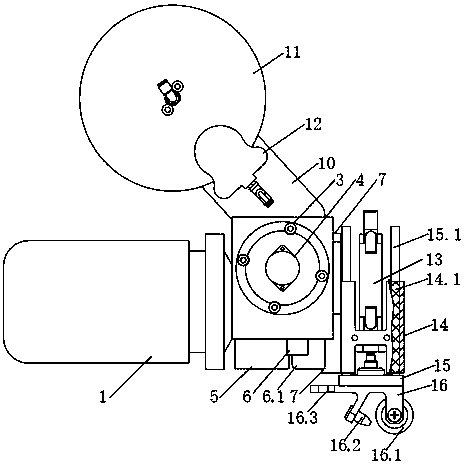

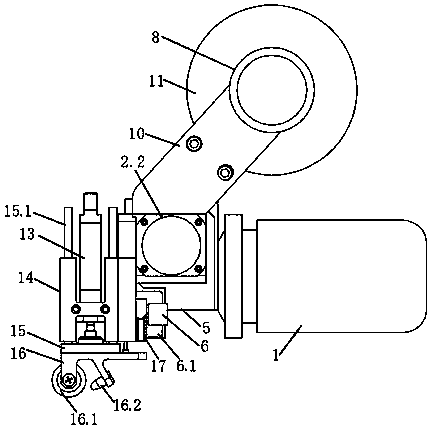

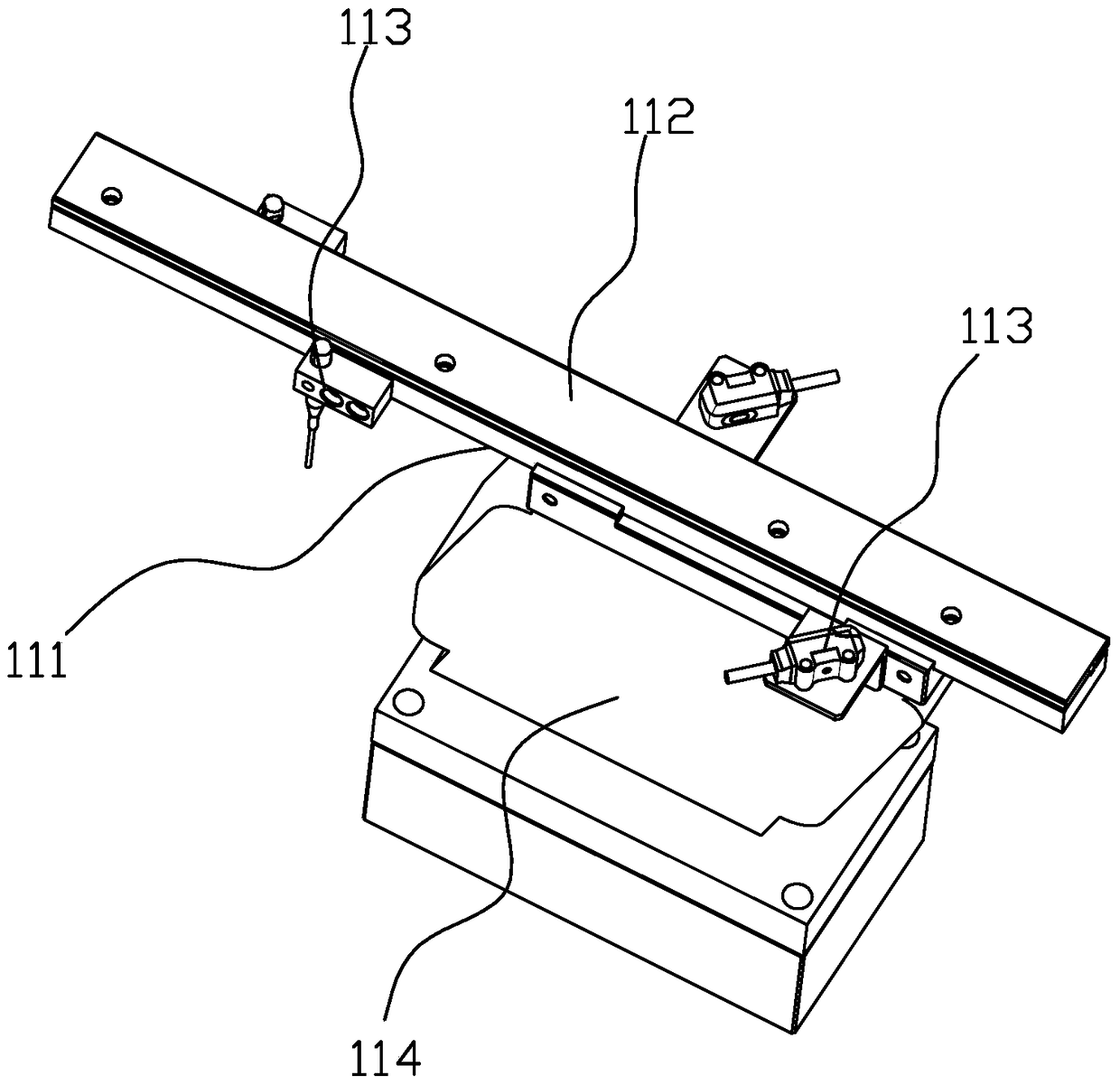

Relay reed insertion mechanism

The present invention relates to the field of relay production technology, especially to a relay reed insertion mechanism. The relay reed insertion mechanism comprises a feeding mechanism configured to convey an outside reed, a pushing mechanism configured to convey an outside relay body, and an insertion mechanism configured to insert the reed transmitted by the feeding mechanism into the relay body transmitted by the pushing mechanism. The relay reed insertion mechanism employs the pushing mechanism, the feeding mechanism and the insertion mechanism to achieve pushing, feeding and insertionautomatic operation in relay production to improve the production efficiency of relays, ensure quality levels of the relays, reduce manpower and reduce the cost.

Owner:SANYOU CORP LTD

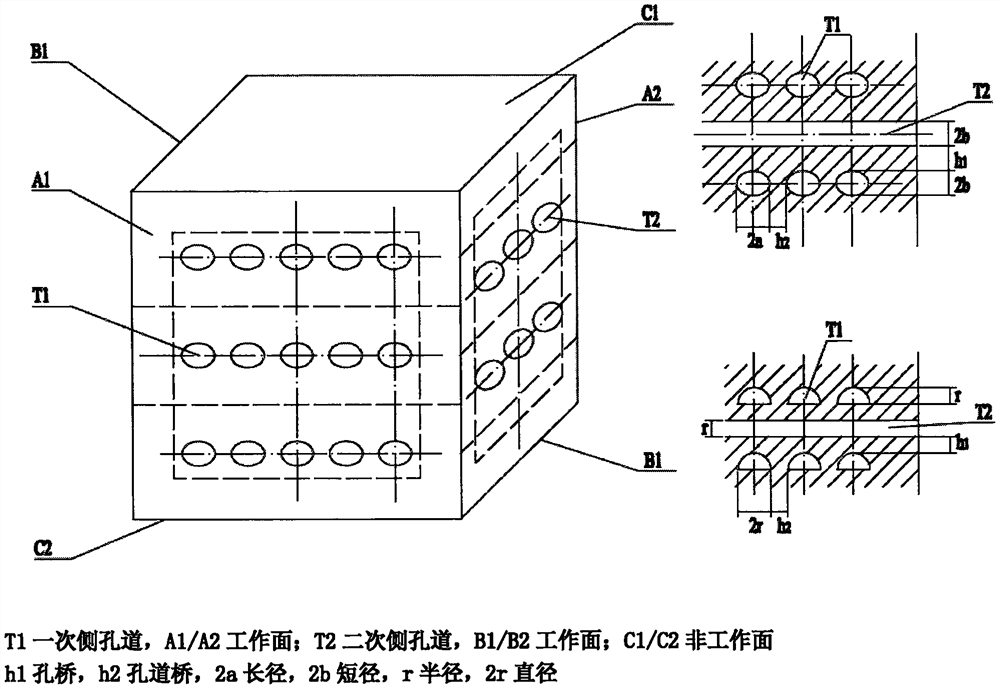

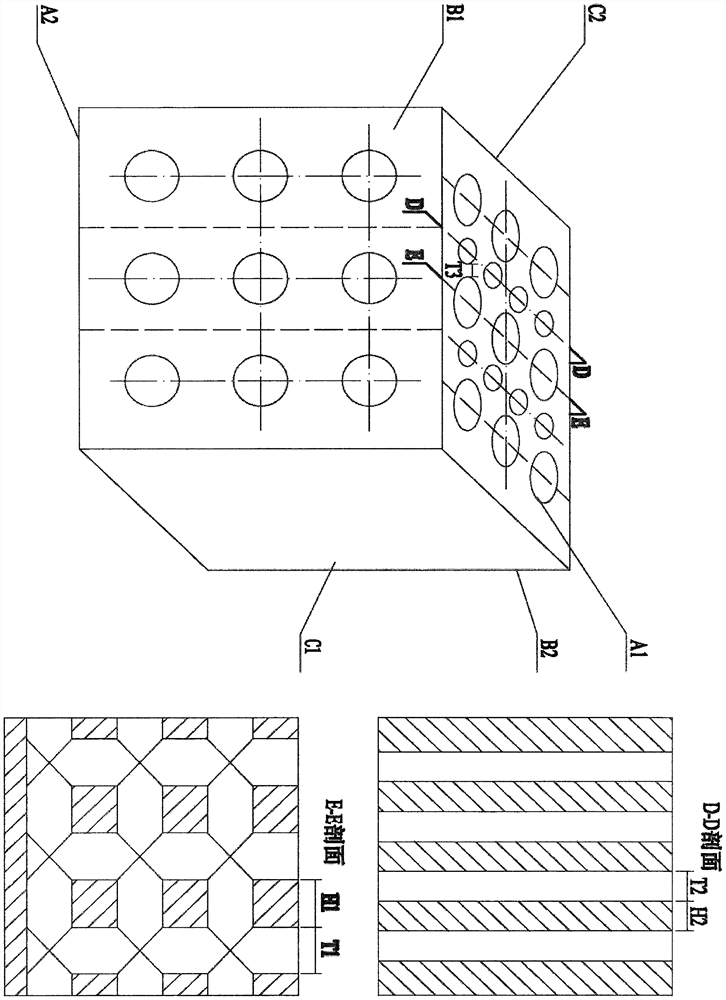

Design scheme of ultrahigh-temperature ultrahigh-pressure pore type heat exchanger/ evaporator

InactiveCN111664427ASafe and stable heat transferImprove heat transfer coefficientNuclear energy generationCooling arrangementUltra high pressureNuclear power

The invention provides a design scheme of an ultrahigh-temperature ultrahigh-pressure pore type heat exchanger / evaporator. Special oval or semicircular or conical pores formed in a heat exchange unitare used for heat exchange. Heat exchange between the pores of small holes or micropores mainly based on clinging type multi-layer metal heat conduction is high in heat transfer coefficient and goodin heat transfer energy efficiency, the heat transfer temperature difference between the primary side and the secondary side is small, safe and stable heat transfer can be achieved between the pores under the extreme high temperature or extreme high pressure condition, and high efficiency, simplicity, safety and reliability are achieved. The pipe breaking and water loss accidents of a traditionalshell-and-tube heat exchanger under the ultrahigh-temperature ultrahigh-pressure work condition can be well avoided. Compared with a shell-and-tube heat exchanger with the same heat transfer capacity,the size, weight and manufacturing cost of the pore type heat exchanger are reduced by one third or above. Under the condition of proper heat exchange unit material selection and proper heat transferpore design selection, heat transfer under the extreme high temperature not exceeding 1000 DEG C or extreme high pressure not exceeding 1000kg under the severe heat transfer condition is supported. The pore type heat exchanger / evaporator belongs to the technical field of heat transfer equipment and is mainly applied to the fields of nuclear power and thermal power, petrochemical engineering, chemical engineering and medicine, metallurgical energy, food and electronics and the like.

Owner:孟想

Processed cheese and processing method thereof

The invention provides processed cheese and a processing method thereof. The processed cheese comprises main materials and auxiliary materials, wherein the main materials include 10-25 parts by weight of chymosin casein, 10-30 parts by weight of plant fat, 1-15 parts by weight of milk fat, 15-40 parts by weight of composite natural cheese and 30-40 parts by weight of water; and the auxiliary materials include 0.5-3 parts by weight of emulsifying salt, 0.3-3 parts by weight of tablet salt, 0.1-1 part by weight of acidity regulator and 0.5-3 parts by weight of nutrient accessories. In a formula, the plant fat is added into the main materials to reduce the cost of raw materials of the processed cheese, a proper amount of milk fat is added to provide many complete fat globules, the chymosin casein as well as the emulsifying salt, acid and table salt at a proper proportion are adopted, and various kinds of natural cheese are added. In a process, a certain adding order is adopted, and the heating of the product and the mechanical effect are controlled. Through perfect match of the formula and process, the pizza cheese with good functionality and flavor is prepared while the cost is reduced.

Owner:孙玉强 +1

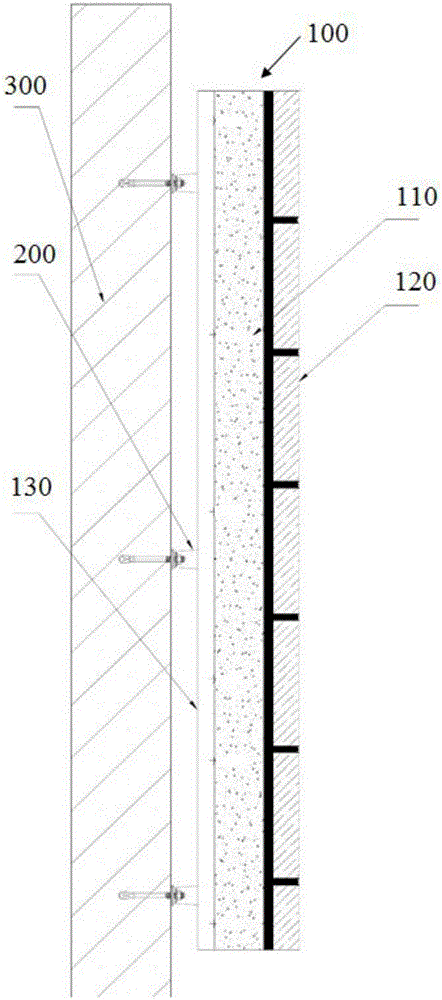

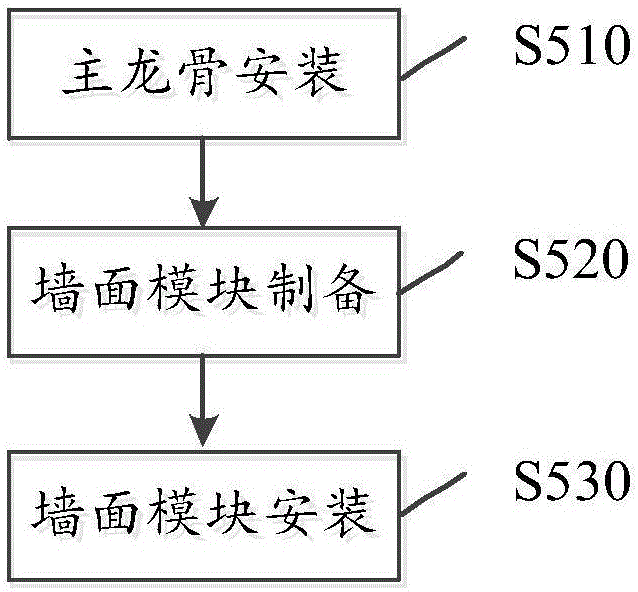

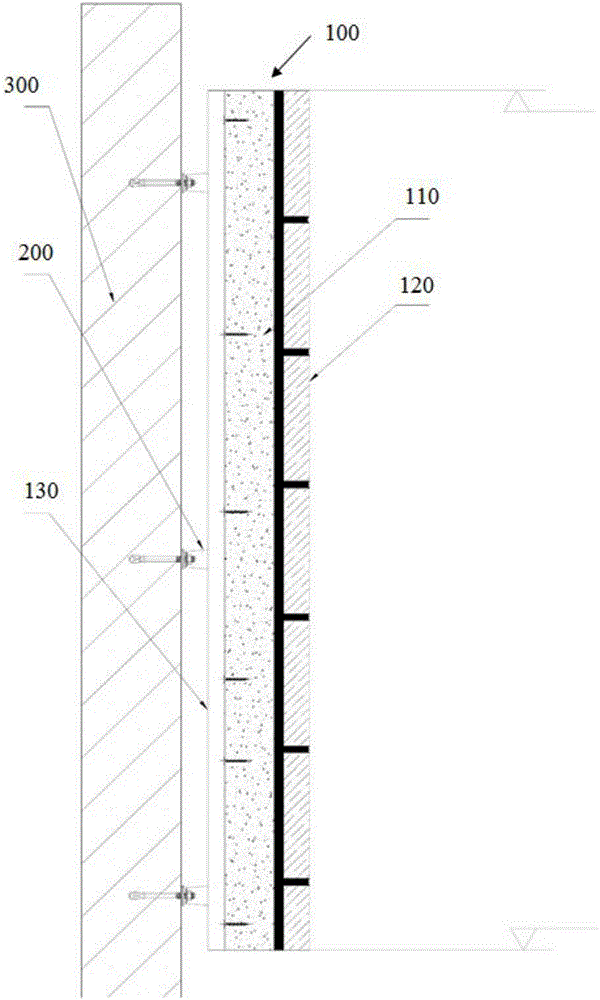

Fabricated ceramic tile wall surface and construction method thereof

The invention discloses a fabricated ceramic tile wall surface and a construction method thereof. The method comprisesinstalling a main keel on a wall body; installing a bearing keel on the inner surface of a cement pressure plate and paving a plurality of ceramictiles on the outer surface of the cement pressure plate to prepare a wall surface module; installing the wall surface module on the wall body by connecting the bearing keel and the main keel in a clamped mode. According to the fabricated ceramic tile wall surface and the construction method thereof, the decorationpurpose of the wall surface module produced in an industrialized mode is achieved by adopting a reliable assembling method and a dry construction method, and therefore the construction period is shortened greatly and the site construction waste and construction pollution are reduced.

Owner:DONG YI RI SHENG HOME DECORATION GRP

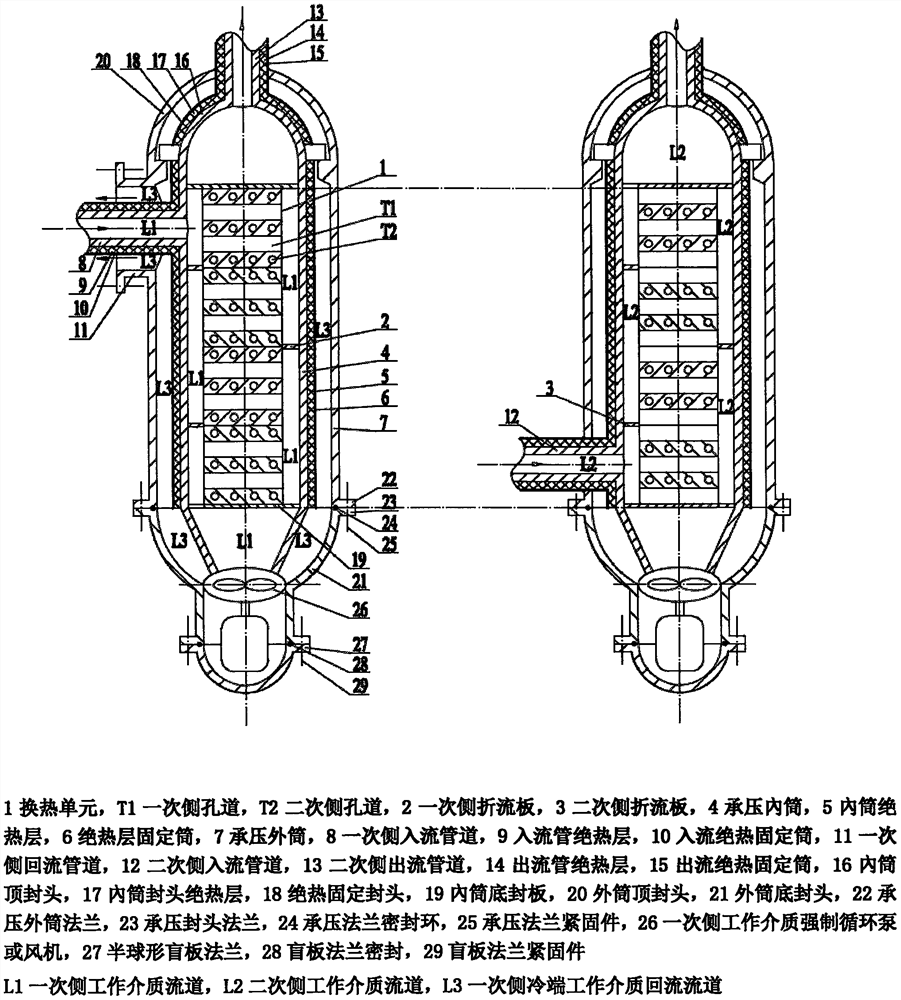

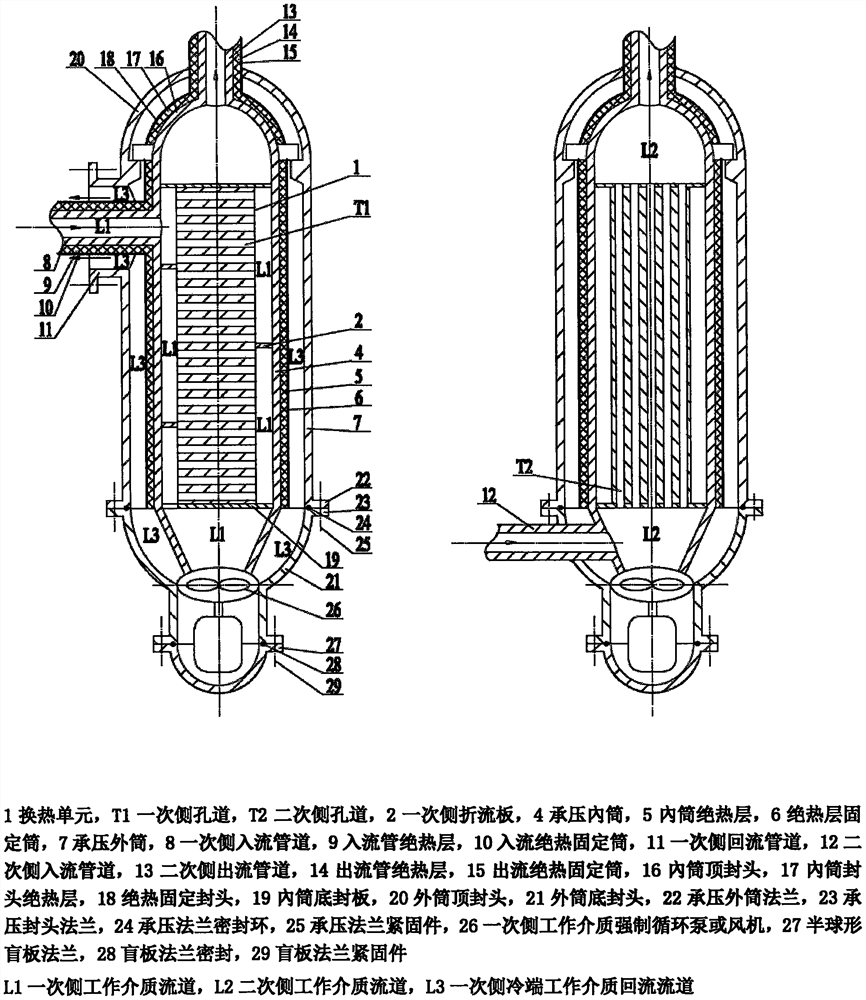

Design scheme of direct-current countercurrent hole channel type heat exchanger/evaporator

PendingCN112071453ASafe and stable heat transferImprove heat transfer coefficientNuclear energy generationCooling arrangementUltra high pressureNuclear power

The invention discloses a design scheme of a direct-current countercurrent hole channel type heat exchanger / evaporator. According to the design scheme, specially-made circular, oval or long circular hole channels arranged in a heat exchange unit are used for direct-current countercurrent heat exchange, and heat exchange between hole channels of small holes or micro holes mainly based on multilayermetal heat conduction and heat convection is achieved, so that the heat transfer coefficient is high, the heat transfer energy efficiency is good, the heat stress is small, the heat transfer temperature difference is small, heat can be safely and stably transferred between the hole channels under the superhigh temperature and superhigh pressure conditions, high efficiency, simplicity, safety andreliability are achieved, and pipe breaking and water loss accidents of a shell-and-tube heat exchanger under the working conditions of ultra-high temperature and ultra-high pressure can be avoided; compared with a shell-and-tube heat exchanger with the same heat transfer capacity, the size, weight and manufacturing cost of the direct-current countercurrent pore channel type heat exchanger are reduced by more than one third, and heat transfer under the severe condition that the extremely high temperature is not higher than 1000 DEG C or the extremely high pressure is not higher than 1000 kg issupported; and the direct-current countercurrent hole channel type heat exchanger belongs to the technical field of heat transfer equipment and is mainly applied to the fields of nuclear power and thermal power, petrochemical engineering, chemical medicine, metallurgical hydrogen production and the like.

Owner:孟想

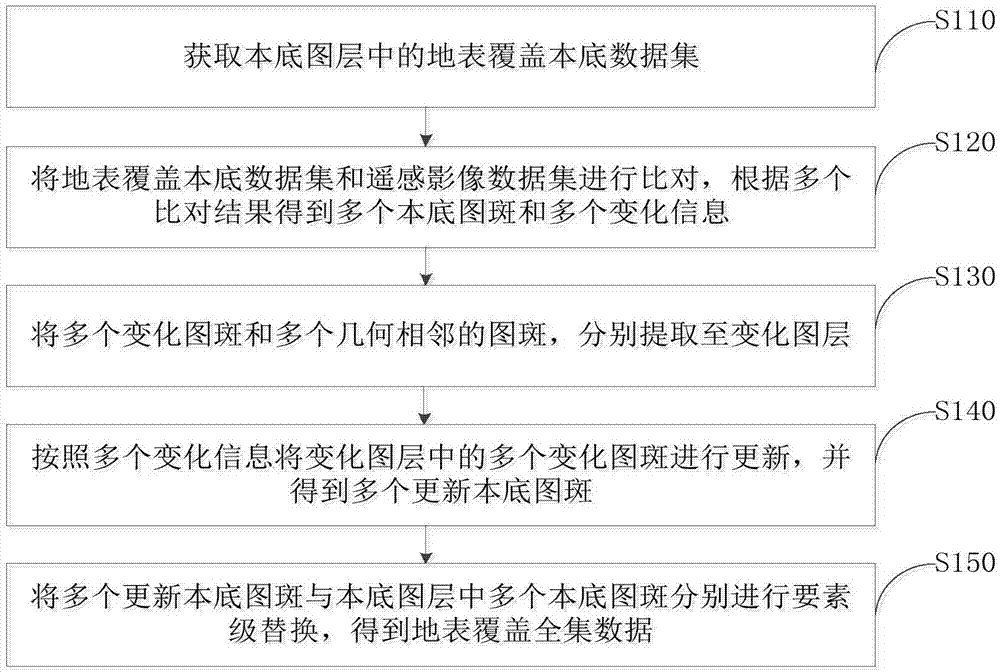

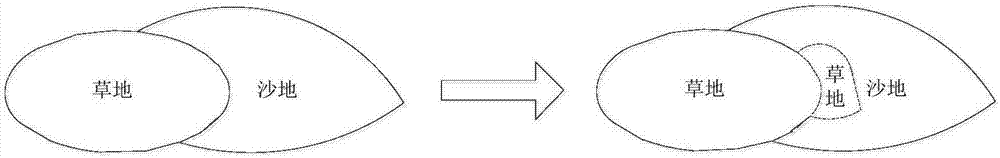

Method and system for iteratively updating high-fidelity land cover data

ActiveCN107506417ASimplify update operationsGuaranteed quality levelTexturing/coloringGeographical information databasesLand coverQuality level

The invention provides a method and system for iteratively updating high-fidelity land cover data, and relates to the technical field of geographic space information. The method comprises the following steps of: obtaining a land cover background data set in a background layer; comparing the land cover background data set with a remote sensing image data set, and obtaining a plurality of background pattern spots and a plurality of pieces of change information according to a plurality of comparison results, wherein the background pattern spots comprise change pattern spots and pattern spots geometrically adjacent to the change pattern spots; respectively extracting a plurality of change pattern spots and a plurality of geometrically adjacent pattern spots to a change layer; updating the plurality of change pattern spots in the change layer according to the plurality of pieces of change information so as to obtain a plurality of updated background pattern spots; and respectively carrying out element-level replacement on the plurality of updated background pattern spots and the plurality of background pattern spots in the background layer so as to obtain land cover universal set data. According to the method and system, pattern spot profiles and topological structures of background data are strictly inherited, land cover updating operations are simplified, new topological problems are not generated, and quality levels of updated layers are ensured.

Owner:NAT GEOMATICS CENT OF CHINA

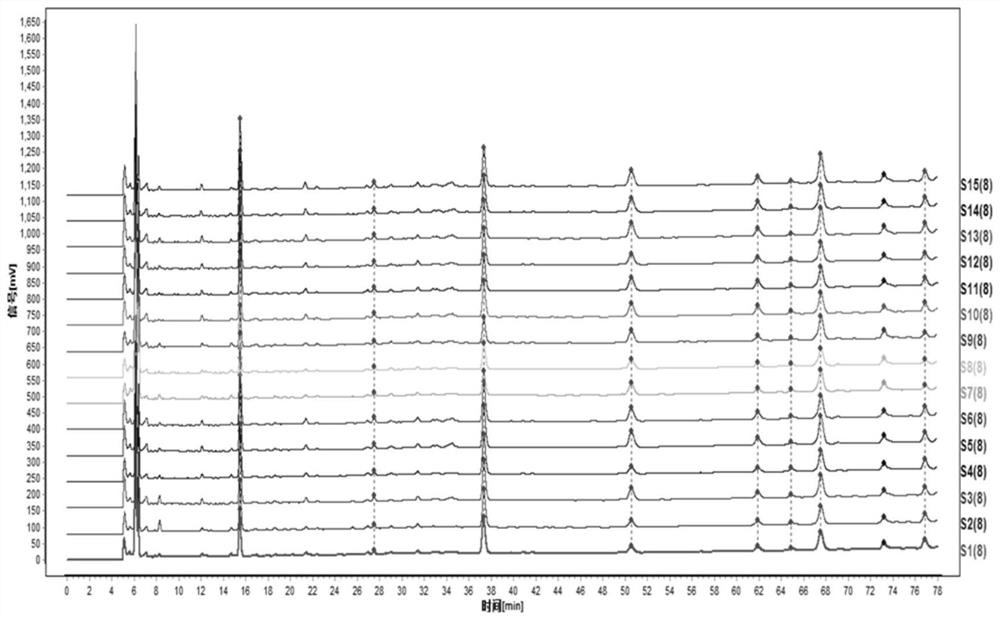

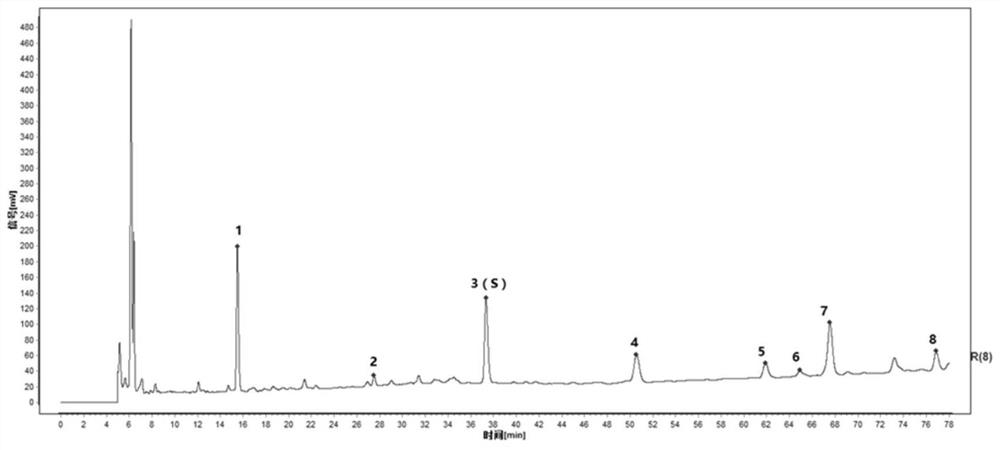

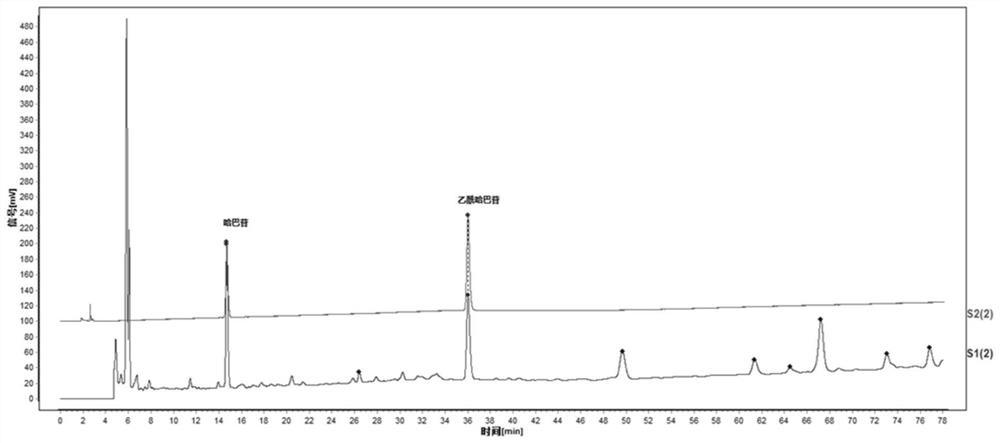

Method for establishing fingerprint spectrum of medicinal preparation of decumbent bugle herb

ActiveCN113155994AImprove securityImprove stabilityComponent separationPlant ingredientsFormularyDrugs preparations

The invention relates to a method for establishing a fingerprint spectrum of a medicinal preparation of decumbent bugle herb. According to the method, decumbent bugle herb formula granules are taken as a detection object, a fingerprint spectrum aiming at the medicinal preparation is established, a traditional Chinese medicine chromatographic fingerprint spectrum similarity evaluation system is adopted to establish a control fingerprint spectrum, eight common characteristic peaks are calibrated, and harpagide at the first peak and acetyl harpagide at the third peak of the common characteristic peaks are confirmed; acetylharpagide at the third peak is selected as an internal reference peak, and the relative retention time of common characteristic peaks of the ajuga ciliata formula granules is determined; and the similarity between fingerprint of the sample to be detected and the contrast fingerprint is evaluated. According to the method disclosed by the invention, the quality of the medicine can be comprehensively and quickly detected, and comprehensive quality detection and overall quality control of the medicine are facilitated, so that the use safety and stability of the medicine are favorably improved. Meanwhile, the method has the advantages of high stability, high precision, high repeatability and the like.

Owner:CHINA RESOURCES SANJIU MEDICAL & PHARMA

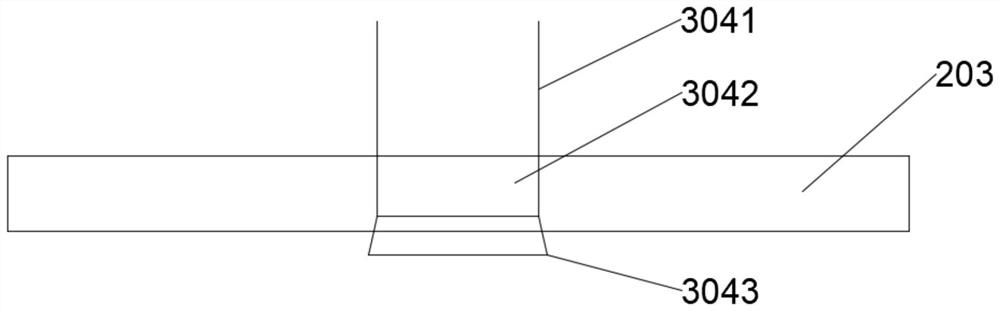

Mixing ratio experiment device and method for ultra-high performance concrete

InactiveCN113276280AGuaranteed quality levelAccurate weighingMixing operation control apparatusIngredients proportioning apparatusStructural engineeringProcess engineering

The invention discloses a mixing ratio experiment device and method for ultra-high performance concrete. The device comprises a raw material mixing mechanism and supporting mechanisms connected to the two sides of the raw material mixing mechanism, wherein a feeding mechanism and a cover body are connected to the upper portion of the raw material mixing mechanism, the cover body is fixedly connected to the upper portion of the feeding mechanism, concrete raw materials enter the feeding mechanism through the cover body, and under the weighing effect of the feeding mechanism, various concrete raw materials with certain mass in the feeding mechanism are preliminarily mixed and enter the raw material mixing mechanism for secondary mixing in the process that the feeding mechanism gets close to the raw material mixing mechanism. According to the device, multiple cavities are connected together, the concrete raw materials pass through the different cavities, are accurately weighed in the conveying process and then are evenly mixed through the mixing mechanism, after the concrete raw materials pass through the whole device, the various concrete raw materials are evenly mixed and flow out, and then the experiment result is more accurate after the concrete raw materials are put into an experiment.

Owner:CCCC THIRD HIGHWAY ENG

Producing method of vacuum glass with edge sealed under normal pressure and opening sealed under low pressure in vacuum furnace

ActiveCN102503094APrevent air leakageAvoid secondary meltingGlass reforming apparatusGlass productionFurnace temperatureQuality level

The invention relates to a producing method of vacuum glass with the edge sealed under normal pressure and the opening sealed under low pressure in a vacuum furnace. The method includes: cutting plates, arranging supports, combining sheets, placing low-melting-point glass powder at the edge, placing air suction pipes on lateral sides and lateral corners, completing edge sealing during rising of interior temperature of a normal pressure furnace from 380 DEG C to 500 DEG C, taking the glass out of the furnace after cooling, moving the glass into the vacuum furnace for vacuumizing, sealing the air suction pipes by electric heating, putting vacuum glass abreast in the vacuum furnace, evacuating the vacuum furnace according to 1X10-1pa-1X10-5pa, controlling the furnace temperature from 100 DEGC to 310 DEG C, and switching on an electric heating device preset at the root of each air suction pipe to fuse glass tube seals. Vacuumization is performed when the vacuum temperature is lower than the edge sealing temperature, secondary melting of sealed low-melting-point glass powder and humidity in a vacuum cavity can be avoided, and high vacuum degree, high yield and low air leakage rate can be achieved. Further, partially sealing the air suction pipes can save energy effectively, production efficiency can be improved effectively by arranging the vacuum glass abreast and sealing the air suction pipes at fixed positions, and quality of the vacuum glass can be guaranteed.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

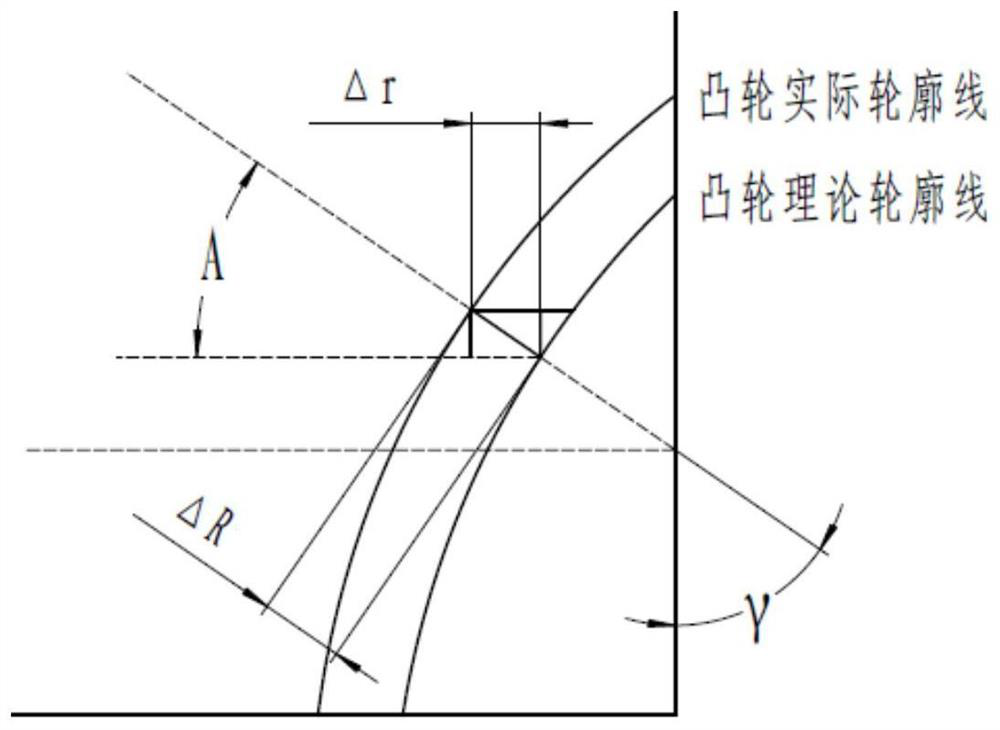

Profile finish machining method based on three-dimensional cam profile materialization model deviation compensation

ActiveCN112526925AEasy to adjustQuick modificationProgramme controlComputer controlNumerical controlAlgorithm

The invention belongs to the technical field of part finish machining, and relates to a profile finish machining method based on three-dimensional cam profile materialization model deviation compensation. The method comprises the following steps of: 1) machining a sample piece according to a three-dimensional cam profile materialization model; (2) detecting radius deviation values delta r of a plurality of original detection qualified point positions and corresponding processing point position poles on the processing sample piece; 3) the delta r is converted into a vector component, and a plurality of new point locations are obtained through conversion; 4) reconstructing a digital model of the three-dimensional cam profile according to the plurality of new point locations and the pluralityof original qualified detection point locations; 5) performing numerical control programming processing on the digital model to obtain a newly processed sample piece; and (6) detecting that the detection results of the plurality of original detection qualified point positions and the corresponding new processing points are consistent on the new processing sample piece. According to the method, the three-dimensional cam profile digital model and the numerical control program can be quickly and accurately compensated and modified according to the measurement and detection result, namely the polar radius deviation value of the three-dimensional cam profile, the cost is low, and the product quality is stable.

Owner:XIAN AERO ENGINE CONTROLS

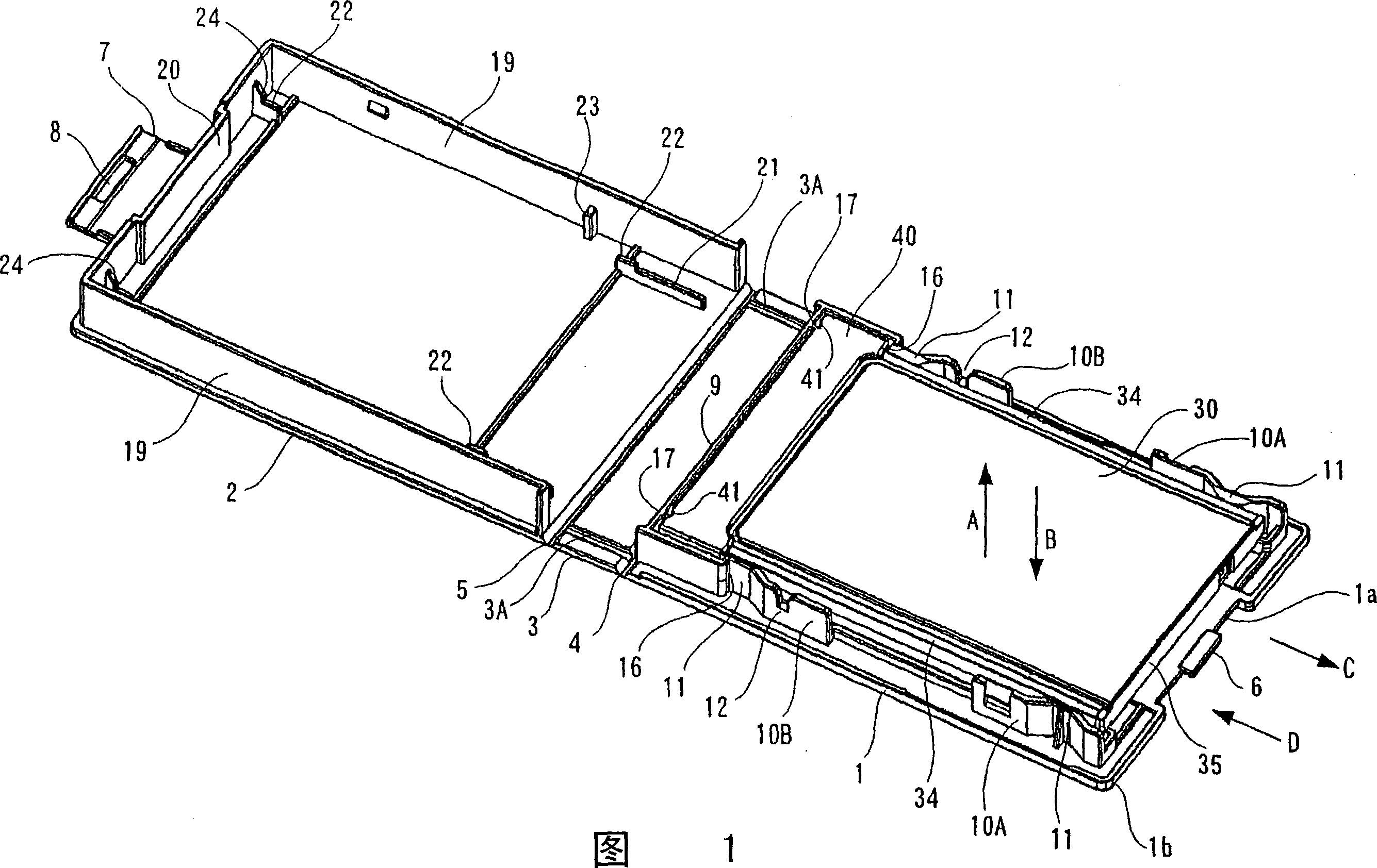

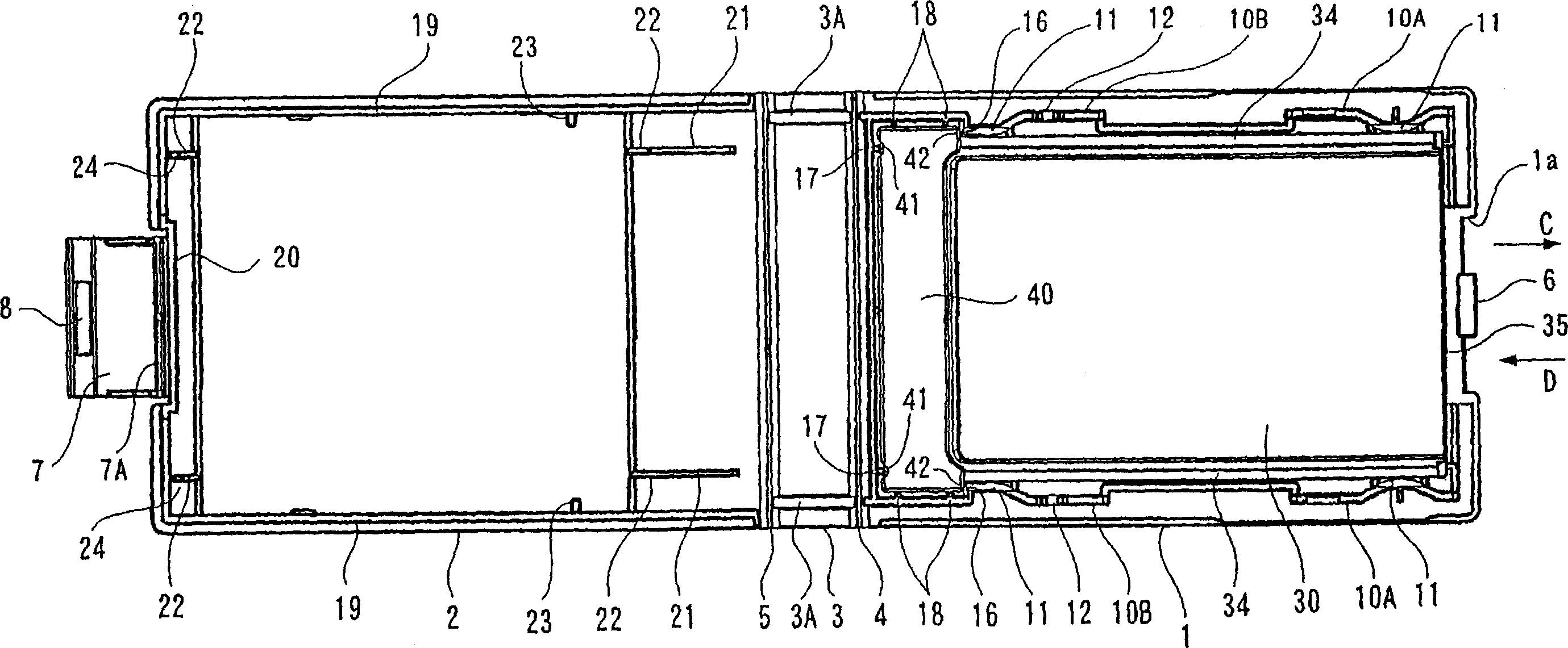

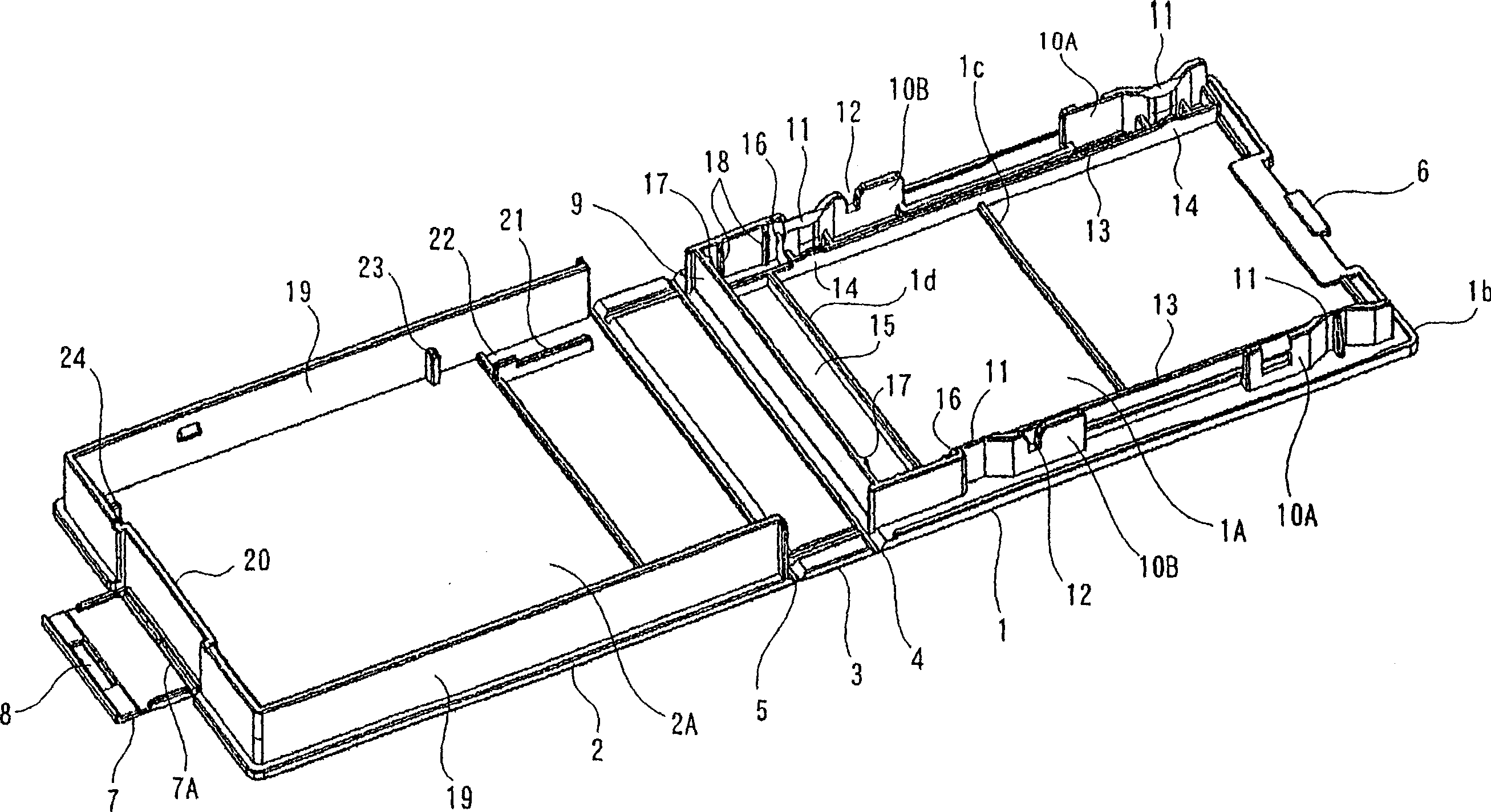

Case of card-type portable information processor

ActiveCN1820238AGuaranteed quality levelGuaranteed reliabilityConveying record carriersDigital data processing detailsEngineeringInformation processor

An inventive card-type portable information processing device case permits a user to select a mode in which a card-type portable information processing device is taken out of the case with a cap attached thereto or a mode in which the card-type portable information processing device is taken out of the case with the cap detached therefrom and engaged with the first cover. The inventive case includes a cap engagement portion (15) provided in a first cover (1). By moving the card-type portable information processing device (30) in a direction A, the card-type portable information processing device (30) is taken out of the case with the cap (40) attached thereto. By moving the card-type portable information processing device (30) in a direction C, only the card-type portable information processing device (30) is taken out of the case with the cap (40) engaged in the cap engagement portion (15) of the first cover (1).

Owner:PANASONIC CORP

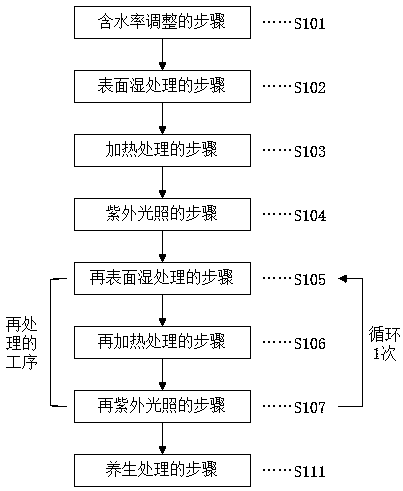

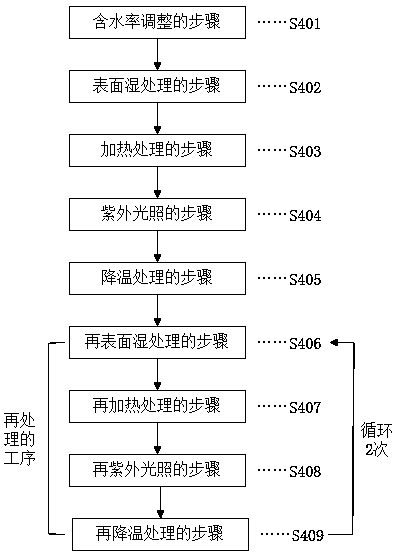

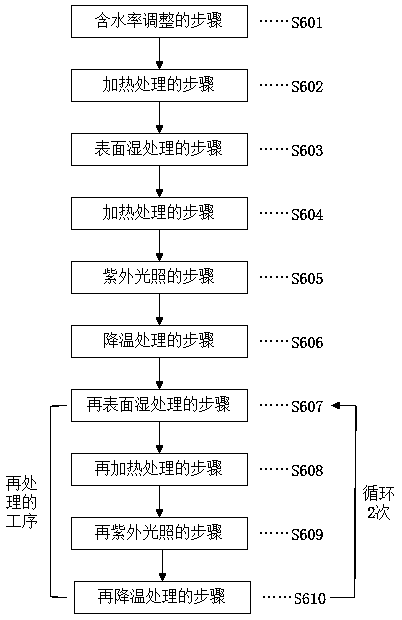

Tectona grandis color change treatment method

ActiveCN110539375AAvoid Surface CracksUniform moisture contentRadiation/waves wood treatmentWood treatment detailsTectonaMoisture

The invention provides a Tectona grandis color change treatment method, which comprises a surface wet treatment step and an ultraviolet irradiation step, and further comprises a heating treatment stepset before the ultraviolet irradiation step, wherein the heating mode in the heating treatment step comprises one or a combination comprising two selected from infrared irradiation heating, convection heating and contact heating so as to heat a Tectona grandis billet material. According to the present invention, by additionally setting the heating treatment step before the ultraviolet irradiationstep, the generation of dark cracks on the surface, end cracks and surface burrs on the surface can be effectively avoided, black gold textures are formed or deepened on the surface of the Tectona grandis billet material, the moisture content of the Tectona grandis billet material is uniform after color changing treatment, and the curing time is shortened, such that the quality and the quality grade of the Tectona grandis billet material are guaranteed while the Tectona grandis color change treatment production efficiency is improved.

Owner:ZHEJIANG LINGGE WOOD

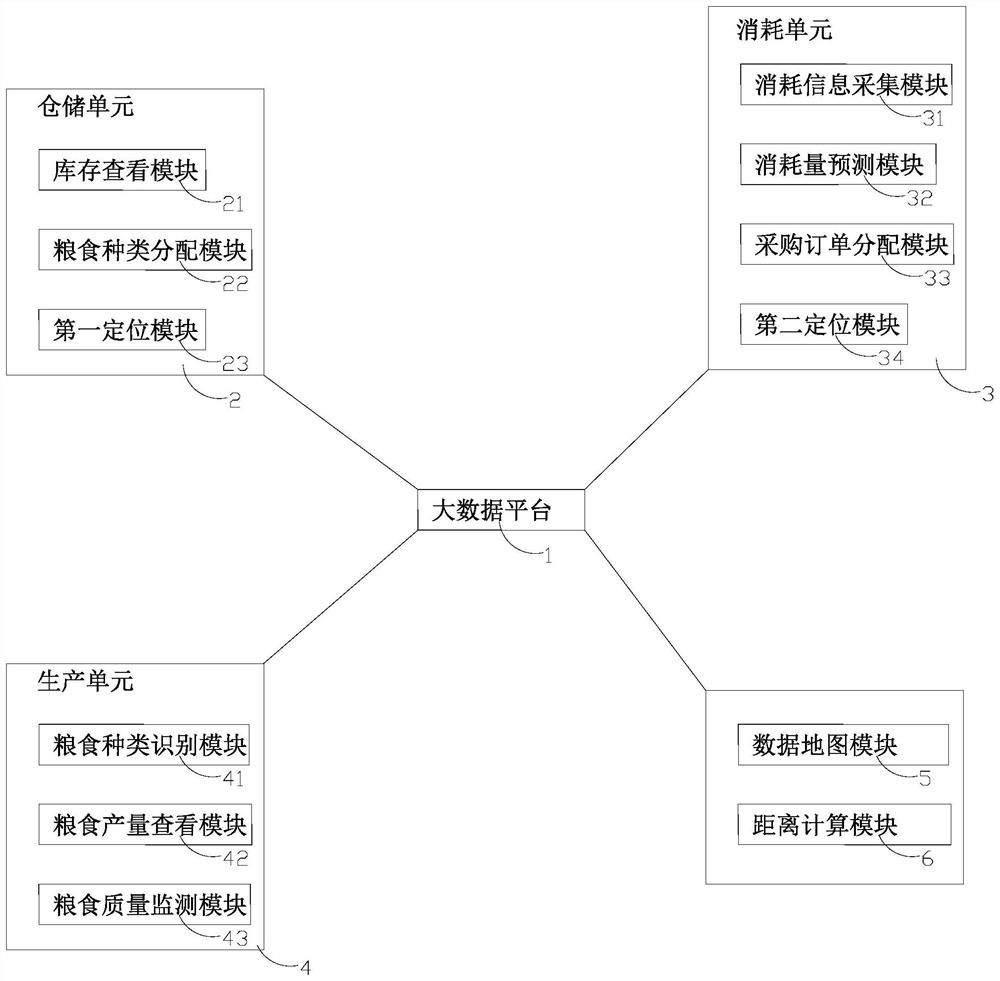

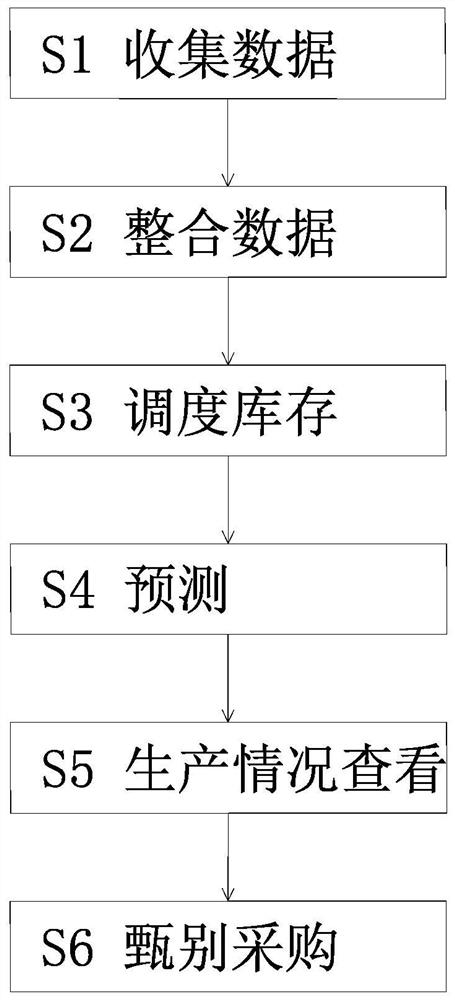

Warehouse management system and management method based on big data

PendingCN114331289AReduce storage costsReduce shipping costsResourcesLogisticsAgricultural scienceAgricultural engineering

The invention relates to a storage management system based on big data. The storage management system comprises a big data platform, a storage unit, a consumption unit and a production unit, wherein the consumption unit is used for collecting grain consumption on the market and predicting consumption in the next period; the production unit is used for collecting the yields of various grains of farmers and the quality levels of the grains; and the storage unit is used for adjusting stock proportions of different types of grains. According to the invention, by calculating the demand quantity of the local crowd for different types of grains, the inventory ratio of different grains in the granary is adjusted, the storage cost and the transportation cost of the grains are reduced, and the adaptive capacity to the actual eating condition of the grains is improved; the demand quantity of grains in the next period is predicted in advance according to existing data, stock distribution of the granary is planned in advance, and the strain capacity and predictability of warehouse management are improved; according to the quality detection of the grain production end, the grain quality is scientifically evaluated, and the quality level of the grain in the storage unit is ensured.

Owner:熊林

Granulator for plastic particle production

The invention relates to a granulator for plastic particle production. The granulator comprises a rack, a motor, a granulating barrel, cutters, a sealing gasket and a material liquid outlet; the motor, the granulating barrel and the cutters are arranged above the rack; a horizontal output shaft of the motor is connected with one end of a granulating shaft through a coupler; the other end of the granulating shaft is coaxially provided with the cutters; the granulating shaft and the cutters are coaxially and horizontally arranged in the granulating barrel; the sealing gasket provided with a center open hole is coaxially and tightly attached to the portion, on the outer side of the open end, of the granulating barrel; and the bottom of the opposite side of the open end of the granulating barrel is communicated with the granulating barrel and is provided with the material liquid outlet. The granulator is simple in structure and convenient to use, in this way, no gap is generated at the connection portion between the granulating barrel and a machine head any more, pelletized plastic particles in a pelletizing barrel cannot leak out of the granulating barrel, production raw materials are greatly saved, and the production efficiency is improved.

Owner:天津思迈德高分子科技股份有限公司

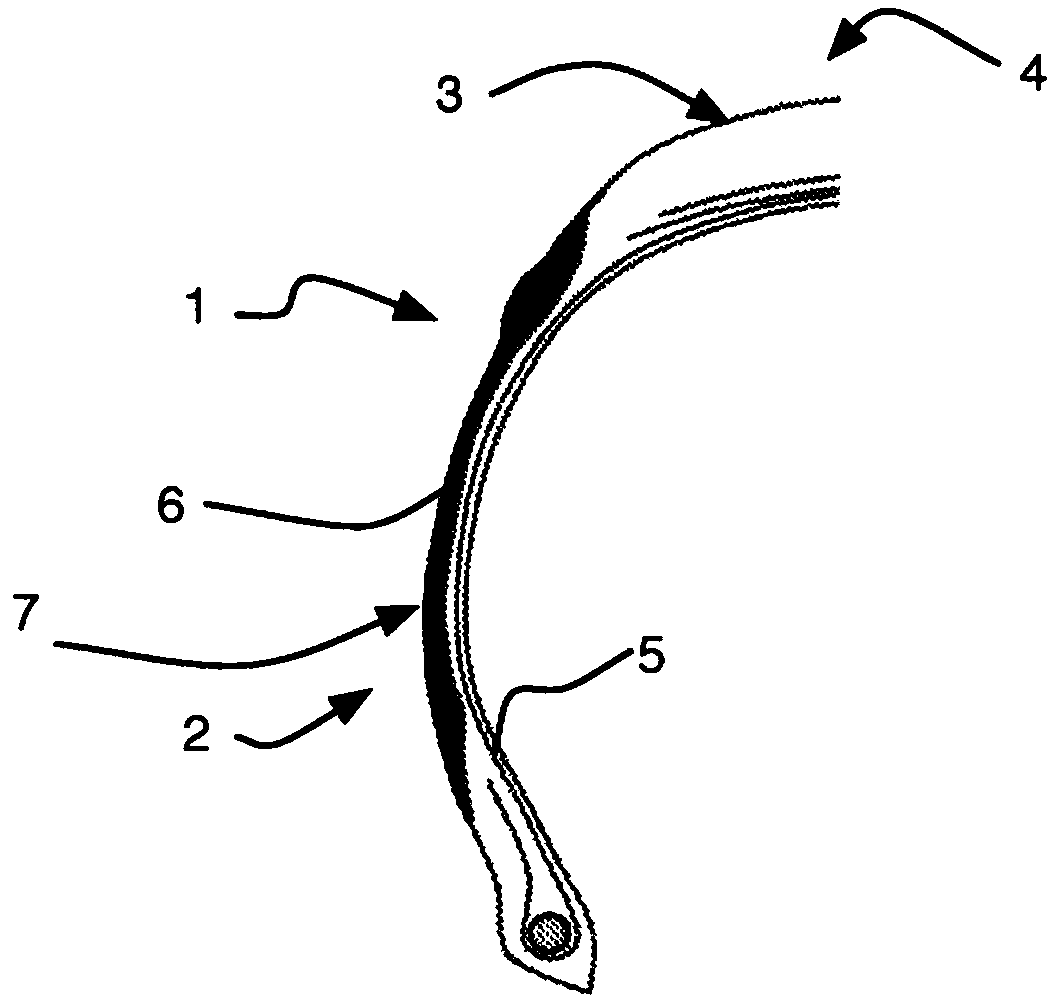

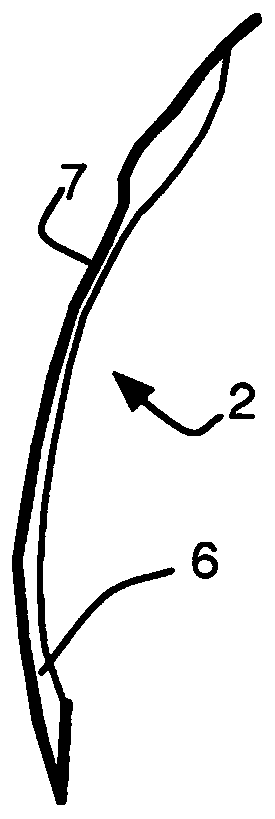

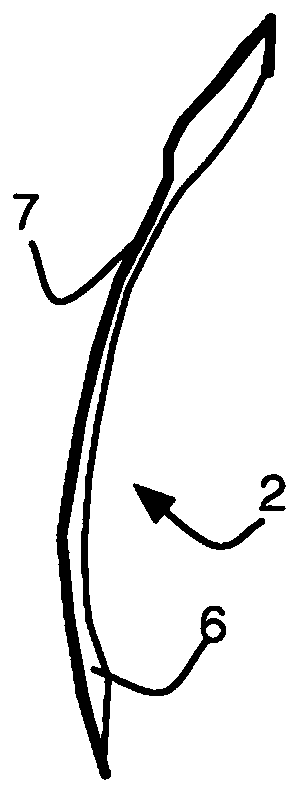

Tire with insert for sidewall

A tire (1) comprising sidewalls (2), a crown zone (3) with a tread (4), a reinforcing structure (5) extending between the sidewalls and passing through the crown zone, the portion of the sidewalls (2)that is axially exterior to the reinforcing structure (5) comprising an insert (6) that includes a first elastomer composition serving as a matrix in which a second elastomer composition derived fromrecycled tires is distributed in a substantially uniform manner, the proportion of the second composition being greater than or equal to 40%, and the insert (6) being axially exteriorly covered by aprotective layer (7).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

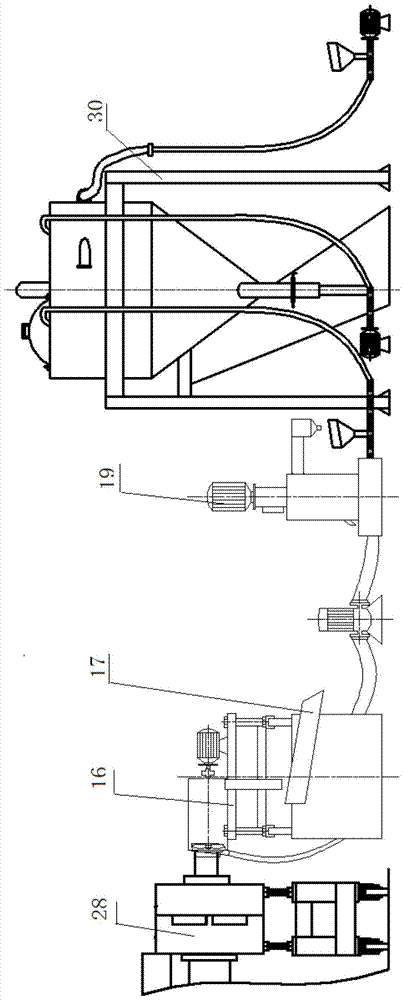

Production system for plastic pellets

ActiveCN105128169BIncrease productivityImprove quality uniformityCoatingsEconomic benefitsWater circulation

The invention relates to a novel plastic granule production system. The system comprises filament extruding machine, a granulator, a filter device, a spin-drying machine and a circulation mixing device which are connected in sequence. Due to the fact that the system is provided with the granulator, the filter device, the spin-drying machine and the circulation mixing device, the system integrates the working procedures of granulation, cooling, filtering, spin-drying, water circulation and the working procedures of granule extruding and mixing successively, the occupied space is greatly saved, the space using rate is improved, energy is saved, the production efficiency of an enterprise is improved, and the production cost of the enterprise is lowered; meanwhile, the circulation mixing device conducts the even mixing operation on plastic granules obtained after granulation, the differences of colors, performances, sizes and other aspects of the plastic granules obtained after granulation are small, the quality uniformity of the finished plastic granules is improved, and economic benefits of the enterprise are improved.

Owner:天津思迈德高分子科技股份有限公司

Corn thread arranging device

The invention relates to a tire producing device, in particular to a corn thread arranging device. The corn thread arranging device is provided with a thread arranging part, a thread wheel fixing partand a thread pressing guiding part; the thread arranging part is provided with a lead screw transmission structure; a lead screw nut is connected with a thread passing frame and an expanding shaft frame; the thread passing frame is connected with a guide rail slider; a lead screw is controlled through a motor, it is achieved that the thread wheel fixing part and the thread pressing guiding part horizontally move along a linear guide rail; the expanding shaft frame of the thread wheel fixing part is connected with a thread wheel mixing shaft; a thread wheel expanding roller connected with oneend of the thread wheel mixing shaft effectively fixes a wire wheel coiled material; a braking disk and a brake connected with the other end of the thread wheel mixing shaft achieve braking on the thread wheel expanding roller; the wire pressing guiding part comprises a cylinder; the cylinder drives a pressing wheel on a pressing wheel frame connected with the telescopic end of the cylinder to ascend and descend; the coiled material cotton thread sequentially penetrates a kidney-shaped through hole in the thread passing groove, a pressing wheel frame guiding hole and a thread connection nozzleto reach the position below the pressing wheel, the acting force of the pressing wheel on the cotton thread is guaranteed, thread arranging is effectively controlled, the automation degree is improved, time and labor are saved, and resource waste is reduced.

Owner:WEIHAI SANFANG RUBBER MACHINERY

Production method of false twist draw-texturing yarns and detection method of over-tail joints in yarn false twist draw-texturing process

ActiveCN111996633AGuaranteed quality levelWon't wastePiercing arrangementsYarnStructural engineering

The invention discloses a production method of false twist draw-texturing yarns and a detection method of over-tail joints in the yarn false twist draw-texturing process. The production method of thefalse twist draw-texturing yarns comprises the steps of enabling multiple yarn coils sequentially connected end to end to be subjected to a false twist draw-texturing process; (1) enabling a yarn of the multiple yarn coils sequentially connected end to end to pass through a detection channel and then to be subjected to the false twist draw-texturing process, wherein the detection channel collectsthe position change information of the next yarn coil sequentially connected end to end switched from one yarn coil with the yarn passing through completely, and each collected position change information identifies an over-tail joint; and (2), when collecting one position change information, replacing a yarn coil with one over-tail joint coiled after false twist draw-texturing, and re-coiling a new false twist draw-texturing yarn, and so on. According to the method, the over-tail joints can be easily cleared, the quality of yarn coils is ensured, and meanwhile, through the automatic detectionof the over-tail joint information, the mis-recording or missing phenomenon easily occurred by excessive reliance on manual intervention is avoided, so that the efficiency is improved and the cost isreduced.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

A production method for false twisting and texturing of yarn and a detection method for tail joints in the process of false twisting and texturing of yarn

ActiveCN111996633BGuaranteed quality levelWon't wastePiercing arrangementsYarnStructural engineering

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD

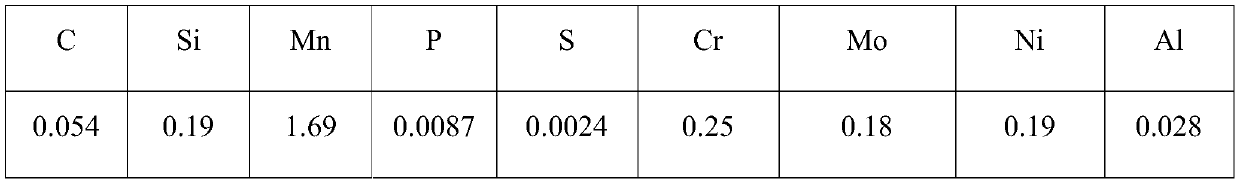

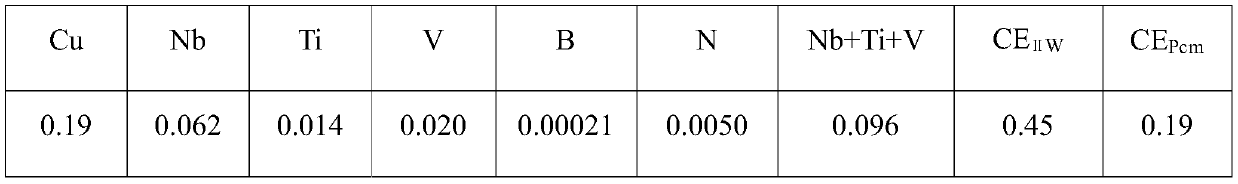

A method for manufacturing super-large diameter thick-walled x80 steel grade spiral submerged arc welded pipe

The invention discloses a manufacturing method for an oversized-pipe-diameter thick-wall X80 steel-grade spiral submerged-arc welded pipe, and belongs to the field of spiral submerged-arc welded pipemanufacturing. The method comprises the following steps of: uncoiling, leveling, edge-milling, pre-bending, forming, pre-welding, fine-welding, tube end rounding, welding seam X-ray detecting, hydrostatic-pressure testing, base material ultrasonic automatic detecting, welding seam ultrasonic automatic detecting, ultrasonic manual detecting, mechanical end-flattening, appearance checking and anticorrosive paint coating, wherein a groove in the edge-milling process is set to be a double-V-shaped composite groove; and the fine-welding process comprises an internal-welding process and an external-welding process, which adopt three-wire serial submerged-arc automatic welding processes. The method provided by the invention can solve the technical problems that the technical requirements on welding seam quality of the oversized-pipe-diameter thick-wall X80 steel-grade spiral submerged-arc welded pipe are difficult to meet, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Processed cheese and processing method thereof

The invention provides processed cheese and a processing method thereof. The processed cheese comprises main materials and auxiliary materials, wherein the main materials include 10-25 parts by weight of chymosin casein, 10-30 parts by weight of plant fat, 1-15 parts by weight of milk fat, 15-40 parts by weight of composite natural cheese and 30-40 parts by weight of water; and the auxiliary materials include 0.5-3 parts by weight of emulsifying salt, 0.3-3 parts by weight of tablet salt, 0.1-1 part by weight of acidity regulator and 0.5-3 parts by weight of nutrient accessories. In a formula, the plant fat is added into the main materials to reduce the cost of raw materials of the processed cheese, a proper amount of milk fat is added to provide many complete fat globules, the chymosin casein as well as the emulsifying salt, acid and table salt at a proper proportion are adopted, and various kinds of natural cheese are added. In a process, a certain adding order is adopted, and the heating of the product and the mechanical effect are controlled. Through perfect match of the formula and process, the pizza cheese with good functionality and flavor is prepared while the cost is reduced.

Owner:孙玉强 +1

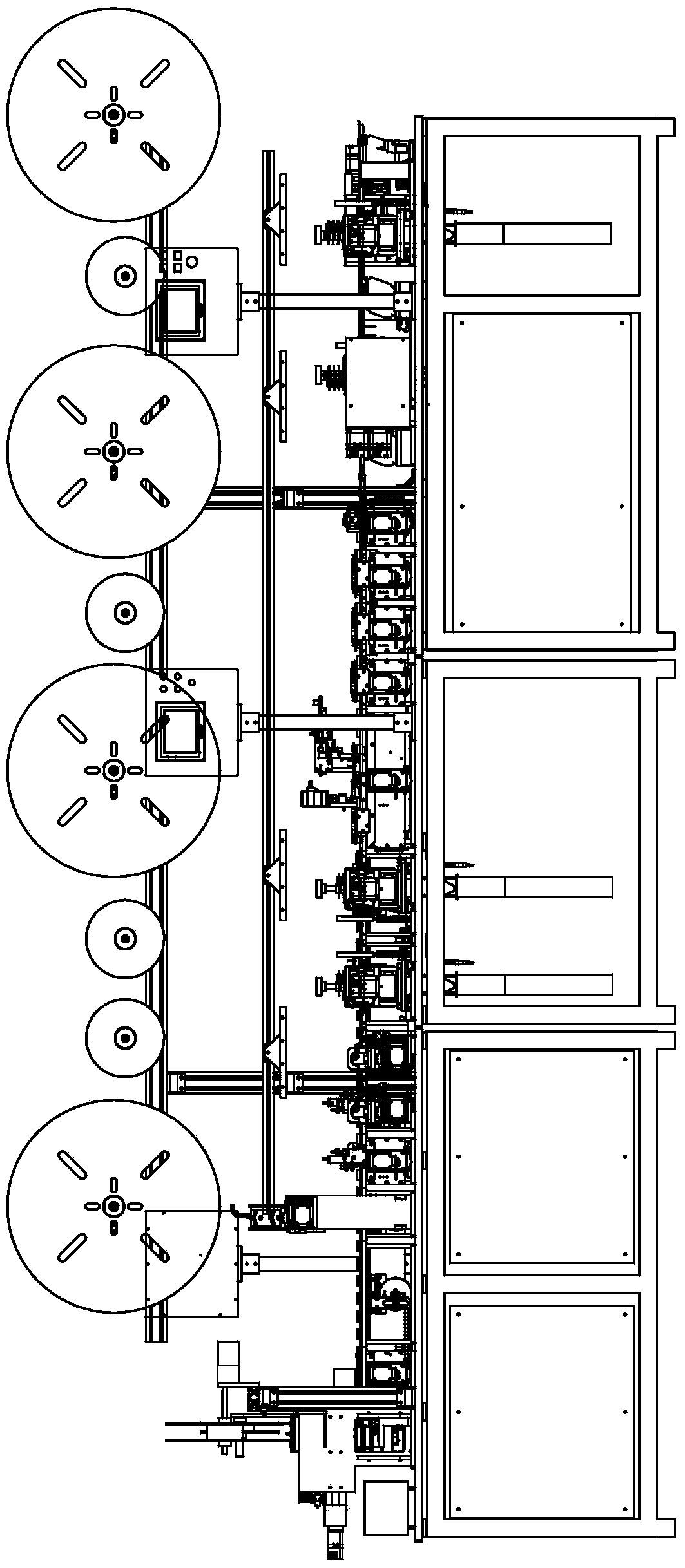

A kind of fpc connector automatic production equipment

InactiveCN105470781BGuaranteed quality levelIncrease productivityContact member assembly/disassemblyState of artLaser

The invention discloses automatic production equipment for FPC connectors. The automatic production equipment for FPC connectors is characterized by comprising a first product vibratory conveying mechanism, a first main body pin accurate pushing mechanism, a front terminal inserting mechanism, a second product vibratory conveying mechanism, a second main body pin accurate pushing mechanism, a rear terminal inserting mechanism, a third product vibratory conveying mechanism, a product separating and carrying mechanism, a product front terminal flattening mechanism, a product rear terminal flattening mechanism, a product withstand voltage detecting mechanism, a product cover mounting mechanism, a product front terminal re-flattening mechanism, a first main body socket welding pad accurate positioning mechanism, a product left welding pad inserting mechanism, a second main body socket welding pad accurate positioning mechanism, a product right welding pad inserting mechanism, a CCD detecting mechanism, a laser marking mechanism, a product NG eliminating mechanism and a product packaging mechanism. The automatic production equipment for FPC connectors has the advantages of high automation degree, high work efficiency, good product quality, high product percent of pass, capability of saving human resources and the like which do not exist in the prior art.

Owner:SHENZHEN YANFENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com