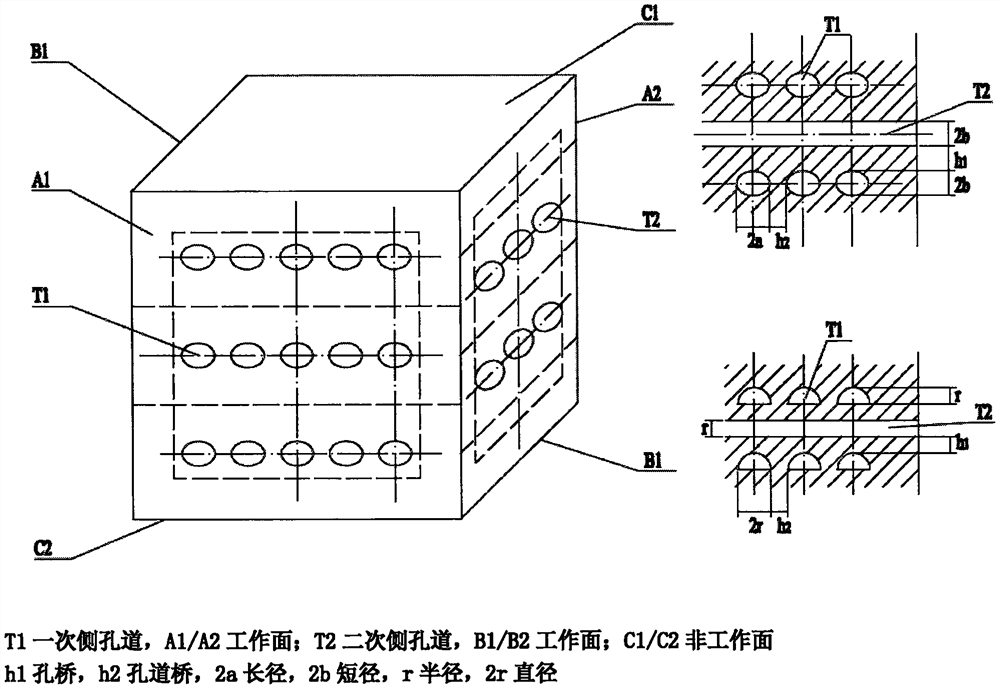

Design scheme of ultrahigh-temperature ultrahigh-pressure pore type heat exchanger/ evaporator

A design scheme, high temperature and high pressure technology, applied in the field of ultra-high temperature and ultra-high pressure tunnel heat exchanger/evaporator design, can solve the problems of broken heat transfer tubes, high cost and expensive equipment, and achieve a heat transfer area Increase, high heat transfer efficiency, and small heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

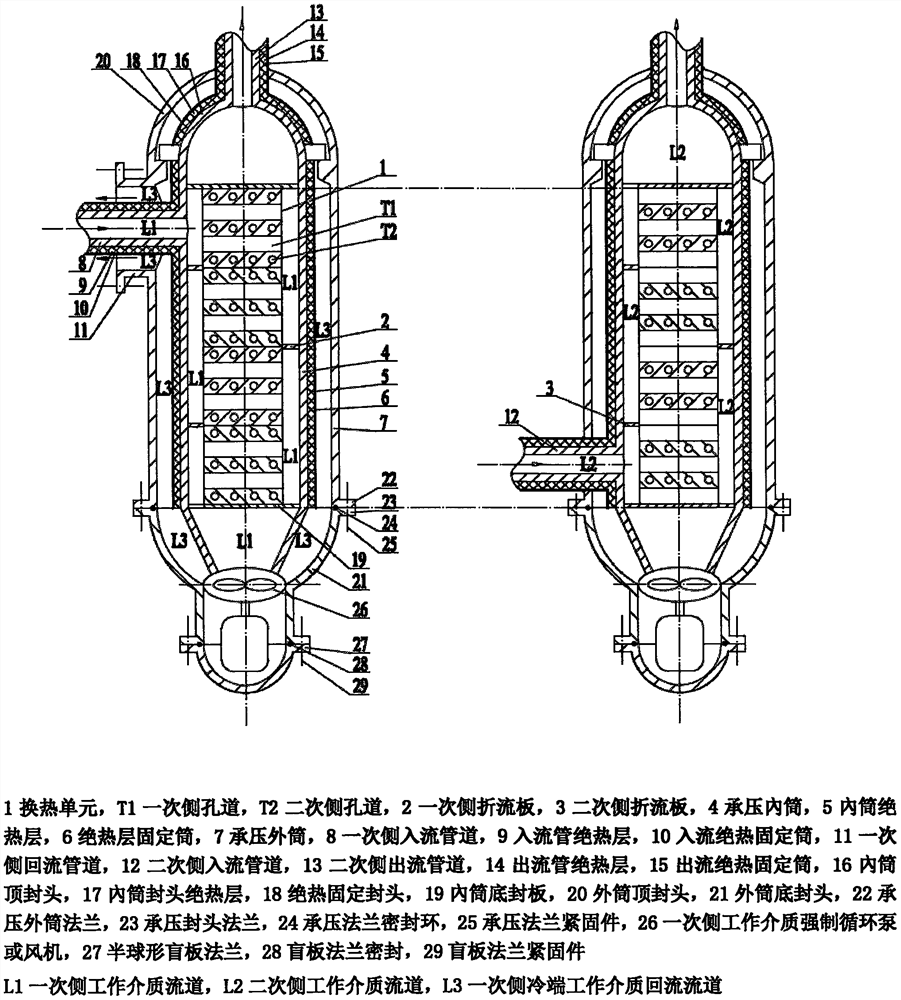

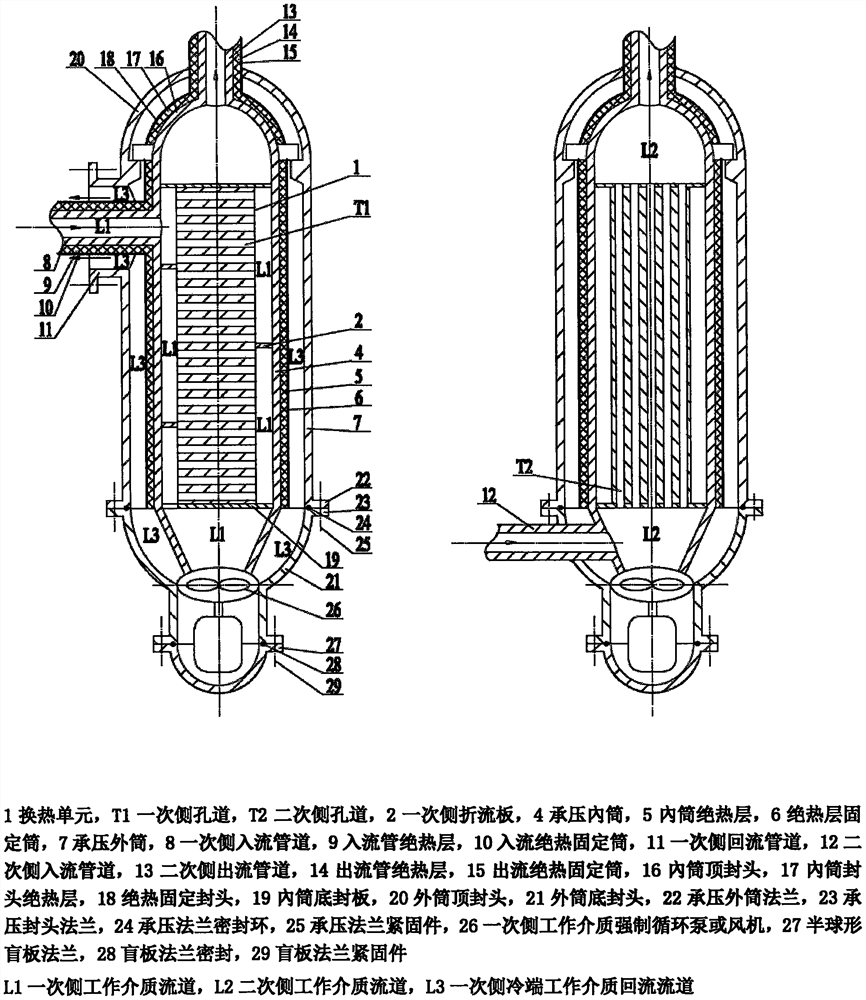

[0032] attached figure 2 It is an embodiment of the present invention in the application aspect of the steam generator / intermediate heat exchanger of a high-temperature gas-cooled reactor or an ultra-high-temperature gas-cooled reactor.

[0033] This embodiment is very suitable for the design of steam generators for high-temperature gas-cooled reactors with ultra-supercritical parameters for power generation. Ultra-high temperature superimposed ultra-high pressure technical parameters are the design difficulties and pain points of this embodiment. Under the high pressure design condition, the reliability of the heat transfer tube is not enough, and the accident of tube breakage and water loss is easy to occur. The working medium on the primary side of the high-temperature gas-cooled reactor is hot helium with a working pressure of 8MPa and a working temperature of 750°C, which flows into the first-stage heat exchange unit (1) and the pressure-bearing inner cylinder (4) throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com