Integral modular channel type heat exchanger structure based on additive manufacturing forming

An additive manufacturing and modular technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of side flow baffle, unclear drainage structure, increased manufacturing cycle, large cross-sectional area, etc. The effect of thermal efficiency and structural rationality, low cost and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

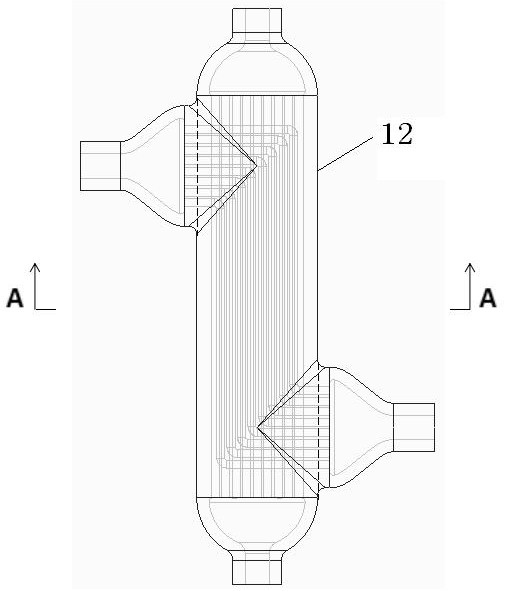

[0025] Such as Figure 1-5 shown.

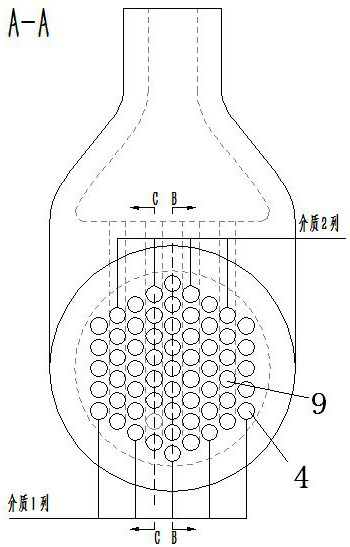

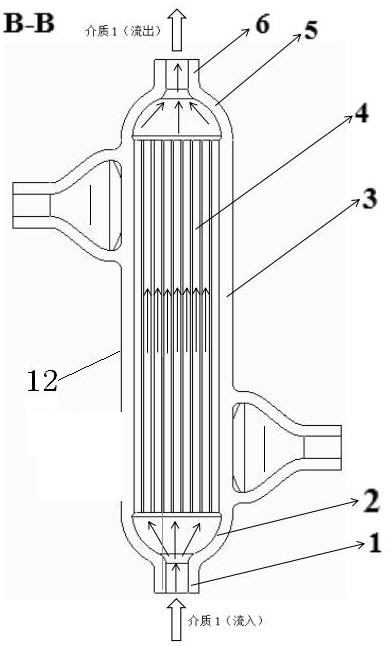

[0026] An integral modular channel heat exchanger structure based on additive manufacturing, which is printed at one time using additive manufacturing technology, and its shape is as follows: figure 1 As shown, it includes a solid heat exchange body section 12, and the heat exchange body section 12 is provided with a direct flow channel 4 for the first medium to flow through and a side flow channel 9 for the second medium to flow through. The direct flow channel 4 and the side flow channel 9 are arranged at intervals, such as figure 2 shown. The cross-sections of the direct flow channel 4 and the side flow channel 9 can be figure 2 The circle shown can also be oval or waist-shaped. The heat exchange unit 3 is formed at the intersection of the direct current channel 4 and the side flow channel 9. The lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com