An additively manufactured heat exchanger with a half "half" loop baffle and drainage structure

An additive manufacturing and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, tubular elements, etc., which can solve the problems of side flow baffles, unclear drainage structures, unreasonable heat exchanger structures, and manufacturing cycles. Increase and other problems to achieve the effect of ensuring heat exchange efficiency and structural rationality, ensuring the safe operation of equipment and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0025] like Figure 1-5 shown.

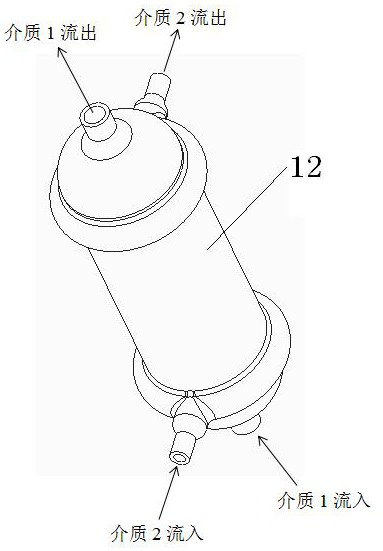

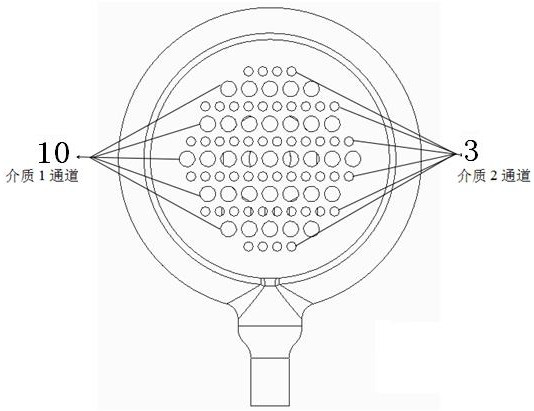

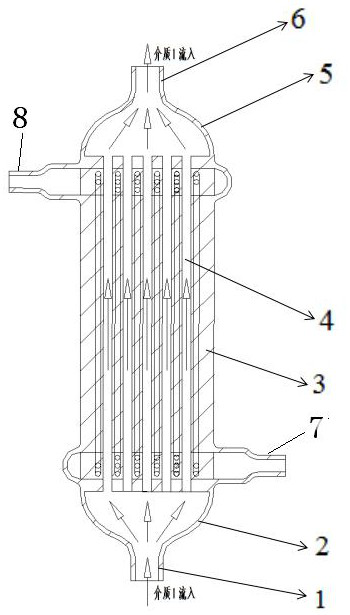

[0026] An additive-manufactured heat exchanger with a semi-"half" annular tube-type baffle and drainage structure, which adopts additive manufacturing as a whole, is printed and formed at one time, and has a shape such as figure 1 As shown, it includes a solid cylindrical body 12, in which the solid cylindrical body 12 is formed with a DC channel 4 that runs up and down and side flow channels 10 arranged at intervals, the lower end of the DC channel 4 is connected to the DC lower head 2, The head 2 is provided with a direct-current inlet pipe 1 for entering the medium 1, and the upper end of the direct-current channel 4 is connected with a direct-current upper head 5, and the direct-current upper head 5 is provided with a direct-current outlet pipe 6 for the medium 1 to flow out. The lower end of 10 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com