engine cooling jacket

A technology for cooling water jackets and engines, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of engine temperature increase, high manufacturing cost, insufficient cooling, etc., to reduce flow resistance, improve flow trajectory, cool down same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

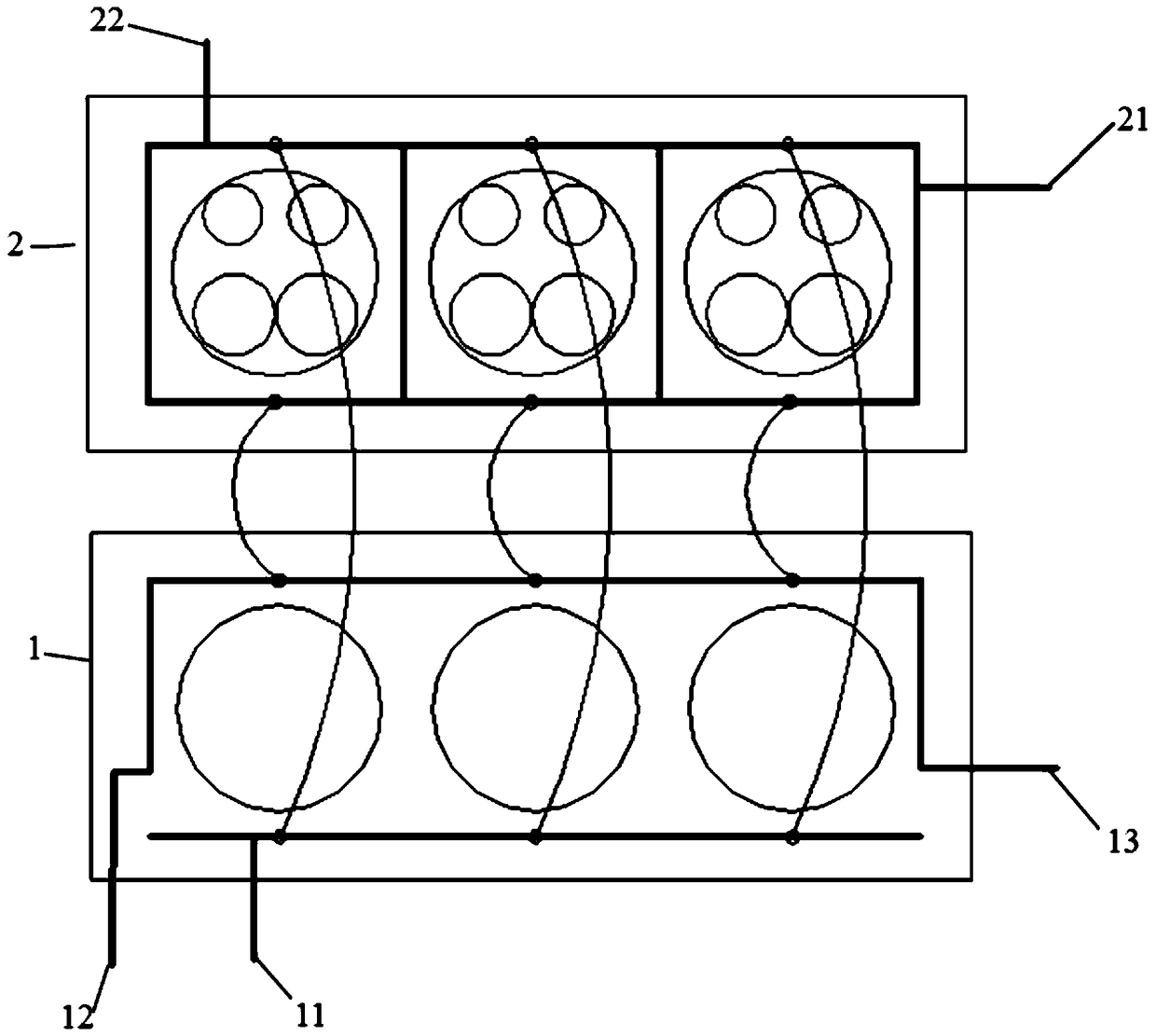

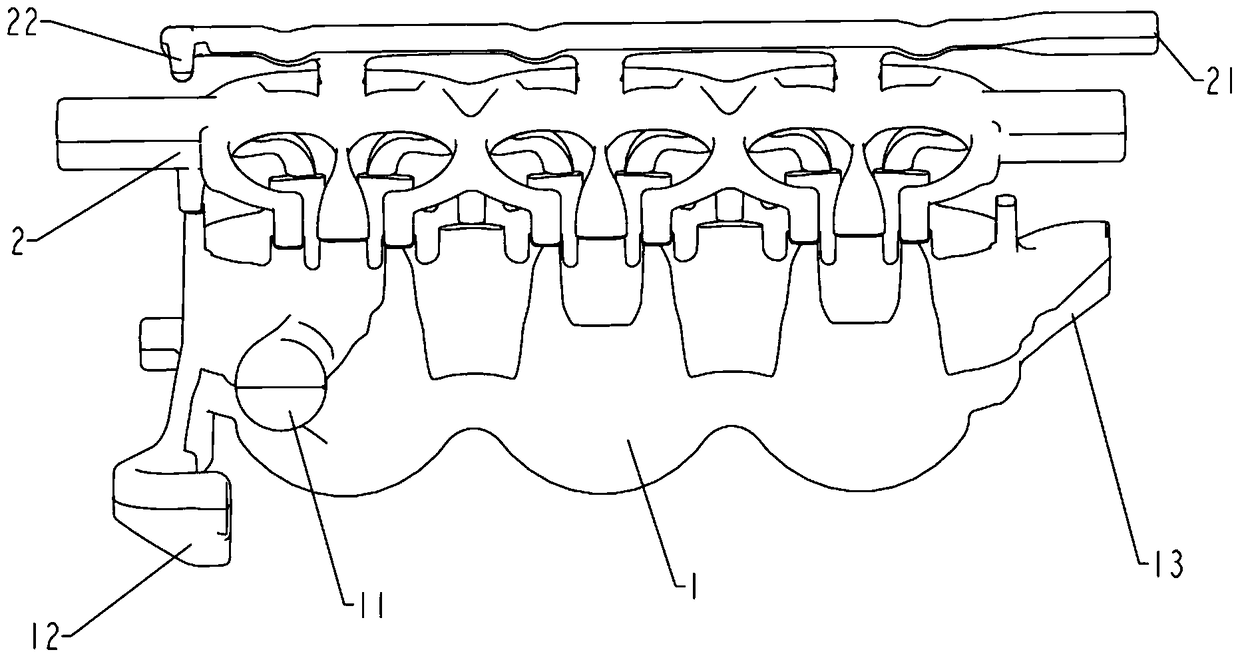

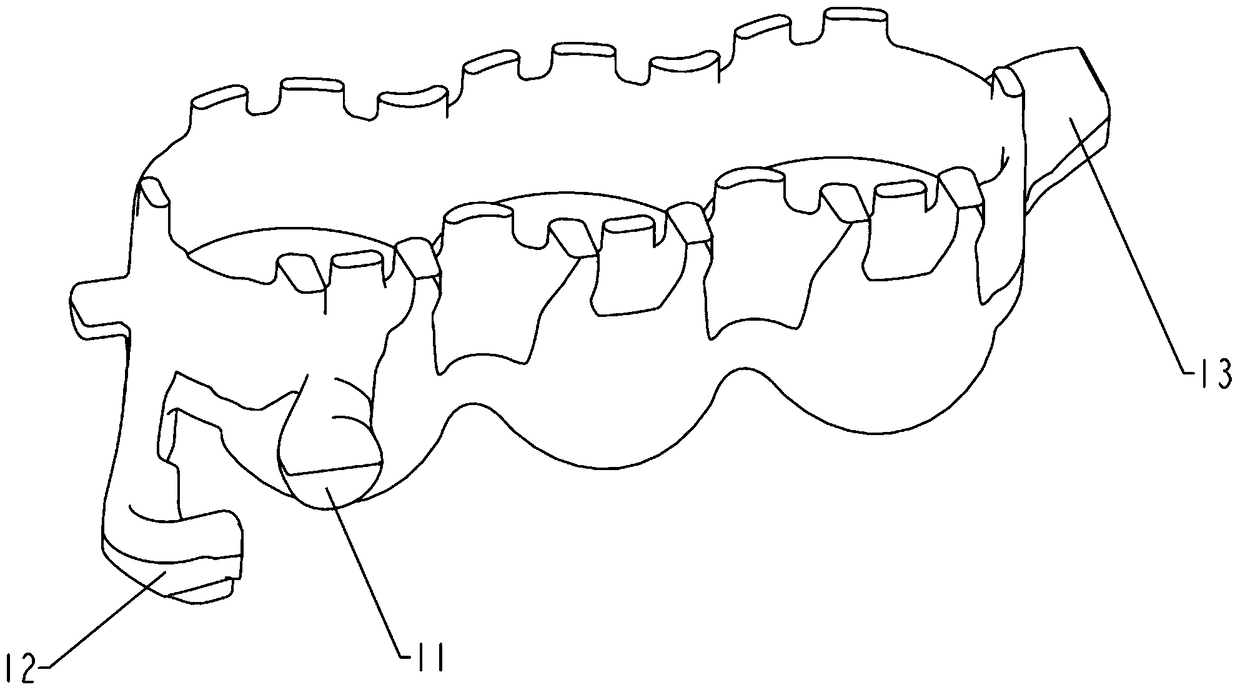

[0034] Such as Figure 1 to Figure 6 The engine cooling water jacket shown includes a cylinder block water jacket 1 and a cylinder head water jacket 2 . Two partitions 14 are arranged inside the cylinder block water jacket 1, and the cylinder block water jacket 1 is divided into two parts, the exhaust side cylinder block water jacket 15 and the intake side cylinder block water jacket 16, by the two partitions 14. The front end of the cylinder block water jacket 15 on the exhaust side is provided with a main water inlet 11, the bottom of the front end of the cylinder block water jacket 16 on the intake side is provided with a secondary water inlet 12, and the rear end of the cylinder block water jacket 16 on the intake side is provided with Main water outlet 13. The cylinder head water jacket 2 includes a first auxiliary water outlet 21, a second auxiliary water outlet 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com