Additive manufacturing heat exchanger with half ''half'' annular pipe type baffling and drainage structure

An additive manufacturing, heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, tubular elements, etc., which can solve problems such as large cross-sectional area, unreasonable heat exchanger structure, and increased manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

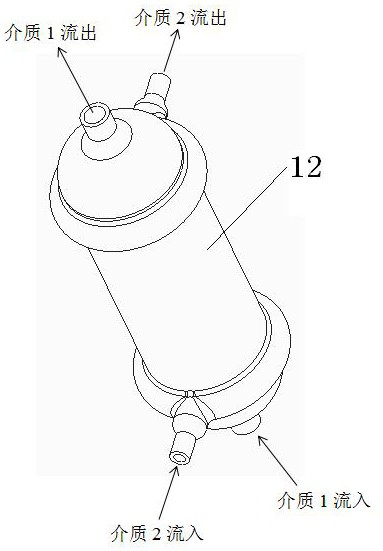

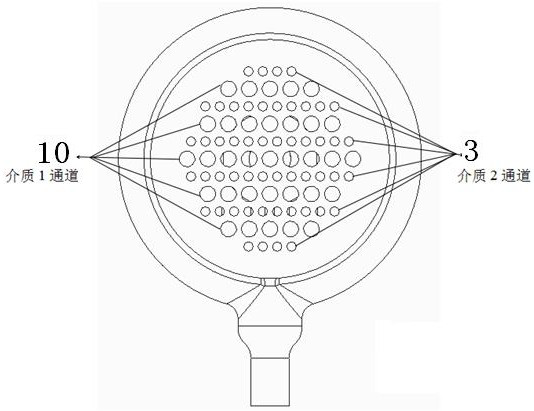

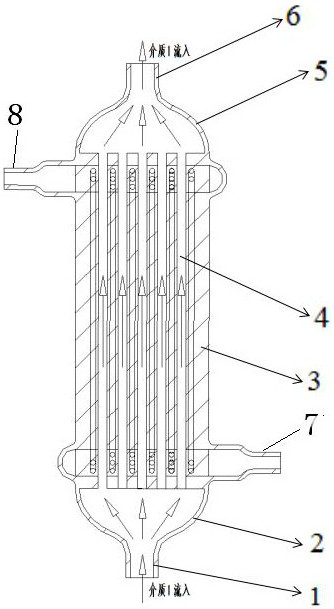

[0025] Such as Figure 1-5 shown.

[0026] An additively manufactured heat exchanger with a half "half" ring-tube baffle and drainage structure, which is entirely manufactured by additive manufacturing and printed at one time. The shape is as follows: figure 1 As shown, it includes a solid cylindrical body 12, in which there are vertically connected direct current passages 4 and side flow passages 10 arranged at intervals. The head 2 is provided with a DC inlet pipe 1 for the medium 1 to enter, and the upper end of the DC channel 4 is connected with the DC upper head 5, and the DC upper head 5 is provided with a DC outlet pipe 6 for the medium 1 to flow out, and the side flow channel The lower end of 10 communicates with the half "half" drainage lower ring pipe 9 through the lower deflection pipe 13, and the half "half" drainage lower ring pipe 9 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com