Corn thread arranging device

A wiring device and cord technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of waste of raw materials, affecting the quality of tires, and the speed of cord unwinding and cord tension can not be uniformly controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

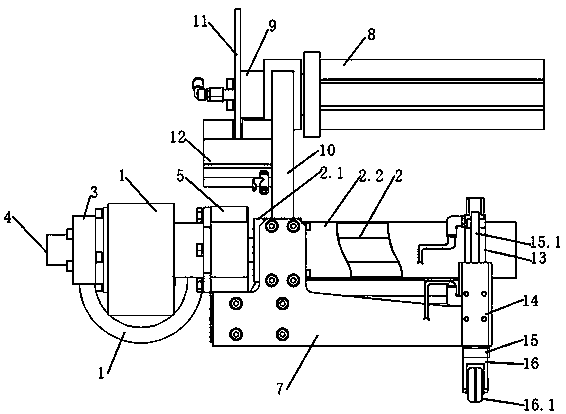

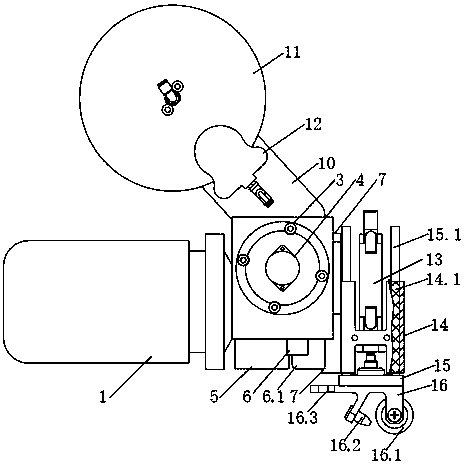

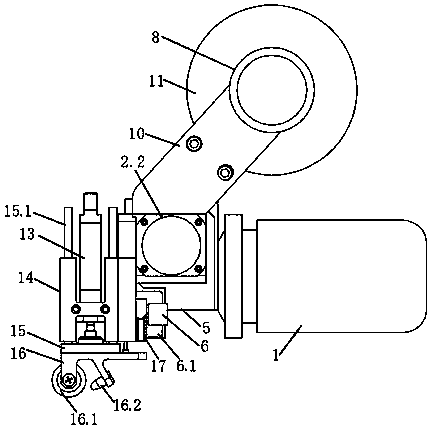

[0019] Combine below Figure 1-Figure 3 The present invention will be further explained.

[0020] Such as Figure 1-Figure 3 As shown, a cord wiring device is used for the production of tire inner supports. It includes a wire-arranging part, a wire wheel fixing part and a wire-pressing guide part. The wire-arranging part includes a screw drive structure: one end of the screw 2 and the output of the motor 1 The screw 2 is a ball screw. When the cord wiring device is not used or transported, the outer circumference of the screw 2 is sleeved with the screw sheath 2.2. The screw sheath 2.2 can effectively protect the screw 2. The sleeve 2.2 is a hollow cylinder with an open end. The screw 2 is sleeved with a screw nut 2.1 at one end close to the motor 1. The central axis of the screw 2, the screw sheath 2.2 and the screw nut 2.1 are the same, and the diameter of the screw nut 2.1 One side is connected with the upper part of the wire rack 7 by bolts, the lower part of the screw 2 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com