A method for manufacturing super-large diameter thick-walled x80 steel grade spiral submerged arc welded pipe

A technology of submerged arc welded pipes and manufacturing methods, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems such as difficulty in ensuring the quality of weld seams of X80 steel grade steel pipes, and achieve the overall quality level and reduce residual stress , the effect of reducing the amount of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

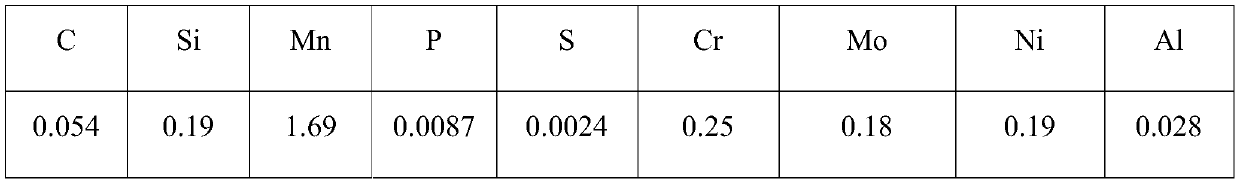

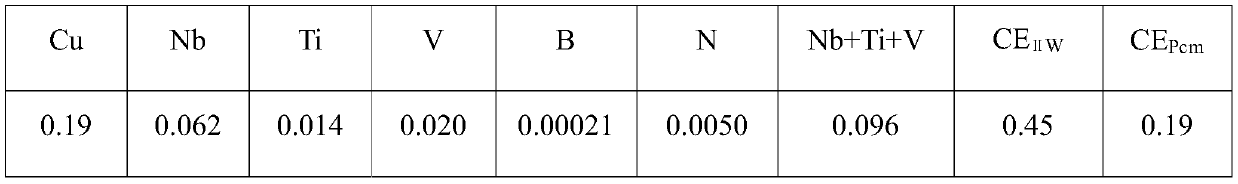

[0065] The main chemical composition of the coil used for the X80 steel grade spiral submerged arc welded pipe in the embodiment of the present invention is shown in Table 1. The weight percentage of the chemical composition of the coil conforms to the American Petroleum Institute API Spec 5L: 2012 standard, and the microstructure is GB +PF (granular bainite + polygonal ferrite), the grain size is greater than or equal to grade 12, the outer diameter of the steel pipe is 1422mm, and the thickness is 21.4mm. The manufacturing process steps of the super large diameter thick wall X80 steel grade spiral submerged arc welded pipe are as follows:

[0066] 1. The coil is uncoiled and leveled;

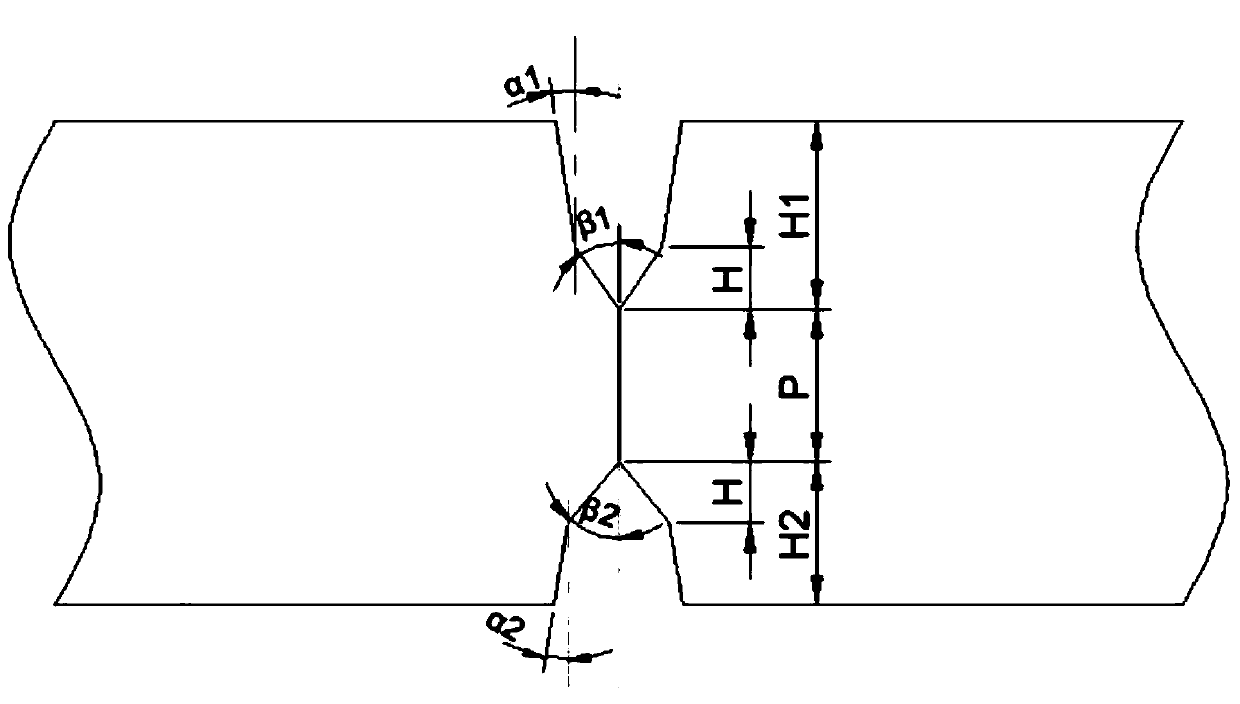

[0067] 2. Edge milling: first rough mill the I-shaped groove, mill the edge width of the plate by 10-20mm to ensure the width of the strip, and remove the plate edge defects and crescent bends caused by the steel billet and the rolling process; then fine milling It is a double V-shaped compou...

Embodiment 2

[0097] The main chemical composition of the coil used for the X80 steel grade spiral submerged arc welded pipe in this embodiment is shown in Table 6. The weight percentage of the chemical composition of the coil conforms to the American Petroleum Institute API Spec 5L: 2012 standard, and the microstructure is GB+PF( Granular bainite + polygonal ferrite), the grain size is greater than or equal to grade 12, the thickness of the steel pipe is 22mm, and the outer diameter of the steel pipe is 1219mm. The manufacturing process steps of the super large diameter thick wall X80 steel grade spiral submerged arc welded pipe are as follows:

[0098] 1. The coil is uncoiled and leveled;

[0099] 2. Edge milling: first rough mill the I-shaped groove, and mill the edge width of the plate by 10-20mm; then finish milling to form a double V-shaped compound groove, and the angle of the outer groove surface of the upper groove is α 1 is 9°, and the angle β of the inner groove surface of the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com