Tectona grandis color change treatment method

A treatment method and technology of teak, which is applied in the field of physical discoloration of teak, can solve the problems of large deviation of moisture content in the board, low treatment efficiency, long health treatment time, etc., achieve uniform moisture content, improve production efficiency, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

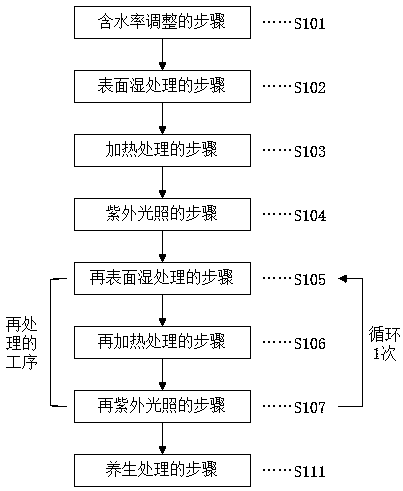

[0036] Embodiment 1: In this embodiment, the season of processing is summer, and outdoor temperature is 35-37 ℃, refer to figure 1 Shown a kind of teak discoloration processing method, comprises following processing steps successively.

[0037] S101. A step of adjusting the moisture content, the step is to adjust the moisture content of the teak wood blank to 10-12%, and the deviation of the moisture content in the board is less than 1.5%.

[0038] S102. A step of surface wet treatment, the step is to use a sponge roller coater to roll-coat a wetting liquid on the surface of the teak wood blank, wherein the wetting liquid is clear water, and the coating amount of the roll coating is 40±1g / ㎡.

[0039] S103. The step of heat treatment. This step is to add a hot air blower in the infrared light tunnel to simultaneously perform infrared light heating and convection heating (hot air heating) on the teak blank. Through the joint action of the infrared light and the hot air blower,...

Embodiment 2

[0047] Example 2: The difference between Example 2 and Example 1 is that in the step of S202. surface wet treatment, the coating amount of roller coating is 28±1g / ㎡; in the step of S203. Completed in the tunnel, through the action of infrared light, a heating temperature of 70±1°C is formed in the infrared illumination tunnel. It takes 20s for the teak blank to enter the infrared illumination tunnel and leave. In this step, the infrared The temperature in the light tunnel is adjusted to a heating temperature of 50±2°C. At this time, the time taken for the teak blank to leave the infrared light tunnel is 25 seconds.

Embodiment 3

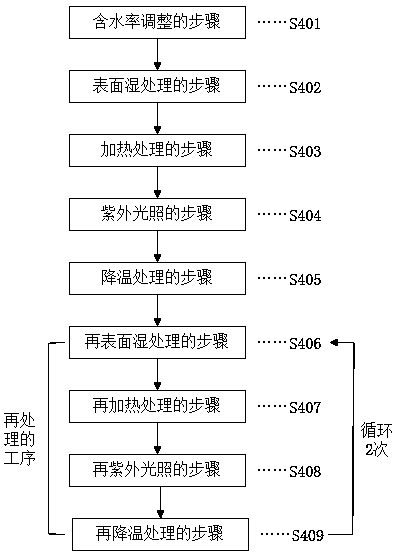

[0048] Embodiment 3: In this embodiment, the treatment season is winter, and the outdoor temperature is minus 5-5°C. A teak discoloration treatment method includes the following treatment steps in sequence.

[0049] S301. A step of adjusting the moisture content, the step is to adjust the moisture content of the teak wood blank to 9-11%, and the deviation of the moisture content in the board is less than 1%.

[0050] S302. The step of surface wet treatment, using a sponge roller coater to roll-coat a wetting liquid on the surface of the teak wood blank, wherein the wetting liquid is a mixture of clear water and a discoloration treatment agent, and the discoloration treatment agent can be any commercially available, for example In the formula of the modified solution containing isocyanate group disclosed in Chinese patent CN 107471358A, the mass feeding ratio of the modified solution containing isocyanate group and clear water is 1: (30-32), and the amount of roll coating is 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com