Thin tungsten copper sheet and preparing method of thin tungsten copper sheet

A technology of tungsten-copper and flakes, which is applied in the field of tungsten-copper flakes and its preparation, can solve problems such as difficulty in pressing large-size flakes, high cost, and difficult mixing of powders, so as to achieve high green compact density and overcome uneven density distribution , The effect of uniform compact density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

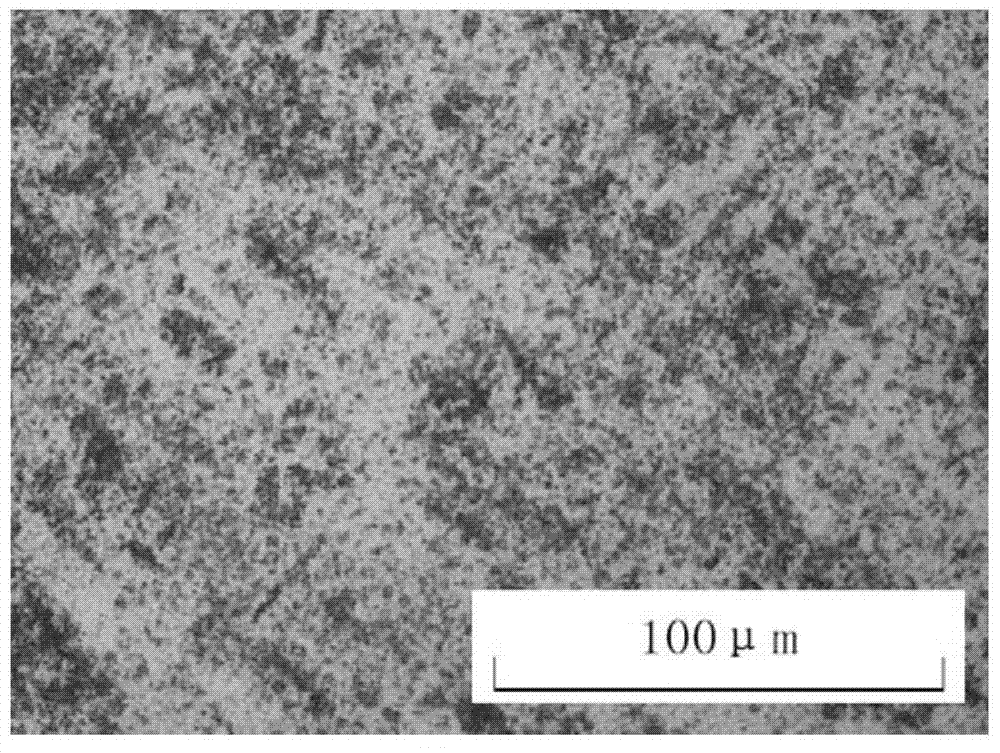

[0087] Embodiment 10.1mm thickness W50Cu50 sheet

[0088] (1) Prepare tungsten copper dispersion powder

[0089] The tungsten-copper dispersion powder used in this example was purchased from Hunan Sairui New Material Co., Ltd., and its brand name is W50Cu50. The tungsten-copper dispersion powder is prepared by chemical co-precipitation of tungsten and copper. The distribution of tungsten and copper is even, and its weight ratio is 1:1.

[0090] (2) Steel mold pressing

[0091] Put the powder of step (1) into a steel mold, press and form it on a hydraulic press, the pressure of the press is 120MPa, and obtain a steel mold-molded green compact with a thickness of 20mm.

[0092] (3) Cold isostatic pressing

[0093] Put the steel molded compact in step (2) into the aluminum-plastic composite film for vacuum packaging, and repress it in a cold isostatic press. The isostatic pressure is 250MPa. Take it out from the vacuum aluminum-plastic composite film to obtain a composite com...

Embodiment 20

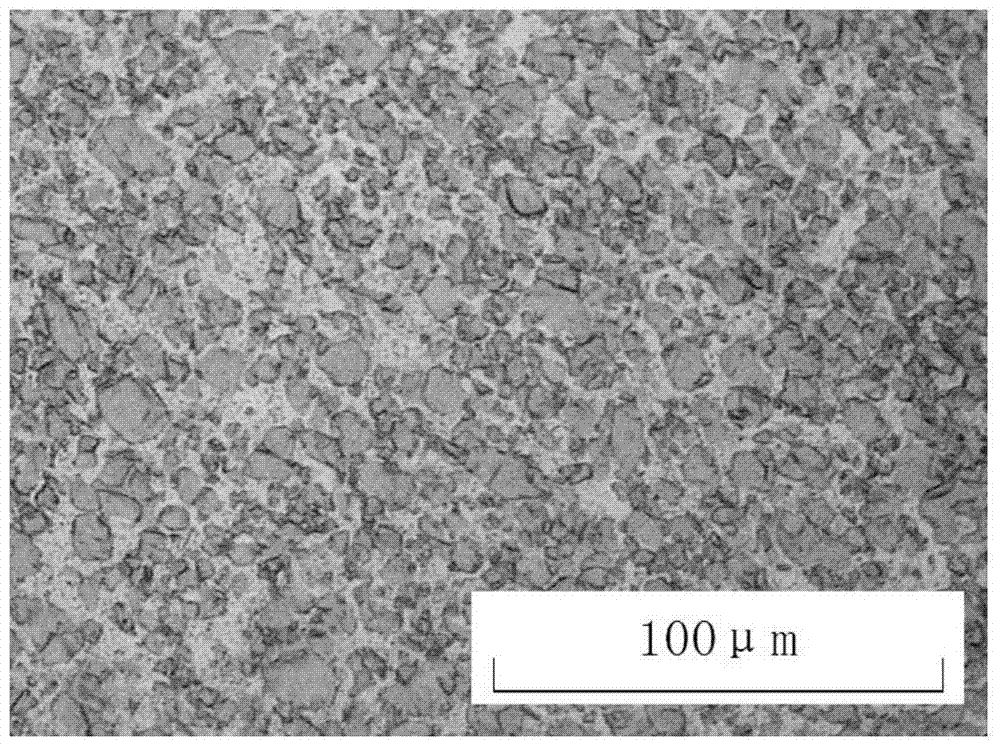

[0114] Embodiment 20.1mm thickness W80Cu20 sheet

[0115] (1) Prepare tungsten copper dispersion powder

[0116] The tungsten-copper dispersion powder used in this example was purchased from Hunan Sairui New Material Co., Ltd., and the brand name is W80Cu20. The tungsten-copper dispersion powder is prepared by chemical co-precipitation method of tungsten and copper. The distribution of tungsten and copper is uniform, and its weight ratio is 4:1.

[0117] (2) Steel mold pressing

[0118] Put the powder of step (1) into a steel mold, press and form it on a hydraulic press, the pressure of the press is 160MPa, and obtain a steel mold-molded green compact with a thickness of 15mm.

[0119] (3) Cold isostatic pressing

[0120] Put the steel molded compact in step (2) into the aluminum-plastic composite film for vacuum packaging, and repress in a cold isostatic press. The isostatic pressure is 260MPa, and then the isostatically pressed tungsten copper Take it out from the vacuum...

Embodiment 30

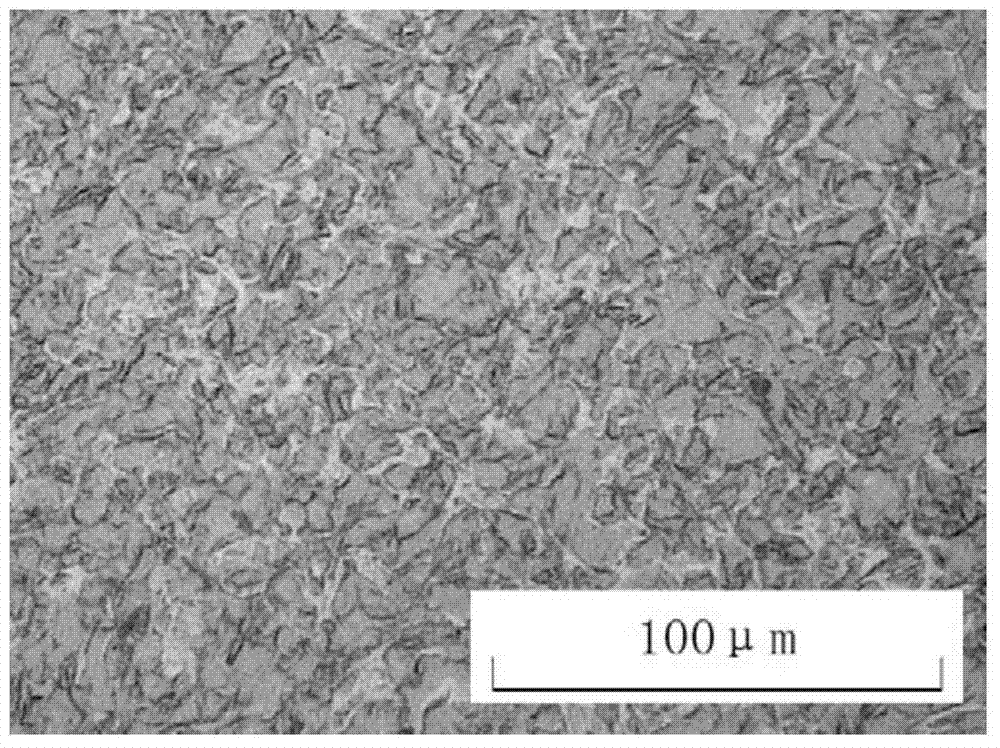

[0141] Embodiment 30.1mm thickness W90Cu10 sheet

[0142] (1) Prepare tungsten copper dispersion powder

[0143] The tungsten-copper dispersion powder used in this example was purchased from Hunan Sairui New Material Co., Ltd., and its brand name is W90Cu10. The tungsten-copper dispersion powder is prepared by chemical co-precipitation of tungsten and copper. The distribution of tungsten and copper is uniform, and its weight ratio is 9:1.

[0144] (2) Steel mold pressing

[0145] Put the powder of step (1) into a steel mold, press and form it on a hydraulic press, the pressure of the press is 160MPa, and obtain a steel mold-molded green compact with a thickness of 10mm.

[0146] (3) Cold isostatic pressing

[0147] Put the steel molded compact in step (2) into the aluminum-plastic composite film for vacuum packaging, and repress it in a cold isostatic press. The isostatic pressure is 280MPa. Take it out from the vacuum aluminum-plastic composite film to obtain a composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com