Patents

Literature

75results about How to "Improve contact tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

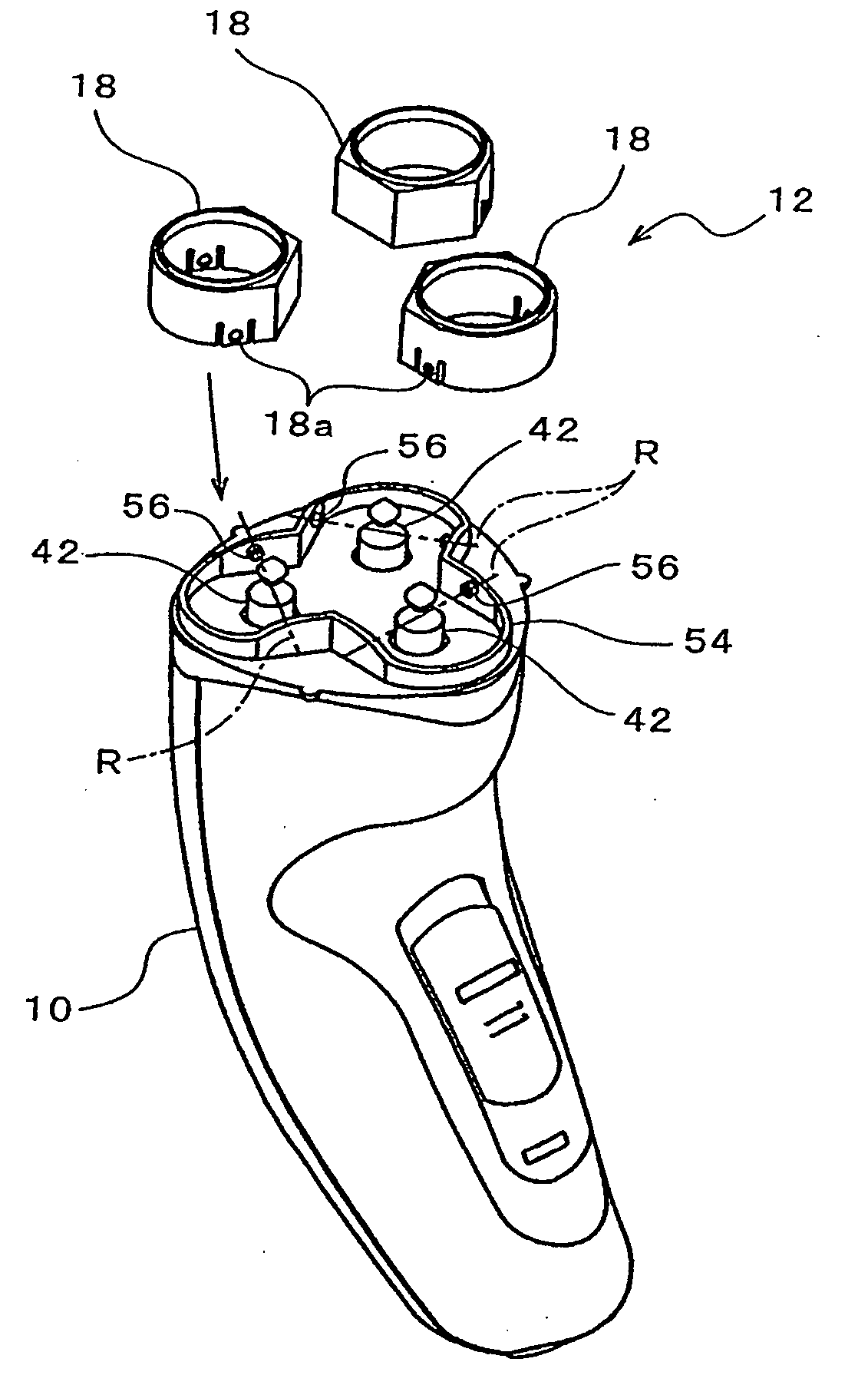

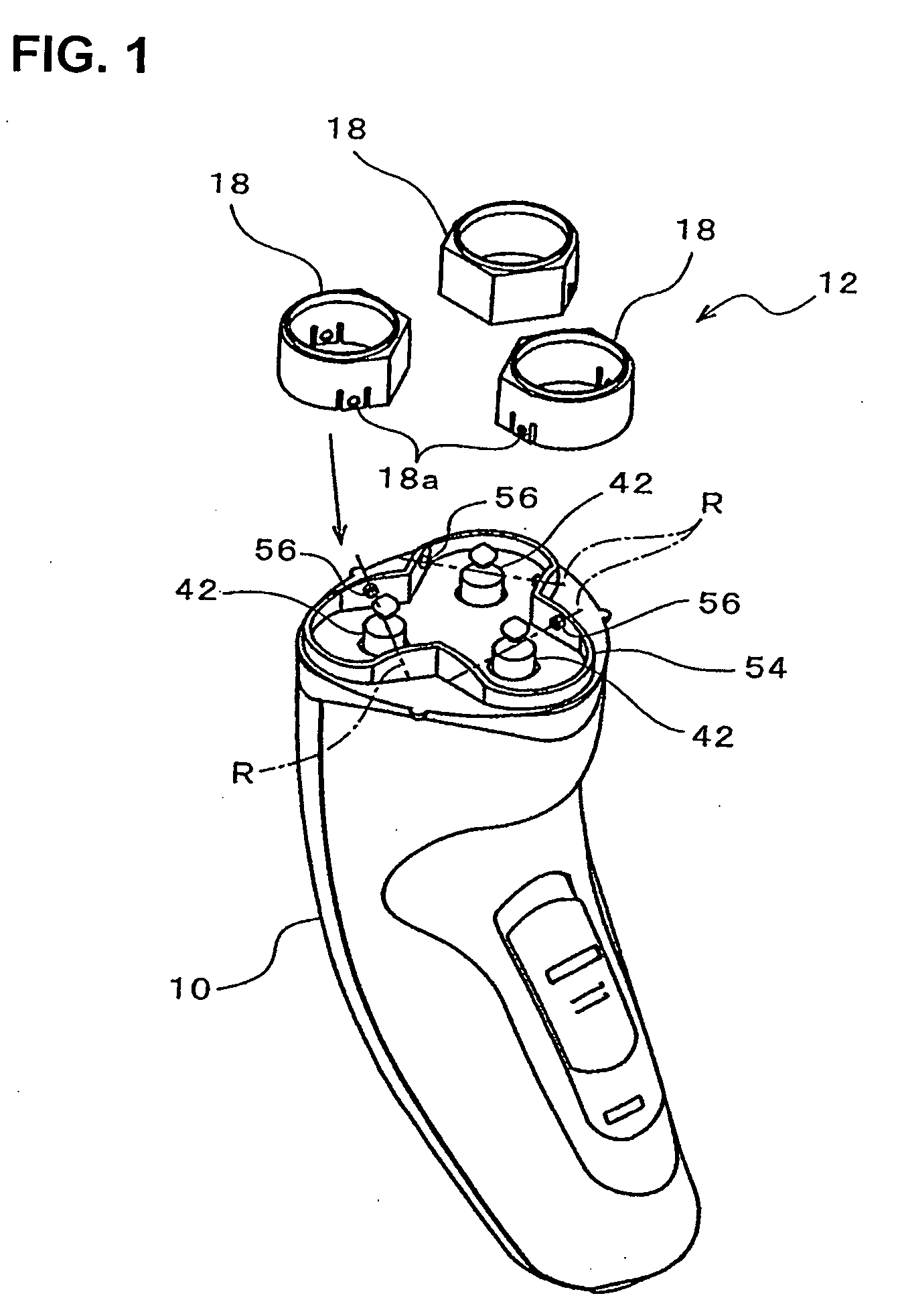

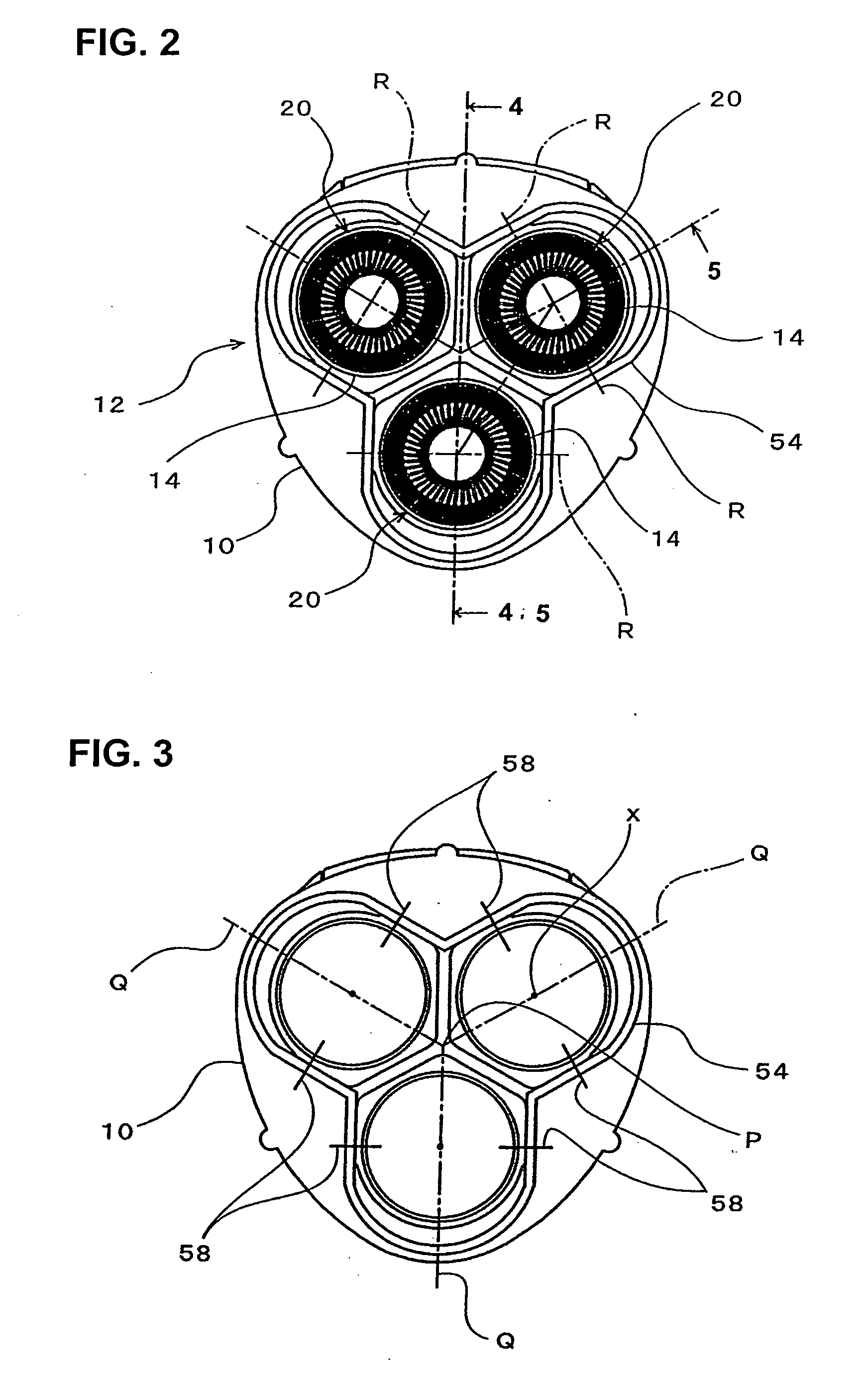

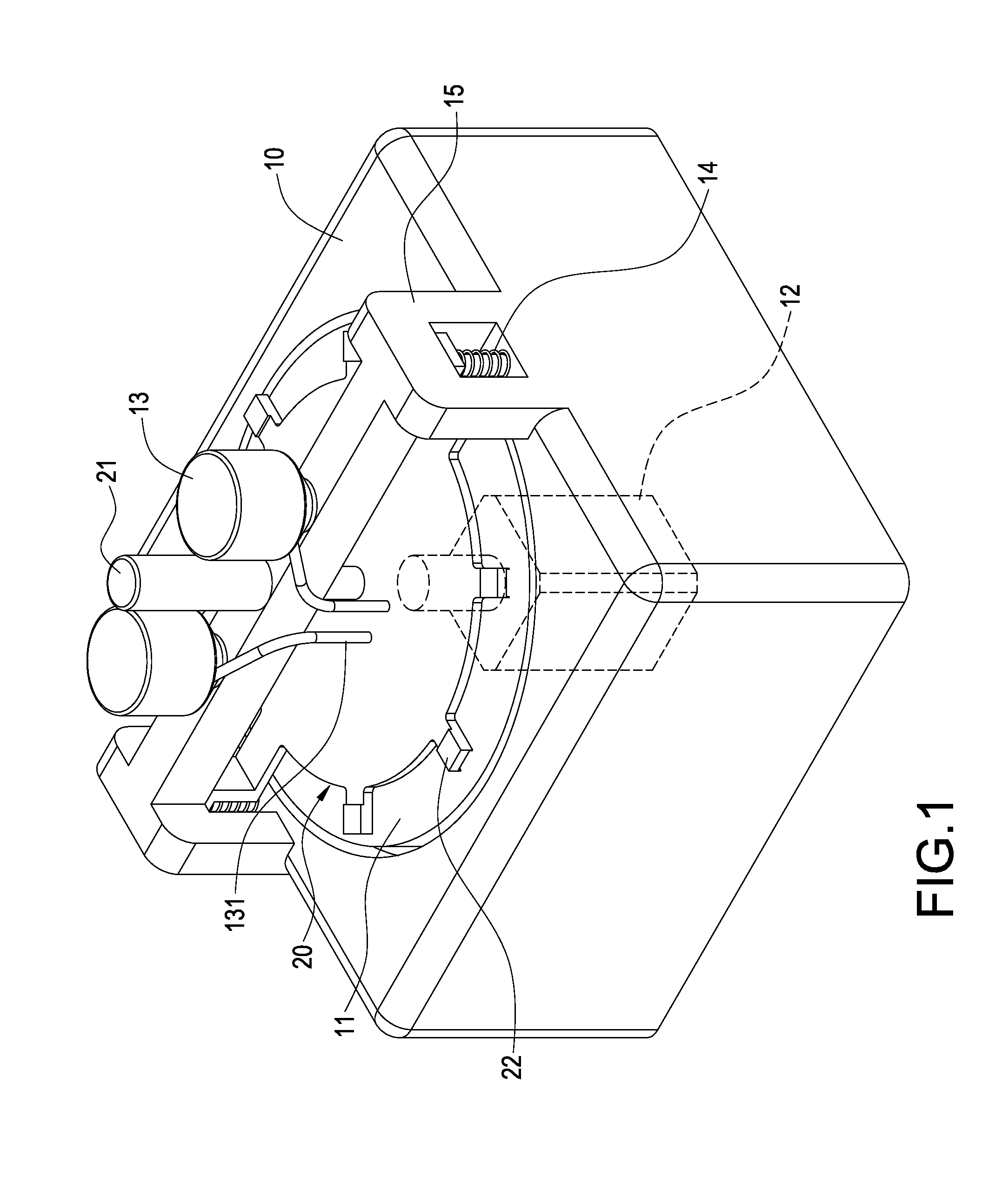

Rotary electric shaver

InactiveUS20070124936A1Extended angle rangeImprove contact tightnessMetal working apparatusElectric machineryEngineering

A rotary electric shaver including a plurality of substantially disc-shaped outer cutters, which are provided in the upper part of a shaver main body housing therein a motor, and inner cutters, which engage the outer cutters from below and are rotationally driven by the motor so as to cut hair entering into the hair introduction openings formed in the outer cutters; and in addition, substantially cylindrical cutter frames 18 for respectively holding the outer cutters in a depressible manner are provided so that cutter frames 18 can pivot in the upper surface of the shaver main body.

Owner:IZUMI PROD CO

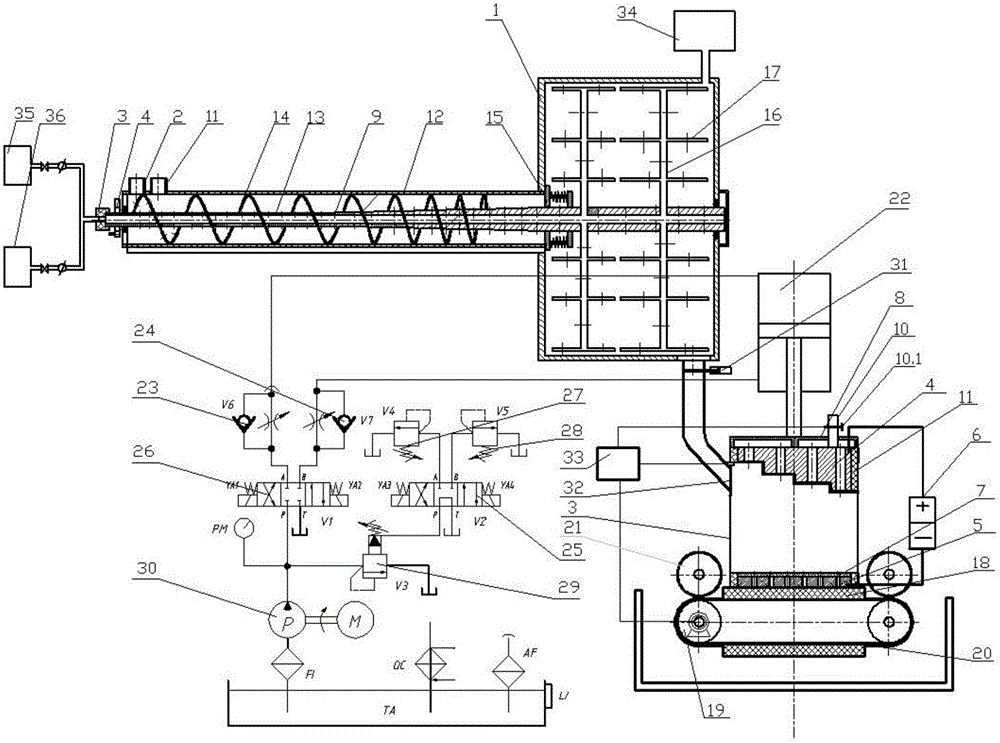

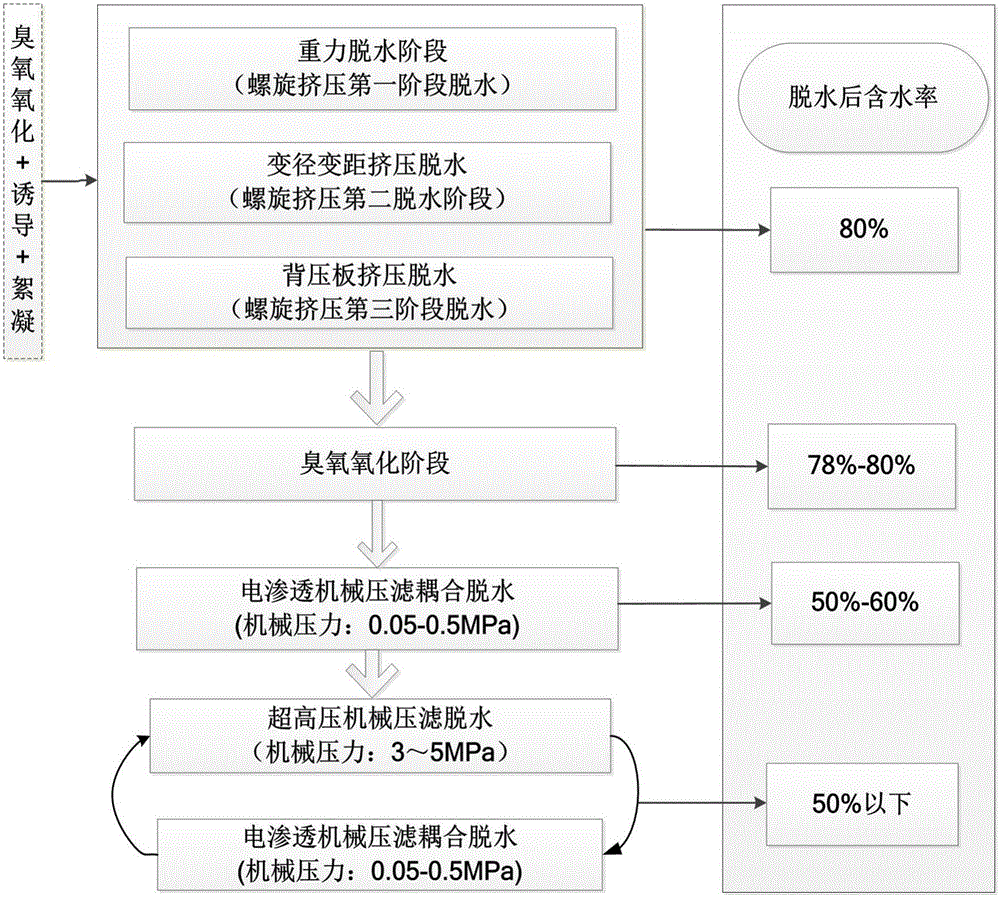

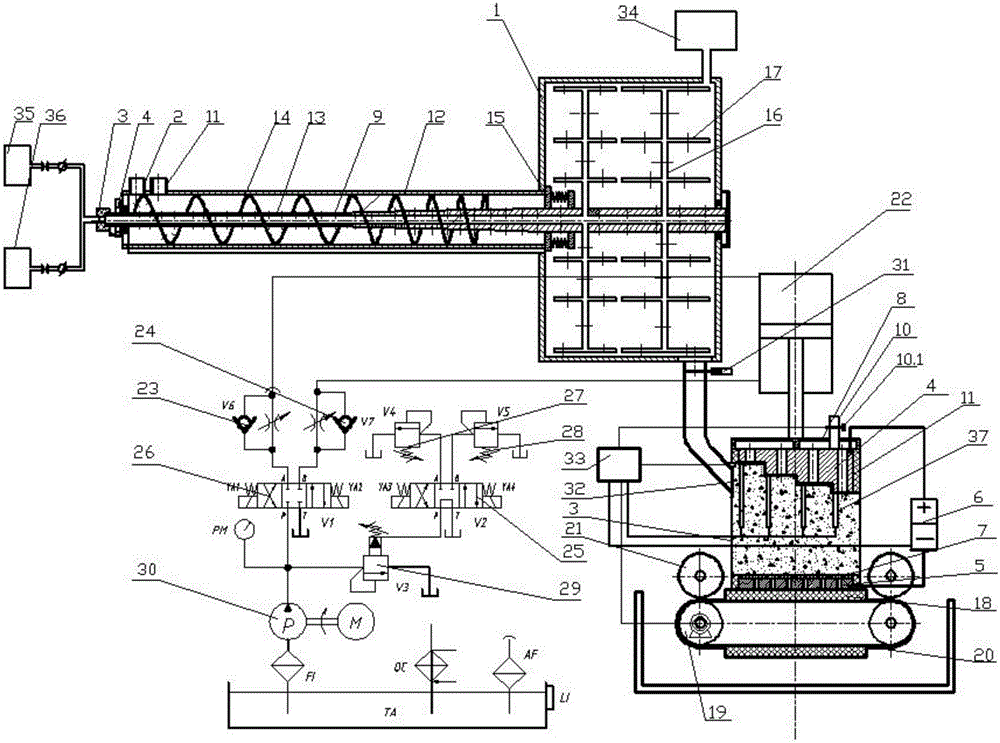

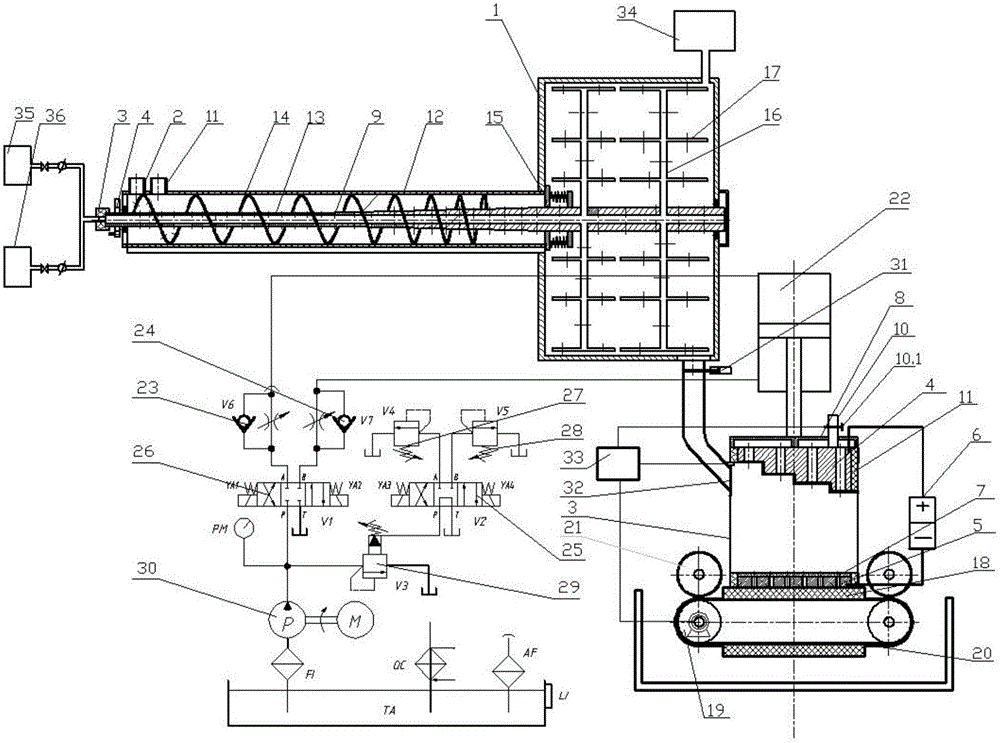

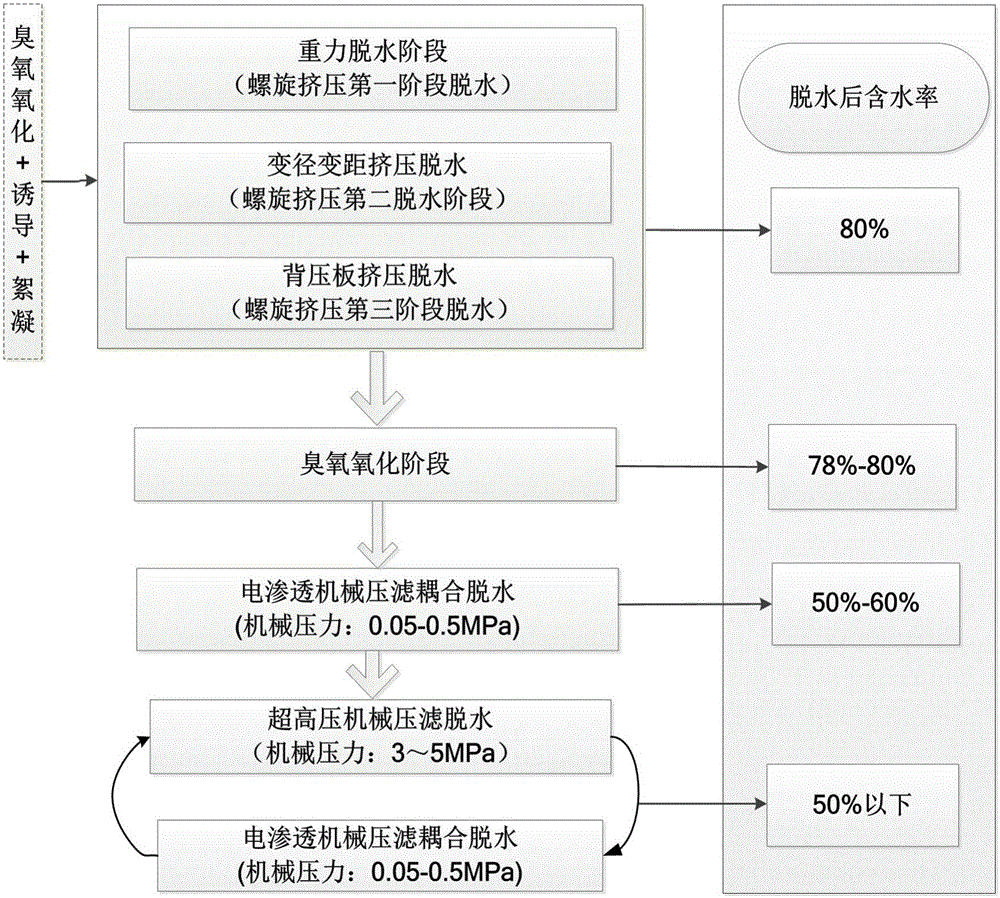

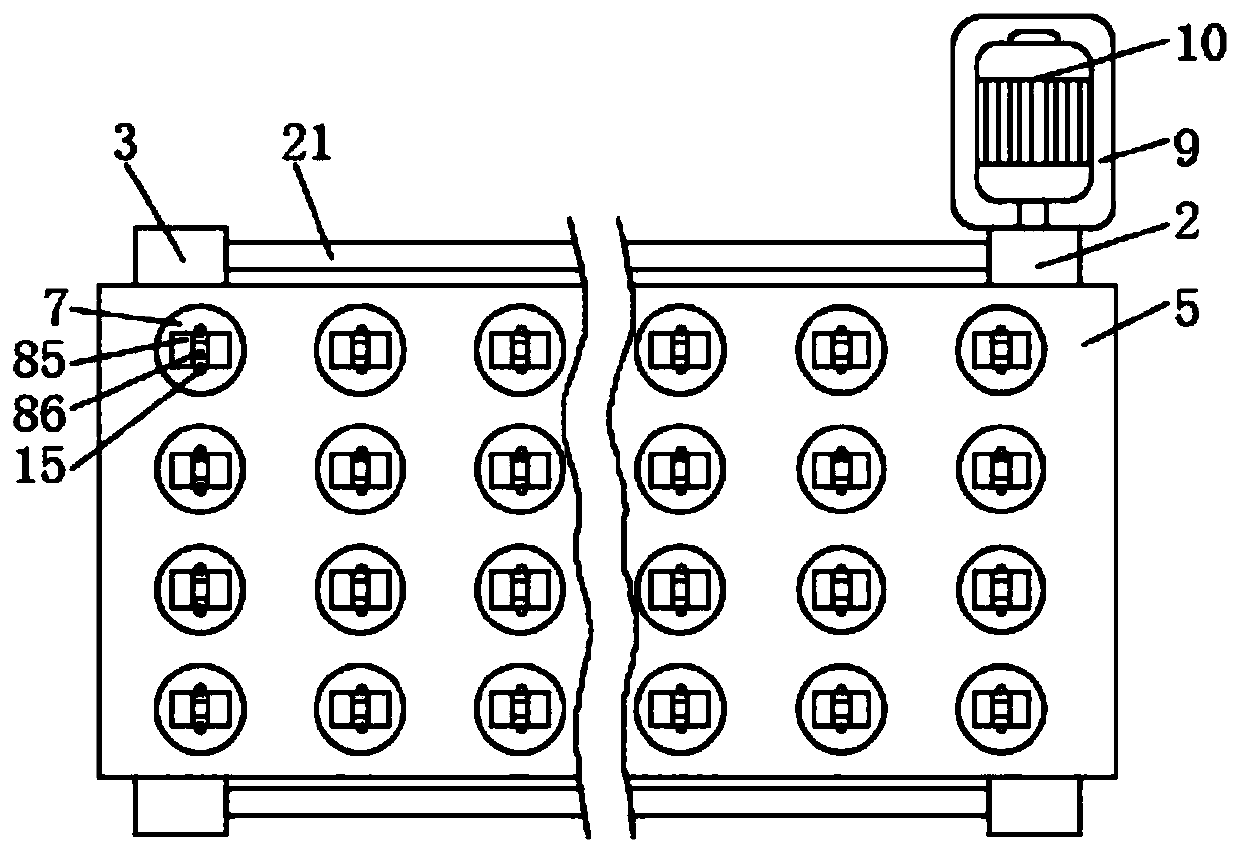

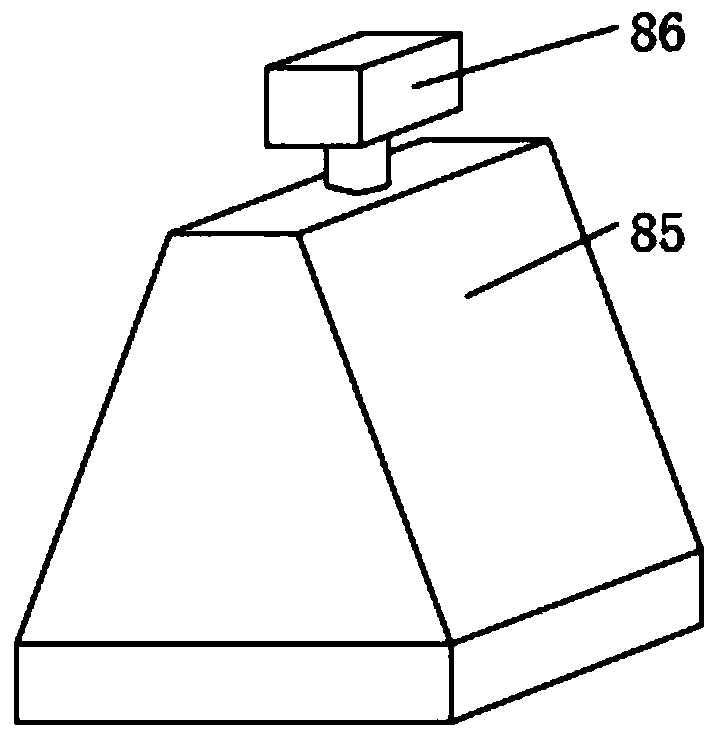

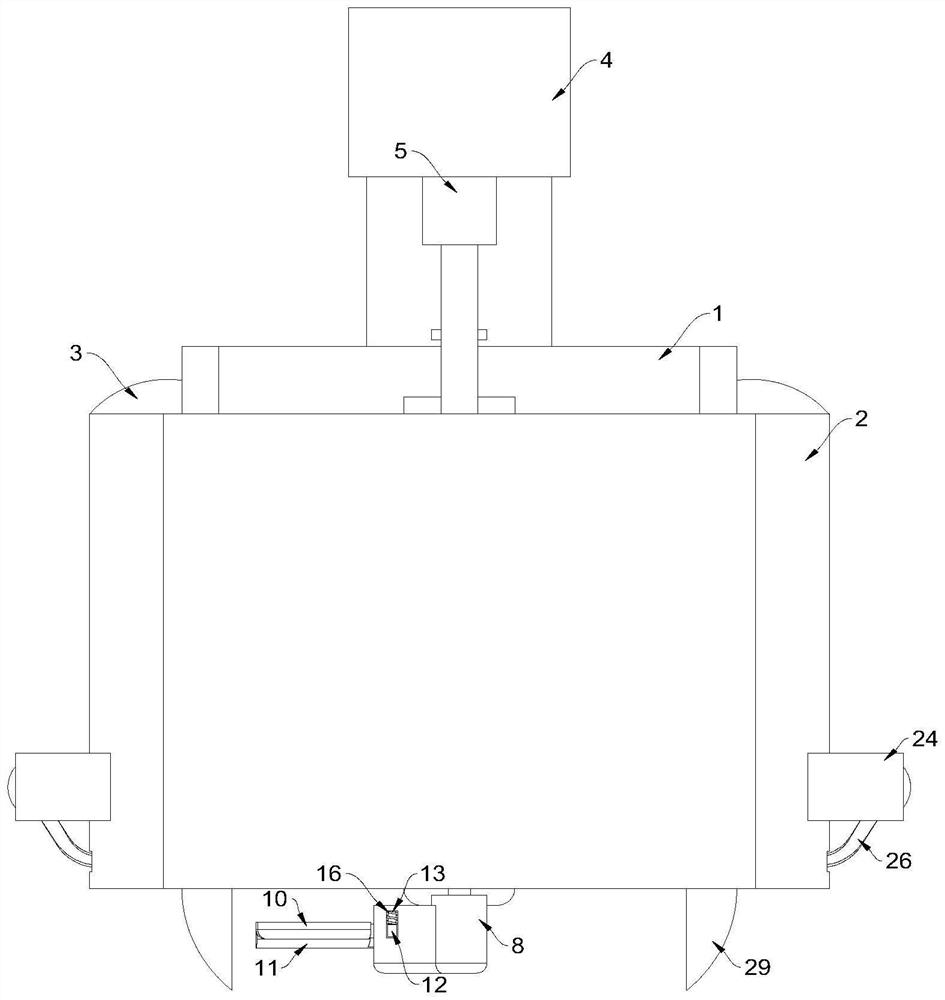

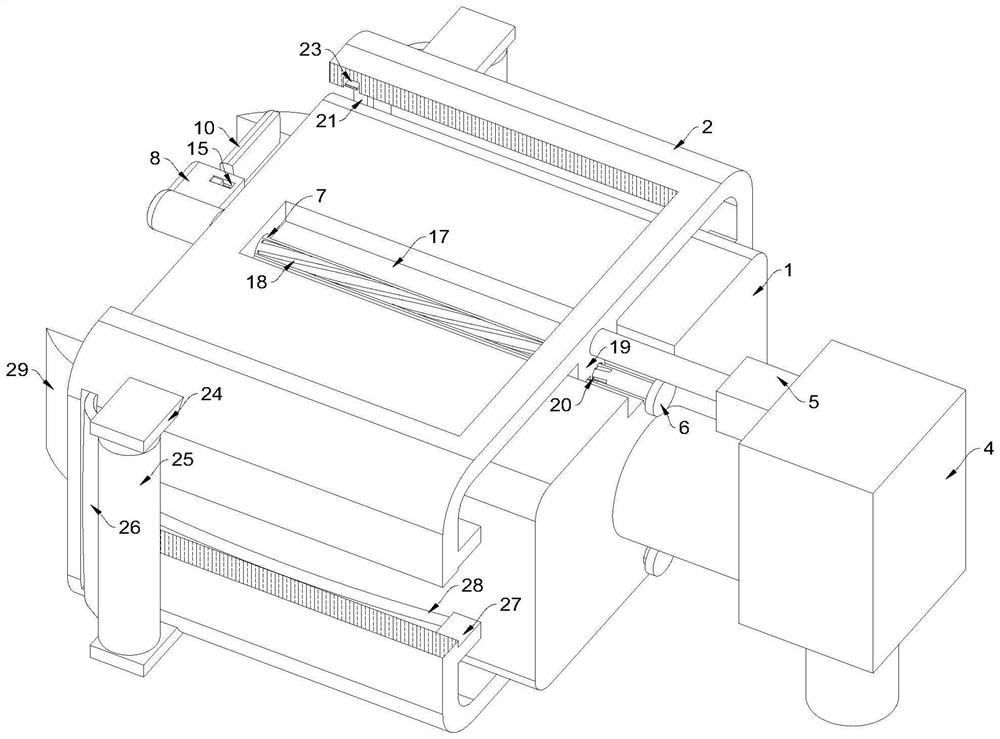

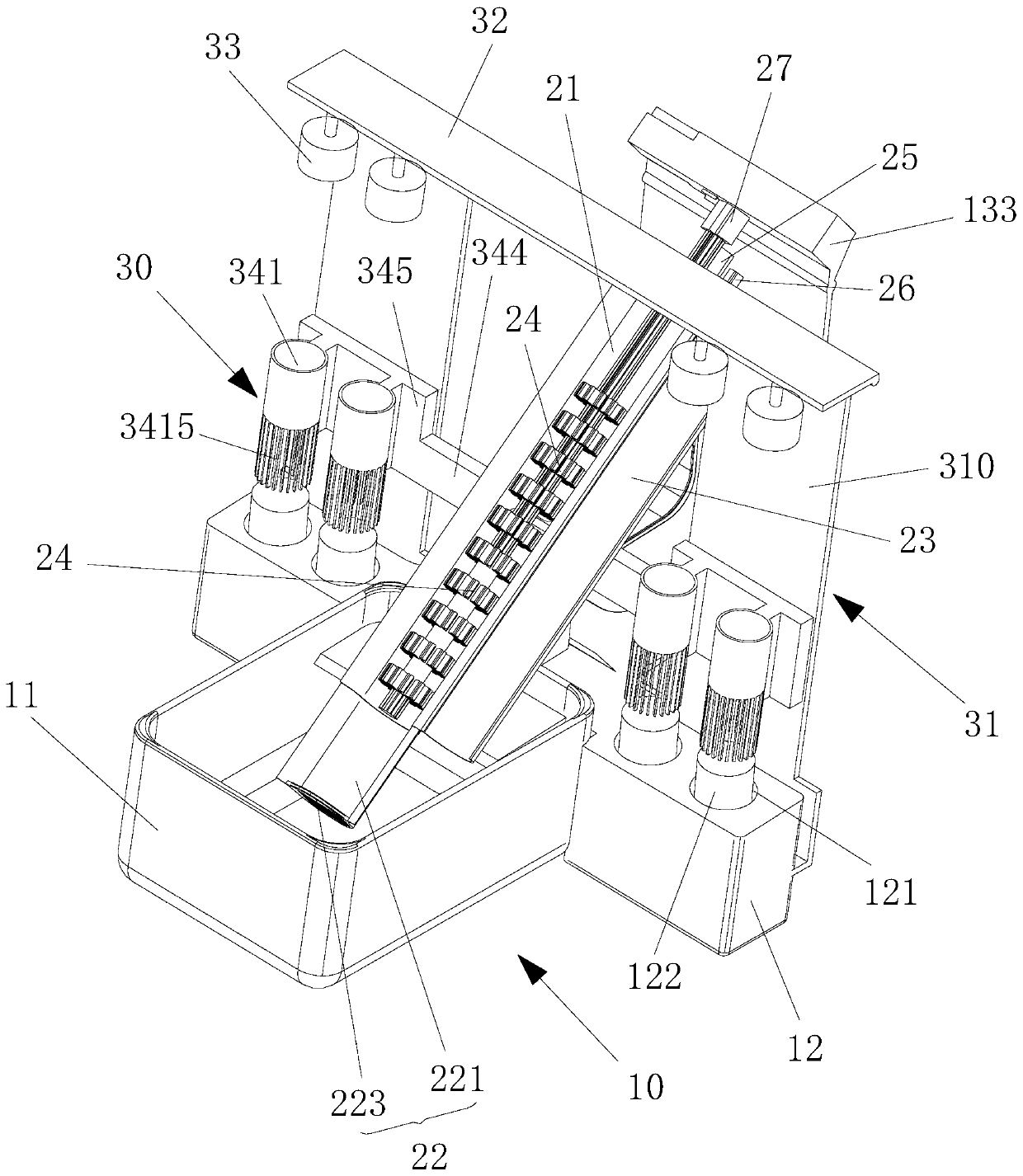

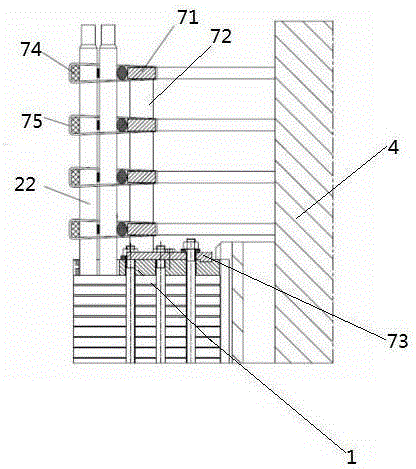

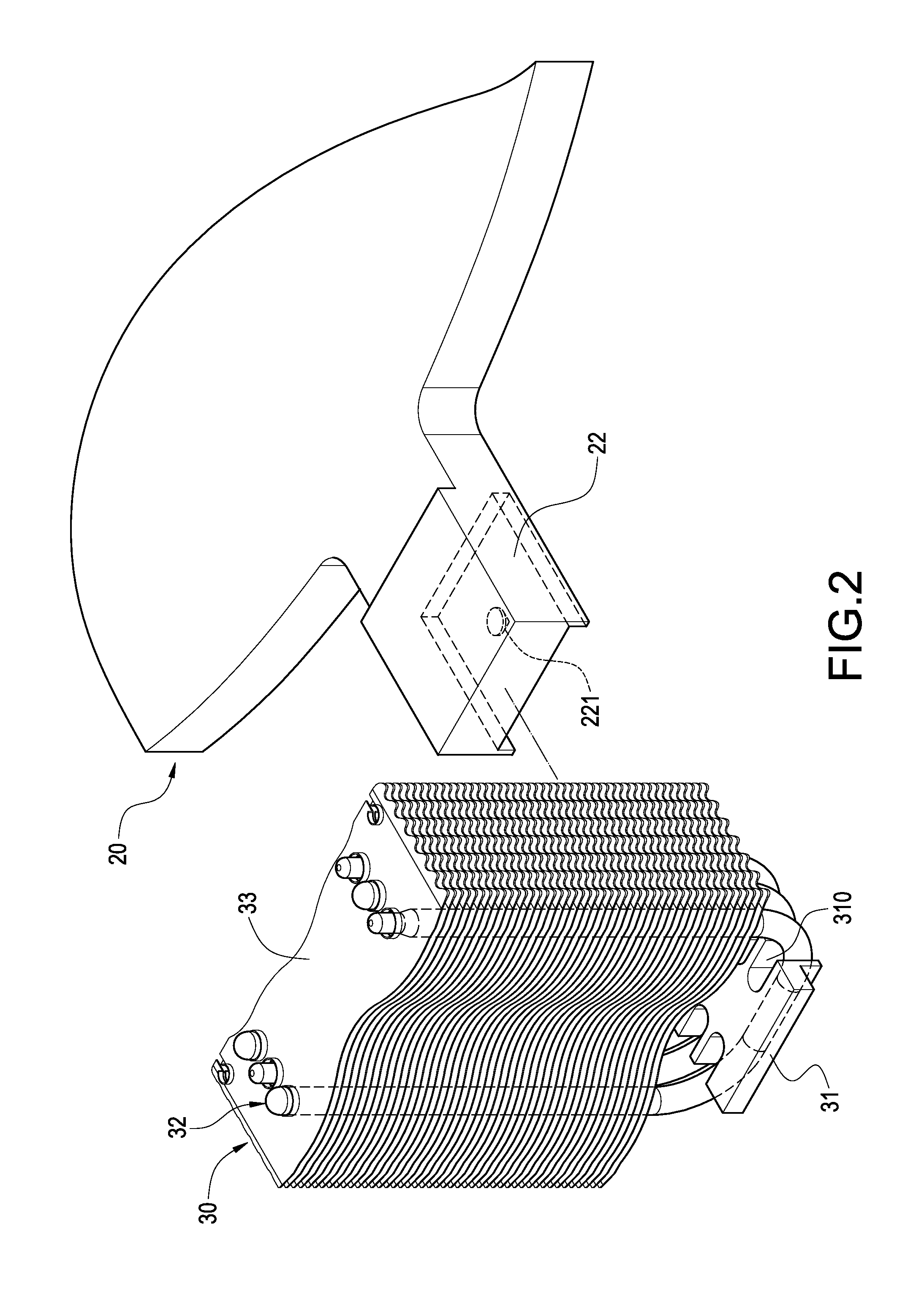

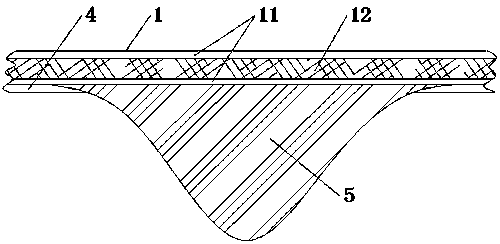

Sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing

InactiveCN105923968AReduce moisture contentImprove contact tightnessSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSewage

The invention discloses a sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing. The sewage sludge dewatering device comprises a spiral filter pressing device, an oxidation cylinder and an electroosmosis extrusion dewatering device, wherein a sewage sludge inlet is formed in the front end of the spiral filter pressing device; the rear end of the spiral filter pressing device is connected with the oxidation cylinder; the oxidation cylinder is communicated with the electroosmosis extrusion dewatering device; the electroosmosis extrusion dewatering device comprises an electroosmosis extrusion container, an anode plate, a cathode plate and a hydraulic system; the anode plate and the cathode plate are arranged in the electroosmosis extrusion container; after electroosmosis dewatering is completed by the electroosmosis extrusion dewatering device, the sludge water content of the anode plate is low, electroosmosis dewatering can be stopped, and pressure between the anode plate and the cathode plate is enlarged, so that ultrahigh pressure filter pressing dewatering is realized; the hydraulic system is connected with the anode plate, and the hydraulic system comprises a hydraulic oil cylinder and a high-low pressure regulating device. According to the sewage sludge dewatering device disclosed by the invention, high-water content sludge can be directly treated, and the dewatering energy consumption and the sludge water content are reduced through a multi-cooperation dewatering mode.

Owner:CHINA JILIANG UNIV

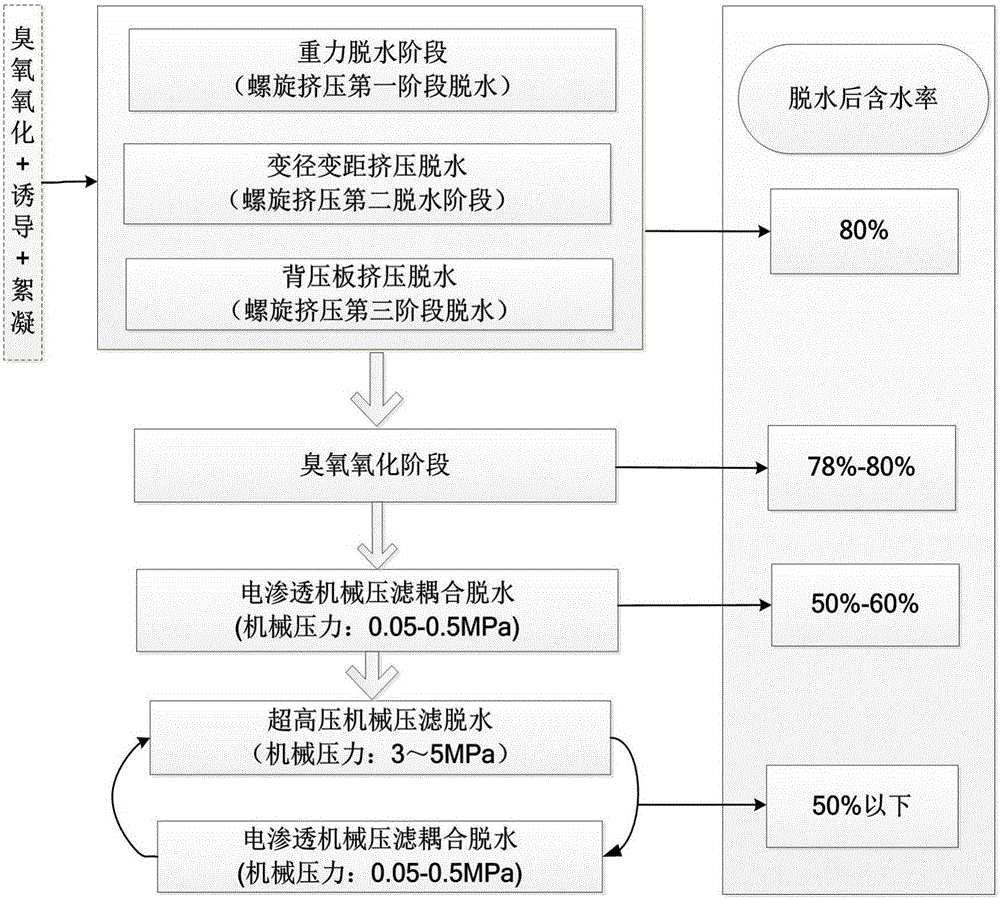

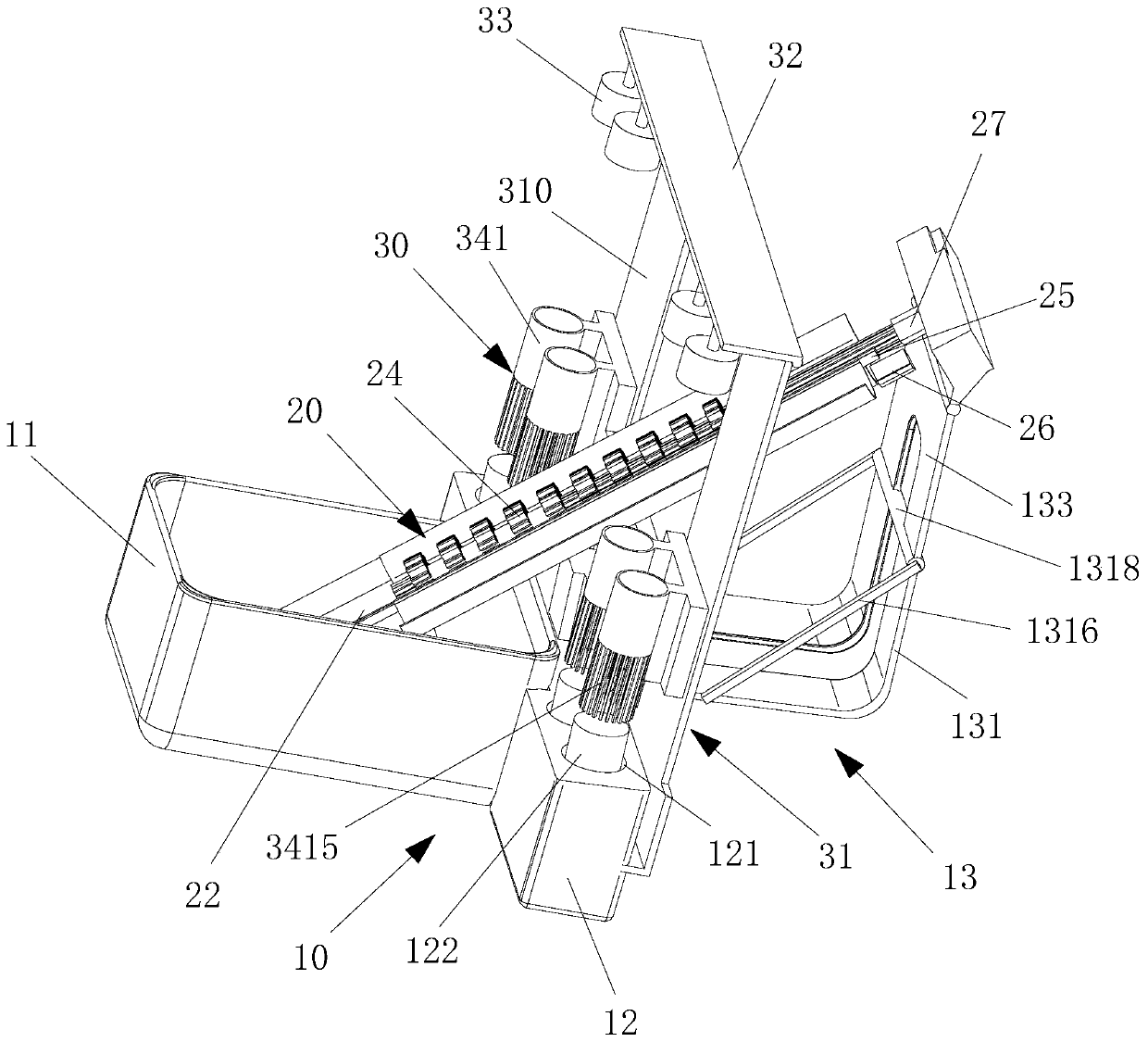

Electric osmosis filter pressing based sewage sludge co-dehydration device

ActiveCN105923952AImprove contact tightnessReduce moisture contentSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentUltra high pressureSludge

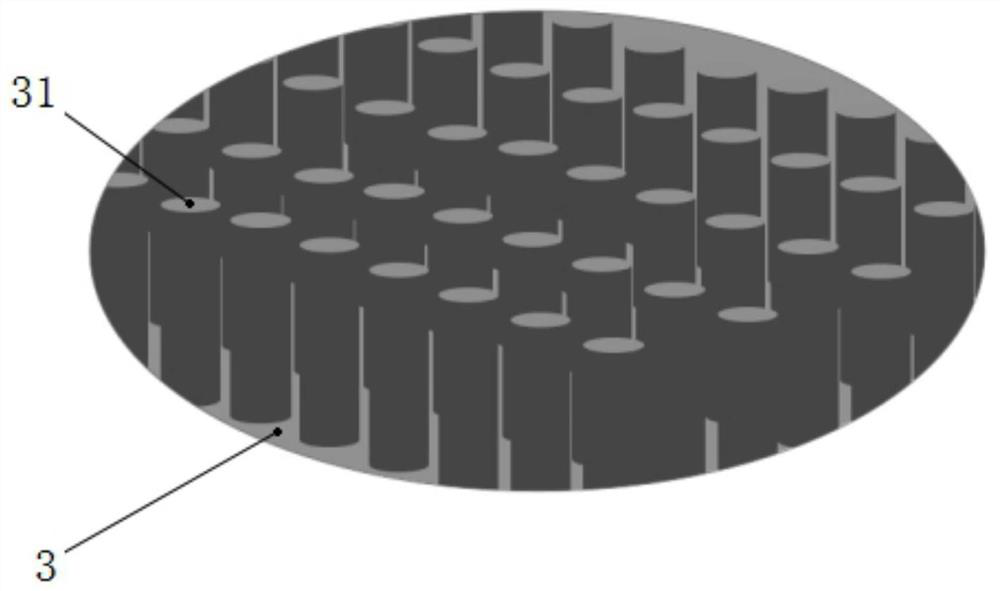

The invention discloses an electric osmosis filter pressing based sewage sludge co-dehydration device, comprising an electric osmosis squeezing container (3), an anode plate (4) and a cathode plate (5), wherein the anode plate (4) and the cathode plate (5) are arranged in the electric osmosis squeezing container (3), sludge particulates move towards the anode plate and water molecules move towards the cathode plate under the influence of an electric field force, and a pressure is exerted between the anode plate and the cathode plate such that electrically osmosed water flows out of an electric osmosis squeezing dehydration device. After the above electric osmosis dehydration is completed, a low water content of sludge of the anode plate (4) is realized, when the sludge becomes dry, the electric osmosis dehydration is stopped, and the pressure between the anode plate (4) and the cathode plate (5) is increased to realize an ultra-high pressure mechanical filter pressing dehydration, so that the water content between the anode plate and the cathode plate is uniform. According to the electric osmosis filter pressing based sewage sludge co-dehydration device disclosed by the invention, as a co-dehydration means in the combination of an electric osmosis coupling dehydration and an ultra-high pressure mechanical dehydration is employed, energy consumption for the dehydration is reduced greatly, and a lower water content of the sludge treated according to the invention is realized.

Owner:浙江诺曼环保工程技术有限公司

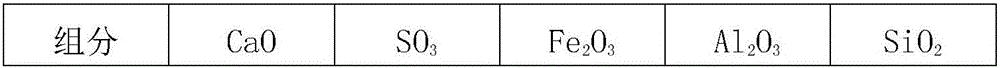

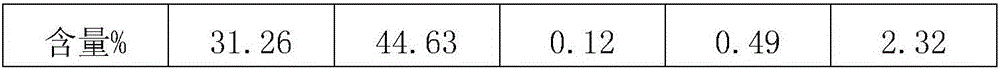

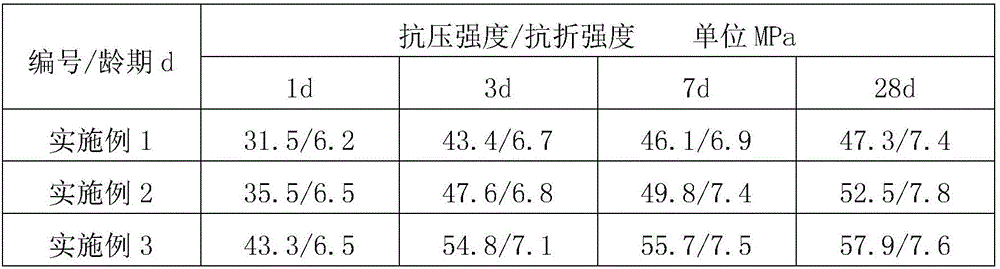

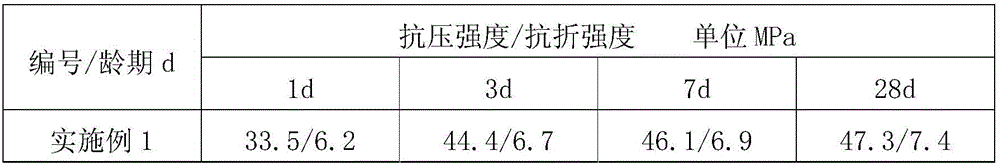

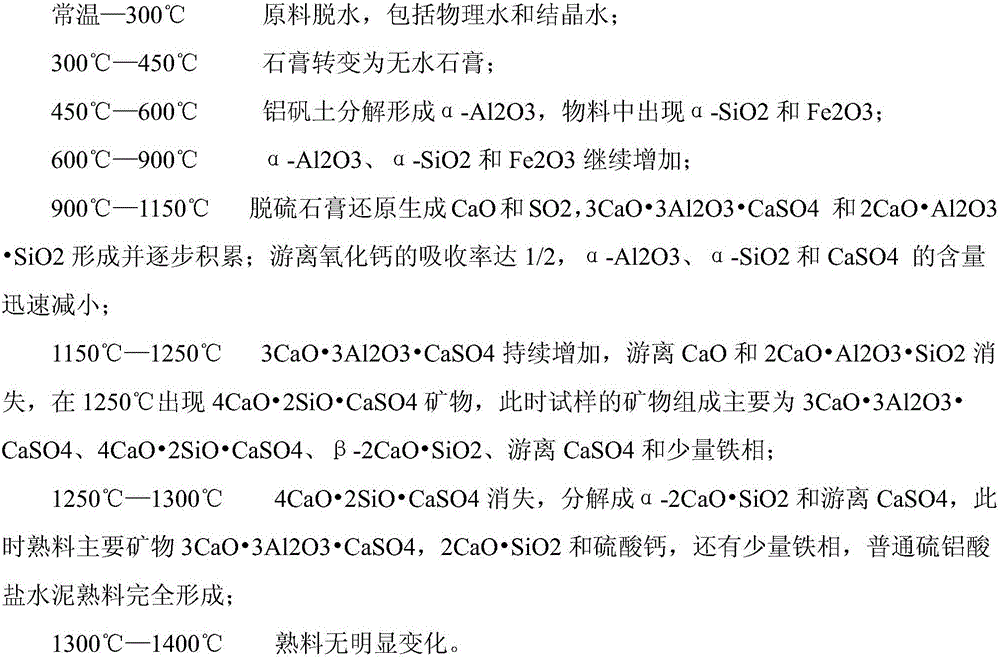

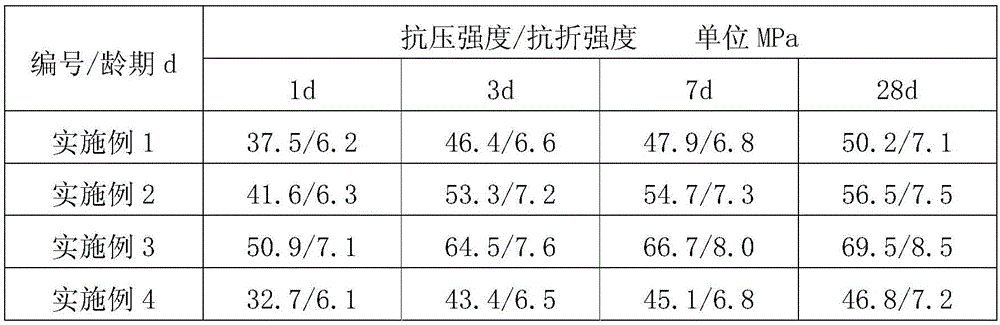

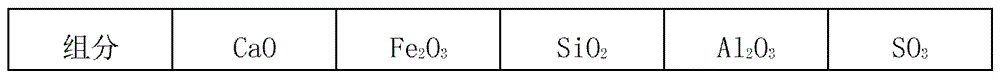

Method for preparing sulphoaluminate cement by calcining ardealite by steps

ActiveCN106630701AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationPolymer science

The invention relates to a method for preparing sulphoaluminate cement by calcining ardealite by steps. Limestone and natural gypsum are completely replaced by ardealite, the ardealite is homogenized with bauxite, solid steel scrap and anthracite duff and then a method for calcining by steps is adopted for preparing the sulphoaluminate cement. According to the invention, the use ratio of the ardealite can be greatly increased and the high-concentration sulfur dioxide tail gas can be absorbed for preparing sulfuric acid. The sulphoaluminate cement prepared according to the invention is high in clinker hardening speed, high in early strength and stable in later strength. A performance test proves that the mechanical strength of the sulphoaluminate cement prepared according to the method provided by the invention meets the sulphoaluminate cement standard.

Owner:KINGENTA NORSTERRA CHEM CO LTD +1

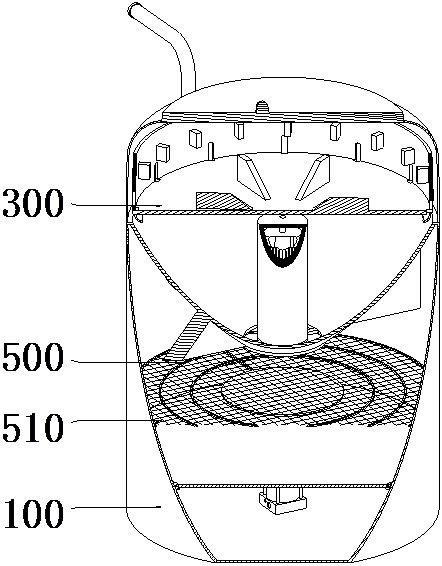

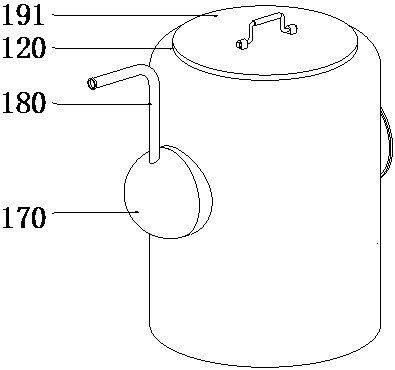

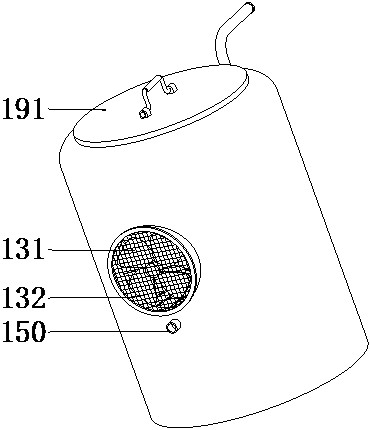

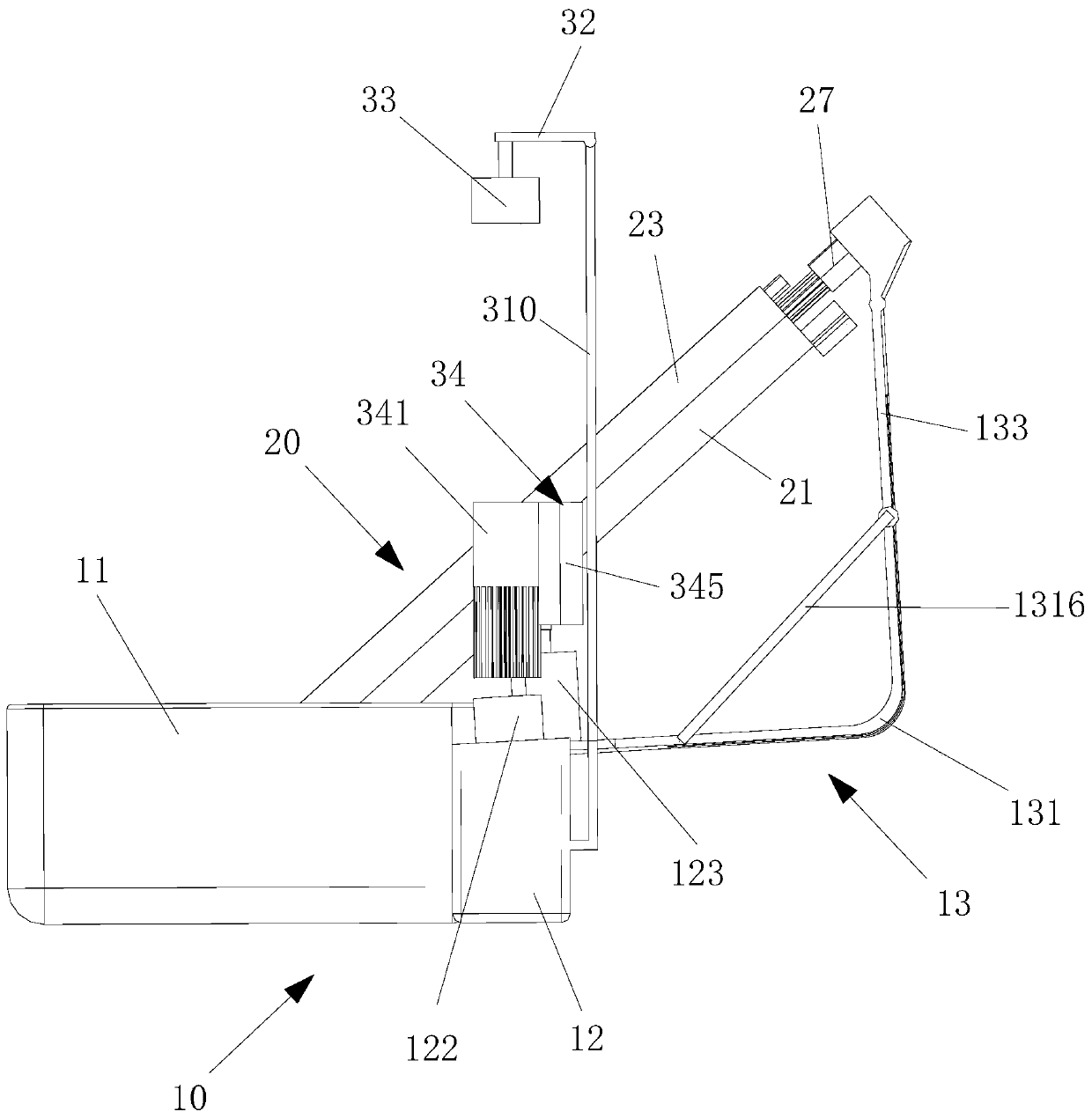

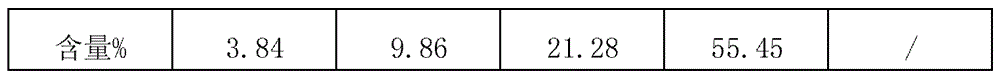

Atomization dosing device for pneumology department

InactiveCN113813476AImprove contact tightnessPrevent leakageMedical atomisersSolid solvent extractionAerosolizePharmaceutical drug

The invention provides an atomization drug delivery device for the pneumology department, and belongs to the technical field of atomization drug delivery. The atomization dosing device for the pneumology department comprises a shell, a smashing assembly and an atomization assembly. A medicine guide plate is arranged in the shell, a baffle is fixedly connected to the medicine guide plate, and the other side of the baffle is fixedly connected to the shell; the smashing assembly is located on the upper side of the medicine guiding plate. The atomization assembly comprises a screen, an ultrasonic vibration plate and a piston part, the screen is fixedly connected to the shell, the ultrasonic vibration plate is located on the lower side of the screen, the piston part is located on the lower side of the ultrasonic vibration plate, the piston part is pushed upwards, medicine liquid is pushed upwards, the screen is made to be located in the middle of the medicine liquid all the time, and the atomization effect is achieved. Large-particle medicines can be sieved, so that the fixed medicines are gradually decomposed. According to the aerosolization device for the pneumology department, operation is easy and convenient, the medicine grinding effect is good, medicine soaking and dissolving are thorough, and the medicine effect is kept.

Owner:顾春风

Oxidization, electric osmosis and mechanical filter pressing based sewage sludge co-dehydration device

ActiveCN105923967AImprove contact tightnessLower resistanceSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSewageEnergy consumption

The invention discloses an oxidization, electric osmosis and mechanical filter pressing based sewage sludge co-dehydration device, comprising a spiral filter pressing device, an oxidizing barrel body and an electric osmosis squeezing dehydration device, wherein a sewage sludge inlet is arranged at the front end of the spiral filter pressing device, the rear end of the spiral filter pressing device is connected with the oxidizing barrel body, the oxidizing barrel body is communicated with the electric osmosis squeezing dehydration device, sewage sludge enters the front end of the spiral filter pressing device from the sewage sludge inlet of the spiral filter pressing device, gravity dehydration is realized under the influence of gravity of the sewage sludge, water is removed continuously as the sewage sludge moves forward, the sewage sludge is discharged out of the spiral filter pressing device and enters the oxidizing barrel body, ozone is replenished into the oxidizing barrel body so that the sewage sludge is mixed and reacted with the ozone, the sewage sludge is discharged out of the oxidization barrel body and enters the electric osmosis squeezing dehydration device for an electric osmosis dehydration. According to the oxidization, electric osmosis and mechanical filter pressing based sewage sludge co-dehydration device, sludge of high water content can be treated directly, energy consumption for the dehydration is reduced greatly as a co-dehydration based on several means is employed, and the sludge treated according to the invention has low water content.

Owner:浙江诺曼环保工程技术有限公司

Method for preparing high-strength sulfate aluminum cement co-production sulfuric acid through calcining by steps

ActiveCN106630703AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationSlag

The invention relates to a method for preparing high-strength sulfate aluminum cement co-production sulfuric acid through calcining by steps. The method comprises the following steps: completely replacing limestone and natural gypsum by ardealite, grinding and homogenizing bauxite, slag, silica and anthracite, and preparing the sulfate aluminum cement through calcining by steps. The ardealite utilization rate is greatly improved, and sulfuric acid can be prepared by absorbing high-concentration sulfur dioxide tail gas. The sulphoaluminate cement clinker prepared by the method disclosed by the invention is high in hardening rate, high in early strength and enhanced and stable in long-term strength. The performance test proves that the mechanical strength of the prepared sulfate aluminum cement meets the rapid hardening sulfate aluminum cement standard.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

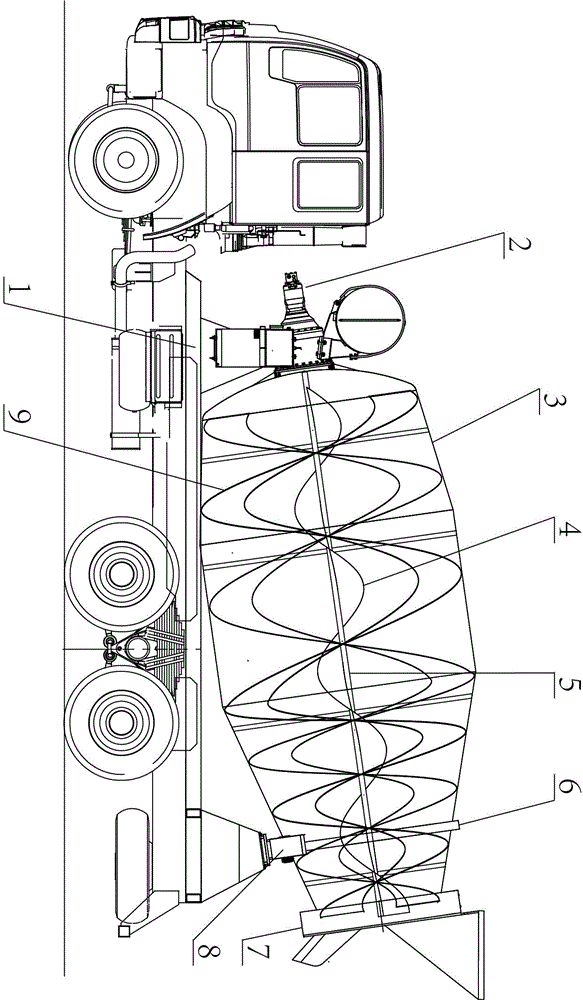

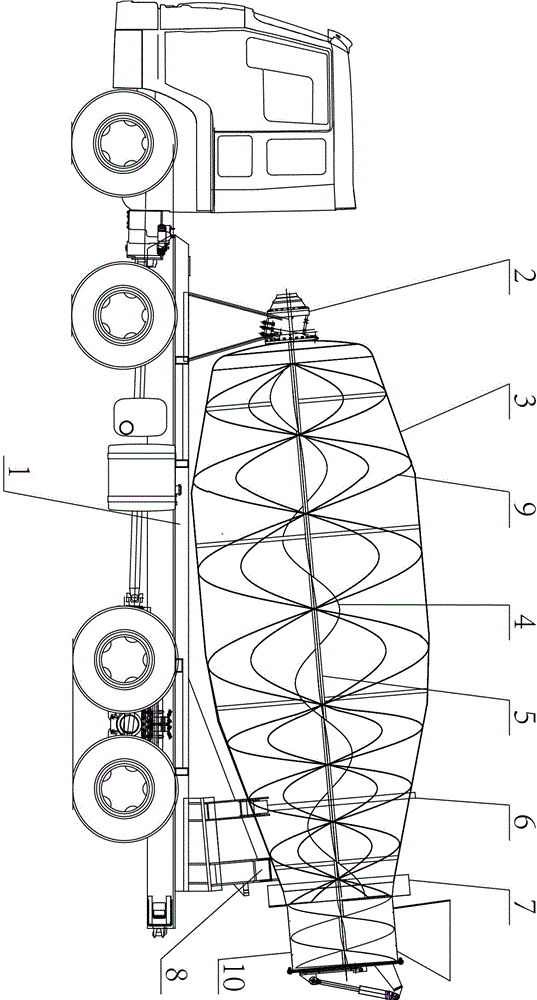

Composite screw transporting vehicle

ActiveCN104385462AStir wellImprove mixing uniformityDischarging apparatusCement mixing apparatusSludgeEngineering

The invention discloses a composite screw transporting vehicle. The rear end of a rotary material cylinder is connected with a rotary sealing mechanism, wherein a main screw blade is spirally mounted on the inner wall of the rotary material cylinder; a center shaft is arranged inside the rotary material cylinder; a secondary screw blade is mounted on the center shaft. The secondary blade and the main blade have synergistic effects. When the composite screw transporting vehicle is used as a high-viscosity concrete transporting vehicle or a sludge transporting vehicle, the loading and unloading rate is relatively high, and the utilization rate of the material cylinder is relatively high; when the composite screw transporting vehicle is used as a concrete transporting vehicle, the concrete is relatively uniformly stirred; the delamination is alleviated; the quality of the high-quality concrete is not influenced.

Owner:YANTAI SHENGLIDA ENG TECH

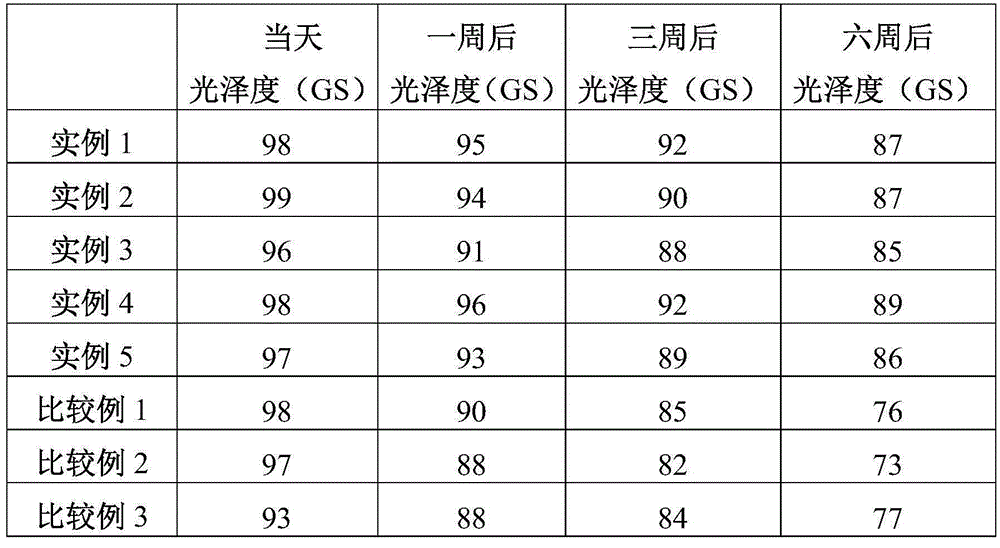

Method for keeping cleanness of stone material laid on red land

ActiveCN105081911AImprove solubilityAvoid excessive corrosionCationic surface-active compoundsOrganic detergent compounding agentsLateritePolypropylene

The invention provides a method for keeping cleanness of stone material laid on red land. The method comprises the following steps that the stone material is coated with gelatinous detergent for cleaning after being ground, and the detergent is an aqueous solution comprising 10-15 g / L of oxalic acid, 1-3 g / L of tetrabutyl ammonium hydroxide, 0.5-1 g / L of pentaerythritol ester and 2-5 g / L of xanthan gum; then a brightening maintenance agent is sprayed on the surface of the stone material for grinding and polishing treatment after the stone material is finely ground, and the brightening maintenance agent comprises 1-3 wt% of polyethylene wax, 0.2-0.8 wt% of polypropylene micronized wax, 5-10 wt% of perfluoroalkyl ethyl acrylate, 2-6% of triethoxysilane, 2-5 wt% of hydroxymethyl cellulose and 0.2-0.4 wt% sodium chloride. The cleaning and maintenance treatment process for the stone material is simple in step, durable in protection effect of the stone material, and the workload of the subsequent daily regular care for the stone material is reduced.

Owner:SUZHOU GOLD MANTIS GREEN LANDSCAPE LIMITED

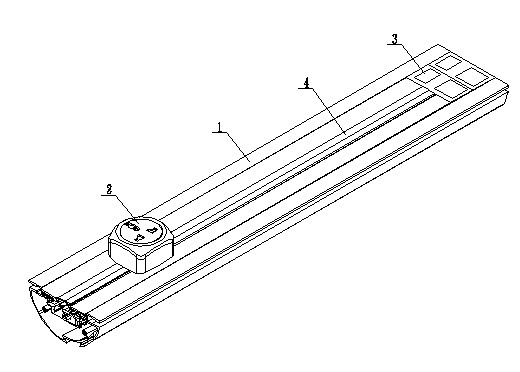

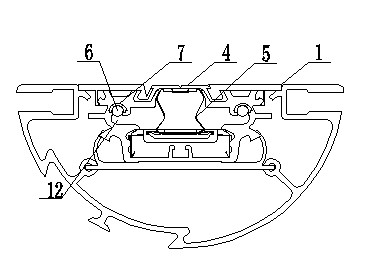

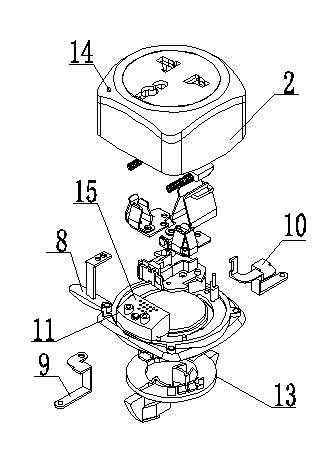

Power communication distribution device

InactiveCN102324672AImprove convenienceImprove contact tightnessCouplings bases/casesCommunication interfaceSliding contact

The invention relates to the technical field of power communication equipment and particularly relates to a power communication distribution device. The power communication distribution device comprises a socket, a plug and a communication interface, wherein the section of the socket is semi-circular, the plug is positioned on one side of the horizontal plane of the socket and in sliding connection with the socket, and a conductive indicator is arranged on the plug. A semi-circular sliding body is arranged at the bottom of the plug, the existing plug-in type contact is changed to the sliding contact, and the convenience in use is greatly improved; the up-down contact way is adopted, thereby improving the contact tightness and the stability in electric conduction; and a user can know the conduction situation of a circuit in a directviewing and clear manner by virtue of the conductive indicator.

Owner:JIANGSU NEWHOPE RENEWABLE ENERGY S & T

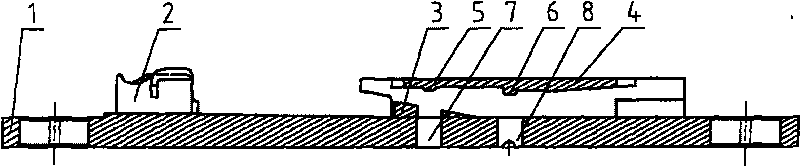

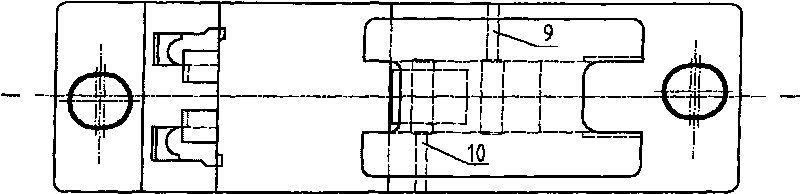

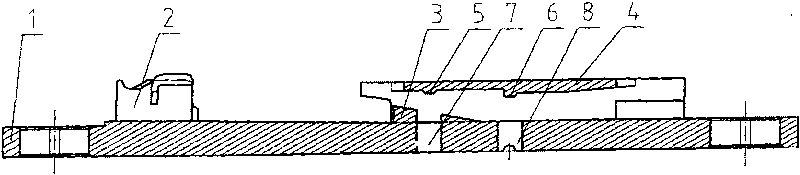

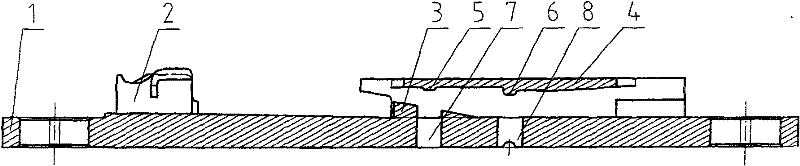

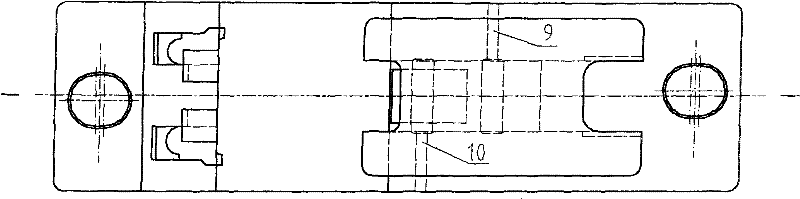

Manufacturing method of railway switch block cast slide plate

A manufacturing method of railway switch block cast slide plate comprises the following steps: A) integrally casting a base plate (1), an iron seat (2), a guide iron (3) and a bedplate (4) with casting technique; B) casting for two long grooves (7, 8) right on a limiting convex plate (5) in the internal cavity of the bedplate (4) and under the supporting convex plate (5); C) accurately processing the limiting convex plate (5) and the supporting convex plate (6); D) processing a water drainage hole (9, 10) respectively on the two sides of the bottom plate (1), wherein the water drainage hole (9, 10) are respectively communicated with the two long grooves (7, 8); E) shining metal the working surface of the bedplate (4). The manufacturing method uses the fusible pattern casting technique to manufacture the block cast slide plate, thereby increasing the whole intensity of the slide plate, ensuring the flatness of the bottom plate and the bedplate, providing good working condition for the switch rail and satisfying the requirement of railway switch to the road safety that the speed per hour is more than 200 miles.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

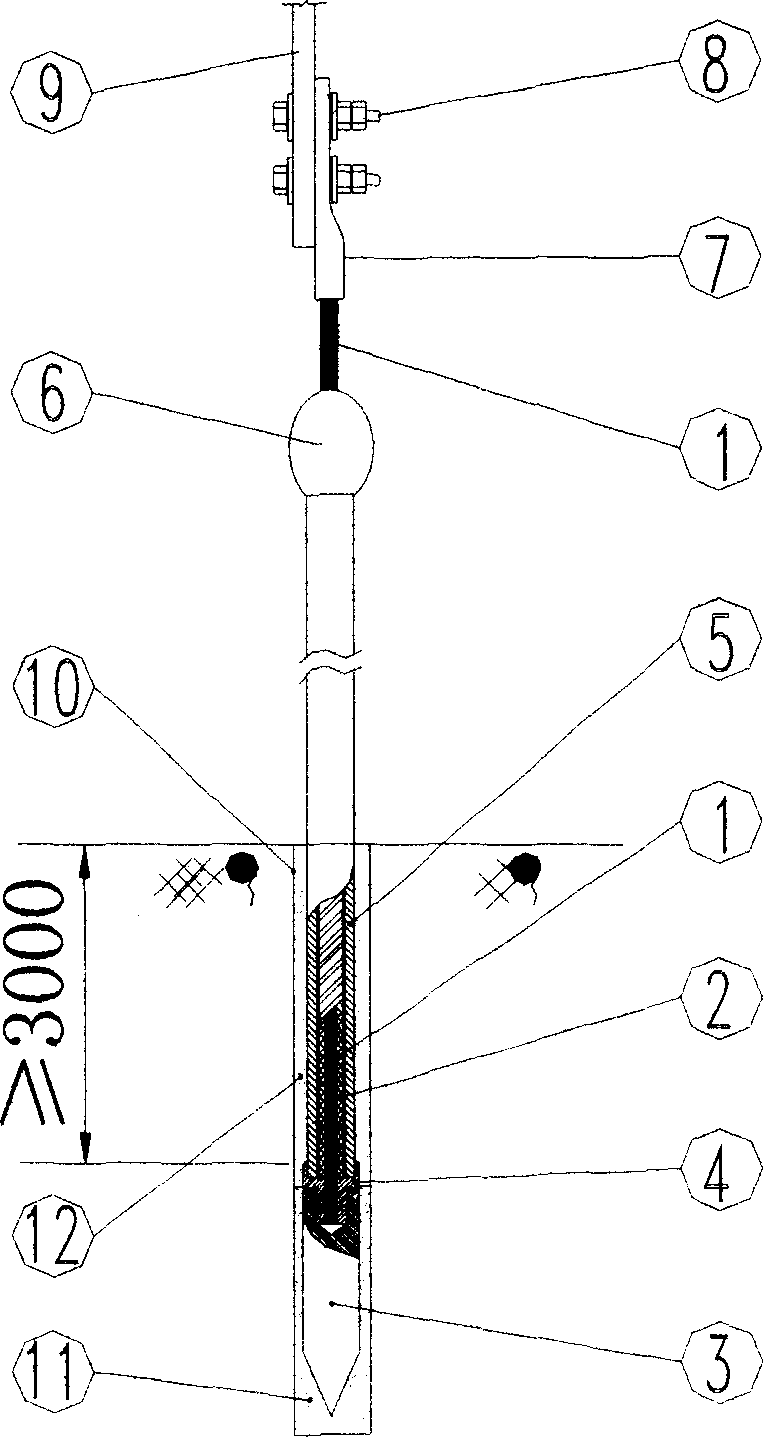

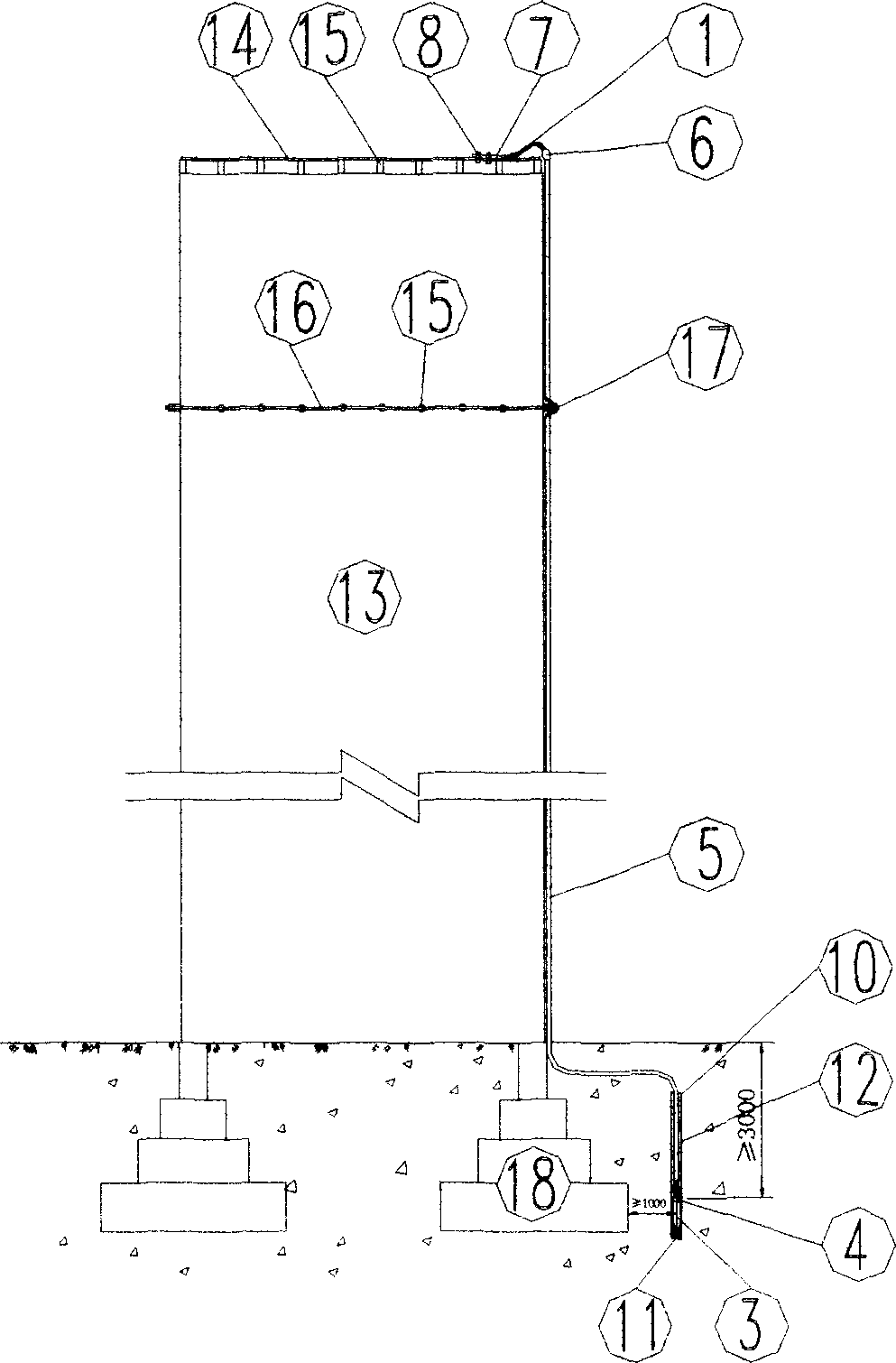

Overvoltage protecting ground device with insulative wire leading underground deeply

InactiveCN1855634AReduce in quantityPrevent proliferationConnection contact member materialElectricityOvervoltage

The invention is designed for use in preventing electric apparatus from damage of earth potential rising caused by discharge to earth from over-voltage and preventing human from danger of contact and step potential. The provided apparatus hasn't a horizontal earth mat and a voltage-sharing mat, and doesn't contact with the metal material in building, and only provides grounding for electric equipment easy to generate discharge. It mainly comprises an earth wire and earthed pole. The earth wire is connected to soil through the earthed wire, and its upper end is connected to an earthed point of a grounded device while its lower end is connected to the earthed pole. The earthed wire is led into underground in a 3 meter depth. It has a hollow structure where multi through holes are opened in order to release conducting ion.

Owner:肖明训

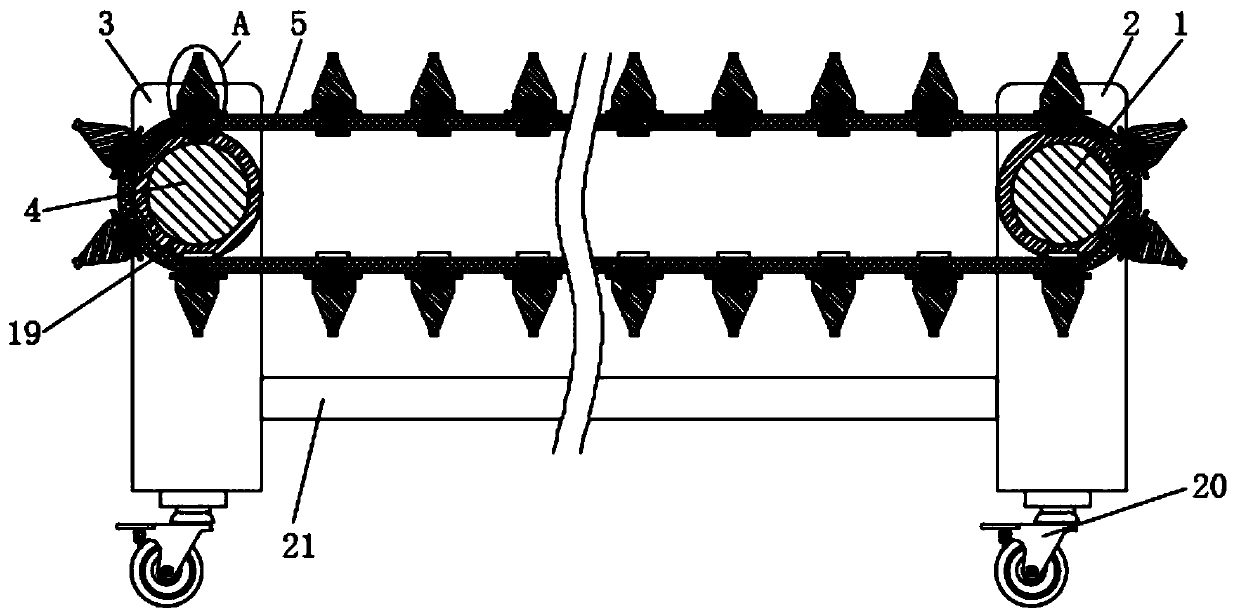

Conveying equipment for stainless steel tube producing and machining

InactiveCN109704024AThe delivery method can be adjustedExpand the scope of production and processingConveyorsSupporting framesElectric machineryEngineering

The invention discloses conveying equipment for stainless steel tube producing and machining. The conveying equipment for stainless steel tube producing and machining comprises a driving roll, the front side and the back side of the surface of the driving roll are each provided with a first bracket, second brackets are arranged on the left sides of the first brackets, a driven roll is movably installed on the inner sides of the second brackets, and the surface of the driven roll is sleeved with a driving belt. According to the conveying equipment for stainless steel tube producing and machining, a conveying mode is adjusted by adjusting a conveying mechanism, then a motor is started to drive the driving roll to rotate, the driving roll drives the driven roll to rotate together through thedriving belt, the driving belt rotates to drive positioning blocks to achieve following moving to complete different modes of conveying, and therefore the problem that transverse tube conveying or longitudinal tube conveying of an existing tube conveying device can not be adjusted for use is solved. The conveying equipment for stainless steel tube producing and machining has the advantage of beingadjustable in conveying mode, the using diversity is increased, the practicability is improved, and the producing and machining range is widened.

Owner:沈勤娟

Internet of Things monitoring camera device

PendingCN114222048AImprove protectionAvoid damageTelevision system detailsMachine supportsEngineeringMechanical engineering

The invention discloses an Internet of Things monitoring camera device which comprises a camera, a shell is arranged on the outer side of the camera, and a rubber sleeve is connected to the side edge of the rear side end of the shell. A first air cylinder works to enable a shell to drive a rubber sleeve to slide on the surface of a camera, hail and water are prevented from entering the shell through the rubber sleeve, the shell moves to enable a rotating rod to rotate through cooperation of clamping teeth on the inner side of a clamping block and a threaded groove, and a first rotating frame and a second rotating frame drive a cleaning plate and an extrusion plate to rotate correspondingly; the extrusion plate extrudes the cleaning plate when being in contact, the pressure of the extrusion plate on the cleaning plate can improve the contact tightness between the cleaning cotton and the camera, and the cleaning plate can conveniently and quickly clean dust and water vapor on the surface of the camera; the camera can completely enter the shell when the shell moves forwards, and at the moment, the front side end of the shell can comprehensively protect the camera of the camera, so that the camera of the camera is prevented from being damaged.

Owner:广州海傍科技有限公司

Manufacturing method of railway switch block cast slide plate

A manufacturing method of railway switch block cast slide plate comprises the following steps: A) integrally casting a base plate (1), an iron seat (2), a guide iron (3) and a bedplate (4) with casting technique; B) casting for two long grooves (7, 8) right on a limiting convex plate (5) in the internal cavity of the bedplate (4) and under the supporting convex plate (5); C) accurately processing the limiting convex plate (5) and the supporting convex plate (6); D) processing a water drainage hole (9, 10) respectively on the two sides of the bottom plate (1), wherein the water drainage hole (9, 10) are respectively communicated with the two long grooves (7, 8); E) shining metal the working surface of the bedplate (4). The manufacturing method uses the fusible pattern casting technique to manufacture the block cast slide plate, thereby increasing the whole intensity of the slide plate, ensuring the flatness of the bottom plate and the bedplate, providing good working condition for the switch rail and satisfying the requirement of railway switch to the road safety that the speed per hour is more than 200 miles.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

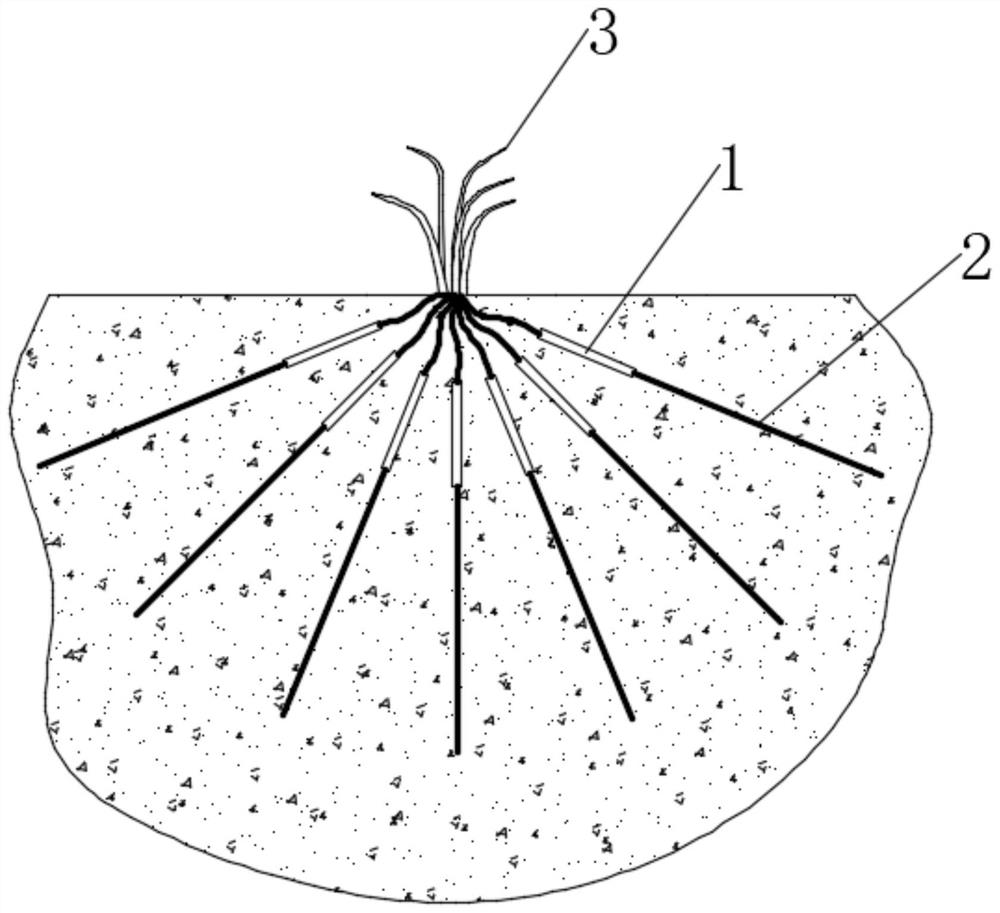

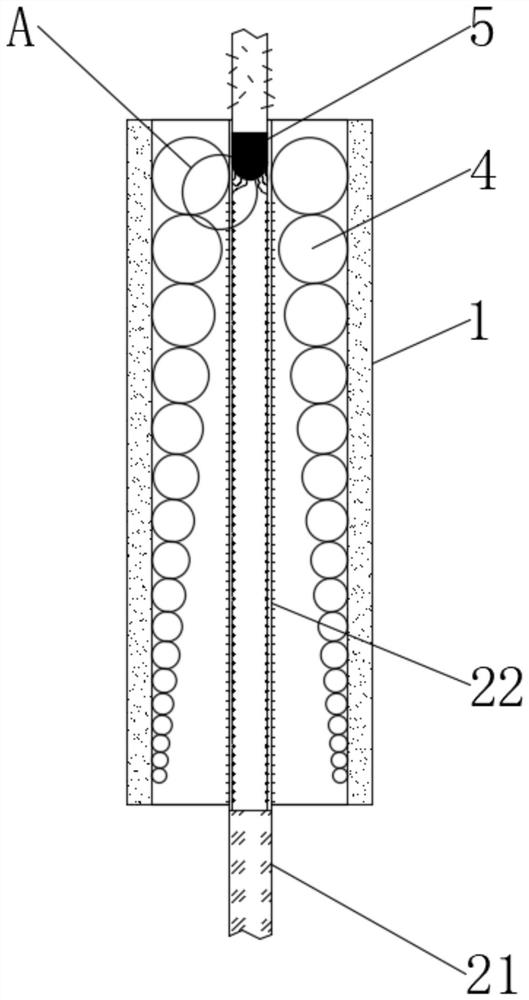

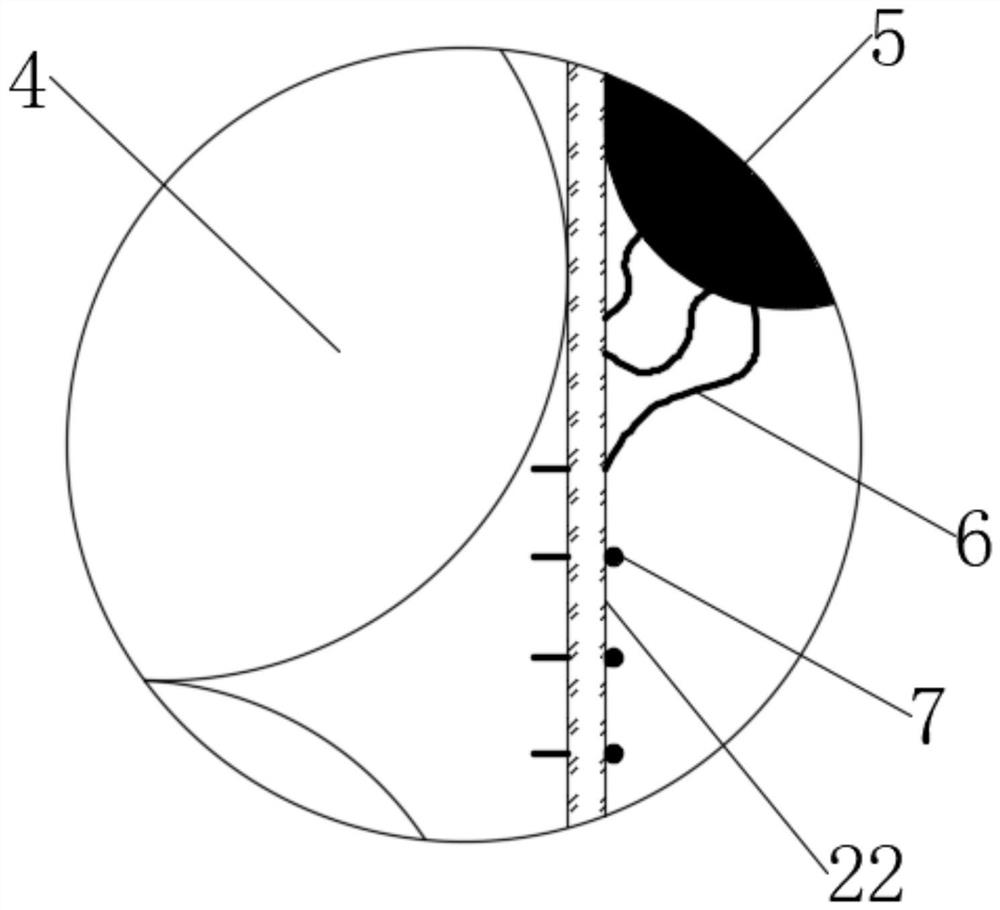

Heavy metal contaminated soil continuous root type combined remediation method

InactiveCN111872109AImprove capture efficiencyPlay an auxiliary role in repairingContaminated soil reclamationFiberMicroorganism

The invention discloses a heavy metal contaminated soil continuous root type combined remediation method, belongs to the technical field of soil remediation, and can realize continuous connection of root systems of heavy metal hyperaccumulation plants through combination of continuous biological isolation tubes and continuous fiber dummy roots to meet remediation requirements of large-scale deep contaminated soil. The method comprises the following steps: absorbing moisture deep in soil by taking the continuous fiber dummy roots as root systems, forcing the moisture to carry heavy metal ions to transfer to the continuous fiber dummy roots, performing complementary remediation based on the combined action of microorganisms in the continuous fiber dummy roots and heavy metal hyperaccumulation plants, and isolating the growth of the microorganisms by utilizing the continuous fiber dummy roots. According to the method, the continuous fiber dummy root and the continuous biological isolationtube can adapt to the growth of the root system of the heavy metal hyperaccumulation plant, provide nutrients required by the growth of the microorganisms and the heavy metal hyperaccumulation plantin real time, and promote the effect of combined remediation.

Owner:达小莉

Polishing device and polishing system

InactiveCN105690227AVibration reliefImprove securityPolishing machinesUltimate tensile strengthSurface flatness

The invention provides a polishing device and a polishing system. The polishing device includes a fixing support, a damping part arranged on the fixing support, and an abrasive cloth installation zone positioned on the damping part. During use, an abrasive cloth is arranged on the abrasive cloth installation zone of the damping part, the fixing support is arranged on a device such a lathe carriage, the position of the damping device on the polishing device is adjusted in a first direction, and then the abrasive cloth is attached to a surface of an article to be polished; and when the article to be polished moves, the article to be polished has a friction with a surface of the abrasive cloth, and then polishing of the surface of the article to be polished can be completed. Through the polishing device, direct contact between an operator and the abrasive cloth and the article to be polished can be avoided; the operation intensity of works can be reduced, and the potential risk during manual operation can be lowered; and in addition, the damping device can effectively relieve vibration of the article to be polished or vibration of the polishing device due to a defect of surface evenness of the article to be polished during a polishing process, the safety can be improved during polishing of the article to be polished, and the polishing effect can be improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

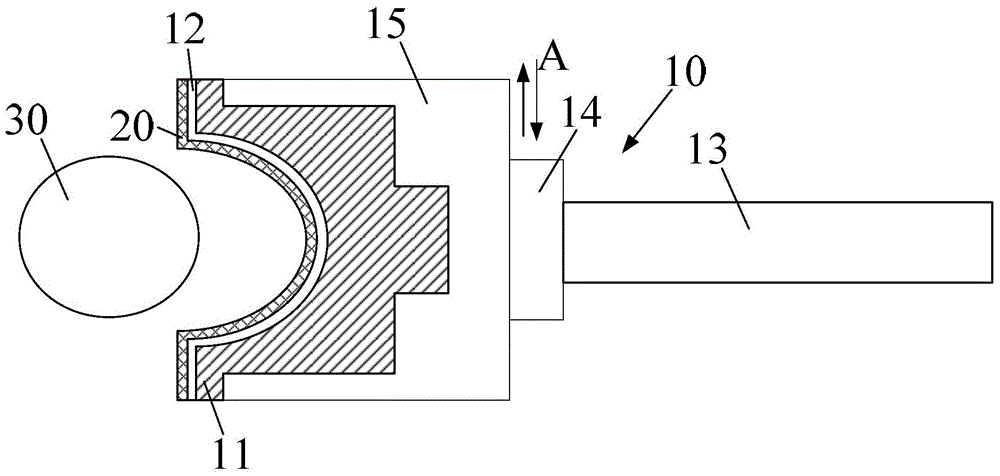

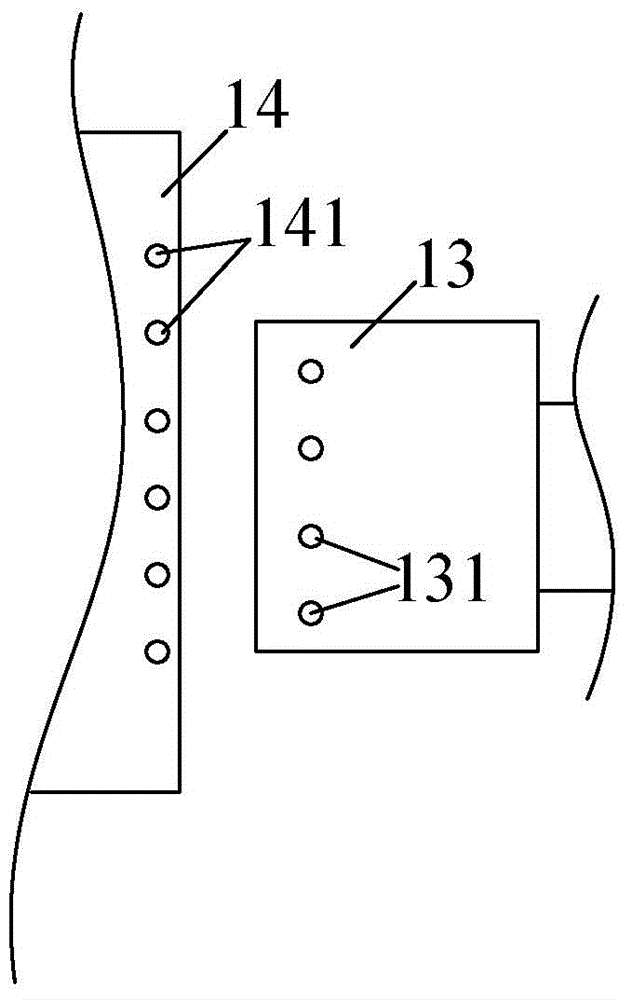

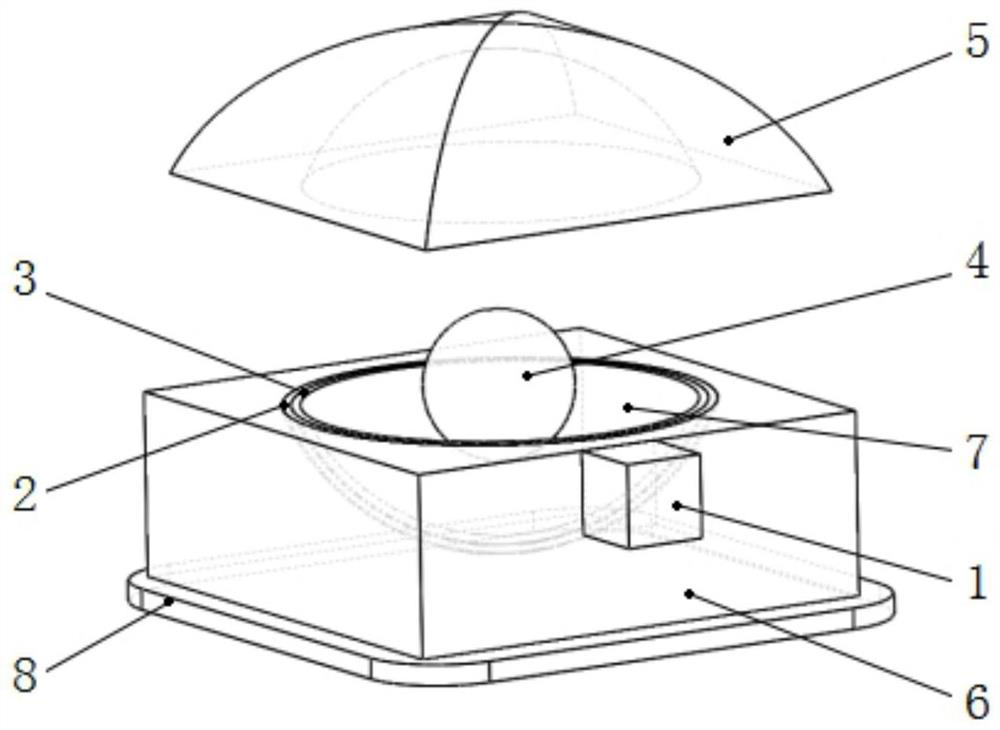

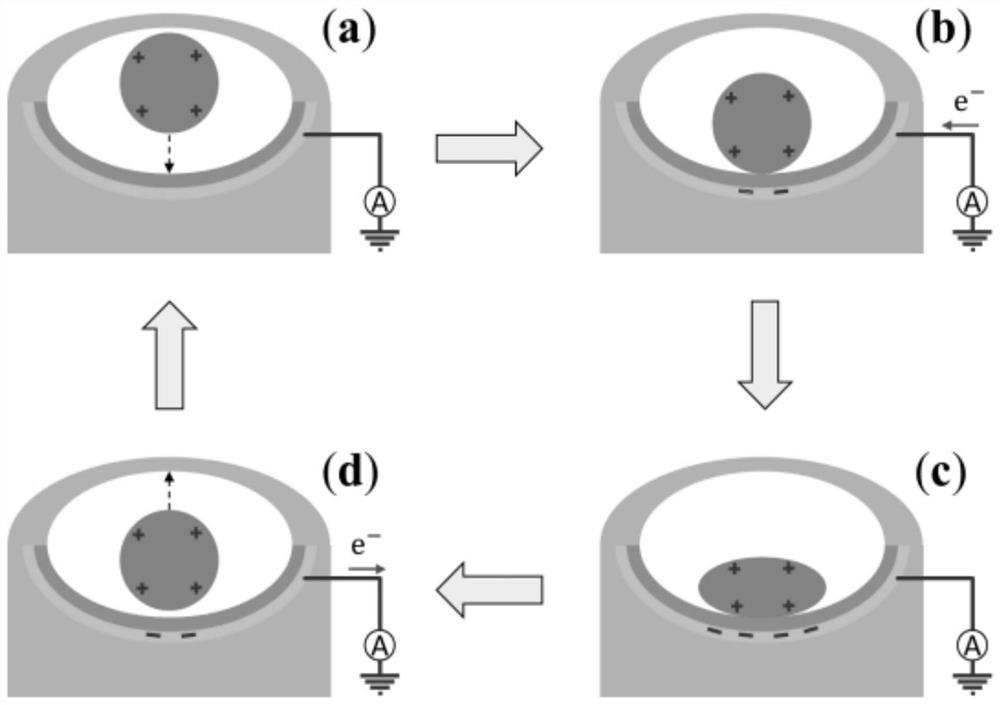

Ship machine vibration self-driven sensing device based on friction nanometer generator

PendingCN113507232AEnabling Self-Driven Vibration SensingHas low-to-medium frequency movement characteristicsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSignal processing circuitsEngineering

The invention relates to a ship machine vibration self-driven sensing device based on a friction nanometer generator. The ship machine vibration self-driven sensing device comprises the friction nanometer generator, a signal processing circuit and an attaching fixed layer. The friction nanometer generator comprises a base, a top cover, a metal electrode, a contact layer and liquid metal. Hemispherical pits are formed in the base and the top cover; the metal electrode is fixedly connected to the inner surface of the pit of the base; the contact layer is fixedly connected to the inner surface of the metal electrode; the liquid metal is arranged between the base and the top cover and can freely vibrate in the spherical space; one end of the signal processing circuit is connected with the friction nanometer motor, and the other end is grounded; the attaching fixed layer is fixedly connected to the bottom side of the friction nanometer generator. The device is small in size, light in weight, low in cost, high in environment compatibility and capable of converting vibration information of the ship mechanical equipment with low and medium frequency motion characteristics into electric signals, and self-driven vibration sensing of the ship mechanical equipment is achieved.

Owner:DALIAN MARITIME UNIVERSITY

Method for preparing sulphoaluminate cement and co-producing sulfuric acid by virtue of segmented calcination of desulfurized gypsum

ActiveCN106630702AIncrease profitRealize resource utilizationSulfur-trioxide/sulfuric-acidHigh concentrationAnthracite

The invention relates to a method for preparing sulphoaluminate cement and co-producing sulfuric acid by virtue of segmented calcination of desulfurized gypsum. The method comprises the following steps: completely replacing limestone and natural gypsum with desulfurized gypsum, mixing bauxite, silica and anthracite with the gypsum to prepare blocks, and then carrying out segmented calcination to prepare the sulphoaluminate cement. According to the method, the utilization rate of the desulfurized gypsum can be greatly improved, and the high-concentration sulfur dioxide tail gas can be used for preparing sulfuric acid through absorption. The prepared sulphoaluminate cement clinker has high hardening speed, the early strength is high, the later strength is also improved stably, and the performance test shows that the mechanical strength of the sulphoaluminate cement prepared by the method conforms to the standard of the fast-hardening sulphoaluminate cement.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

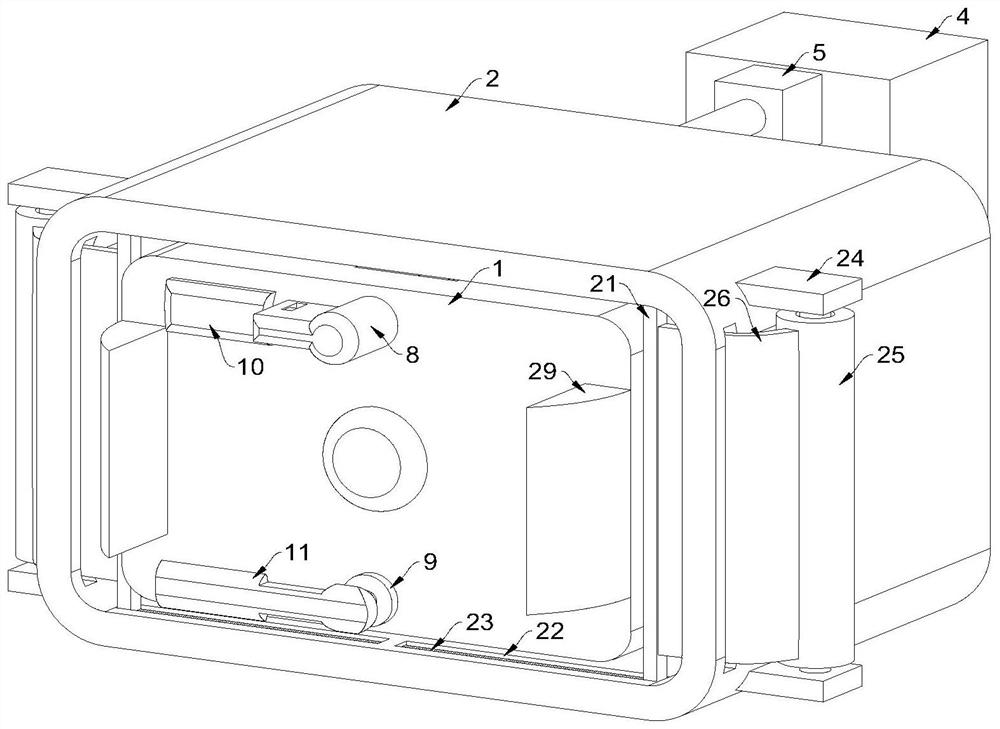

Cleaning and drying system for heat collecting pipe of solar water heater

ActiveCN111570425AWon't interfereEasy to dryHollow article cleaningDrying machines with local agitationThermodynamicsSolar water

The invention relates to a cleaning and drying system for a heat collecting pipe of a solar water heater. The cleaning and drying system for the heat collecting pipe of the solar water heater comprises a water collecting assembly, a cleaning assembly and a drying assembly. The water collecting assembly comprises a water collecting tank, a transverse seat and a rotating frame, the transverse seat is arranged on one side of the water collecting tank, a plurality of containing grooves are formed in the transverse seat, drying columns are arranged in the containing grooves, a lifting cylinder is arranged in the middle of the transverse seat, a lifting part is arranged on an output shaft of the lifting cylinder, the rotating frame is installed on the side, away from the water collecting tank, of the transverse seat, and a water injection pipe is arranged at the top of the rotating frame. The cleaning and drying system for the heat collecting pipe of the solar water heater has high cleaningand drying efficiency on the heat collecting pipe.

Owner:褚孔雅

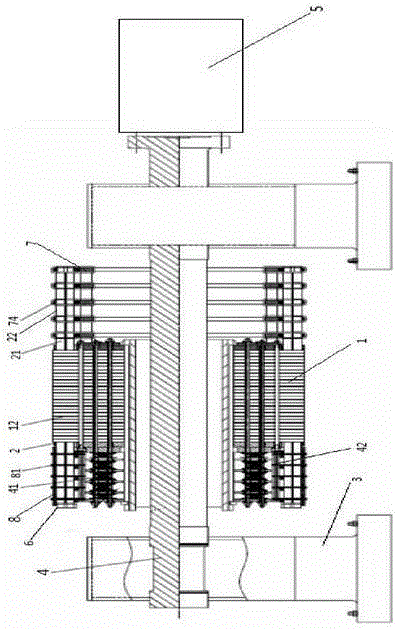

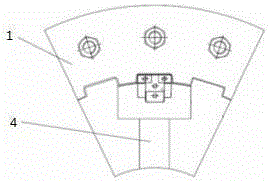

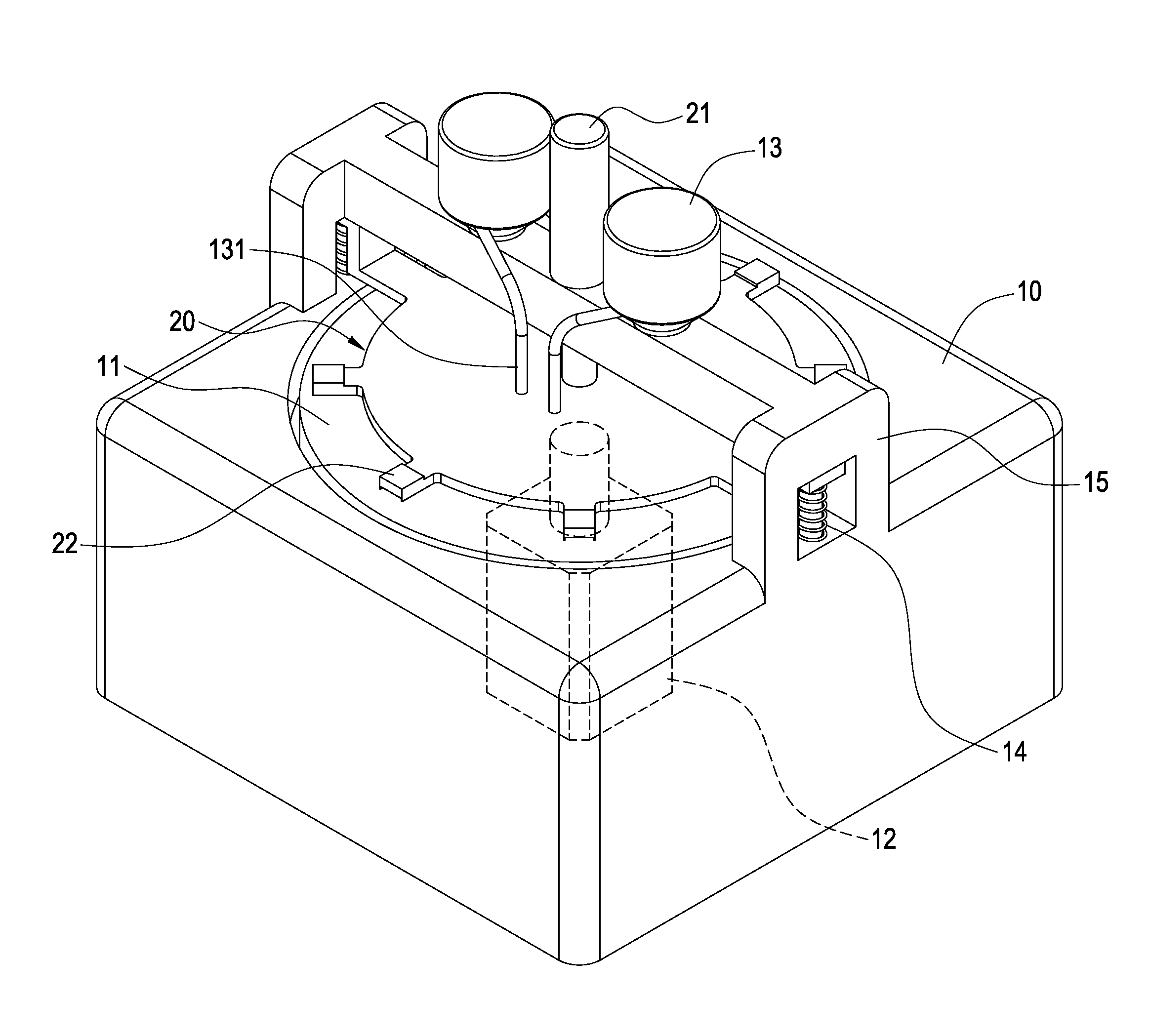

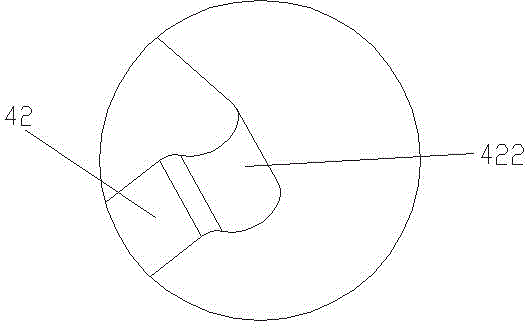

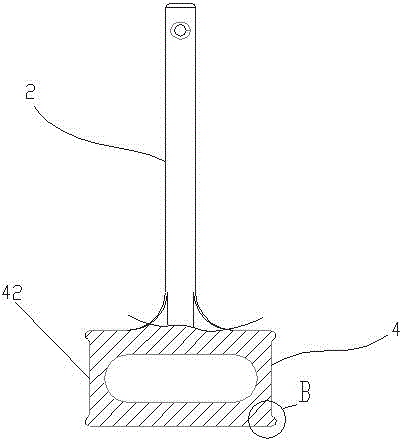

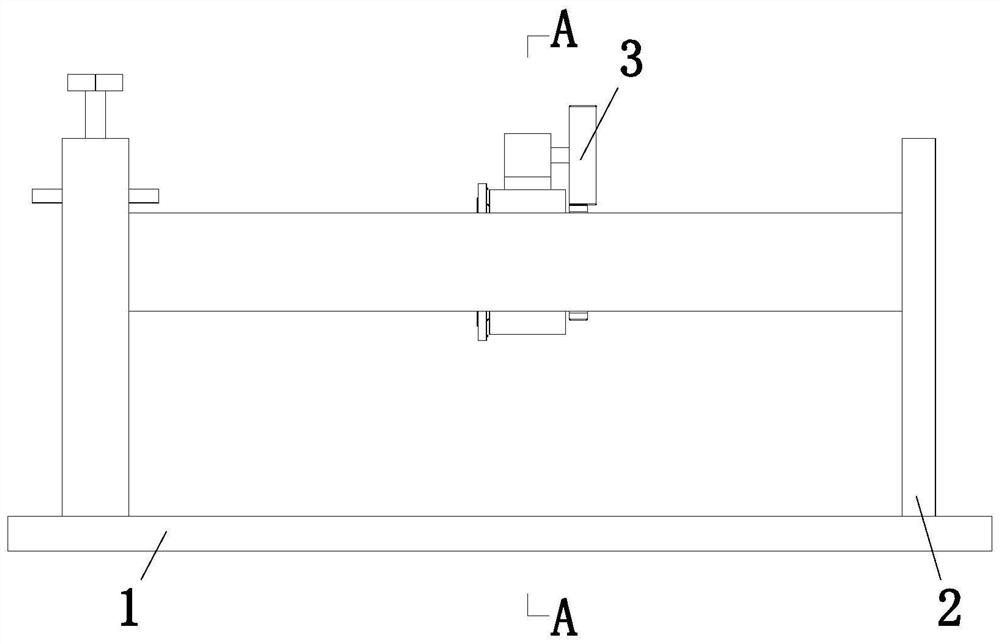

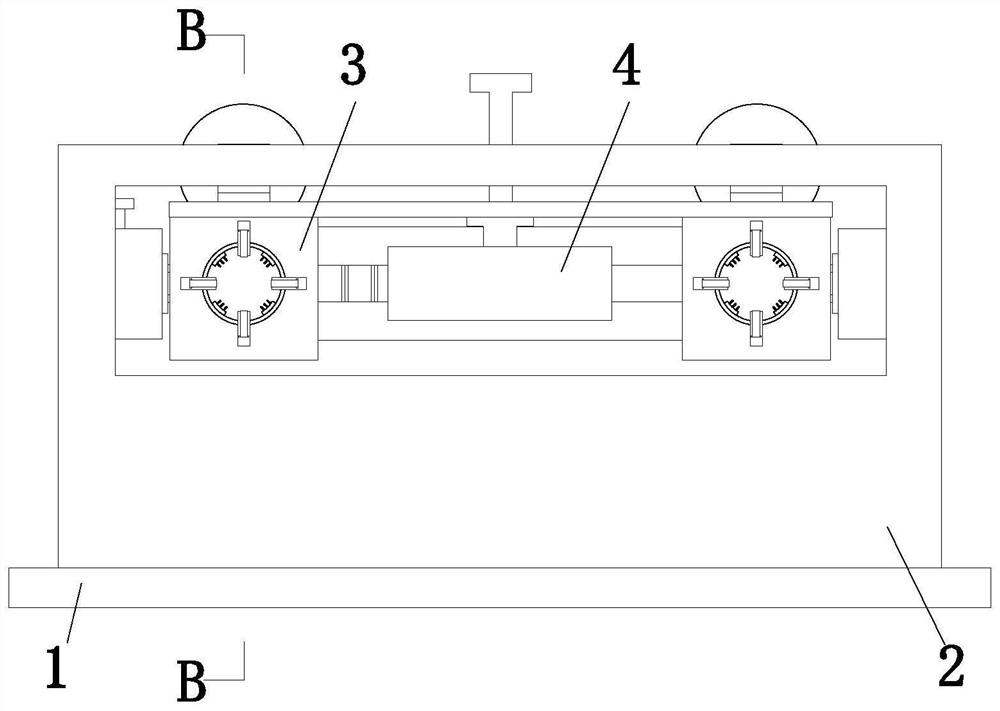

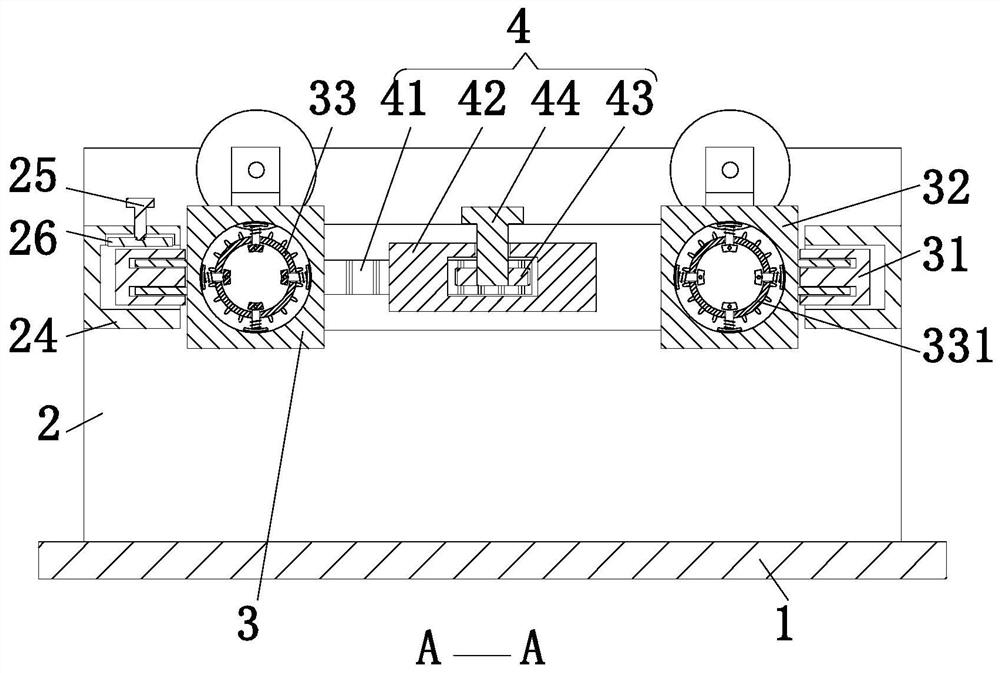

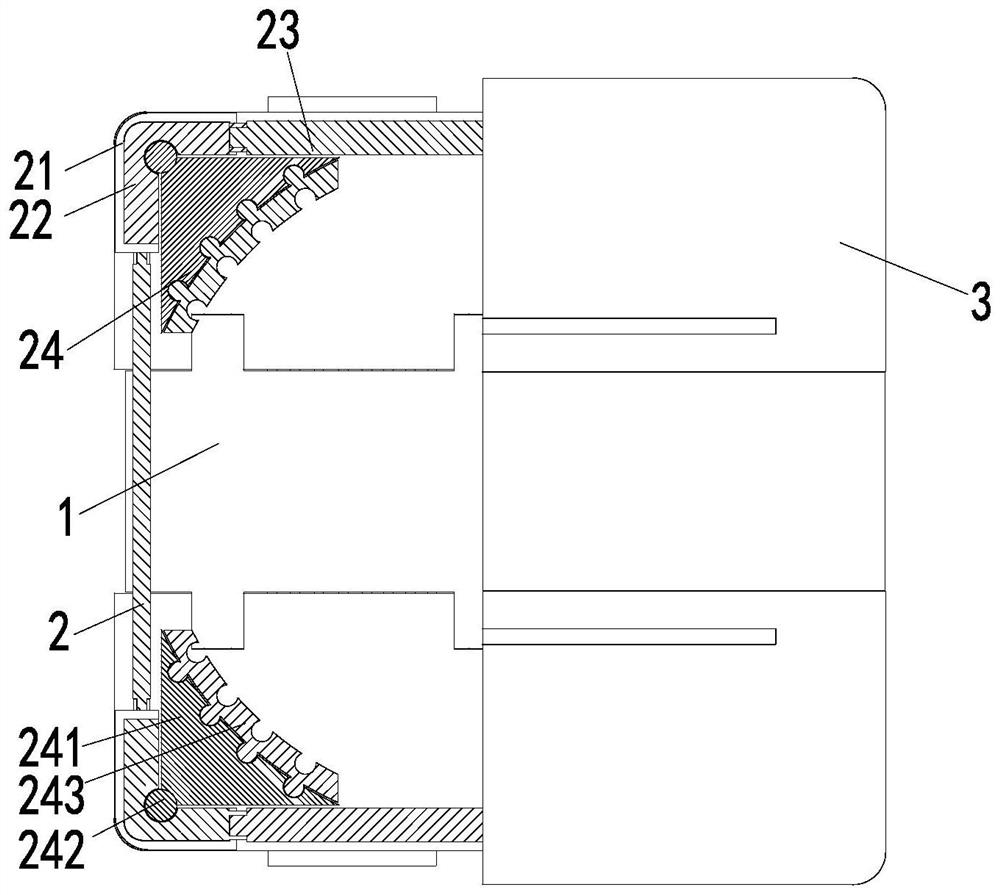

Mechanical model device for rotor of motor

ActiveCN105181325AEasy to operateSimple and fast operationMachine part testingTesting dielectric strengthExperimental researchElectric machine

The invention discloses a mechanical model device for a rotor of a motor and relates to the technical field of test machinery. The mechanical model device comprises a rotor and a rotor winding, wherein an axial winding slot is arranged along an axial direction of the rotor; a winding bar of the rotor winding is inserted into the axial winding slot; a winding tail end of the winding bar exposed from the axial direction of the rotor is formed into an end winding; end fixing devices are fixedly arranged at the two ends of the rotor; the end fixing devices are used for fixing the end winding. The mechanical model device is fit for high-capacity winding type rotor machinery, especially for the experimental research for the fixing mode of the rotor winding end and the detection and test analysis for the safe reliability of the fixing of the winding bar end of the rotor and the electric insulating property of the rotor winding.

Owner:DONGFANG ELECTRIC MACHINERY

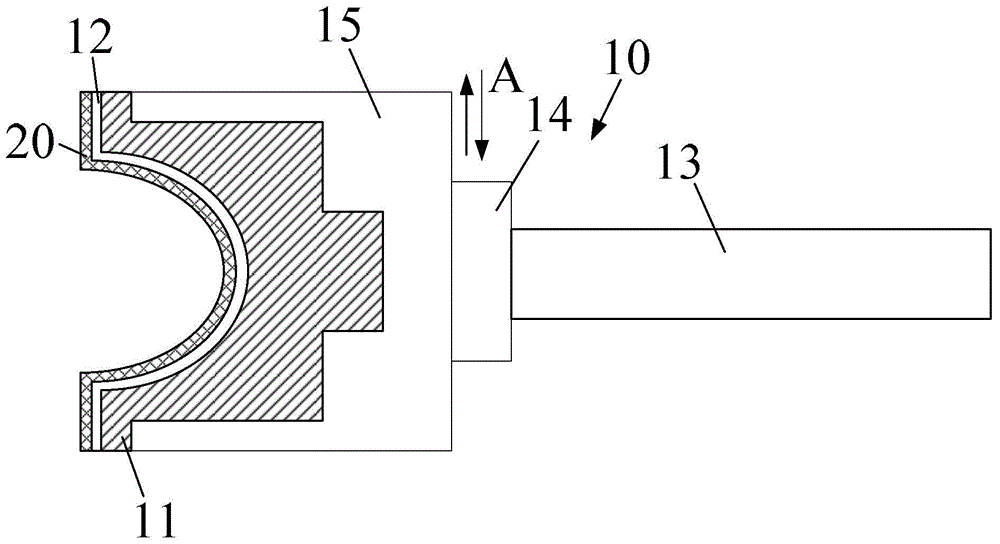

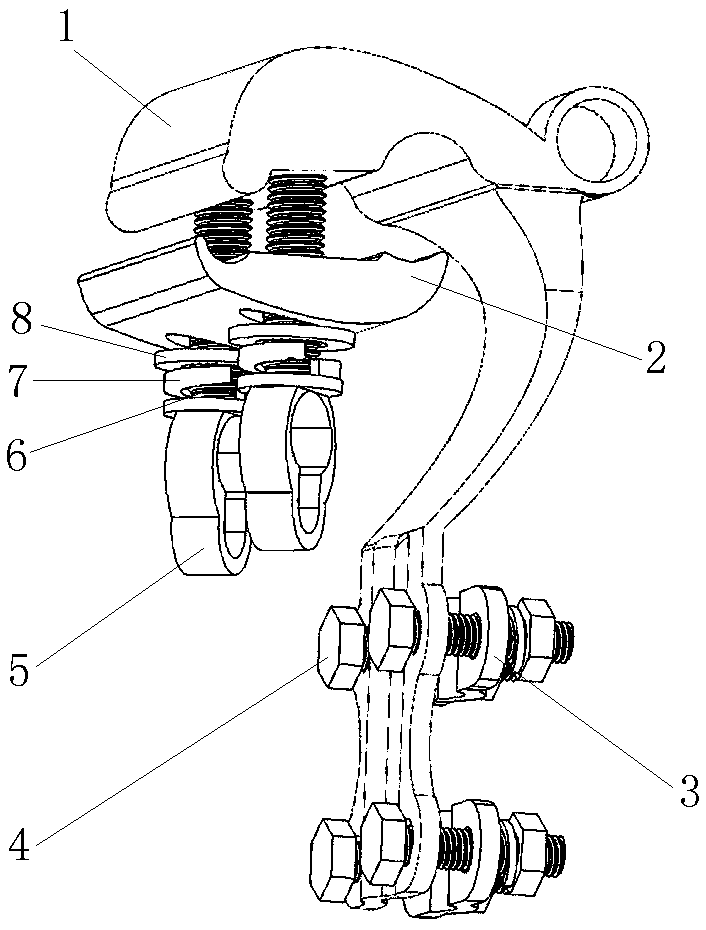

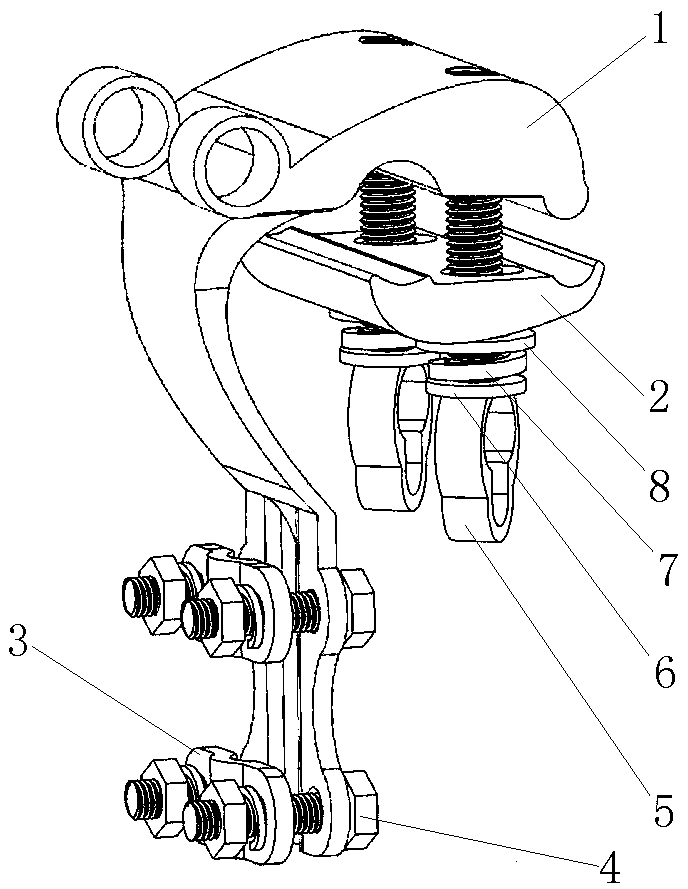

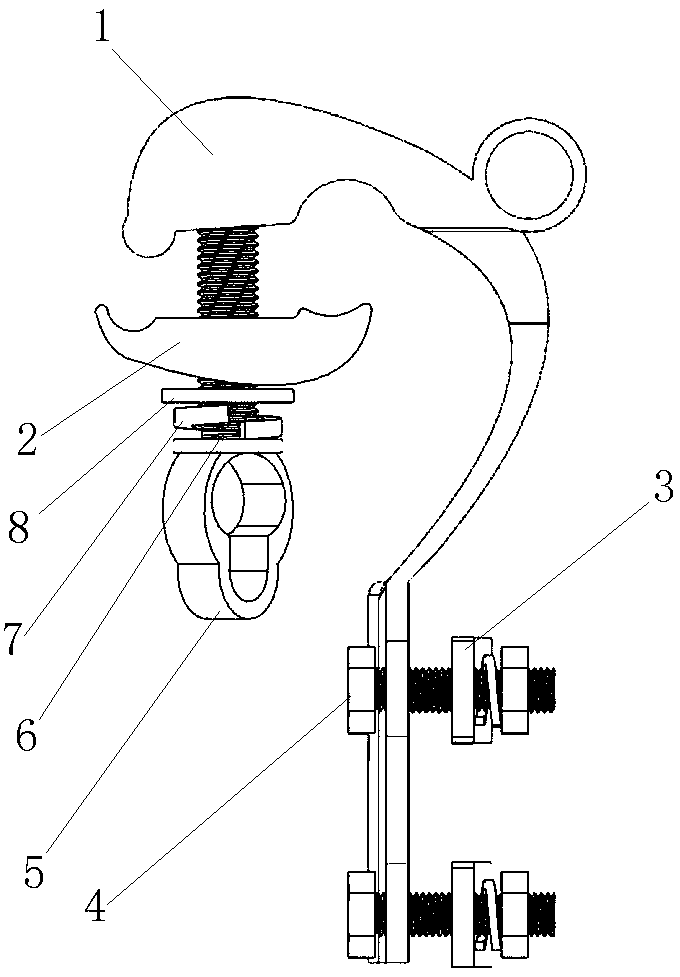

Easy-to-operate permanent fastening large-load live wire connection clamp

PendingCN110336147AEasy accessEasy to disengageClamped/spring connectionsApparatus for overhead lines/cablesRear quarterUltimate tensile strength

The invention discloses an easy-to-operate permanent fastening large-load live wire connection clamp, which comprises a hanging plate (1), a main line pressing plate (2) and a drainage line pressing plate (3), wherein a hanging ring bolt (6) at one side of the hanging plate (1) is sleeved with a spring pad (7) and a flat pad (8), passes through the main line pressing plate (2) and is screwed to the hanging plate (1); a fastening bolt (4) passes through the lower end of the hanging plate (1) and is sleeved with the drainage line pressing plate (3) and a nut is screwed for connection; two ends of a top plate (9) are provided with supporting plates (16) and lug holes (11), a wire clamping groove A (10) is arranged below the middle part, one lower side is provided with a side plate (12), the lower part of the side plate (12) is provided with a fastening bolt hole A (13) and a wire clamping groove B (14), and the protruding top end on the top plate (9) is provided with a hanging ring bolt hole A (15). The clamp has reasonable effects, operation by an operator is simple and easy, single-person single-pole operation in all directions is achieved, the operation strength of the operator islessened, and the operation time is shortened.

Owner:王伦海

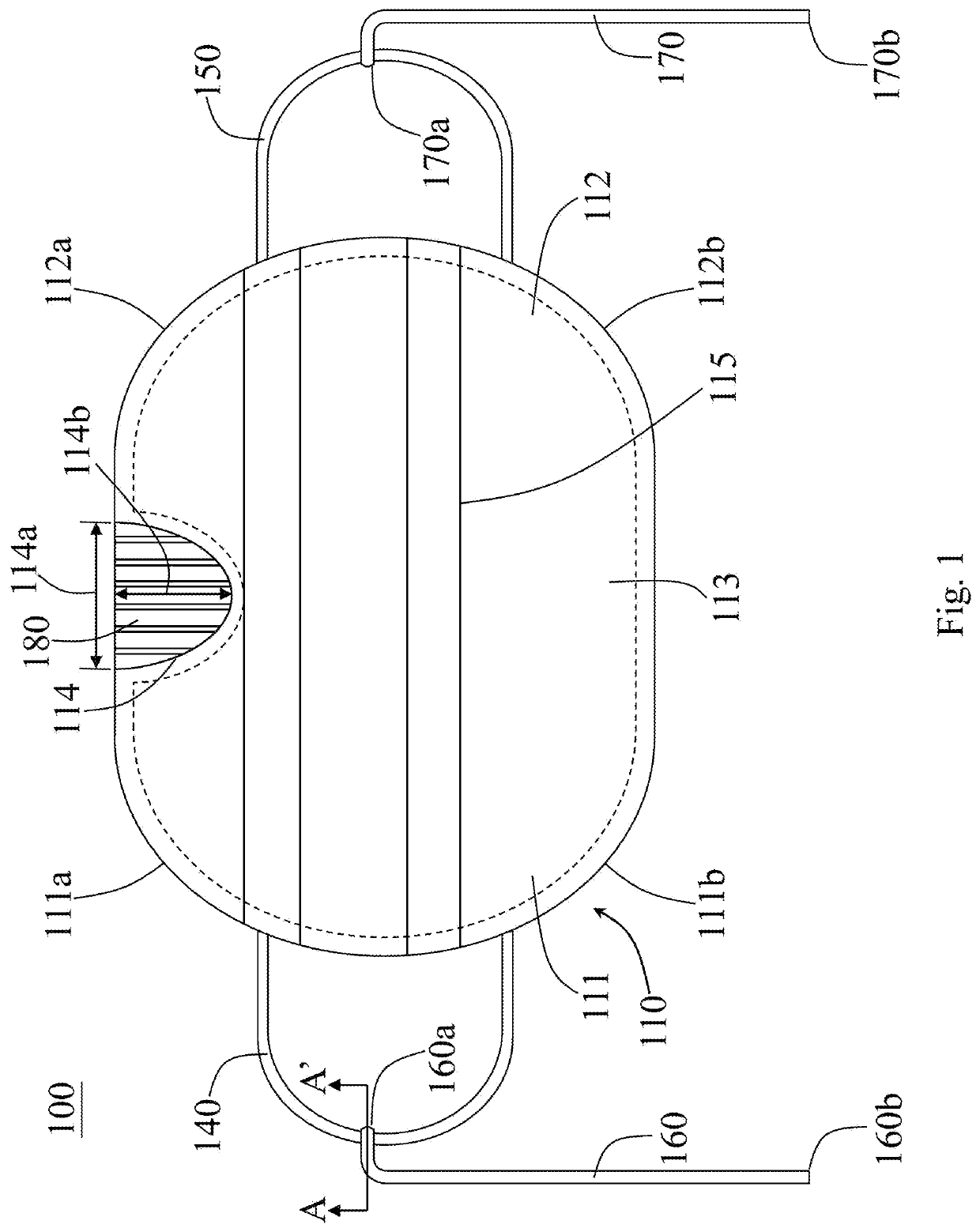

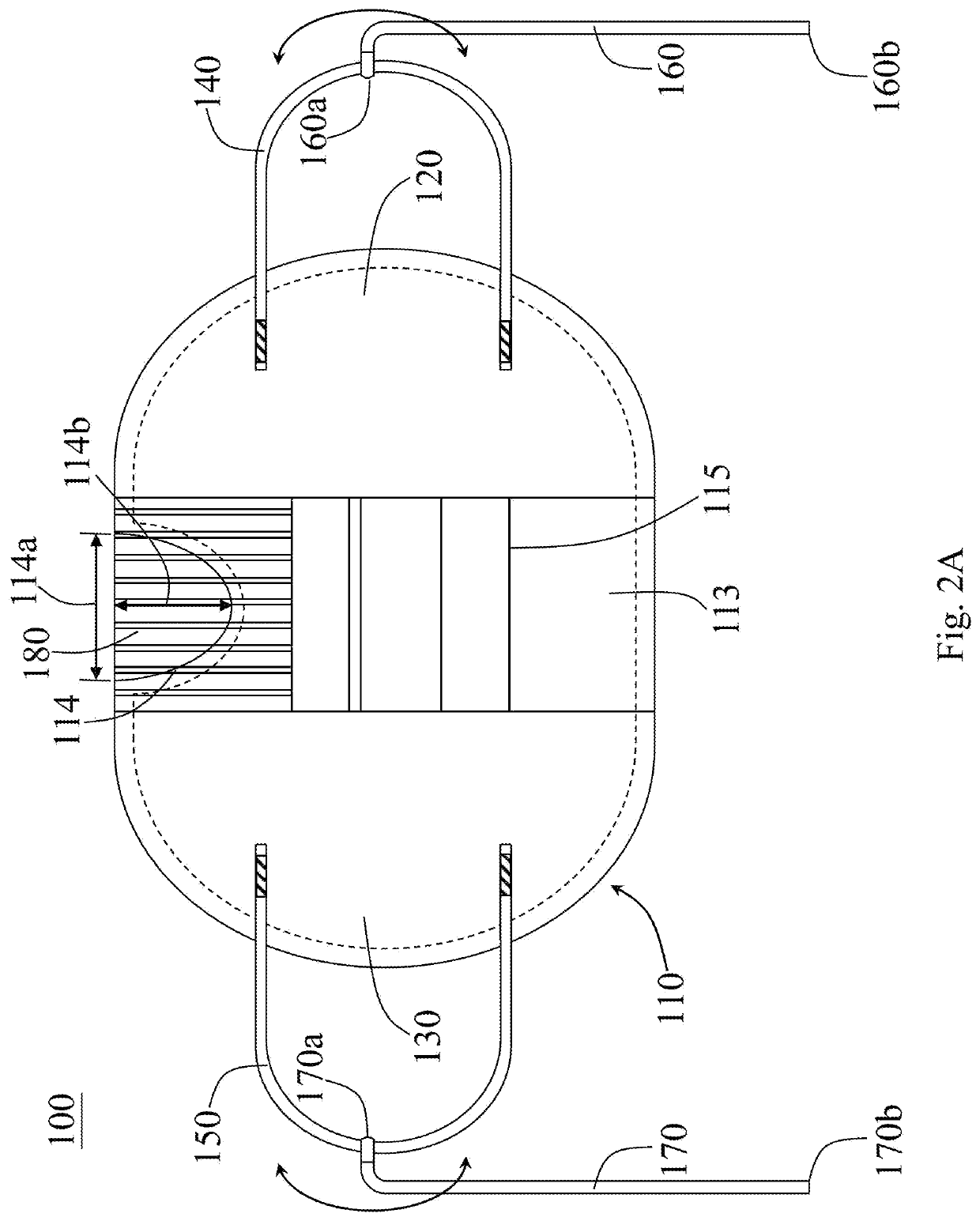

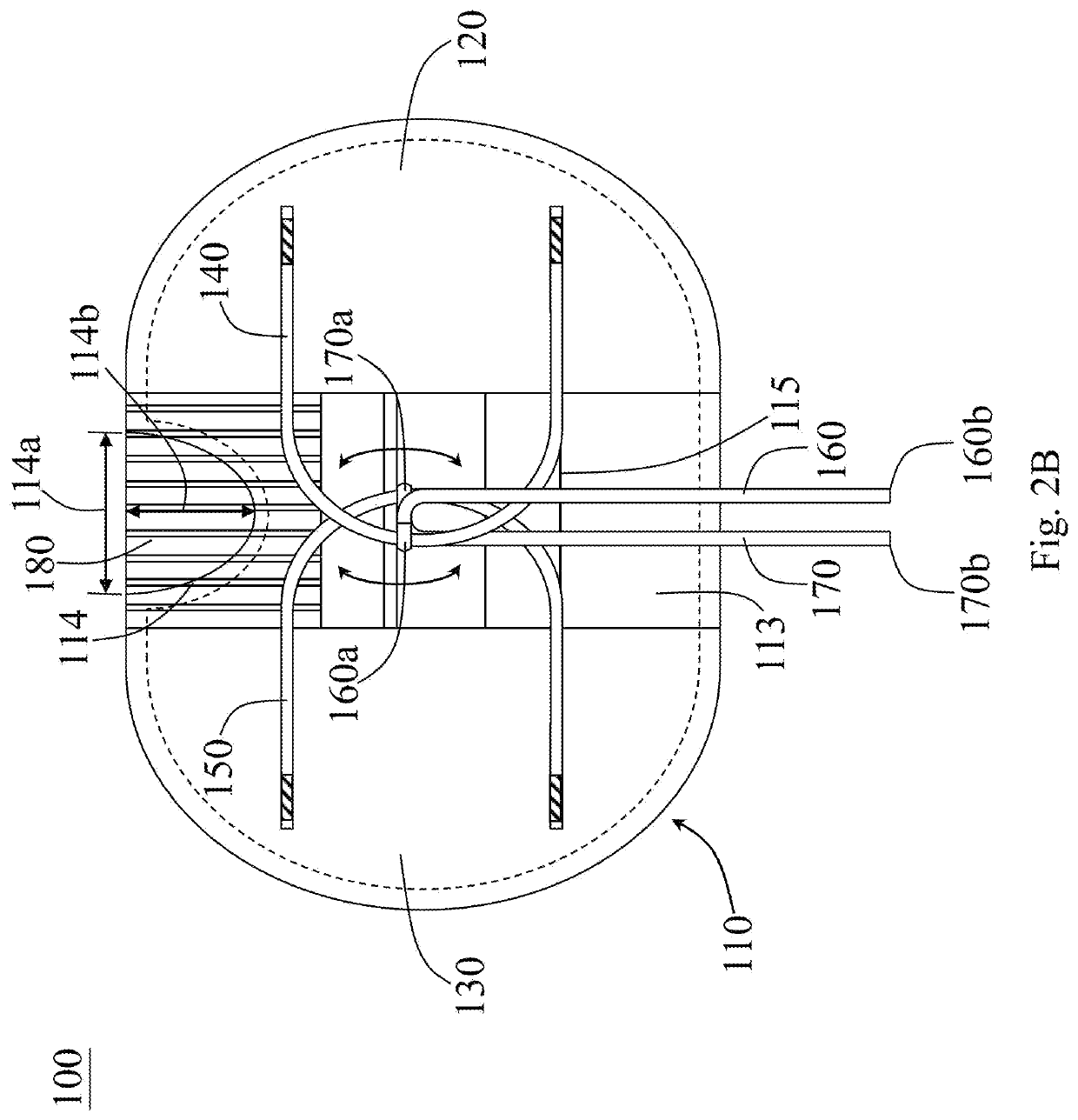

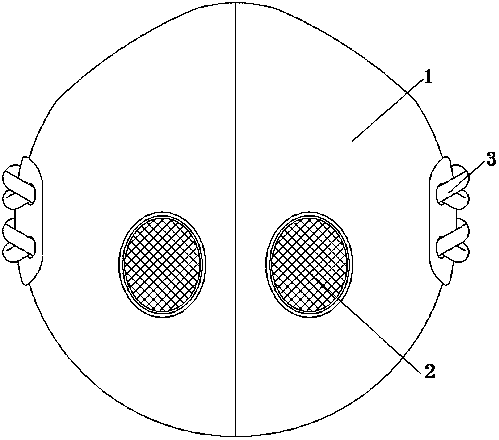

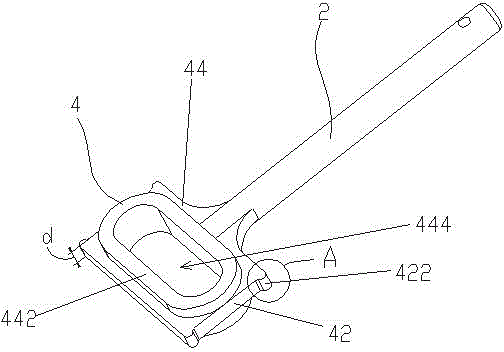

Face Mask and Method for Manufacturing Thereof

A face mask and a method for manufacturing the face mask are disclosed. The face mask comprises a sheet, a first lateral flap, a second lateral flap, a first loop, a second loop and an elastic film. The sheet comprises a central portion, a first lateral portion, a second lateral portion and an opening. The first lateral flap is coupled to the first lateral portion to form a first chamber. The second lateral flap is coupled to the second lateral portion to form a second chamber. The first loop connects to a first strap and is coupled to the first lateral flap. The second loop connects to a second strap and is coupled to the second lateral flap. The elastic film is coupled to the sheet and covers the opening.

Owner:TSUEI ALEXANDER CHIERUEN

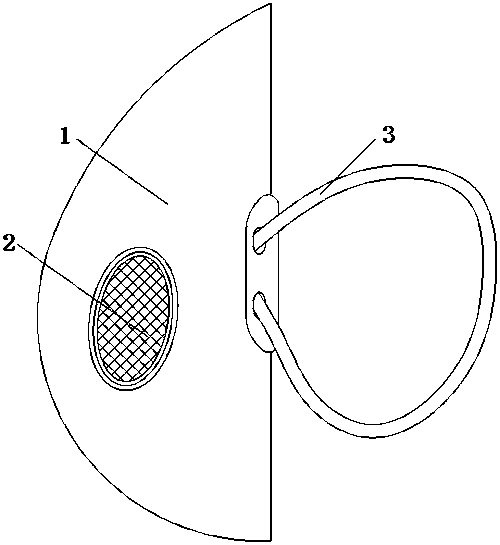

Cooler having ground heated plane for cooling heating electronic component

InactiveUS20120160458A1Improve flatnessIncrease roughnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

A method for making heated plane of a cooler to obtain better flatness and roughness includes a grinder with a grinding plate and a fixture. Then, the cooler is arranged onto the fixture. Next, the abrasive is injected into the gap between the grinding plate and the heated plane, making the fixture press and clamp the cooler in a way, such that the heated plane of the cooler contacts the abrasive closely. Finally, the grinding plate is rotated to make at least one grinding process to the heated plane, making the heated plane obtain a surface with better roughness and flatness, further enhancing the contact tightness between the heated plane and a heating element, and therefore promoting the thermally conductive efficiency between the cooler and the heating element.

Owner:LIN KUO LEN +4

Anti-bacterial protective mask

PendingCN109998195AReduce dust contentReduce odorBreathing filtersProtective garmentAnti bacterialActive carbon

The invention belongs to the technical field of masks, and in particular relates to an anti-bacterial protective mask. The anti-bacterial protective mask comprises a mask body, filters are erected onthe side surfaces of the mask body, an embedding ring is placed inside each filter in an embedding manner, a filtering bag is placed inside each embedding ring, hanging ropes are sewn to the two endsof the mask body, the mask body comprises non-woven fabrics and first filtering cotton, two layers of non-woven fabrics are arranged, and the first filtering cotton is laid inside the non-woven fabrics; and latex plates are additionally arranged on the side surface of the device, sealing cotton is arranged on the inner-side surfaces of the latex plates, when the mask body is fixed on the face of auser, the latex plates promote the contact tightness of the mask body with the face, the sealing cotton is used for blocking the gap of the side face of the nose bridge of the user, during the use process of the filters, second filtering cotton is used for filtering air, so that the dust content in the air is reduced, due to active carbon, the foreign smell in the air is reduced, and due to sterilizing layers, bacteria are killed.

Owner:普宁市康达健科技有限公司

Method for simultaneously producing sulphate aluminum cement and sulfuric acid through segmented calcination of phosphorus gypsum

ActiveCN106365478AIncrease profitRealize resource utilizationSulfur compoundsHigh concentrationCalcination

The invention relates to a method for simultaneously producing sulphate aluminum cement and sulfuric acid through segmented calcination of phosphorus gypsum. The method comprises the following steps: entirely replacing limestone and natural gypsum by using the phosphorus gypsum, grinding and homogenizing the phosphorus gypsum, bauxite and anthracite, then preparing the sulphate aluminum cement via a segmented calcinations method. Through the method, the utilization rate of the phosphorus gypsum can be greatly increased; high-concentration sulfur dioxide tail gas can be absorbed for preparing the sulfuric acid; sulphate aluminum cement clinker prepared by the method is rapid in hardening speed, high in early strength and highly stable in later strength; a performance test shows that the mechanical strength of the sulphate aluminum cement prepared by the method meets the standard of rapidly-hardened sulphate aluminum cement.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Valve rod

InactiveCN103953789AExtended service lifeReduce contact areaValve arrangementsBiomedical engineering

Owner:江苏宇海环保设备有限公司

A welding robot for automobile manufacturing

InactiveCN111390690BAchieve removalImprove contact tightnessEdge grinding machinesGrinding drivesExhaust pipeMuffler

The invention relates to an automobile manufacturing welding robot. The automobile manufacturing welding robot comprises a bottom plate, a carrying device, grinding devices and an adjusting device, wherein the carrying device is arranged at the upper end of the bottom plate; the grinding devices are symmetrically arranged in the middle of the carrying device; and the grinding devices are connectedwith the carrying device in a sliding fit way. Through the adoption of the automobile manufacturing welding robot, the problem of incomplete removal of weld beading and degradation of the grinding effect since the angle cannot be adjusted during grinding and equipment cannot be matched with the weld beading perfectly in the process of removing the weld beading generated during welding of a muffler and a connection pipe in an automobile exhaust pipe, the problem of degradation of the grinding efficiency since two connection pipes cannot be cleaned at the same time, as well as the problems of increase of the weld beading grinding steps, degradation of the grinding efficiency and the like since the weld beading generated at other places of the surfaces of the connection pipes cannot be removed under the condition of not changing the positions of the connection pipes in existing equipment are solved.

Owner:上海银田机电工程有限公司

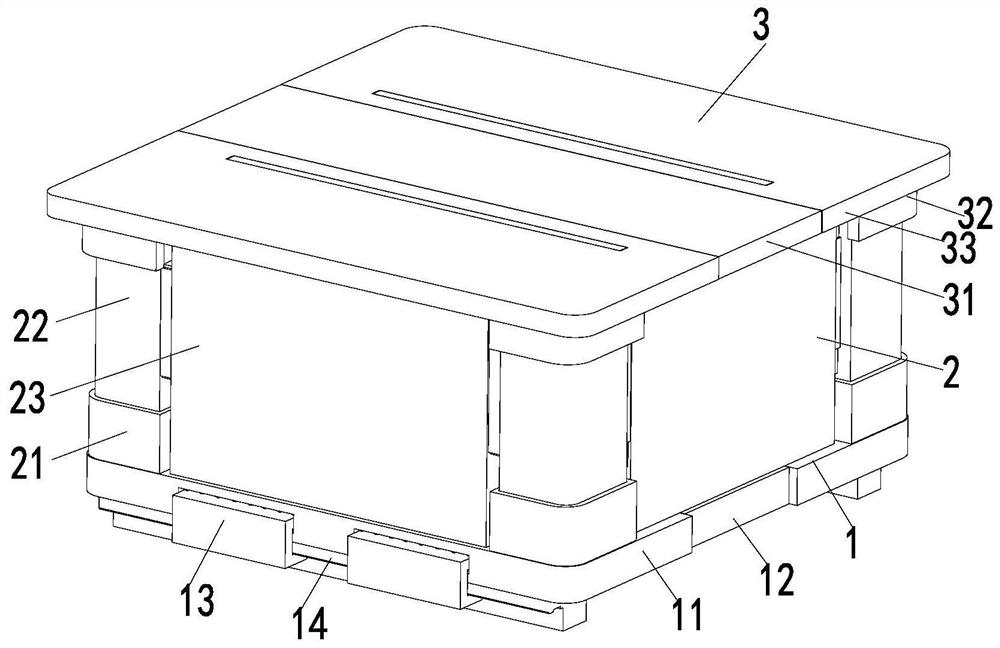

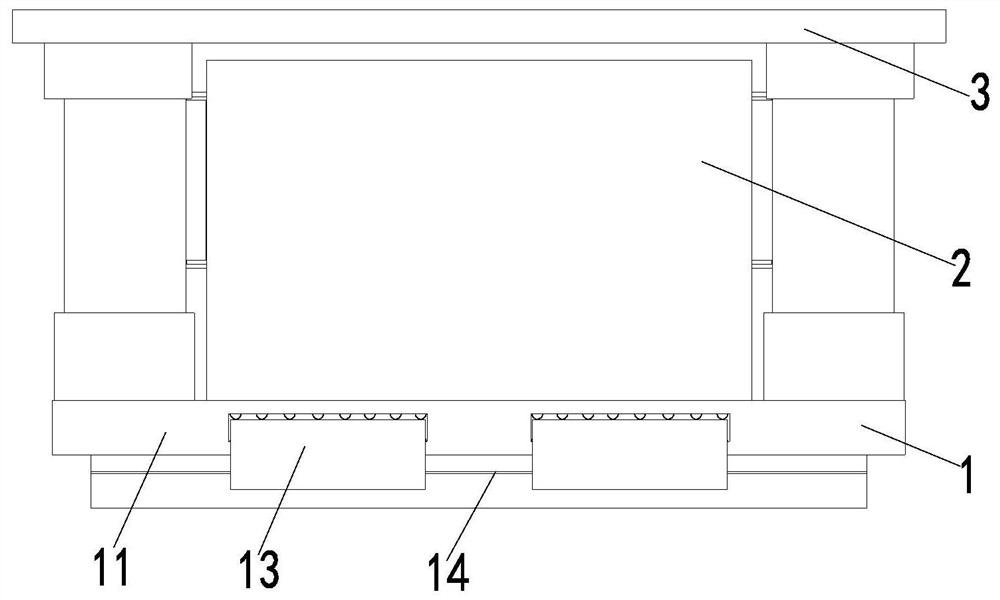

A spliced foamed plastic structure

ActiveCN110356680BEasy to adjustReduce manufacturing costRigid containersClassical mechanicsManufacturing line

The invention relates to a spliced foamed plastic structure, which comprises a base, an enclosure mechanism and a top cover. The enclosure mechanism is installed on the upper end of the base, and the top cover is installed on the upper end of the enclosure mechanism. The base includes a bottom plate, a connecting plate, and a support frame. and the base, the enclosure mechanism includes the installation seat, the installation column, the enclosure plate and the compression frame; The connecting plate includes a connecting end, a clamping end and a clamping block, stacking grooves are provided on the inner wall of the foundation frame and the inner wall of the pressing plate, and stacking columns are arranged on the outer wall of the pressing plate. The invention provides a spliced foamed plastic structure, each part is detachably connected to facilitate the adjustment of the packaging size according to actual needs, each part is produced in a modular manner, and there is no need to open up packages for different sizes. The corresponding production line saves production costs.

Owner:盐城苏洁仕环保服务有限公司

A method for cleaning stone laid on red soil

ActiveCN105081911BPromote infiltrationProlong the action timeCationic surface-active compoundsOrganic detergent compounding agentsLateritePolypropylene

The invention provides a method for keeping cleanness of stone material laid on red land. The method comprises the following steps that the stone material is coated with gelatinous detergent for cleaning after being ground, and the detergent is an aqueous solution comprising 10-15 g / L of oxalic acid, 1-3 g / L of tetrabutyl ammonium hydroxide, 0.5-1 g / L of pentaerythritol ester and 2-5 g / L of xanthan gum; then a brightening maintenance agent is sprayed on the surface of the stone material for grinding and polishing treatment after the stone material is finely ground, and the brightening maintenance agent comprises 1-3 wt% of polyethylene wax, 0.2-0.8 wt% of polypropylene micronized wax, 5-10 wt% of perfluoroalkyl ethyl acrylate, 2-6% of triethoxysilane, 2-5 wt% of hydroxymethyl cellulose and 0.2-0.4 wt% sodium chloride. The cleaning and maintenance treatment process for the stone material is simple in step, durable in protection effect of the stone material, and the workload of the subsequent daily regular care for the stone material is reduced.

Owner:SUZHOU GOLD MANTIS GREEN LANDSCAPE LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com