Cooler having ground heated plane for cooling heating electronic component

a technology of electronic components and cooling planes, which is applied in the field of cooling devices with ground heated planes, can solve the problems of reducing operation efficiency, overheating of electronic components, and increasing power consumption, so as to improve the effect of thermal conduction, improve the flatness and surface roughness, and improve the contact tightness between the heated plane and the heating electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In cooperation with attached drawings, the technical contents and detailed description of the present invention are described thereinafter according to a number of preferable embodiments, not used to limit its executing scope. Any equivalent variation and modification made according to appended claims is all covered by the claims claimed by the present invention.

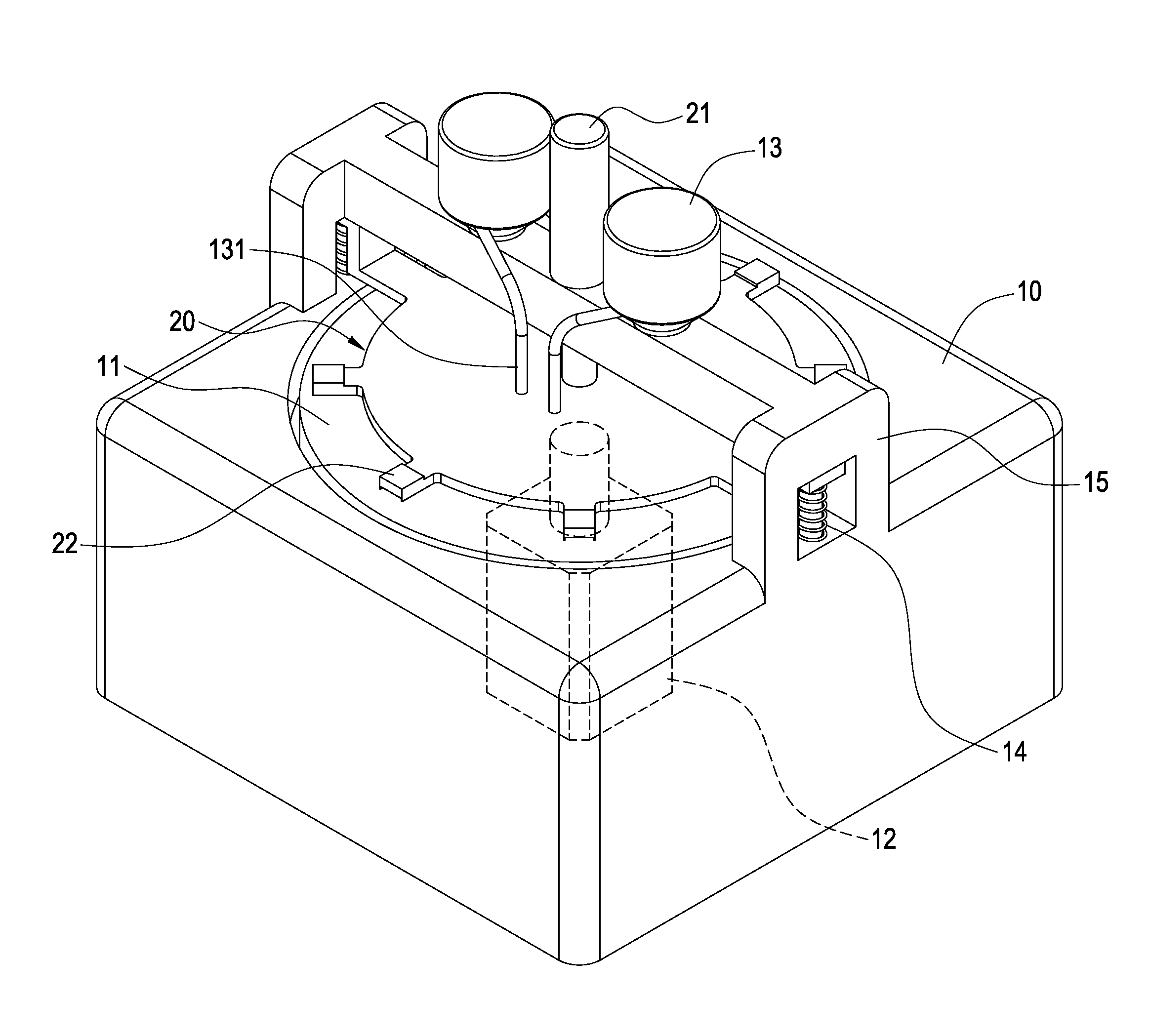

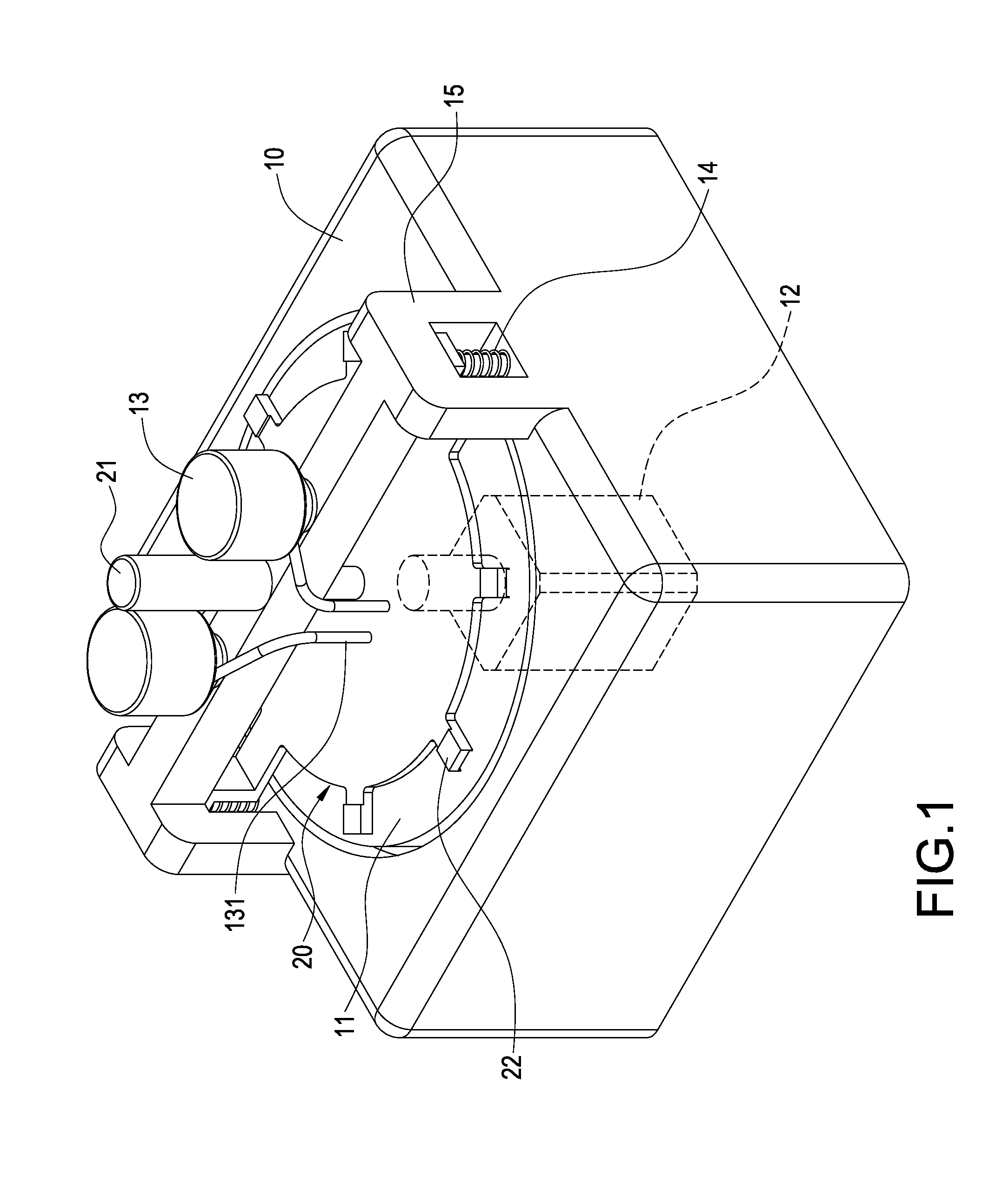

[0027]Please refer to FIG. 1, which is an assembled illustration of a grinder and a fixture according to the present invention. The invention is to provide a method for grinding the heated plane of a cooler, in which a grinder 10 having grinding plate 11 and fixing frame 15 is provided. The grinding plate 11 is actuated by a motor 12 to rotate. The fixing frame 15 is fixed onto the grinder 10 and is arranged an abrasive supply barrel 13 thereon. The abrasive supply barrel 13 is filled with abrasive and has a nozzle 131 to inject the abrasive onto the grinding plate 11.

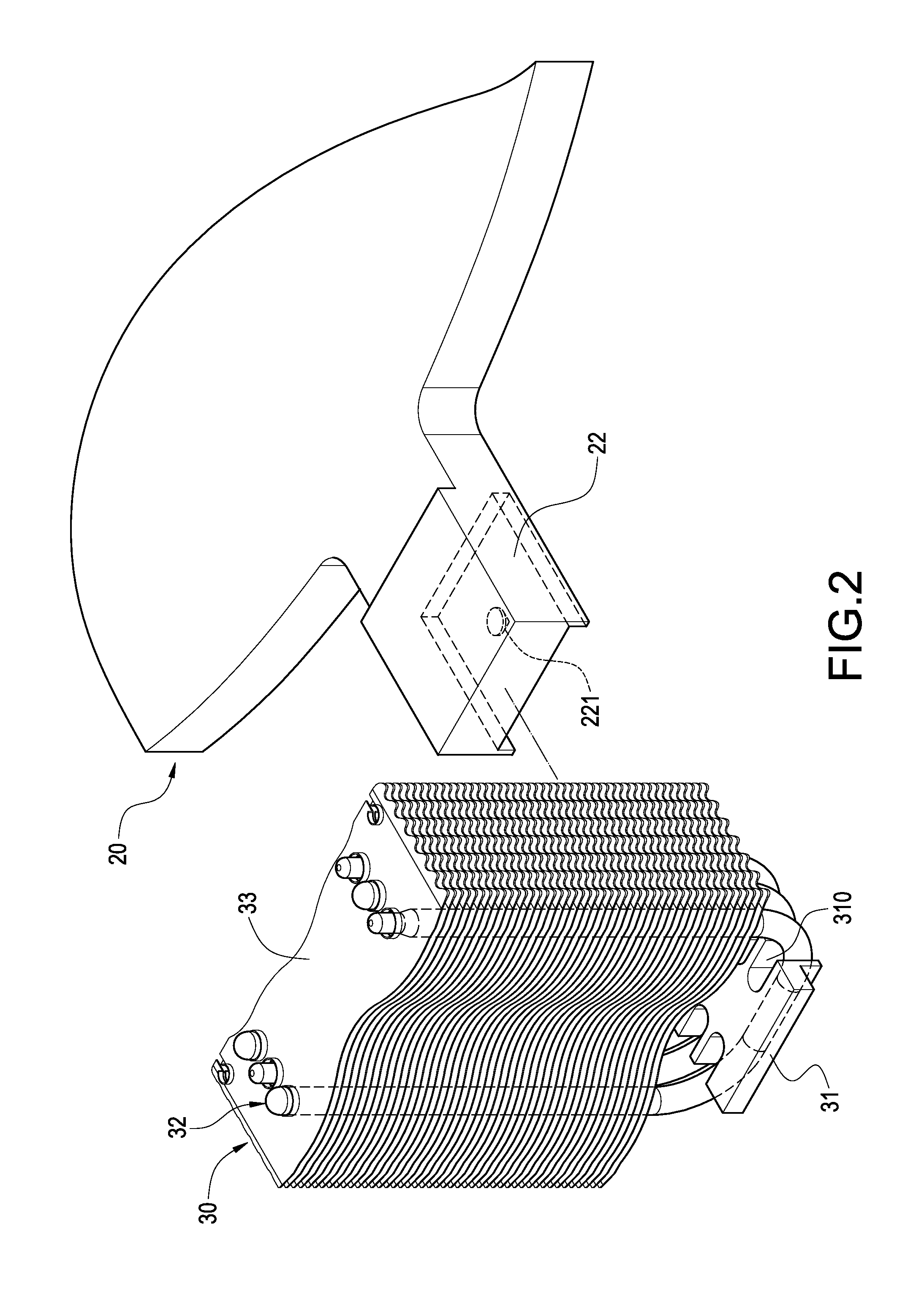

[0028]Above the grinding plate 11, the grinder 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com