Easy-to-operate permanent fastening large-load live wire connection clamp

A large-load, easy-to-operate technology, applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problems of hidden dangers of operation, hidden dangers of heating, and high physical energy consumption, and achieve good diversion effects and increased contact tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

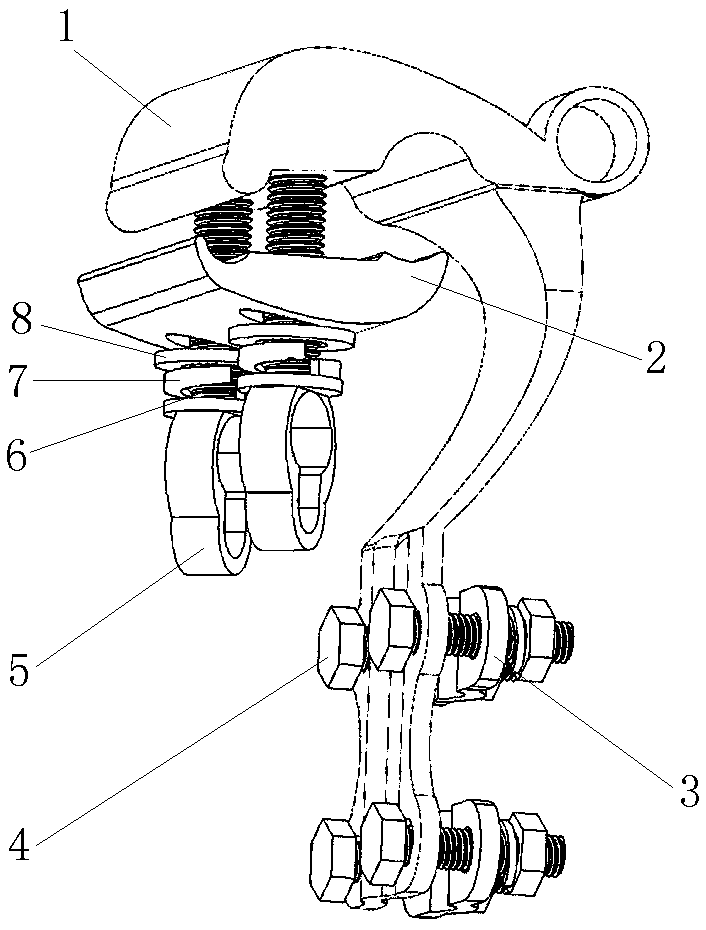

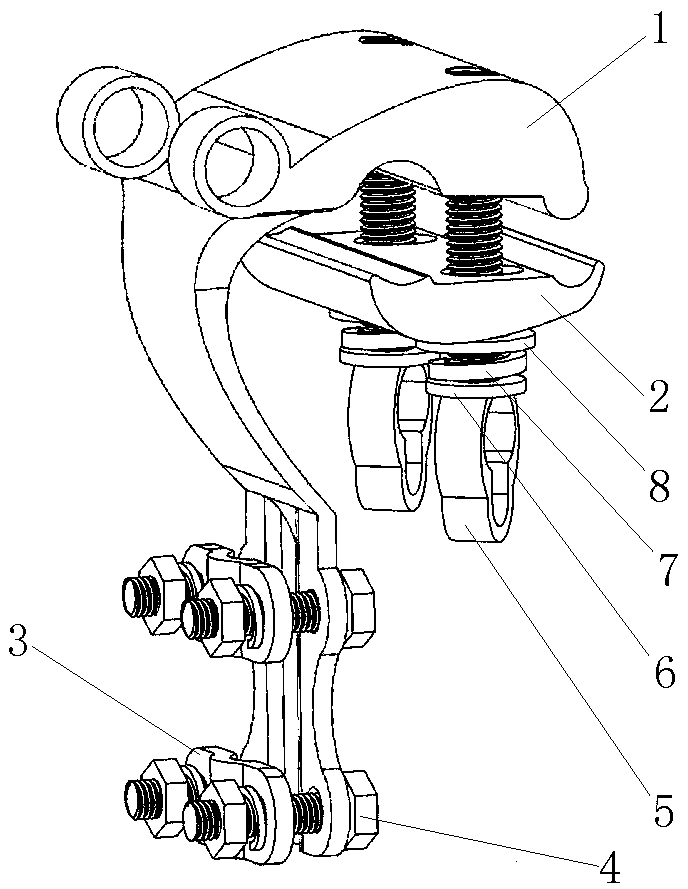

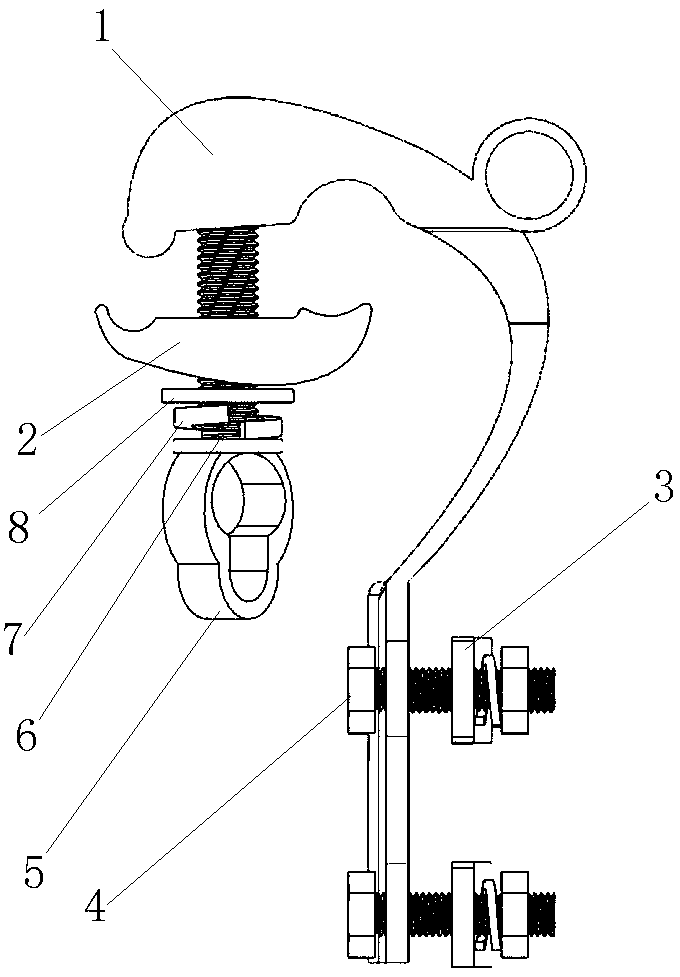

[0026] An easy-to-operate permanent fastening large-load live wire clip of the present invention includes a hanging plate 1, a main line pressing plate 2, and a drain line pressing plate 3, and is characterized in that it is put on the hanging ring bolt 6 on one side of the hanging plate 1 The spring pad 7 and the flat pad 8 are screwed into the hanging plate 1 through the main line pressing plate 2, and the lower end of the hanging plate 1 penetrates the fastening bolt 4 to cover the drain line pressing plate 3 and screw on the nut to connect, and the hanging plate 1 is connected by the top plate 9, It is composed of clamping groove A10, ear hole 11, side plate 12, fastening bolt hole A13, clamping groove B14, hanging ring bolt hole A15, and support point 16. The left and right ends of the top plate 9 are respectively provided with integrated support point 16 and ear hole. 11. There is an upwardly protruding arc-shaped wire holding groove A10 under the middle part, and an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com