Patents

Literature

409results about How to "Improve the diversion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

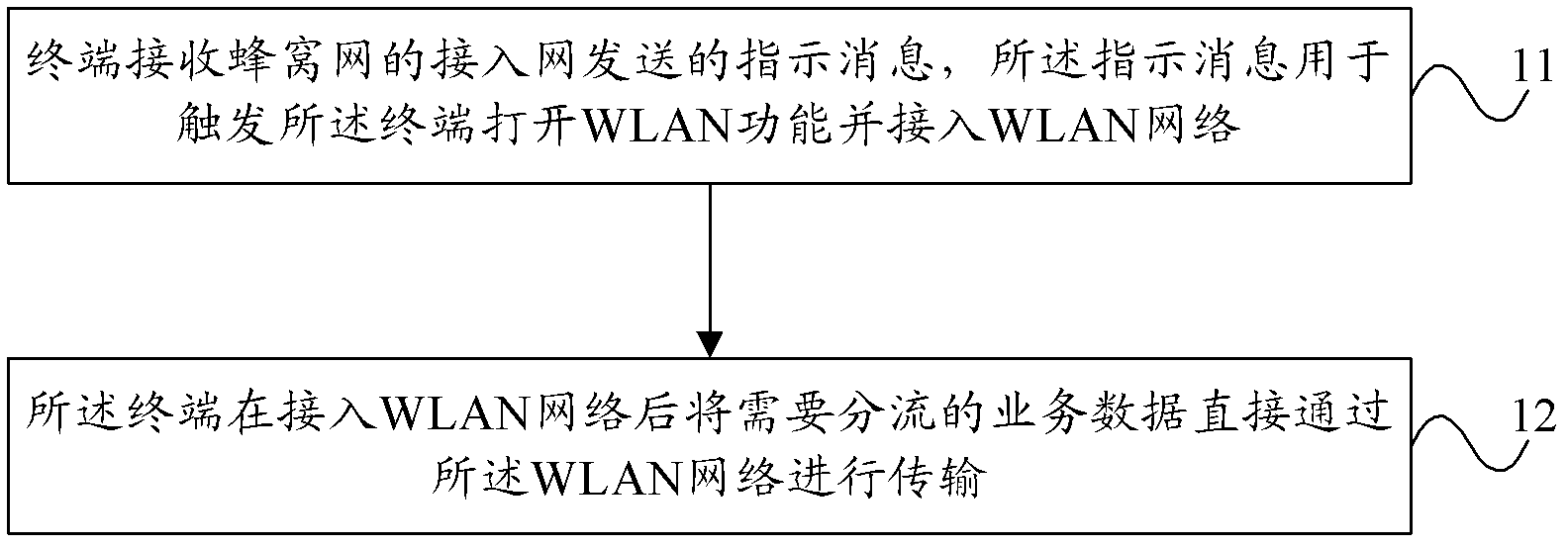

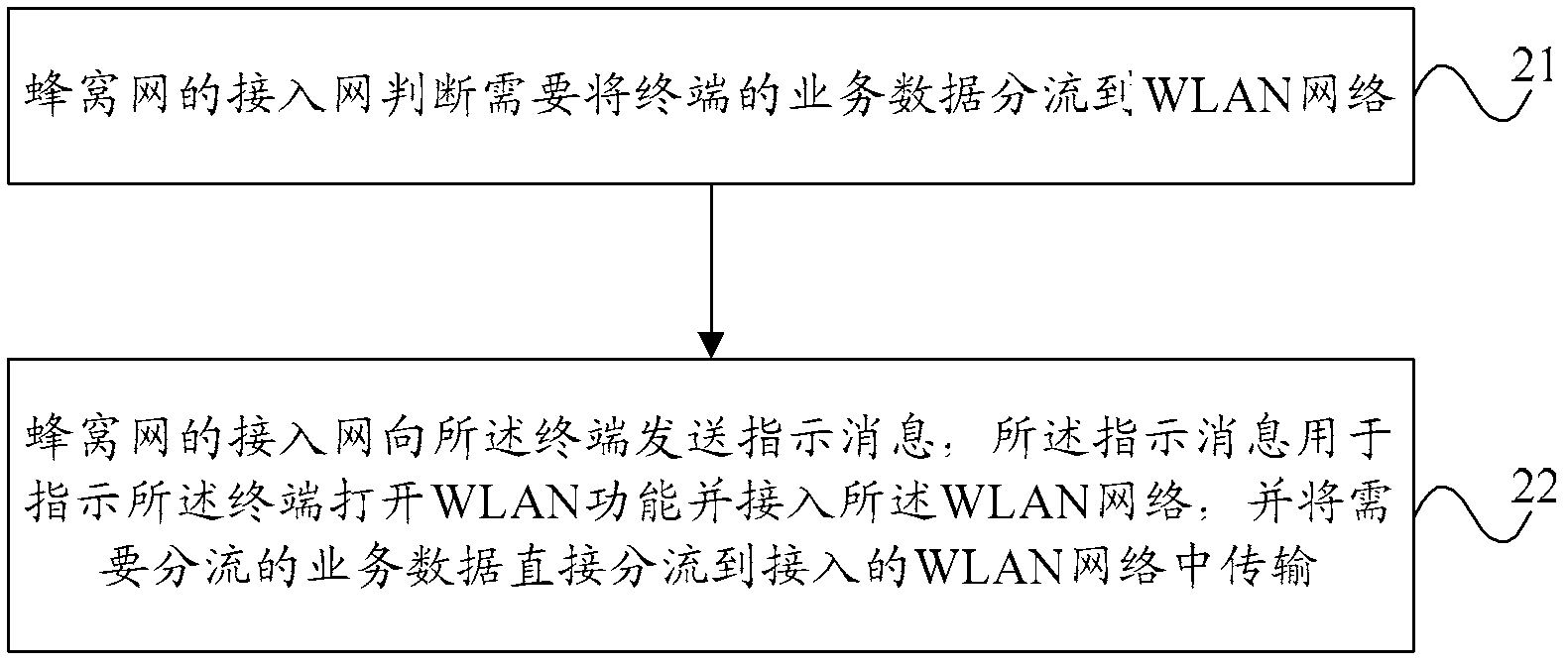

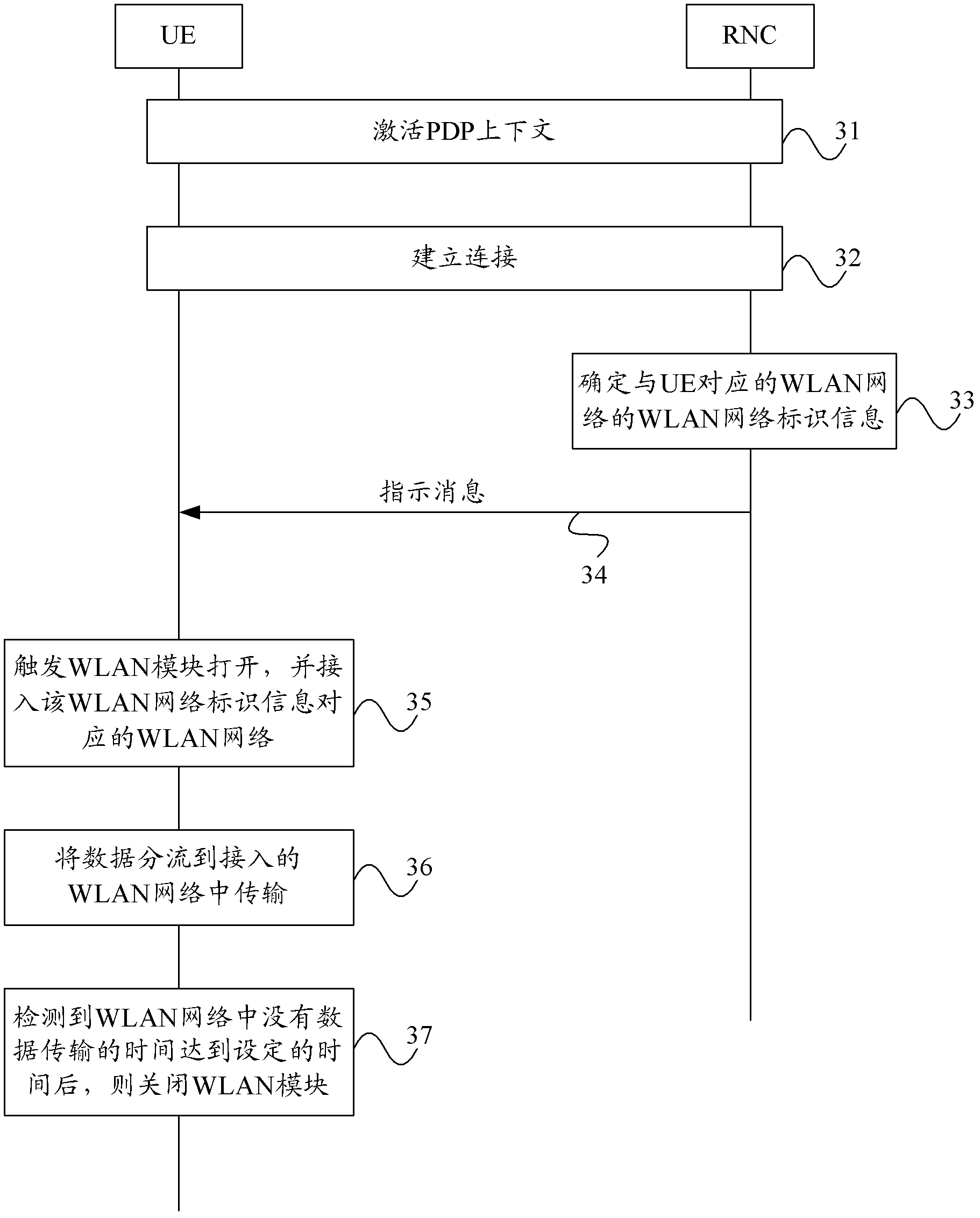

Method, terminal and network equipment for distributing data to wireless local area network

ActiveCN102833813AReduce power consumptionAvoid problems that cannot be shuntedPower managementAssess restrictionBusiness dataCellular network

The invention provides a method, terminal and network equipment for distributing data to a wireless local area network. The method comprises the following steps that: the terminal receives indication information sent from an access network of a cellular network, wherein the indication information is used for triggering the terminal to start a wireless local area network (WLAN) function and access the WLAN; and then the terminal directly transmits business data to be distributed through the WLAN after accessing the WLAN. According to the embodiment of the invention, the distribution effect can be improved.

Owner:HUAWEI TECH CO LTD

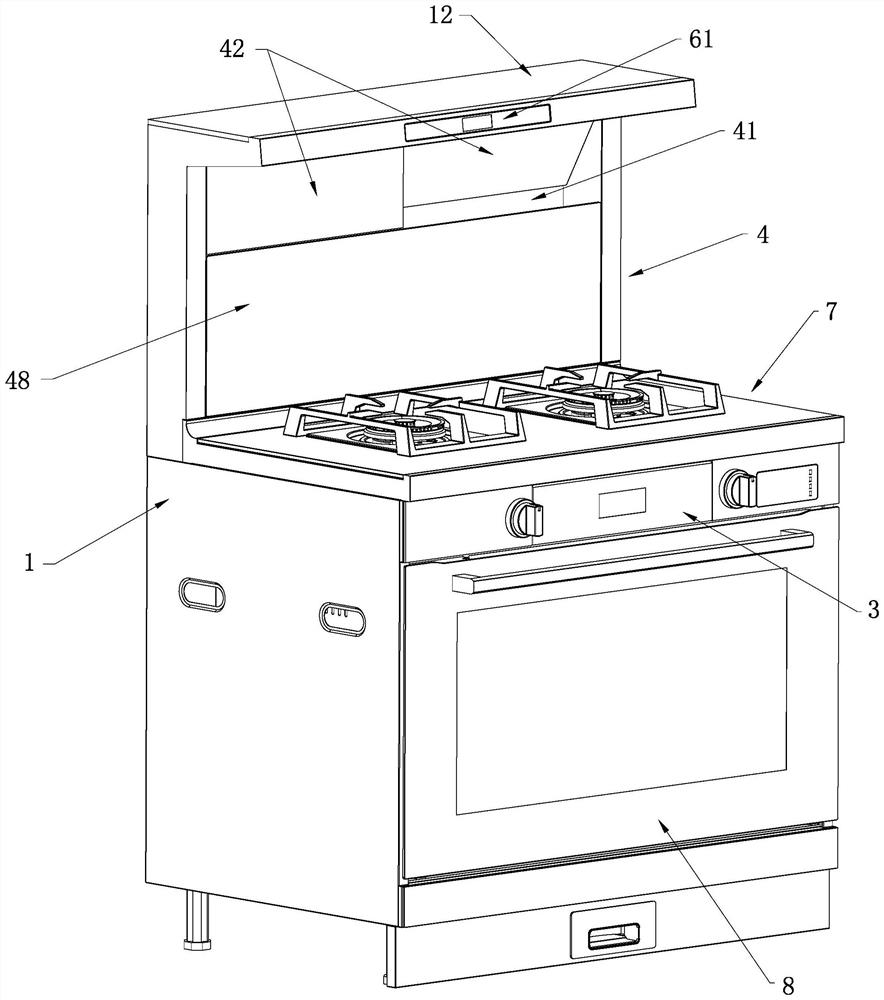

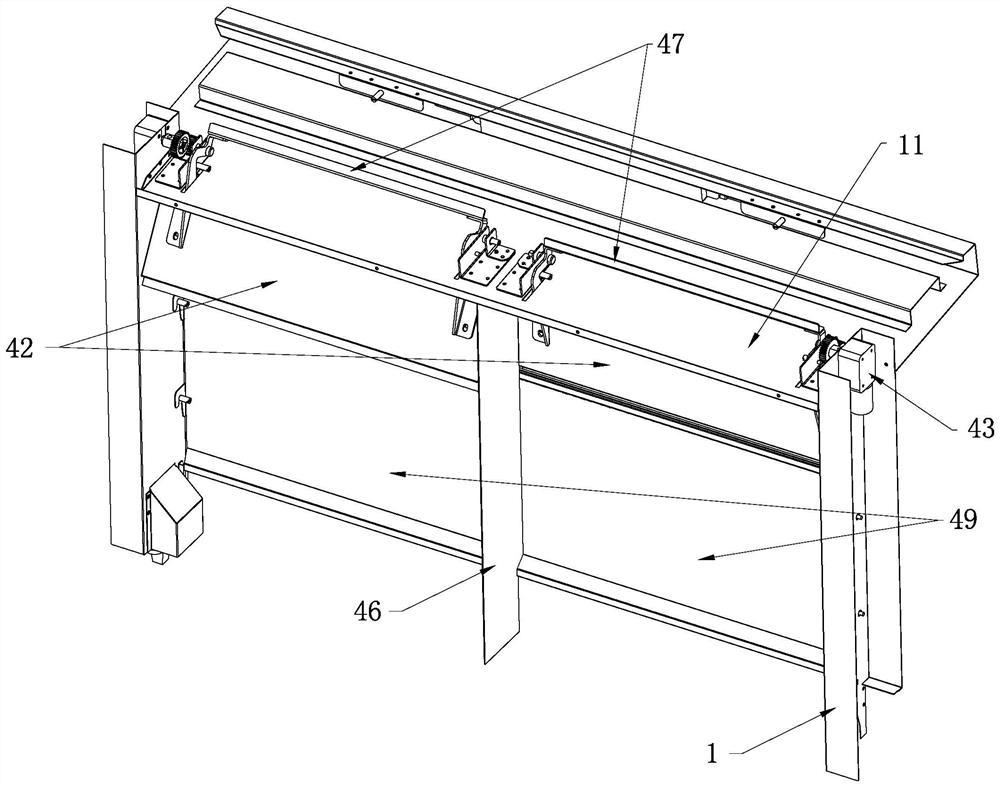

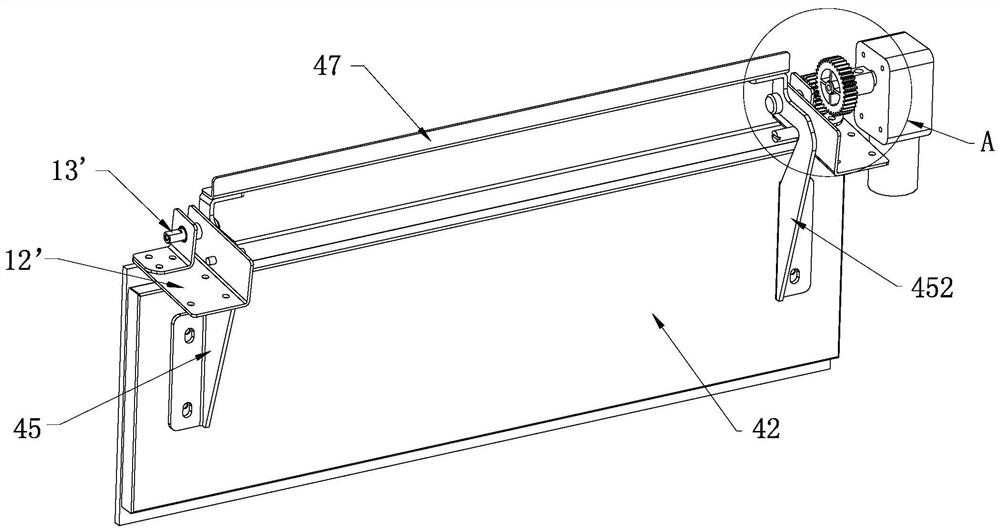

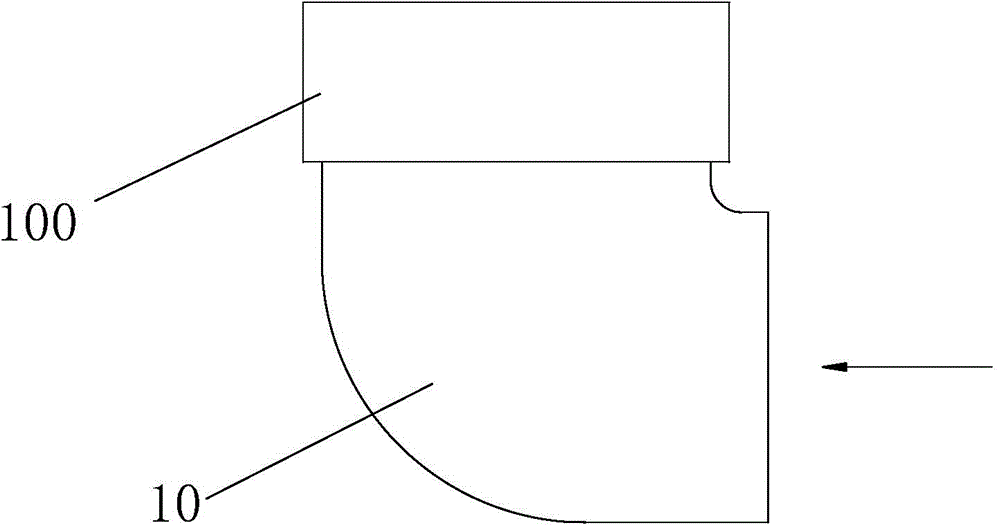

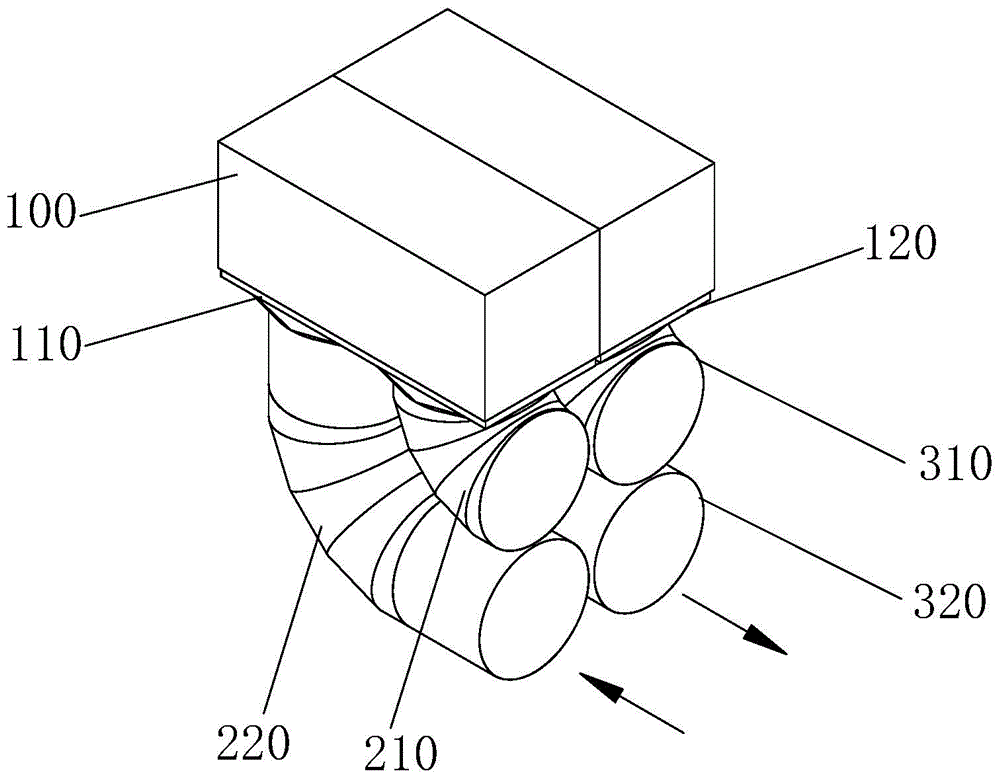

Integrated cooker

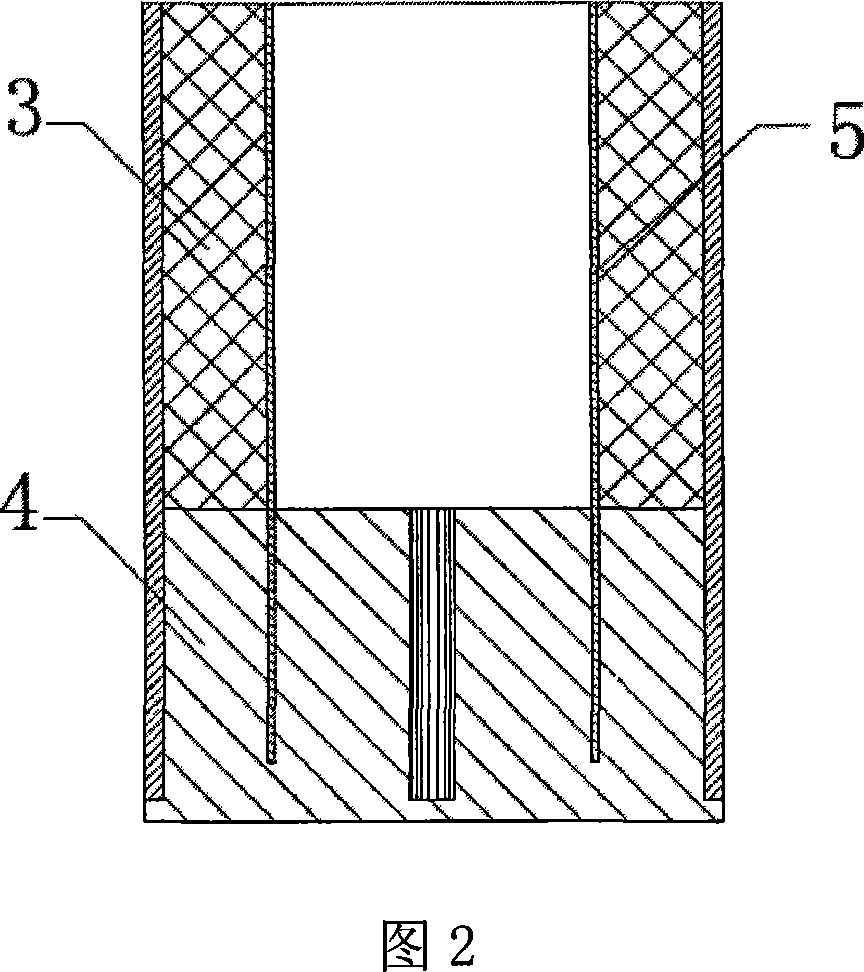

PendingCN112555906AOutstanding and Beneficial Technical EffectsGuaranteed tightnessDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention belongs to the technical field of kitchen appliances, and particularly relates to an integrated cooker. The integrated cooker comprises a machine body and a range hood body; the range hood body comprises an air inlet, an air collecting box and a fan assembly; the air collecting box communicates with the air inlet; the fan assembly is arranged in the air collecting box; a volute air duct of the fan assembly extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with an air outlet base; and an air outlet is formed in one side of the air outlet base. According to the integrated cooker, the volute air duct extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with the air outlet base; the air outlet base is directly located on the outer side of the air collecting box, and the situation that a channel is located inside and occupies too much space is avoided; a through hole does not need to be additionally formed in the side edge of the machine body, and leakproofnessof the side face of the machine body is guaranteed; and meanwhile, the air outlet base is rotatably arranged, so that a user can conveniently adjust the air outlet direction according to actual needs,and humanization is achieved.

Owner:浙江安德电器有限公司

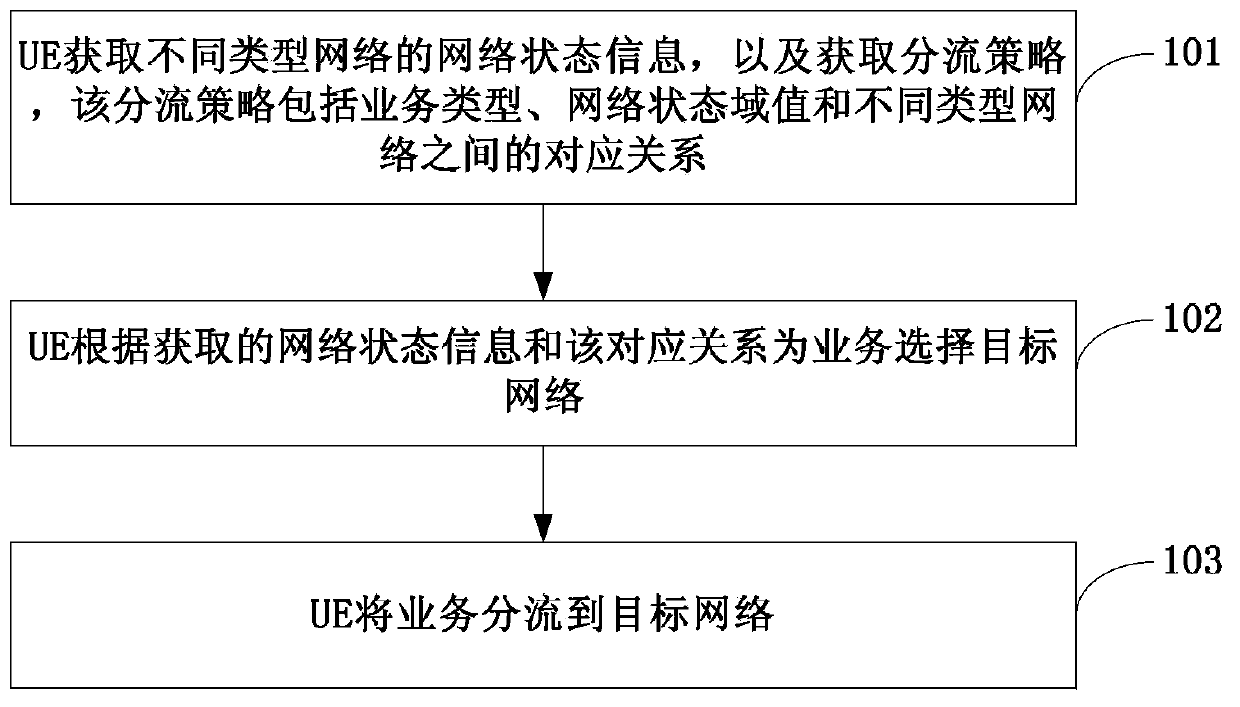

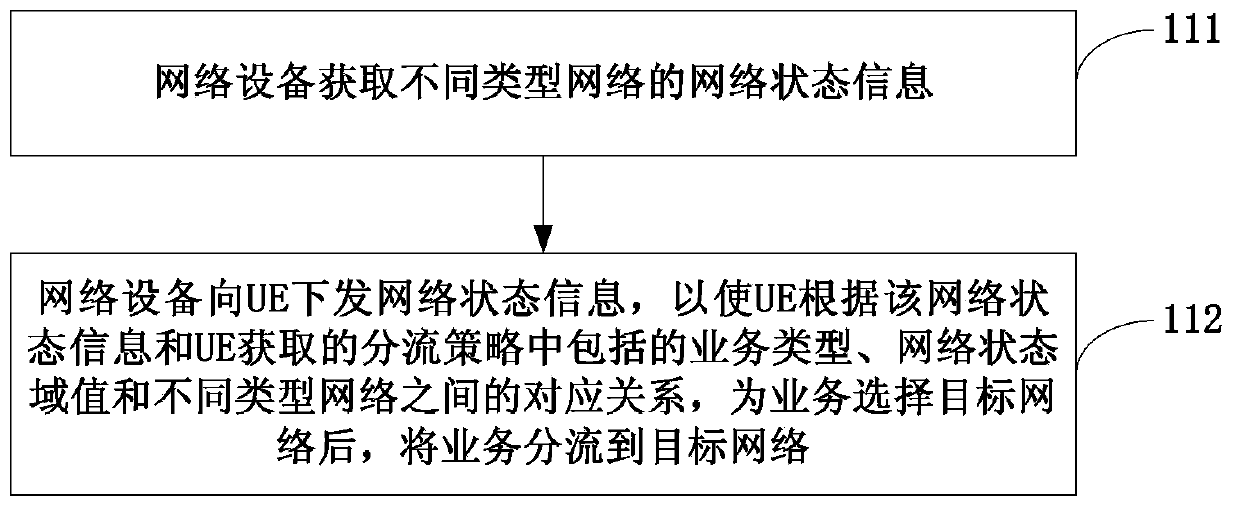

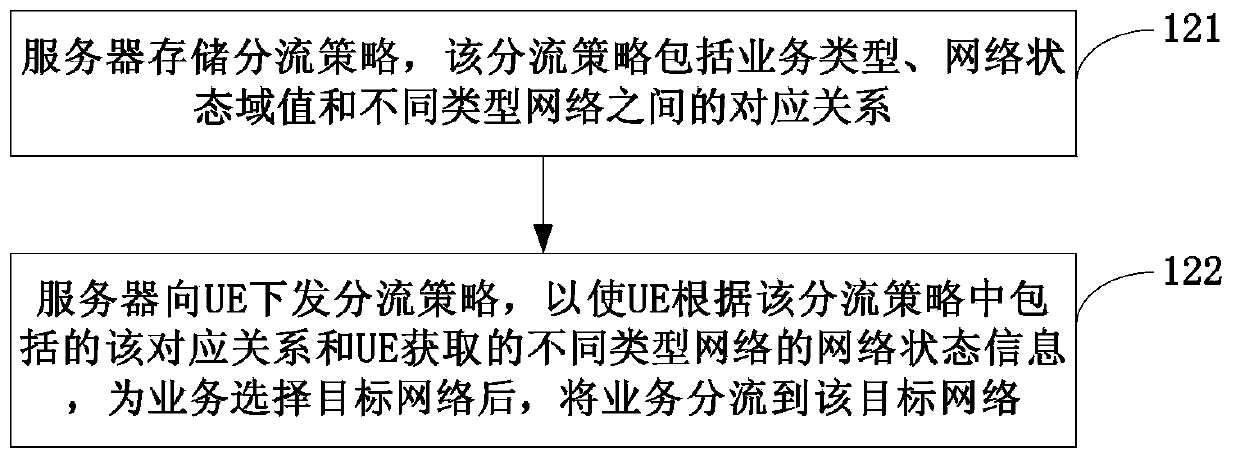

Shunting control method, UE, network equipment and server

ActiveCN103974335AGuaranteed experienceImprove performanceNetwork traffic/resource managementAssess restrictionAccess networkDistributed computing

Disclosed are a method for controlling offloading, a UE, a network device and a server. The method comprises: a UE acquiring network state information about different types of networks, and acquiring an offloading strategy, wherein the offloading strategy comprises service types, network state domain values and the correlation between the different types of networks; the UE selecting a target network for a service according to the network state information and the correlation; and the UE offloading the service to the target network. The embodiments of the present invention not only perform offloading according to service attributes, but can also offload a service based on the network states of different access networks, thereby improving the effect of offloading, improving the service quality and enhancing the overall performance of a convergence network while ensuring the user experience.

Owner:HUAWEI TECH CO LTD

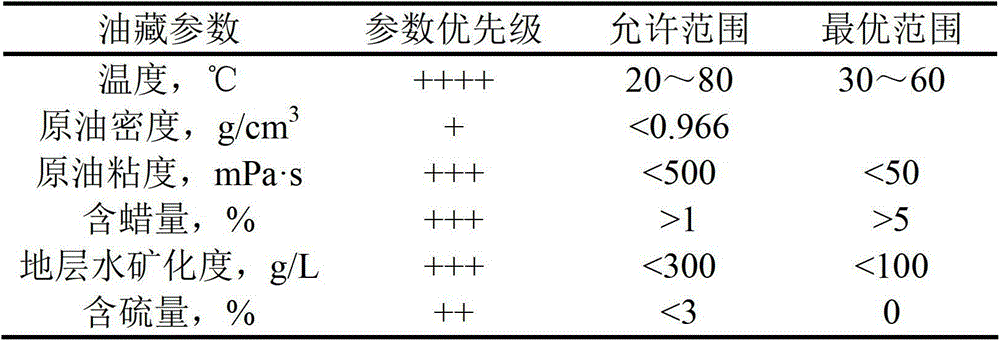

High titanium type petroleum oil pressing crack propping agent and production method thereof

InactiveCN1730422AReduce manufacturing costImprove low efficiencySolid waste managementClaywaresSurface finishingAluminium

The invention provides a high-titanium type petroleum fracturing propping agent, whose chemical constituents comprise (by weight ratio) 5-45% of high-titanium blast furnace slag, 10-30% of high-alumina brick, 17-77% of bauxite, and 4-8% of composite agglutinant, its preparation process comprises the following steps, (1) grinding the raw material, making mother balls with an atomizing granulation system, charging the mother balls into a sugar-coating machine, squeezing and dressing so as to obtain blank pellets, (2) drying the blank pellets through a drying system, loading into high temperature kiln for agglutination, (3) cooling down and carrying out surface polishing through high speed rotation in a friction tube, (4) elevating the temperature to 80-100 deg. C, carrying out surface treatment with acid-resisting organics, finally cold-setting.

Owner:攀枝花环业冶金渣开发有限责任公司

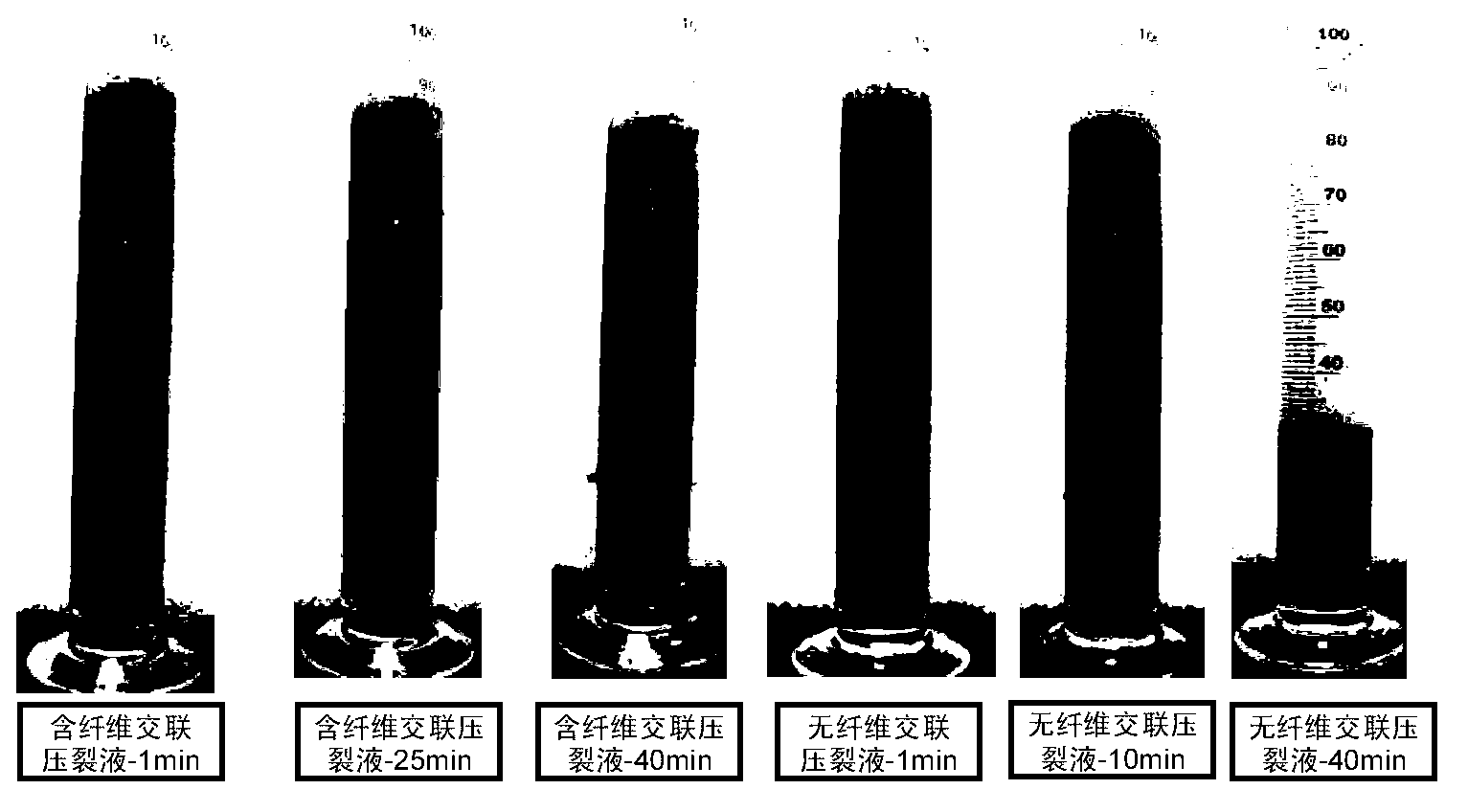

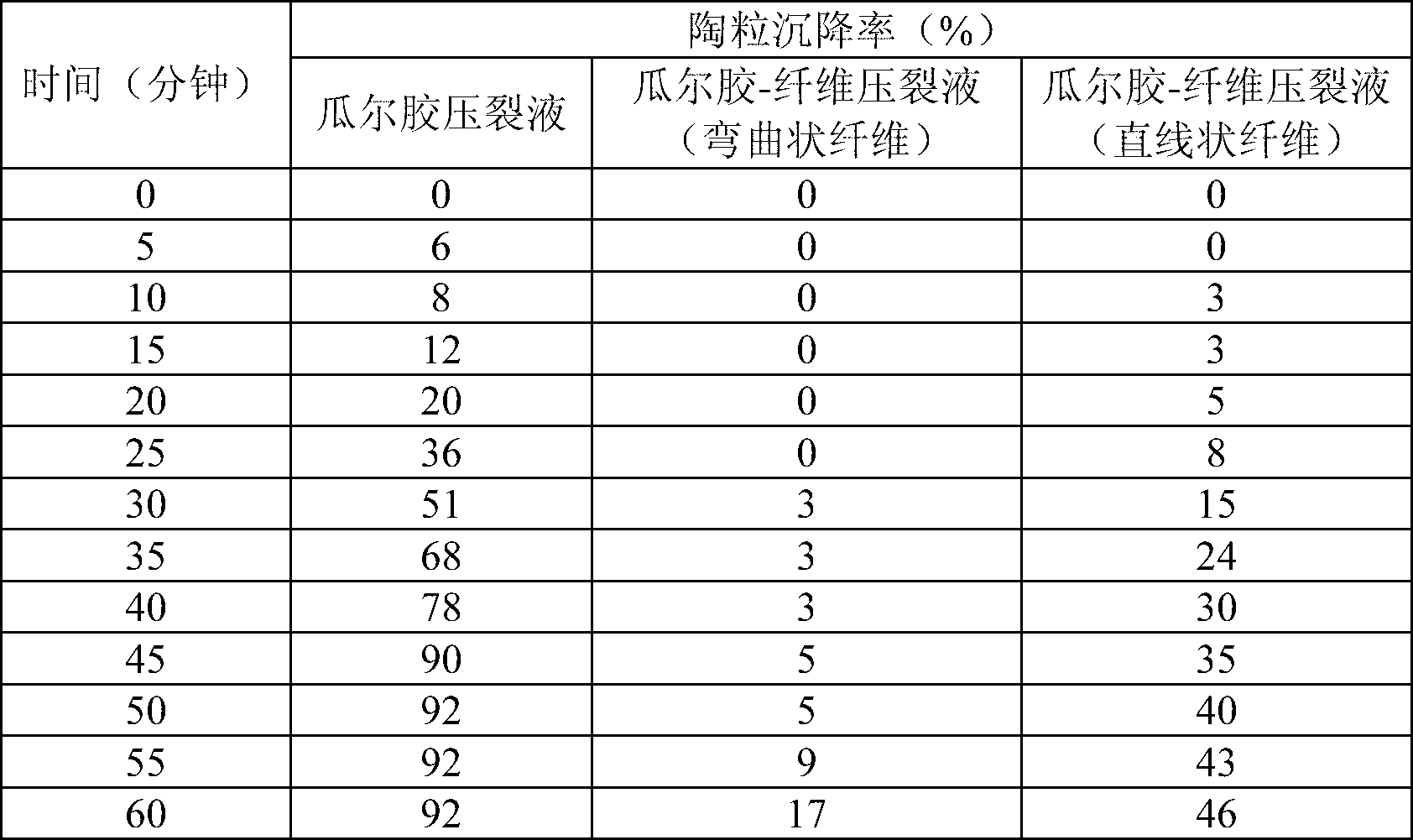

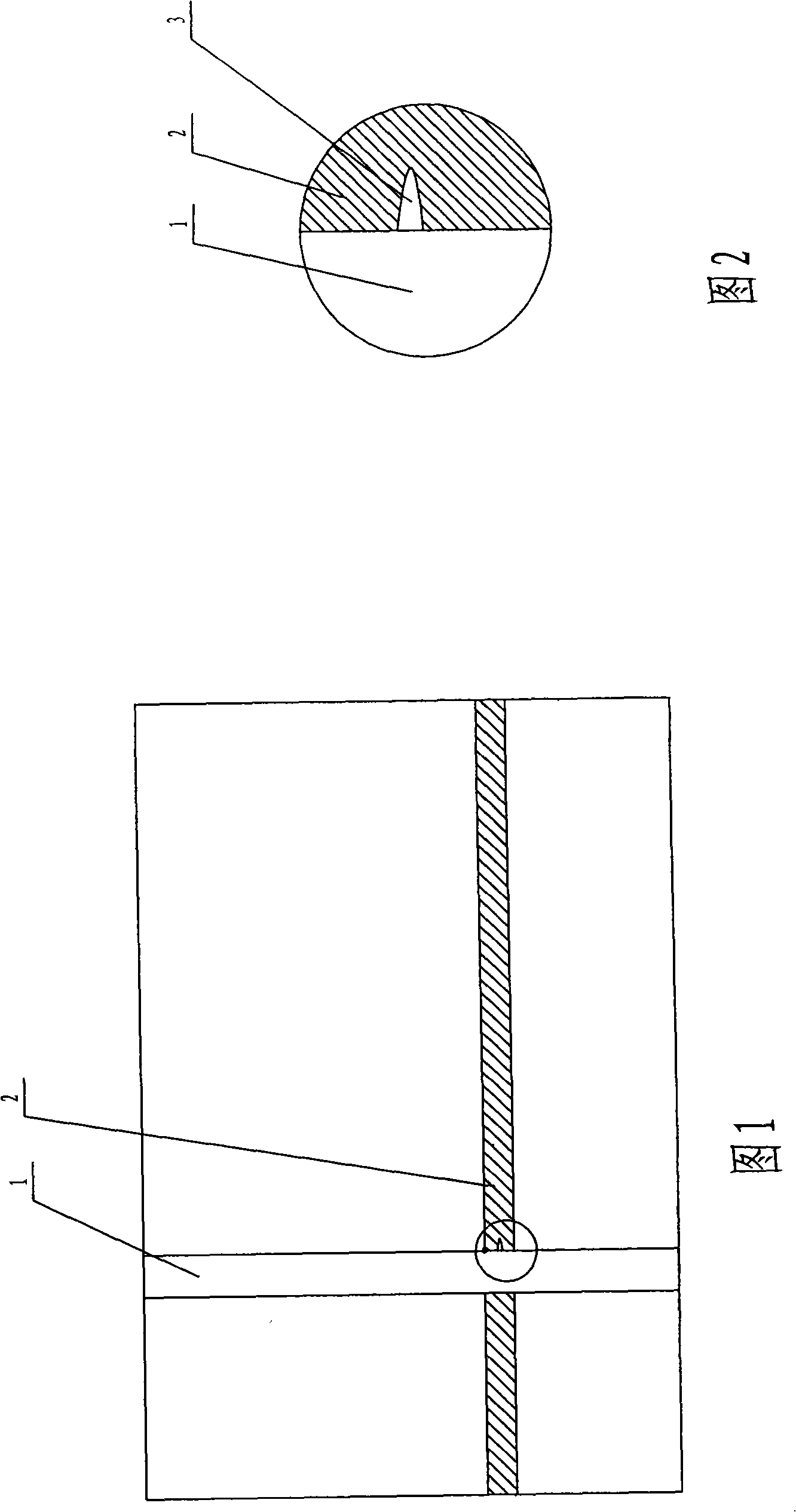

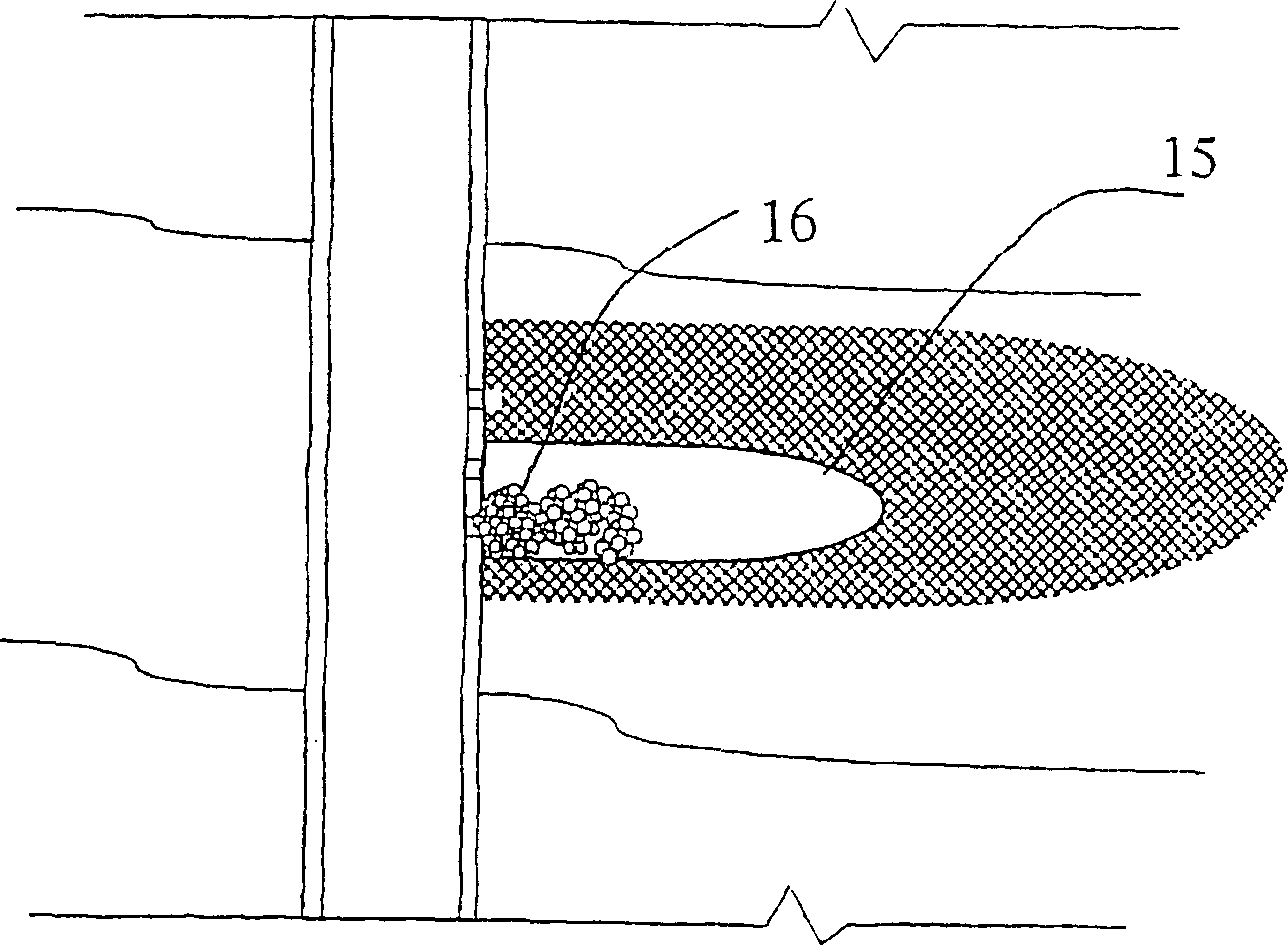

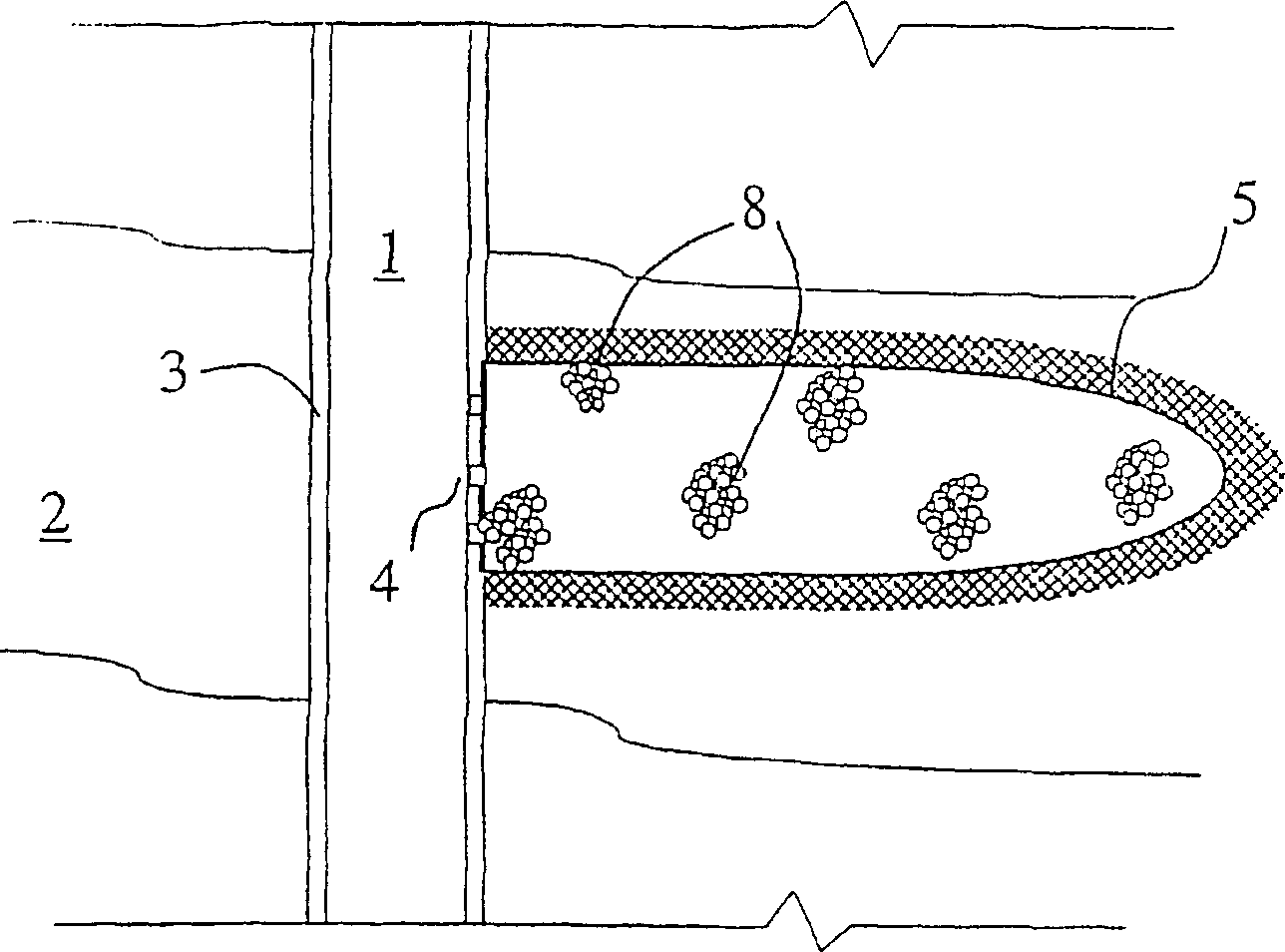

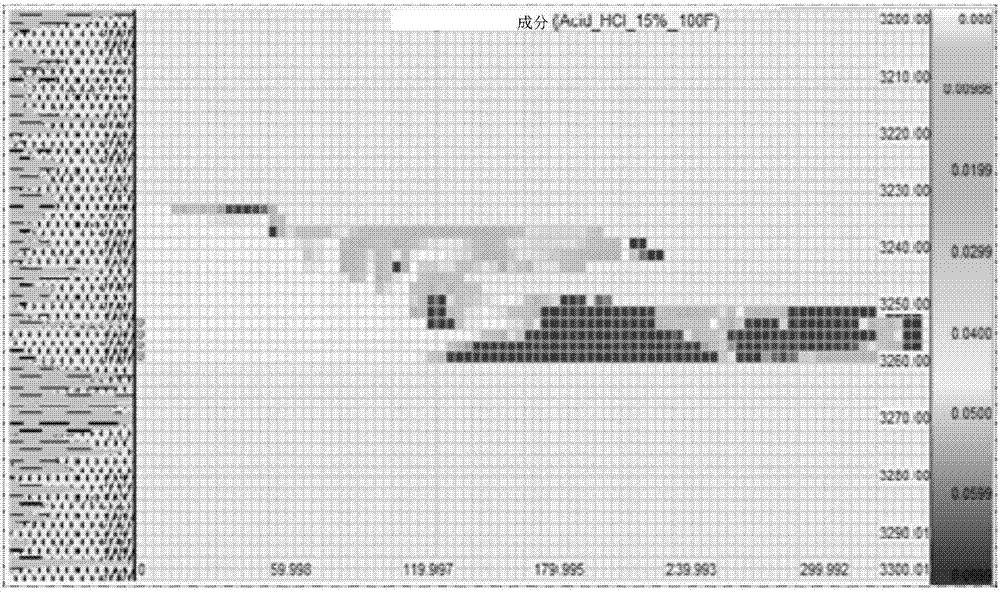

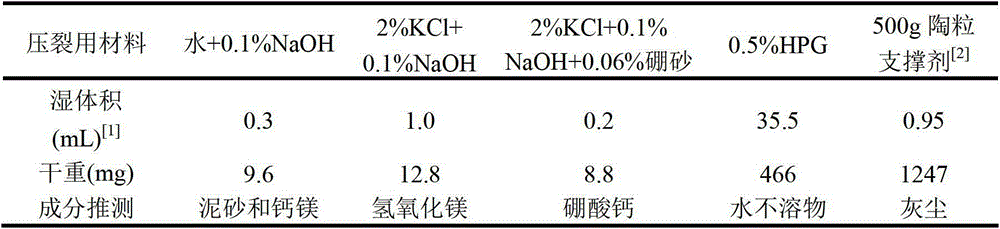

Fracturing fluid and fracturing method for increasing applicaiton efficiency of support agent in fractured cracks

ActiveCN103013486AReduce sedimentation rateEvenly distributedFluid removalDrilling compositionGuar gumEnvironmental geology

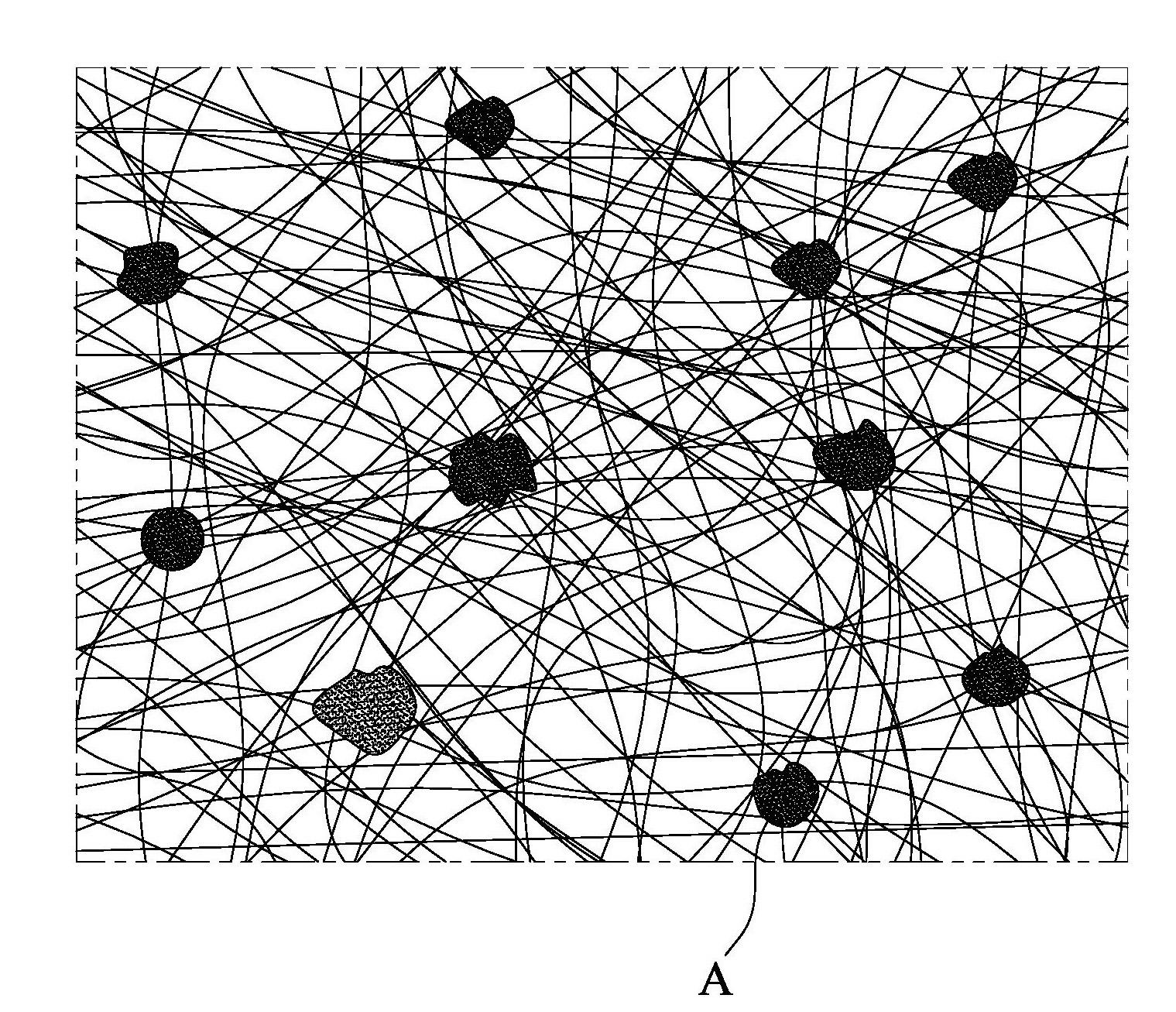

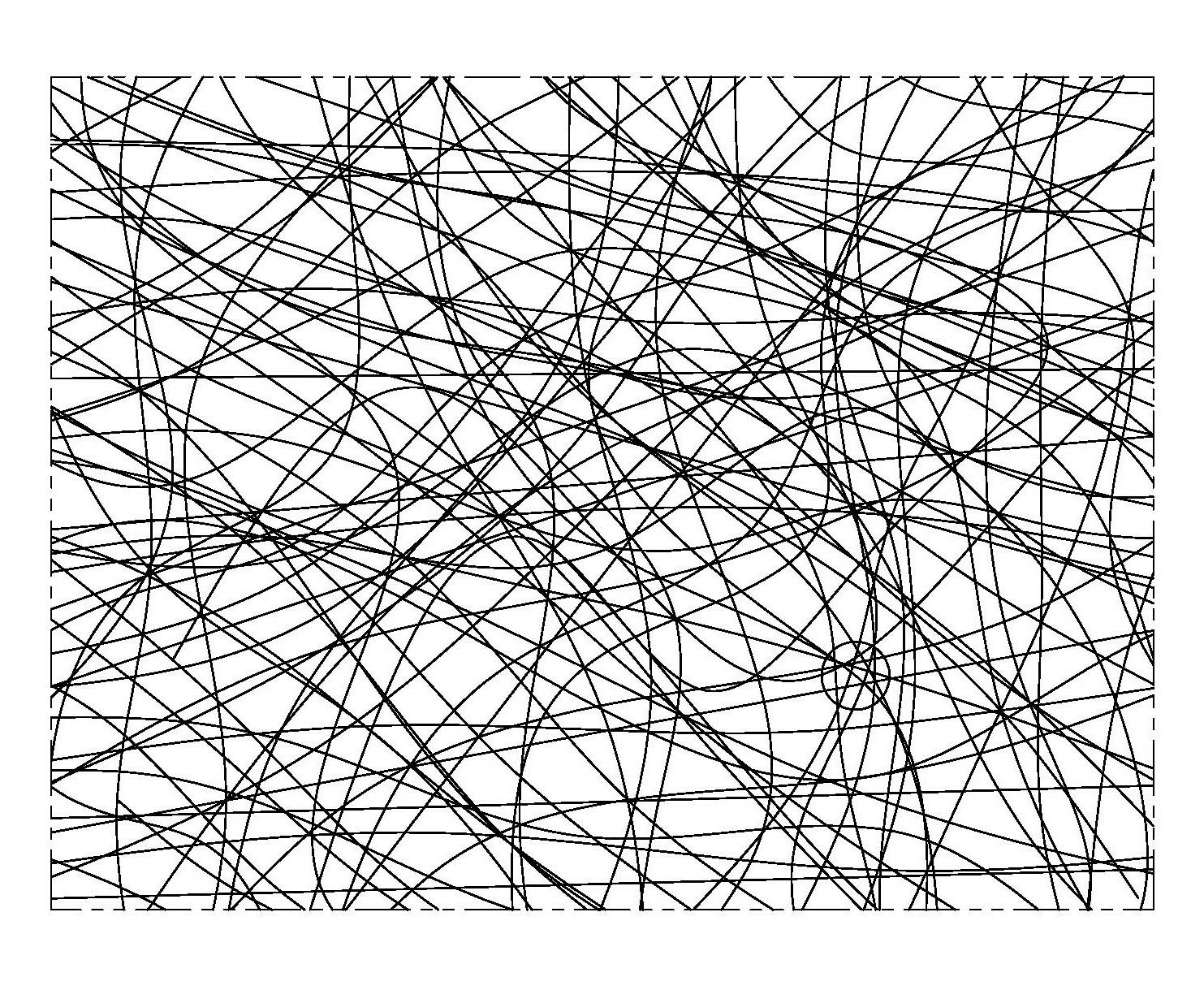

The invention relates to a fracturing fluid and fracturing method for increasing the application efficiency of a support agent in a fractured crack. The fracturing fluid is a water-based fracturing fluid and comprises sand-suspending fibers and a thickening agent, wherein the sand-suspending fibers are hydrophilic high-strength bent organic fibers or inorganic fibers. The fracturing method comprises the step of injecting the fracturing fluid serving as a sand carrying fluid into a formation crack, wherein the injection parameters of the sand-carrying fluid are as follows: the consumption is 40-3000m<3> and the injection speed is 2.0-15.0m<3> / min. The support agent is suspended by using a three-dimensional net structure formed by the sand-suspending fibers. According to the method, the content of guar gum in the sand-carrying fluid can be reduced, and the application efficiency of the support agent in a longitudinal direction is increased, and therefore, the support agent is more uniformly distributed in the longitudinal direction of a manual fractured crack, the guide performance of the crack in the whole longitudinal profile is improved, and the economic benefit of fracturing constructing is increased.

Owner:PETROCHINA CO LTD +1

Fracturing technique for relieving fracturing fluid pollution

The invention relates to an oil exploitation technology, in detail a fracturing process for releasing the pollution of fracturing liquid. It solves the problem that fracturing liquid hurts the storing layer in water-power fracturing construction for oil exploitation existing in prior technology. Procedures comprise that ahead fluid is injected into the oil storing layer; when cracks appear on the oil storing layer sand carrying liquid is injected continuously; then replacing liquid or isolating liquid is injected continuously; chlorine dioxide resultant is injected singly in the process mentioned above. Filter cake and concentrated fracturing liquid in ground crack can be eliminated more thoroughly and guiding flow capability of support sands in crack is improved. Permeability and retention can achieve more than 90%.

Owner:郝东 +1

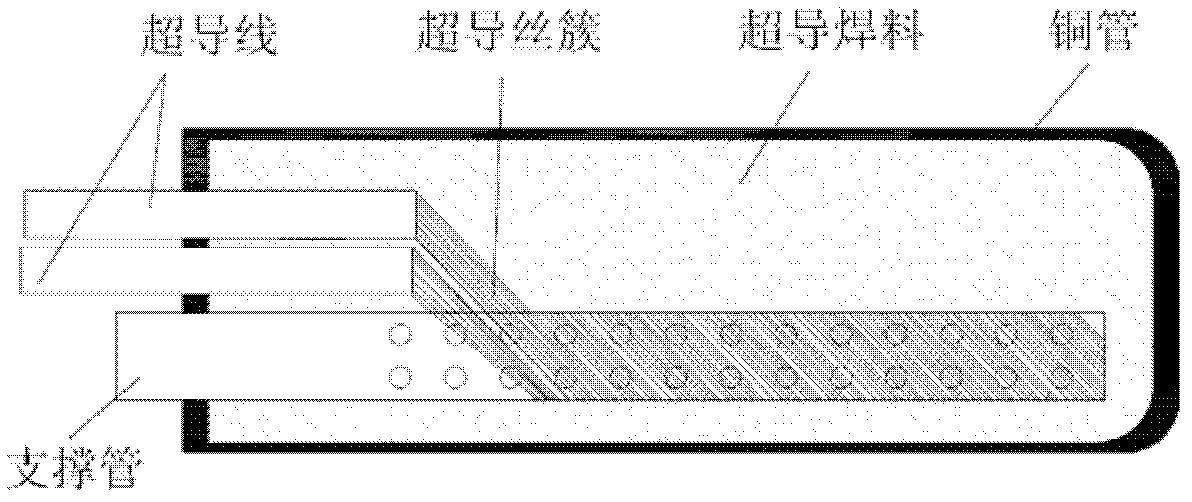

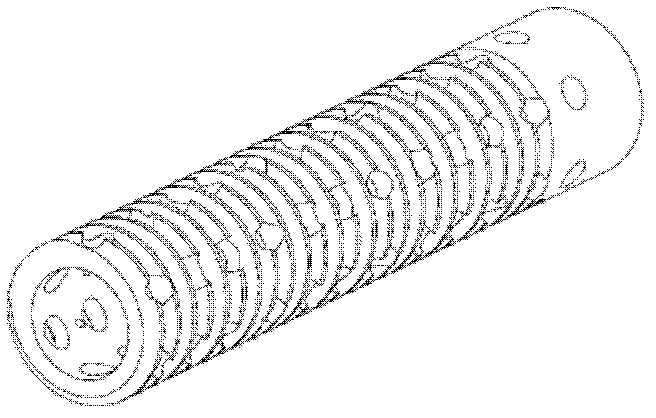

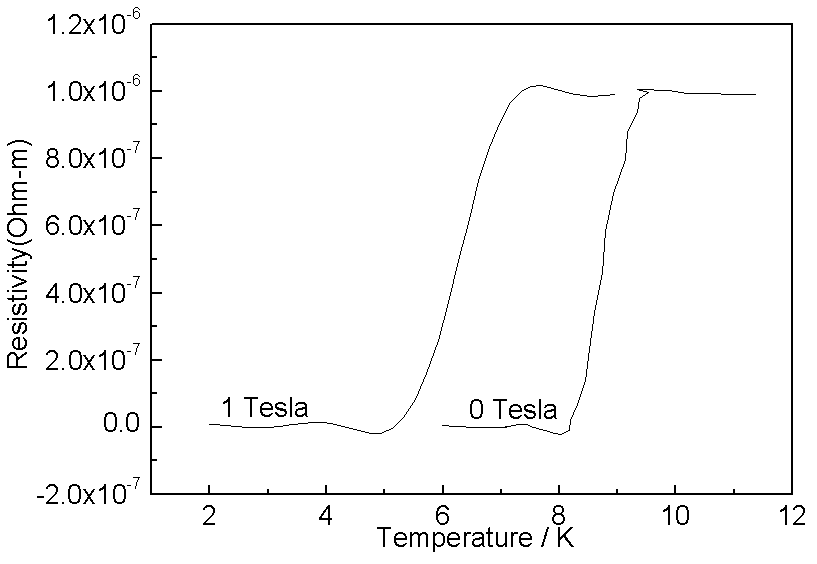

Superconducting wire joint

ActiveCN102593621ALower resistanceRealize superconducting direct connectionLine/current collector detailsSuperconductors/hyperconductorsEngineeringAlloy

The invention provides a superconducting wire joint which comprises a support tube, a superconductive filament cluster of a superconducting wire to be connected, a copper pipe and superconductive solder. An external cylindrical surface of the support tube is provided with a spiral groove, and both the external cylindrical surface and the groove are provided with through holes along a radial direction. After the superconductive filament cluster of the superconducting wire to be connected is twisted round the spiral groove of the support tube, the support tube which is twisted with the superconductive filament cluster is integrally inserted into the copper pipe with a segment of the superconducting wire, and other space in the copper pipe is filled with the superconductive solder. Material purity of the copper pipe is 99.999%, and in an annealing state, the support tube is NbTi superconductive alloy material. Components of the superconductive solder are Bi, Pb and Sn with the following mass ratio by weight: 53%-55% of Bi, 36% of Pb and allowance of Sn. The superconducting wire joint prepared by the invention has the advantages of low resistivity, simple preparation process, small damage and threat to superconducting wire performance and suitability for project field practical operation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

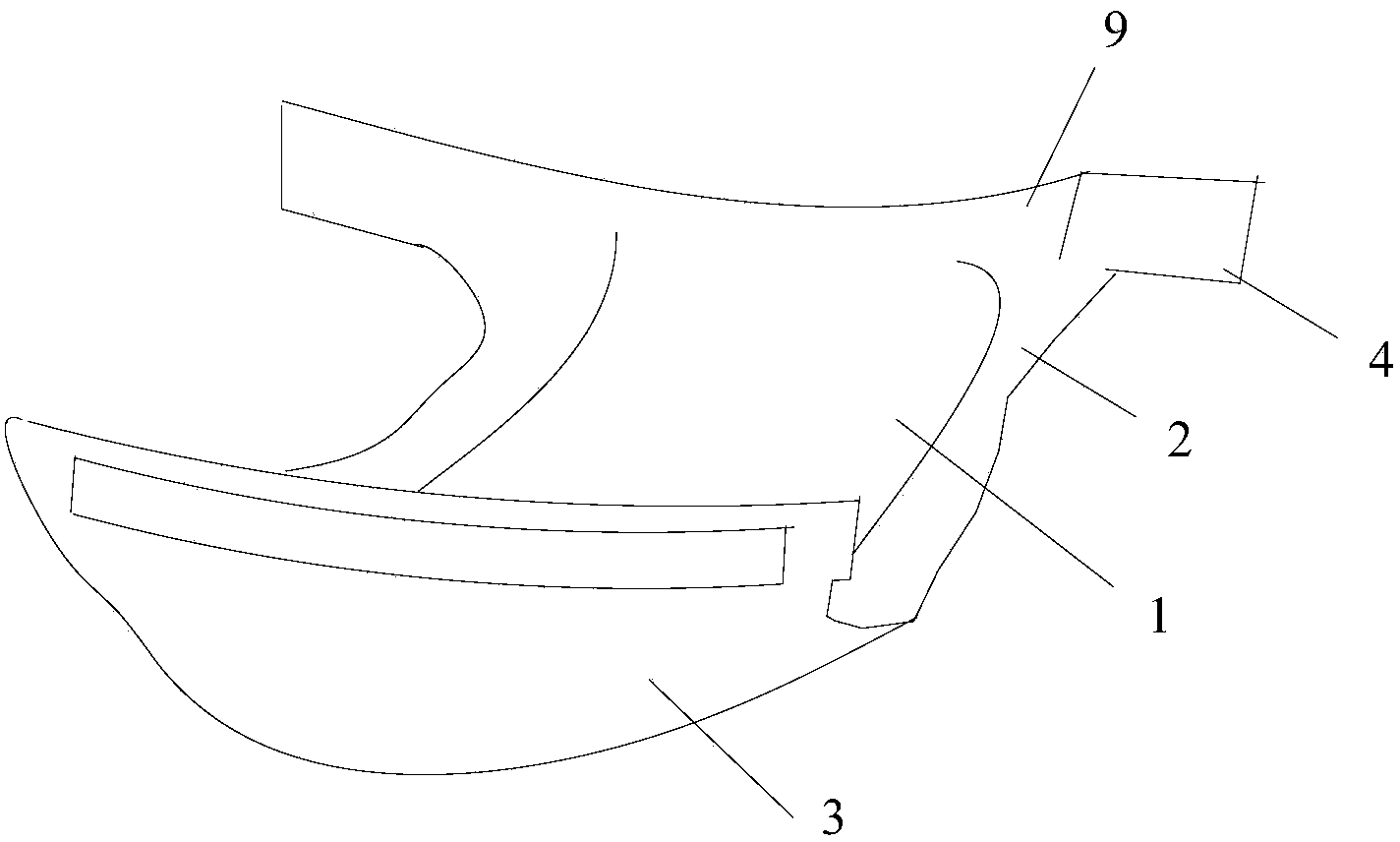

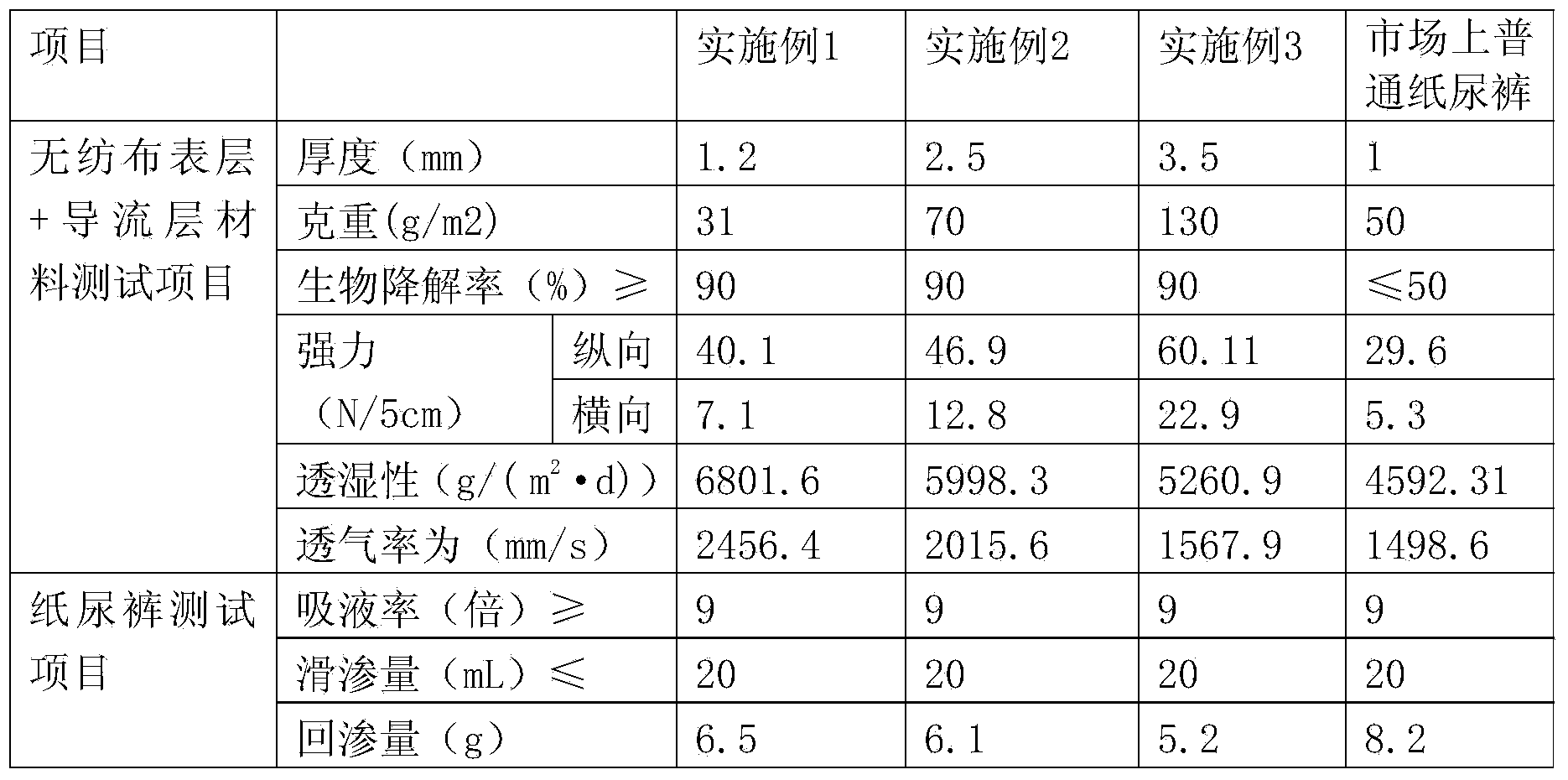

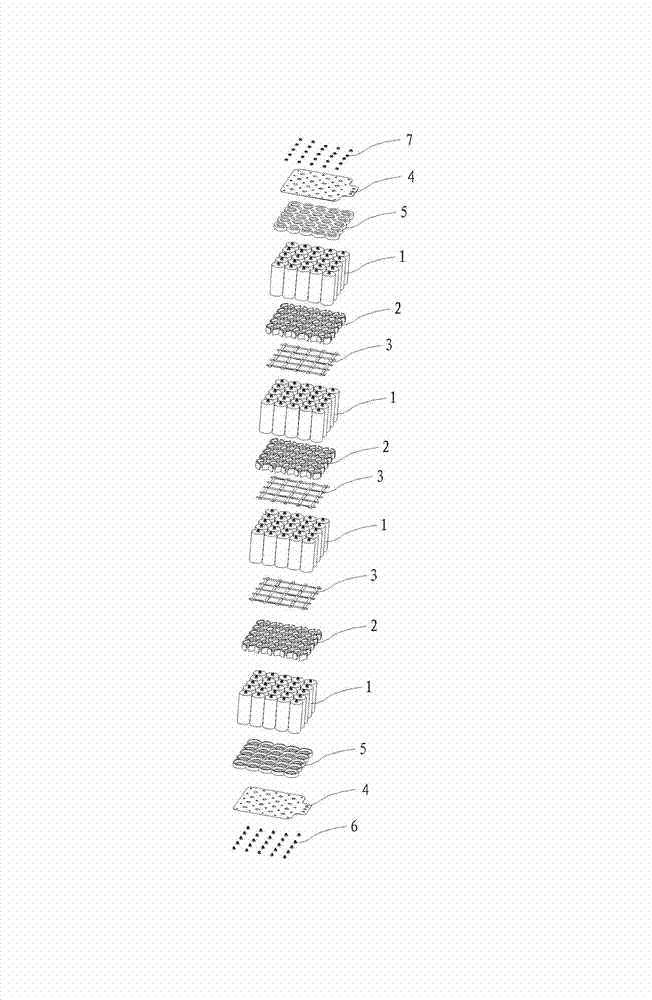

PLA (polylactic acid) non-woven fabric diaper with high breathability and preparation method thereof

ActiveCN104138310AImprove breathabilityGood moisture managementAbsorbent padsNon-woven fabricsSurface layerEngineering

The invention discloses a PLA (polylactic acid) non-woven fabric diaper with high breathability. The PLA non-woven fabric diaper comprises a surface material, a water absorption core layer and a bottom membrane from inside to outside, wherein the surface material adopts a three-layer structure consisting of an upper layer, a middle layer and a lower layer, PLA short fiber webs are arranged on the upper layer and the lower layer, PLA long fiber non-woven fabric is arranged on the middle layer, and guide holes with pore diameters of 10-30 meshes are distributed on the PLA long fiber non-woven fabric. According to the diaper with the high breathability, upper-layer PLA short fiber non-woven fabric in three-layer PLA fiber webs is adopted as a surface layer, lower-layer PLA short fiber non-woven fabric is adopted as a guide layer, middle PLA filament non-woven fabric is adopts as an isolated layer, the three layers are bonded into integral non-woven fabric in a hot melting compound manner, the method for compounding the guide layer and the non-woven fabric on the surface layer through glue spraying in the production process of conventional diapers is not required, and the breathability between the surface layer and the non-woven fabric on the guide layer is greatly improved.

Owner:马鞍山同杰良生物材料有限公司

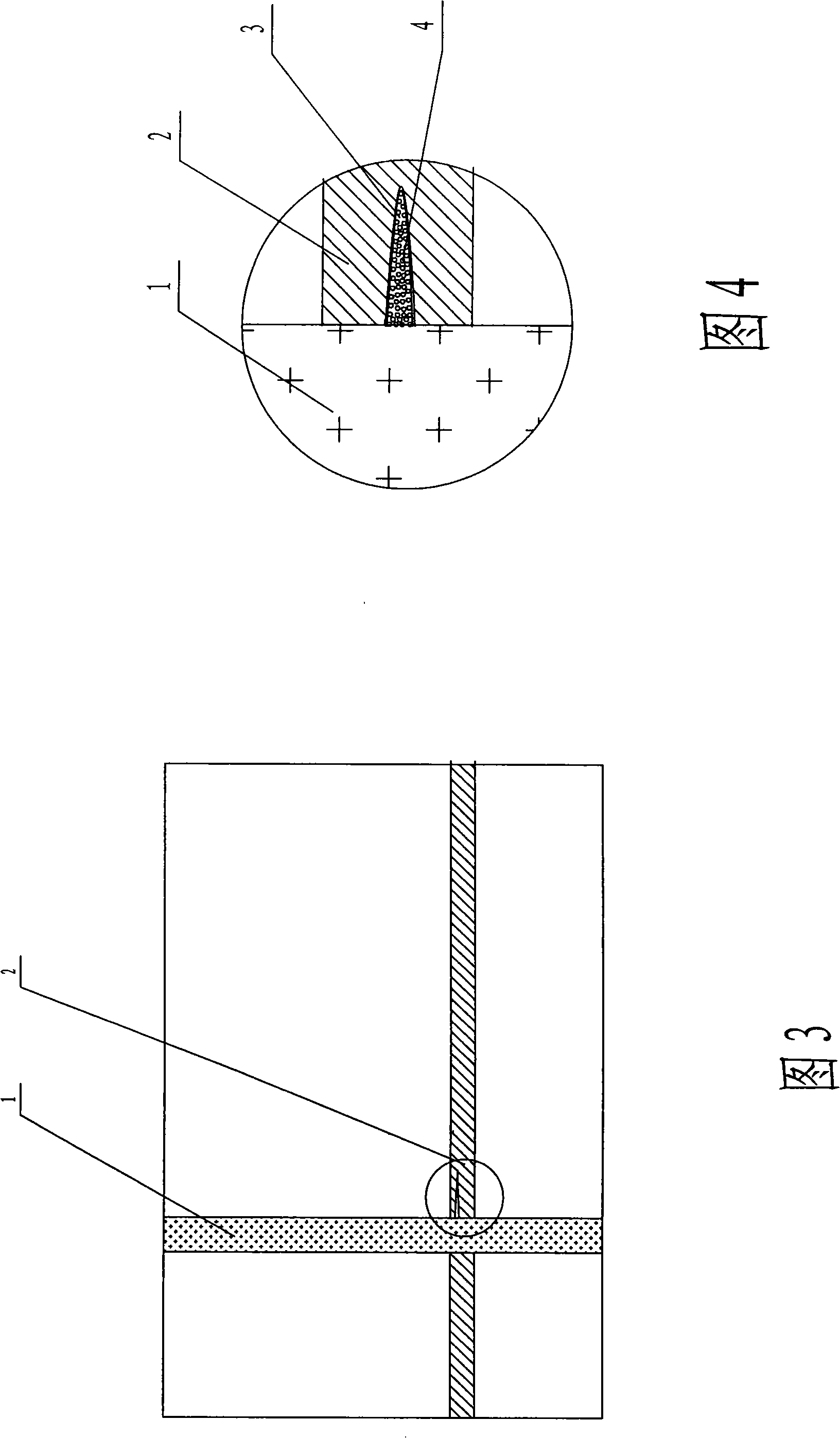

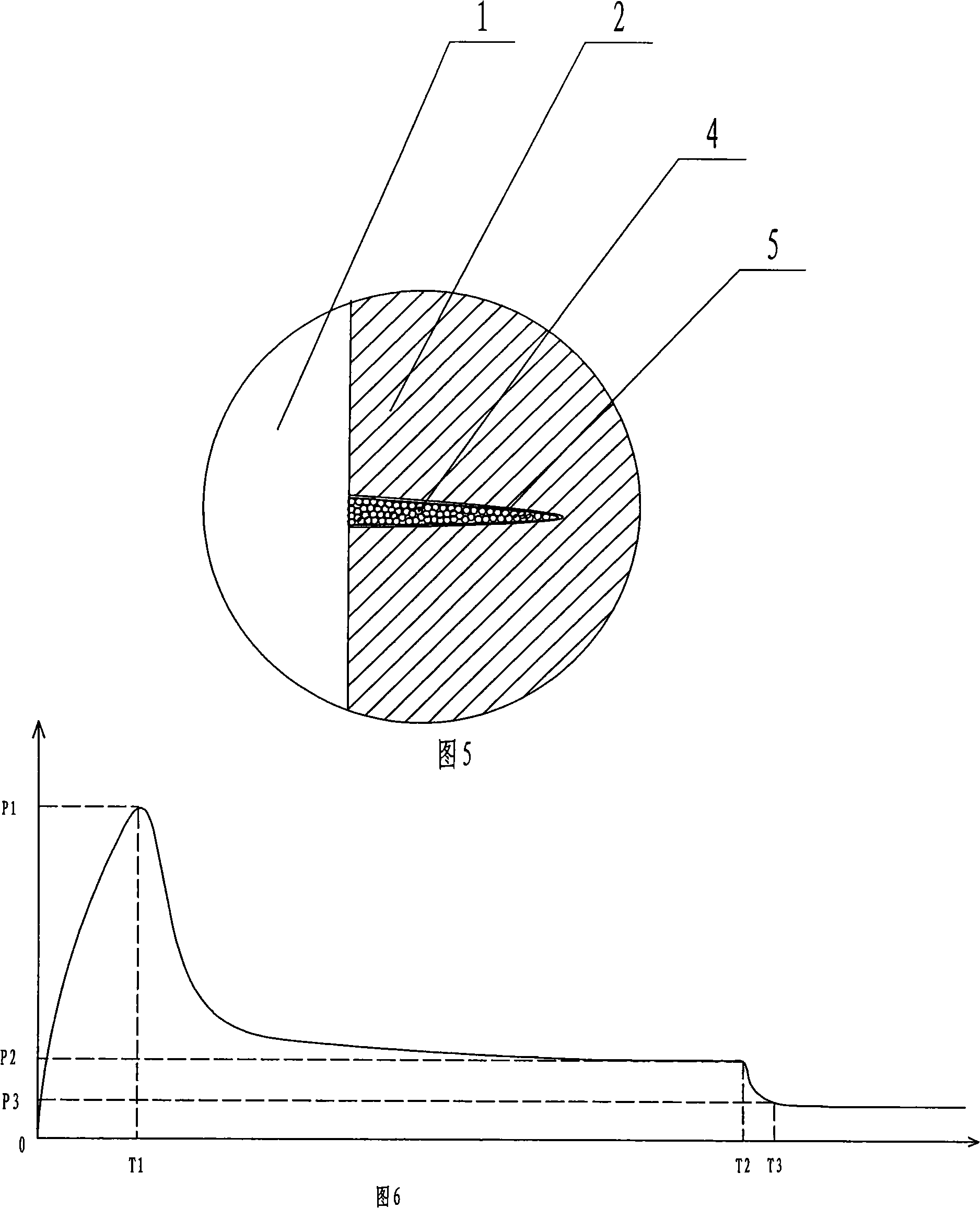

Fracturing process for removing breakdown fluid contamination

The invention relates to a mining technology for the petroleum, natural gas and the coal seam gas, in particular to a compression fracture process which avoids the fracturing fluid pollution and solves the problem that the fracture conductivity is reduced caused by the dense filter cake formed on the surface of the strata fracture by the thickener added in the fracturing fluid applied in all the compression fracture constructions found in the prior art. The construction steps include that the pad fluid is injected into the oil gas storage strata; the sand-laden fluid is injected continuously when the oil gas storage strata generates fractures; subsequently, the displacement fluid is injected; then the pump on the ground is stopped; 60 minutes later after the fracture closing time T3 and the pressure is lower than the fracture closing pressure P3, the oxidant solution such as the chlorine dioxide result solution, the potassium permanganate, the hydrogen peroxide solution or the persulphate which can degrade the polymers is injected into the fractures as the fracturing post pad fluid; finally, the displacement fluid is injected to extrude all the compression fracture post pad fluid to the strata fractures. The compression fracture process can radically avoid the pollution block of the fracturing fluid, exert the potential of the fracturing technology and increase the yield.

Owner:郝东 +1

Method of hydraulic fracture of subterranean formation

InactiveCN1671945AEffectively increase productionPromote production increaseFluid removalFracturing fluidWellbore

This invention relates generally to the art of hydraulic fracturing in subterranean formations and more particularly to a method and means for optimizing fracture conductivity. According to the present invention, the well productivity is increased by sequentially injecting into the wellbore alternate stages of fracturing fluids having a contrast in their ability to transport propping agents to improve proppant placement, or having a contrast in the amount of transported propping agents.

Owner:SCHLUMBERGER TECH LTD BV

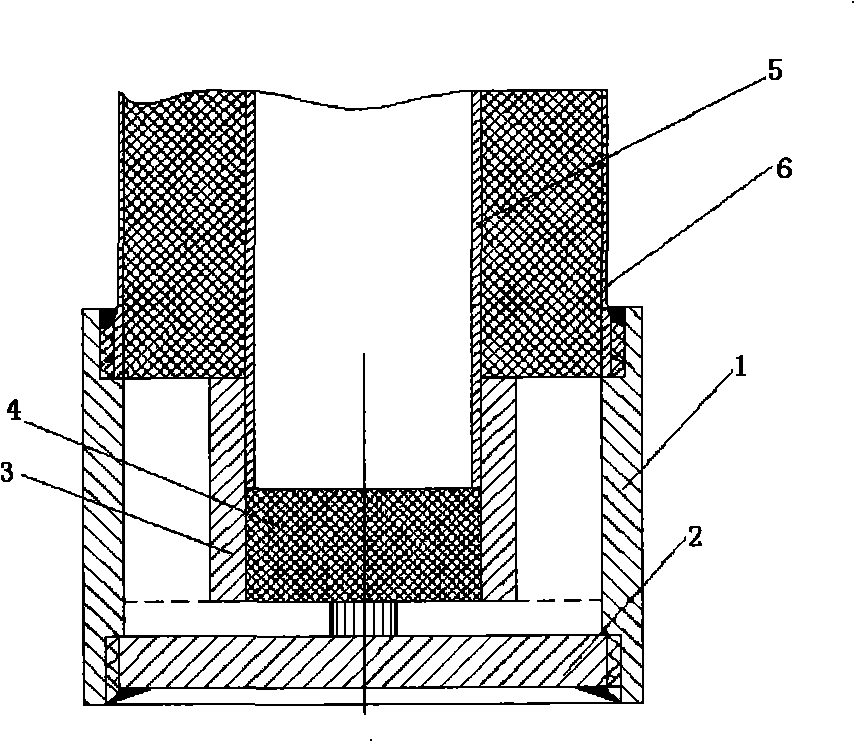

Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

InactiveCN101298948AIncrease the heat exchange areaSmall pressure lossCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

The invention discloses a thread weld integral slit type cold head of the coxial vessle refrigerator in the refrigeration technology field, including an upper cold head, a lower cold head, a cold end baffle and a copper wire, wherein the upper cold head and the lower cold head are welded again after the threaded connection, the cold baffle is arranged at the middle of the cold head integer, and the cold baffle is filled with the copper wire, wherein the lower cold head is divided into a base seat and a boss having the uniformly distributed slots in the axial symmetry. The depth of the slot is the same with the height of the boss, and the external thread is arranged at the cirumferential of the base seat; a cylinder is arranged on the upper cold head, a round hole at the center and radial slots in the distributed uniformly arranged at the cirumferential of the round hole. The width of the slot is consistent with the slot of the lower cold head; the internal thread structure of the upper cold head is matched with the external thread of the lower cold head, with the other end in the thread match with the cold accumulator, and is left with the margin for welding after being matched. The invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

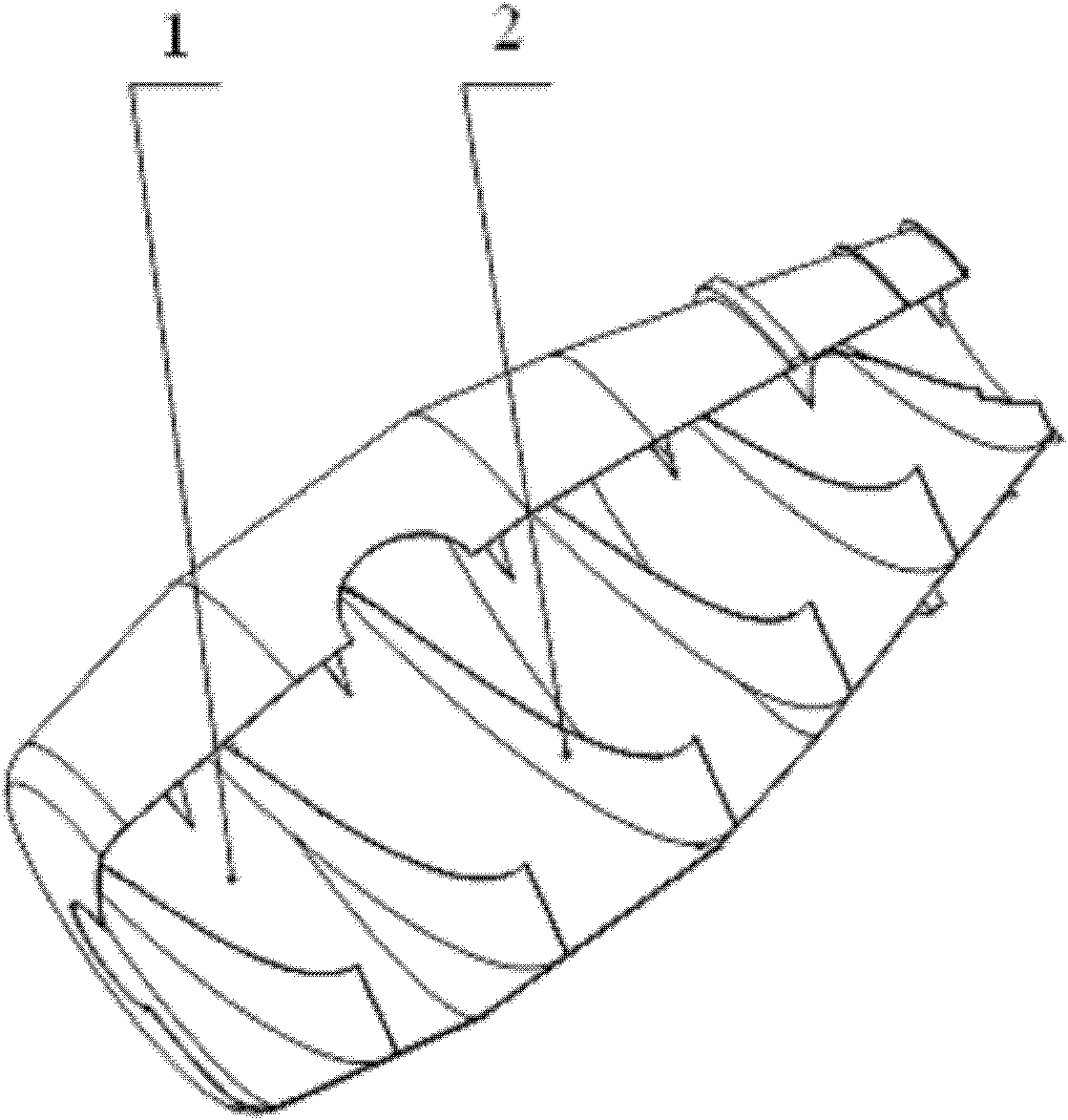

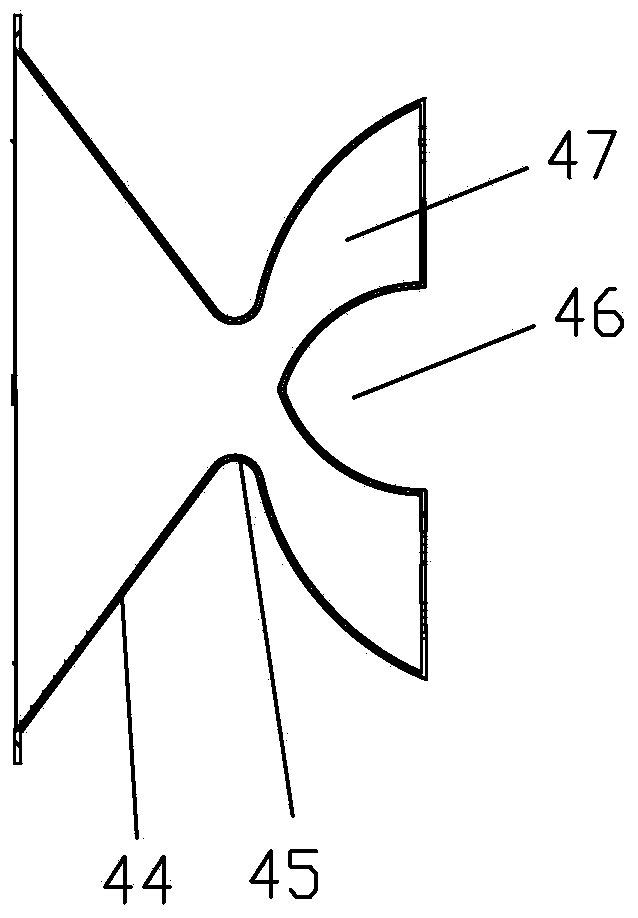

Concrete mixing truck as well as mixing drum and mixing drum blade structure thereof

The invention provides a mixing drum blade structure and mixing drum of a concrete mixing truck as well as the concrete mixing truck. The mixing drum blade structure comprises a first blade part which is connected to the inner wall of the mixing drum and a second blade part which is intersected with the first blade part. According to the mixing drum blade structure provided by the invention, the first blade part and the second blade part are intersected with each other, so that the strength of the whole mixing drum blade structure is enhanced, the mixing drum blade structure can better adapt to the concrete mixing, the mixing effect is optimized, the mixing becomes more uniform, and the segregation phenomenon is prevented from occurring in a mixing process. The mixing drum provided by the invention has the mixing drum blade structure, so that the mixing drum has the advantages of better abrasion resisting property, better flow-guiding effect, prolonged service life, more uniform mixing effect and increased feeding and discharging speeds. Besides, the concrete mixing truck which is provided with the mixing drum provided by the invention can be used for maintaining the excellent quality of the concrete which is transported.

Owner:ZOOMLION HEAVY IND CO LTD

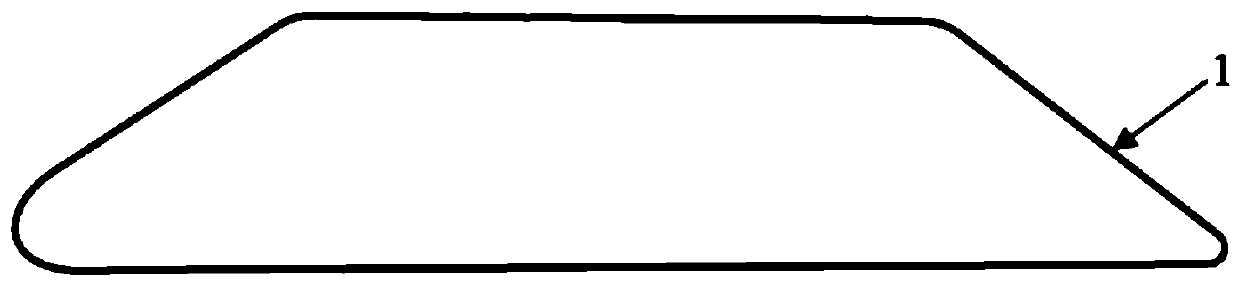

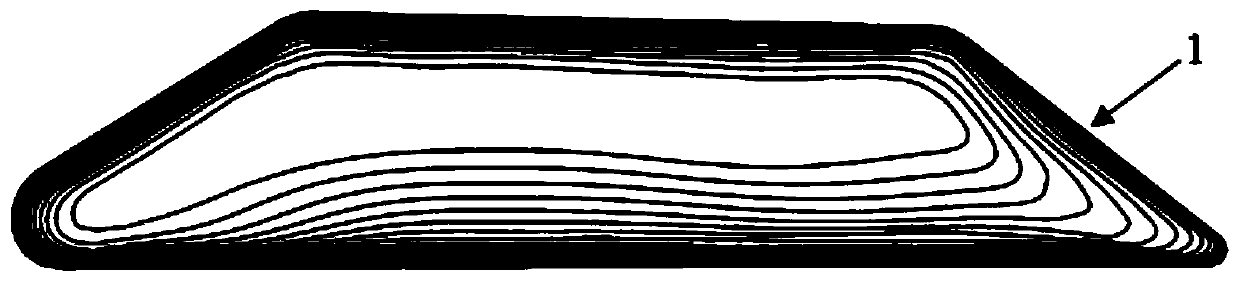

Abnormal-shape filament non-woven fabric and manufacture technology thereof

InactiveCN102560904AAvoid secondary pollutionReduce transportation linksFilament/thread formingNon-woven fabricsManufacturing cost reductionPolymer science

The invention provides an abnormal-shape filament non-woven fabric, wherein non-woven fabric coiled material consists of abnormal-shape fiber filaments, the length of each abnormal-shape fiber filament is more than or equal to 1000mm, the specific surface area of the abnormal-shape filament is more than 1.3 compared with that of the fiber with the same material, the equal denier and the circular cross section, the abnormal-shape fiber filaments consist of low-melting point thermoplastic high polymers and high-melting point thermoplastic high polymers, the low-melting point thermoplastic high polymers of which the melting point is less than 150 DEG C are arranged on the surface layers of the abnormal-shape fiber filaments, the abnormal-shape fiber filaments are glued with one another by the low-melting point thermoplastic high polymers arranged on the surface layers of the abnormal-shape fibers to form into the non-woven fabric coiled material, each gluing point among each abnormal-shape fiber is the surface layers of the low-melting point thermoplastic high polymers of two abnormal-shape fiber filaments contacted with each other, and the mean value of the area of each gluing point is less than 0.01 square millimeters. The non-woven fabric is fluffy and flexible, thereby being elastic; the transportation link is reduced, and the manufacture cost is reduced; and the non-woven fabric is quick in liquid absorption and good in flow guide effect.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

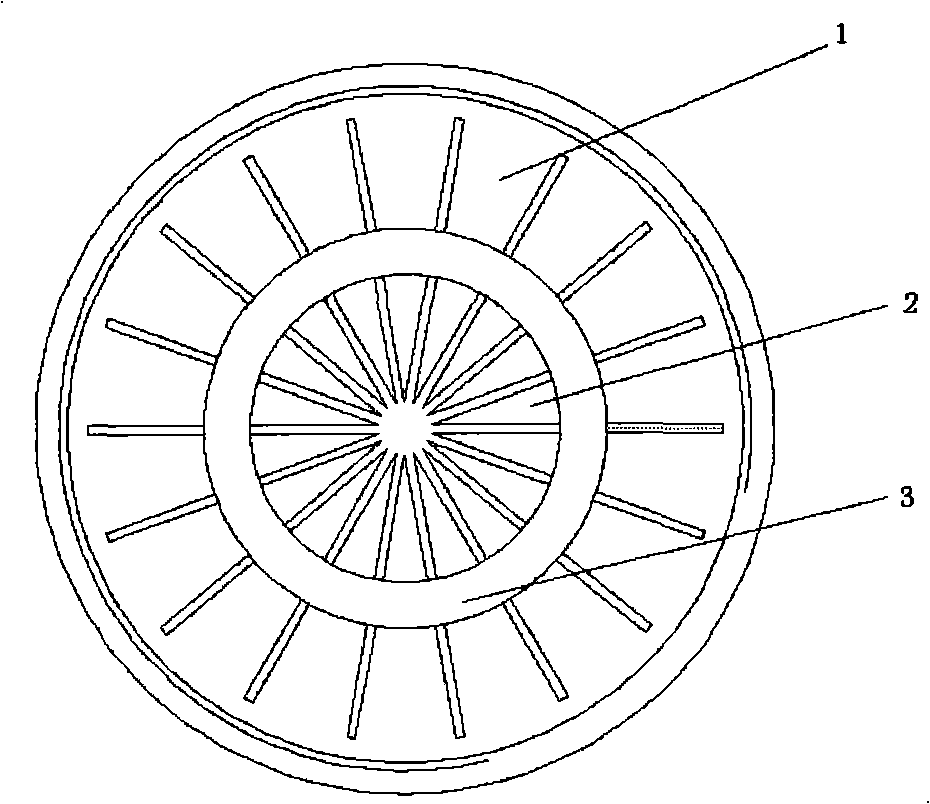

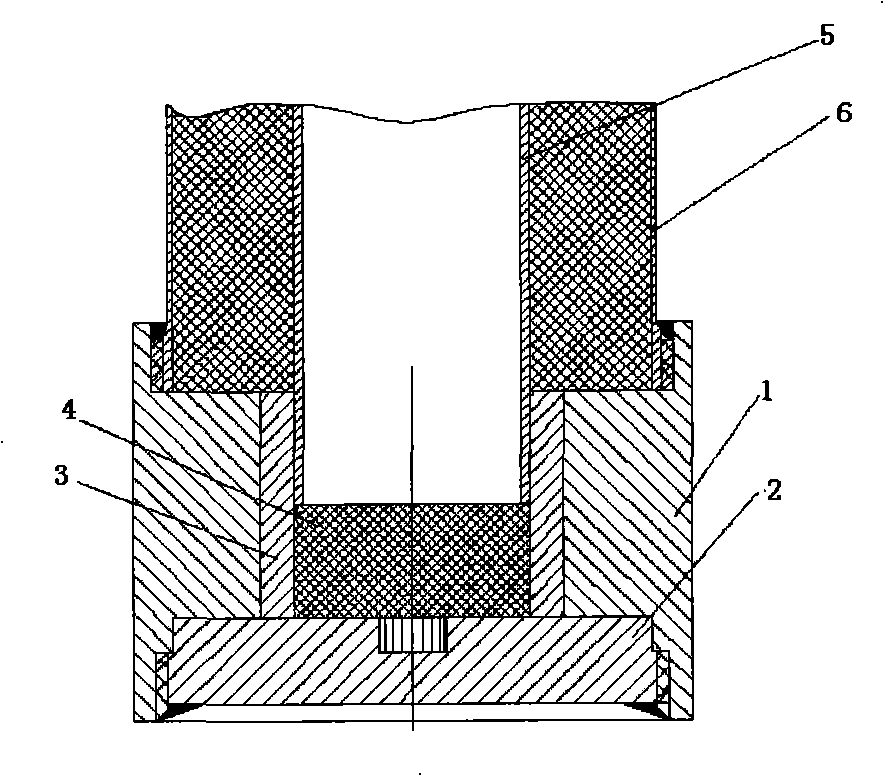

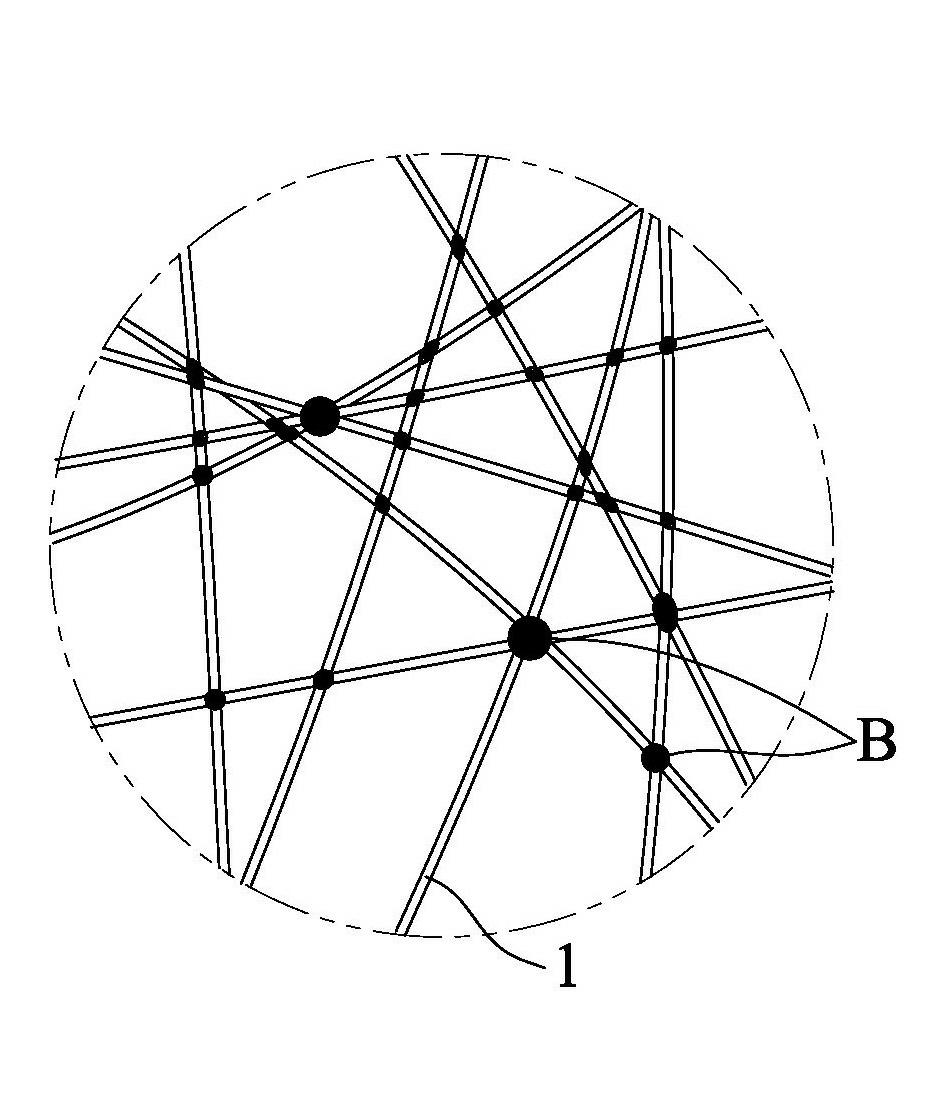

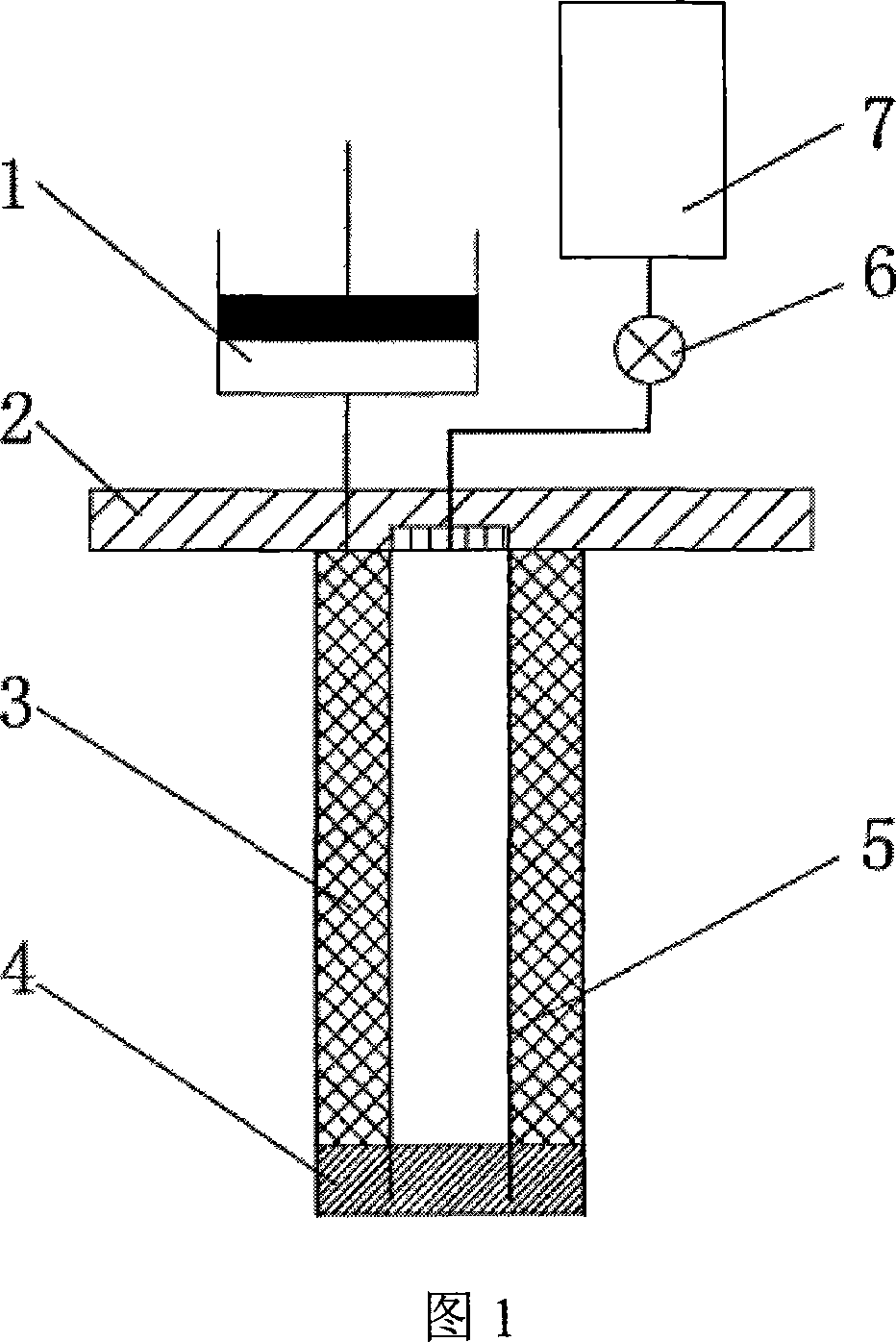

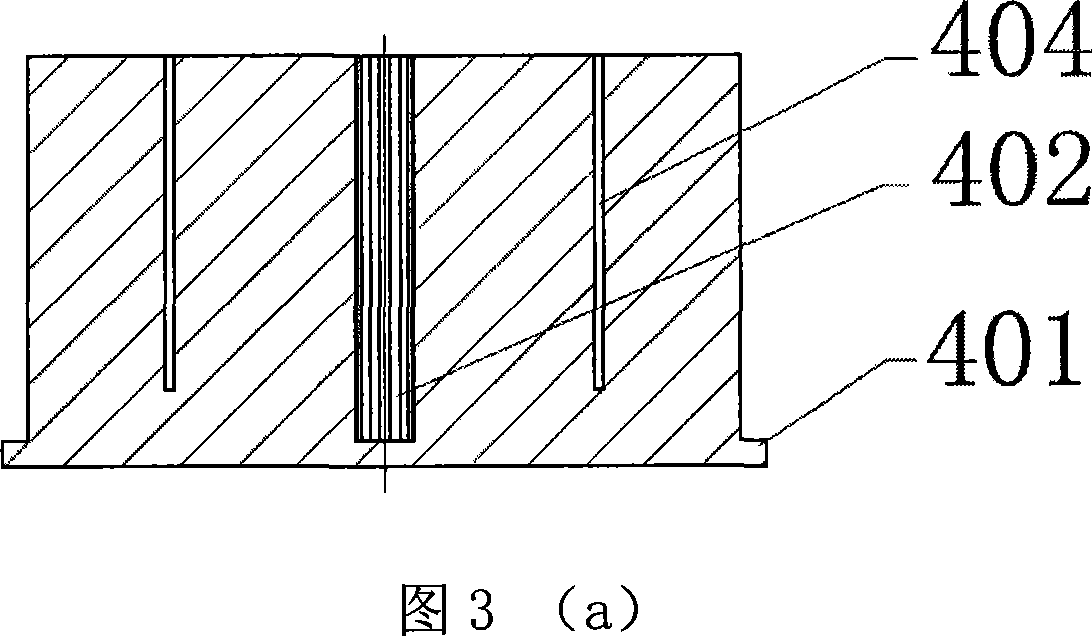

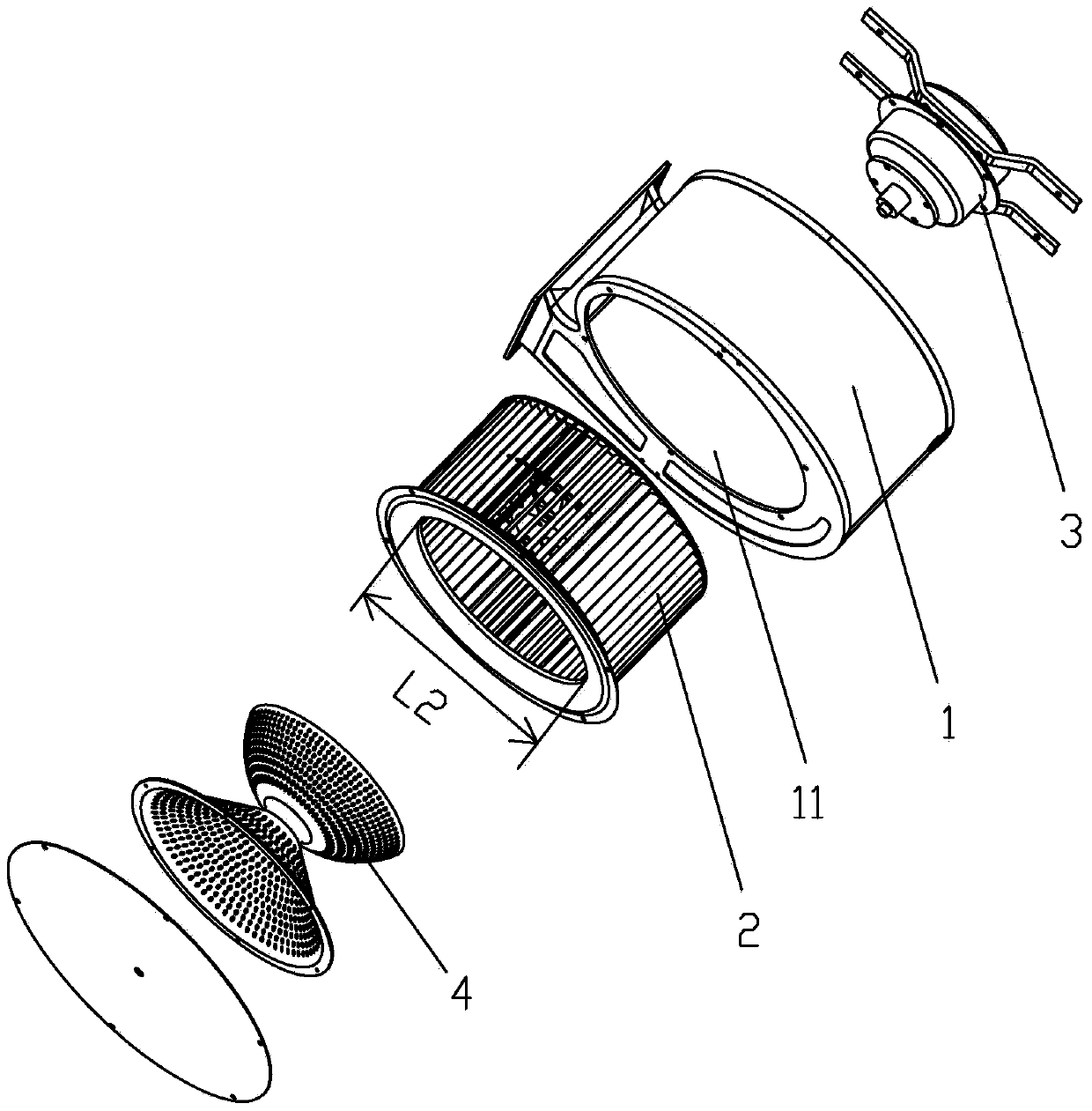

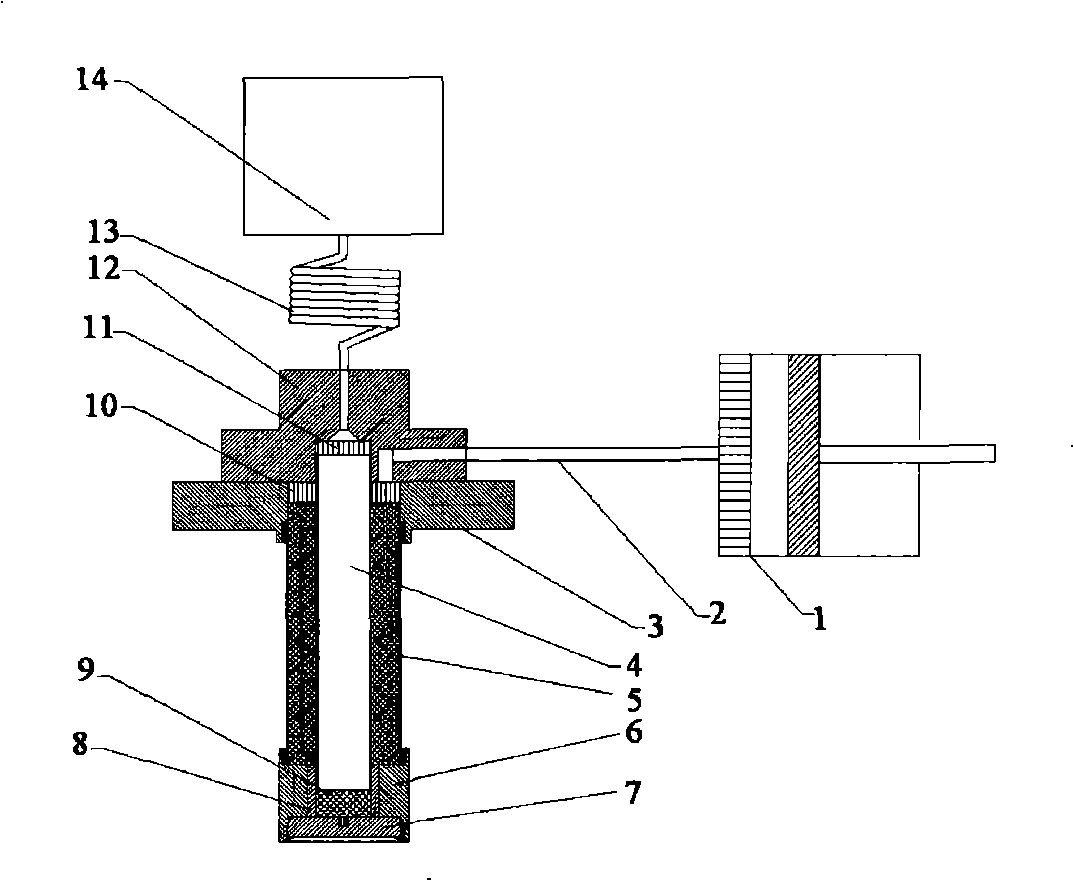

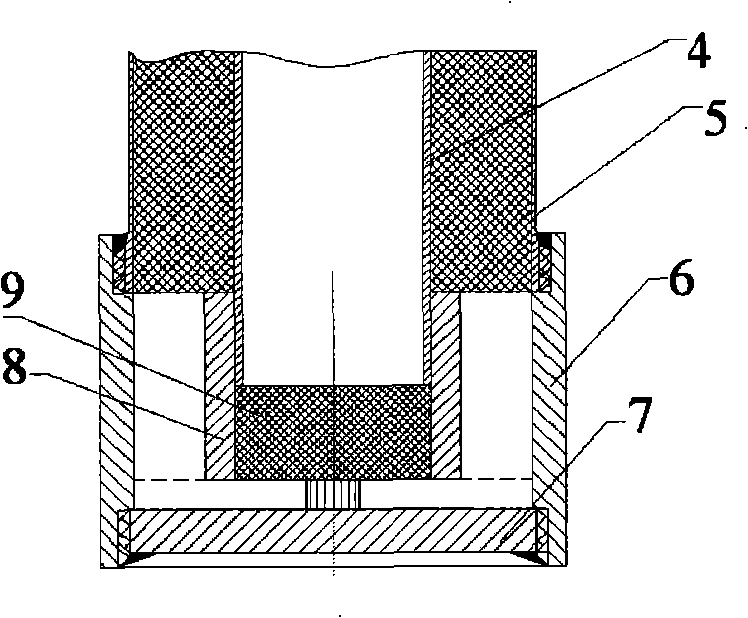

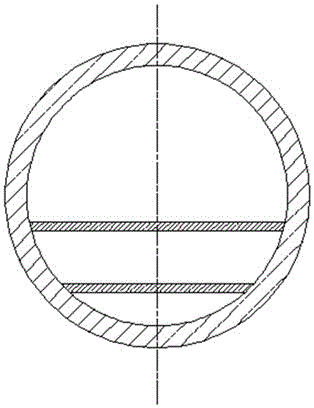

Integrated cold head used for co-axial pulse tube refrigerator

InactiveCN101067523AImprove uniform distributionImprove the diversion effectCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

A kind of integrated cold head is used to the coaxial vas freezer and the cold head is made of the high heat conductivity material and at the bottom along the outside around there is a flanged edge used to weld with the shell of storage cold equipment and in the middle of it opens a round hole and around of the round hole opens radial gap uniformly and the depth of gap is the same with the depth of round hole and there is coaxial opening a ring conduit used to the vas of freezer for inserting. The vas adapts with the inserted ring conduit tightly and the cold head adapts with the shell of storage cold equipment tightly and the flanged edge of cold head welds with the shell of storage cold equipment. So the outside of the ring conduit is the storage cold equipment's cold end gas uniform equipment and the inside of the ring conduit is the vas's cold end gas vane. And the gas in the storage equipment and the vas is conducted by the gap of the bottom of integrated cold head. The maxim merit of it is that: the heat exchange area is large and the affection of guiding flow is well and the points of welding are little and it can deliver the quantity of refrigeration of the vas freezer to the outside face of cold head effectively so it improves performance of the coaxial vas freezer largely.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

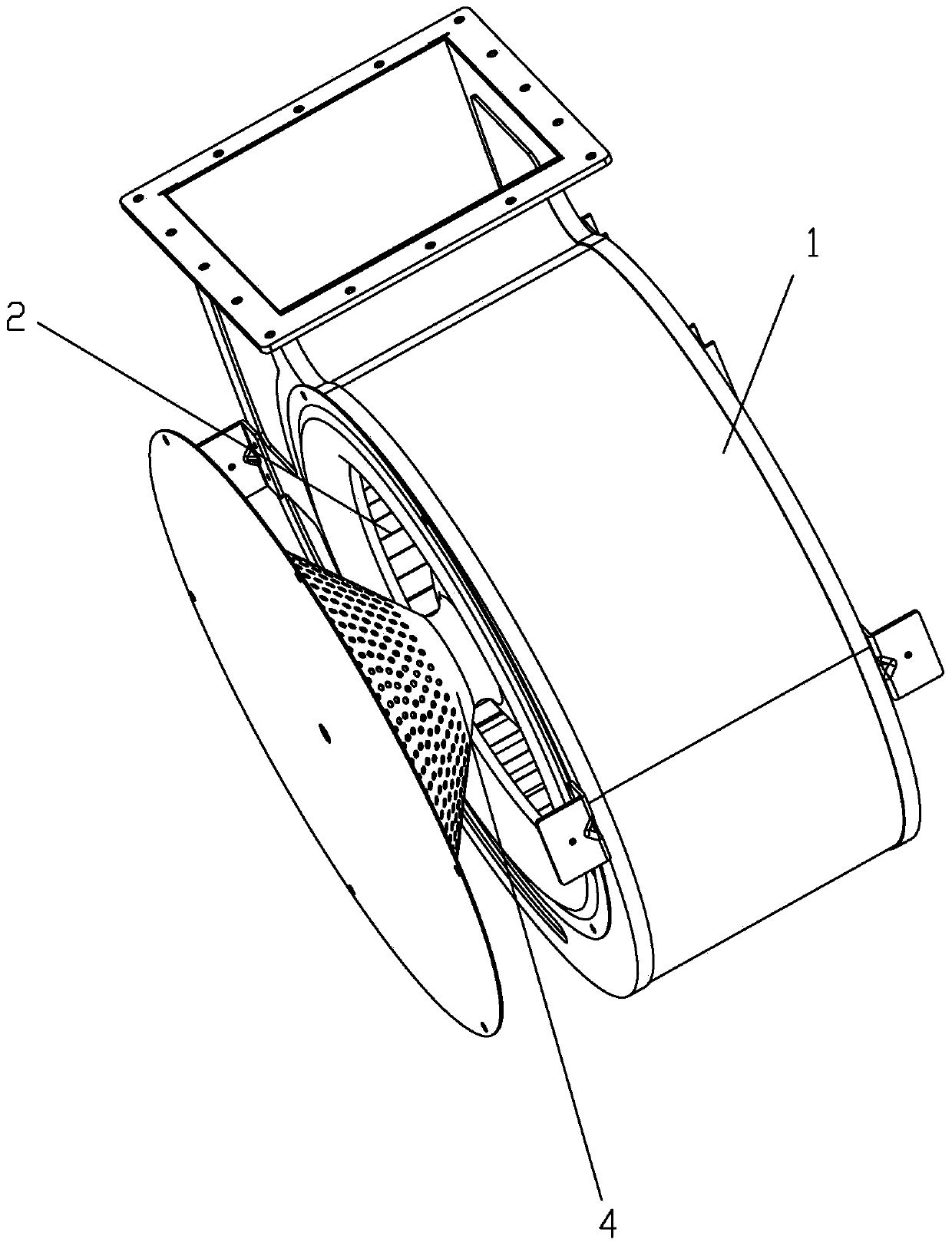

Oil fume absorbing and noise reducing device of range hood

ActiveCN104180412APrevent outward spreadReduce noiseDomestic stoves or rangesLighting and heating apparatusEngineeringTurbine

The invention discloses an oil fume absorbing and noise reducing device of a range hood. The device comprises a volute fixedly connected with a box body of the range hood, wherein a wind turbine and a motor driving the wind turbine to rotate are arranged in the volute, a sound absorbing member connected with the box body is arranged inside the wind turbine, the sound absorbing member comprises a sound absorbing shell which is provided with a shell cavity, a plurality of sound absorbing through holes communicated with the shell cavity are formed in the wall of the sound absorbing shell, and the shell cavity is filled with a sound absorbing material. The device is simple in structure and good in noise reducing effect.

Owner:VATTI CORP LTD

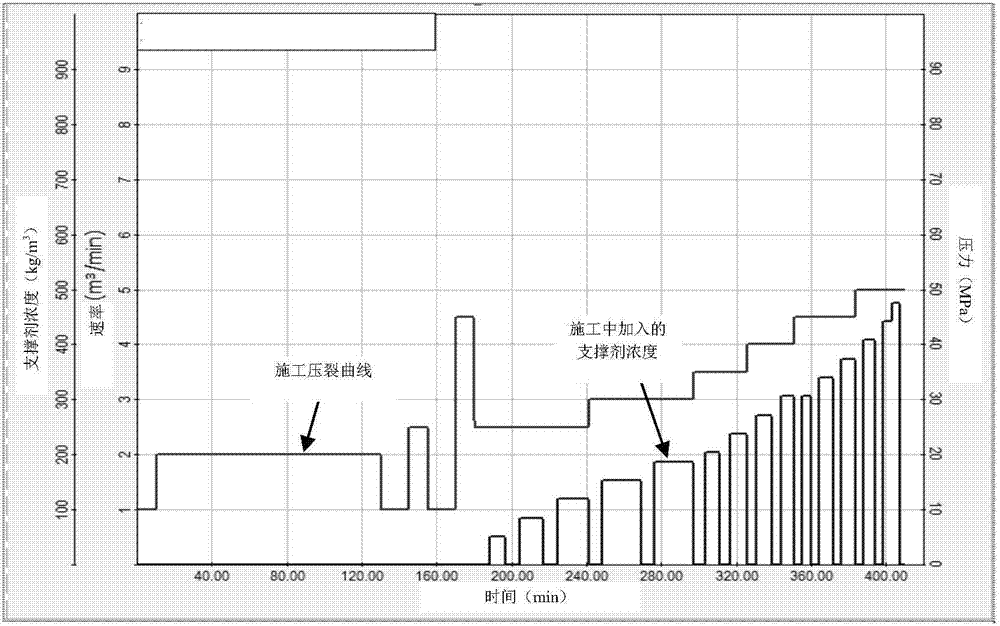

Acid injection fracturing method

The invention provides an acid injection fracturing method. The method comprises the steps that at the front liquid fissure forming stage, an alternative acid injection mode is adopted for fissure fracturing transformation, the alternative acid injection mode comprises the step that 1-5 levels of slugs are alternatively injected into fissures, and each level of slugs are composed of acid liquid and displacing liquid which are injected in sequence. According to the acid injection fracturing method, by combining with technical advantages of fracturing and acidification, through optimization of an alternative injection technology, the relation range of the acid liquid in a fissure fracturing system is enlarged to the greatest extent, and the porosity and permeability of fissure wall rock areimproved; a micro-fissure and branch fissure extension system is expanded and extended, increase of fissure complexity degree and transformation volume is promoted, and the duration time of keeping the flow diversion capacity of the fracturing system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

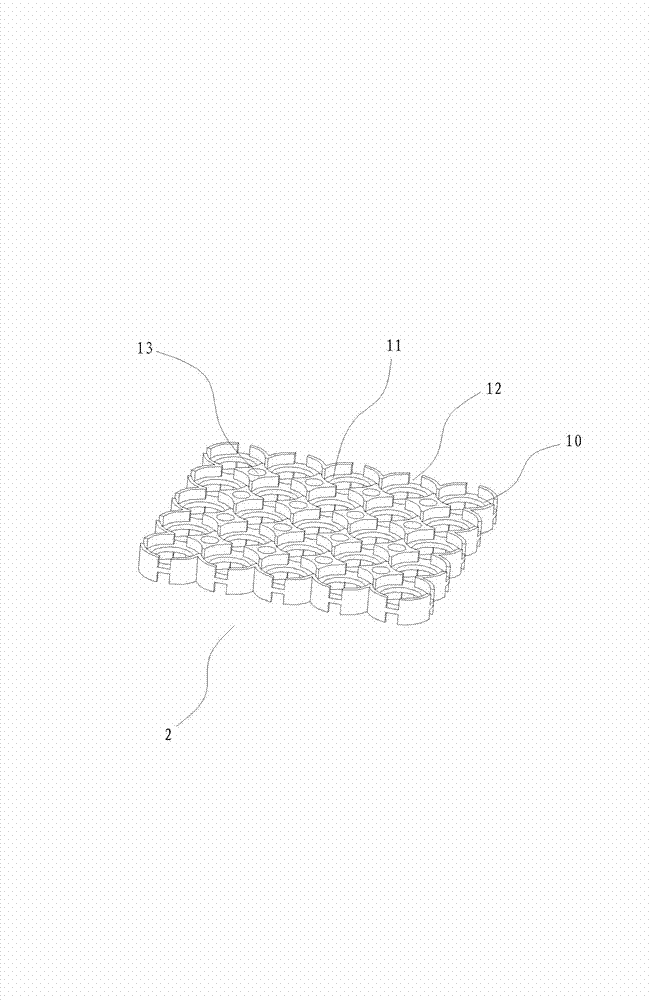

Storage battery

InactiveCN102760854ASimplify the installation processBeautiful appearanceCell temperature controlCell component detailsElectric vehicleEngineering

Owner:李相哲 +1

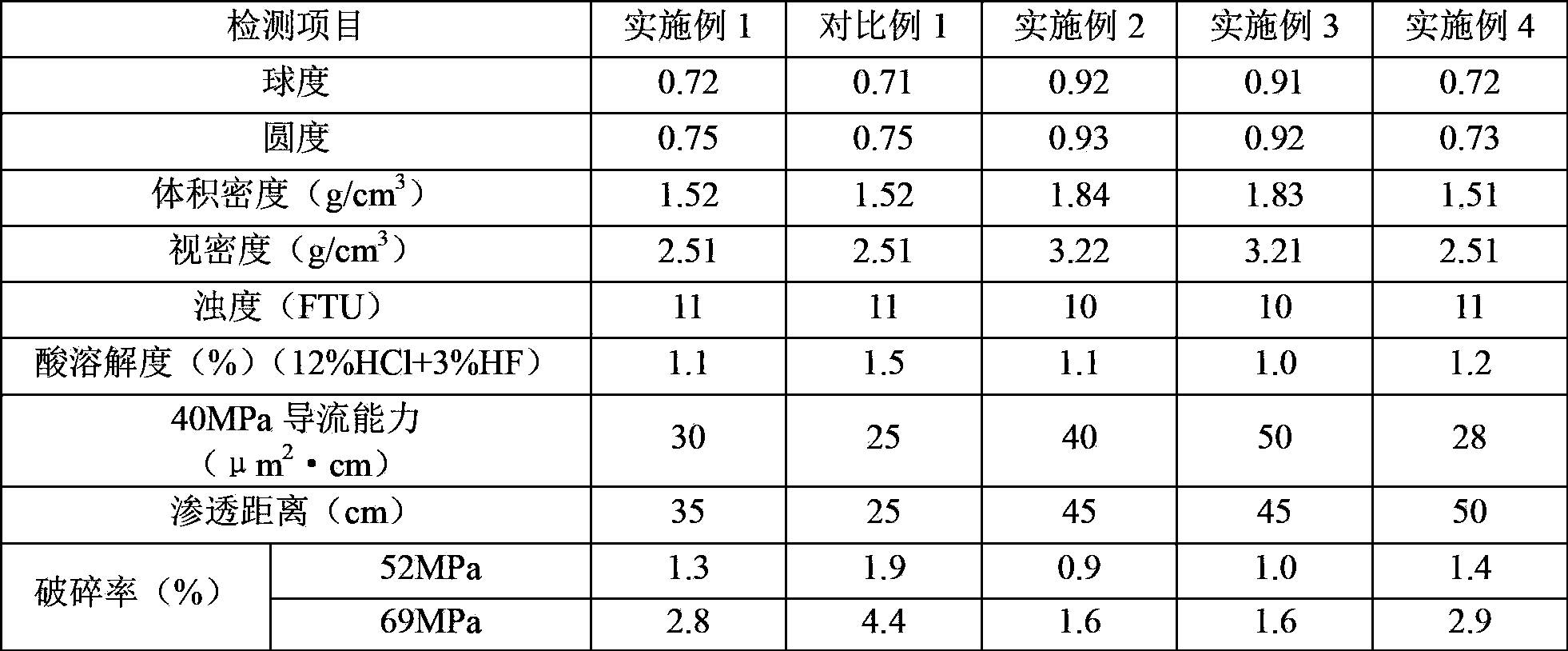

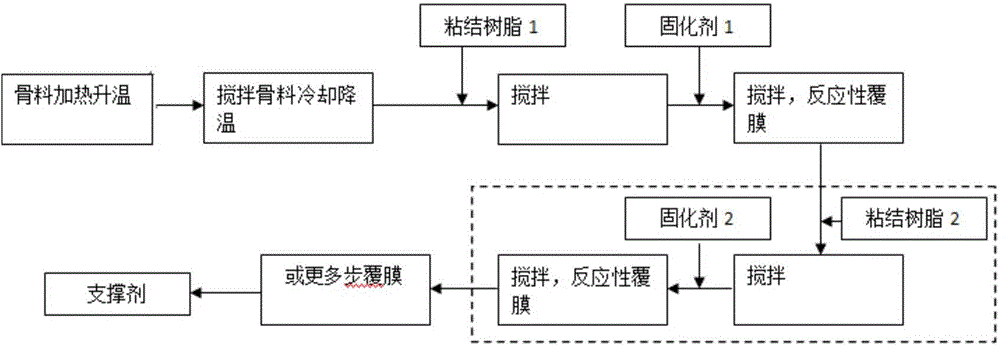

Fracturing propping agent and its preparation method

InactiveCN103849371AImprove broken rateReduce breakage rateFluid removalDrilling compositionBreakage rateConstruction aggregate

The invention provides a fracturing propping agent preparation method, and a fracturing propping agent prepared through the method. The fracturing propping agent comprises aggregate particles, and a silane coupling agent layer and a resin layer sequentially coated on the surfaces of the aggregate particles. The fracturing propping agent has the advantages of low breakage rate, good diversion capability and great industrial application prospect.

Owner:ELION RESOURCE GROUP

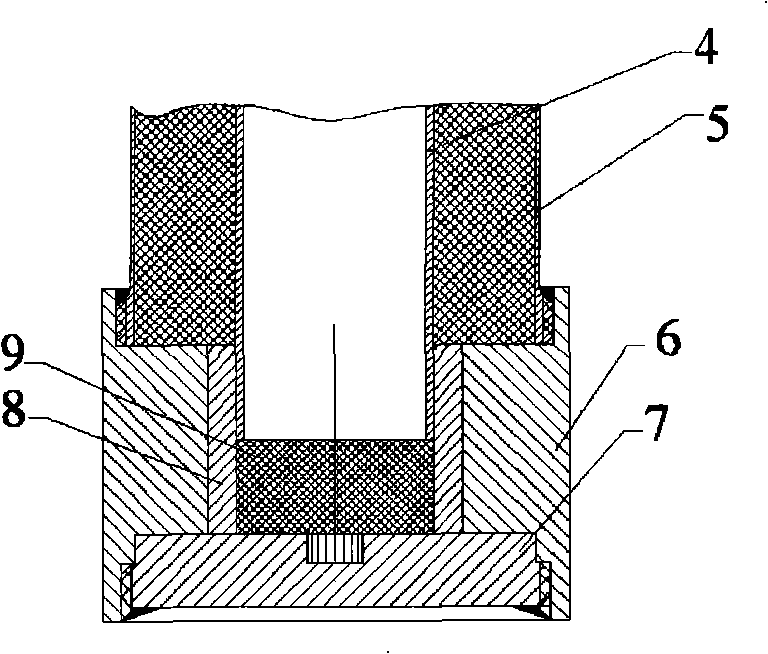

Screw thread welding integral narrow slit type coaxial pulse-tube refrigerator

InactiveCN101298947AIncrease the heat exchange areaGood diversion effectCompression machinesGas cycle refrigeration machinesCopper wireEngineering

The invention discloses a thread weld integral slit type coxial vessle refrigerator, including a compressor, an air line, a fire end flange, a vessle, a cold accumulator, an upper cold head, a lower cold head, a cold end baffle, a copper wire, a first fire end diffuser, a second fire end diffuser, a cold accumulator core plug, a long neck tube and an air reservior, wherein the two ends of the upper cold head have a internal thread with one end welded with the threaded connection of the lower cold head and the other end welded with one end of the cold accumulator after the threaded connection; a round hole is arranged at the center of the upper cold head, and radial slot distributed uniformly are arranged round the round hole; a cold end baffle is arranged in the round hole, and the part of the outside of the cold end baffle is the cold accumulator cold end air applicator part, while the inner part of the cold end baffle is the stacked copper wire and a vessle extending section of the vessle cold end diffuser. The air in the cold accumulator and the vessle communicate with the slot of the upper cold head and the lower cold head by the welding way. The cold head of the invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

Method for improving productivity of hydraulic fractured well through compound activator

ActiveCN103912254AEfficient removalImprove the diversion effectFluid removalMetaboliteMicrobial agent

The invention discloses a method for improving productivity of a hydraulic fractured well through compound activator. The method for improving the productivity of the hydraulic fractured well through the compound activator includes that leading compound activator A composed of an electron acceptor and nutrient or compound activator B composed of the electron acceptor, the nutrient and microbial agent into a target stratum, and selectively controlling the multiplication and metabolic activity of microorganism in the target stratum to remove stratum pollutant and generate useful metabolites to improve the productivity of the fractured well. According to the method for improving the productivity of the hydraulic fractured well through the compound activator, a microorganism field is generated in the reservoir space of the target stratum, residual guanidine gum filter cakes caused by fracturing or the heavy hydrocarbon pollutant generated by oil and gas production is eliminated, the current guide ability of the hydraulic crack body is improved, and meanwhile, the useful microorganism metabolites are generated, the oil and water phase interface tension is lowered, the crude oil is emulsified and is high in liquidity, and accordingly the productivity increasing effect of the fracturing construction is improved, and the productivity of the fractured well is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

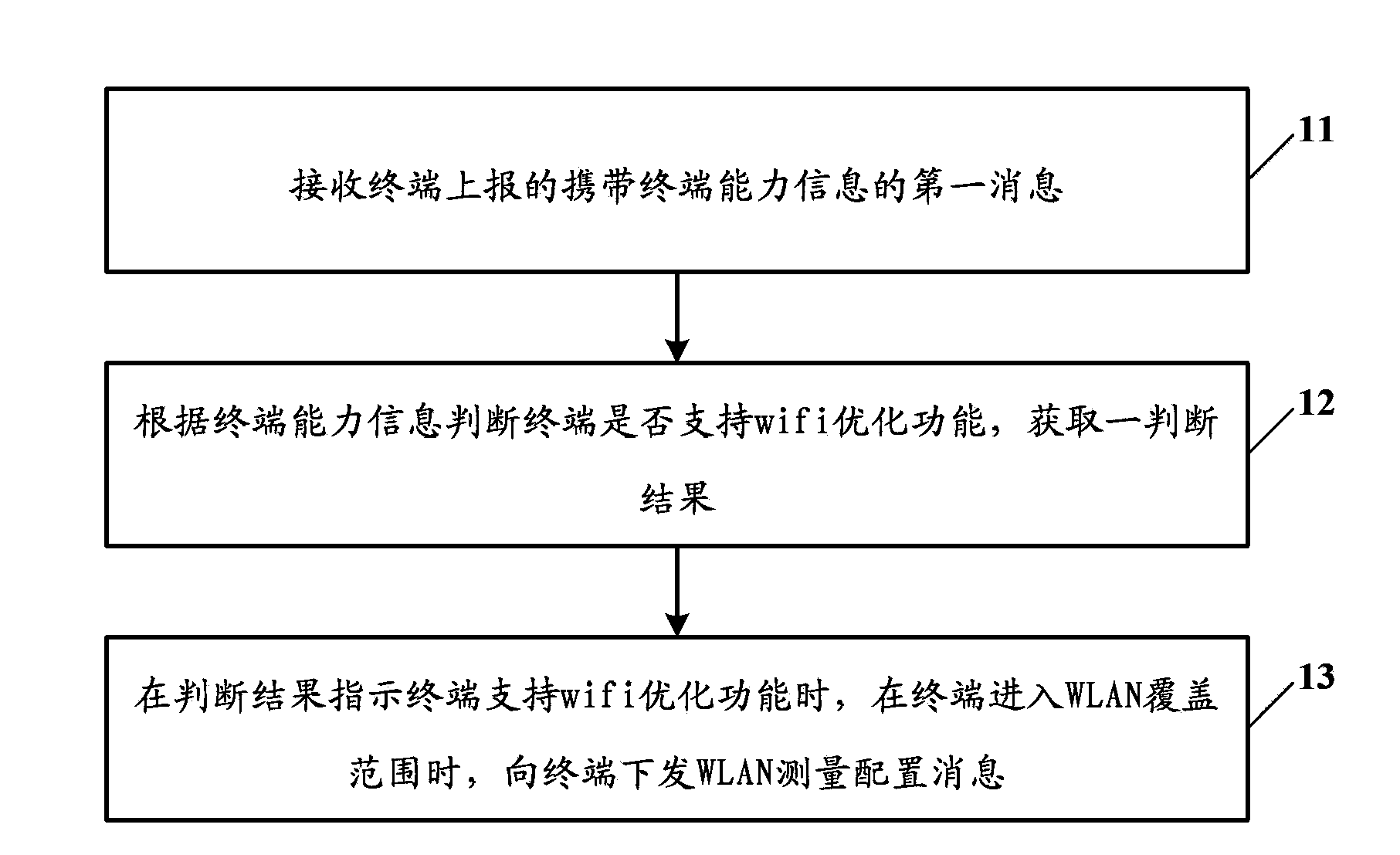

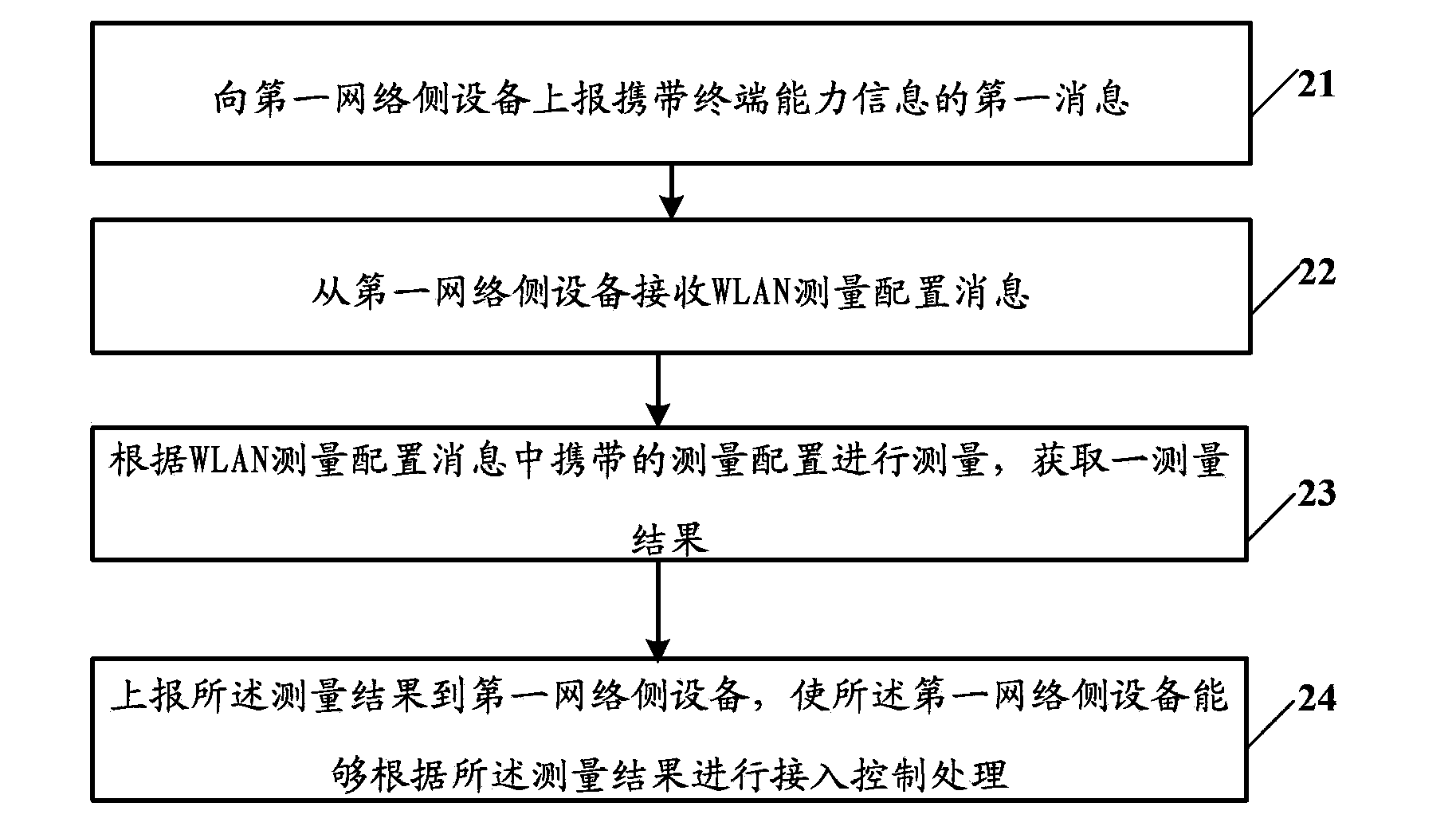

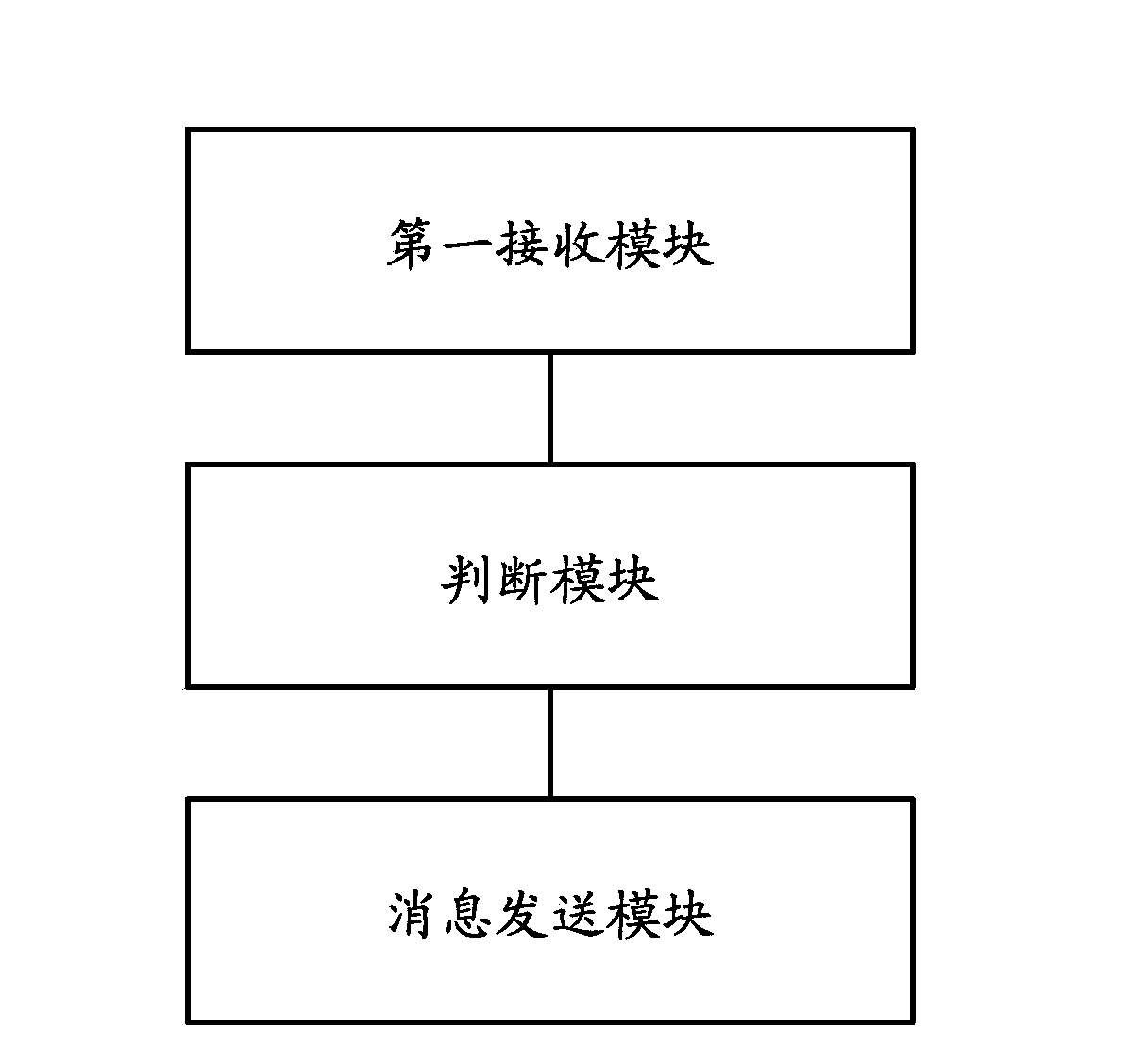

Network access control method and apparatus, network side device, and terminal

InactiveCN103781090AAffect the experienceImprove the diversion effectAssess restrictionNetwork topologiesComputer hardwareNetwork Access Control

The invention provides a network access control method and apparatus, a network side device, and a terminal. The network access control method is used for a first network side device. The method comprises the following steps: receiving a first message which is reported by a terminal and carries terminal capability information; according to the terminal capability information, determining whether the terminal supports a Wifi optimization function, and obtaining a determination result; and when the determination result indicates that the terminal supports the Wifi optimization function, and when the terminal enters a WLAN coverage scope, issuing a WLAN measuring configuration message to the terminal to enable the terminal to carry out measuring according to measuring configuration carried in the WLAN measuring configuration message, and obtaining a measuring result for access control processing. According to the invention, related measuring configuration is only performed on a terminal which supports a Wifi optimization function and enters a WLAN coverage scope so that user experience is prevented from being affected due to generation of unnecessary signaling cost.

Owner:CHINA MOBILE COMM GRP CO LTD

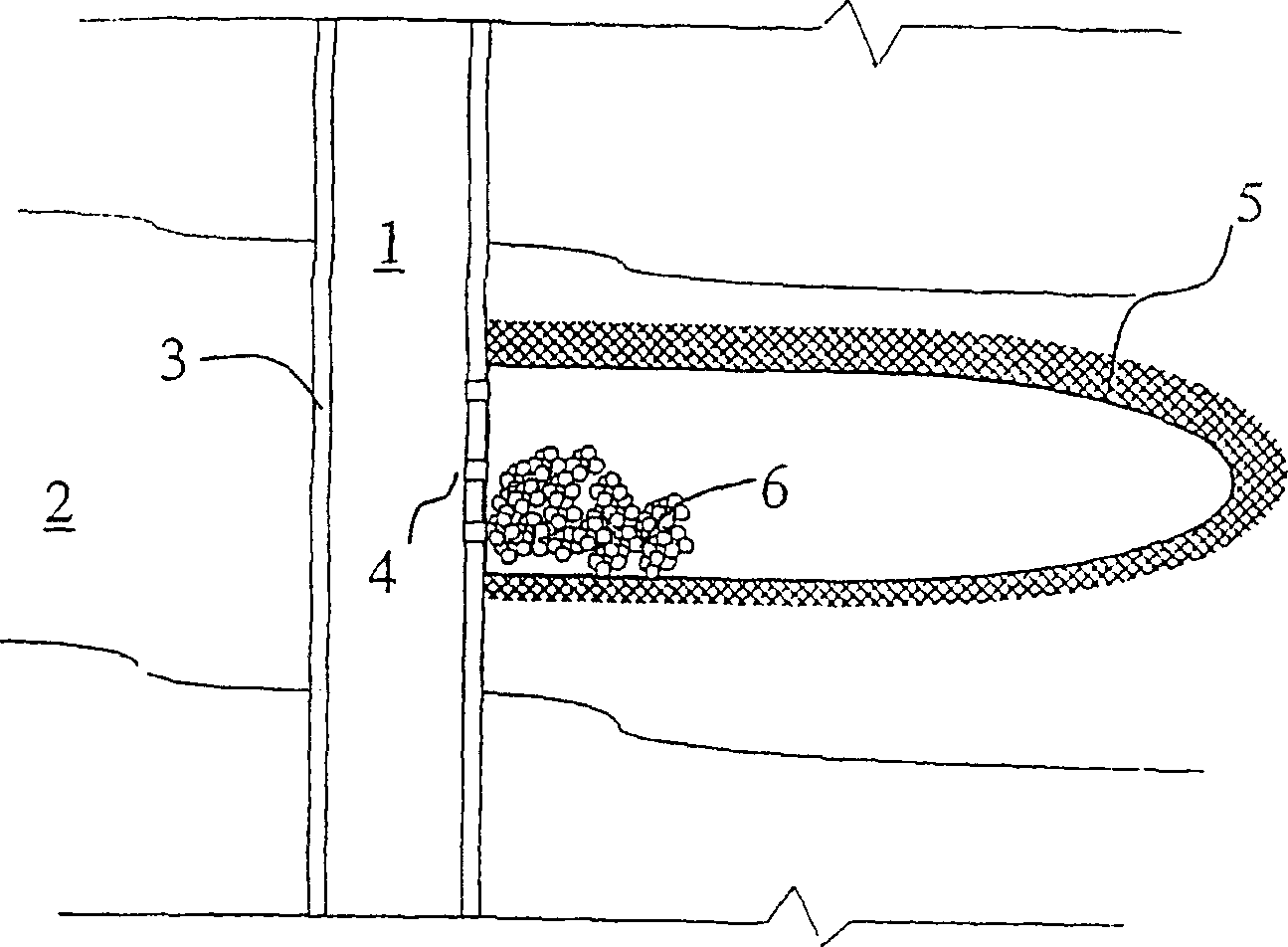

Sand fracturing technology

The invention discloses a sand fracturing technology. The technology is characterized in that fibrous sand-carrying fluid and pure gel interval fluid are pumped into oil-gas well cracks in a manner of alternate circulation; the fibrous sand-carrying fluid entering the oil-gas well cracks is dispersed into clusters different in shape by perforation shot holes in a tubular column; the cluster-shaped fibrous sand-carrying fluid is piled from inside to outside to form a sand column in the cracks; a gap between the adjacent fibrous sand-carrying fluid clusters in the sand column is filled by the pure gel interval fluid; the cross section of the whole sand column is in the shape of a piled stone wall; the cracks during a closing process and closed cracks are supported by the sand column; pure gel interval fluid parts in the sand column form a low-resistance and high-flow rate seepage passage of oil gas after gel breaking. According to the sand fracturing technology disclosed by the invention, under the flow conductivity of the excellent support of the oil-gas well cracks, the oil gas seeps at large area, low resistance and high flow rate, and further, the well yield of an oil-gas well is greatly increased, and the production cost of the oil-gas well is effectively reduced; the sand fracturing technology is strong in practicability and high in reliability.

Owner:CHINA PETROLEUM & CHEM CORP +1

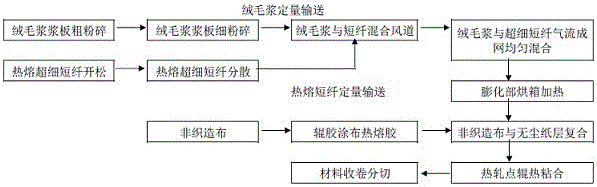

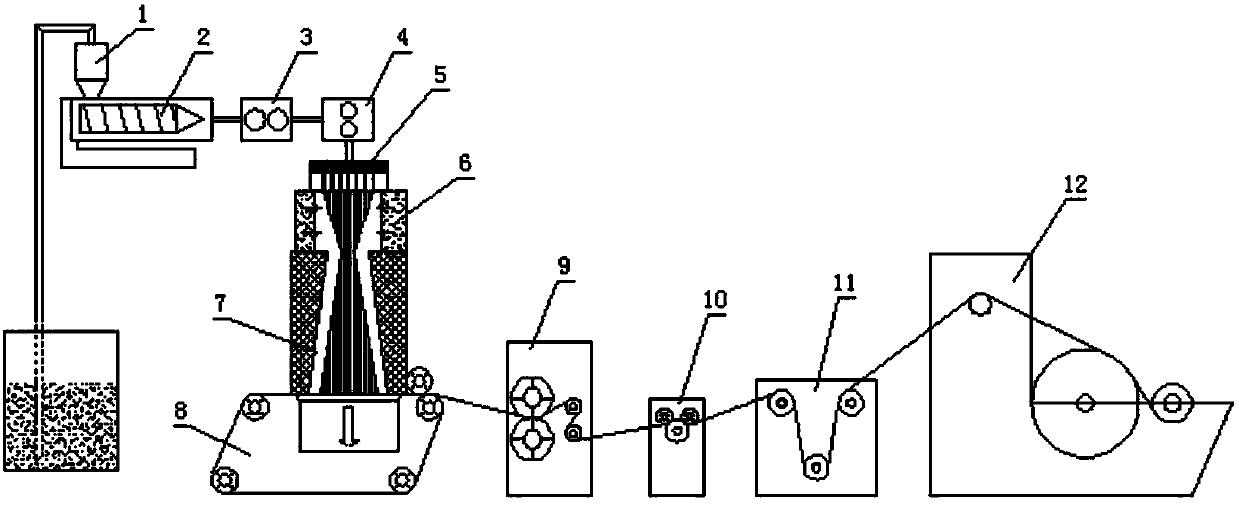

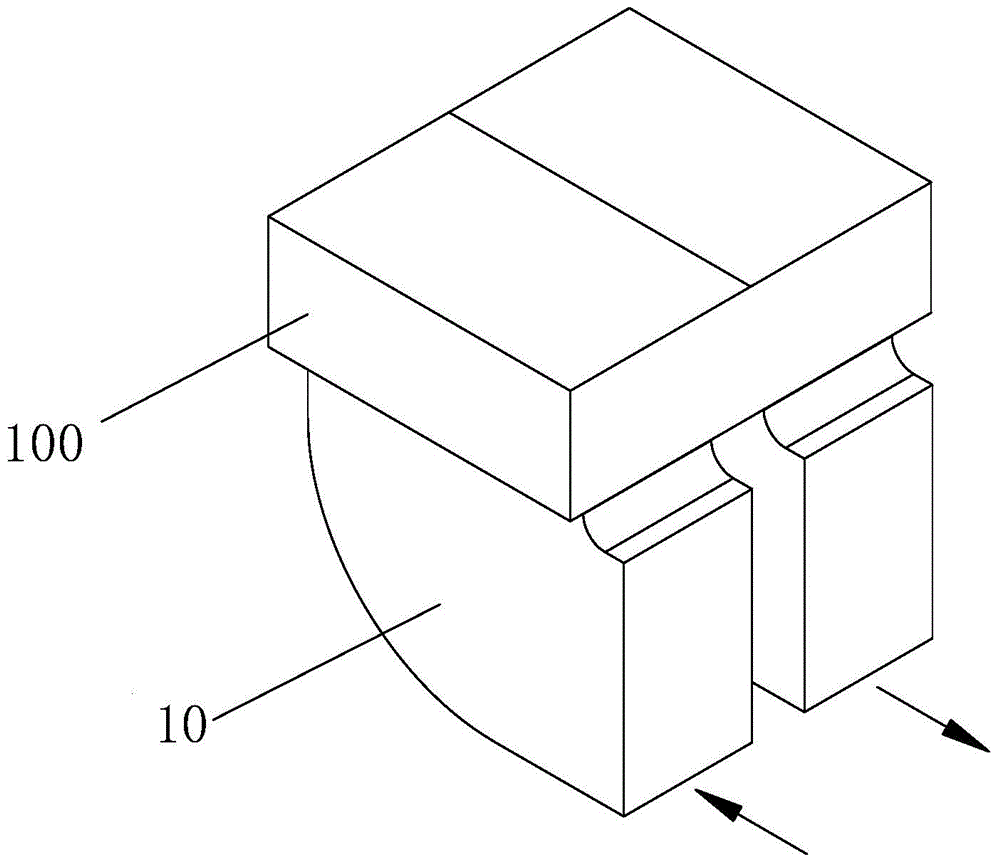

Integrally-formed low-gram-weight composite air-laid paper

ActiveCN106012309AImprove drynessMeet the strength requirements of high-speed productionNon-woven fabricsAdhesivesComing outSurface layer

The invention relates to integrally-formed low-gram-weight composite air-laid paper. A low-gram-weight air-laid paper layer prepared from fluff pulp and superfine hot-melting staple is arranged on the surface layer of the air-laid paper, and a non-woven cloth layer prepared from hot-melting chemical fiber is arranged on the bottom layer of the air-laid paper. Fluff pulp boards are roughly smashed and fine smashed for fiber decomposition to form fluff pulp fiber, the fluff pulp fiber and the superfine hot-melting staple are quantitatively and uniformly sprayed on a net band, and the superfine hot-melting staple and the fluff pulp fiber are subjected to heat bonding through an oven air duct to form the low-gram-weight air-laid paper layer; the non-woven cloth layer is subjected to glue applying or directly compounded with the air-laid paper layer coming out of the oven air duct to form the low-gram-weight composite air-laid paper. According to the low-gram-weight composite air-laid paper, the heat bonding of the air-laid paper layer and the non-woven cloth layer is achieved through hot pressing points or ultrasonic waves. Due to integrally-formed composite non-woven cloth, the strength of the composite air-laid paper is much higher than that of traditional air-laid paper, and the strength requirement for air-laid paper materials during high-speed production on a moisture-absorption article device is met.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

Petroleum propping agent with ultra-low density and high strength

InactiveCN102002356AReduce breakage rateLow density and high crushing rateFluid removalHydraulic fracturingALUMINUM PHOSPHATE

The invention discloses a petroleum propping agent with ultra-low density and high strength. The petroleum propping agent is prepared by uniformly mixing 30 to 50 weight percent of white mud, 30 to 50 weight percent of kaolin and 10 to 20 weight percent of feldspar serving as raw materials, adding a reinforcing agent such as aluminum sol, silicon sol or aluminum phosphate sol and the like in an amount which is 2 to 5 percent of the total weight of the three raw materials and performing wet ball milling, superfine grinding, spray drying, rolling forming, drying, screening and high-temperature sintering. The petroleum propping agent with ultra-low density and high strength has the characteristics of ultra-low apparent density, high strength and low crushing rate, so the propping agent has good flow conductivity, can quickly fill fractures in hydraulic fracturing, effectively props the fractures all the time after the hydraulic fracturing is finished, prevents reclosing of the fractures,enables the stratum fluid to enter the fractures in a linear mode, improves the hydraulic fracturing effect, and is favorable for petroleum yield increment. Meanwhile, the local resources can be fully utilized as raw materials for preparation so as to reduce the manufacturing cost of the propping agent.

Owner:徐益民 +3

Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

InactiveCN107904787AFluffy goodExcellent suction speedNon-woven fabricsBandagesReverse osmosisEngineering

The invention discloses a spun-bonded non-woven fabric for a diaper diversion layer and a production technology of the fabric. The non-woven fabric comprises an absorption core which is formed by coarse denier fiber, the direction of the coarse denier fiber is the longitudinal direction, the pattern of the coarse denier fiber is the strip pattern, the pattern of the absorption core is the patternof the character 'yi', and the pattern direction of the absorption core is consistent with the fiber direction. Compared with the prior art, the fabric has the advantages that a hot wind non-woven fabric can be replaced, the production speed of the spun-bonded non-woven fabric is higher than that of the hot wind short fiber, the cost is low, and the effect is good; the coarse denier product is good in diversion effect, diffusion is accelerated, the diffusion length is increased, and the amount of reverse osmosis is lowered; compared with ordinary hot wind non-woven fabrics and other products,the fluffiness is better, and the liquid absorbing speed is higher.

Owner:山东恒鹏卫生用品有限公司

Wet desulphurization mechanism

ActiveCN103953939AImprove heat transfer efficiencyEliminate risks such as blockage downtimeChimneysPlate heat exchangerEngineering

The invention discloses a wet desulphurization mechanism. The wet desulphurization mechanism comprises an original smoke deflector and a smoke heat exchanger, wherein an original smoke opening is formed in the smoke heat exchanger, the cross section of the original smoke opening is rectangular, the original smoke deflector comprises a first elbow and a second elbow, the cross sections of the first elbow and the second elbow are round, and both the first elbow and the second elbow are mounted on the original smoke opening of the smoke heat exchanger. As the first elbow and the second elbow, of which the cross sections are round, are arranged at the original smoke opening of the smoke heat exchanger, smoke can be shunt by the first elbow and the second elbow before entering the smoke heat exchanger, and sufficient bending spaces are available at the first elbow and the second elbow. Besides, the first elbow and the second elbow have smaller round cross sections and great deflecting functions, the whole flow field becomes more uniform, the heat exchange efficiency of the smoke heat exchanger is effectively improved, and the risks that the easily torn deflector plate designed in the traditional rectangular runner causes corroded cracks, corroded flues, runner blocking shutdown and the like are eliminated.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Design method of pressure measuring rake special for deformed flow channel of wing body fusion airplane ventilation model

ActiveCN111551339ATotal pressure distribution measurement accuracy guaranteeImprove matchAerodynamic testingMechanical engineeringMechanics

The invention discloses a design method of a pressure measuring rake special for a deformed flow channel of a wing body fusion airplane ventilation model. According to the invention, the design methodcomprises the steps: acquiring the flow characteristics of the deformed inner flow channel under the interaction of the inner flow of the inner flow channel and the outer flow of the model through anumerical simulation method; performing sub-region division on a measurement cross section according to a numerical simulation result; taking the areas of the sub-regions as weights of calculation ofinternal flow parameters in the sub-regions, determining the number and position distribution of total pressure measuring points and static pressure measuring points on a measuring cross section, anddesigning a rake body to reduce the blocking interference effect. Therefore, the special pressure measuring rake suitable for the deformed internal flow channel of the wing body fusion layout airplaneventilation test model is designed through the process.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

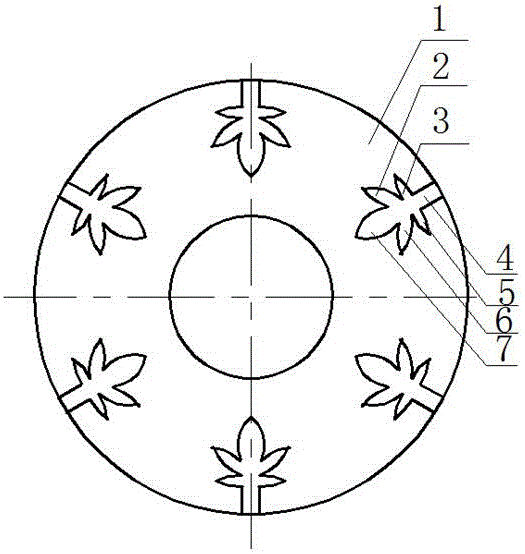

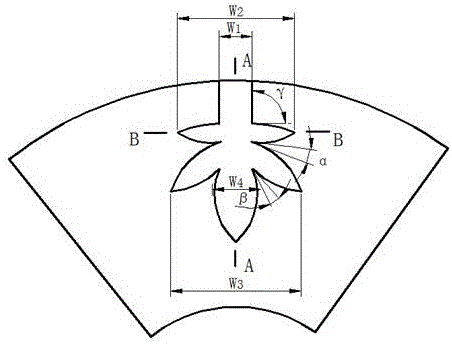

Mechanical seal ring with maple-leaf-like grooves

The invention relates to a mechanical seal ring with maple-leaf-like grooves. 2-50 maple-leaf-like grooves are circumferentially and evenly distributed in one end surface of the seal ring and are 1-100 mu m deep; each maple-leaf-like groove comprises a radial linear groove and five grooves, four of the five grooves are symmetrically distributed on two sides of the radial linear groove, another groove is connected with one end, close to the inner diameter of the seal ring, of the radial linear groove, and the radial linear groove is opened in the edge of the outer diameter of the seal ring; and the maple-leaf-like grooves are symmetric about the radial central axis. The seal ring is applicable to one-way rotation and two-way rotation machinery, is used for liquid sealing or dry gas sealing, can effectively reduce abrasions of seal end surfaces, has the relatively good flow guiding effect, the better opening force and the smaller leakage amount, has the better sealing effect and dynamic pressure performance, runs more stably and is wider in application range, and the cost is saved.

Owner:云南流体规划研究院有限公司

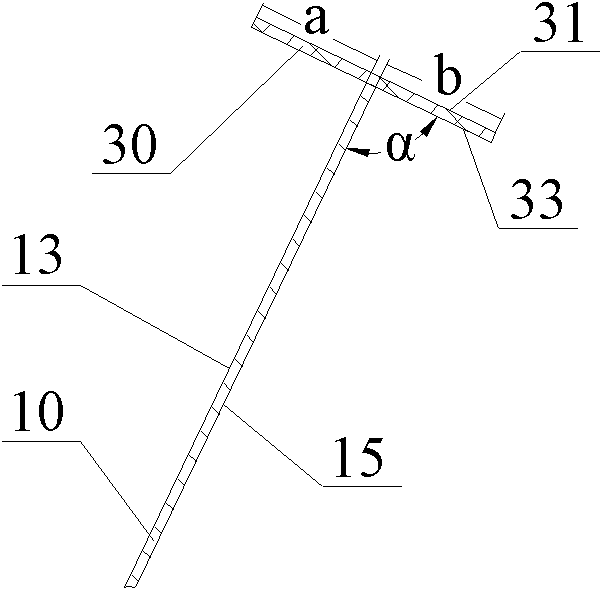

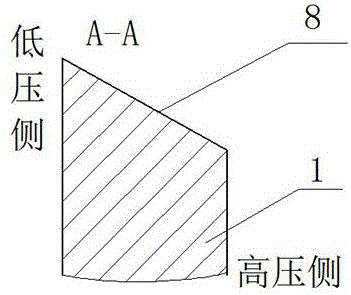

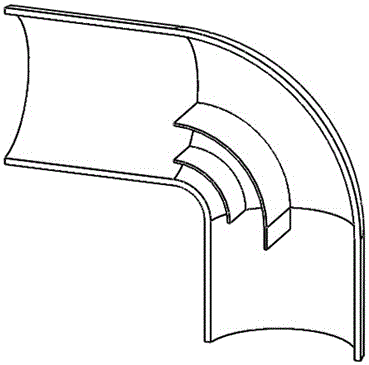

90-degree bent pipe guide piece arrangement method

The invention discloses a 90-degree bent pipe guide piece arrangement method. The 90-degree bent pipe guide piece arrangement method comprises a 90-degree bent pipe, a guide piece A and a guide piece B. Two guide pieces are arranged in the 90-degree bent pipe, and are respectively the guide piece A and the guide piece B; the guide piece A is near the inner side of the bent pipe; and the guide piece B is near the outer side of the bent pipe. The guide pieces are arranged according to a golden ratio, that is, the guide piece B is arranged in the inner diameter place of the bent pipe from the inner wall of the outer side of the bent pipe by 0.618 time, and the guide piece A is arranged on the guide piece B from the inner wall of the inner side of the bent pipe by 0.618 time in the longitudinal section of the bent pipe. In the fluid flowing direction, after the guide piece B passes through the bent pipe, one part of extension section is generated; and the distance of the extension section is 0.3 time of the inner diameter of the bent pipe. The guide pieces in the bent pipe are reasonably arranged to reduce or eliminate complex flowing conditions in an elbow, so that the flowing field distribution is effectively improved, the pipe noise caused by unstable flowing is reduced, the reliability of the bent pipe is improved, and the service life is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

Proppant and preparation method thereof

The invention discloses a proppant and a preparation method thereof, and belongs to the technical field of oil and gas exploitation. The proppant comprises an aggregate and at least two layers of resin coated films coated on the aggregate, wherein the weight ratio of the aggregate to the resin coated film is 100:3-100:13; and the aggregate is quartz sand, ceramsite, glass microspheres, sintered bauxite, sintered aluminum oxide, sintered zirconium oxide or a mixture thereof, and the size of the aggregate is 10-200 meshes, preferably 20-70 meshes. By virtue of a multilayer film coating technology, the sphericity of the proppant can be improved, the density of the proppant can be reduced, and the chemical inertness and strength can be improved. The proppant disclosed by the invention can be widely applied to oil and gas field exploitation, is beneficial to improvement of the sand ratio, reduces the usage of fracturing fluid, eases the embedding of the proppant, improves the water resistance of the proppant, improves the fracture conductivity, and prolongs the effective fracturing period.

Owner:BEIJING RECHSAND SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com