Method for improving productivity of hydraulic fractured well through compound activator

A hydraulic fracturing and activator technology, which is applied in the field of fracturing fluid for oil drilling, can solve the problems of low permeability in low-permeability reservoirs, difficulty in microbial injection, and inability to achieve migration, so as to improve conductivity and increase production Effect, the effect of improving the conduction energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

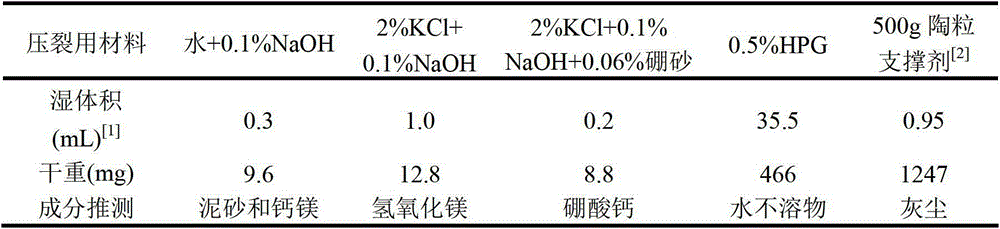

[0066] Test of the properties of the fracturing fluid residue to be tested:

[0067] In order to reveal the source of fracturing fluid residues, the experiment was designed as follows:

[0068] ① Prepare the aqueous solutions of various fracturing additives with on-site water samples, and observe them after standing for several days.

[0069] ②Take a single solution and mix with each other to observe the compatibility with each other.

[0070] ③ If a precipitate precipitates, centrifuge the precipitated precipitate, and measure the mass after drying at 105°C to constant weight.

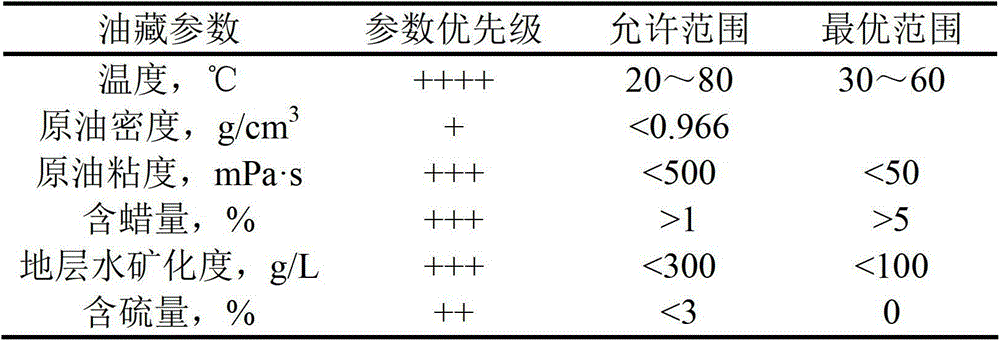

[0071] Table 2 Amount of water-insoluble matter from different sources in HPG fracturing fluid (1L)

[0072]

[0073] Note: 1. 3000r / min centrifugal volume for 20 minutes; 2. Puyang Tongzhou Ceramsite Sand Factory 0.45~0.90mm, 69MPa ceramsite.

[0074] Test results: Potassium chloride aqueous solution contains a small amount of black water-insoluble matter, which is dissolved in brownish-yellow...

Embodiment 2

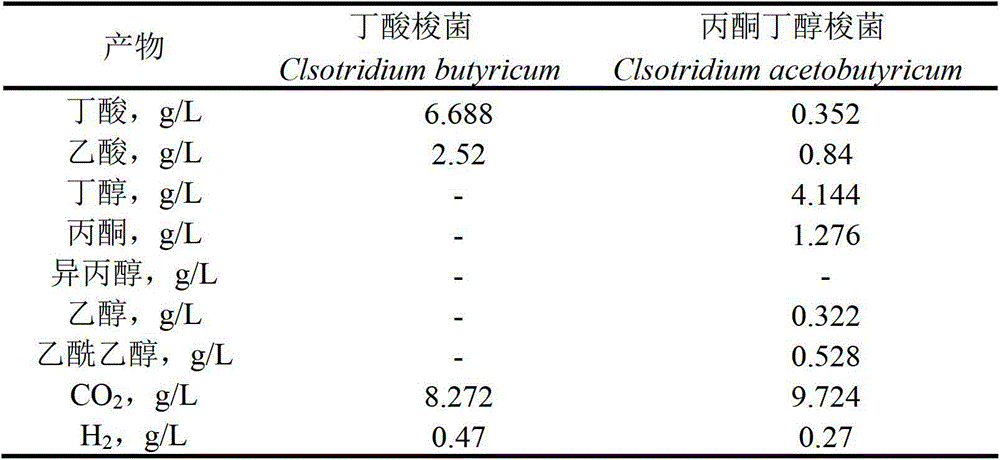

[0078] Guar gum anaerobic degradation test: Clostridium butyricum (Clsotridium butyricum CGMCC1.336) and Clostridium acetobutyricum (Clsotridium acetobutyricum CGMCC1.70) were used in the anaerobic degradation test of guar gum, wherein the concentration of Clostridium butyricum in the Clostridium butyricum bacterial agent was 2~5×10 7 CFU / ml, the amount of the microbial agent in the filtrate is 1% of the volume of the filtrate by volume ratio; the concentration of microorganisms in the Clostridium acetonebutylicum agent is 2~5×10 7 CFU / ml, the amount of the microbial agent in the filtrate is calculated as 1% of the volume of the filtrate by volume ratio; its gel breaking ability in the formation is tested according to the method of "SY / T5107-2005 Water-based Pressure Fluid Performance Evaluation Method" . The test was filled with N 2 The lactic acid tube was carried out, and the guar gum after ammonium persulfate (APS) was broken was used as the nutrient substrate. The gas...

Embodiment 3

[0084] Microorganisms used in guar gum damage formation plugging removal performance evaluation experiment:Use the low-permeability natural core of Songnan igneous rock, drill the natural core in the direction parallel to the fluid flow of the reservoir to drill a cylinder, grind the two ends flat, and be perpendicular to the smooth cylindrical surface. The diameter of the core is 25mm-25.4mm or 37mm-38mm, and the length of the core is 1-1.5 times of the diameter. Prepare three rock cores of the same specifications according to the above standards, named respectively as rock core A, rock core B, and rock core C, and reserve them for later use in the experiment; the cleaning and drying of the rock cores are carried out in accordance with SY / T5336-1996, and the gas permeability of the rock cores after cleaning and drying And the determination of pore volume is carried out according to SY / T5336-1996. The determined rock core shall establish the irreducible water saturation acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com