Patents

Literature

65results about How to "Improve uniform distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

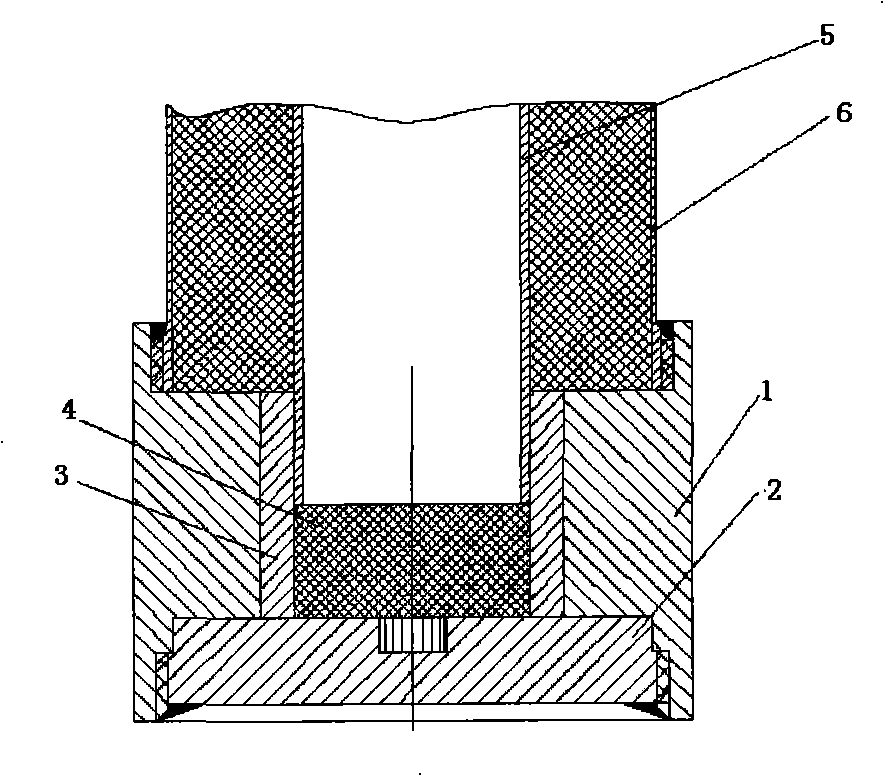

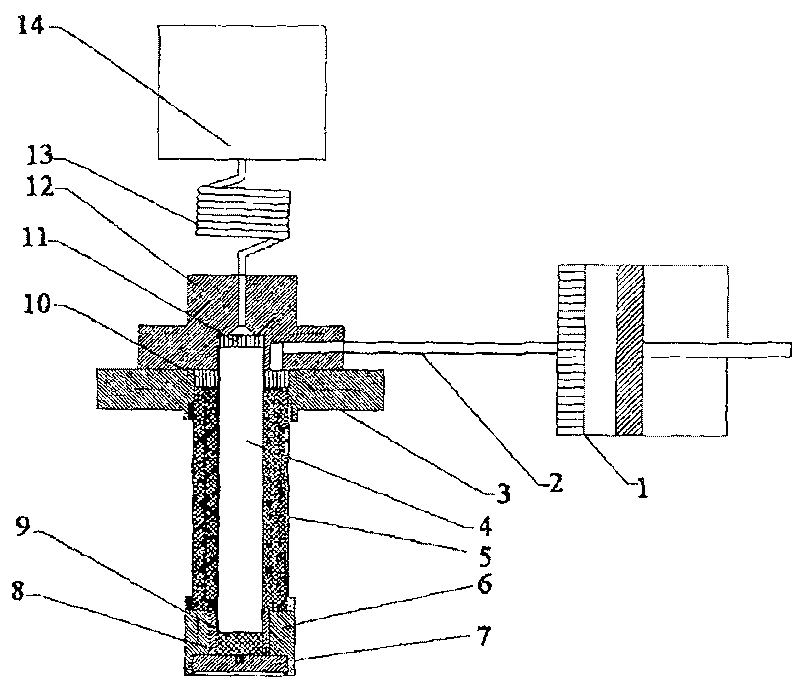

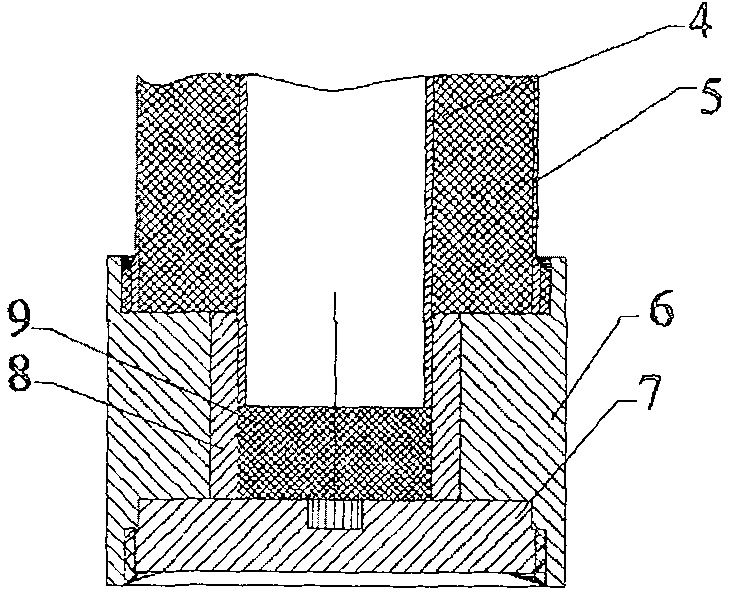

Screw thread welding integral narrow slit type cold junction for coaxial pulse-tube refrigerator

InactiveCN101298948AIncrease the heat exchange areaSmall pressure lossCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

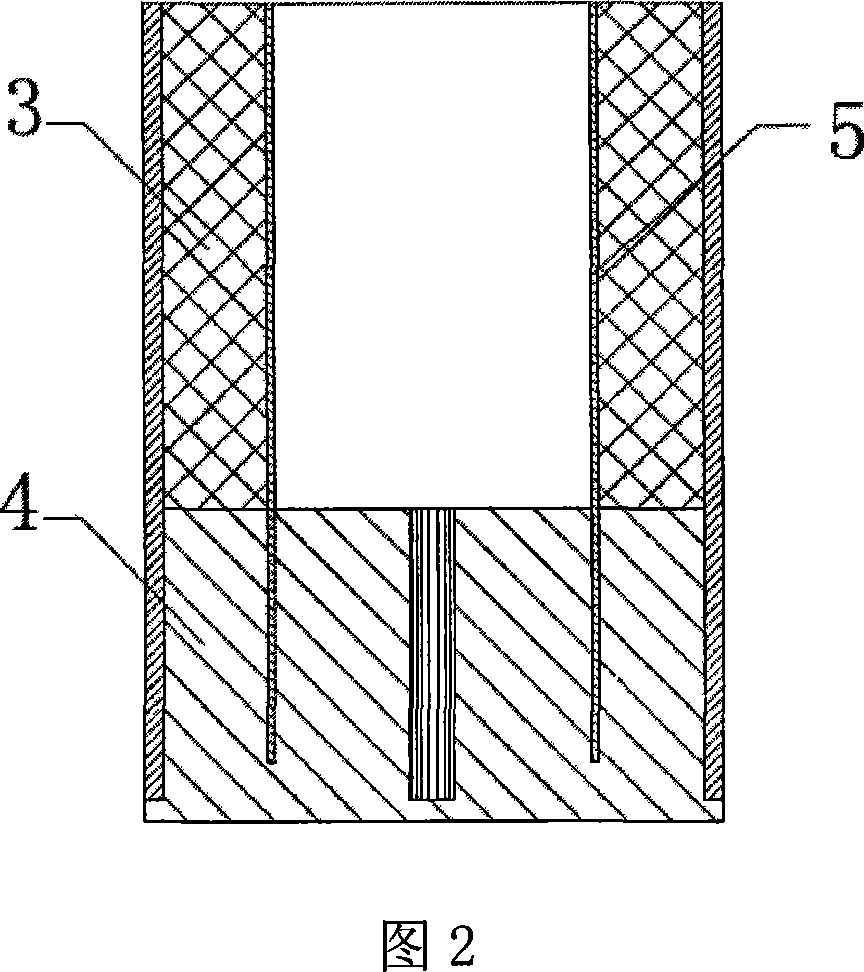

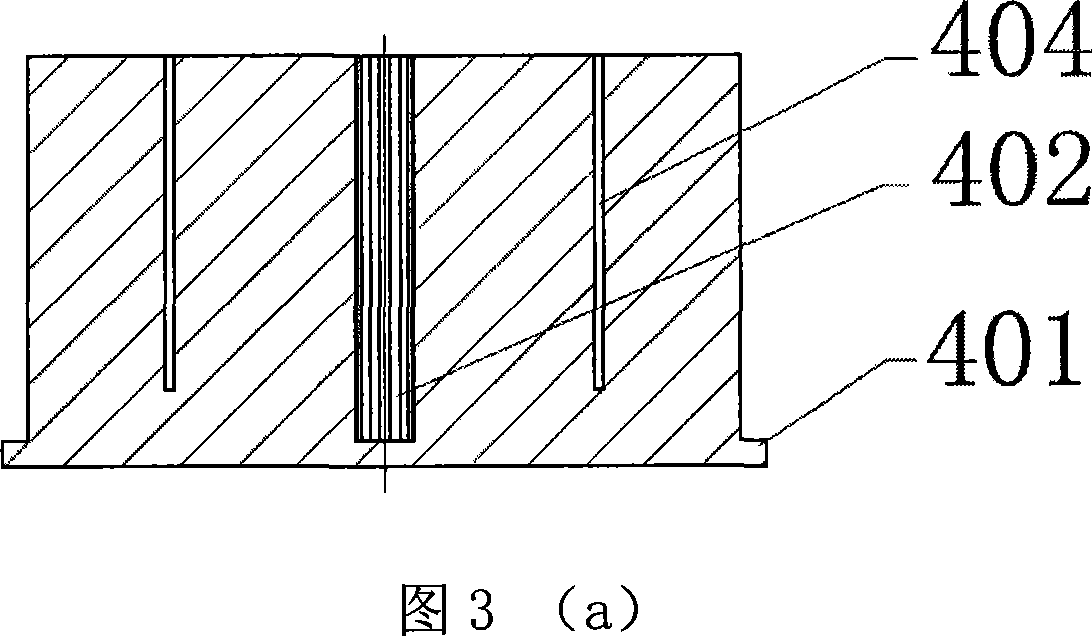

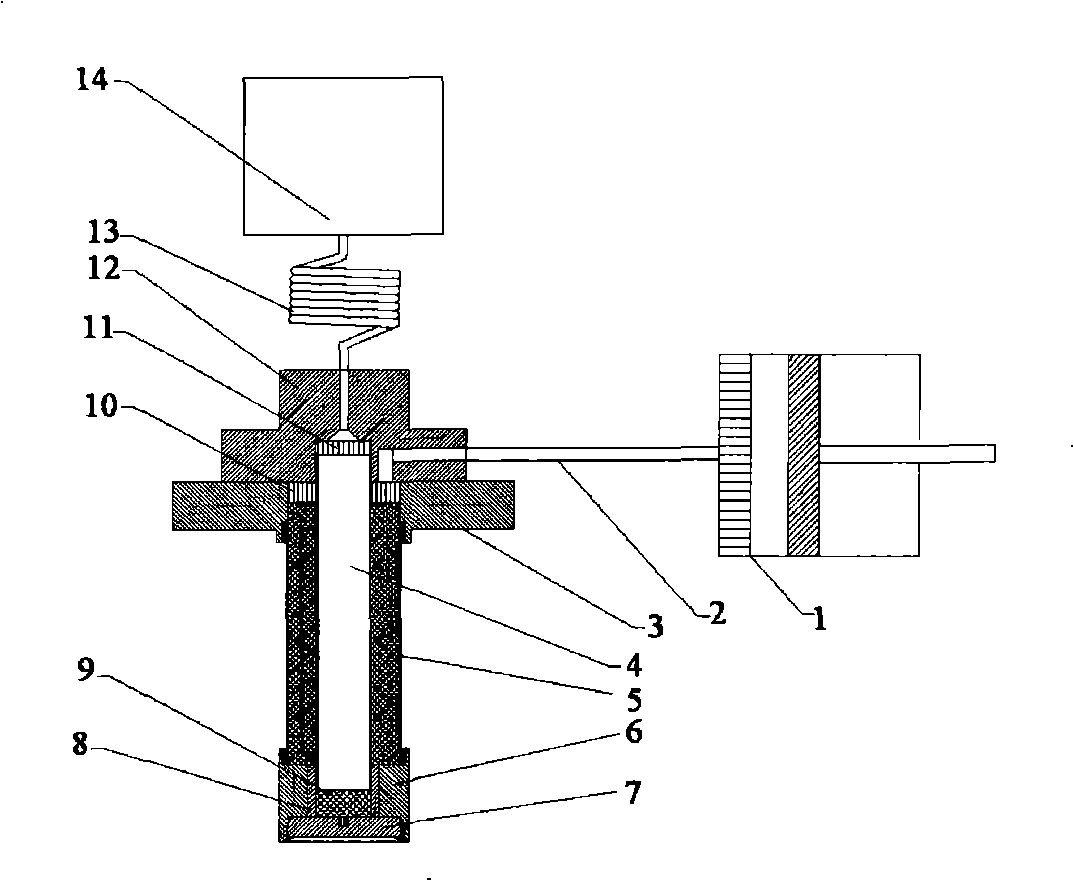

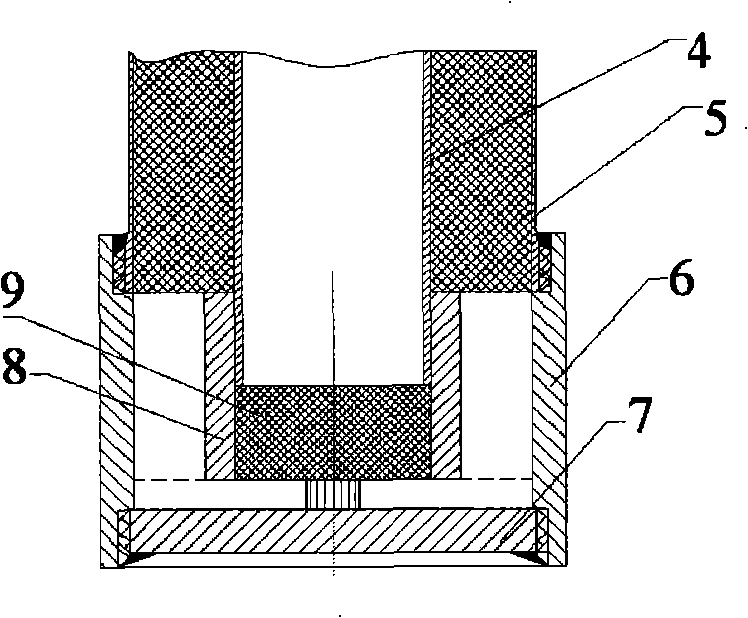

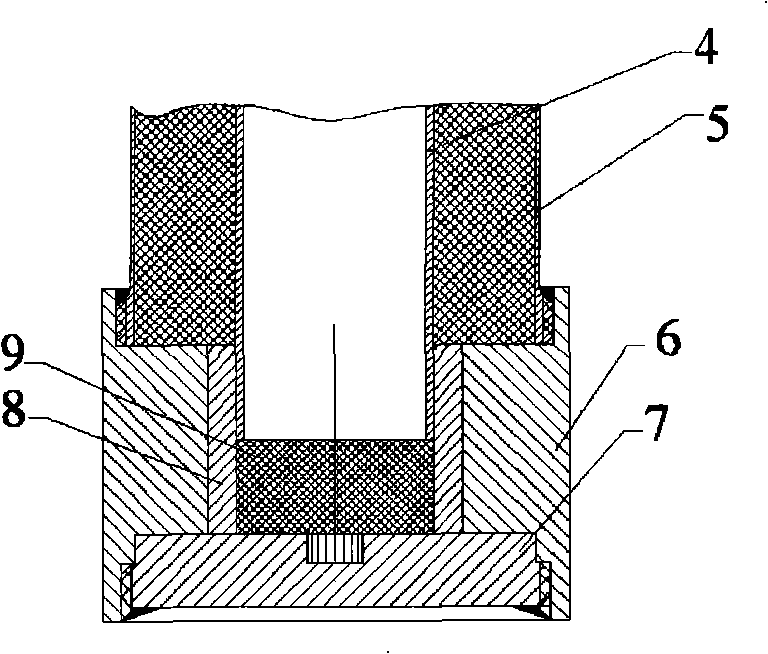

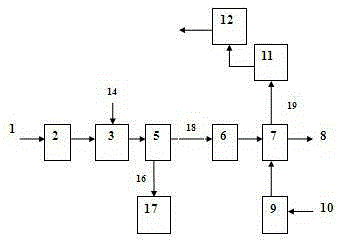

The invention discloses a thread weld integral slit type cold head of the coxial vessle refrigerator in the refrigeration technology field, including an upper cold head, a lower cold head, a cold end baffle and a copper wire, wherein the upper cold head and the lower cold head are welded again after the threaded connection, the cold baffle is arranged at the middle of the cold head integer, and the cold baffle is filled with the copper wire, wherein the lower cold head is divided into a base seat and a boss having the uniformly distributed slots in the axial symmetry. The depth of the slot is the same with the height of the boss, and the external thread is arranged at the cirumferential of the base seat; a cylinder is arranged on the upper cold head, a round hole at the center and radial slots in the distributed uniformly arranged at the cirumferential of the round hole. The width of the slot is consistent with the slot of the lower cold head; the internal thread structure of the upper cold head is matched with the external thread of the lower cold head, with the other end in the thread match with the cold accumulator, and is left with the margin for welding after being matched. The invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

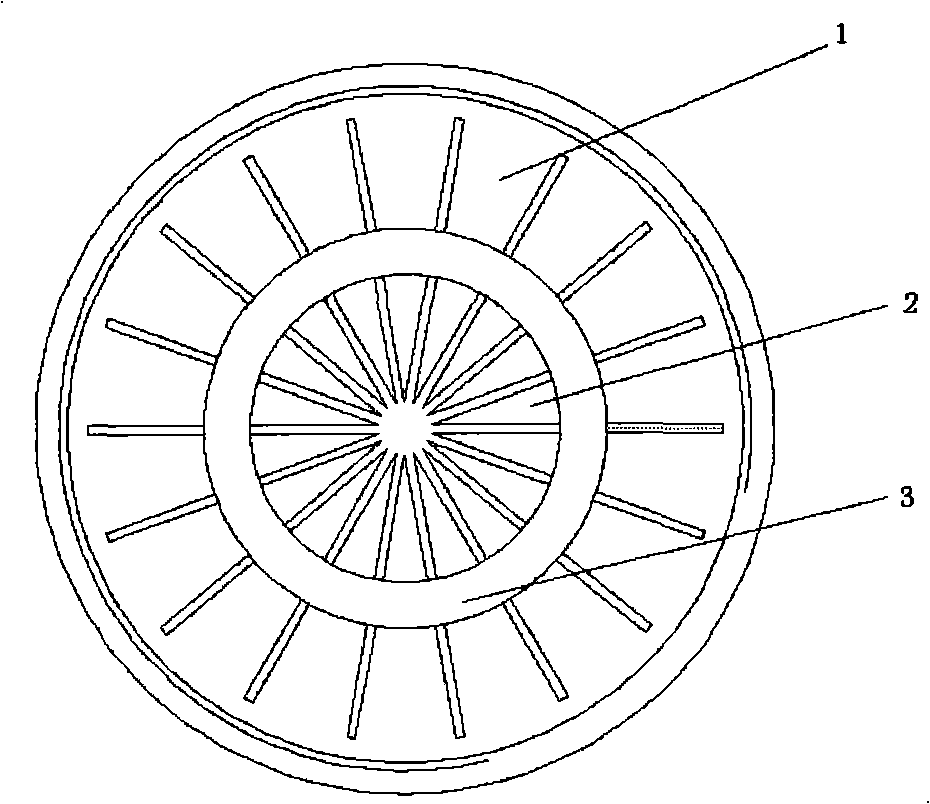

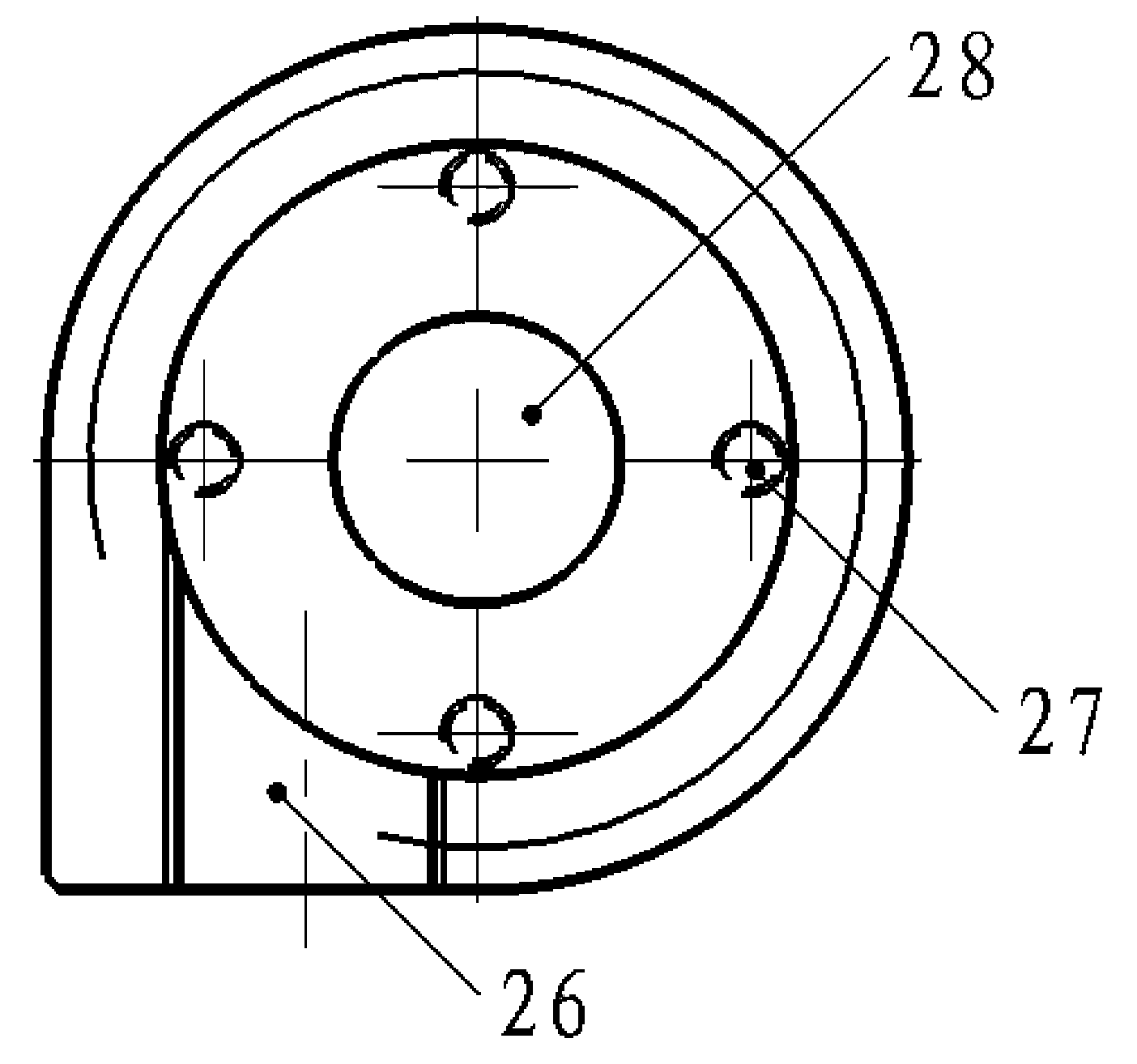

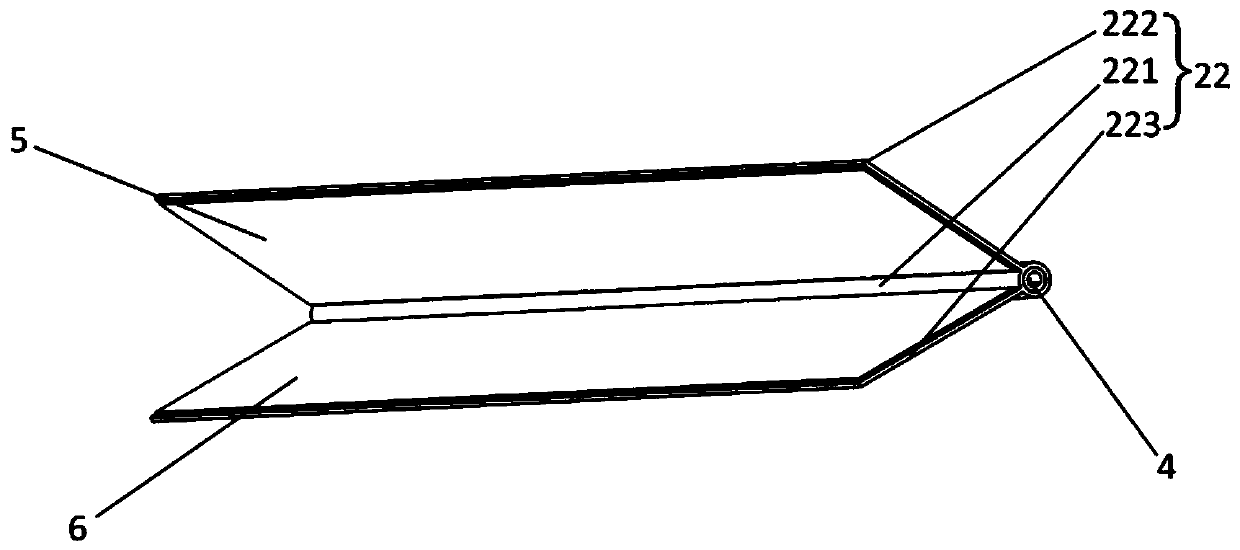

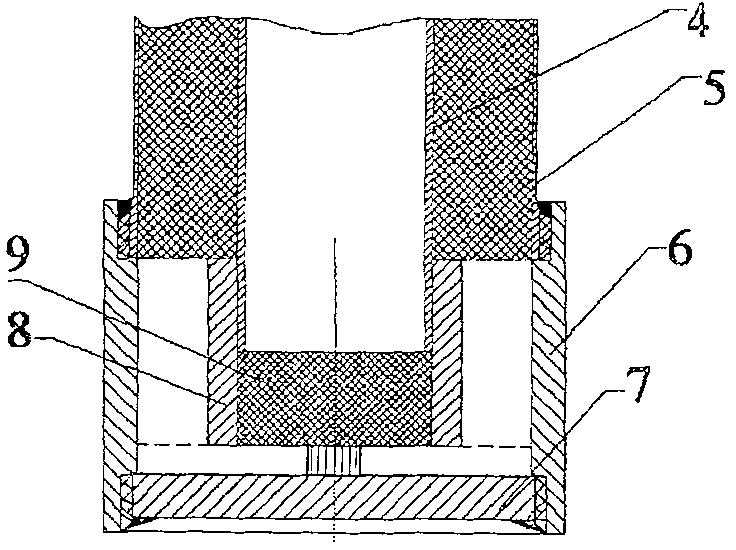

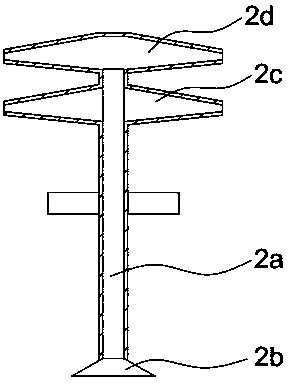

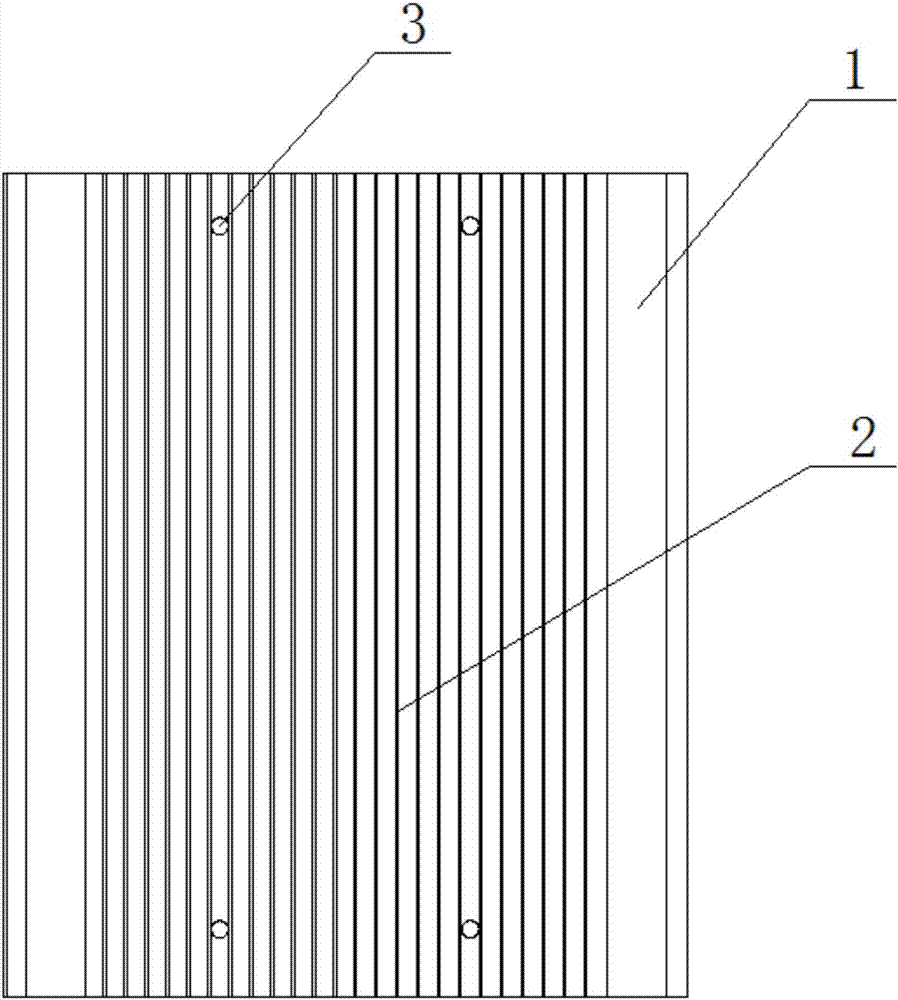

Integrated cold head used for co-axial pulse tube refrigerator

InactiveCN101067523AImprove uniform distributionImprove the diversion effectCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

A kind of integrated cold head is used to the coaxial vas freezer and the cold head is made of the high heat conductivity material and at the bottom along the outside around there is a flanged edge used to weld with the shell of storage cold equipment and in the middle of it opens a round hole and around of the round hole opens radial gap uniformly and the depth of gap is the same with the depth of round hole and there is coaxial opening a ring conduit used to the vas of freezer for inserting. The vas adapts with the inserted ring conduit tightly and the cold head adapts with the shell of storage cold equipment tightly and the flanged edge of cold head welds with the shell of storage cold equipment. So the outside of the ring conduit is the storage cold equipment's cold end gas uniform equipment and the inside of the ring conduit is the vas's cold end gas vane. And the gas in the storage equipment and the vas is conducted by the gap of the bottom of integrated cold head. The maxim merit of it is that: the heat exchange area is large and the affection of guiding flow is well and the points of welding are little and it can deliver the quantity of refrigeration of the vas freezer to the outside face of cold head effectively so it improves performance of the coaxial vas freezer largely.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

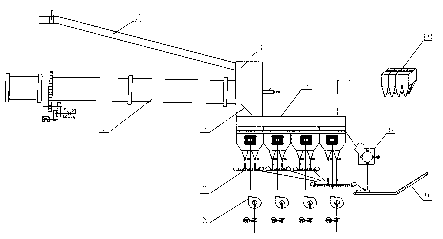

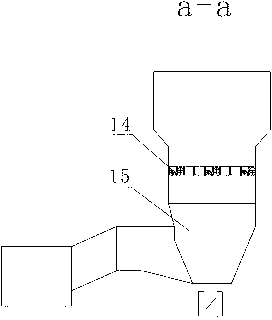

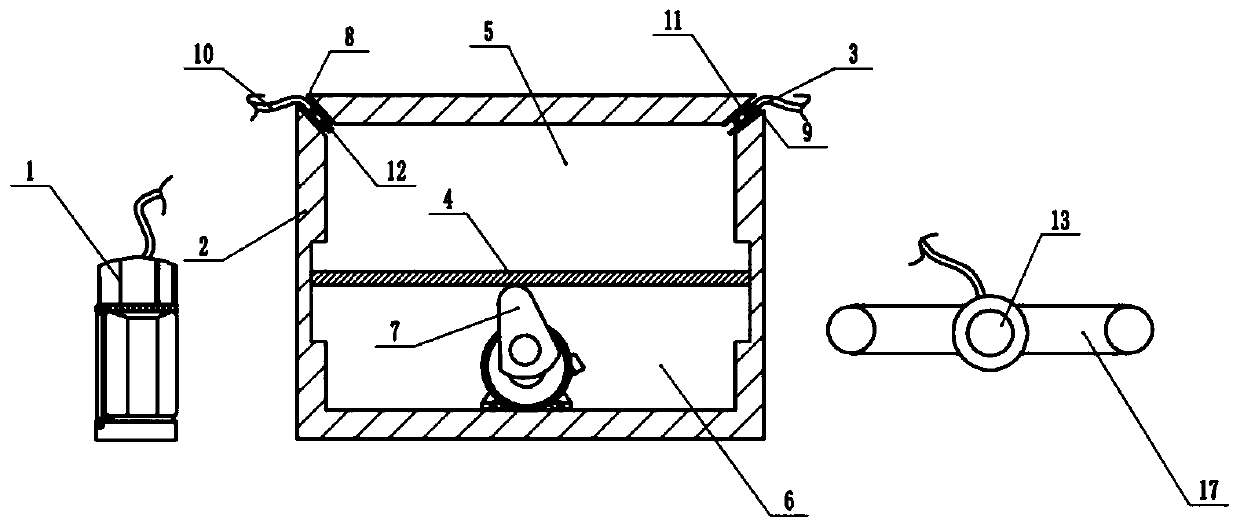

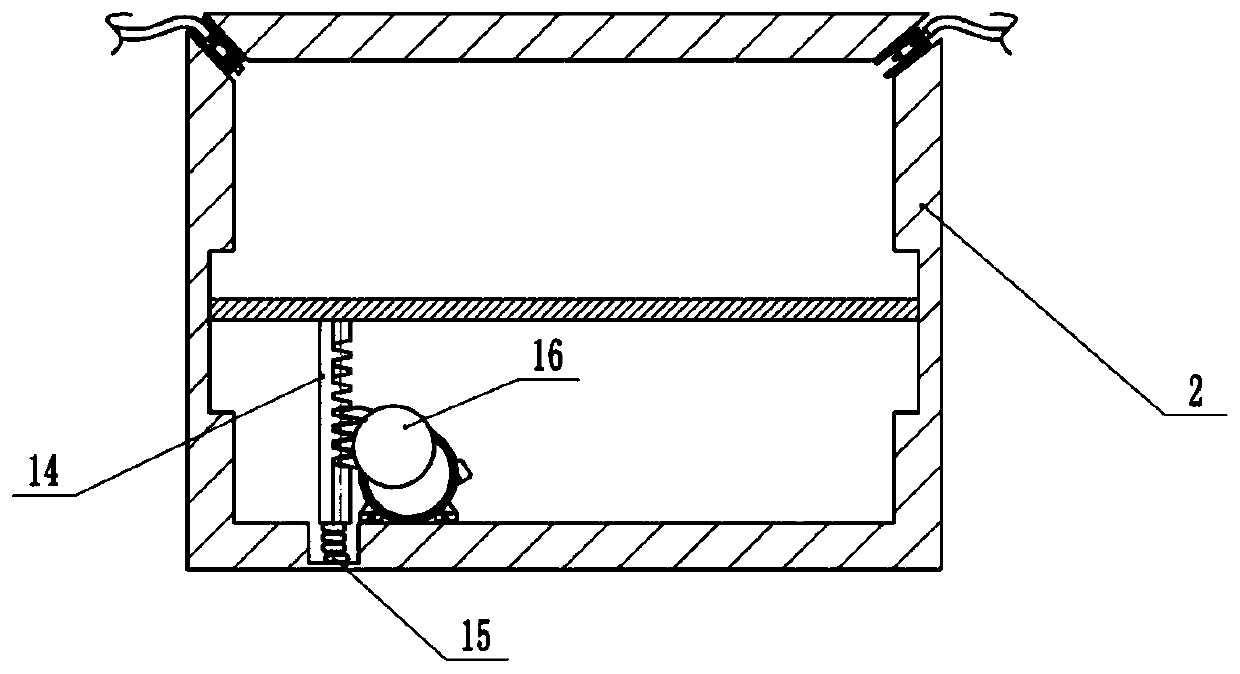

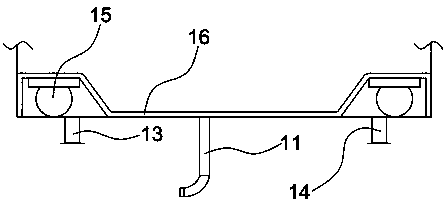

Multi-channel dumping grain drying machine

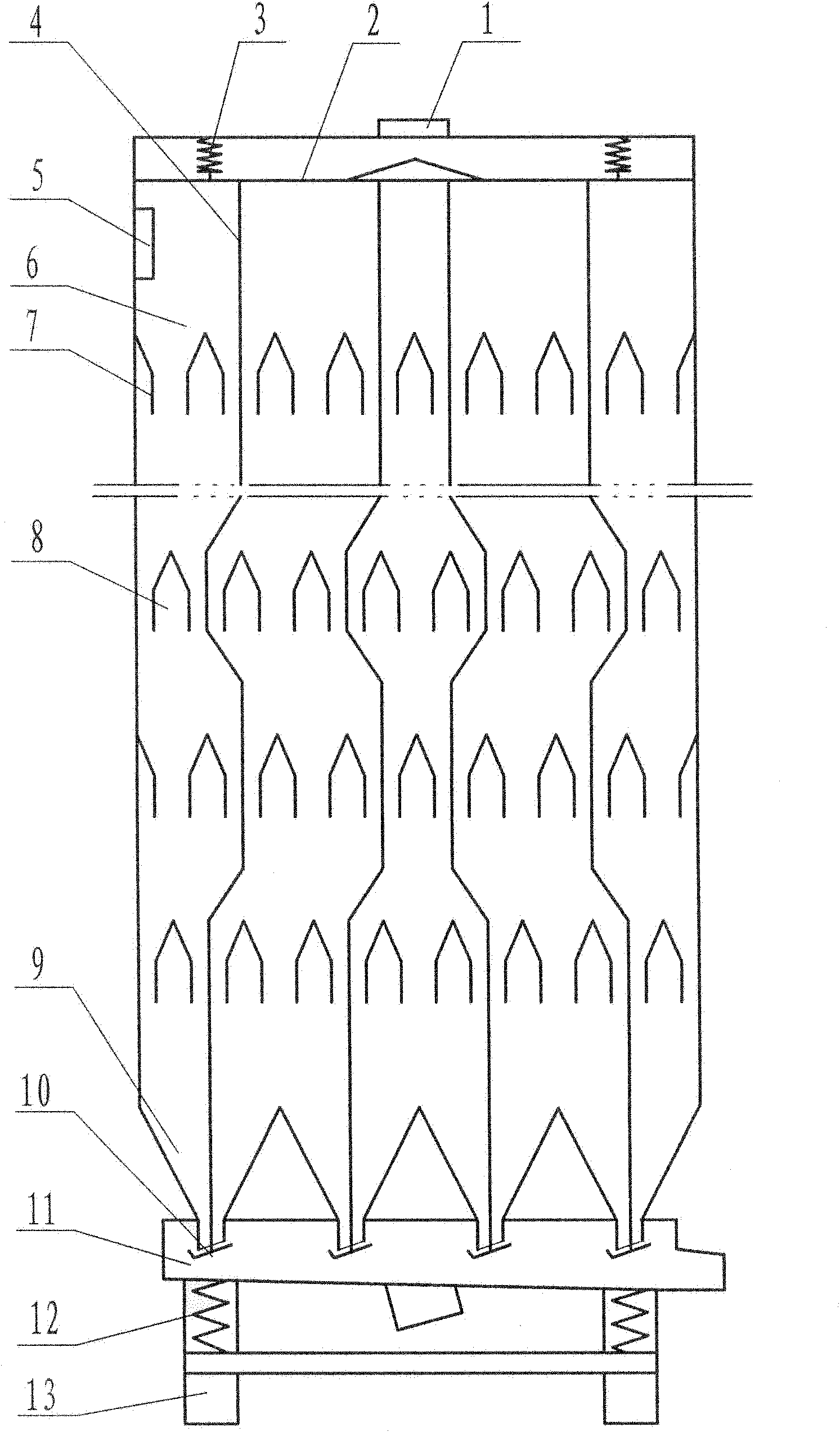

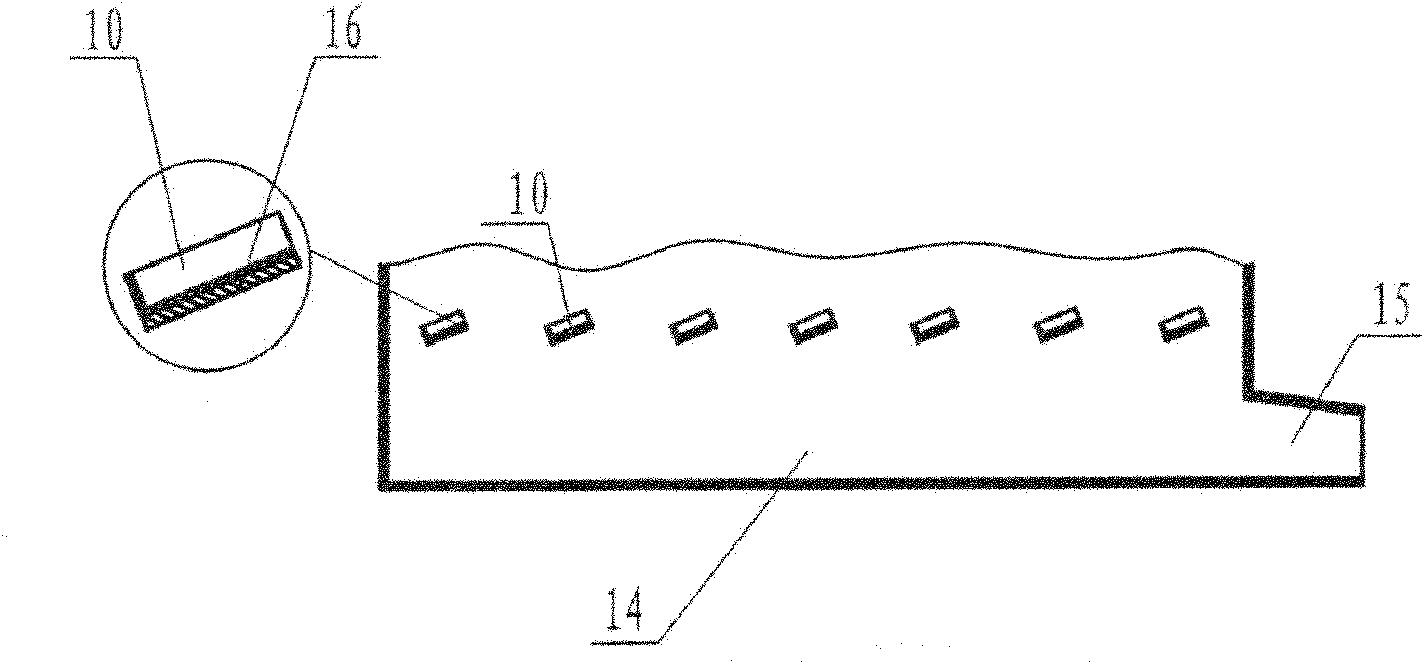

InactiveCN101946822AReduces accumulation of dead spaceUniform movementSeed preservation by dryingMechanical engineeringTetrahedron

The invention discloses a multi-channel dumping grain drying machine. The technical points include that: the lower part of the drying machine is a parallel dumping channel (9) composed of a tetrahedron inverse cone, a multi-channel dumping mechanism (11) is arranged on an elastic support (12), the aggregate bin (14) of the multi-channel dumping mechanism (11) is internally and uniformly provided with support frames (16), the mounting dip angle of the support frame (16) and the horizontal plane is 15-25 degrees. The support frame (16) is provided with metering blocks (10) with the same quantity of that of dumping channels; a distance of 10-50mm is kept between the metering block (10) and the dumping channel port (19) of the parallel dumping channel (9); a levelling grid (2) at the upper part of the drying machine is hung on an elastic hanger (3), the lower end of a guiding rod (4) is connected with a guiding rod support (25) on the metering block (10), the guiding rod (4) penetrates a drying chamber (6) upward from the dumping channel port (19) of the parallel dumping channel (9) of the drying machine, and the guiding rod (4) is connected with the levelling grid (2) at the top of the drying machine. The invention has the advantages that structure is simple, motion of material in the machine is uniform, material drying precipitation is uniform and drying speed is high, and drying quality of material can be fully maintained.

Owner:WUHAN POLYTECHNIC UNIVERSITY

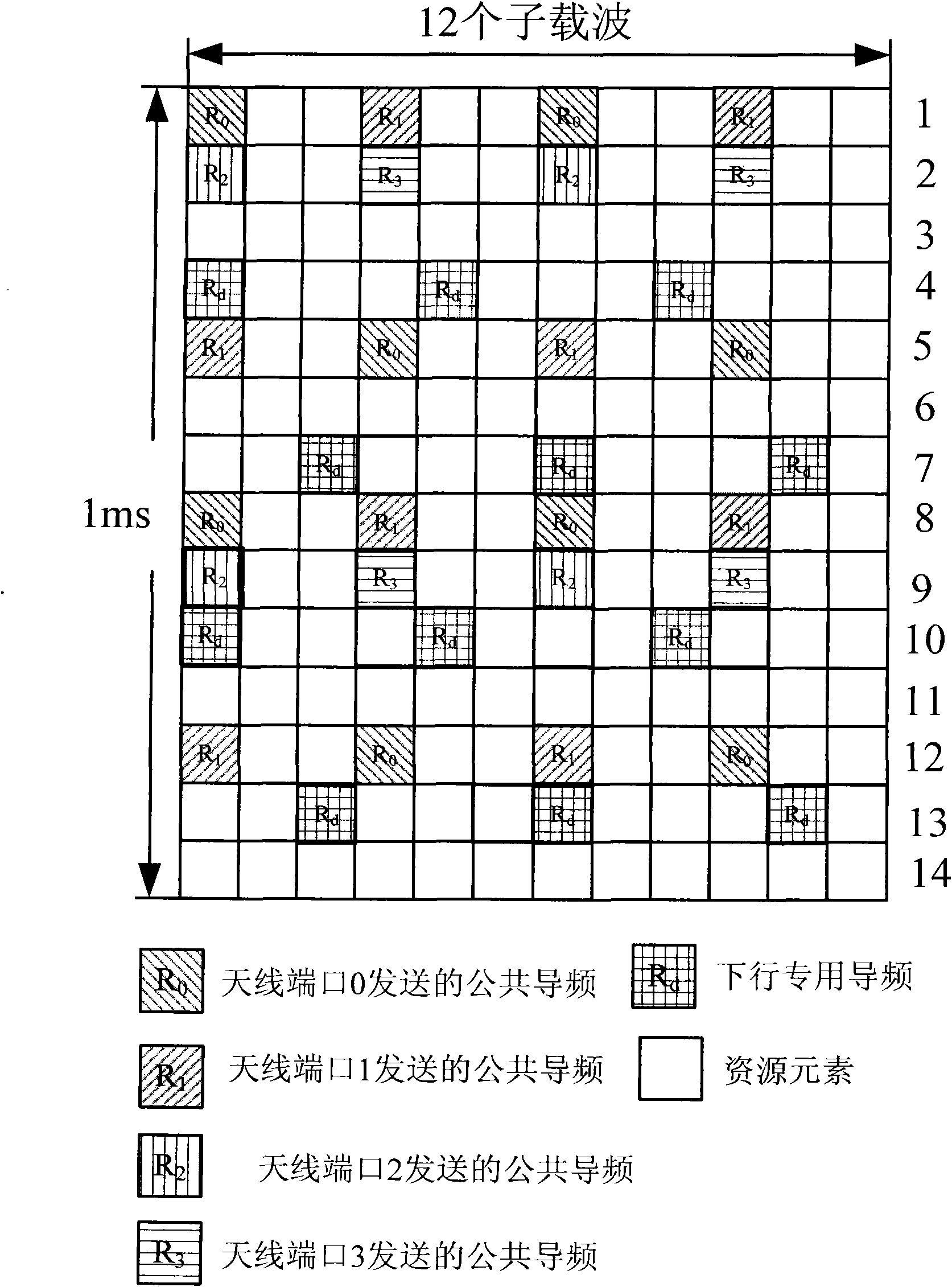

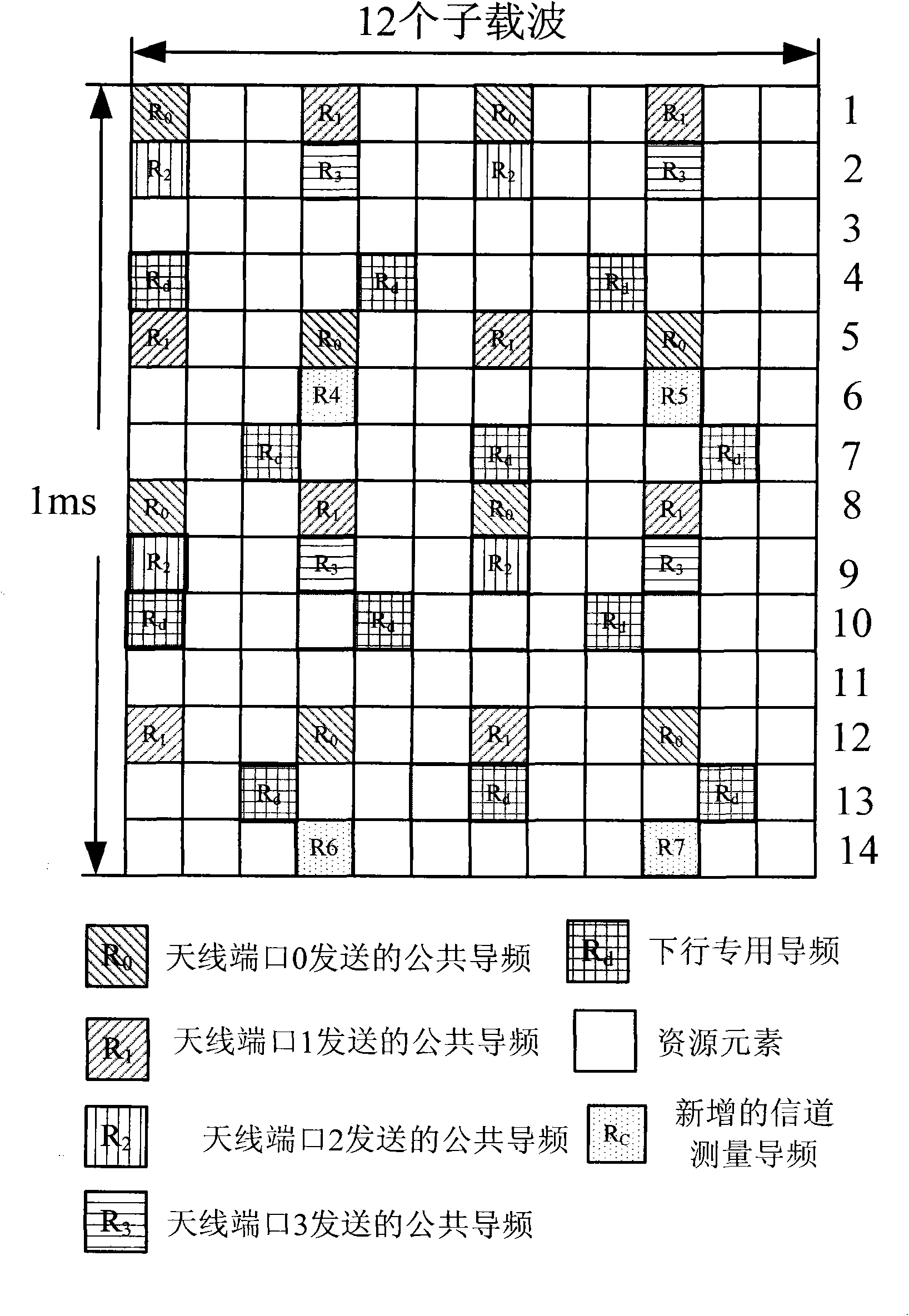

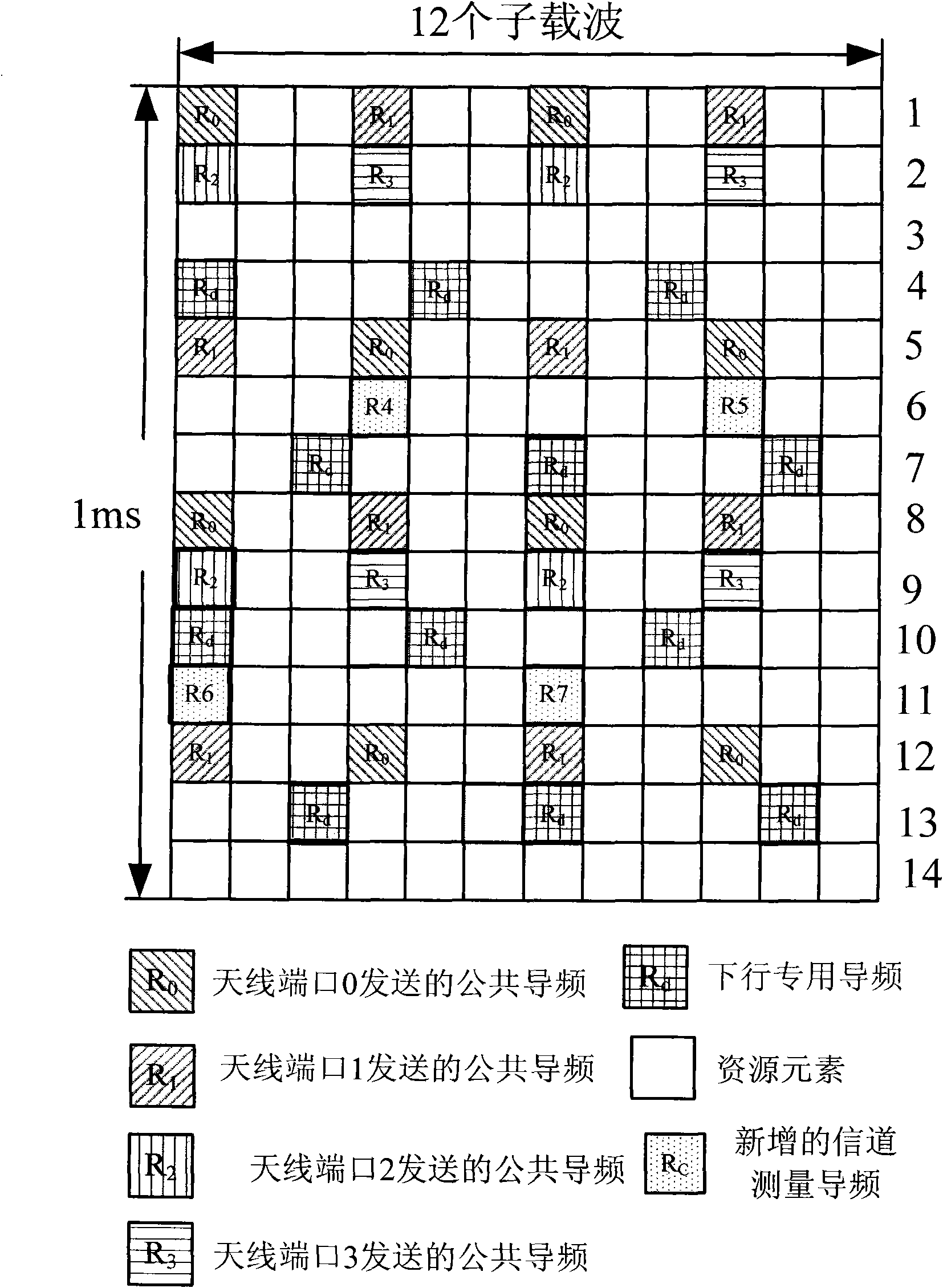

Mapping method of channel measurement pilot frequency and physical resource block

InactiveCN101867949AReduce overheadReduce performance degradationCriteria allocationSignal allocationResource blockBase station

The invention discloses a mapping method of a channel measurement pilot frequency and a physical resource block, which are applied in an advanced long-term evolution system, and comprises the following step that: the base station is provided with one or a plurality of antenna ports adopting a common pilot frequency specified in the long-term evolution system to be as the channel measurement pilot frequency, and is provided with the channel measure pilot frequencies of other antenna parts to avoid the mapping positions of the common pilot frequency and downlink dedicated pilot frequency in the long-term evolution system. The invention can save system overhead, and can not cause large influence on performance of the user of the long-term evolution system.

Owner:ZTE CORP

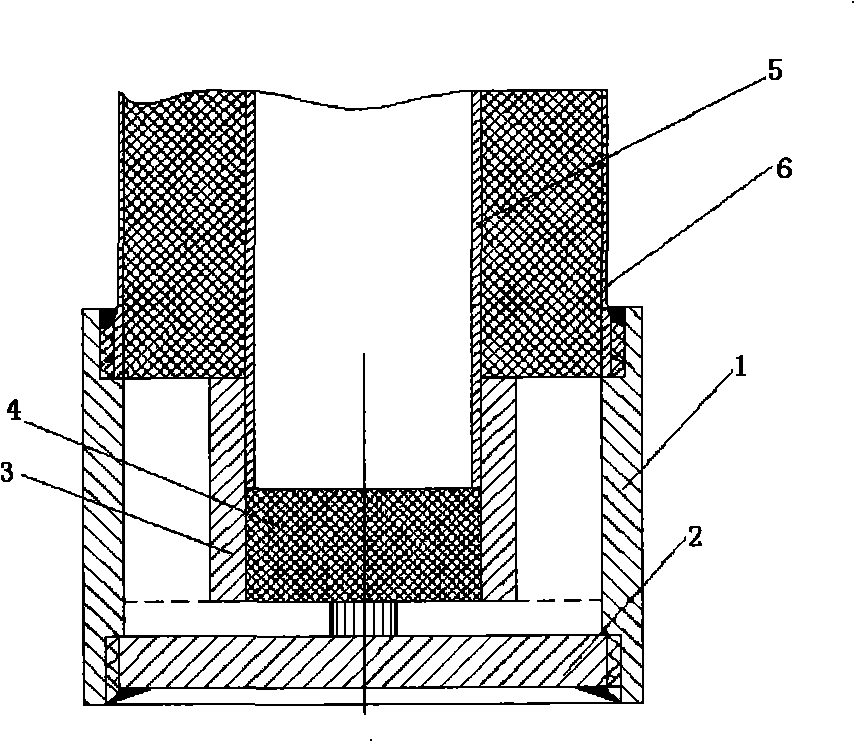

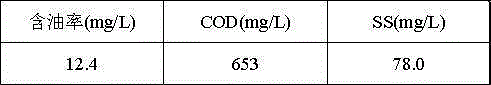

Screw thread welding integral narrow slit type coaxial pulse-tube refrigerator

InactiveCN101298947AIncrease the heat exchange areaGood diversion effectCompression machinesGas cycle refrigeration machinesCopper wireEngineering

The invention discloses a thread weld integral slit type coxial vessle refrigerator, including a compressor, an air line, a fire end flange, a vessle, a cold accumulator, an upper cold head, a lower cold head, a cold end baffle, a copper wire, a first fire end diffuser, a second fire end diffuser, a cold accumulator core plug, a long neck tube and an air reservior, wherein the two ends of the upper cold head have a internal thread with one end welded with the threaded connection of the lower cold head and the other end welded with one end of the cold accumulator after the threaded connection; a round hole is arranged at the center of the upper cold head, and radial slot distributed uniformly are arranged round the round hole; a cold end baffle is arranged in the round hole, and the part of the outside of the cold end baffle is the cold accumulator cold end air applicator part, while the inner part of the cold end baffle is the stacked copper wire and a vessle extending section of the vessle cold end diffuser. The air in the cold accumulator and the vessle communicate with the slot of the upper cold head and the lower cold head by the welding way. The cold head of the invention has large heat exchange area, and the welding structure ensures the leak detection safety of the pressure gas the welding reliability.

Owner:SHANGHAI JIAO TONG UNIV

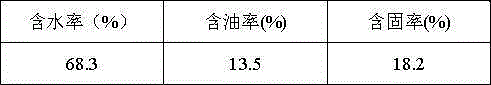

Low energy consumption drying treatment technology of residual activated sludge

InactiveCN106698886AImprove dehydration efficiencyDehydration fastSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeActivated sludge

The invention discloses a low energy consumption drying treatment technology of residual activated sludge. The treatment technology comprises the following steps: sending the residual activated sludge to a high speed shearing homogenizing tank, adding a treatment agent to the homogenizing tank, shearing and homogenizing the residual activated sludge and the treatment agent at 0-20 DEG C for 0.5-1 h, sending the obtained mixture to a sludge dehydrating machine, dehydrating the mixture to obtain a dehydrated sludge cake and sewage, sending the sewage to a sewage plant, further treating the sewage, sending the dehydrated sludge to a molding machine, extruding the dehydrated sludge to form strips, allowing the strips to enter a solar multilayer mesh belt type low temperature drying box through a conveyor belt, and drying the strips to obtain dried sludge with the water content being less than 15%. The technology decreases the water content of the residual sludge to 15% or less from 97% or above, and greatly reduces the volume of the sludge, and the dried sludge can be used as a further recycling raw material, or can be burnt.

Owner:CHINA PETROLEUM & CHEM CORP +1

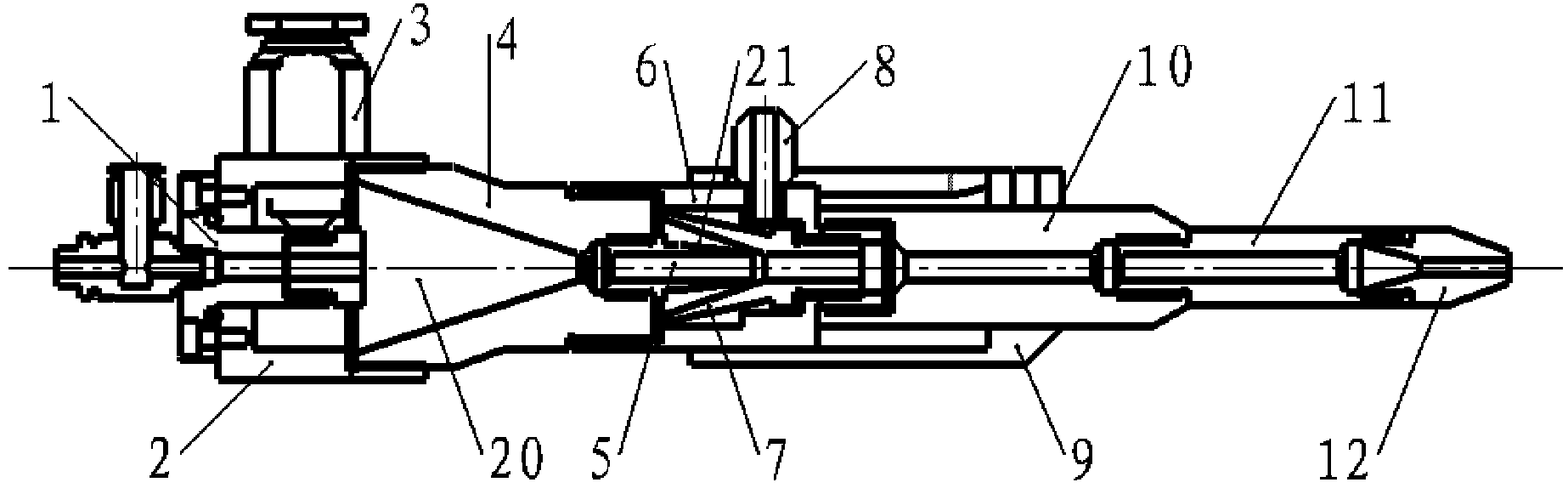

Paraxial powder-feeding working head for laser powder processing

ActiveCN103526199AInput satisfiesPrecise control of flow rateMetallic material coating processesFixed frameMetallurgy

The invention relates to a paraxial powder-feeding working head for laser powder processing. The paraxial powder-feeding working head comprises a powder-gas separator, a powder-gas input chamber, a fast-plug connector, a powder collecting chamber, a first powder conveying tube, a processing gas input chamber, a processing gas collecting piece, a processing gas input joint, a fixed frame, a second powder conveying tube, a third powder conveying tube and a powder spray nozzle, wherein the processing gas collecting piece is a gradual-contraction funnel shaped component; a throttle valve is used for outputting a powder-carrying gas input by a powder feeder; a stainless steel wire net is arranged at the front end of the throttle valve. According to the paraxial powder-feeding working head disclosed by the invention, separation of metal powder and conveyed powder-carrying gas is realized, so that on one hand, outflow rate of the metal powder from the spray nozzle is lowered to ensure stability of powder conveying amount, and therefore, stable powder output amount requirements in laser powder processing processes of laser cladding, and the like are satisfied; on the other hand, a gas different from the powder-carrying gas is input from the processing gas input joint to achieve a purpose of protecting a processing piece; meanwhile, powder spraying speed of the powder feeding spray nozzle can be adjusted in an assisted manner, so that processing effect is controlled better.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

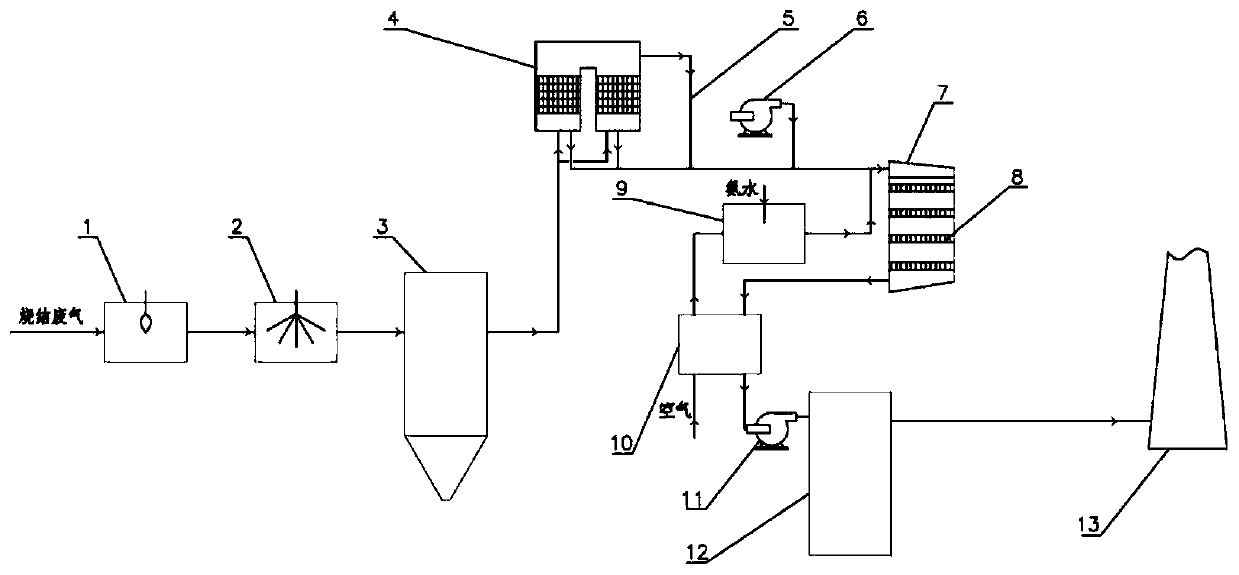

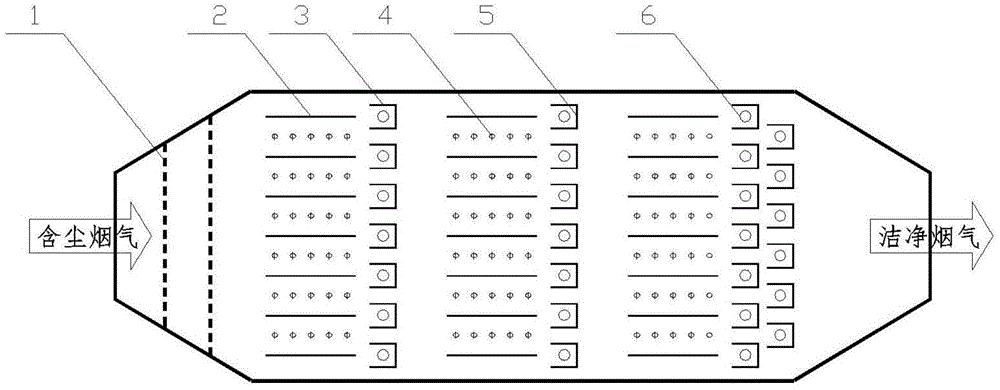

Filter-screen wet-type electric dust removing device and method

The invention discloses a filter-screen wet-type electric dust removing device. The electric dust removing device comprises a flue gas inlet device, a flue gas processing device and a flue gas discharging device, wherein the flue gas inlet device, the flue gas processing device and the flue gas discharging device are sequentially and closely connected with one another to form an integrated semi-enclosed device which is provided with openings in the two ends; a plurality of parallel anode plates and cathode wires arranged among the anode plates are arranged inside the flue gas processing device; dust collecting devices are arranged at the tail ends of the anode plates, and are used for capturing dust escaping from the tail ends of the anode plates. The electric dust removing device is efficiently intelligentized, and can effectively capture dust escaping along the surfaces of the dust collecting anode plates, increase the dust collecting areas of electric fields of dust removers, improve the dust collecting efficiency and avoid reentrainment pollution; in the wet-type soot cleaning process, the dust temperature can be further reduced, the dust moisture is increased, the dust specific resistance is reduced, and the dust removing efficiency is improved; meanwhile, when atmosphere hazardous materials are removed, effective ingredients in pollutants are extracted and converted into useful chemical fertilizers, low carbon and environment protection are realized, and the sustainable development of enterprises is facilitated.

Owner:YIXING IDEAL TECH CO LTD

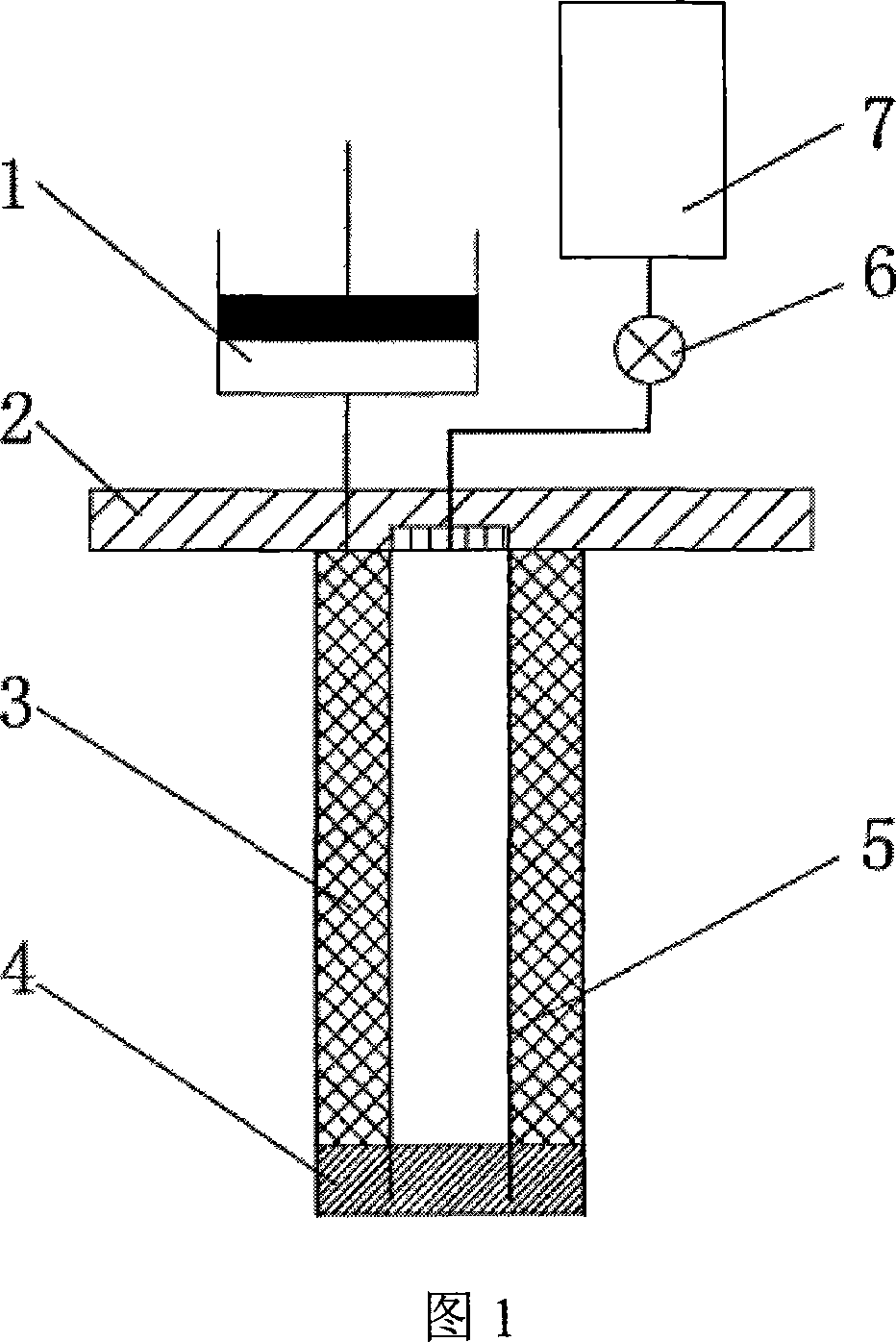

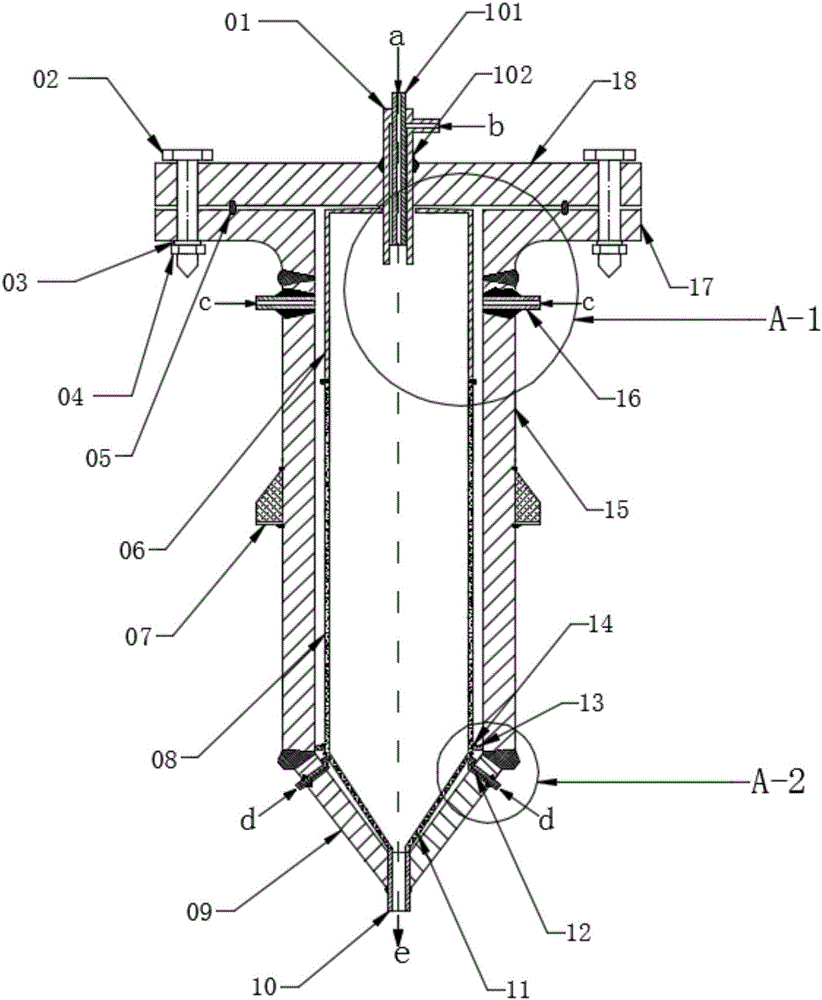

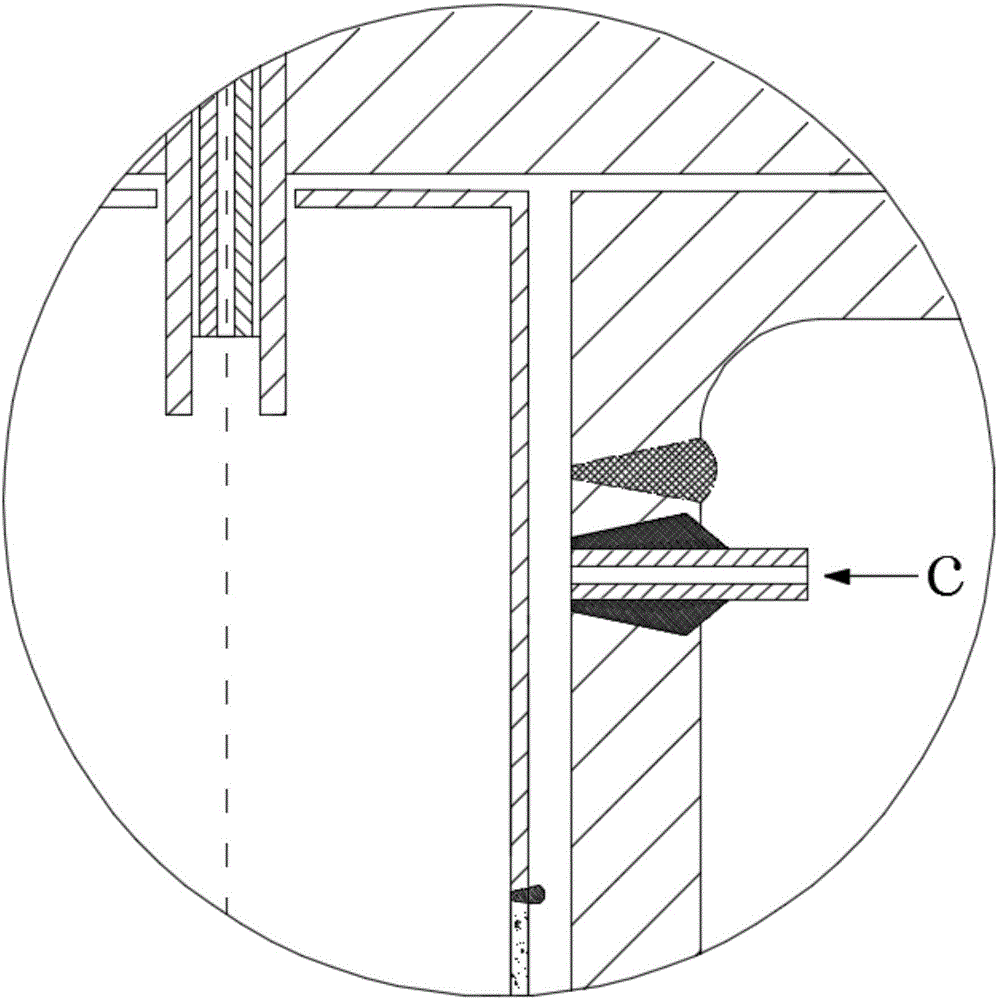

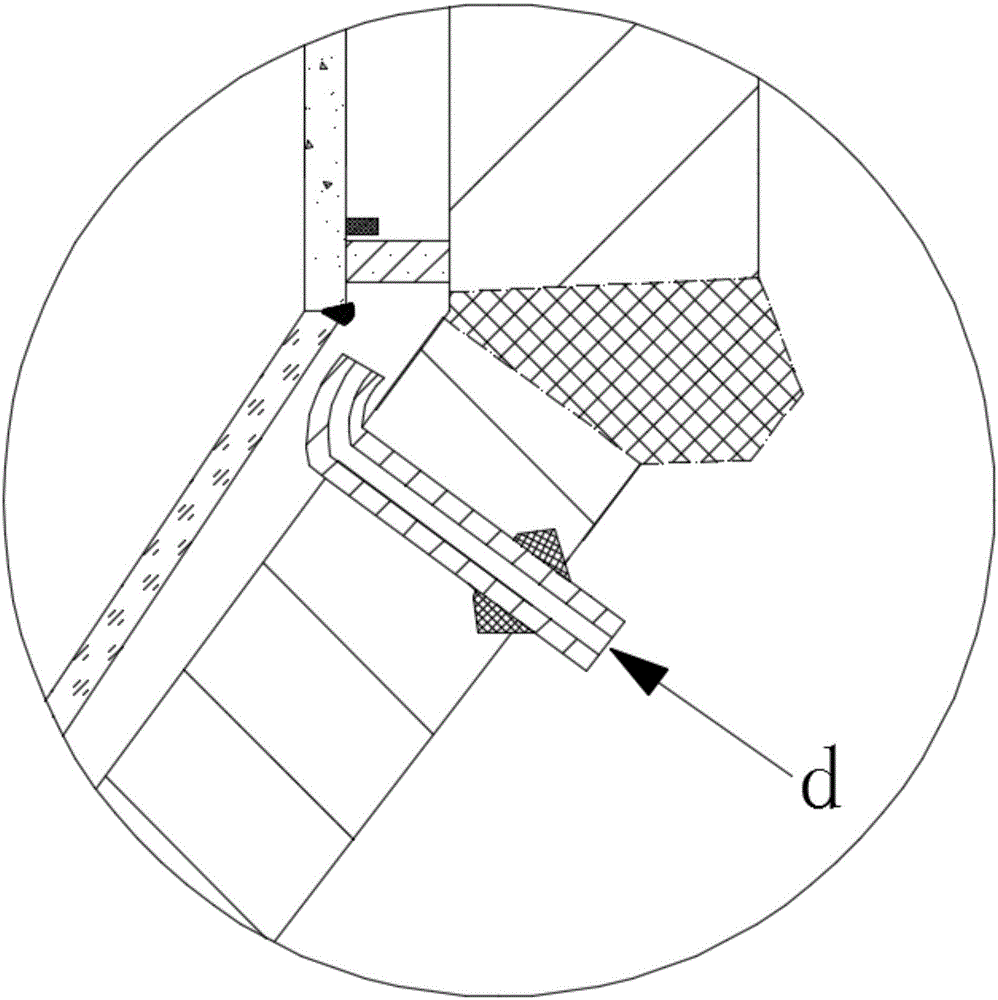

Supercritical water oxidation reactor

ActiveCN106219725AEvenly distributedImprove protectionWater treatment parameter controlSludge treatmentEngineeringSupercritical water oxidation

The invention relates to technical fields of environment protection and chemical engineering, in particular to a supercritical water oxidation reactor. The supercritical water oxidation reactor comprises an inner shell and an outer shell which are coaxially arranged; the inner shell is divided into an upper cylinder and a lower cone; the cylinder comprises an upper-section hole-free pipe and a lower-section straight porous pipe; the cone is of a tapered porous wall; the outer shell comprises an upper connection flange, a middle straight pressure bearing wall and a lower tapered bearing wall; a first ring gap is formed between the cylinder portion and the straight pressure bearing wall as well as the connection flange; a second ring gap is formed between the tapered porous wall and the tapered pressure bearing wall; an isolation ring is arranged between the first ring gap and the second ring gap; a high-temperature evaporated-water injection pipe is arranged on the upper portion of the straight pressure bearing wall; a low-temperature evaporated-water injection pipe is arranged on the upper portion of the tapered pressure bearing wall, and an outlet pipe is arranged at the bottom of the tapered pressure bearing wall; a nozzle pipe penetrating the top center of the inner shell is coaxially arranged on the connection flange. By the arrangement, evaporated water can be distributed evenly, and inhibition to center reaction during operation is avoided.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for labeling alizarin red S of inner shell of Sepiella maindroni

InactiveCN101731163AImprove uniform distributionEasy to operateClimate change adaptationPisciculture and aquariaAcute angleSepiella inermis

The invention discloses a method for labeling alizarin red S of the inner shell of Sepiella maindroni, comprising the following steps of: (1) anesthesia: selecting Sepiella maindroni to be labeled and placing the Sepiella maindroni into an anesthetic solution MS-222 with the concentration ranging from 40ppm to 70ppm for 0.5 minute to 4 minutes; and (2) labeling: injecting a staining solution into the inner shell of the Sepiella maindroni treated in the step (1) with an injector. Because the invention performs anesthesia treatment on the Sepiella maindroni by using the anesthetic solution MS-222, the Sepiella maindroni basically has no stress when injected, the operation can be conveniently carried out, and the harm to the Sepiella maindroni can be reduced. In addition, a mode of staining solution injection is adopted, the injection is carried out at an acute angle, thus, the staining solution can be uniformly distributed on the inner shell favourably, and the invention is especially suitable for Sepiella. Moreover, the method does not need temporary culture for removing floating color after the Sepiella maindroni recovers, and the Sepiella maindroni can be released immediately.

Owner:ZHEJIANG OCEAN UNIV

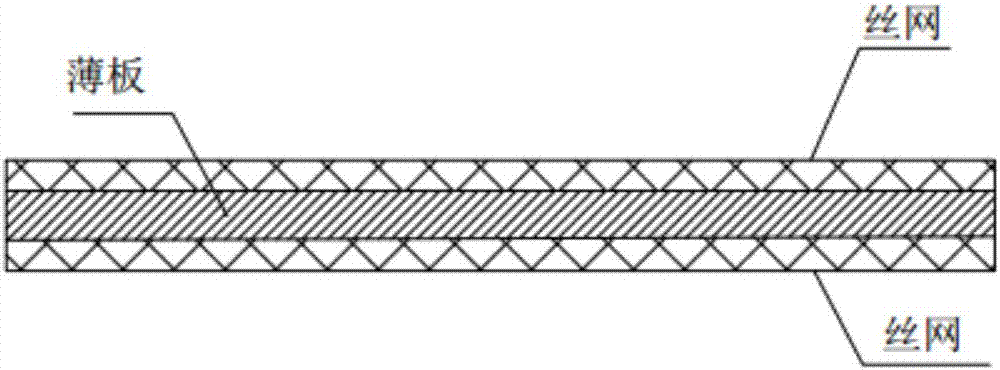

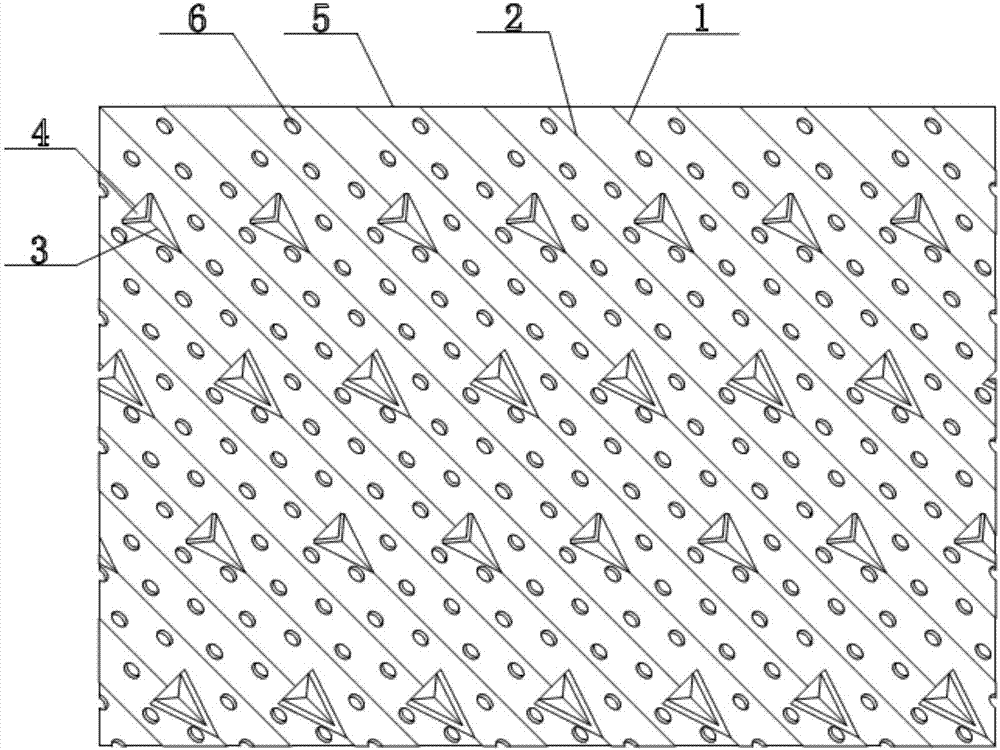

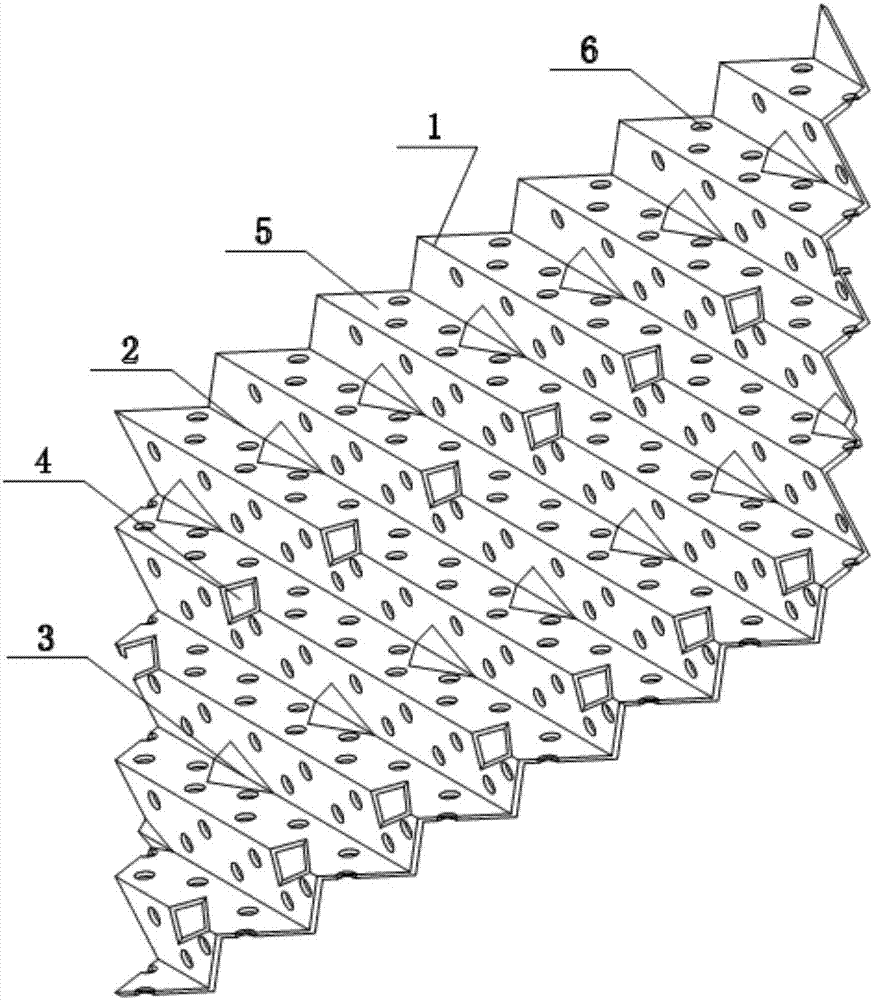

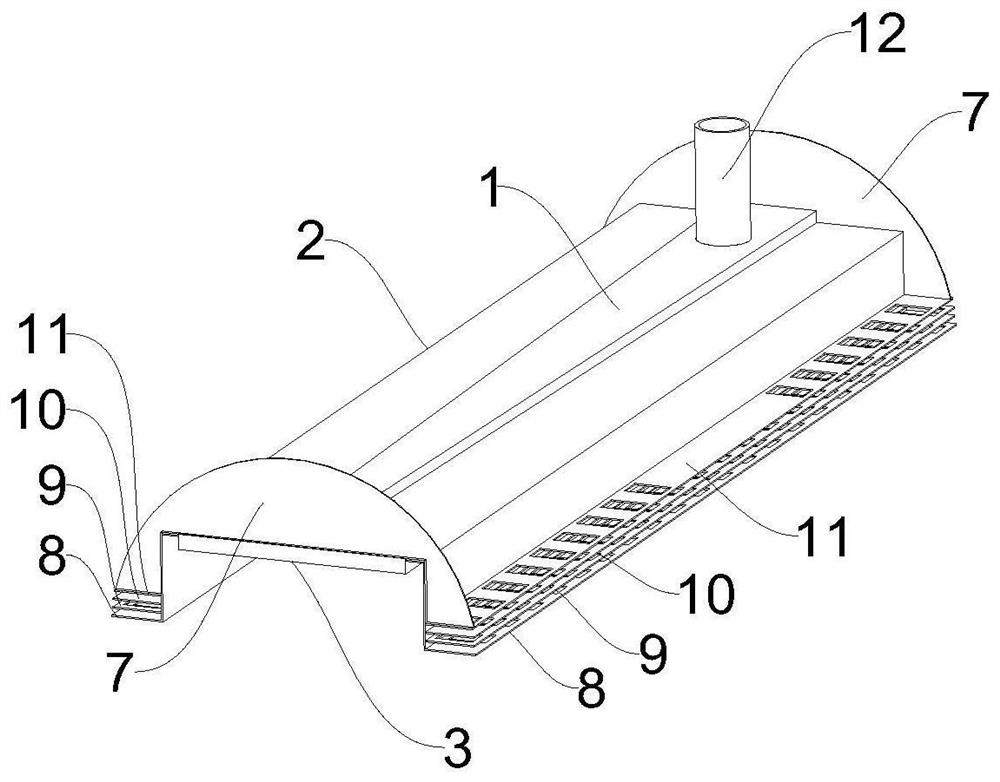

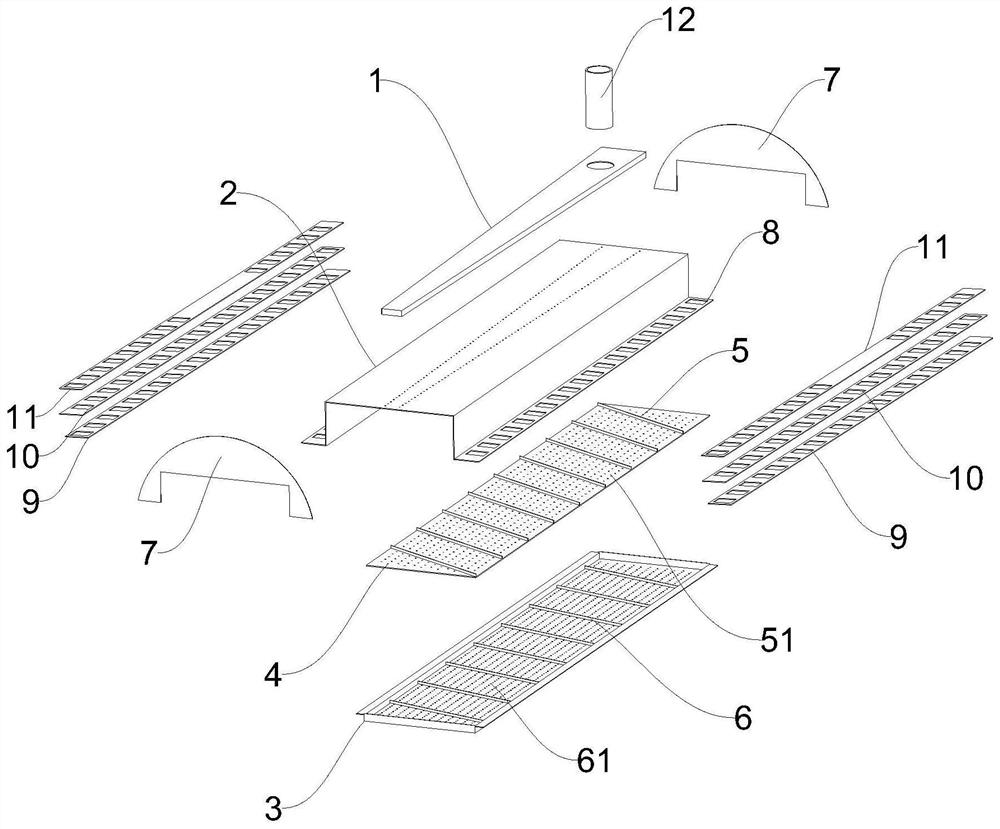

Windowed flow guide type sheet and structured packing

InactiveCN107952407ALarge specific surface areaEffective wettabilityChemical/physical/physico-chemical processesThin slabEngineering

The invention provides a windowed flow guide type sheet and structured packing. The windowed flow guide type sheet is characterized in that a packing sheet is a composite plate, a layer of thin platesis sandwiched between two layers of screens to form the composite plate, wave crests and wave troughs of the ripple packing sheet are windowed, and holes are formed in wave surfaces between the wavecrests and the wave troughs of the packing sheets. Windows at the wave crests and the wave troughs of the packing sheet comprise flow guide window bodies and window apertures; the windows on the wavecrests and the wave troughs are arranged on a horizontal line, the distance from an optional window to the adjacent upper window is equal to the distance from the optional window to the adjacent lowerwindow in the vertical direction, and the optional window, the adjacent upper window and the adjacent lower window are arranged on a vertical line. The structured packing comprises a plurality of packing sheets with parallelly arrayed ripples and a wall flow preventive ring. The windowed flow guide type sheet and the structured packing have the advantages that all merits of existing windowed flowguide packing are inherited, the windowed flow guide type sheet and the structured packing have large specific surface areas and are effective in wettability, uniform liquid distribution and liquid film updating can be reinforced, dead spaces in the packing can be diminished, and the mass transfer efficiency can be obviously improved.

Owner:TIANJIN UNIV

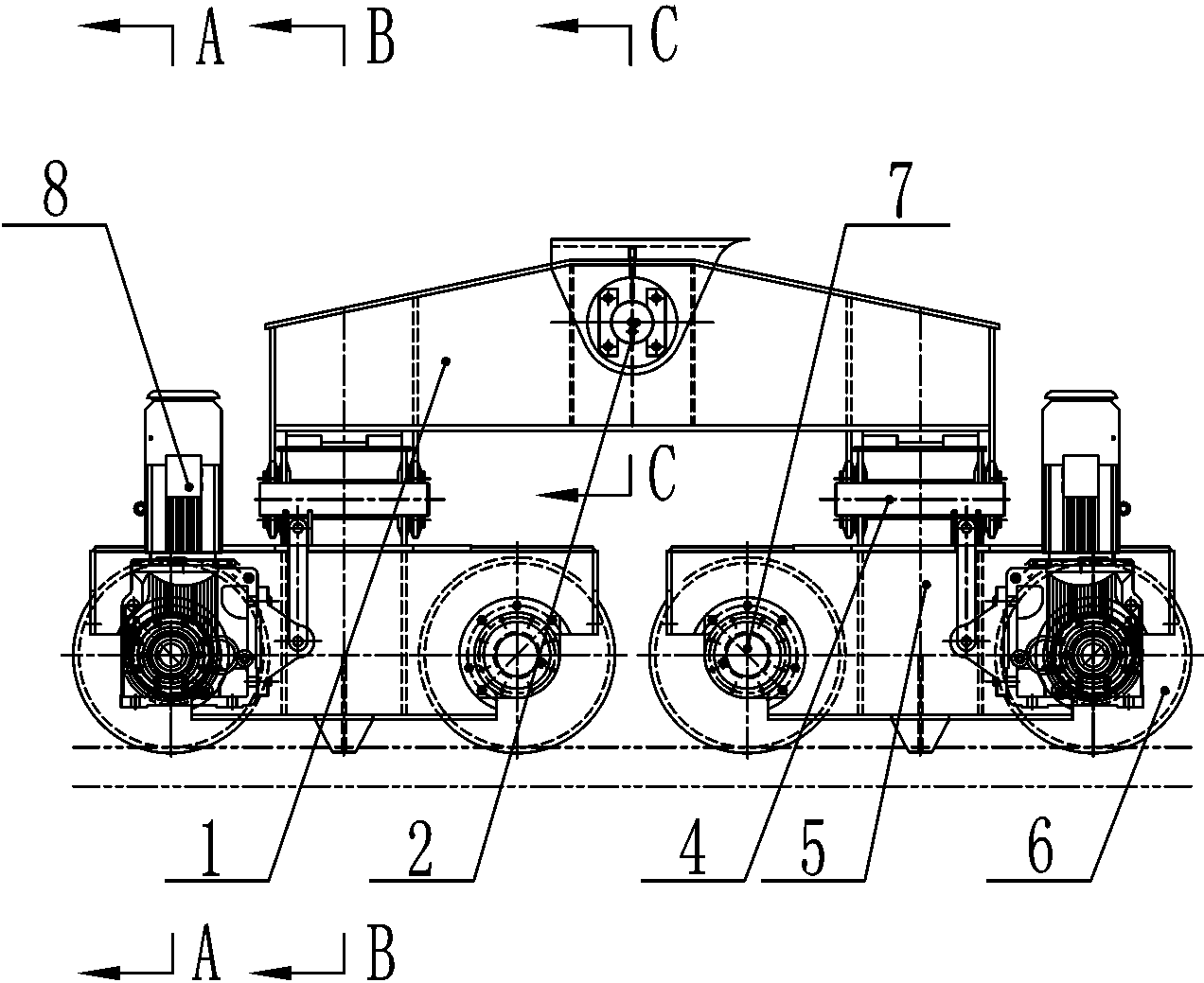

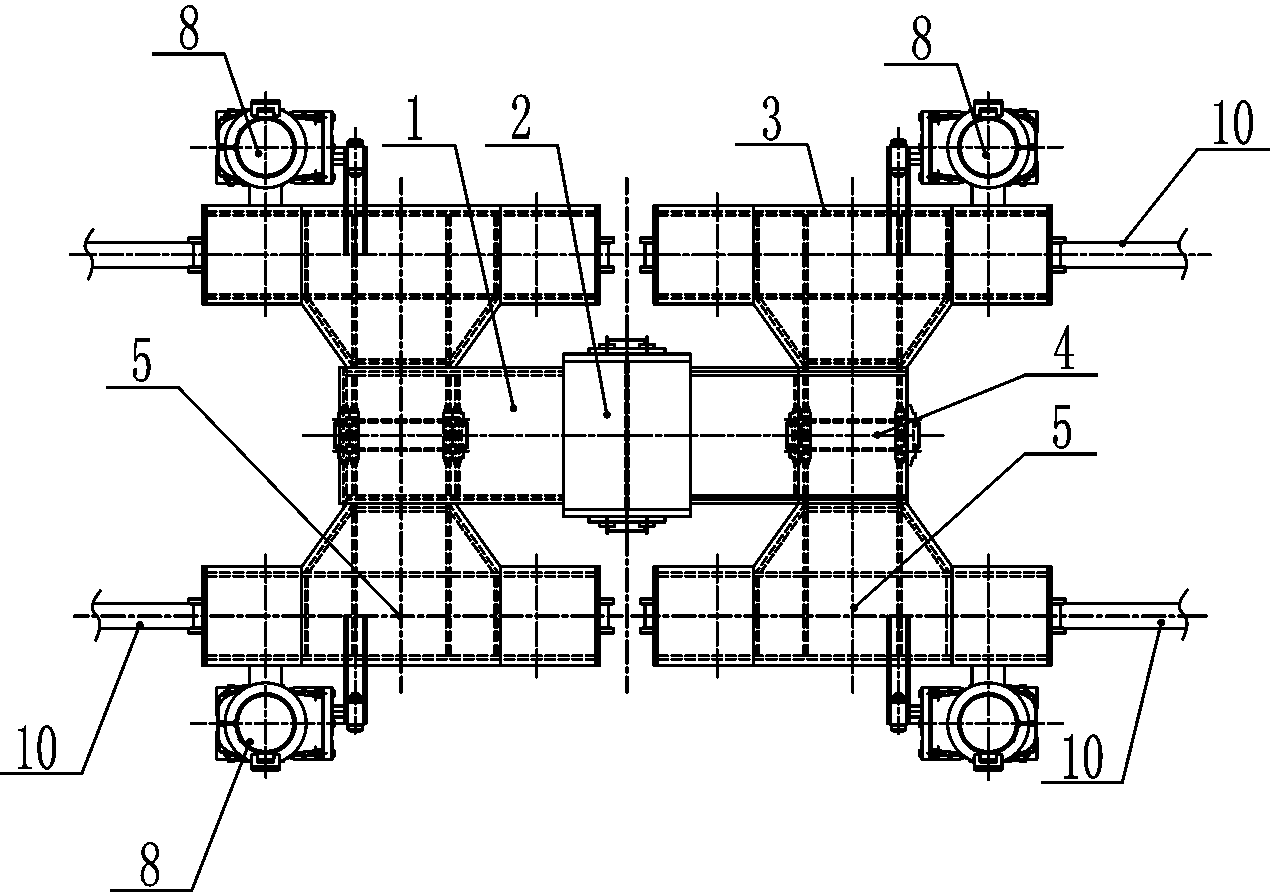

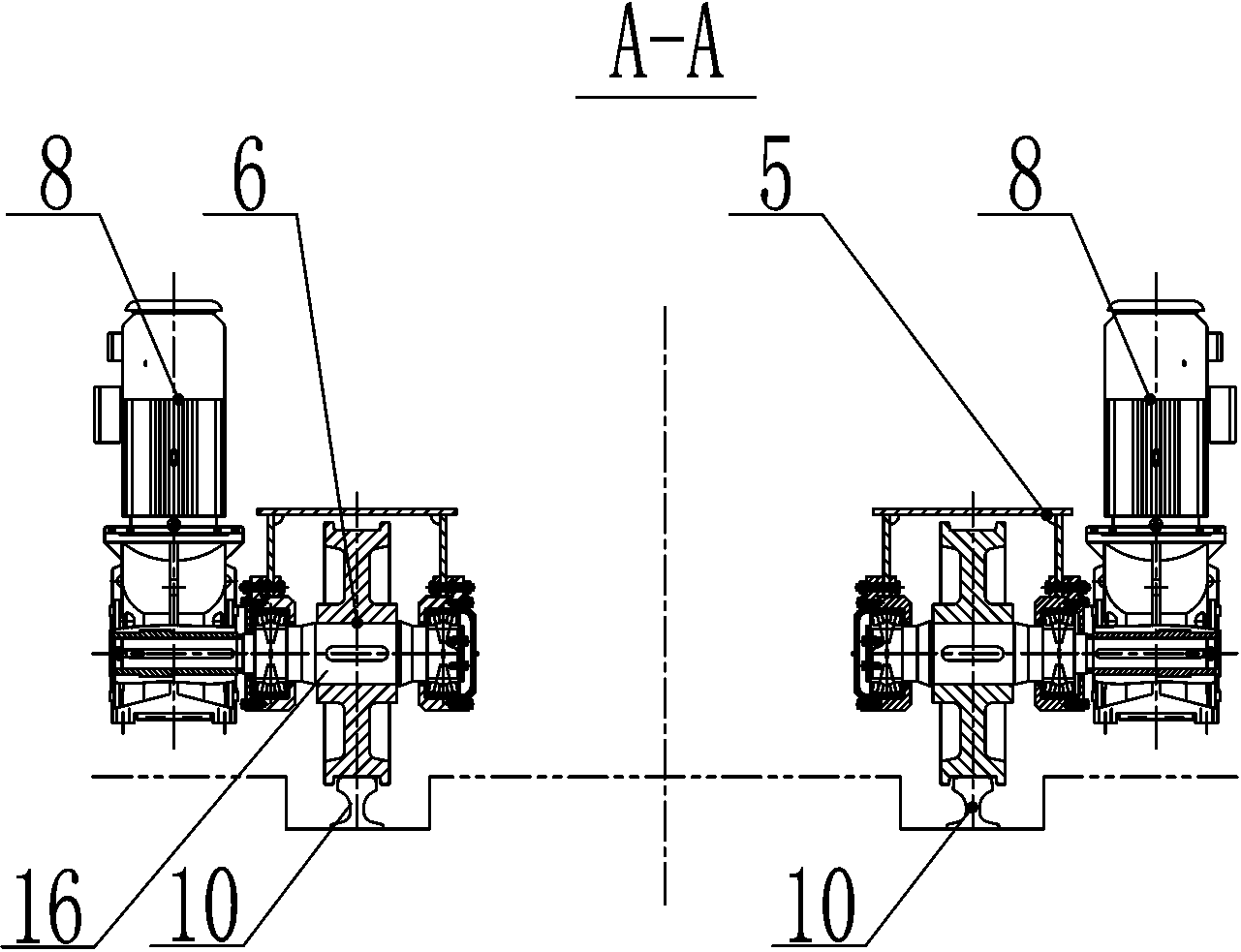

Double-track trolley group running mechanism for ultra-large gantry crane

ActiveCN104176633AImprove uniform distributionReduce lateral forceTravelling gearRunwaysVehicle frameDrive wheel

The invention discloses a double-track trolley group running mechanism for an ultra-large gantry crane. The double-track trolley group running mechanism comprises an equalizing beam and double-track trolleys. The double-track trolley group running mechanism is characterized in that each double-track trolley is a four-wheel double-drive mechanism which is formed by travelling wheels and driven wheels which are symmetrically arranged on two sides of a trolley frame; the double-track trolleys are fixedly arranged at the two ends of the equalizing beam through hinged shafts, and the double-track trolleys are in hinged connection with the equalizing beam; the trolley frame is of an I-shaped box structure; the travelling wheels are driving wheels provided with driving mechanisms, and the driving mechanisms can enable the traveling wheels and the driven wheels to drive a trolley group composed of the two double-track trolleys to run on tracks. Compared with the prior art, the double-track trolley group running mechanism has the advantages of low wheel pressure of the traveling wheels, uniform distribution of wheel pressure, and is capable of greatly weakening lateral force, effectively avoiding the rail gnawing phenomenon, enlarging the working range, reducing the working blind area and further reducing project construction cost. The double-track trolley group running mechanism is simple in structure and greatly convenient to maintain.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

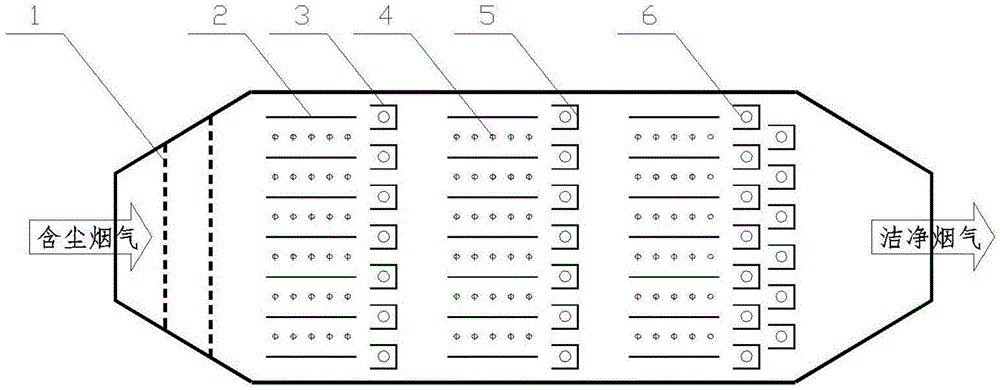

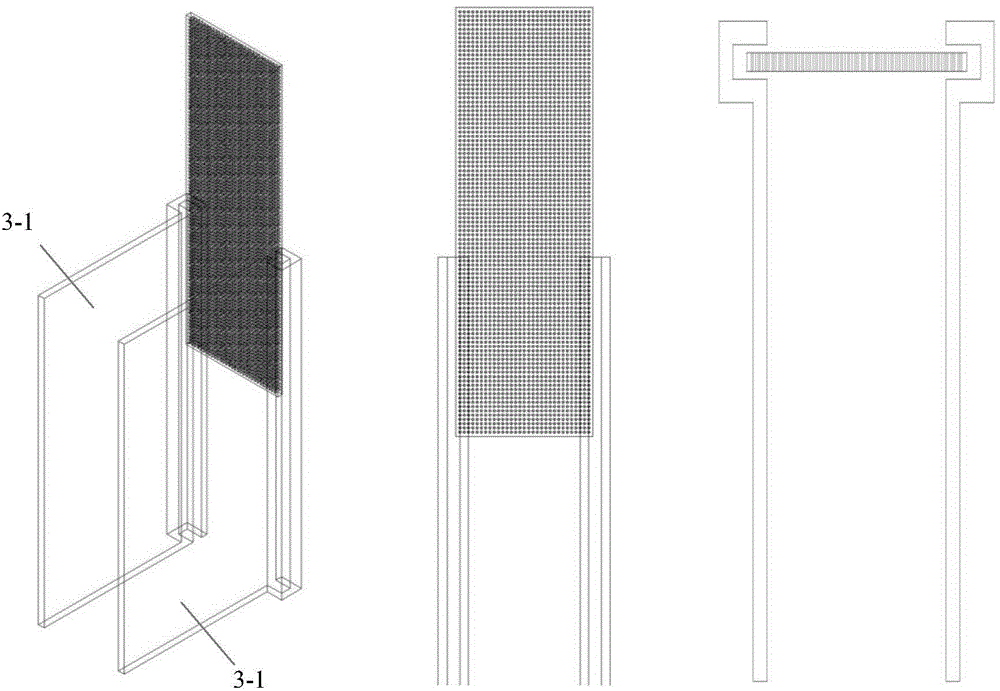

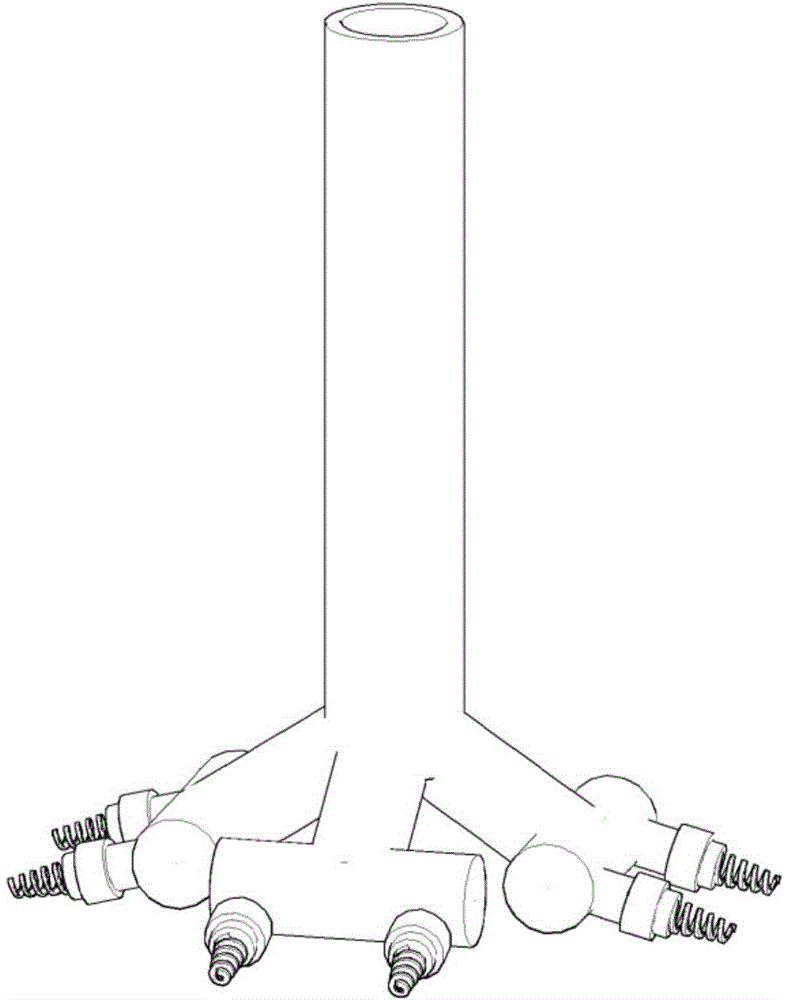

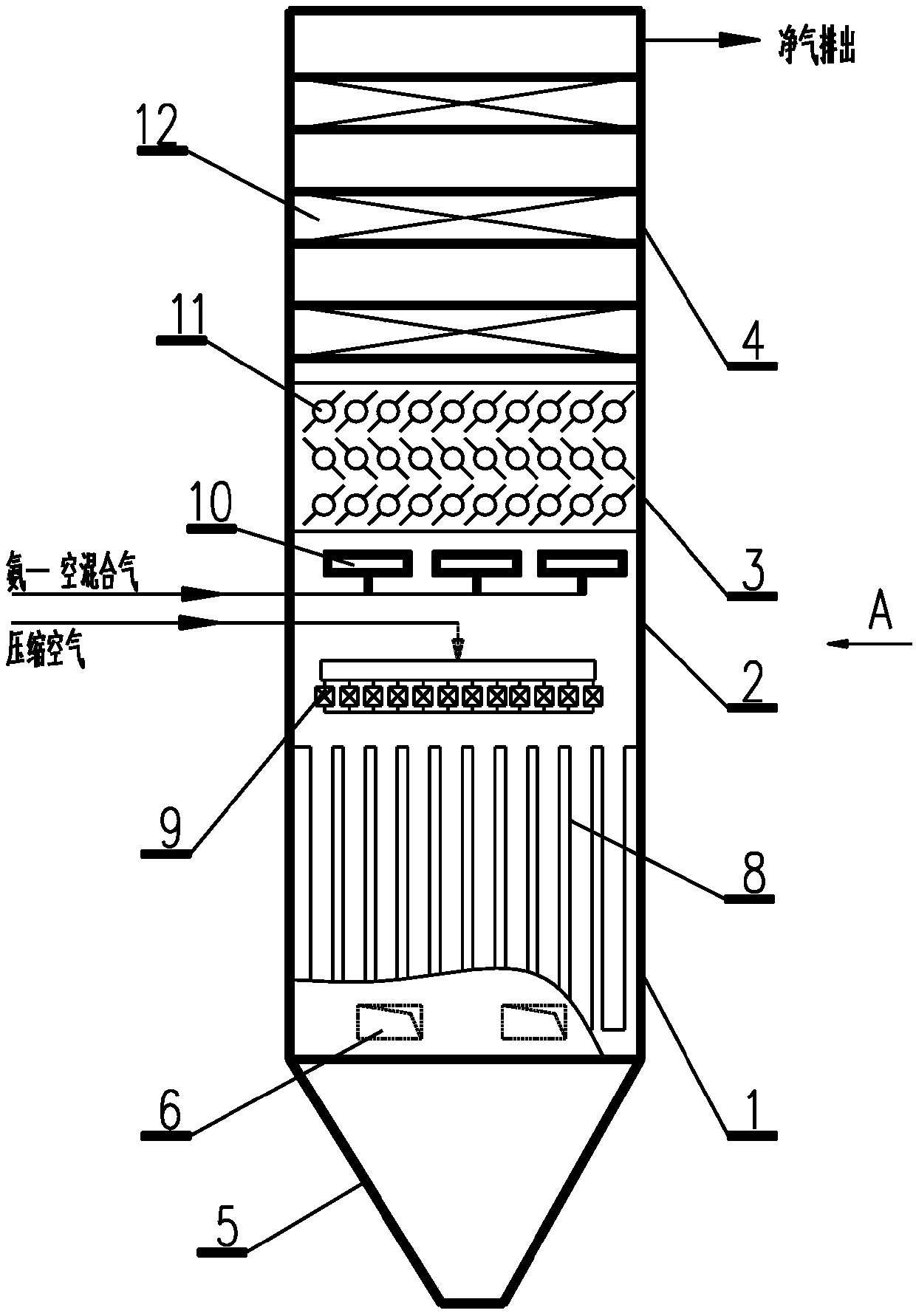

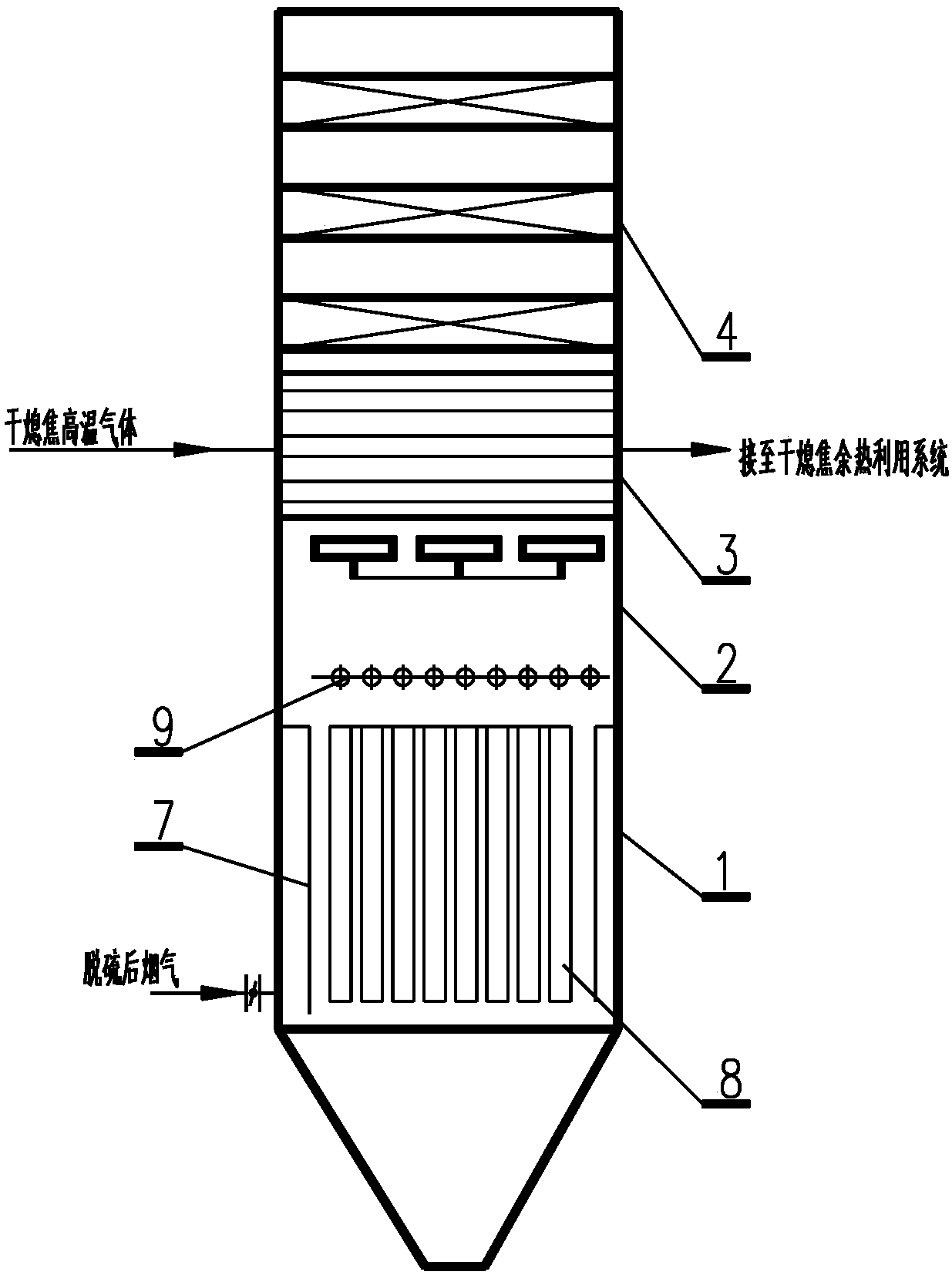

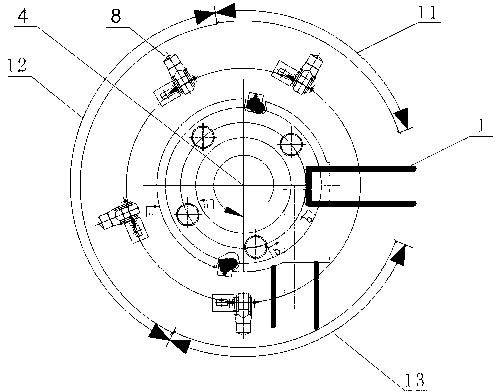

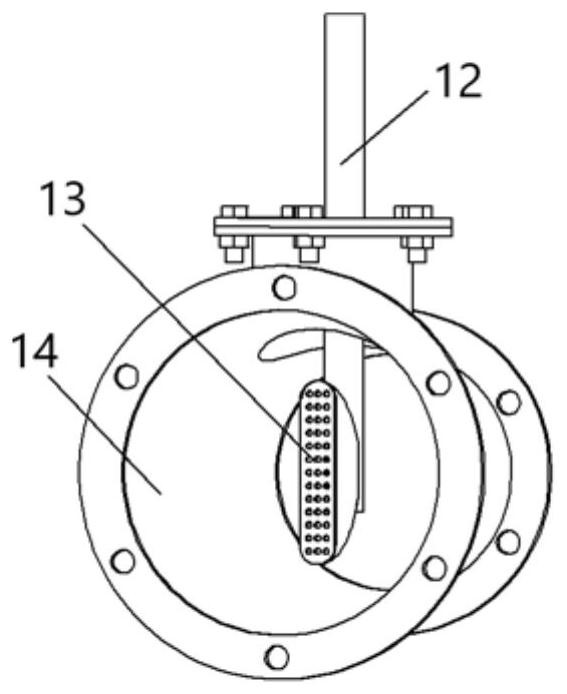

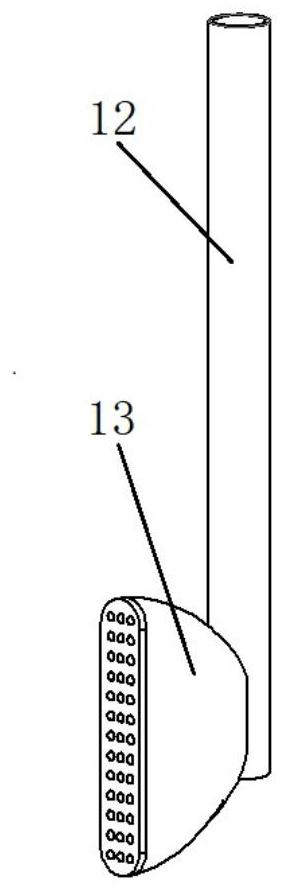

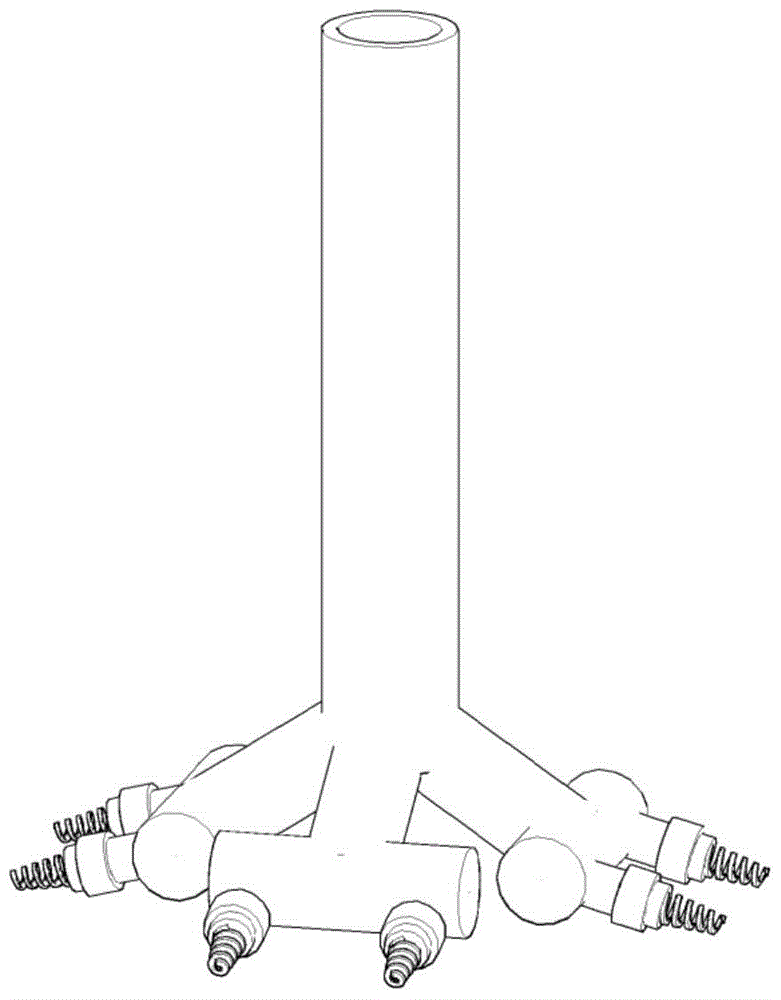

A dust removing-denitration integrated device and method for medium- and low-temperature flue gas

PendingCN107890776AHigh removal rateAdapt to fluctuationsGas treatmentDispersed particle filtrationFlue gasAmmonia

The invention relates to a dust removing-denitration integrated device and method for medium- and low-temperature flue gas. The device includes a dust removing purification unit, an ammonia-air mixingand injecting unit, a heat exchange unit and a denitration unit which are arranged in a column body in order from bottom to top. The lower part of the column body of the dust removing purification unit is provided with a plurality of air inlets along the circumferential direction. Each air inlet is connected to one end of a flue gas feeding pipe through an air feeding branch pipe. The other end of the flue gas feeding pipe is connected to a desulfurated flue gas outlet of an outer desulfuration unit. Air inflow evenly-distributing guide plates and filter bags are disposed in the column body of the dust removing purification unit. A plurality of rows of the filter bags are evenly and vertically distributed in the column body. The air inflow evenly-distributing guide plates are disposed between the air inlets and the filter bags. Pulse-jetting apparatuses are arranged above the filter bags, and are connected to an outer compressed air conveying pipe. The device and the method integratedust removing, heat exchange and denitration, and are high in dust and NOx removing efficiencies. The device is simple in structure, reliable to operate, low in investment and operation cost, and longin service lifetime.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

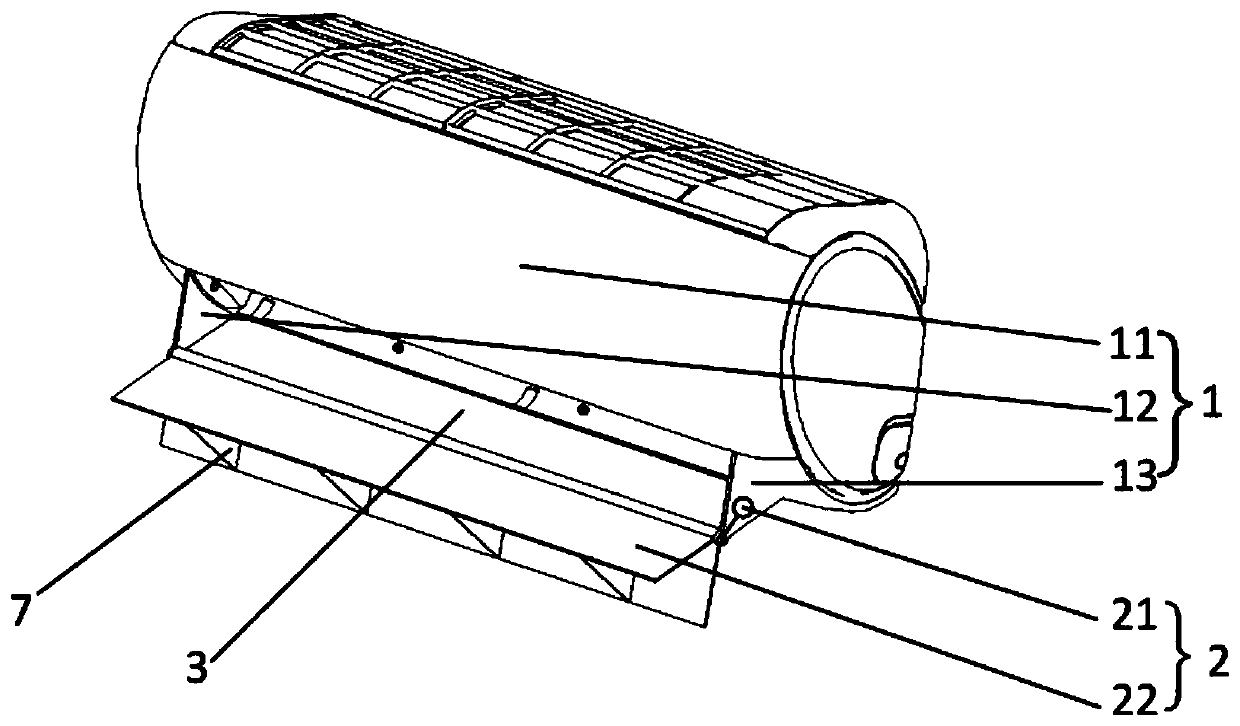

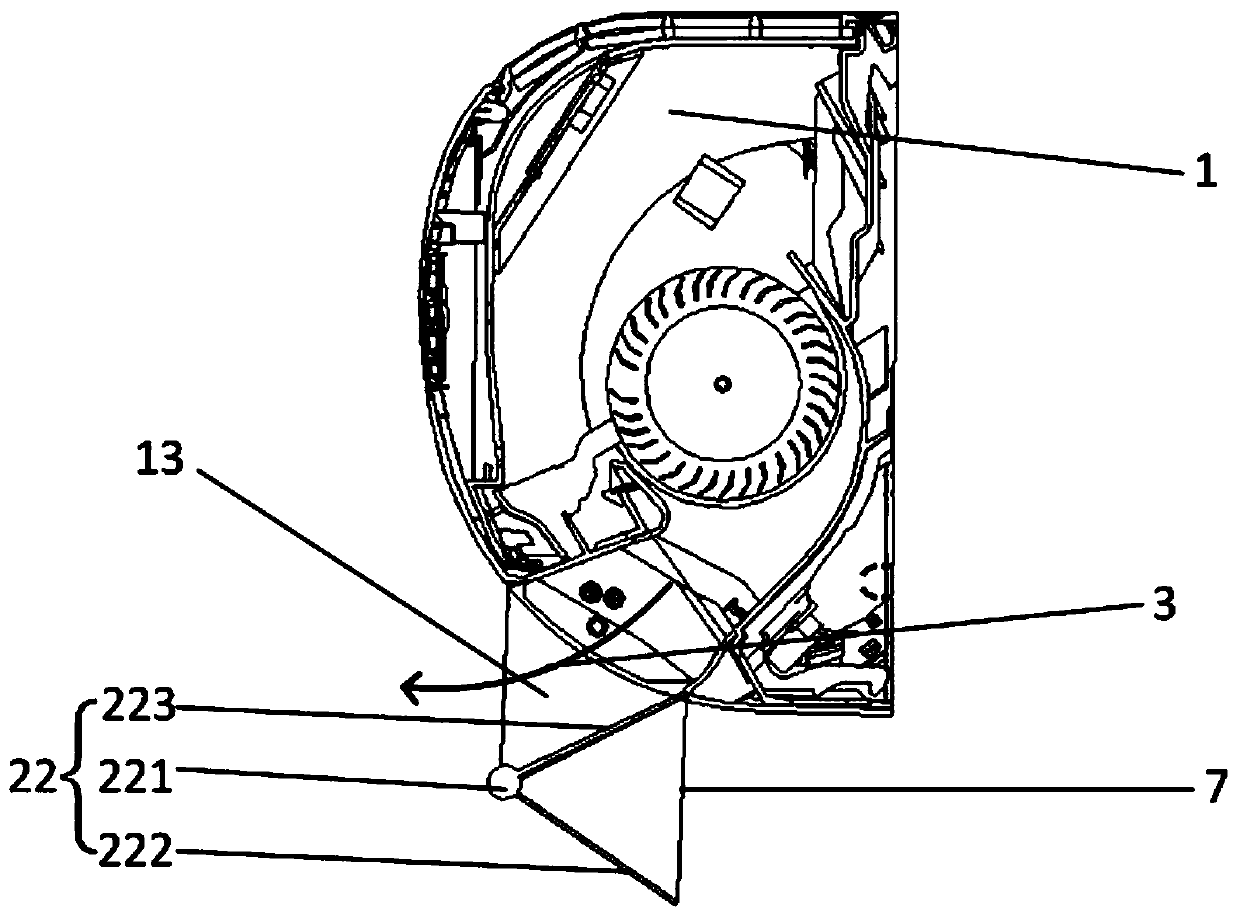

Indoor unit of air conditioner

ActiveCN110486800AUniform temperature distributionAvoid blowingLighting and heating apparatusAir conditioning systemsRefrigerationElectrical and Electronics engineering

The invention belongs to the technical field of air conditioners and aims to solve the problems that the temperature of air discharged from an existing indoor unit of an air conditioner is not distributed uniformly and a user is easily blown straightly. For the purpose, the invention provides an indoor unit of an air conditioner. The indoor unit of the air conditioner comprises a housing and a rotary air guide mechanism which is arranged on the housing; the housing is provided with an air outlet; the rotary air guide mechanism is arranged at the air outlet; the rotary air guide mechanism is configured to rotate to a first position when the air conditioner executes a refrigeration mode so that the air discharged from the indoor unit can be guided out upwards, rotate to a second position when the air conditioner executes a heating mode so that the air discharged from the indoor unit is guided out downwards and rotate to a third position when the air conditioner executes a straight-blow-preventing mode so that the air discharged from the indoor unit is guided out after being divided up and down. According to the indoor unit provided by the invention, when the air conditioner is in a refrigeration mode or in a heating mode, the temperature of discharged air is distributed uniformly; moreover the user can make the air conditioner execute a straight-blow-preventing mode when the useris close to the indoor unit, so the user is prevented from straight blowing and is prevented from feeling uncomfortable.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

Method for treating residual active sludge

ActiveCN109912139AReduce dosageKeep aliveSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisActivated sludgeSewage

The invention discloses a method for treating residual active sludge. The method comprises: feeding remaining active sludge into a homogenization groove, adding a treatment agent to the homogenizationgroove, treating, carrying out thermal hydrolysis wall breaking treatment on the treated sludge, feeding the wall-broken sludge into a sludge dewatering machine, dewatering to obtain dewatered mud cake and sewage, feeding the sewage to a sewage treatment plant so as to be further treated, and carrying out molding drying on the obtained dewatered mud cake to obtain dried sludge. With the method ofthe present invention, the water content of the remaining sludge can be reduced to less than 15%, the volume of the sludge can be greatly reduced, and the dried sludge can be used as the further resource raw material or can be incinerated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cement clinker cooling system and method

InactiveCN103322818ASave civil investmentImprove operational reliabilityHandling discharged materialBaghouseChain conveyor

The invention discloses a cement clinker cooling system and method. The cooling system comprises a rotary kiln, a hot kiln hood, an annular cooling machine, a bag-type dust collector, a zipper machine, a crusher and a bucket chain conveyor. The annular cooling machine is divided into three cooling sections. Cement clinker is cooled through the three cooling sections, and hot air generated in each cooling section is utilized. The cement clinker cooling system and method can overcome the defects in the prior art of being large in device investment, floor area and civil engineering investment, more in accessory devices, troublesome in device maintaining and overhauling and the like.

Owner:CITIC HEAVY INDUSTRIES CO LTD

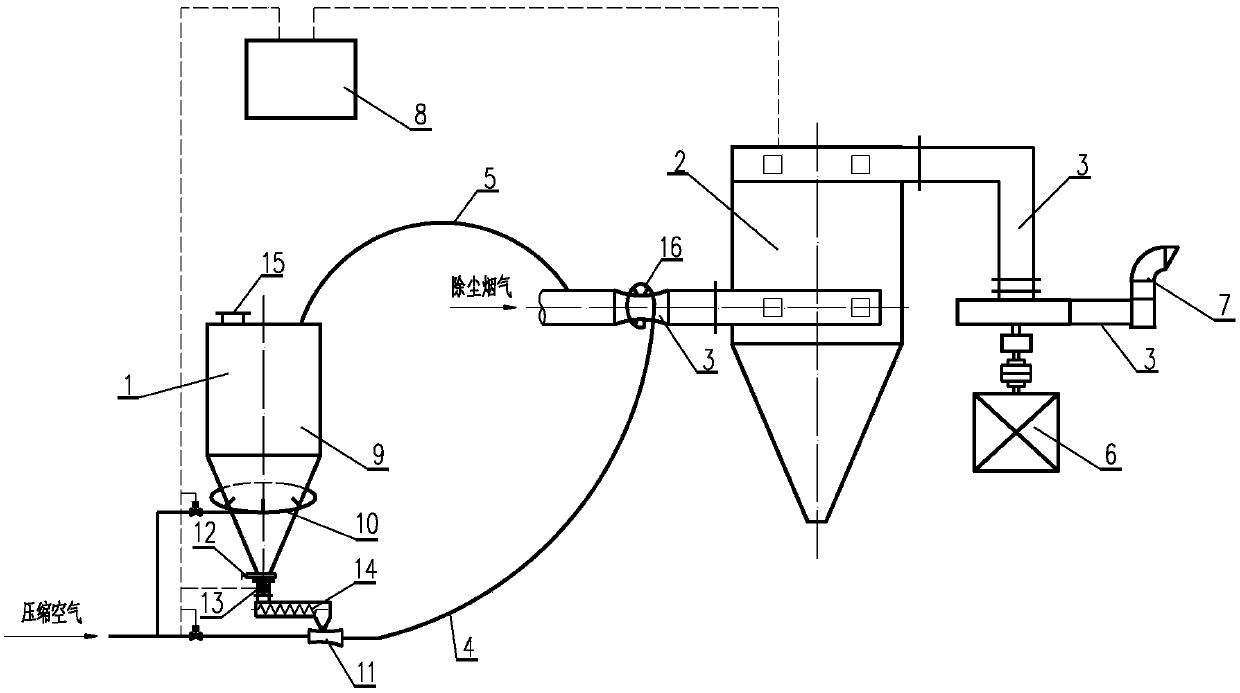

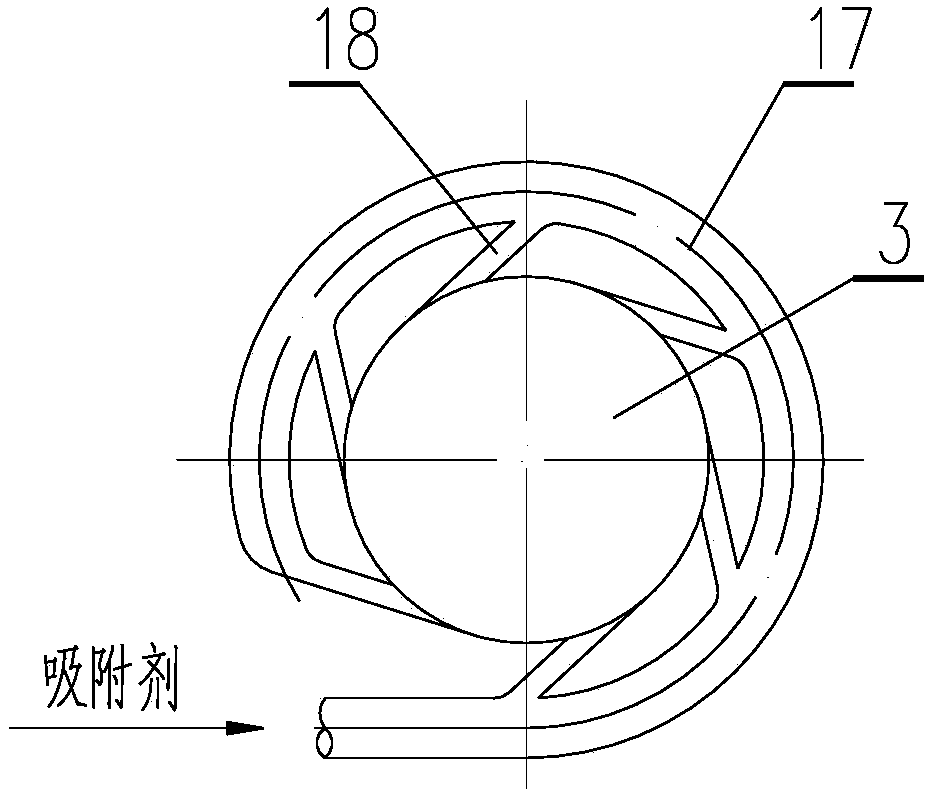

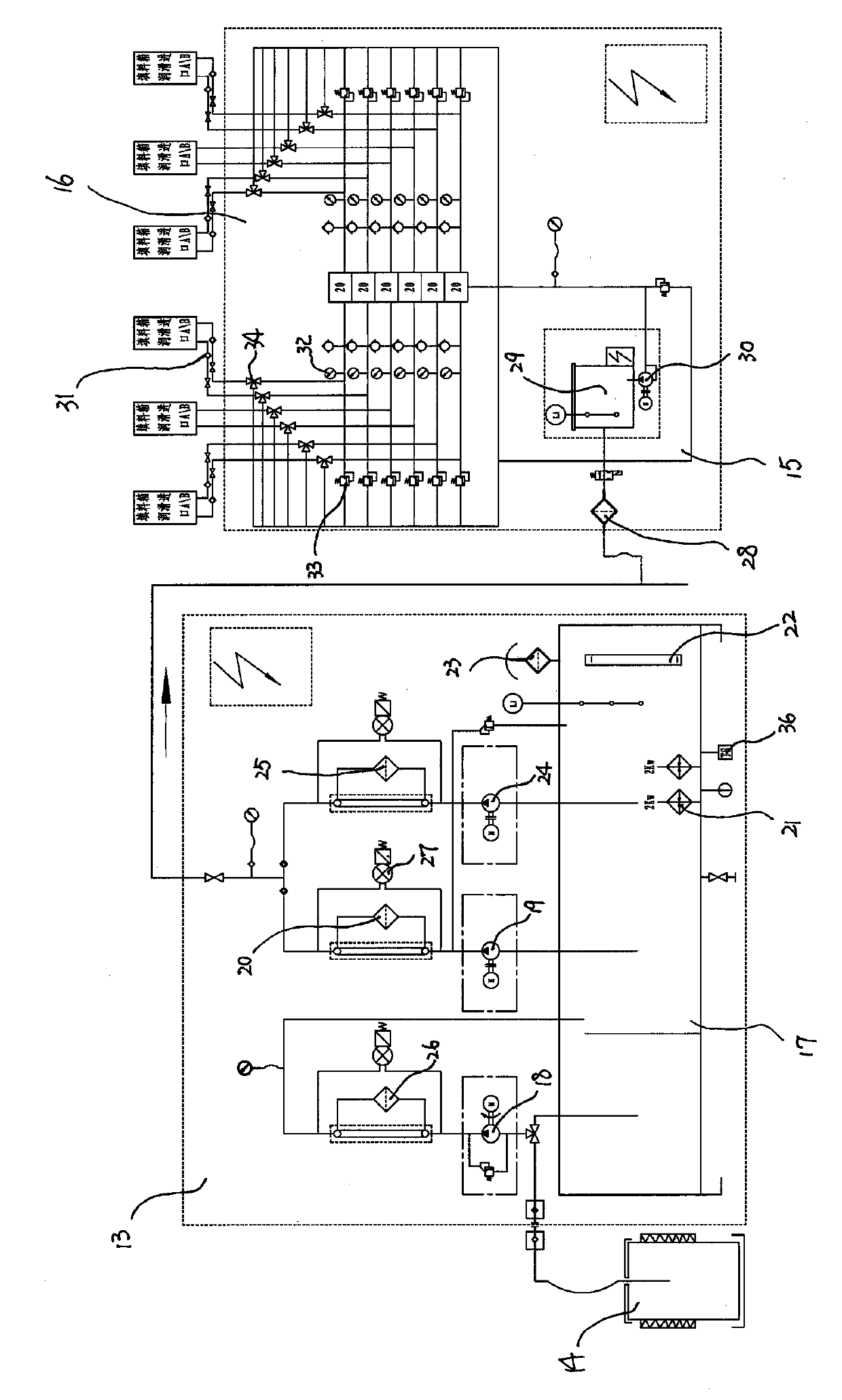

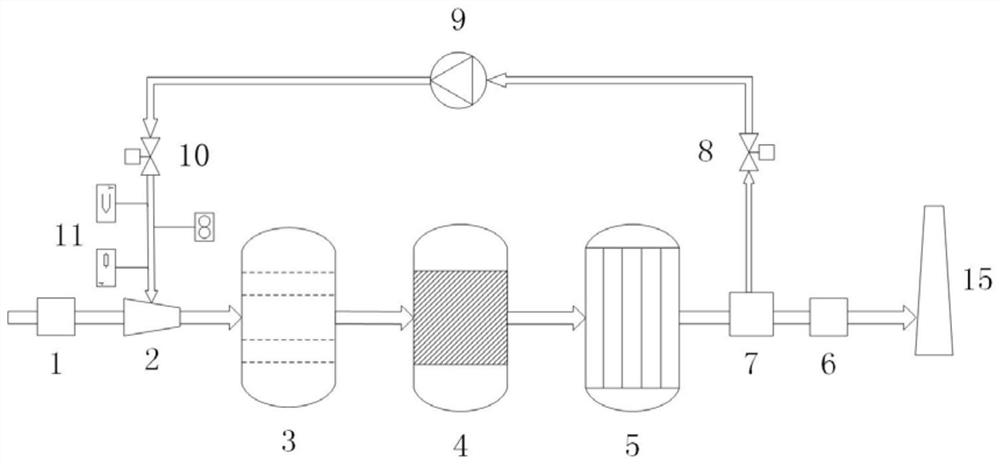

Device and method for carrying out adsorption purification treatment on sticky or moisture-containing dust smoke

The invention relates to a device and a method for carrying out adsorption purification treatment on sticky or moisture-containing dust smoke. The device comprises an adsorbent storage unit, a smoke purification unit, a pipeline unit, an adsorbent conveying unit, an air pressure balance unit, a fan unit, a chimney and a control unit, wherein the bottom of the adsorbent storage unit is connected with the adsorbent conveying unit, a feeding hole of the adsorbent conveying unit is connected with the pipeline unit at an entrance of the smoke purification unit, and an exit of the smoke purificationunit, the fan unit and the chimney are connected by virtue of the pipeline unit; the air pressure balance unit is arranged at the top of the adsorbent storage unit, and the other end of the air pressure balance unit is connected with the pipeline unit at the entrance of the smoke purification unit; and the control unit controls the whole adsorption purification technological process. Compared with the prior art, the invention has the beneficial effects that the device and the method have good purification effect on sticky or moisture-containing dust smoke and have the characteristics of low investment cost, simple structure, high purification efficiency and long service life.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

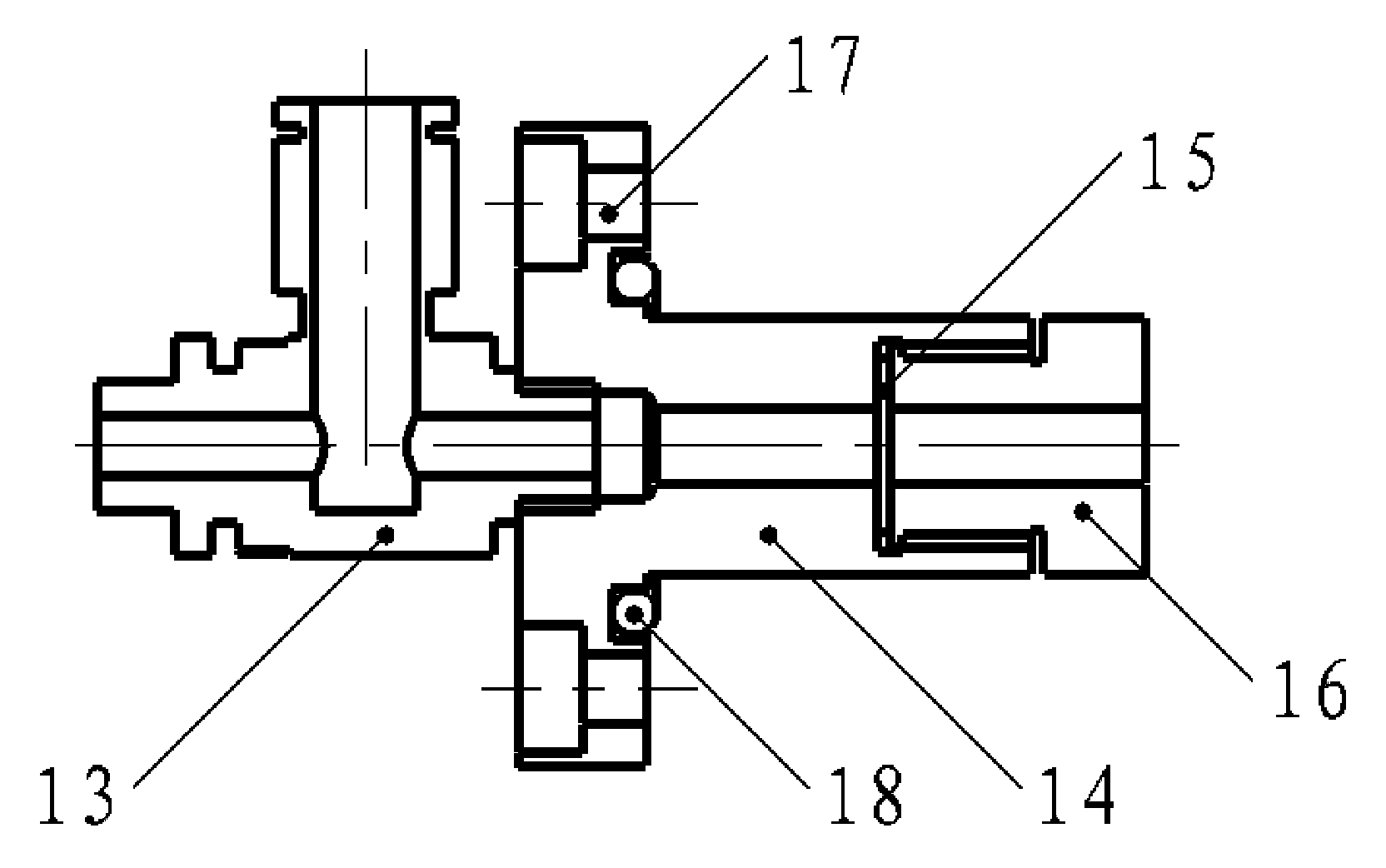

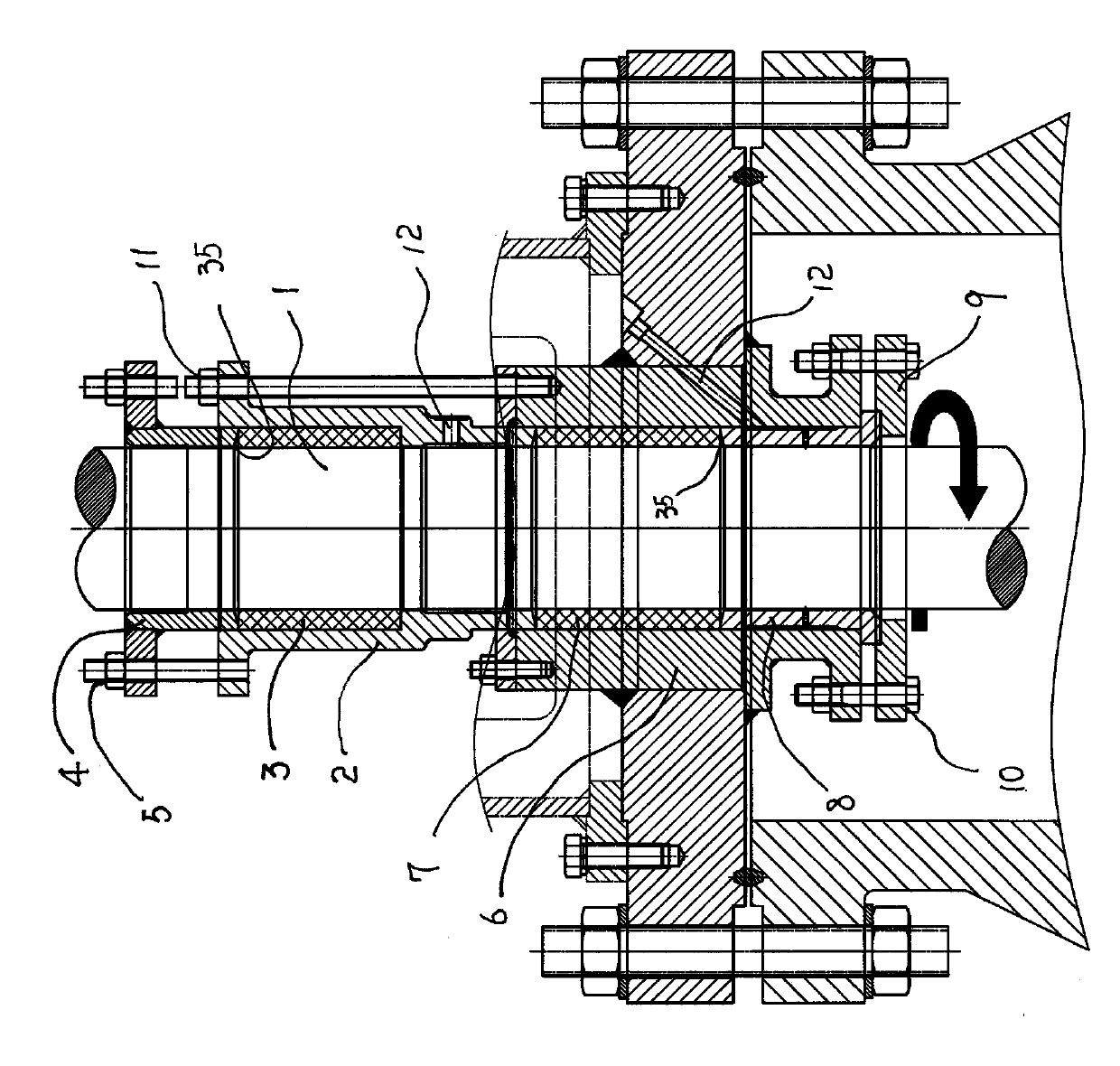

High-pressure large-torque axial sealing and lubricating system

InactiveCN103807443ASystem connections are compactReliable oil supply performanceEngine sealsLubrication check valvesLubricationSatellite

The invention relates to a high-pressure large-torque axial sealing and lubricating system. A second-stage packing box, second-stage packing and a second-stage gland are arranged on the periphery of the upper portion of a transmission shaft, a first-stage packing box, first-stage packing, an oil separating ring and a first-stage gland are arranged on the periphery of the lower portion of the transmission shaft, the lower end of the second-stage packing box is connected into the first-stage packing box in an inserted mode through middle nut studs, and the second-stage packing box and the first-stage packing box are provided with lubricating oil inlets respectively. The lubricating system comprises a main oil station, an oil supplementing station, a satellite station and a distributor. The main oil station internally comprises a main oil tank, an oil supplementing pump, a main oil filling pump and a main filter, an outlet of the main filter is connected to the satellite station, and the satellite station delivers lubricating oil to lubricating oil inlets through the distributor. By means of the design, the high-pressure large-torque axial sealing and lubricating system is compact in connection and reliable in oil supplying performance, the oil can be automatically supplemented, grading pressure partition and grading lubricating are beneficial to even distribution of radial sealing force and lubrication, abrasions are reduced, and the high-pressure large-torque axial sealing and lubricating system has the advantages of being good in sealing effect and high in operation stability.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Synergistic efficient denitration device and process for treating electroplating sludge sintering waste gas

PendingCN111495144AGuaranteed uptimePrecise control of inlet flue gas temperatureGas treatmentDispersed particle filtrationCombustorSludge

The invention discloses a synergistic efficient denitration device for treating electroplating sludge sintering waste gas. The device comprises a powder spraying device, a bag-type dust collector, a heat storage oxidation device, a selective catalytic reduction denitration device, an induced draft fan and a wet desulphurization tower which are arranged in sequence, the device further comprises a thermal bypass branch and a combustor used for heating the thermal bypass branch. The inlet of the thermal bypass branch is communicated with the outlet in the top of the heat storage oxidation device,and the outlet of the thermal bypass branch is communicated with an outlet in the bottom of the heat storage oxidation device and the outlet of the cooling fan and then is connected with an inlet inthe top of the selective catalytic reduction denitration device. The invention further provides a denitration process based on the denitration device. The selective catalytic reduction method denitration device has the beneficial effects that by improving the front dust removal and affiliated ammonia evaporation unit of the selective catalytic reduction method denitration device, the gas inlet condition of the selective catalytic reduction method denitration device is improved, the denitration efficiency of the selective catalytic reduction method denitration device is synergistically improved, and the ultralow emission standard is achieved.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Liquid homogenizing device and air conditioner

InactiveCN112344604AImprove uniformityPlay an isolation roleEvaporators/condensersStationary conduit assembliesPhysicsPressure cell

The invention belongs to the technical field of heat exchange, and aims at solving the problems that an existing air conditioner has high requirements for the assembly precision of a liquid homogenizing device, and the dry burning phenomenon of a heat exchange tube bundle of the air conditioner cannot be thoroughly solved. To achieve the purpose, the invention provides the liquid homogenizing device. The liquid homogenizing device comprises a pressure box, an upper box, a lower box and at least one layer of middle baffle arranged between the upper box and the lower box, wherein the pressure box is arranged in the length direction of the upper box, and a plurality of liquid holes are uniformly distributed in a bottom plate of the pressure box, middle baffles and the lower box; a plurality of first liquid baffles are arranged on the middle baffles, so that each middle baffle is divided into a plurality of first liquid film uniform sections; and a plurality of second liquid baffles are arranged on the lower box, so that the lower box is divided into a plurality of second liquid film uniform sections. The liquid homogenizing effect of the liquid homogenizing device can be improved, theassembling precision requirement of the liquid homogenizing device is lowered, the dry burning phenomenon caused by uneven distribution of refrigerants on the heat exchange tube bundle is avoided, the utilization rate of heat exchange tubes is increased, and then the performance of the air conditioner is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Treatment device and system for asthma patients

PendingCN111450362ARealize intelligent drug suction operationRealize regulationMedical atomisersEngineeringAsthmatic patient

The invention discloses a treatment device and system for asthma patients in the field of medical instruments to solve the problem that self-adaptive medicine inhalation cannot be achieved in the prior art, and constructs an atomization device and system capable of performing automatic circulation of medicine inhalation and medicine output. The device comprises a liquid inlet bottle group, an atomization generator and an atomization liquid output tube, wherein the atomization generator comprises a barrel body, and a lateral push plate is in sliding connection to the inner part of the barrel body and is used for dividing the barrel body into an upper chamber and a lower chamber; a power assembly for driving the push plate to be in reciprocating motion is arranged in the lower chamber; the upper chamber comprises a group of passages which are in mutual opposite arrangement, one passage is a liquid inlet, and the other passage is a liquid outlet; and the liquid inlet communicates with theliquid inlet bottle group through an atomization liquid inlet tube, the liquid outlet communicates with the atomization liquid outlet tube, a one-way liquid output valve is arranged at the communication position of the atomization liquid output tube and the liquid outlet, and a one-way liquid inlet valve is arranged at the communication position of the atomization liquid inlet tube and the liquidinlet. According to the technical scheme of the device disclosed by the invention, through the reciprocating change situation of the upper chamber and the lower chamber, a medicine supply and medicine output integrated device is realized.

Owner:深圳市龙华区中心医院

Screw thread welding integral narrow slit type coaxial pulse-tube refrigerator

InactiveCN101298947BImprove uniform distributionImprove the diversion effectCompression machinesGas cycle refrigeration machinesCopper wirePulse tube refrigerator

Owner:SHANGHAI JIAOTONG UNIV

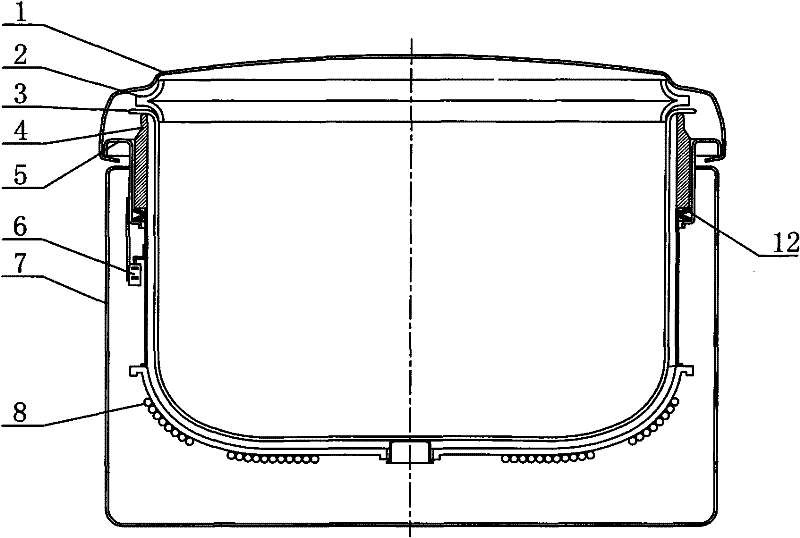

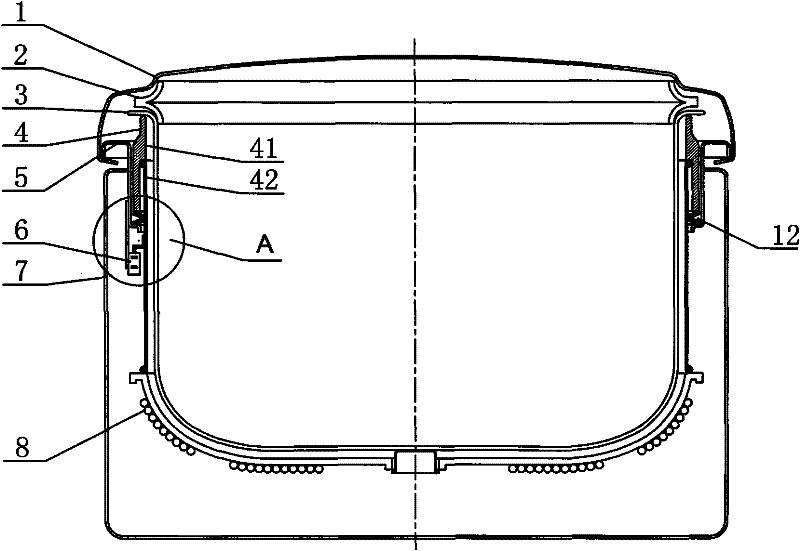

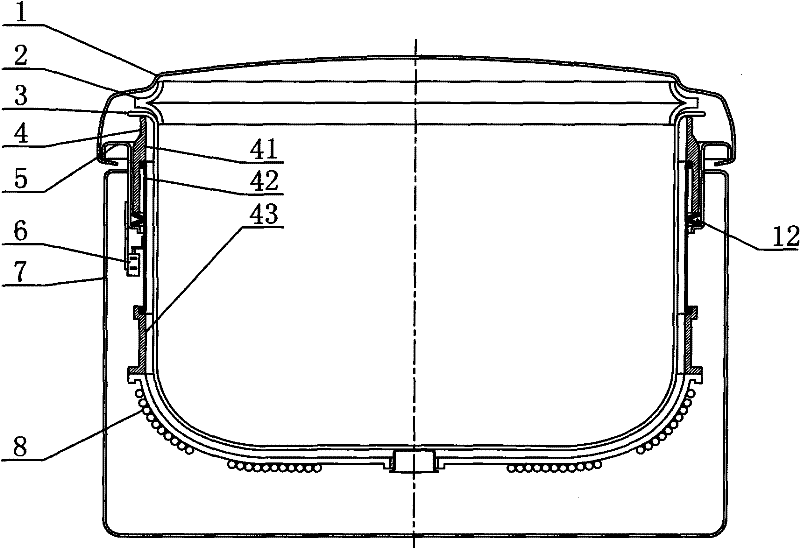

Electromagnetic heating pressure cooking device

ActiveCN101744527AControl pressureDoes not affect the design spaceWarming devicesEngineeringContact position

The invention discloses an electromagnetic heating pressure cooking device, which comprises a pot cover, a sealing ring, an inner pot, a shell, an outer pot ring fixed in the shell, and a displacement detection switch connected with a control circuit. The outer pot ring is rigidly connected when the pot cover is screwed, the sealing ring is positioned between the inner pot and the pot cover, a coil disc is arranged between the bottom of the inner pot and the shell, a pressure ring and an elastic mechanism are arranged between the inner pot and the outer pot ring, the top of the pressure ring is rigidly contacted with the pot edge of the inner pot, or a heat insulation pad which is used for separating the inner pot and the pressure ring is arranged at the contact position of the pressure ring and the inner pot edge, the lower part of the pressure ring is fixedly connected with the coil disc, the displacement end of the elastic mechanism is in movable rigid connection with the pressure ring, and the static end of the elastic mechanism is fixedly connected with the outer pot ring. The electromagnetic heating pressure cooking device can conveniently realize even heating of the whole pot bottom and achieve good cooking effect, and meanwhile has the advantages of simple structure, strong manufacturability, low cost, safety and reliability.

Owner:谛卓(北京)咨询顾问有限公司

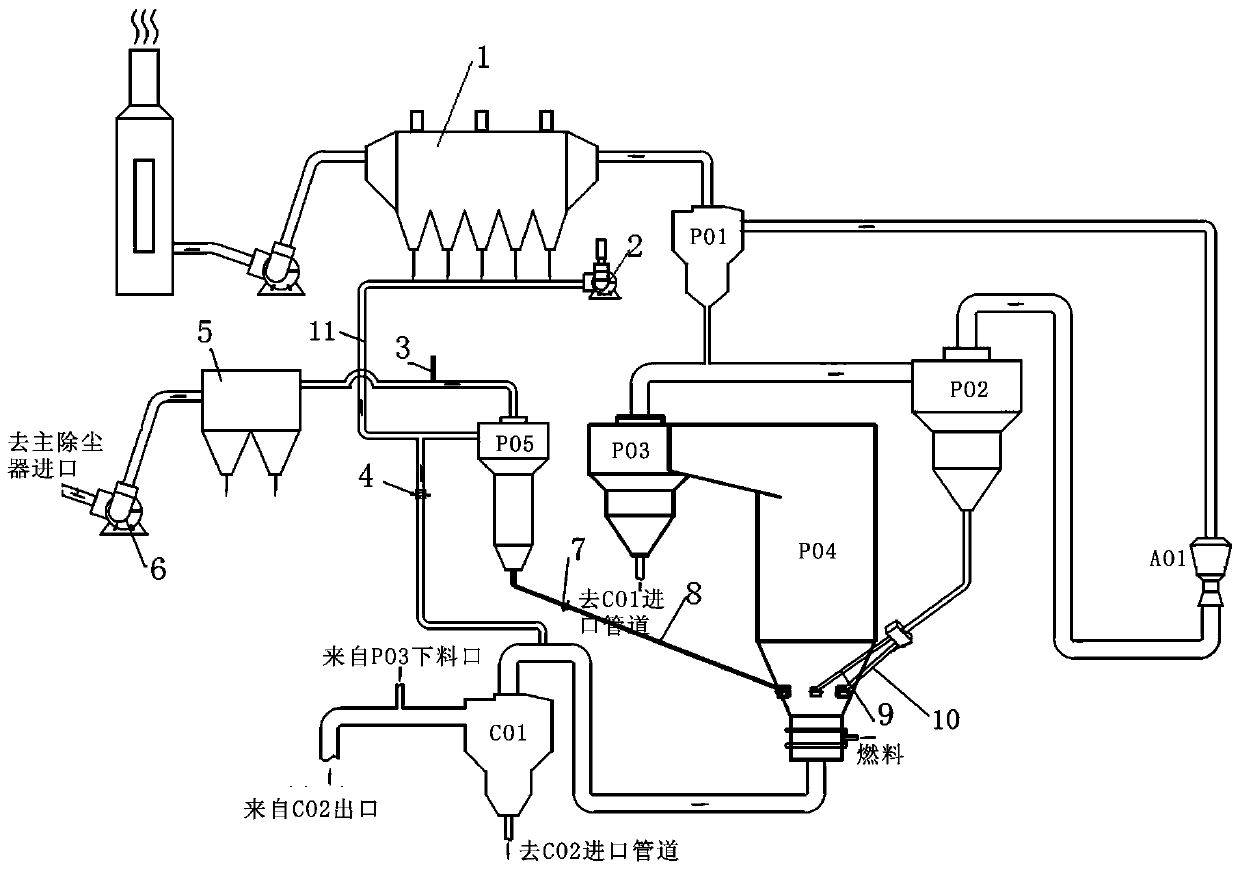

Material return process and device for alumina roasting furnace

InactiveCN110319696AIncrease temperatureReduce burning rateAluminium compoundsCharge composition/stateAluminium hydroxideCoarse particle

The invention discloses a material return process for an alumina roasting furnace. Aluminum hydroxide captured by a main dust remover and discharged along with waste gas after being dried is preheatedand then separated, fine particles are discharged along with the waste gas and collected by a secondary dust remover, and coarse particles are discharged into the roasting furnace to be roasted. A device comprises the main dust remover serially connected to an exhaust port of a preheating cyclone PO1 for aluminum hydroxide raw materials in alumina roasting equipment; and a charge port of a separator PO5 is connected with a discharge port in the bottom of the main dust remover through a material pipe; the exhaust port is connected with the secondary dust remover; and the discharge port is connected with the roasting furnace PO4. The collected mixture of about 15% of alumina and aluminum hydroxide is subjected to conveying, preheating, suspension and mixed dehydration, cyclone dust collection, and cloth-bag dust collection, and then discharged into the main dust remover through a fan, wherein large particles subjected to the cyclone dust collection are fed into the lower middle part ofthe roasting furnace PO4 to continue to be roasted; and the fine particles are collected and discharged through the cloth-bag dust collection for export sales for other alumina products or other applications.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

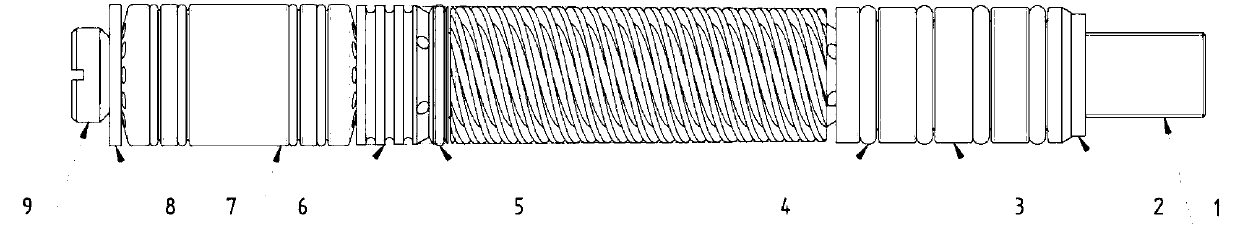

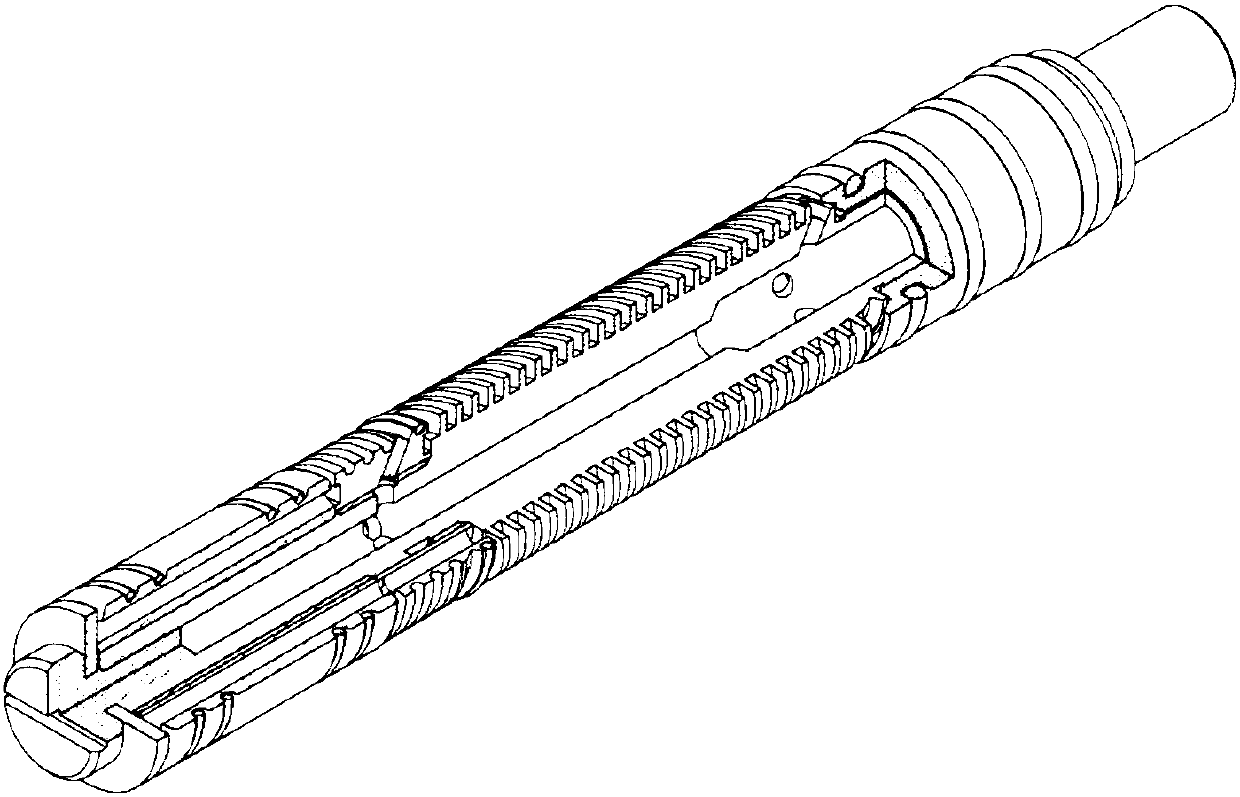

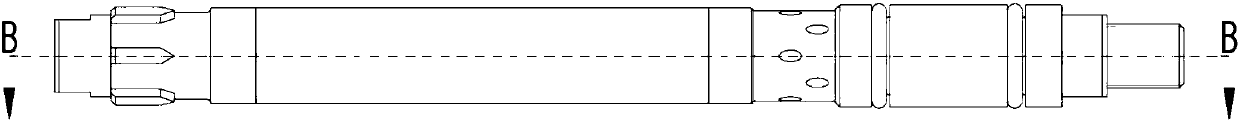

Electrolytic polishing cathode for inner hole of deep and long tube

PendingCN107893257AHigh trafficImprove uniform distributionElectrolysis componentsArchitectural engineeringMulti segment

The invention discloses an electrolytic polishing cathode for an inner hole of a deep and long tube. The electrolytic polishing cathode is used for solving the technical problem that an existing innerhole electrolytic polishing cathode is poor in practicability. According to the technical scheme, the electrolytic polishing cathode comprises a cathode body, a water sealing washer, a front guide body, centering O-shaped sealing rings, a cathode body annular groove section, a flow-dividing O-shaped sealing ring, a rear guide body, a back-pressure rubber washer and a screw cap; the cathode body serves as a centre shaft, and the left end of the cathode body is connected to the cathode body annular groove section and the rear guide body in a threaded mode, is sleeved with the back-pressure rubber washer and then is tightly pressed with the screw cap; the right end of the cathode body is connected to the front guide body in a threaded mode and is sleeved with the water sealing washer; the flow-dividing O-shaped rubber ring and the two sets of centering O-shaped sealing rings are arranged in annular grooves corresponding to the front guide body, the rear guide body and the cathode body annular groove section; the threaded bonding surfaces of the front guide body, the rear guide body and the cathode body are coated with adhesives so as to be connected; and a multi-wire spiral groove section in the cathode body and a annular groove section body in the cathode body annular groove section form an electrolytic working area. The multi-wire spiral groove section in the cathode body and the cathode body annular groove section provide electrolyte separately, and therefore the smoothness of the inner hole of the deep and long pipe can be improved, and the practicability is good.

Owner:XIAN KUNLUN IND GRP

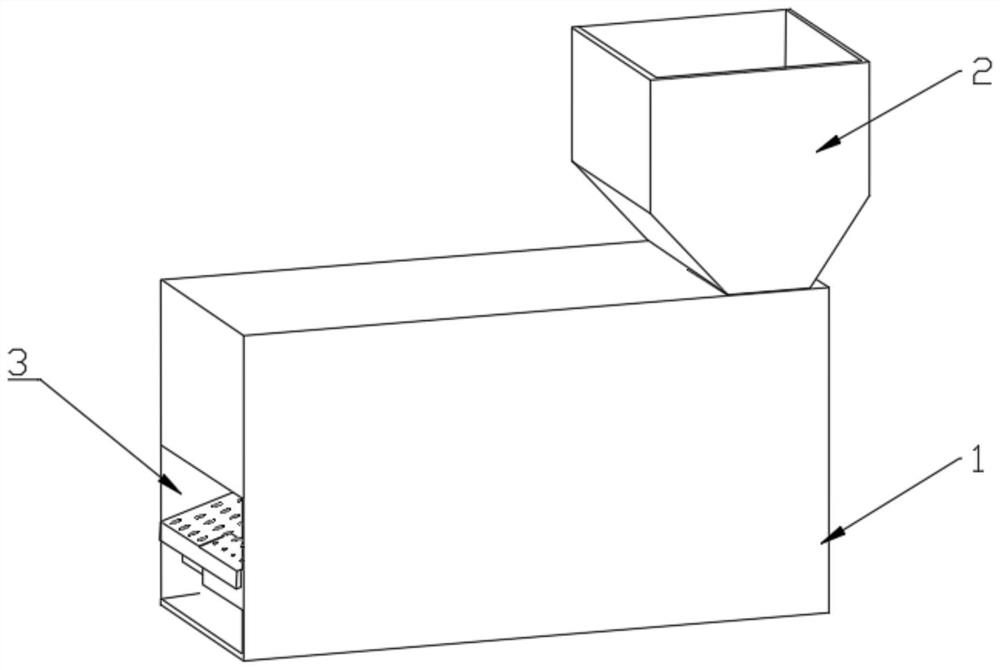

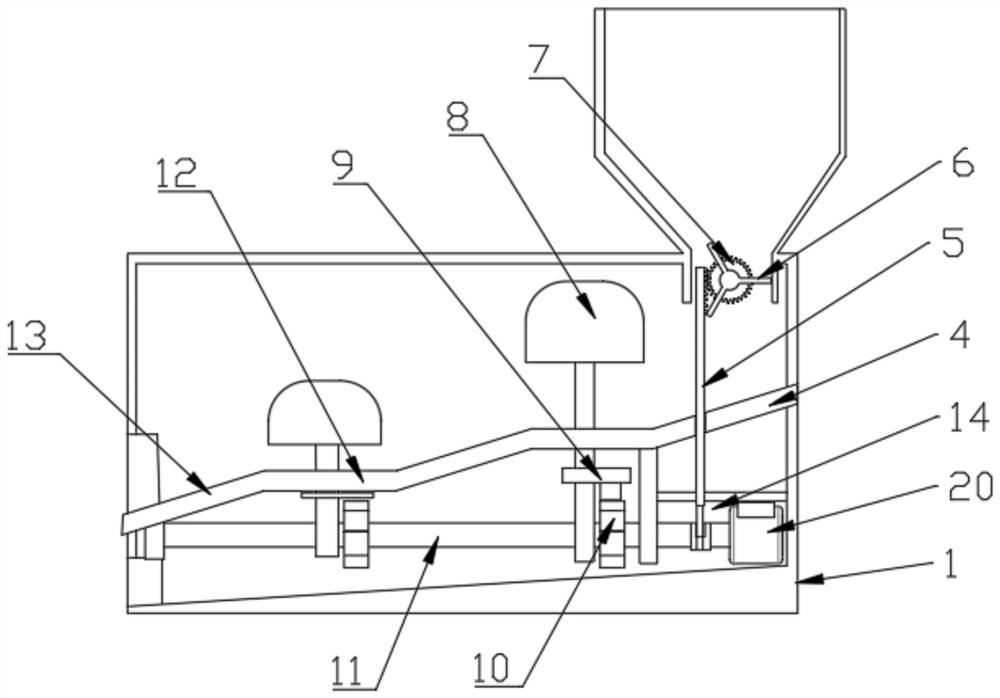

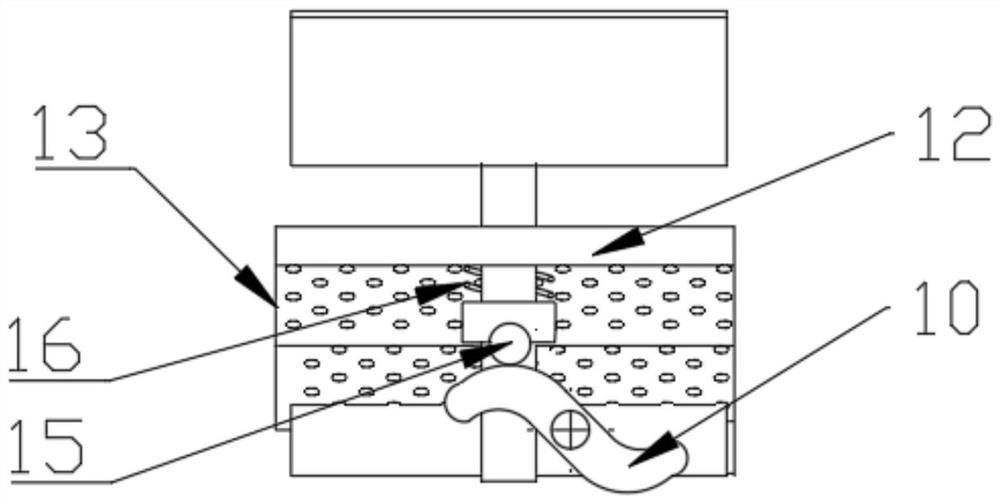

A mining crushing equipment

The present invention is applicable to the technical field of mining machinery, and provides a crushing equipment for mine development. The crushing equipment for mine development includes: a shell with a crushing space formed inside, and a discharge opening is opened on the side wall at one end; a feed hopper, Connected to the top of the shell, it is used to hold the ore to be crushed; the sieve plate is fixed and inclined to be installed inside the shell, and is used to screen the broken ore and support the broken ore; the transmission rod is set at the The inside of the shell is in the same direction as the sieve plate; at least one breaker is installed, and it can be lifted through the sieve plate through the support rod to crush the ore on the sieve plate; the S-shaped ejector rod is connected to the On the transmission rod, it is used to lift the breaking hammer up; the driving part is connected with the transmission rod, and is used to drive the transmission rod to rotate; among them, the flow end of the sieve plate extends out of the discharge port, and the discharge port is divided into upper and lower parts. outlet. The invention has the advantages of simple structure, high crushing efficiency, strong crushing capacity and good continuity.

Owner:荆门城控窑湾建材有限公司

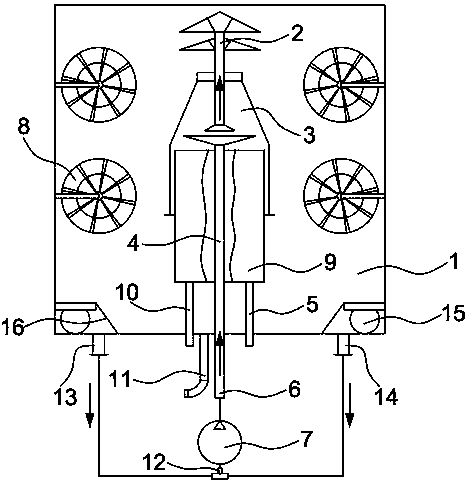

Wort boiling device based on circulation pump

The invention discloses a wort boiling device based on a circulation pump and belongs to the technical field of beer brewing. The device comprises a shell and a heat exchanger. The heat exchanger is arranged in the center of the shell. The inner side wall of the shell is connected to a water wheel. The upper end of the heat exchanger is connected to a reflux cylinder. The upper end of the reflux cylinder is connected to a uniform distribution device. The lower end of the shell is connected to a wort inlet. The upper end of the wort inlet is connected to a heating pipe. The heating pipe passesthrough the heat exchanger and is connected to an ejector. One side of the wort inlet is provided with a wort discharge pipe connected to the bottom of the shell. The bottom of the shell is connectedto a circulation outlet I and a circulation outlet II. The wort boiling device has a simple whole structure, is easy to operate, realizes uniform heating of the wort in a flowing state, has good heating effects and has low energy consumption. The water wheel improves the wort water vaporization, the air distribution in the device and the beer taste.

Owner:浦江县泰如食品科技有限公司

Industrial tail gas pollutant removal system and method

PendingCN112915737AImprove removal effectReduce escape rateGas treatmentDispersed particle separationNitrogen oxidesFlue gas

The invention discloses an industrial tail gas pollutant removal system which comprises a main flue gas purification system, wherein the main flue gas purification system comprises a desulfurization tower, a denitration tower and an other pollutant removal device. The industrial tail gas pollutant removal system further comprises an external circulation gas extraction system which is used for extracting part of purified and undischarged industrial tail gas to enter the desulfurization tower for circulation purification. The main flue gas purification system further comprises an inlet flue gas online monitoring device used for detecting inlet industrial tail gas, a flue gas mixer used for mixing the detected inlet industrial tail gas with the industrial tail gas part extracted by the external circulation gas extraction system, and an outlet flue gas on-line monitoring device used for detecting the discharged industrial tail gas. According to the invention, the external circulation gas extraction system is arranged, and the main flue gas purification system is used for recycling and purifying industrial tail gas, so that the removal effect of pollutants such as sulfur dioxide and nitrogen oxide is further enhanced while an additional pollutant removal device is avoided.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

A filter-type wet electrostatic precipitator and method

The invention discloses a filter-screen wet-type electric dust removing device. The electric dust removing device comprises a flue gas inlet device, a flue gas processing device and a flue gas discharging device, wherein the flue gas inlet device, the flue gas processing device and the flue gas discharging device are sequentially and closely connected with one another to form an integrated semi-enclosed device which is provided with openings in the two ends; a plurality of parallel anode plates and cathode wires arranged among the anode plates are arranged inside the flue gas processing device; dust collecting devices are arranged at the tail ends of the anode plates, and are used for capturing dust escaping from the tail ends of the anode plates. The electric dust removing device is efficiently intelligentized, and can effectively capture dust escaping along the surfaces of the dust collecting anode plates, increase the dust collecting areas of electric fields of dust removers, improve the dust collecting efficiency and avoid reentrainment pollution; in the wet-type soot cleaning process, the dust temperature can be further reduced, the dust moisture is increased, the dust specific resistance is reduced, and the dust removing efficiency is improved; meanwhile, when atmosphere hazardous materials are removed, effective ingredients in pollutants are extracted and converted into useful chemical fertilizers, low carbon and environment protection are realized, and the sustainable development of enterprises is facilitated.

Owner:YIXING IDEAL TECH CO LTD

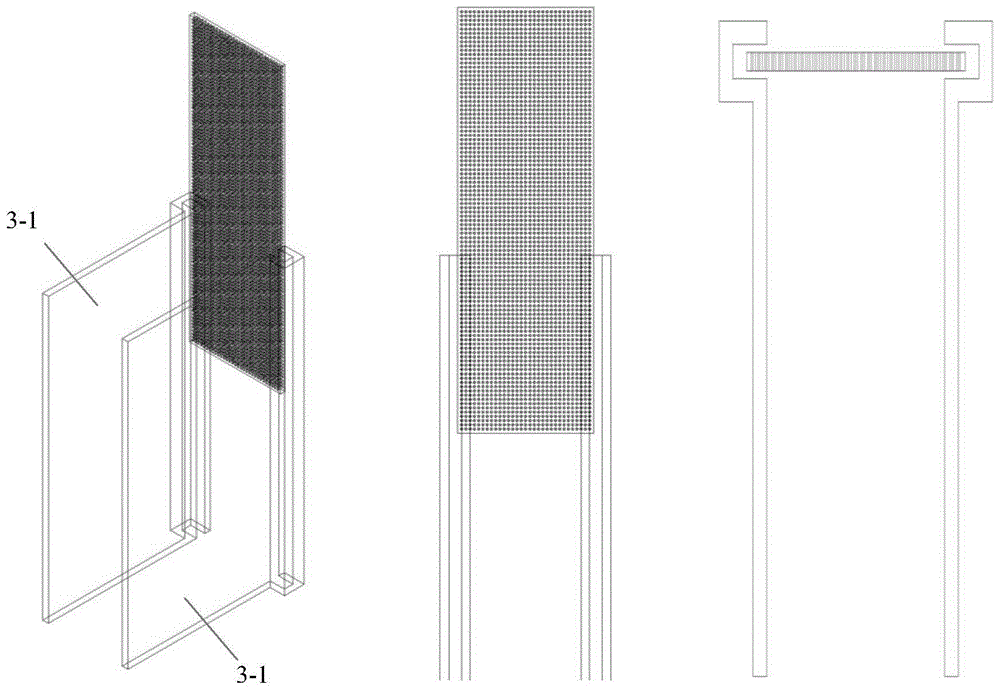

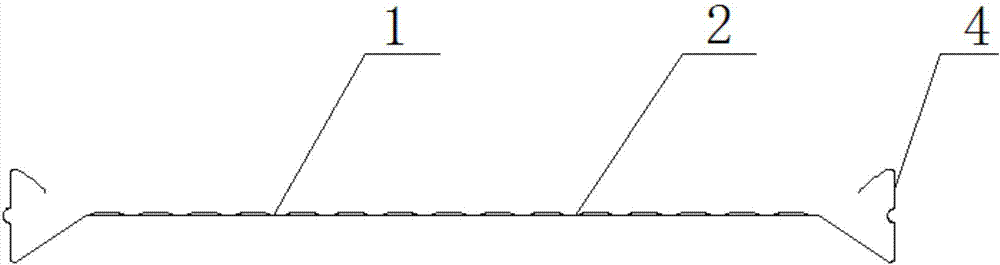

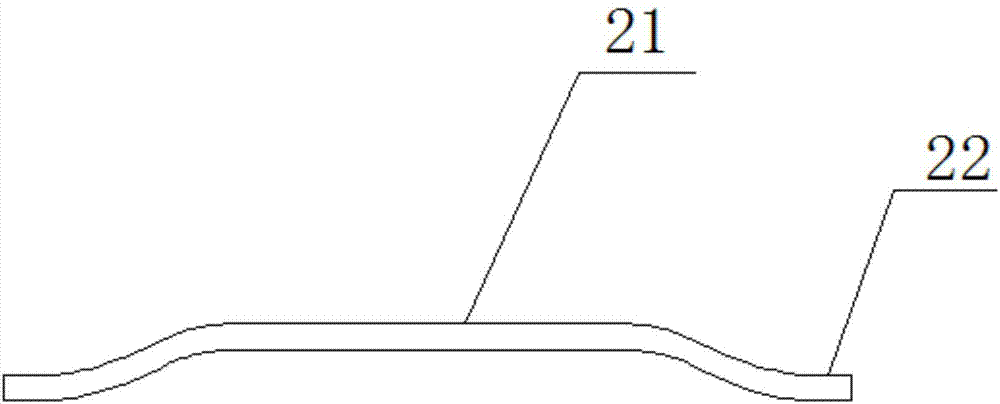

Anode plate for wet type electrostatic dust collector

InactiveCN107138280AEasy to installImprove uniform distributionExternal electric electrostatic seperatorElectrode constructionsEngineeringElectric field

The invention discloses an anode plate for a wet electrostatic precipitator, which comprises an anode plate body and a corrugated part. The upper and lower ends of the anode plate body are provided with fixing holes, and the left and right ends of the anode plate body are provided with bent suspension beams; the suspension beam at one end is provided with U-shaped grooves, U-shaped A clamping block is arranged annularly on the groove, a U-shaped projection is arranged on the suspension beam at the other end, and a clamping groove is arranged annularly on the U-shaped projection. The good flatness, waviness and rigidity of the present invention ensure the electrode spacing between the cathode and the anode, are conducive to the formation of a stable electric field, facilitate the uniform distribution of the water film, and improve the process selectability of the wet electrostatic precipitator.

Owner:ZHEJIANG NANYUAN ENVIRONMENT ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com