Double-track trolley group running mechanism for ultra-large gantry crane

A super-large door and operating mechanism technology, applied in the directions of walking mechanism, rail system, transportation and packaging, etc., can solve the problems of high manufacturing cost, weakened horizontal rigidity, complex stress, etc., to facilitate maintenance and maintenance, and reduce construction costs. , the effect of increasing the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

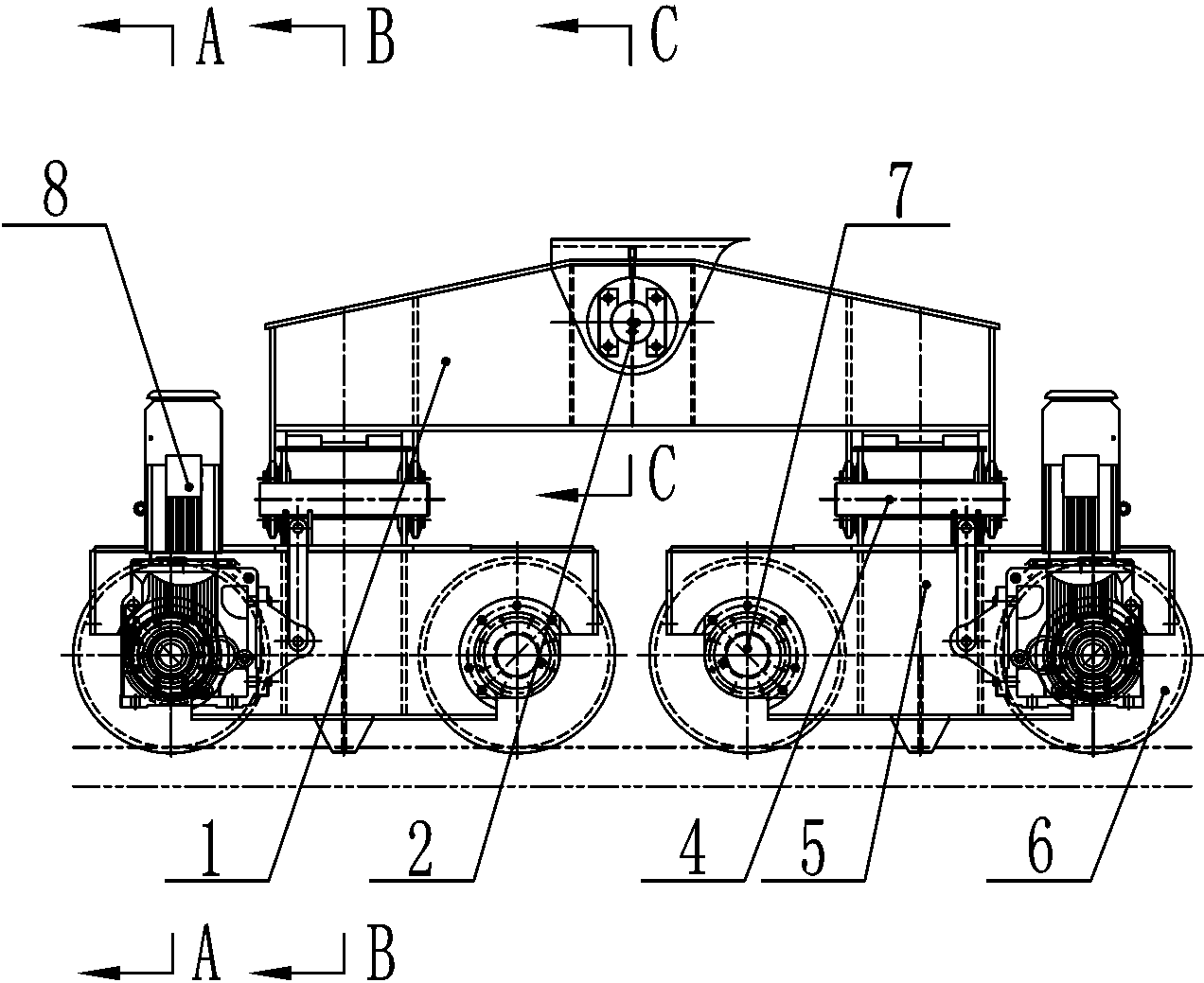

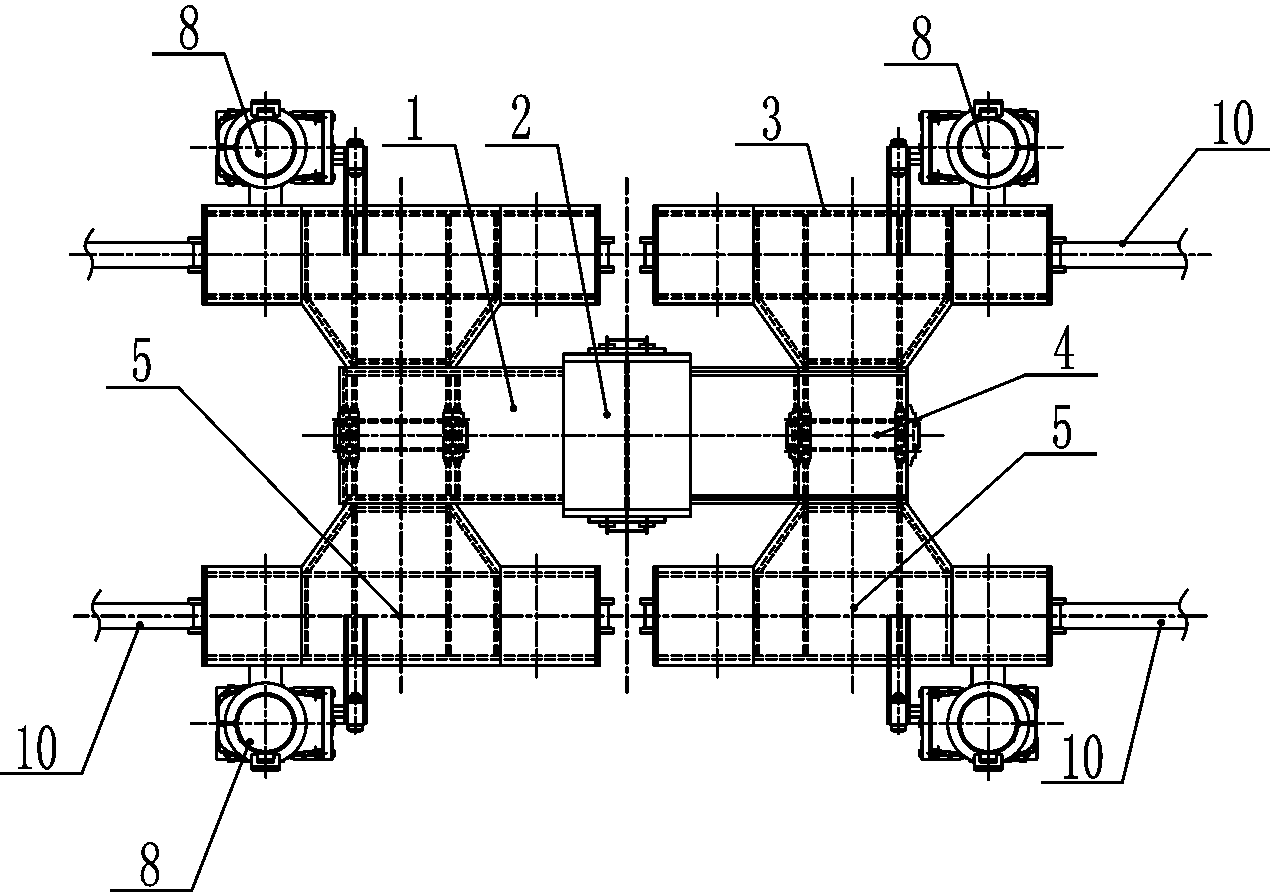

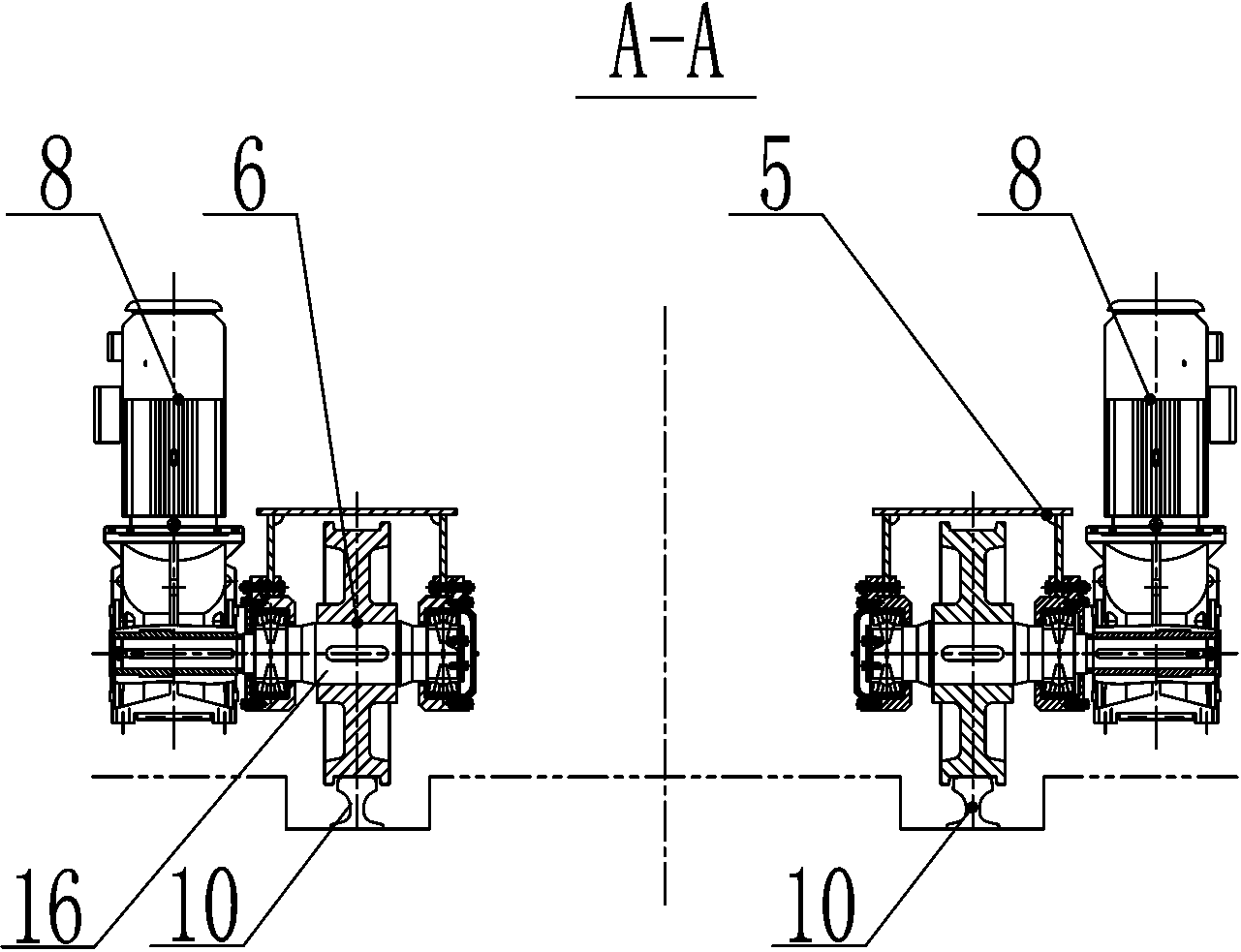

[0020] See attached figure 1 ~ attached figure 2 , the present invention is made up of balance beam 1 and double-track trolley 3, and described double-track trolley 3 is a four-wheel dual-drive mechanism composed of running wheels 6 and driven wheels 7 symmetrically arranged on both sides of vehicle frame 5. The double-track trolley 3 is fixedly arranged at both ends of the balance beam 1 by the hinge shaft 4, and the double-track trolley 3 and the balance beam 1 are hingedly connected. The vehicle frame 5 is an "I"-shaped box structure. The driven wheel 7 is fixedly arranged on the vehicle frame 5 by a wheel shaft. Described traveling wheel 6 is the driving wheel that is provided with driving mechanism 8, and driving mechanism 8 makes traveling wheel 6 promote driven wheel 7 and drives the trolley group that is made up of two double-track trolleys 3 to run on track 10 together. The driving mechanism 8 is a three-in-one device of a motor, a reducer and a brake. The driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com