Anode plate for wet type electrostatic dust collector

A wet electrostatic and anode plate technology, applied in the field of electrostatic precipitator equipment and anode plates for wet electrostatic precipitators, can solve the problems of dust capture effect, unsatisfactory adhesion effect, inability to form a complete water film smoothly, and affect the dust removal effect, etc., to achieve It is beneficial to the uniform distribution of water film, simple installation and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

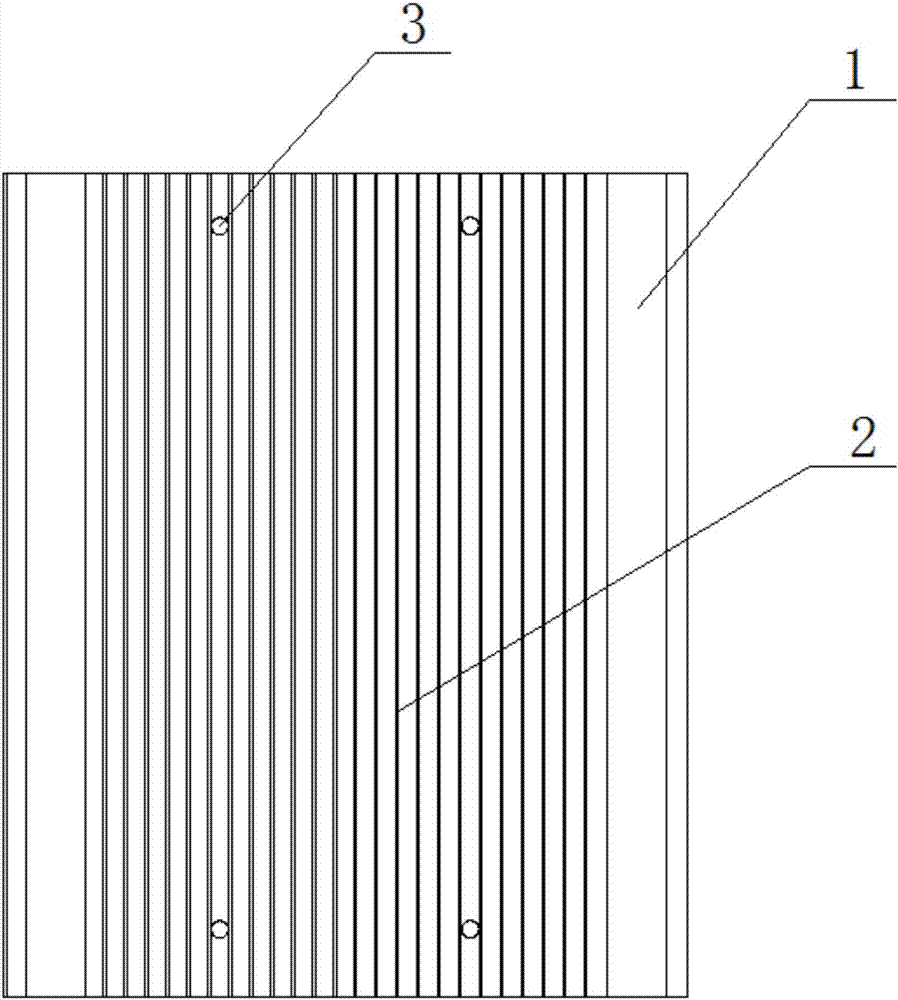

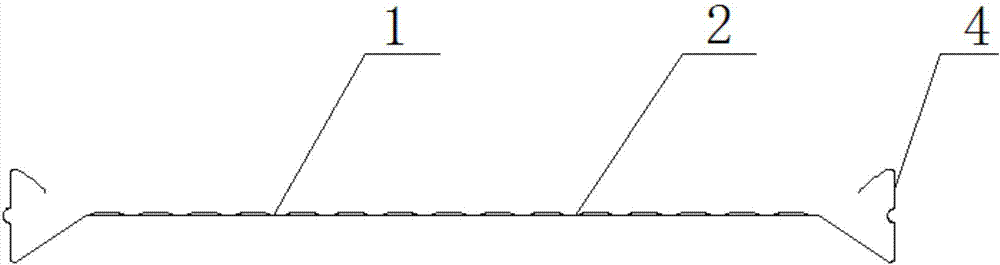

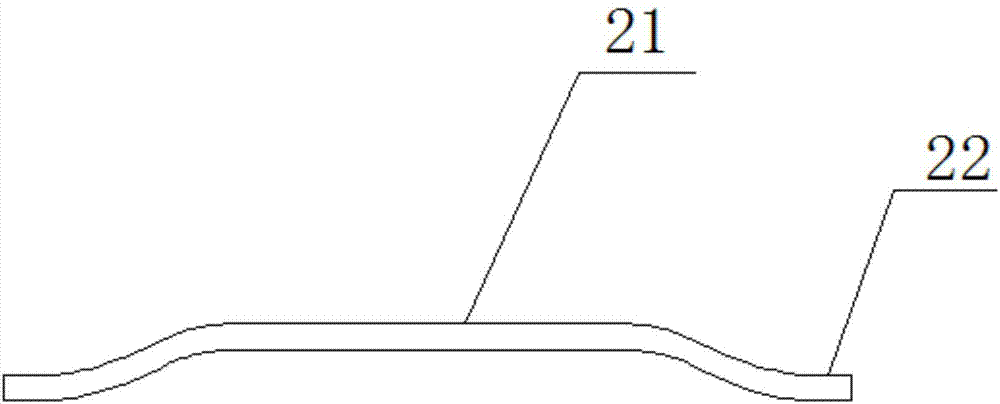

[0024] refer to Figure 1 to Figure 5 , the present invention includes an anode plate body 1 and a corrugated part 2, which is characterized in that: the anode plate body 1 is provided with a corrugated part 2, and the cross section of the corrugated part 2 is formed by connecting several convex surfaces 21 and concave surfaces 22 in circular arcs Corrugated; the upper and lower ends of the anode plate body 1 are provided with fixing holes 3, and the left and right ends of the anode plate body 1 are provided with bent suspension beams 4; the suspension beam 4 at one end is provided with a U-shaped groove 41, the U-shaped slot 41 is provided with a clamping block 42 in a ring, the suspension beam 4 at the other end is provided with a U-shaped protrusion 43, and the U-shaped protrusion 43 is provided with a clamping groove 44 in a ring. The U-shaped protrusion 43 fits with the U-shaped groove 41 , and the locking block 42 is locked in the locking groove 44 . The anode plate bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com