Patents

Literature

130results about How to "Easy to pave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

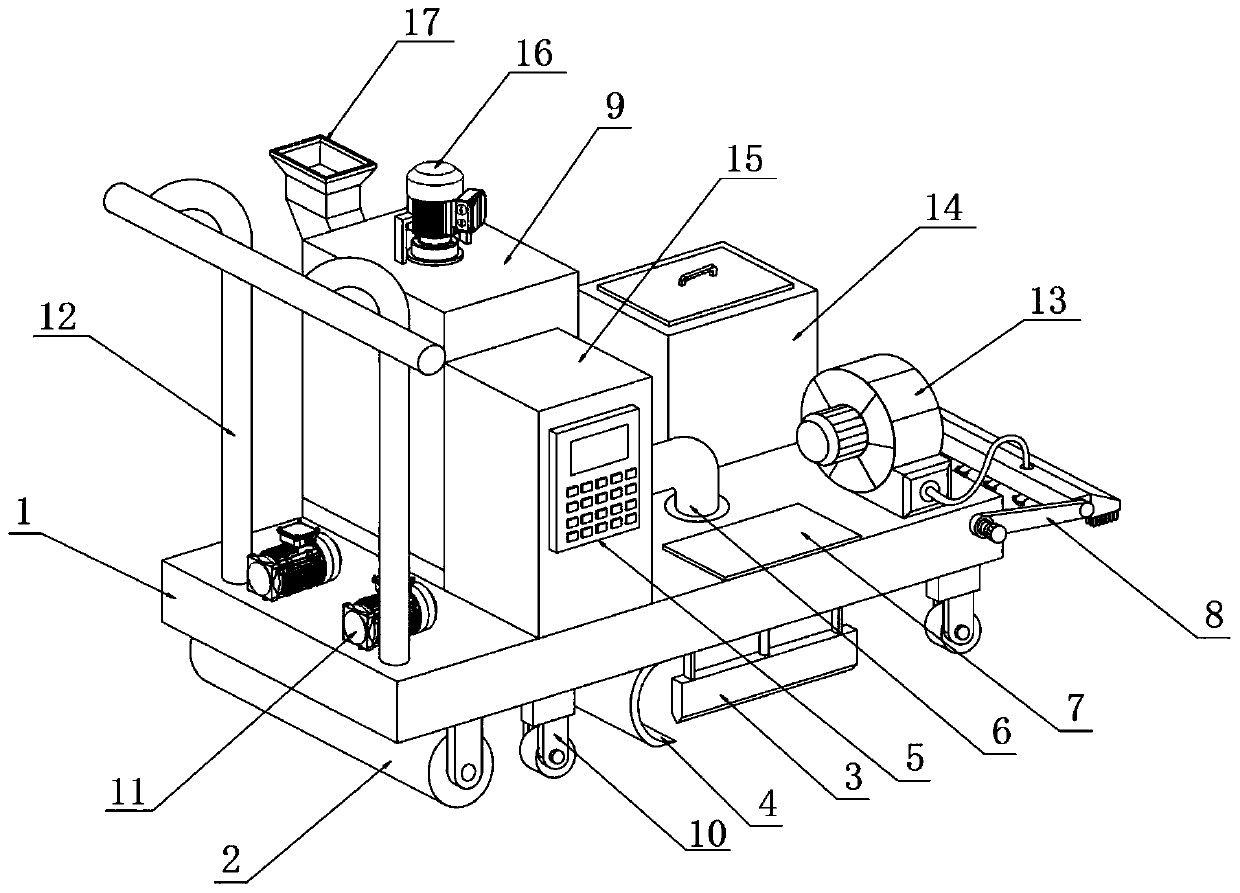

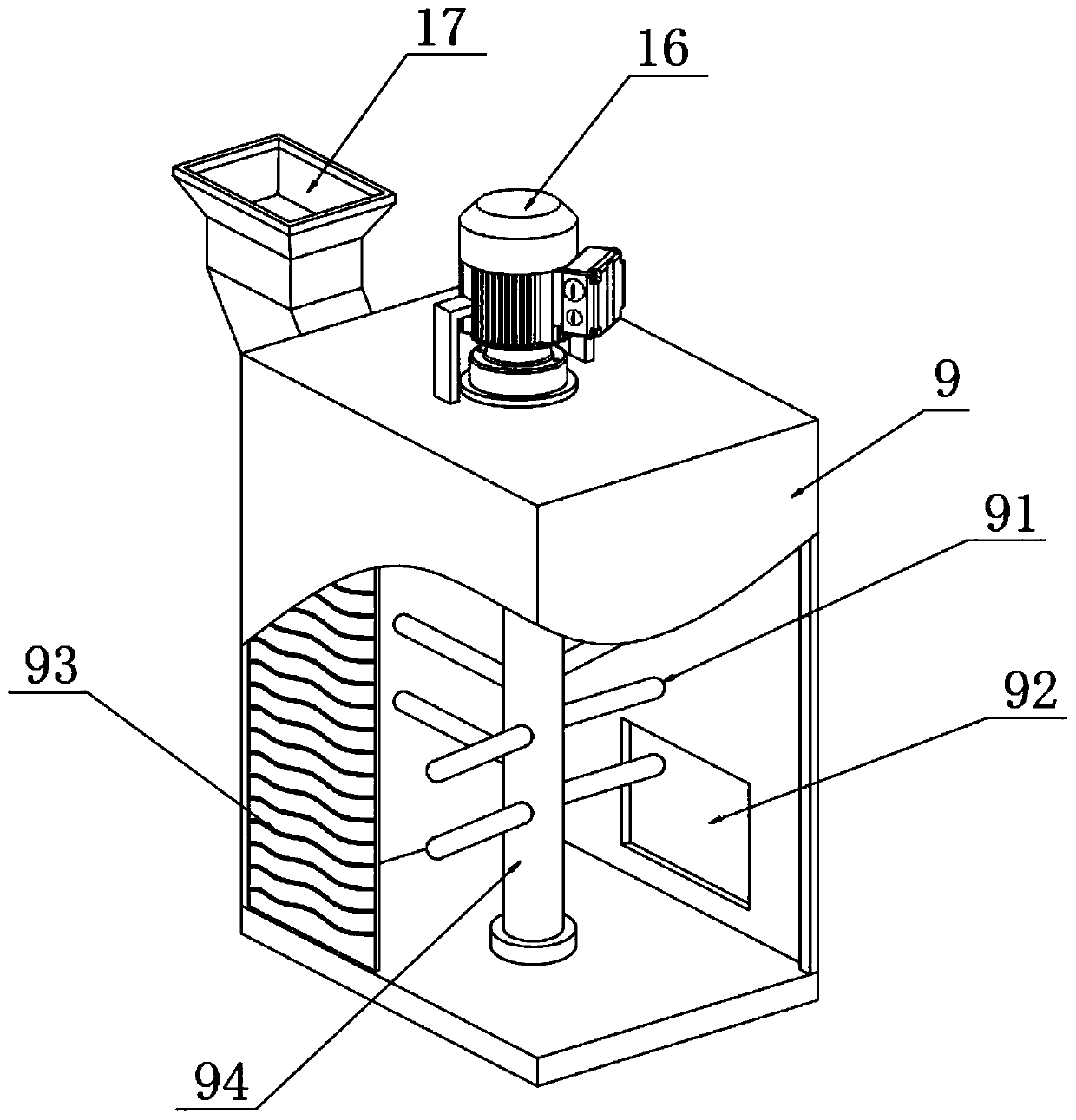

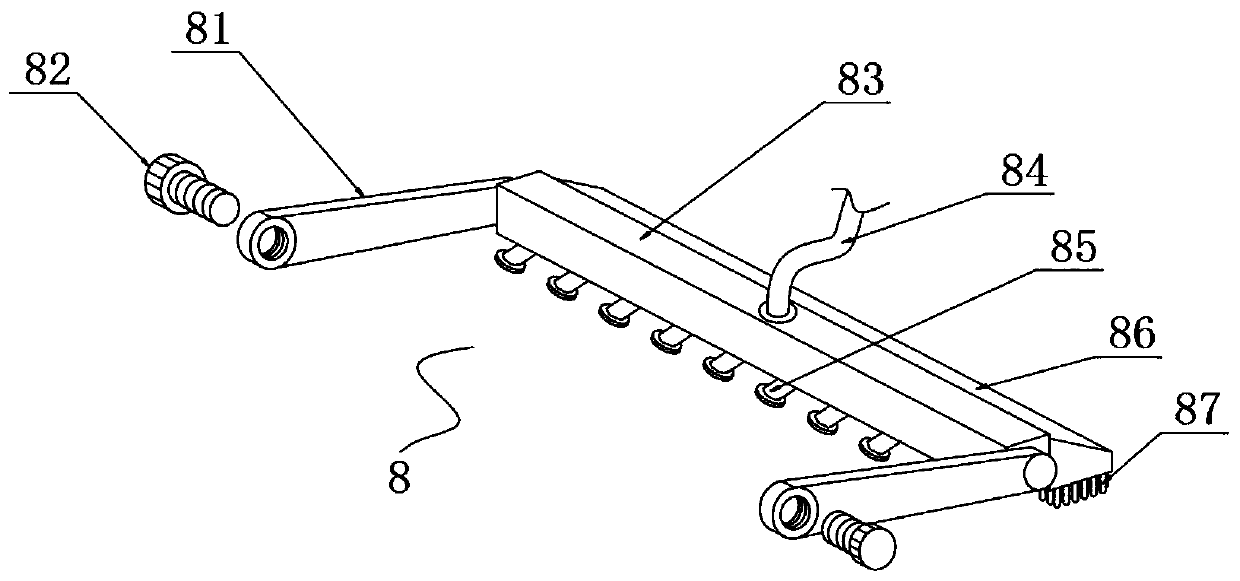

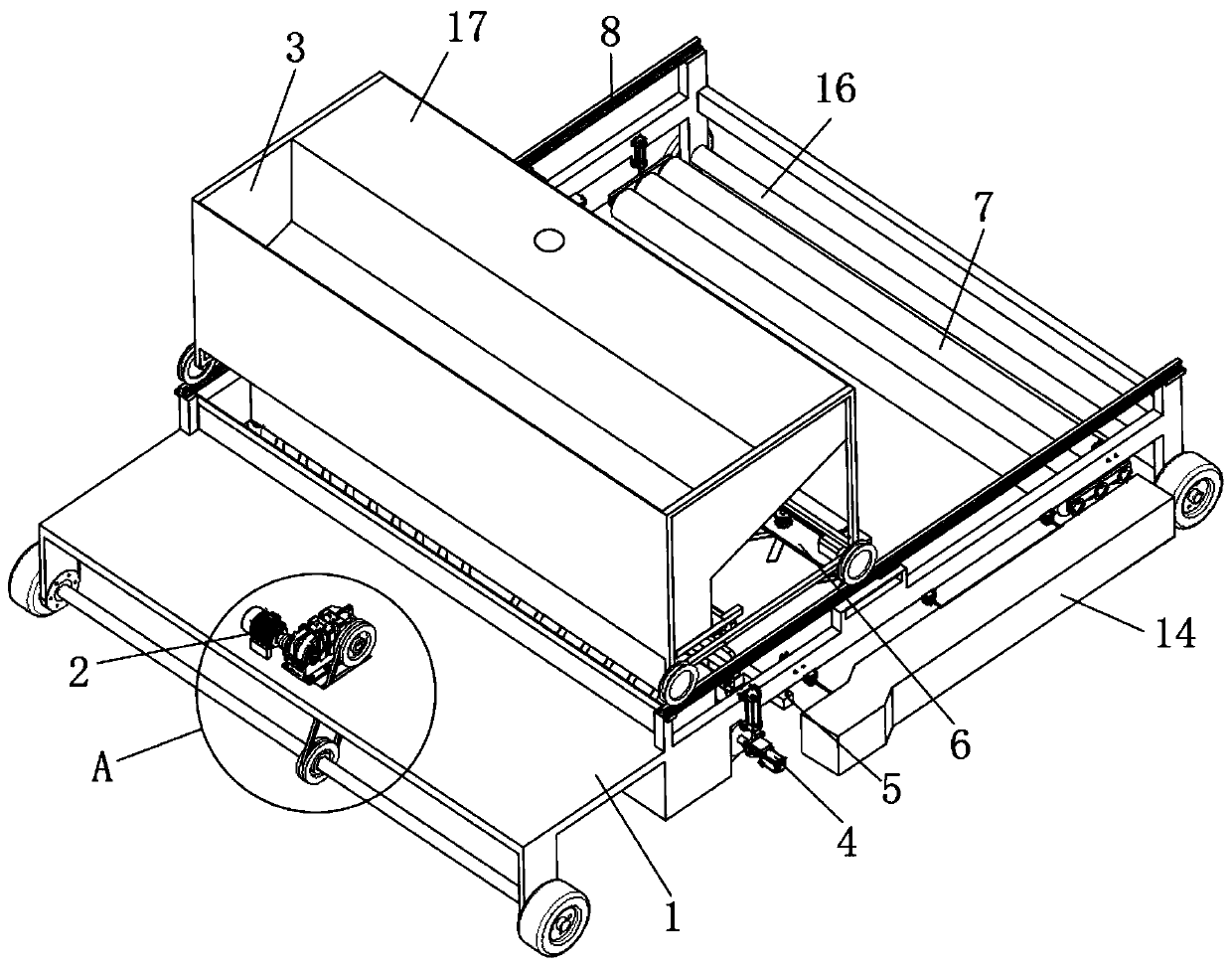

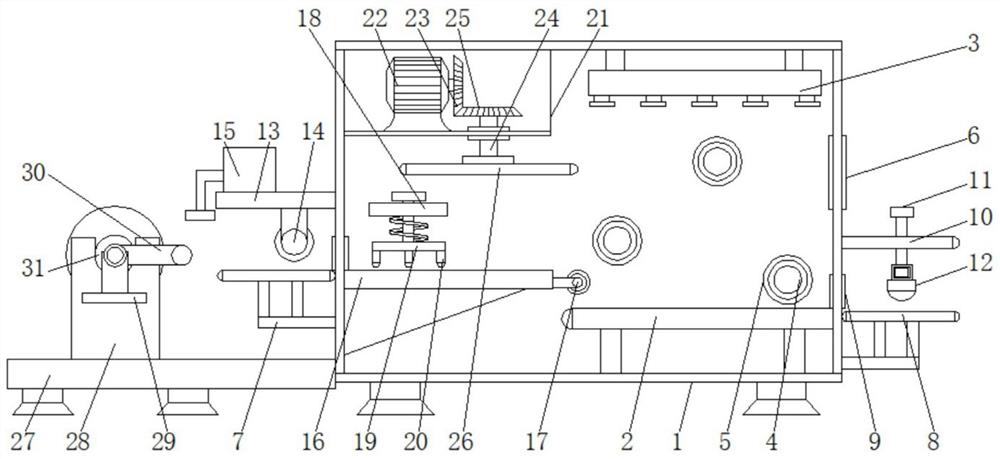

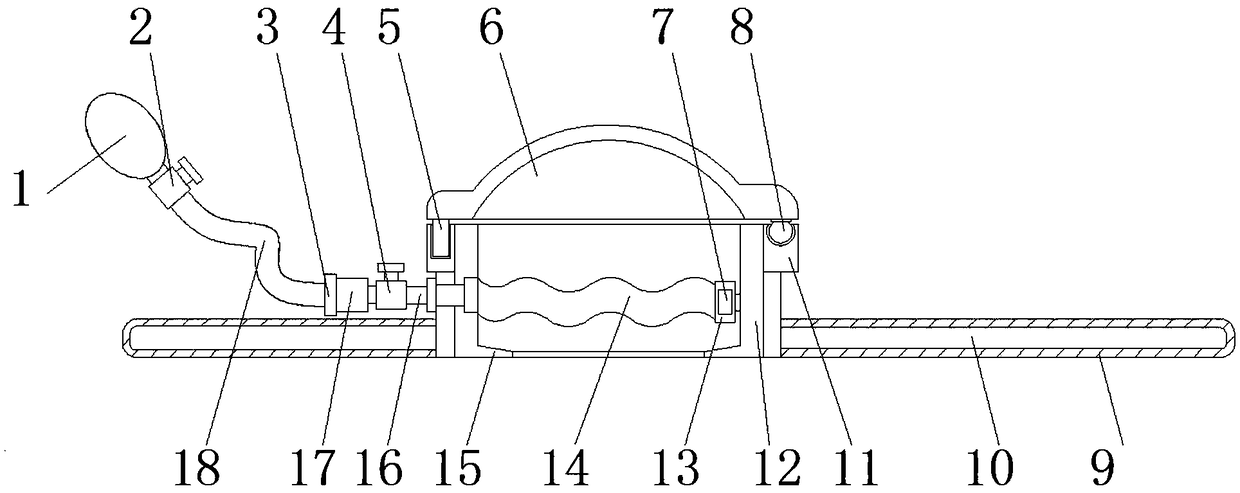

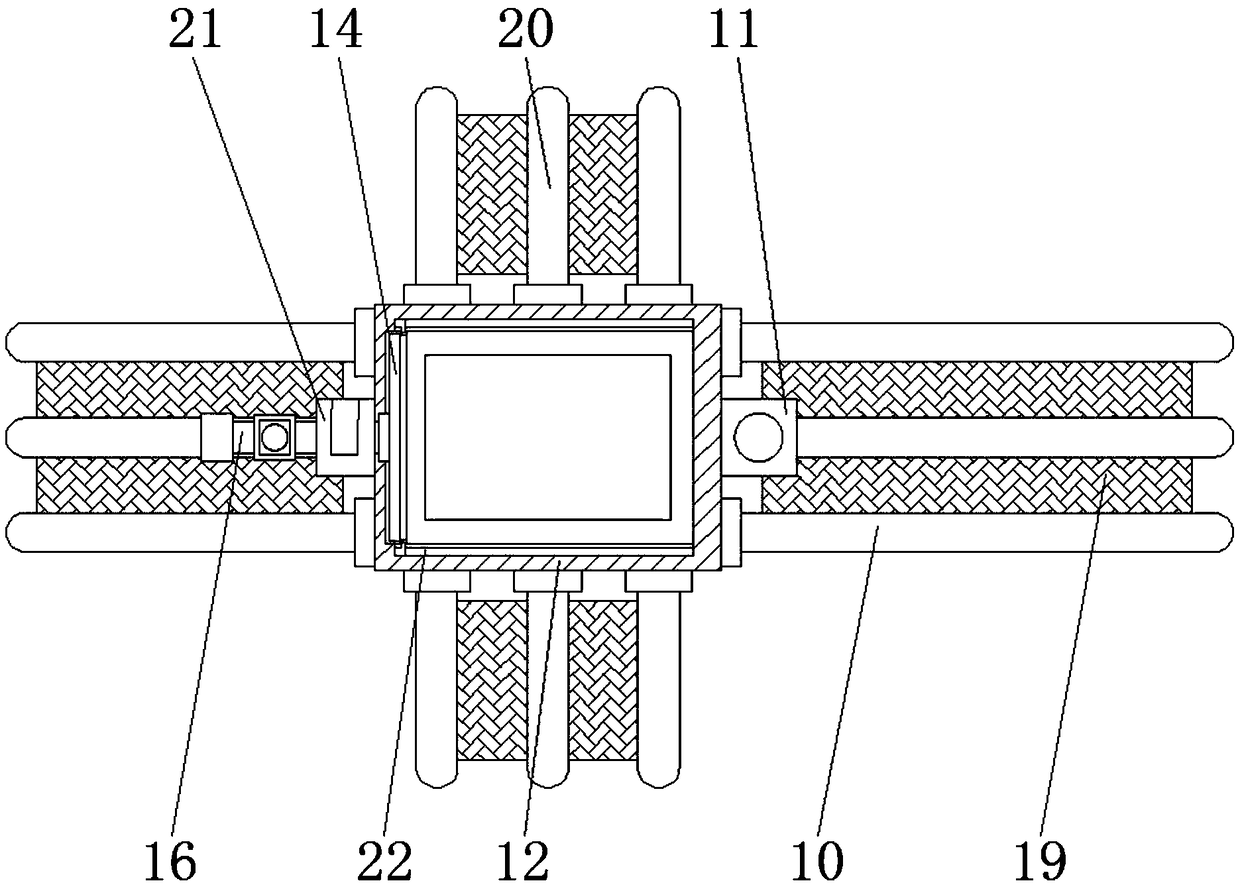

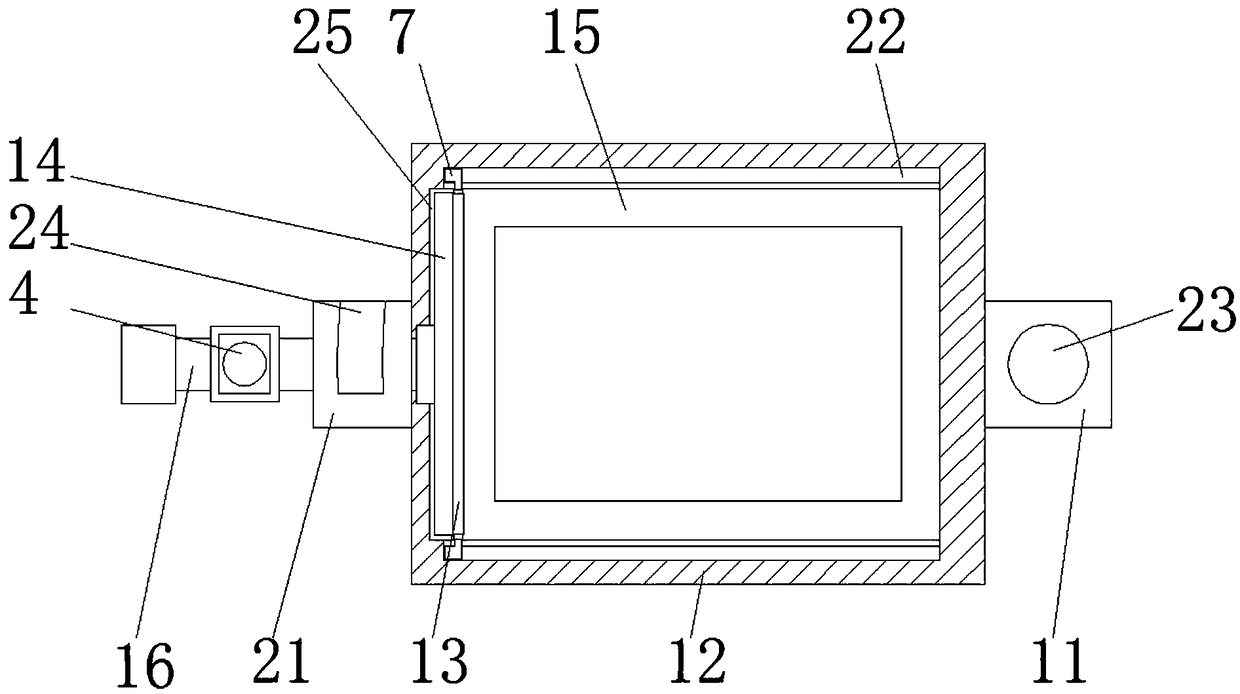

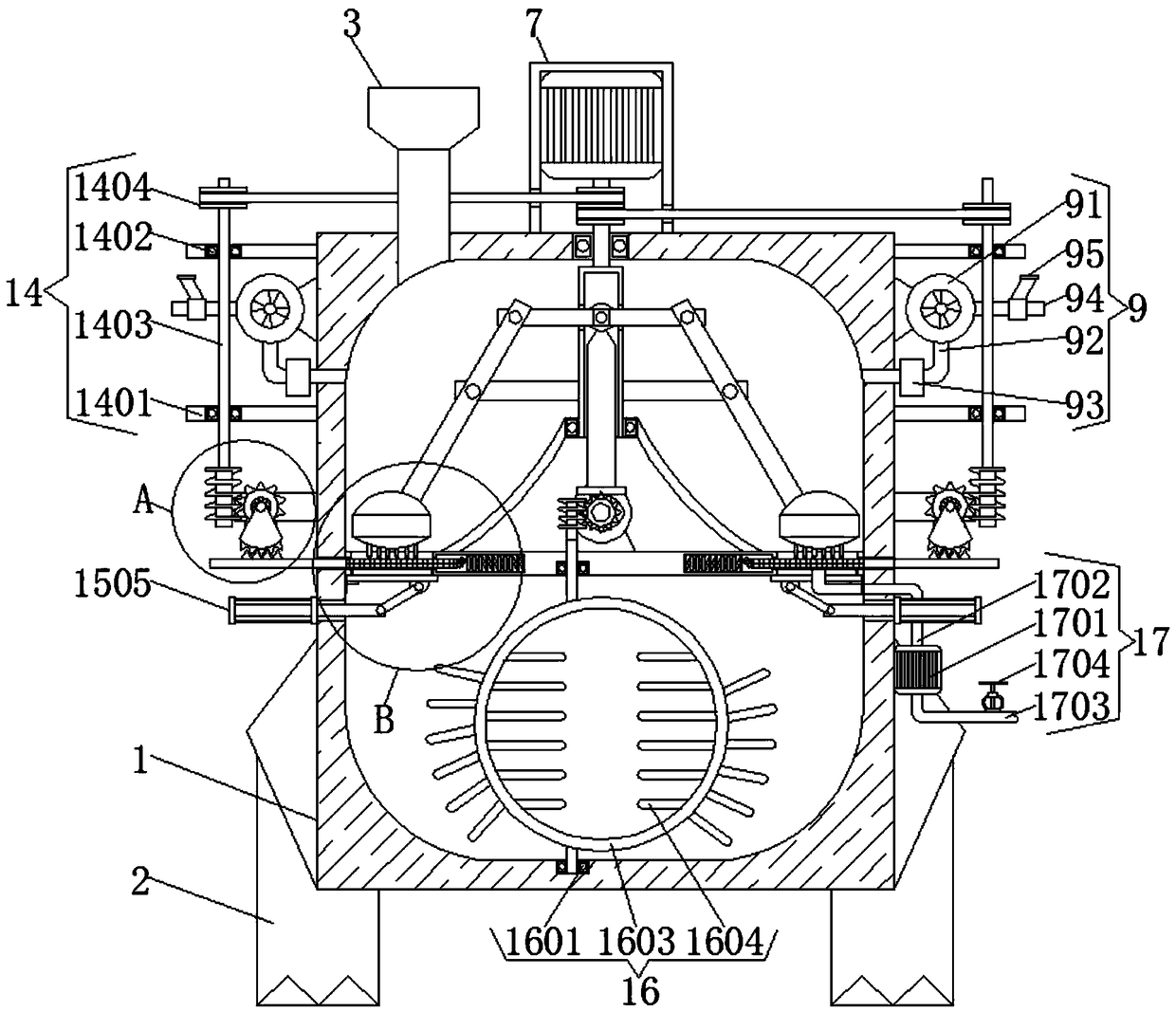

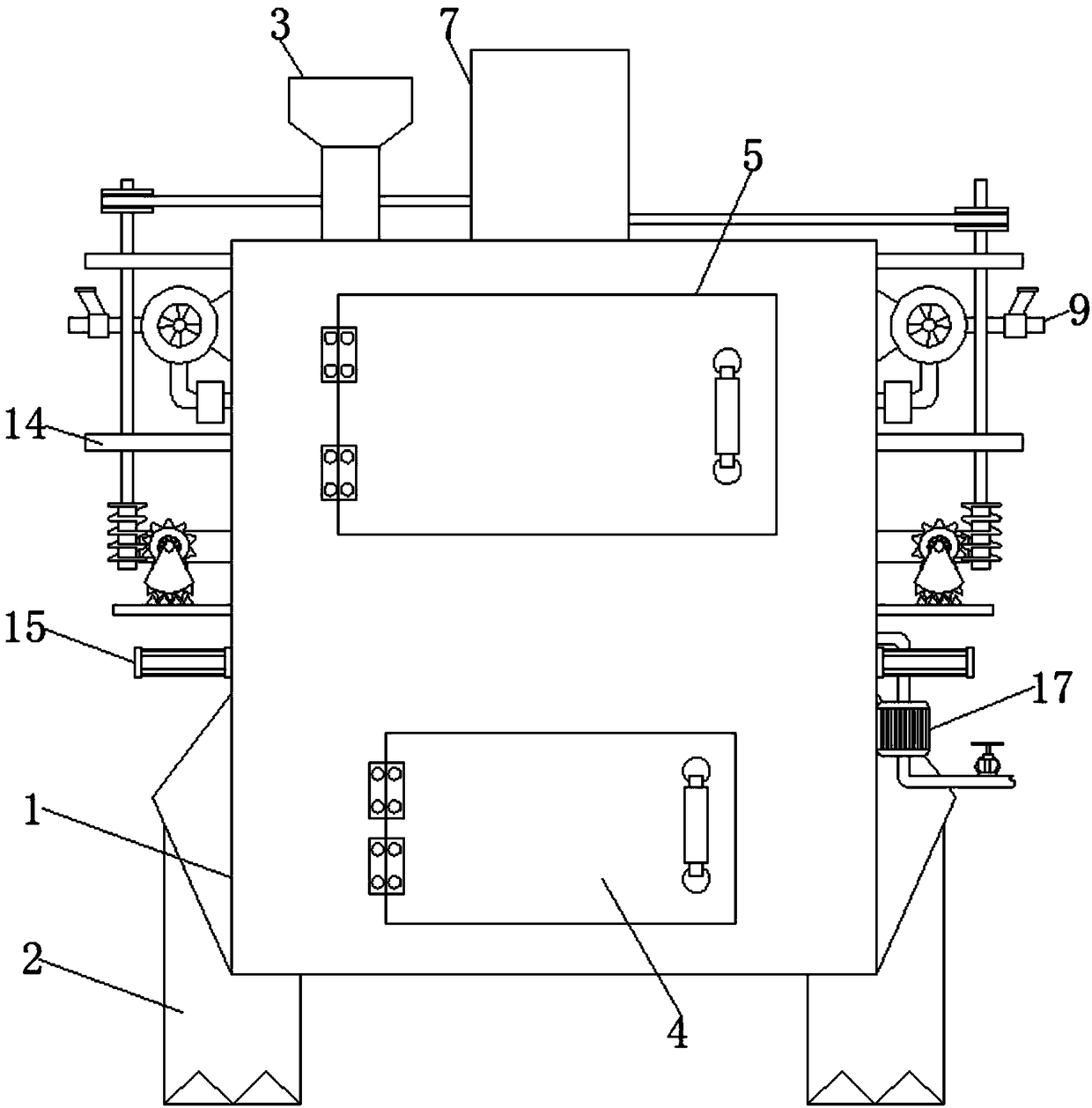

Road engineering pavement asphalt paving equipment

InactiveCN110424220AEnsure smoothness and uniformityEasy to rollRoad cleaningRoads maintainenceRoad engineeringVibration motor

The invention relates to the technical field of road engineering, in particular to road engineering pavement asphalt paving equipment. The road engineering pavement asphalt paving equipment comprisesa base, a pressing roller is installed at the rear end of the lower surface of the base, and a vibration motor is installed at one side position, close to a pushing handle, of the upper surface of thebase; and a stirring bin is installed on the upper surface, on the front side of the vibration motor, of the base, a discharging pipe is connected to the lower end of the front surface of the stirring bin in a penetrating mode, and a sweeping mechanism is arranged at the front end of the base. According to the road engineering pavement asphalt paving equipment, the adjustable sweeping mechanism is additionally arranged, so that the road surface can be further cleaned when the road is laid, and the quality of asphalt paving is ensured; and a paving board is additionally arranged at the bottomof the device and is matched with a threaded rod and a servo motor for using so that the paving board can uniformly spread the discharged asphalt, the flatness and uniformity of asphalt paving are ensured, rolling of the asphalt by a compression roller in subsequent process is facilitated, the operation is simple and convenient, the cost is low, and the paving effect of the asphalt is good.

Owner:淄博询知方技术开发有限公司

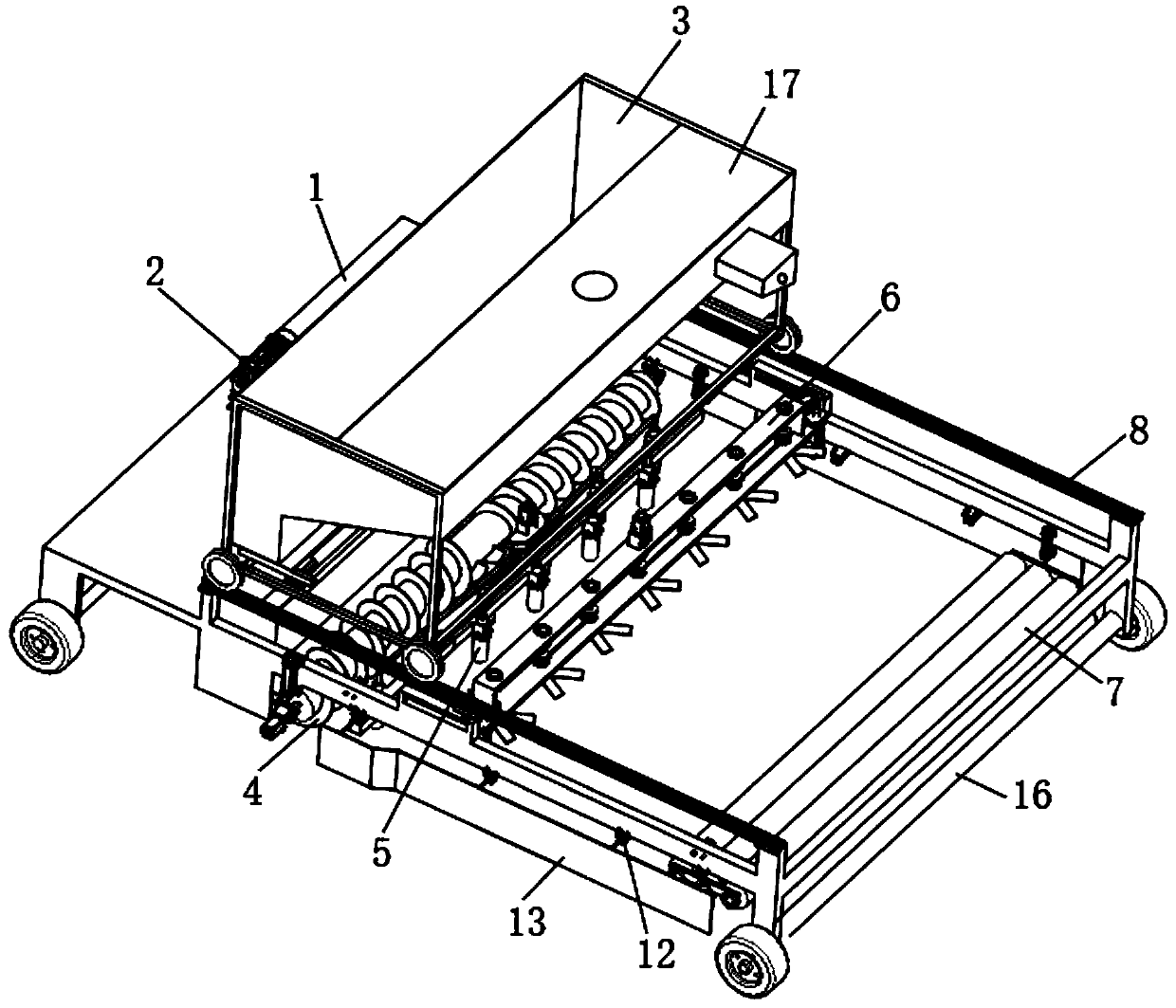

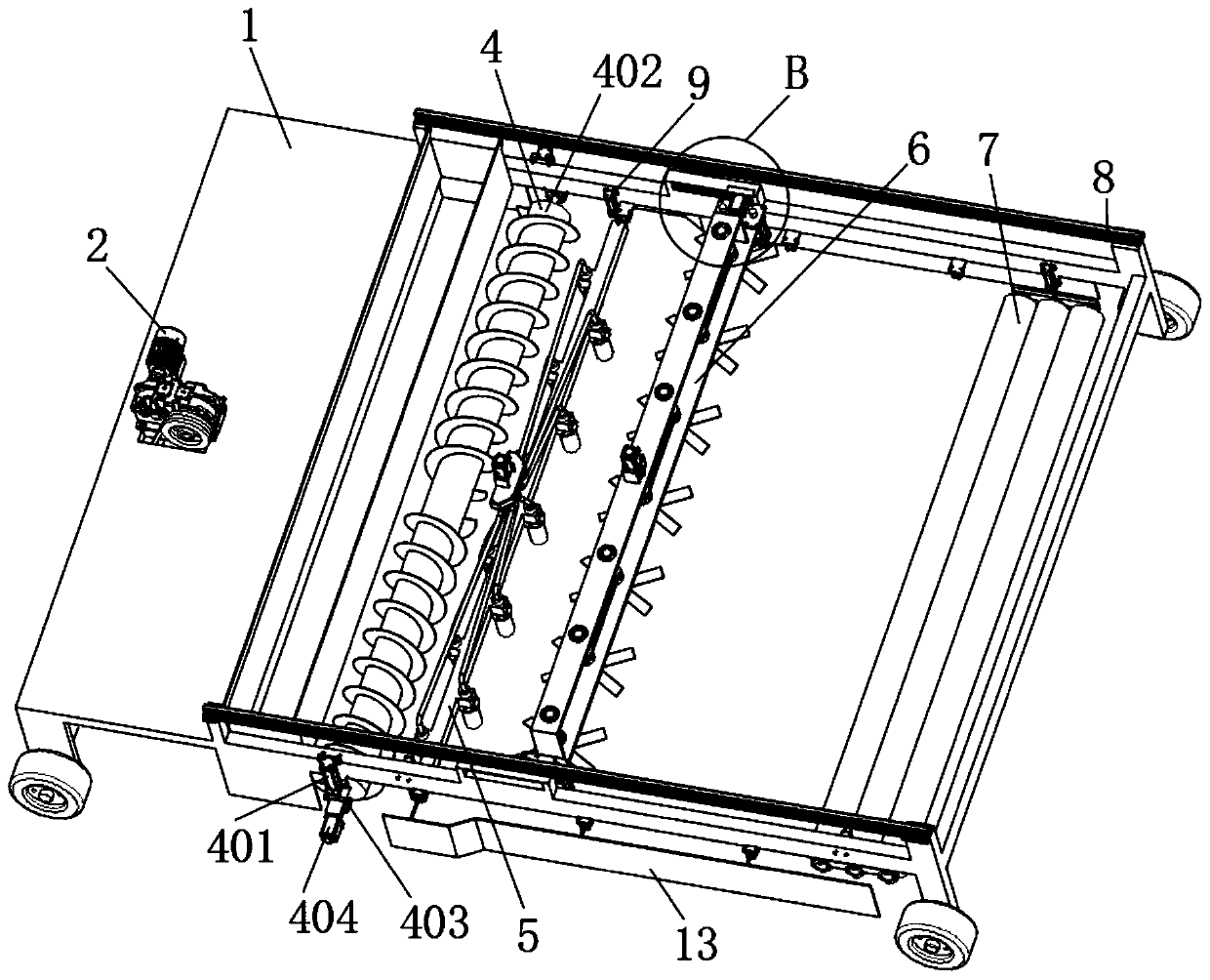

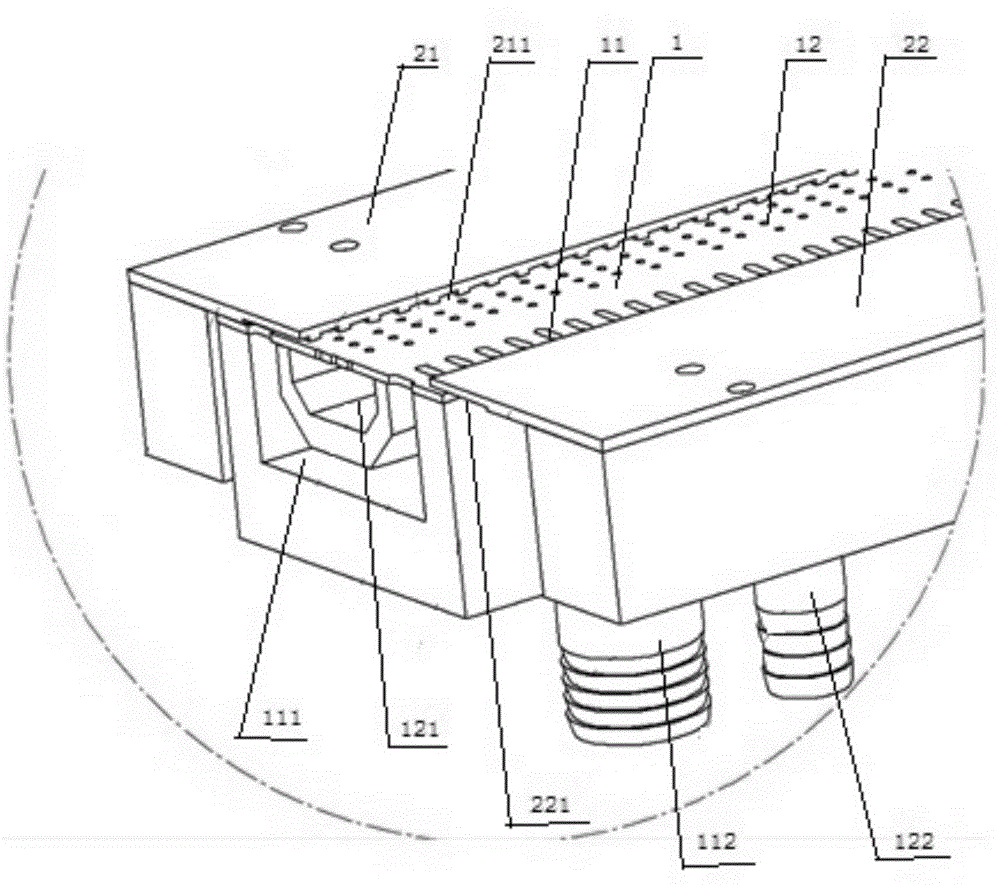

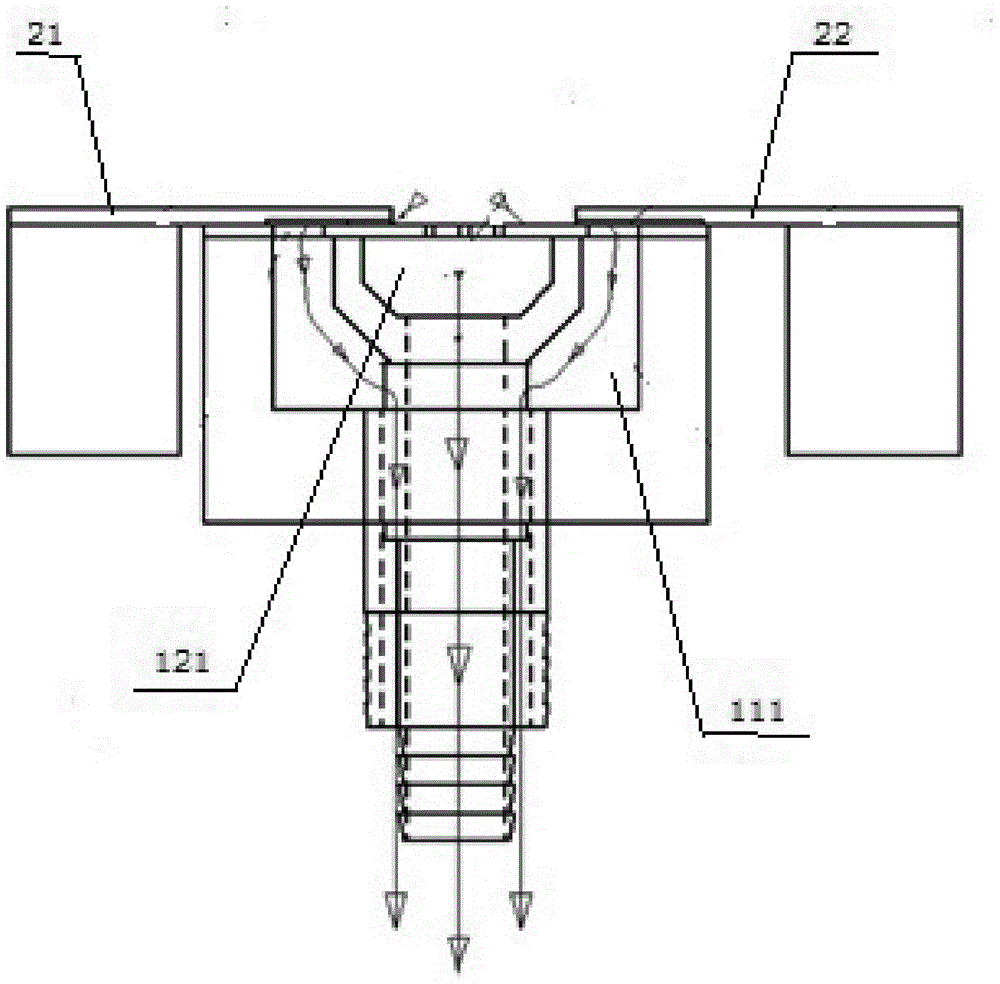

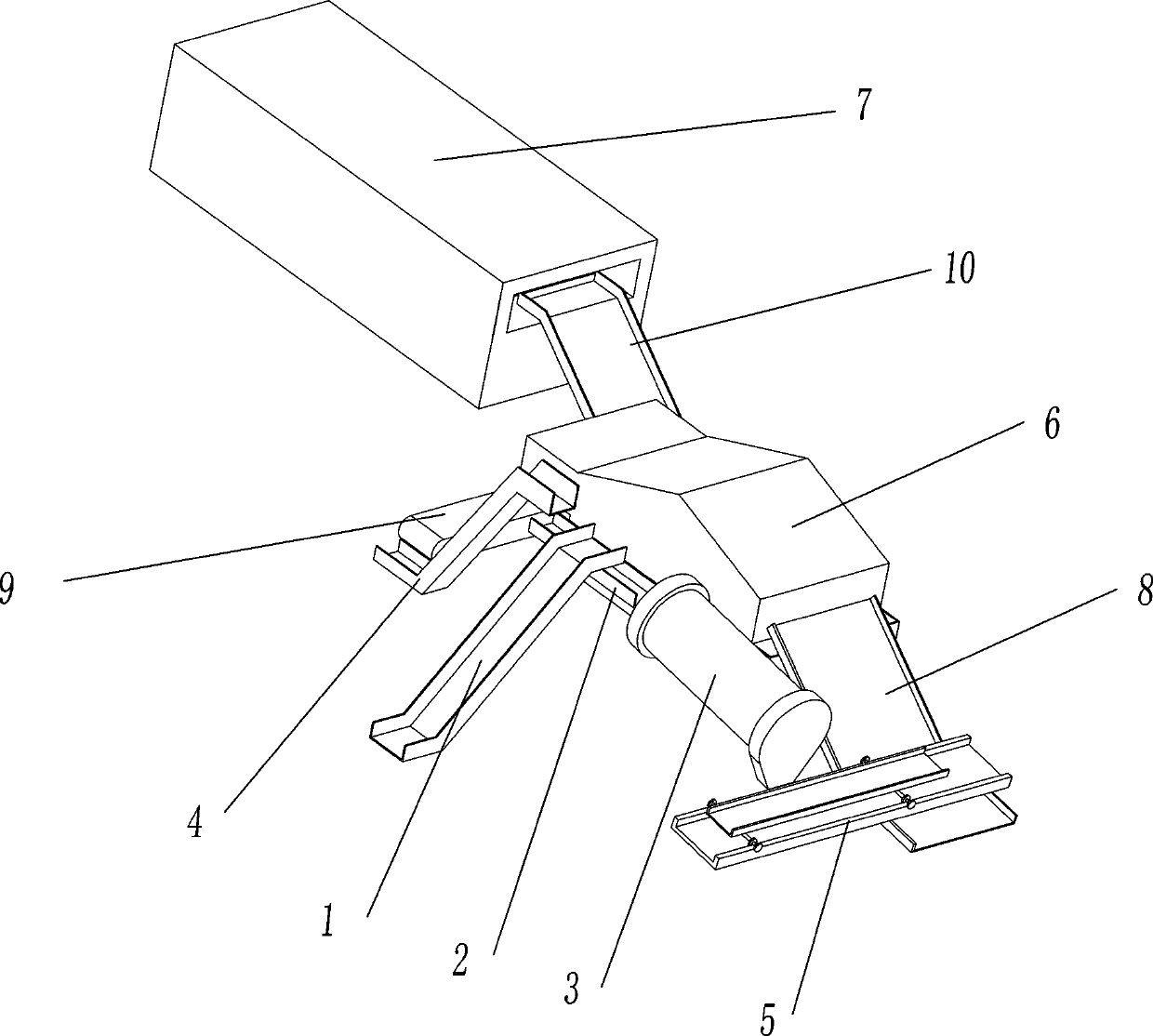

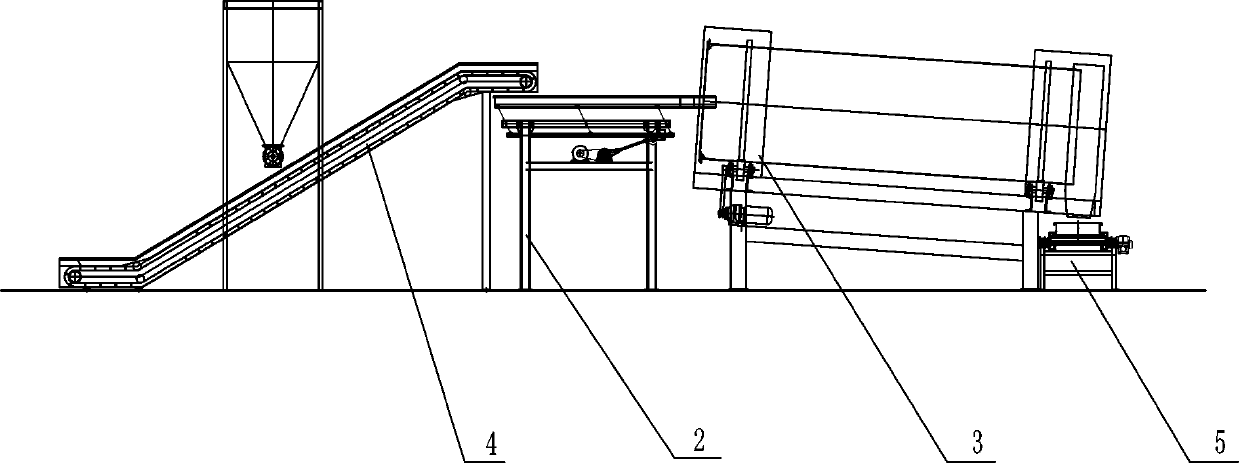

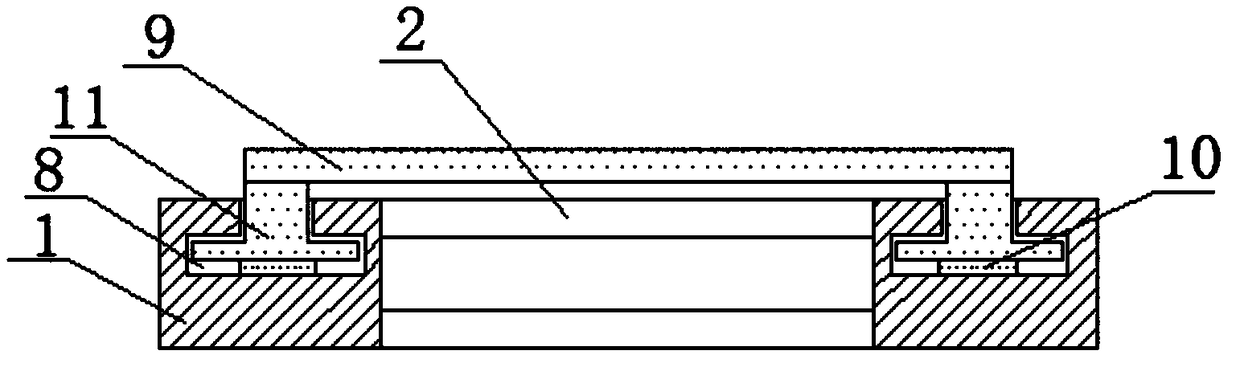

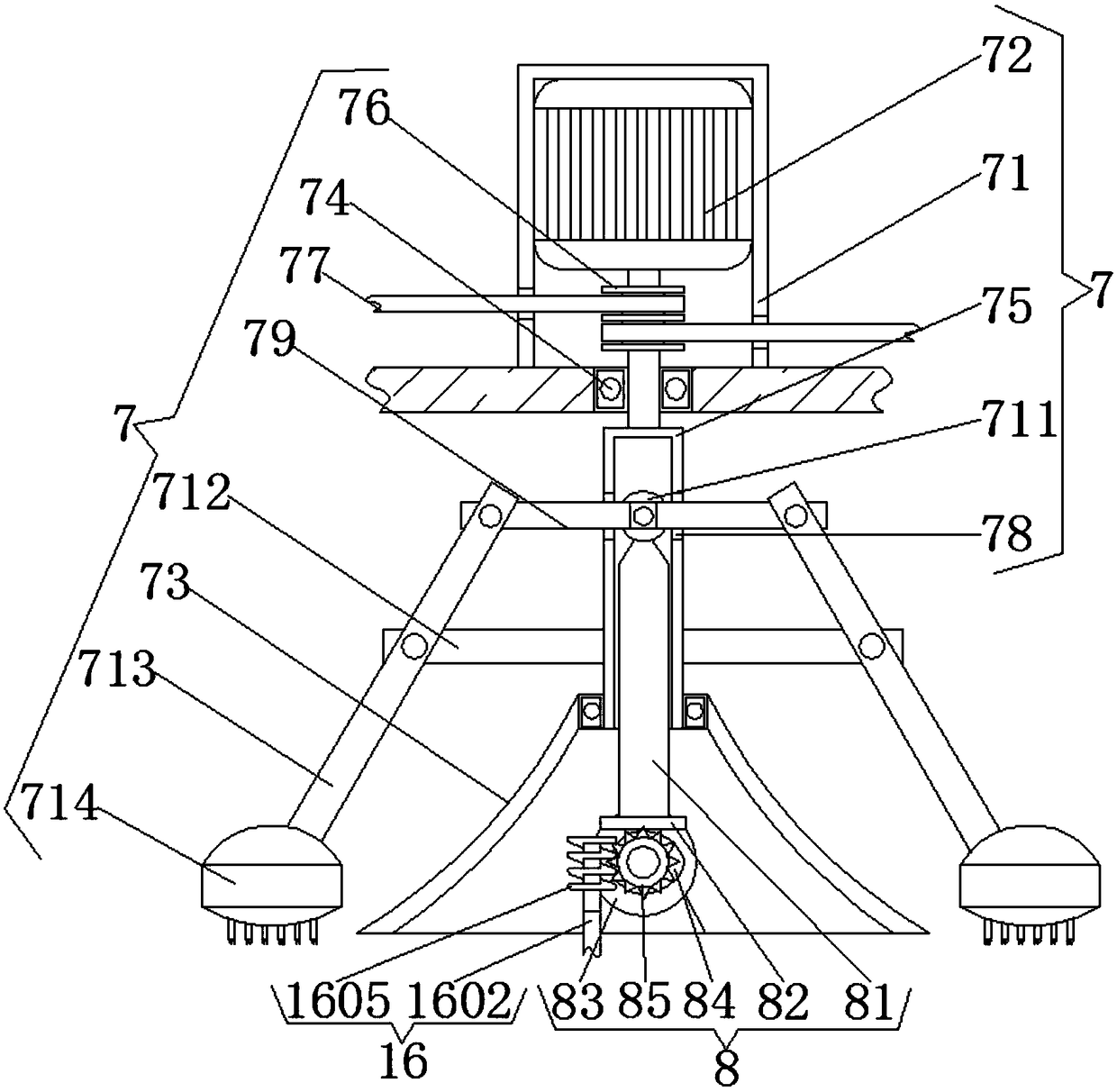

Cement pavement paving and maintaining all-in-one machine for road construction

ActiveCN111379209ATo achieve the purpose of maintenanceEfficient pavingRoads maintainenceHydraulic cylinderArchitectural engineering

The invention discloses a cement pavement paving and maintaining all-in-one machine for road construction, and belongs to the field of road construction. A striker plate storage box is arranged on a vehicle body, the striker plate is pushed to an outlet of the striker plate storage box through the hydraulic cylinder c, the vacuum sucker sucks the striker plate, the cement material can be discharged to the position between the material blocking plates, the paving training is further improved, a film roller and a water tank are also arranged, and then, after the cement laying is completed, the cement pavement is subjected to water spraying and film covering operation, so the goal of maintaining the cement pavement is further achieved; and meanwhile, the cement discharging mechanism, the cement paving mechanism, the cement vibrating mechanism, the grinding mechanism and the leveling mechanism are matched for use, the device can automatically pave, gather, grind and flatten cement on a pavement, the purpose of efficiently and conveniently paving the cement is achieved, the structural design is simple and reasonable, the device has the advantage of quickly paving and maintaining the cement pavement, and the device is convenient and quick to use and suitable for application and popularization.

Owner:杨明 +4

Fabric folding mechanism

The invention relates to a fabric folding mechanism which can be used for flanging one edge, two edges and a plurality of edges. The fabric folding mechanism comprises a platform, the platform is provided with a side air draught through hole, the platform is provided with a cover plate which can cover the side air draught through hole, the lower surface of the cover plate is provided with a groove, the opening of the groove faces to and covers the side air draught through hole, one edge of the cover plate is close to the center of the platform, another edge being symmetric with the edge is relatively far away from the center of the platform, one end of the groove extends to the edge of the cover plate close to the center of the platform, a side air draught chamber being in communication with the side air draught through hole is disposed under the platform, and the side air draught chamber is connected to an air draught device. The cover plate having the groove in the lower surface is added to the platform having the hole, lower air draught is changed into side air draught, edges of fabrics can be folded, the fabrics close to the groove of the edge of the cover plate can be vertical to form a flanging, the flanging with width being less than 3mm of fabrics can be normally machined, positioning is easy, and the fabrics hardly rebound and deform.

Owner:中山市阿米达机电设备有限公司

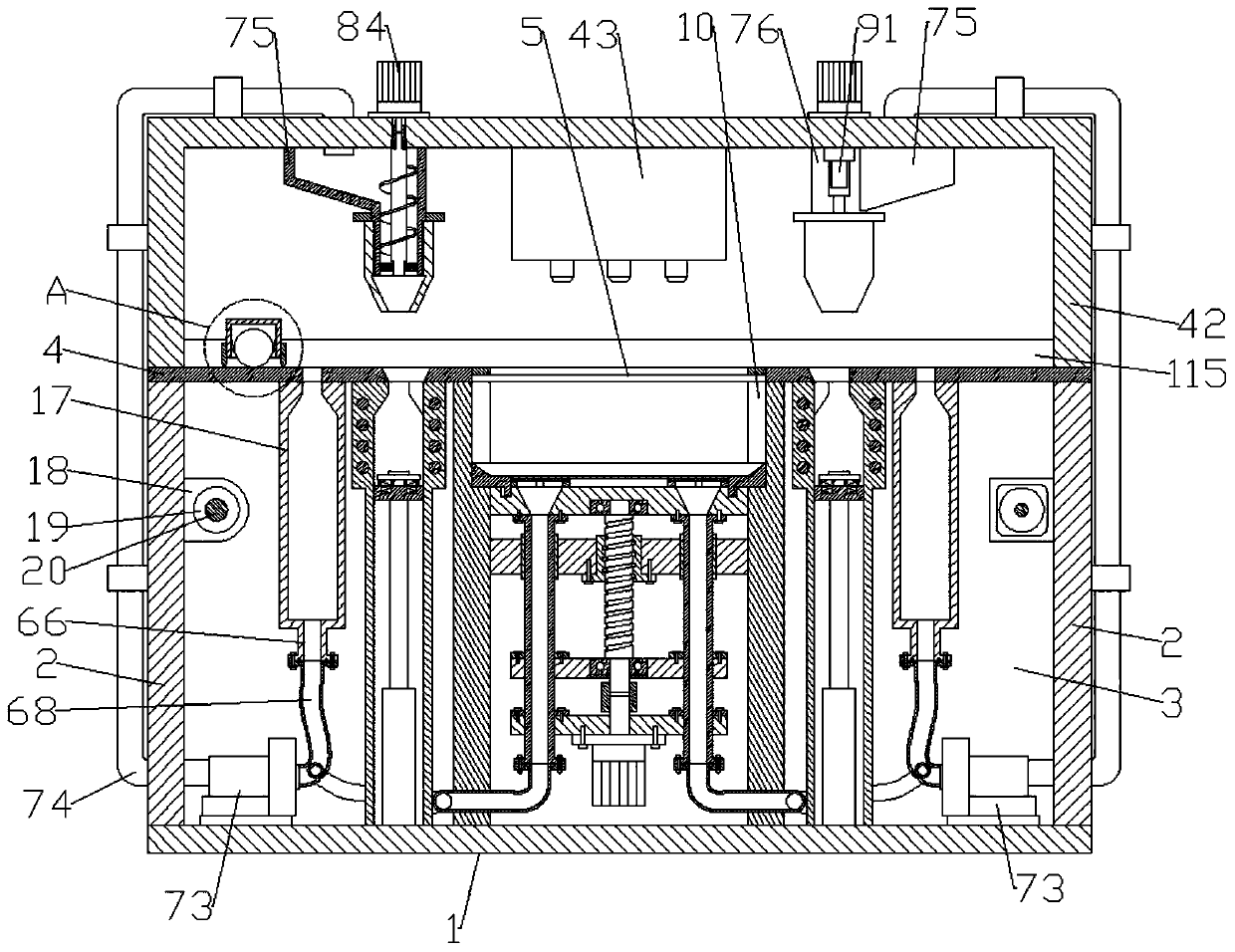

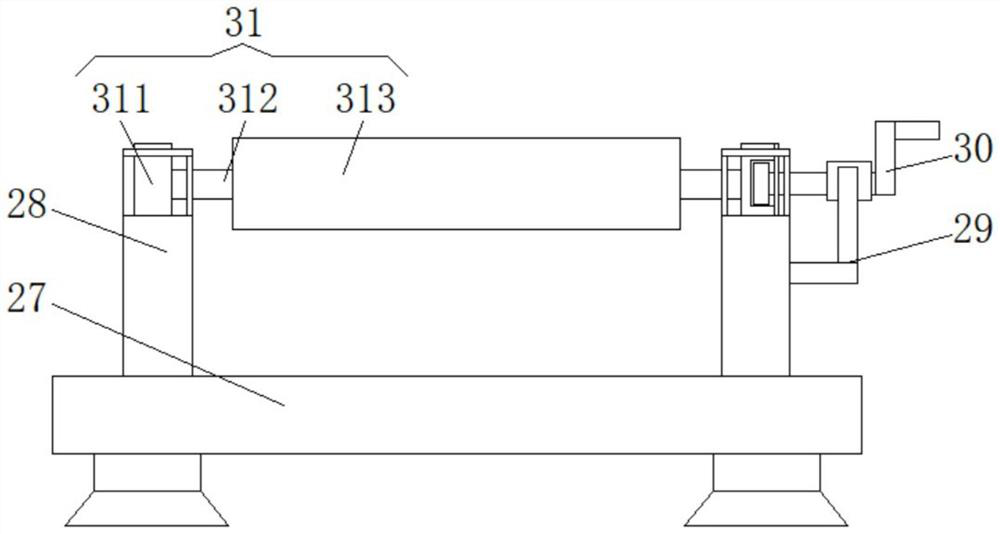

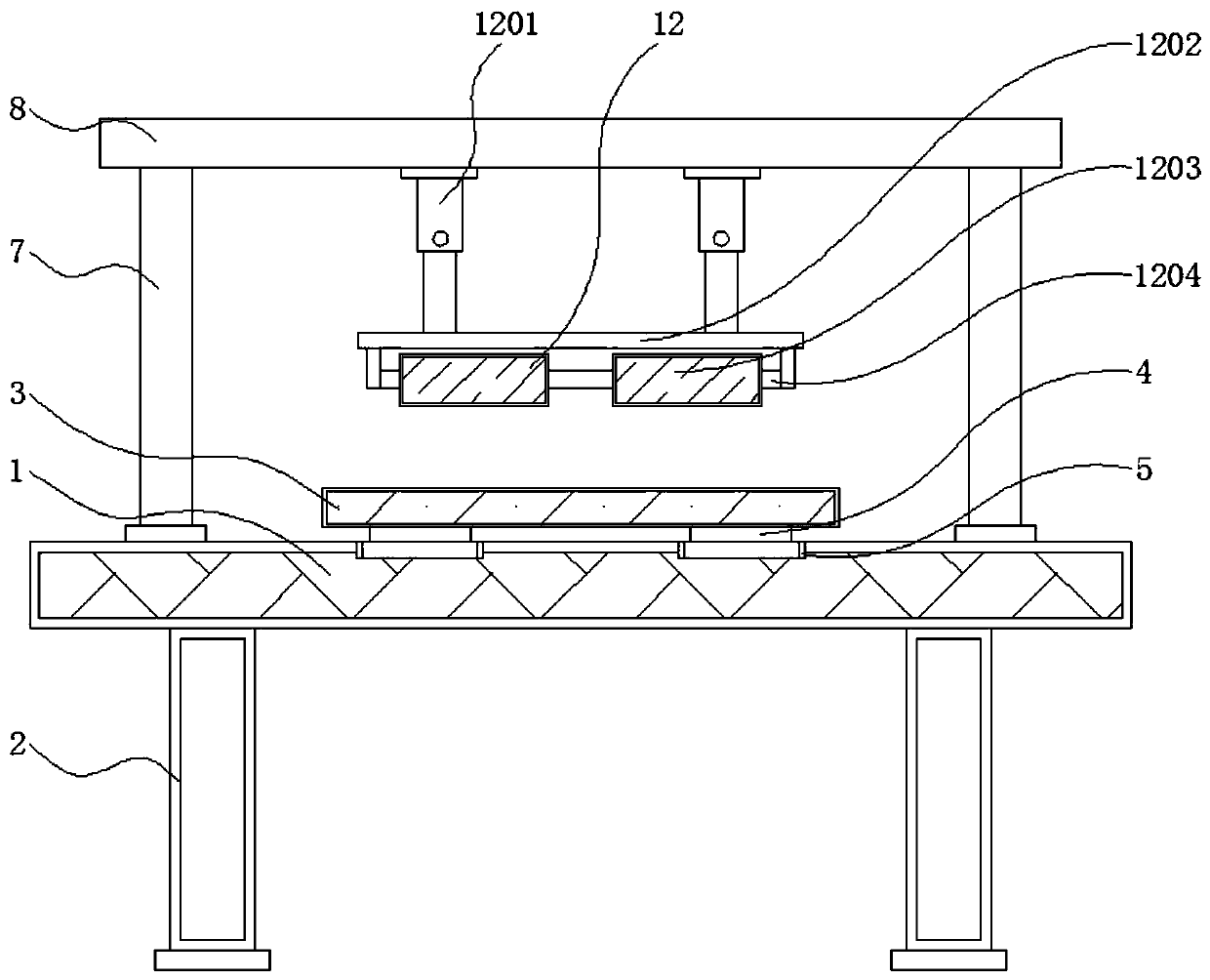

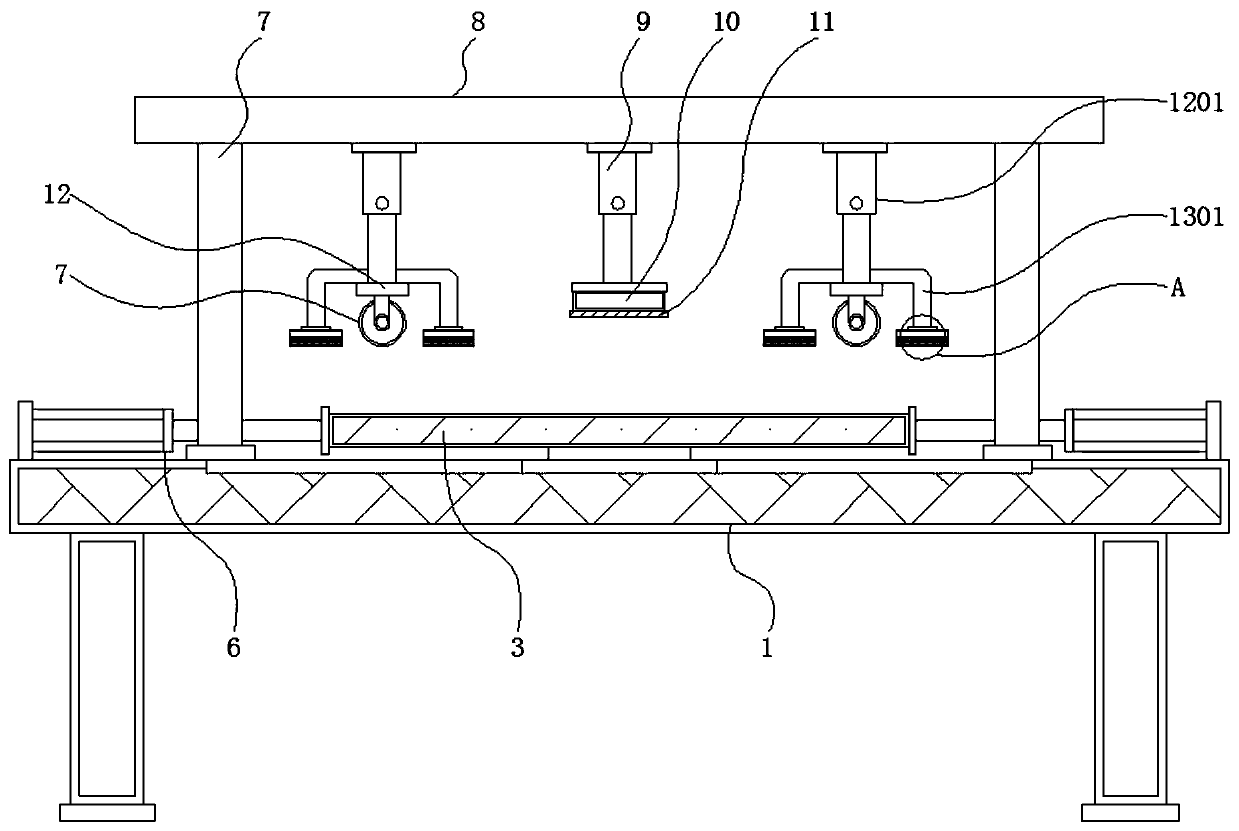

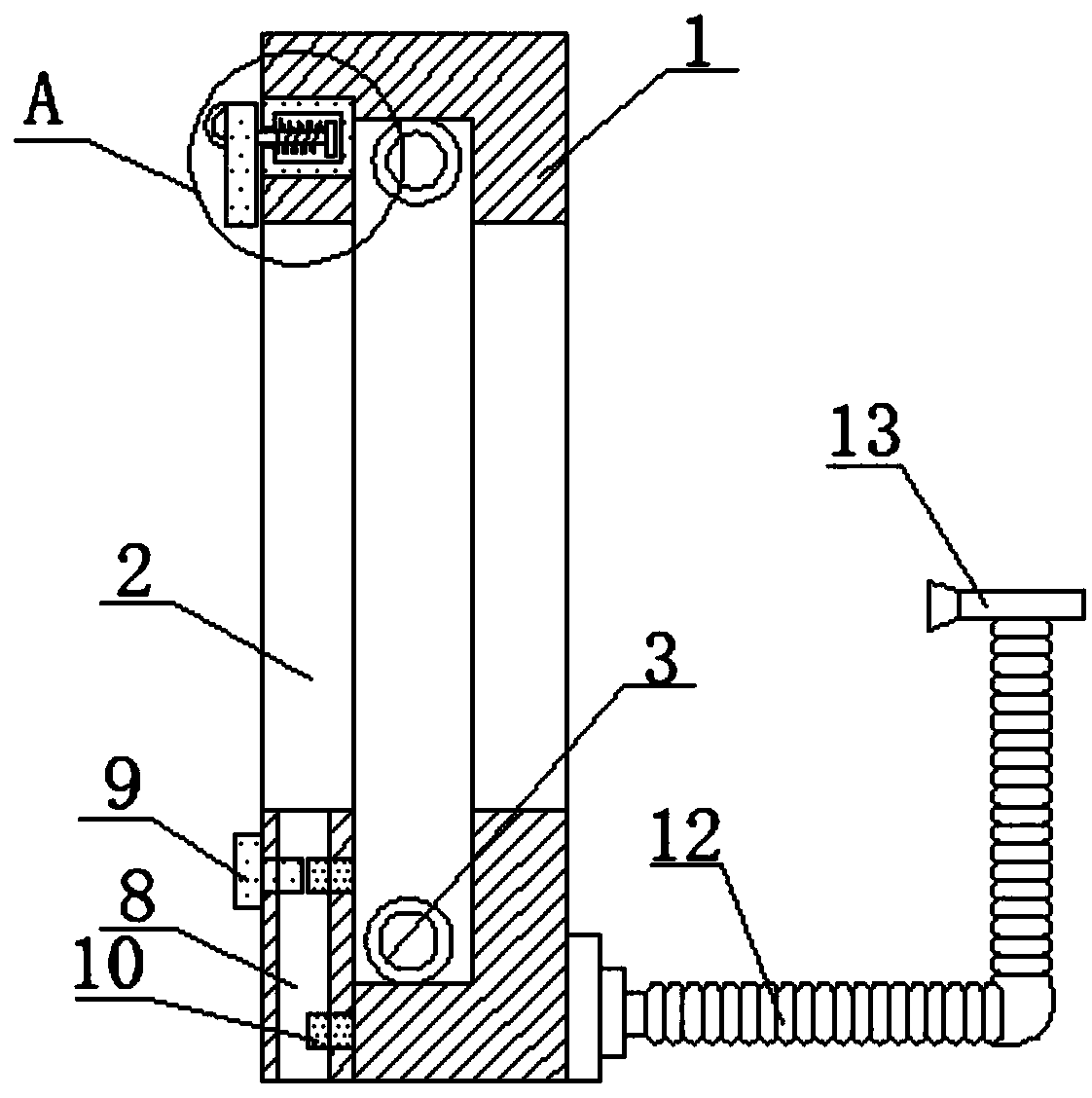

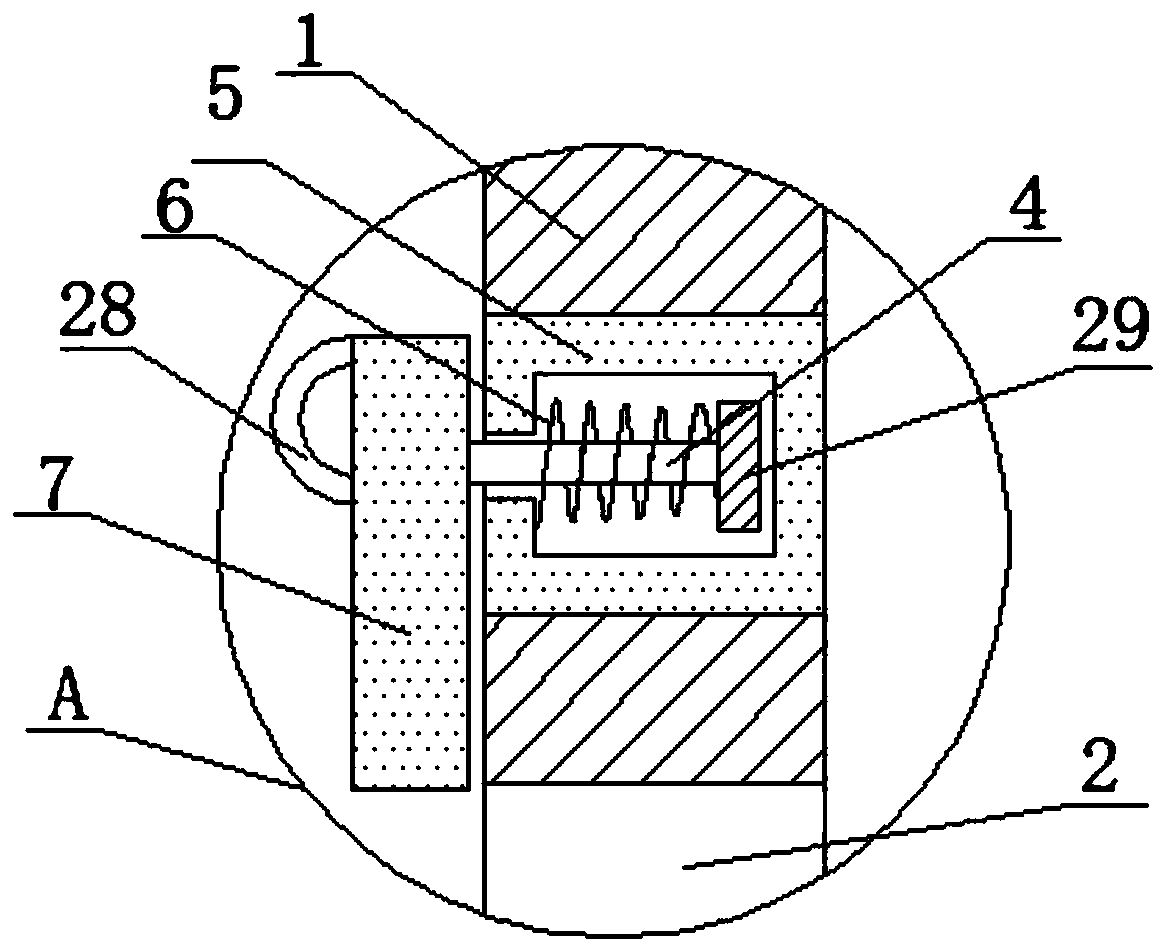

3D printer for metal powder

ActiveCN109877322AEasy to paveImprove compactionAdditive manufacturing apparatusMaterial resources3d printer

The invention relates to a 3D printer for metal powder and belongs to the field of 3D printing equipment. According to the 3D printer for the metal powder, the structural design is reasonable, operation is convenient, the powder laying quality is good, the powder is preheated uniformly, the part machining time is greatly shortened, formed parts are taken easily and conveniently, automatic powder adding operation can be achieved, a large quantity of manpower and material resources are saved, and an operator is prevented from inhaling a large amount of the powder. According to the adopted technical scheme, a first electric push rod is mounted on the inner side of a powder outlet sleeve, a lifting device is mounted on the inner sides of a connecting plate and a positioning plate, a conical hole, a shielding plate, a jacking rod and a guiding pipe connected with the conical hole are arranged on a lifting plate to suck the powder around the parts, an electric heating pipe is arranged on theinner side of the upper end of the powder outlet sleeve to preheat the powder, an anti-sticking part is arranged on a powder laying roller, a sealing cover is mounted on an operating panel, and a feeding sleeve, a telescopic sleeve and a feeding screw are arranged at the upper end of a sealing cover to achieve material-adding operation.

Owner:HANGZHOU HIMALAYA INFORMATION TECH

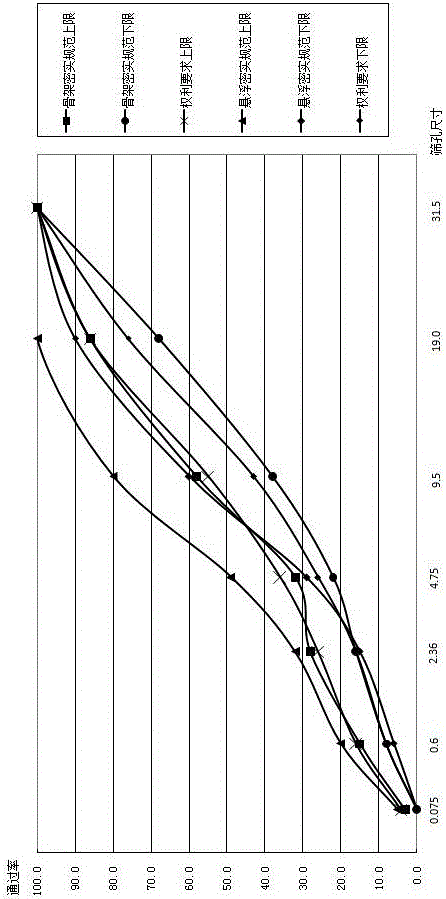

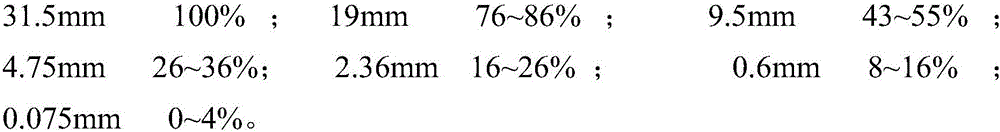

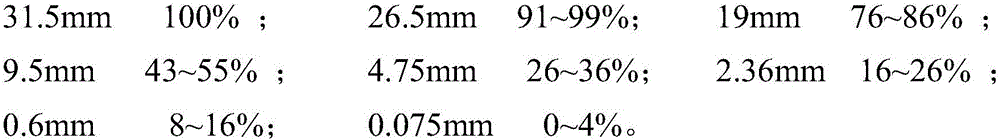

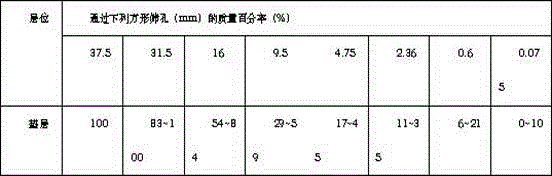

Cement-stabilized-macadam mixture design method

The invention discloses a cement-stabilized-macadam mixture design method, and belongs to the field of road engineering. The cement-stabilized-macadam mixture design method is characterized in that the fractional step mixing method is adopted in the mixture mixing process, the rotating compaction forming method is combined, and a test piece is obtained. Compared with an existing design method, by means of the cement-stabilized-macadam mixture design method, the technical problem that as the actual compaction state of a pavement-base construction site cannot be reflected in the traditional design process, the performance of the mixture is uneven is solved, the using amount of cement and the using amount of water are reduced on the premise that the performance requirements can be met, the aims that the design performance of the mixture is stable, economical and environmentally friendly are achieved, and the cement-stabilized-macadam mixture design method has the quite-good popularization and application value.

Owner:SHANDONG TRANSPORTATION INST

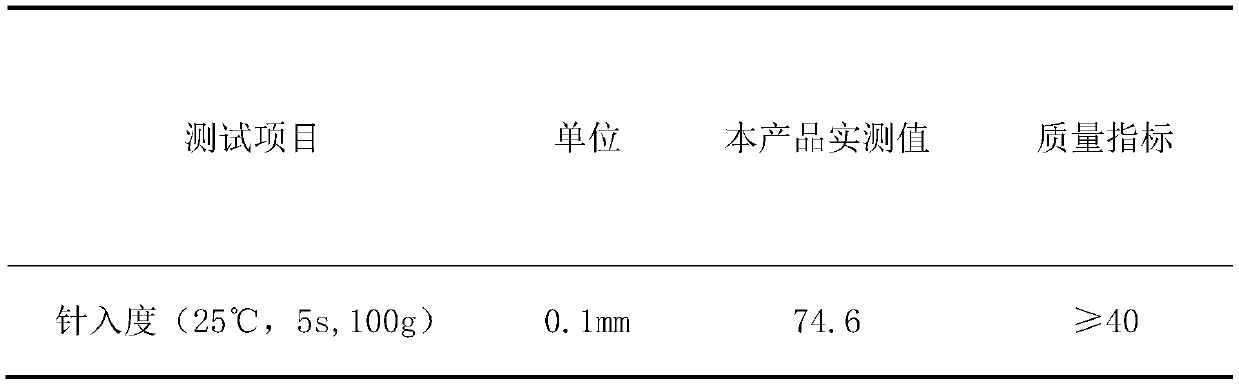

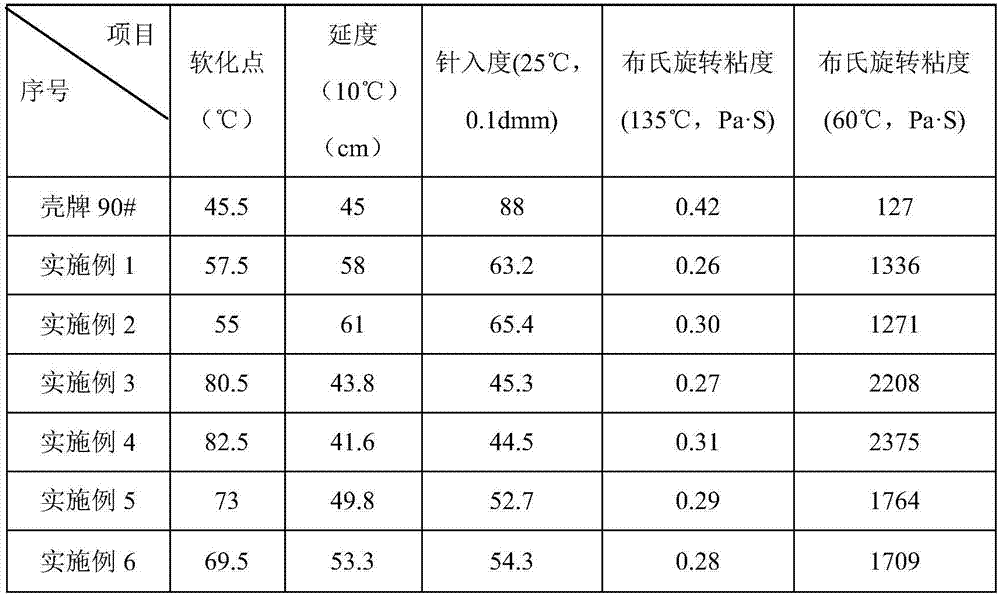

High-adhesion modified asphalt and preparation method thereof

InactiveCN109852085AIncreased durabilityImprove engineering structureBuilding insulationsPolyesterPolymer science

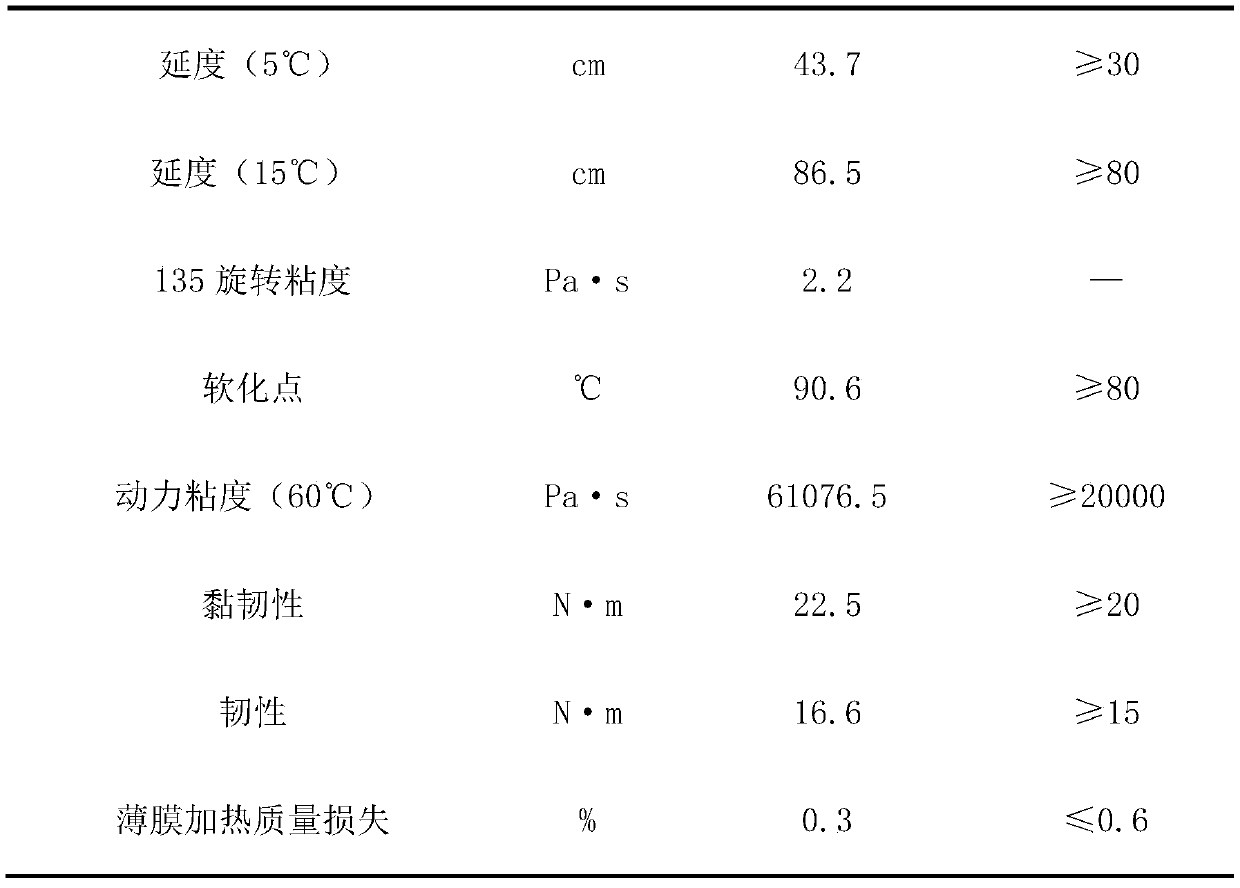

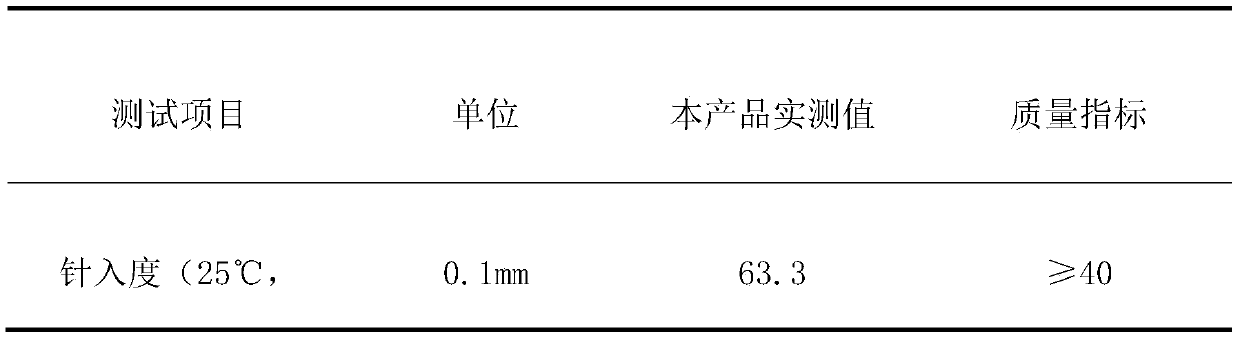

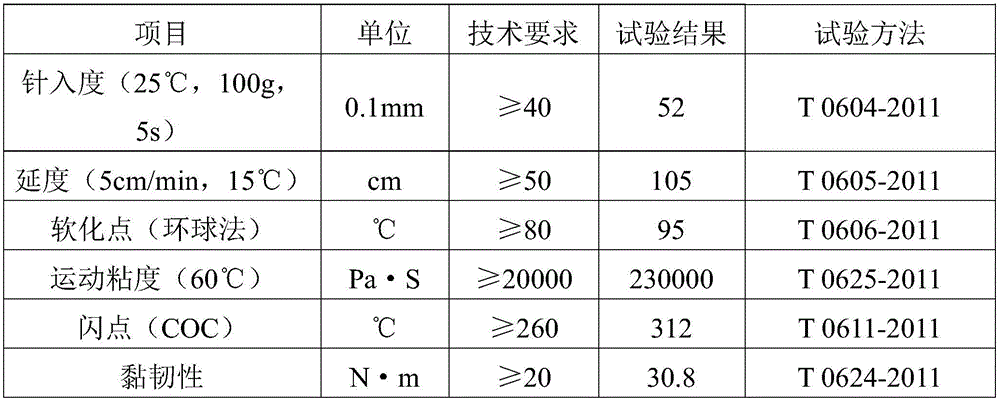

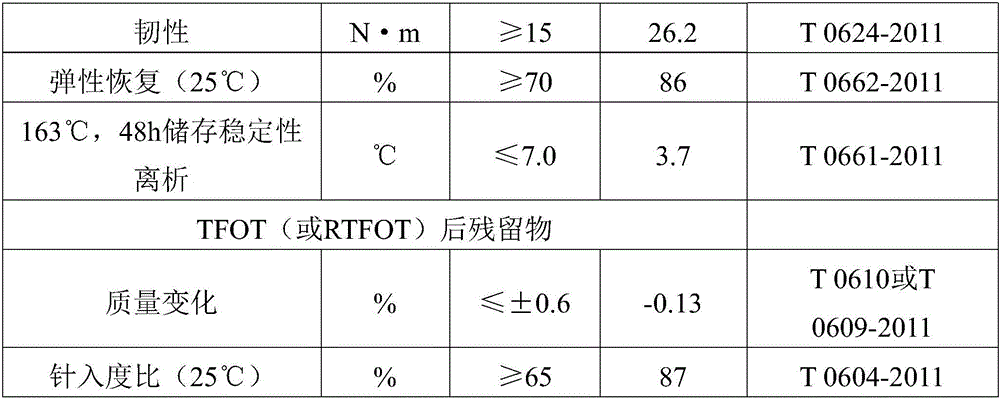

The invention discloses high-adhesion modified asphalt and a preparation method thereof, and belongs to the technical field of road engineering materials. The raw materials of the high-adhesion modified asphalt comprises 500 parts of base asphalt, 300-400 parts of an additive and 10-20 parts of composite reinforcing fibers, and the composite reinforcing fibers are prepared by compounding basalt fibers and polyester fibers and then being coated with base asphalt thin films. When preparing the high-adhesion modified asphalt, the composite reinforcing fibers are added, so that the adhesion, high-temperature stability, fatigue durability of asphalt pavements are greatly improved, and the asphalt has the properties of low-temperature crack prevention and reflection crack prevention. The tensile, shear, compressive and impact strength are effectively improved, and the thermal stability and low temperature resistance of the asphalt are improved.

Owner:河北长大交通科技有限公司

High-viscosity asphalt additive modifier and preparation method thereof and high-viscosity modified asphalt and preparation method thereof

The invention relates to a high-viscosity asphalt additive modifier and a preparation method thereof. The high-viscosity asphalt additive modifier is prepared from, by weight, 100 parts of thermoplastic resin, 10-20 parts of viscosity resin, 20-30 parts of EVA and 1-2 parts of zinc stearate. The invention further relates to a high-viscosity modified asphalt and a preparation method thereof. To solve the problem of traditional high-viscosity modified asphalt, the high-viscosity asphalt additive modifier with low cost and good performance is provided, the high-viscosity modified asphalt is not needed to be prepared in advance, only the modifier is manually or automatically added in a asphalt mixture when in use, and the high-viscosity modified asphalt mixture is then formed after aggregating, shearing and stirring are conducted in sequence.

Owner:SUZHOU TOPOLINE TECH

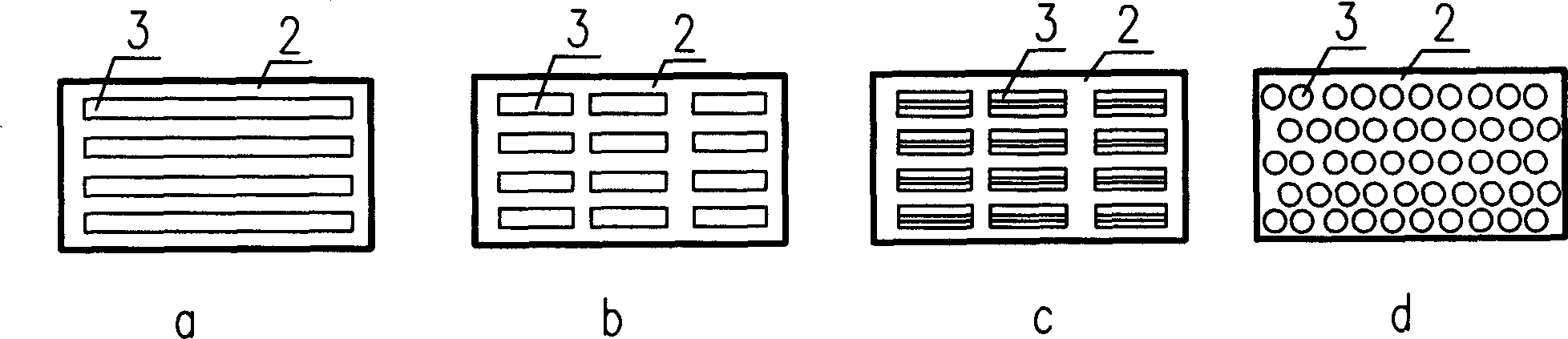

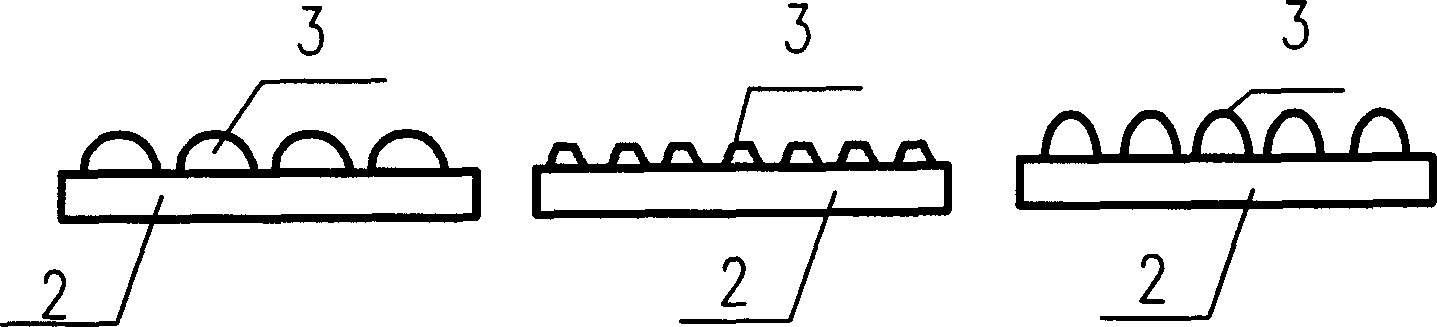

Air-entraining thermal insulation board and its producing method and special forming device

InactiveCN1458356AReduce weightHigh strengthLayered productsHeat proofingPolymer scienceFoaming agent

The air-entraining thermal insulation board is produced with cement, flyash, pearlite or foamed bulk material, and water in certain proportion through mixing and other steps. The air-entraining thermal insulation board has air closing cavities in the diameter or equivalent diameter of 10-150 mm, the continuous length of 30-1000 mm, the ratio between the transverse projection length and the boardwidth of 50-75 % and volume accounting for 25-50 % of total board volume. The air-entraining thermal insulation board has light weight, high strength, and high thermal insulating effect. The production process has less steps, no any chemical foaming agent added and no pollutant and noise produced.

Owner:王凤蕊

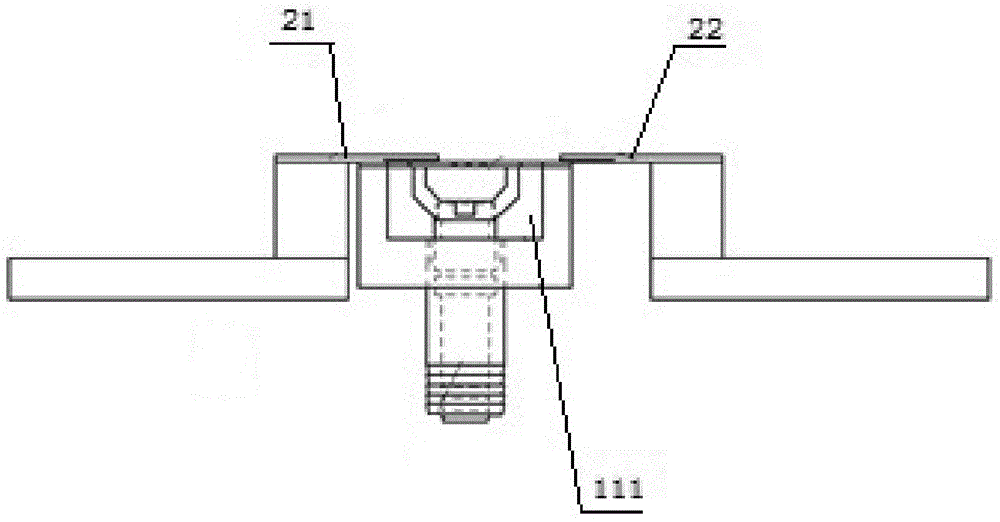

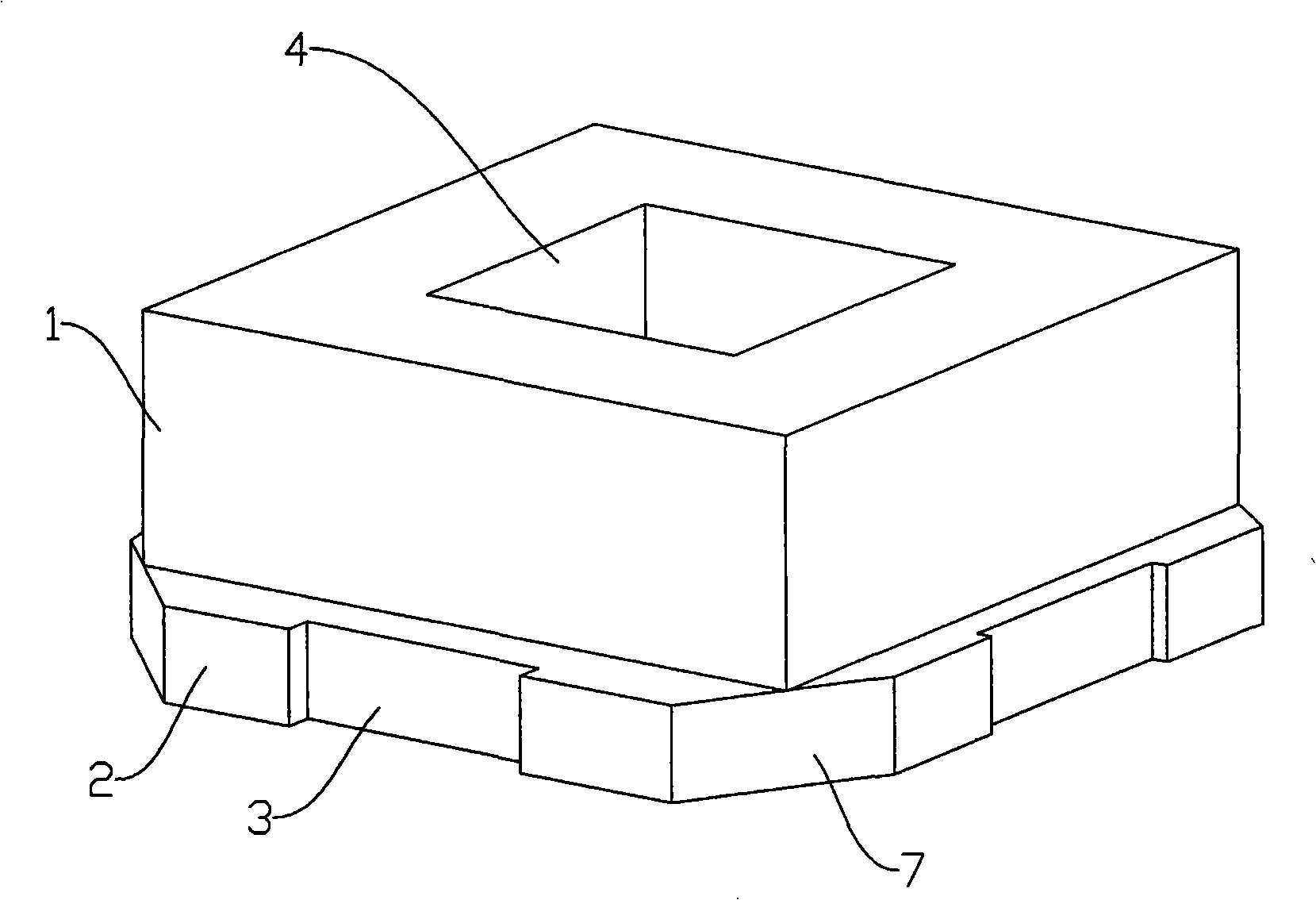

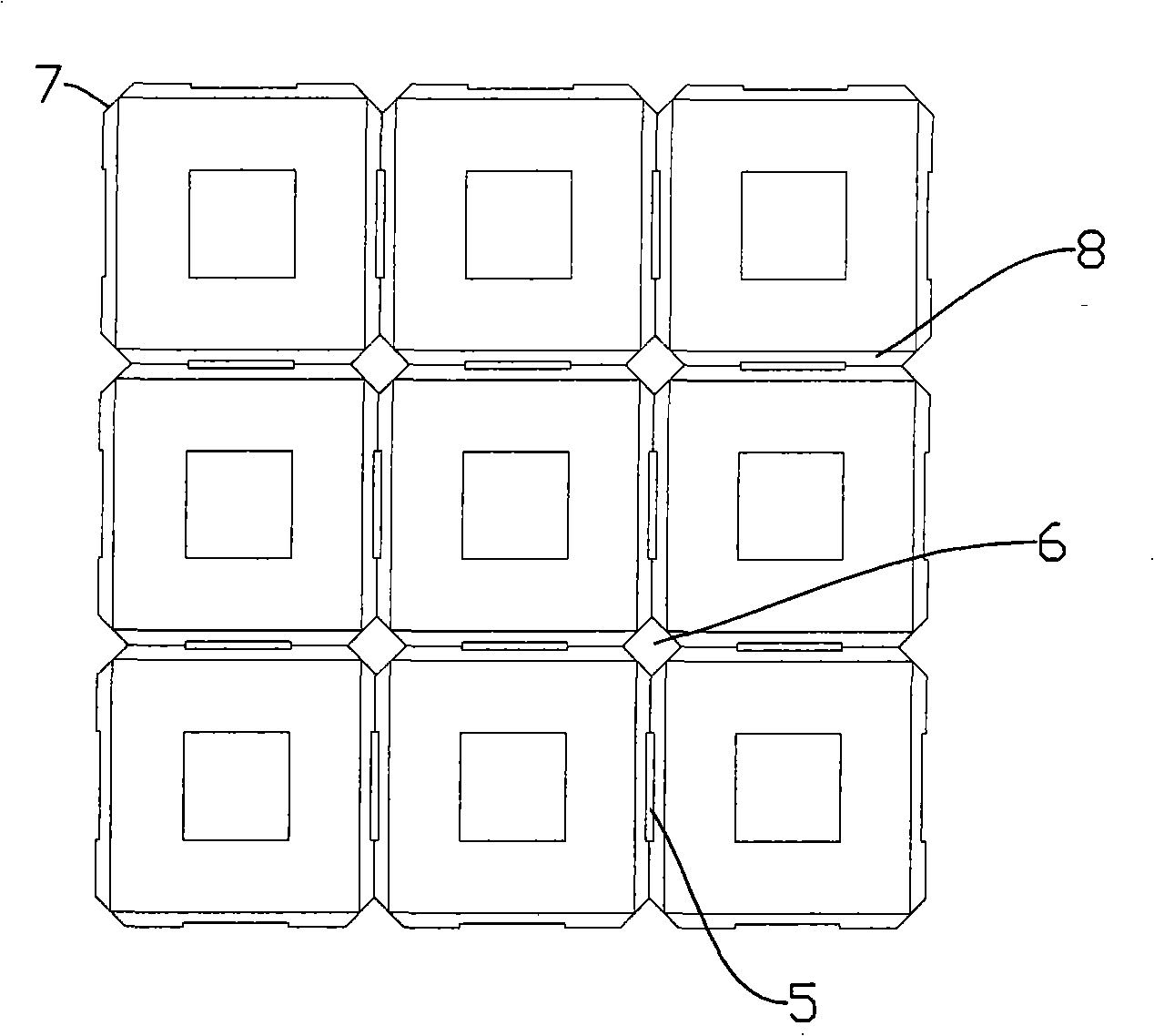

Fast water-permeable brick for stopping pad and laying method

ActiveCN101403209AWon't cause stagnant waterConducive to beautificationSingle unit pavingsWater storageBrick

The invention discloses a rapid permeable brick used for a parking lot, and a laying method, belonging to the technical field of construction. The rapid permeable brick comprises a permeable brick body, and a permeable through hole is arranged in the middle of the permeable brick body. The rapid permeable brick is characterized in that convex edges are arranged at the lower part of the surrounding of the permeable brick body; shallow grooves are arranged in the middle of the convex edges; and four corners of the edges of the permeable brick body are chamfers with 45 degrees. The laying method comprises the following steps: a water storage macadam substrate is laid, the permeable bricks are tiled on the surface of the water storage macadam substrate, groove-typed seams and permeable seams formed by the shallow grooves are formed at the edge joint part of the adjacent permeable bricks; cement mortar is infused in limber holes at nodes connected with the four corners of the permeable bricks; macadam or fine stone concrete is filled in the groove-typed seams; and macadam or pebbles are filled into the permeable through hole in the middle of the permeable bricks. The rapid permeable brick used for a parking lot is low in cost and convenient in the laying method, and a large amount of rainwater can penetrate underground.

Owner:SHENZHEN INST OF BUILDING RES

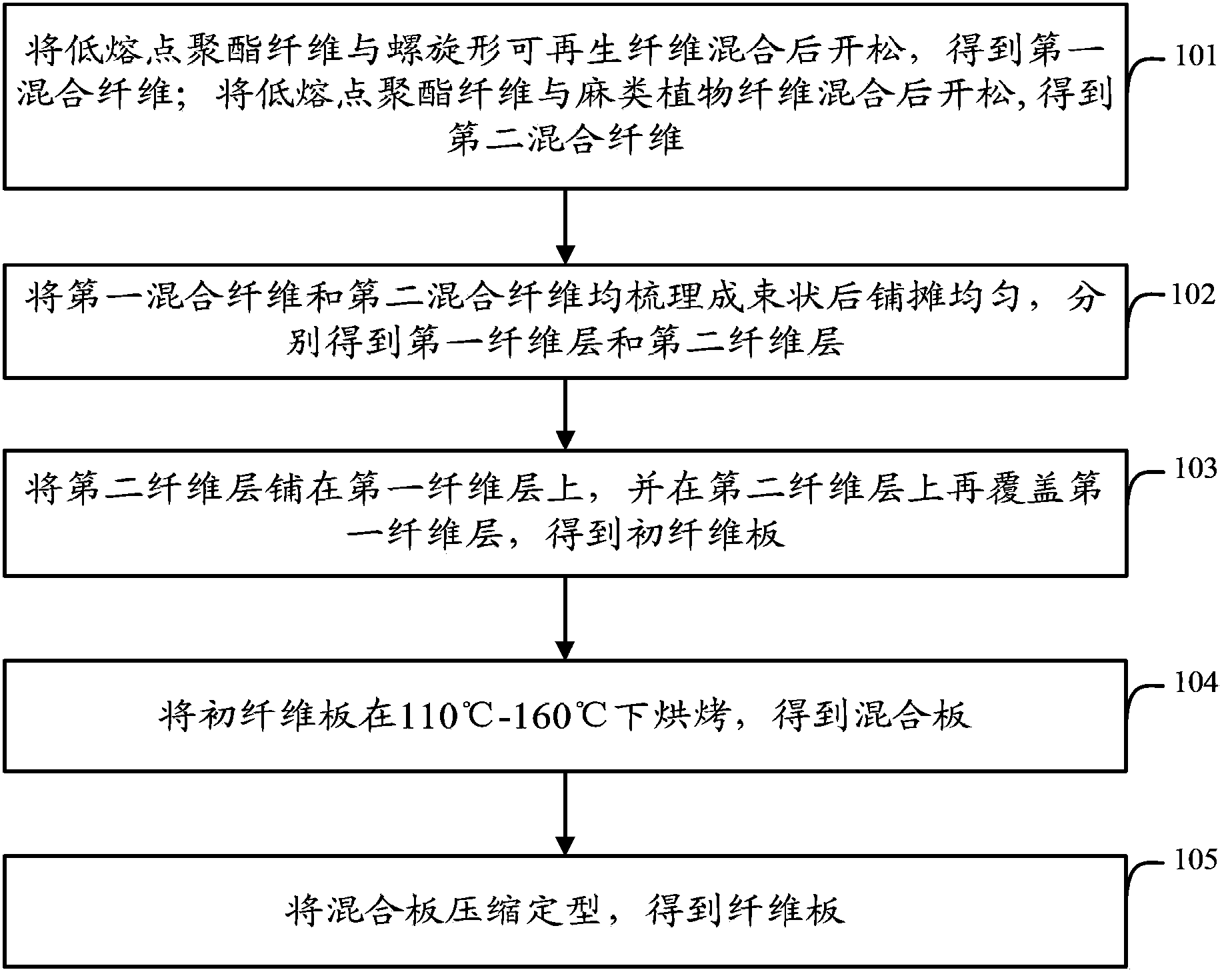

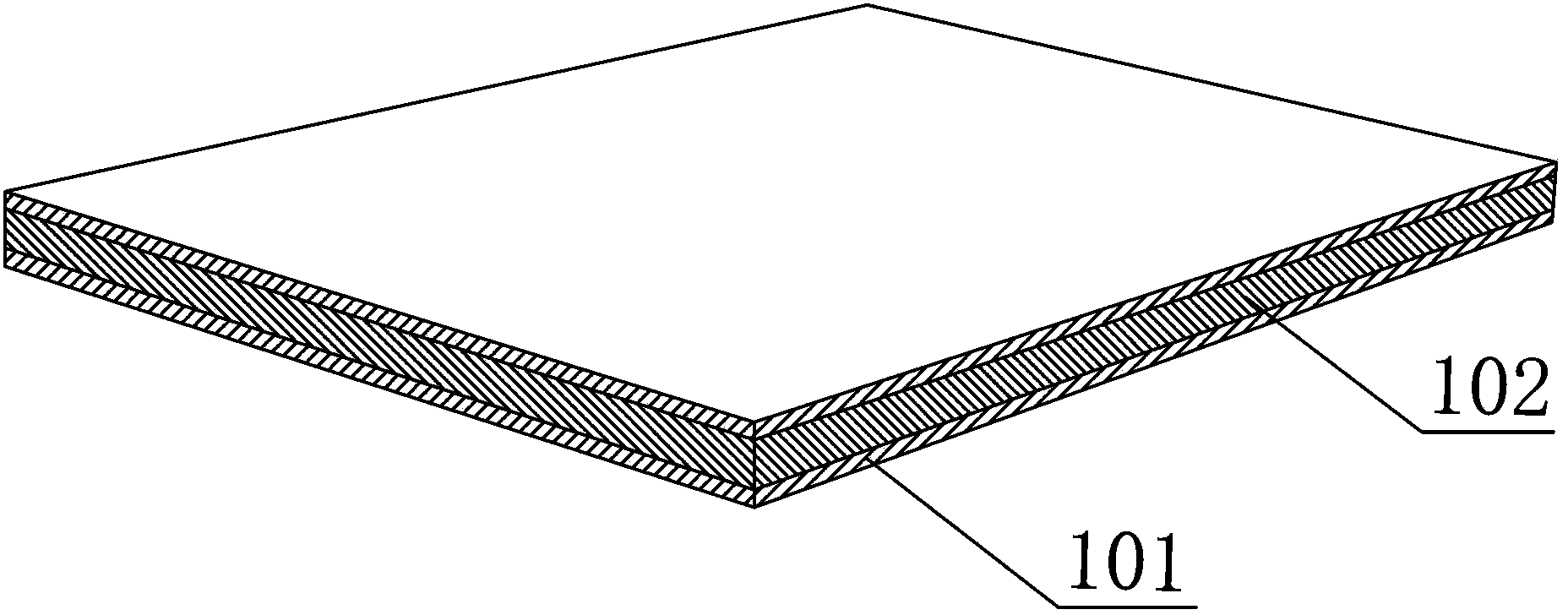

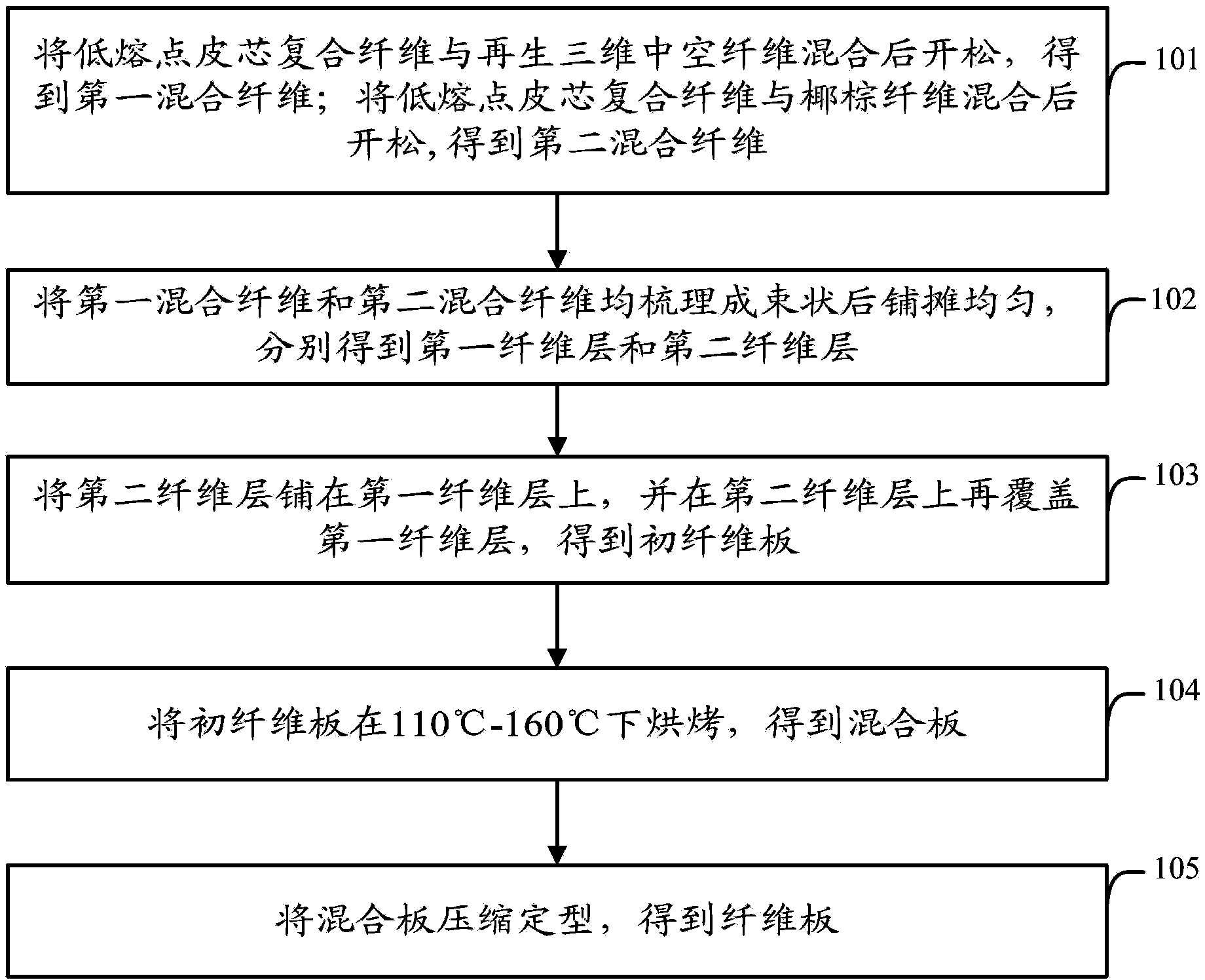

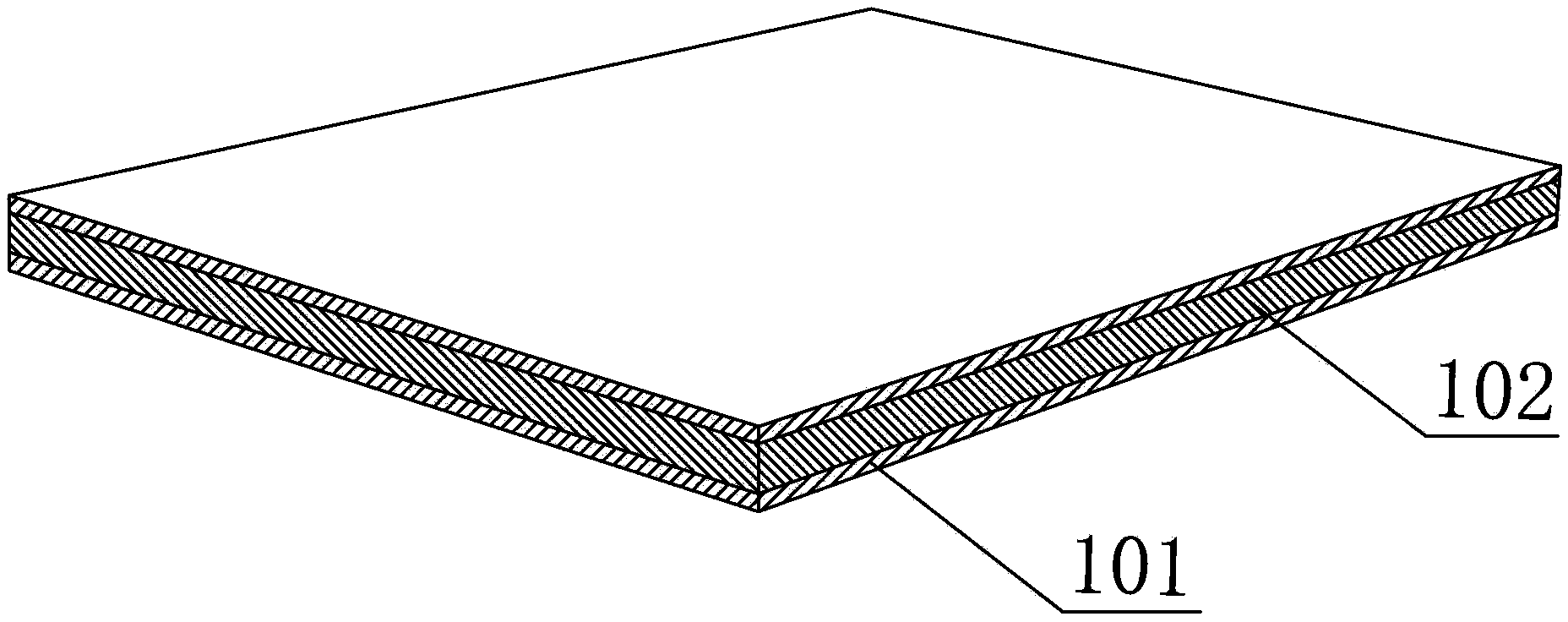

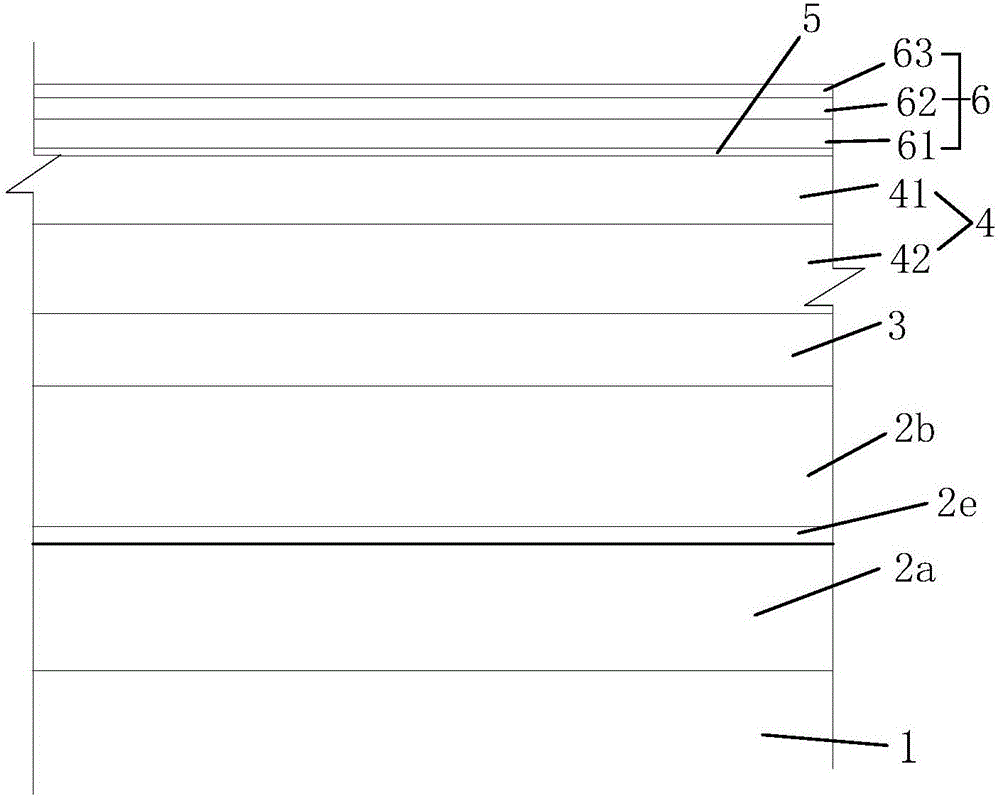

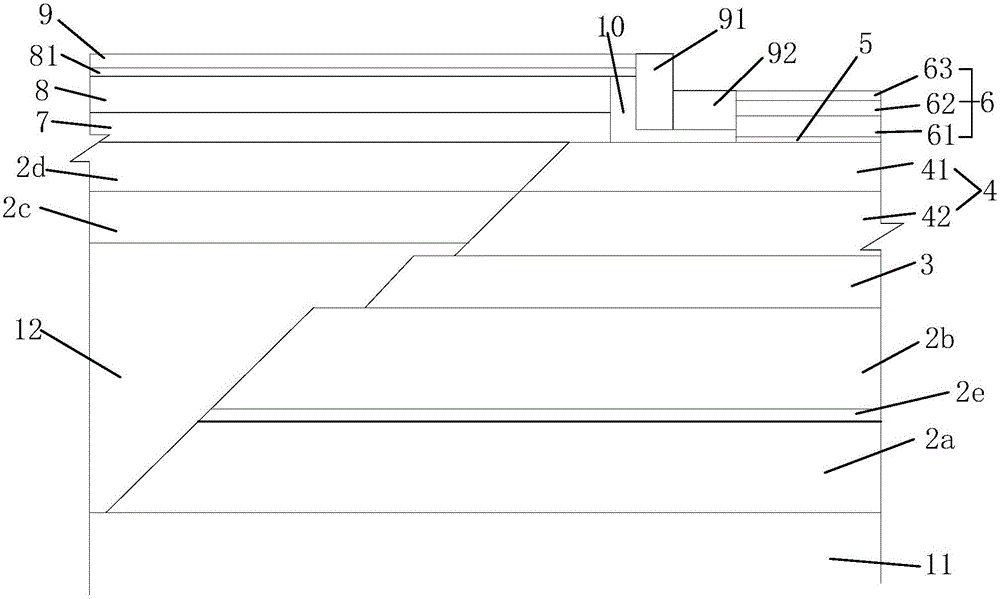

Fiberboard and preparation method thereof

InactiveCN103352319ALess prone to mildewLess prone to wormsStuffed mattressesSpring mattressesPolyesterPlant fibre

The invention discloses a fiberboard and a preparation method thereof. The fiberboard comprises first fiber layers and a second fiber layer, wherein the first fiber layers are arranged on the top surface and bottom surface of the second fiber layer; and the radial shadow shapes of the first and second fiber layers are the same. The preparation method comprises the following steps of: mixing low-melting point polyester fibers with spiral regenerated fibers and then opening the mixture, thus obtaining first mixed fibers; mixing the low-melting point polyester fibers with hemp plant fibers and then opening the mixture, thus obtaining second mixed fibers; carding the first and second mixed fibers into bundles and then spreading the mixed fibers uniformly, thus respectively obtaining the first fiber layers and the second fiber layer; paving the second fiber layer on one first fiber layer and then covering the second fiber layer with the other first fiber layer, thus obtaining a primary fiberboard; roasting the primary fiberboard at 110-160 DEG C, thus obtaining a mixed board; and forming the mixed board through compression, thus obtaining the fiberboard. The fiberboard is not easily mildewed and eaten by worms in a long-term use process.

Owner:HUNAN WEIYI ENVIRONMENTAL PROTECTION & TECH CO LTD

Dryer for textile processing and production

InactiveCN111928618AEasy to spread outAvoid affecting the drying effectDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringIndustrial engineering

The invention relates to the technical field of textile auxiliary equipment, and discloses a dryer for textile processing and production. The dryer comprises a drying box body, wherein a placement frame plate is fixedly arranged on one side of the bottom of an inner cavity of the drying box body, and the inner cavity of the drying box body is fixedly provided with a dryer body located above the placement frame plate in a sleeving mode; movable rods located between the placement frame plate and the dryer body are arranged inside the drying box body, and the outer portions of the movable rods are fixedly provided with rotating rollers in a sleeved mode; and one side of the drying box body is fixedly provided with a ventilation exhaust window located between the placement frame plate and thedryer body in a sleeved mode, and the bottoms of the two sides of the drying box body are fixedly connected with fixing frames. According to the dryer for textile processing and production, through aplacement sleeve plate, a positioning plate, an adjusting device and a flattening plate, to-be-dried textile fabric is conveniently spread, so that the situation that the drying effect is affected dueto the fact that the textile fabric is wrinkled together before entering the drying box body is avoided, normal drying is guaranteed, and the practicability of the device is improved.

Owner:东阳市川泽户外用品有限公司

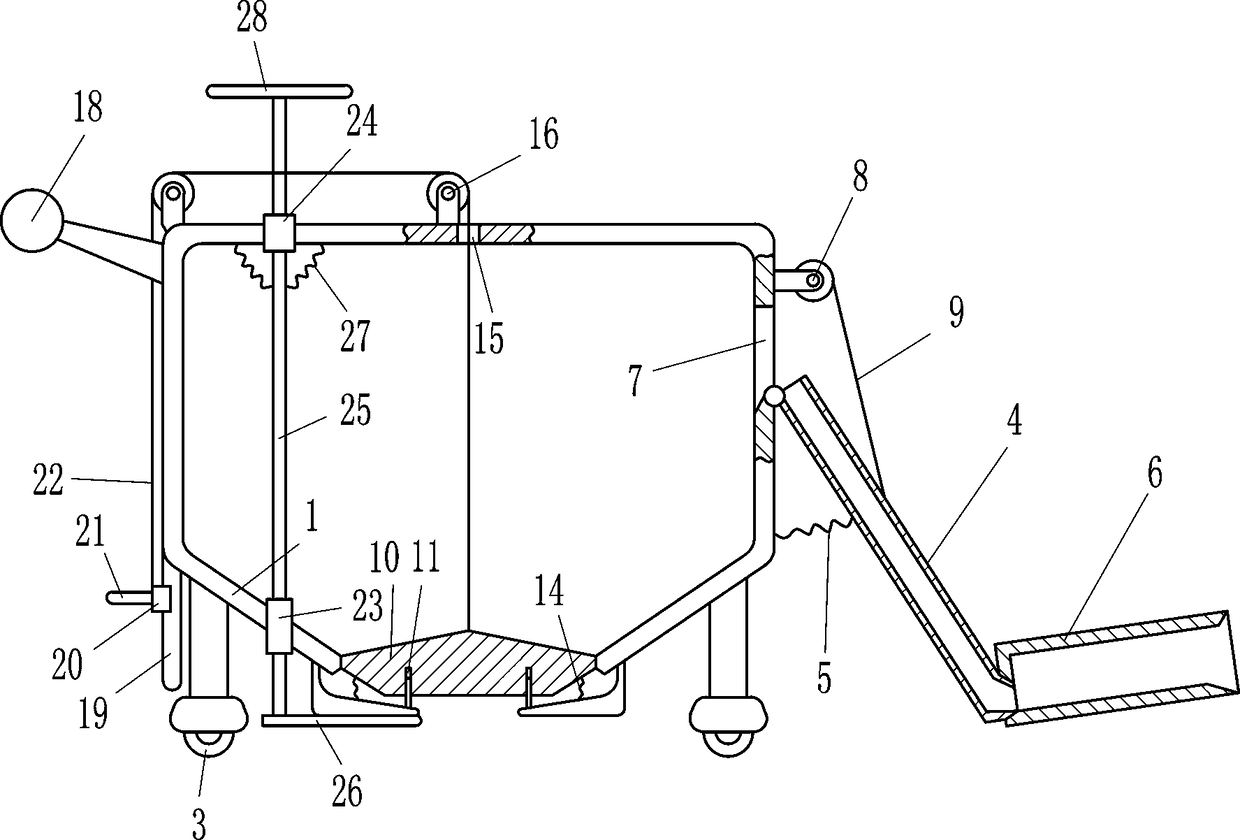

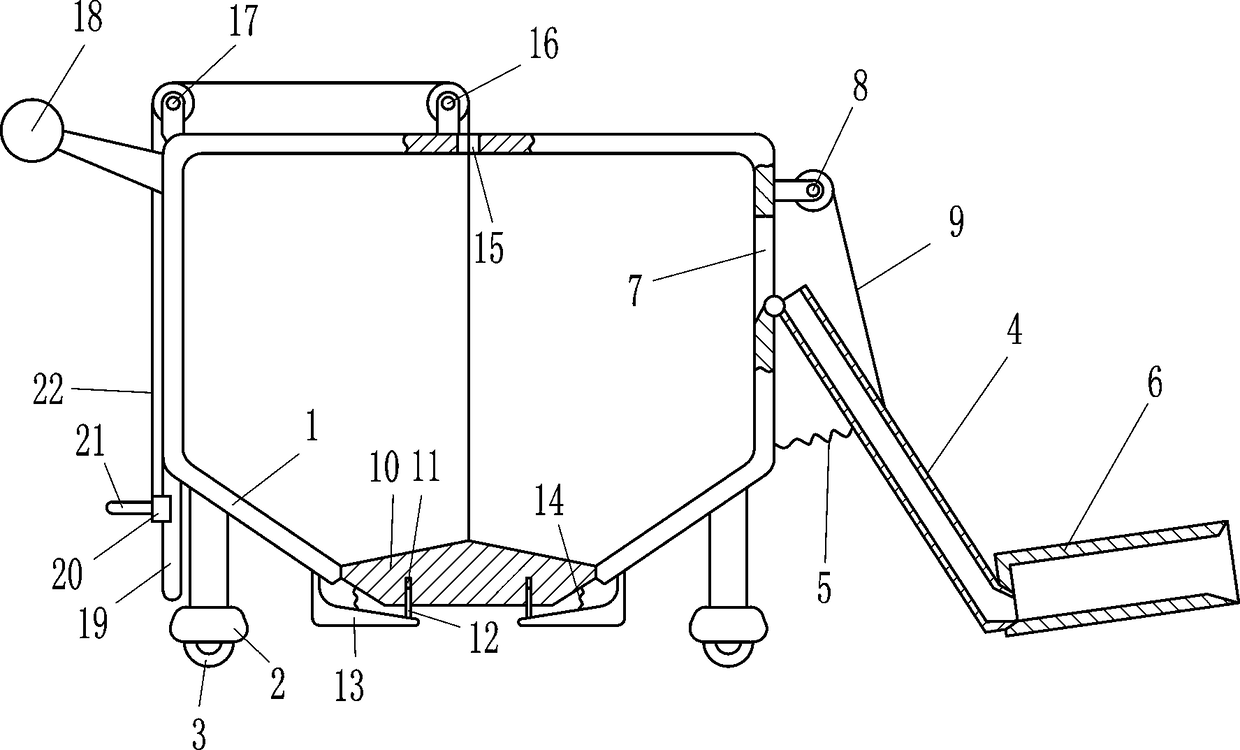

Foundation soil flattening equipment for building construction

The invention relates to foundation soil flattening equipment, in particular to foundation soil flattening equipment for building construction. The technical problem of the invention is to provide thefoundation soil flattening equipment for building construction which can automatically shovel soil protruding from the ground, can conveniently fill the soil shoveled out into a concave place of theground, can automatically flatten the soil filled in the concave place of the ground and automatically breaks the large soil shoveled out into pieces. According to the technical scheme, the foundationsoil flattening equipment for building construction comprises a funnel-shaped frame, supporting legs, wheels, a hollow pipe, a first spring, a shovel, an electric reel and the like, wherein the lowerparts of the left side and right side of the funnel-shaped frame are symmetrically connected to the supporting legs. According to the foundation soil flattening equipment for building construction, the soil protruding from the ground is automatically shoveled by using a shovel and is poured into the funnel-shaped frame through the hollow pipe, so that the protruding soil can be collected easily.The foundation soil flattening equipment moves downwards by stepping on the pedal, so that the soil collected in the funnel-shaped frame can be used to fill and level up the concave part of the ground, so that the filling of the soil is relatively easy and convenient.

Owner:钟丹红

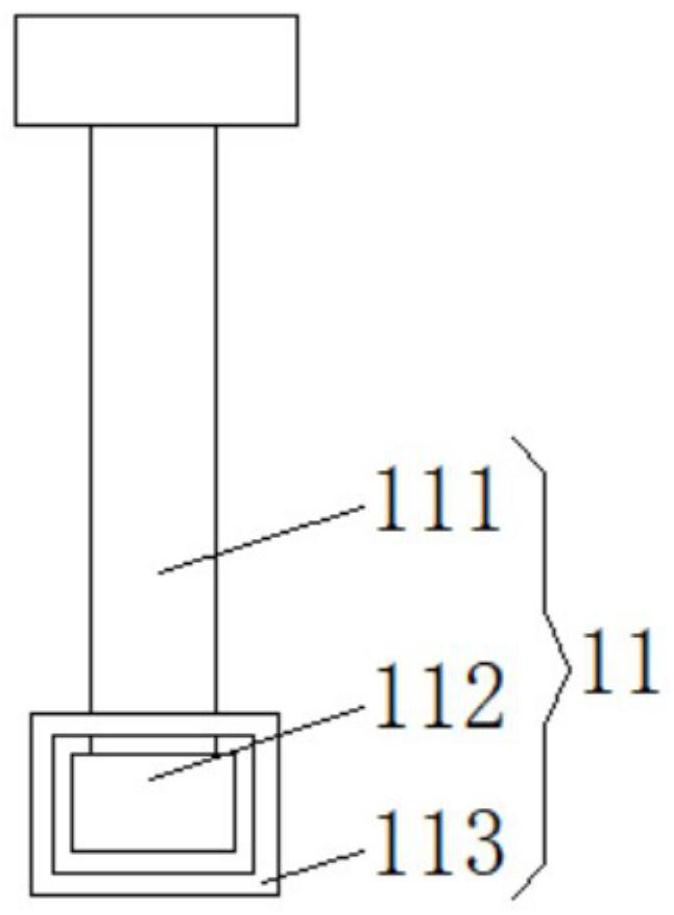

Sleeve plastic heat sealing device for raincoat production

InactiveCN110861308AEasy to moveImprove processing efficiencyDomestic articlesRotational axisEngineering

The invention discloses a sleeve plastic heat sealing device for raincoat production, and relates to the technical field of raincoat production. The sleeve plastic heat sealing device for raincoat production comprises a workbench, a leveling mechanism and heat sealing tanks, wherein support columns are installed below the workbench; a heat sealing base is arranged above the workbench; sliding blocks are fixed on the two sides of the bottom of the heat sealing base; sliding grooves are arranged on the outer sides of the lower sides of the sliding blocks; air cylinders are installed at the two ends of the heat sealing base; supporting rods are fixed on the two sides of the upper portion of the workbench; and a top plate is installed on the upper portions of the supporting rods. The sleeve plastic heat sealing device for raincoat production has the beneficial effects that the leveling mechanism is arranged to facilitate leveling of raincoat sleeves; second electric push rods can conveniently telescopically adjust the position height of mounting frames and leveling rollers; the leveling rollers form a rotatable structure with the mounting frames through rotating shafts so that the leveling rollers can rotate through the rotating shafts to perform rolling leveling on the heat sealing positions of the raincoat sleeves in the heat sealing tanks below to prevent the heat sealing positions from wrinkling.

Owner:章玉奎

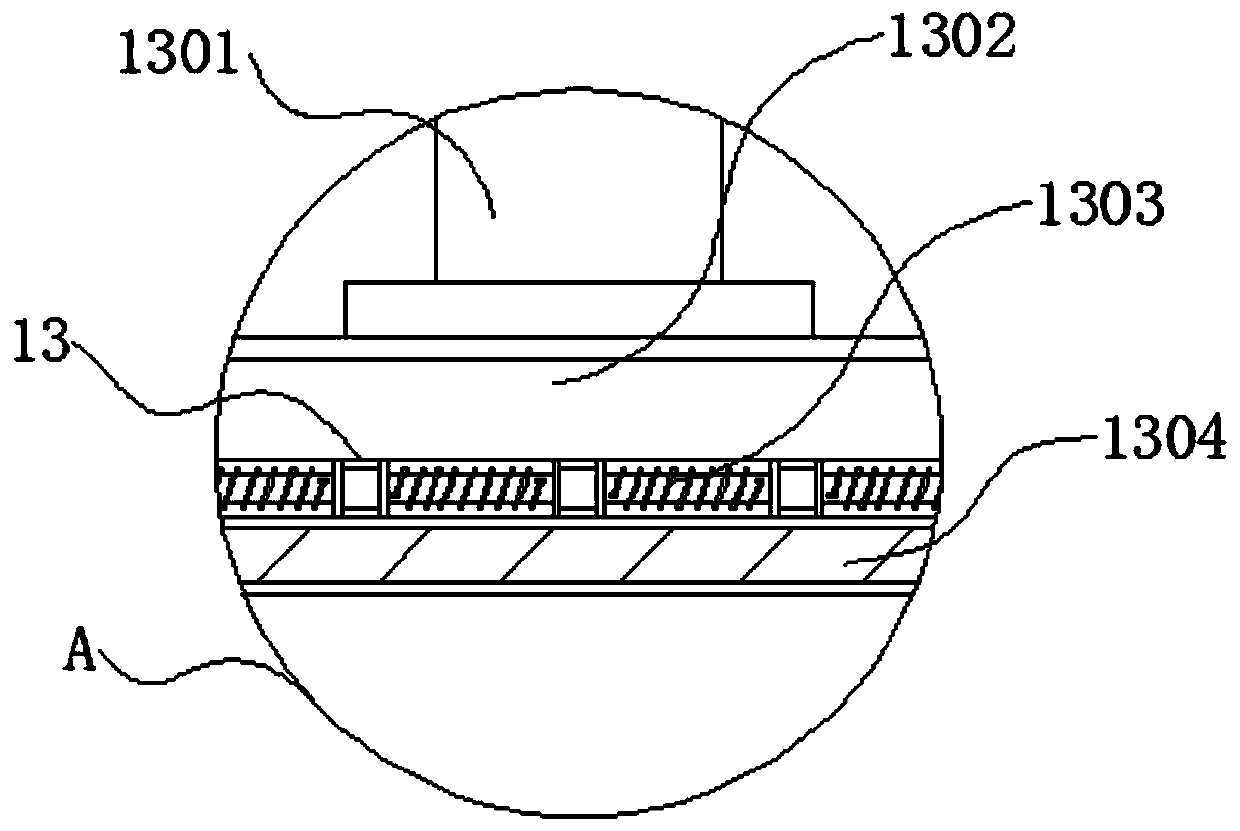

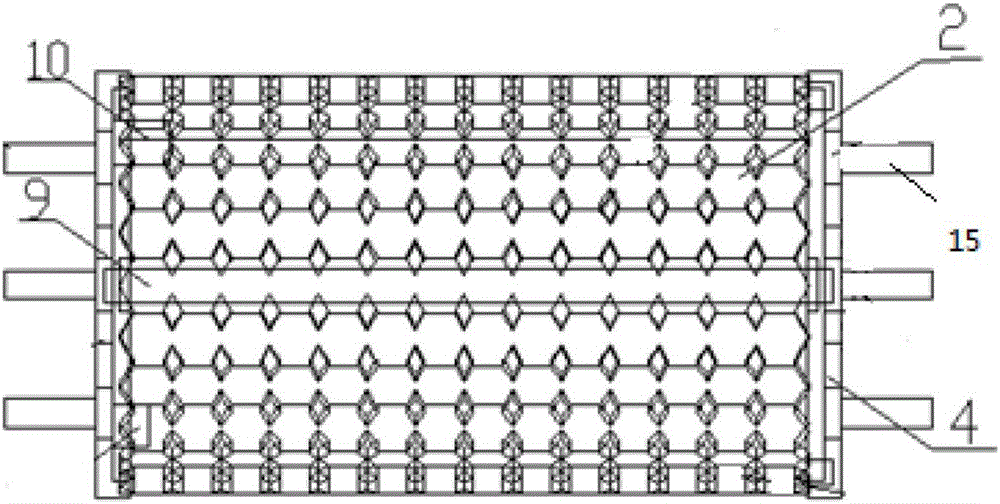

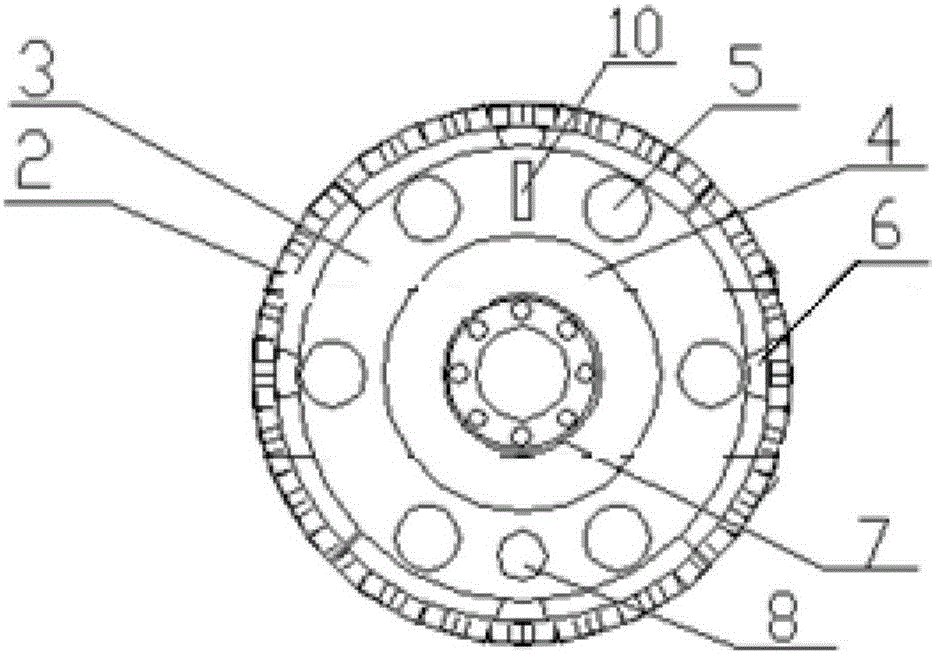

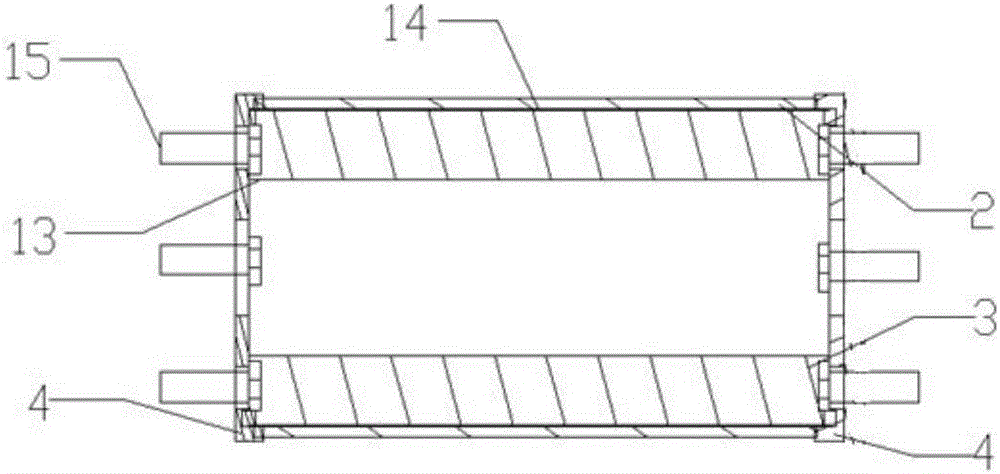

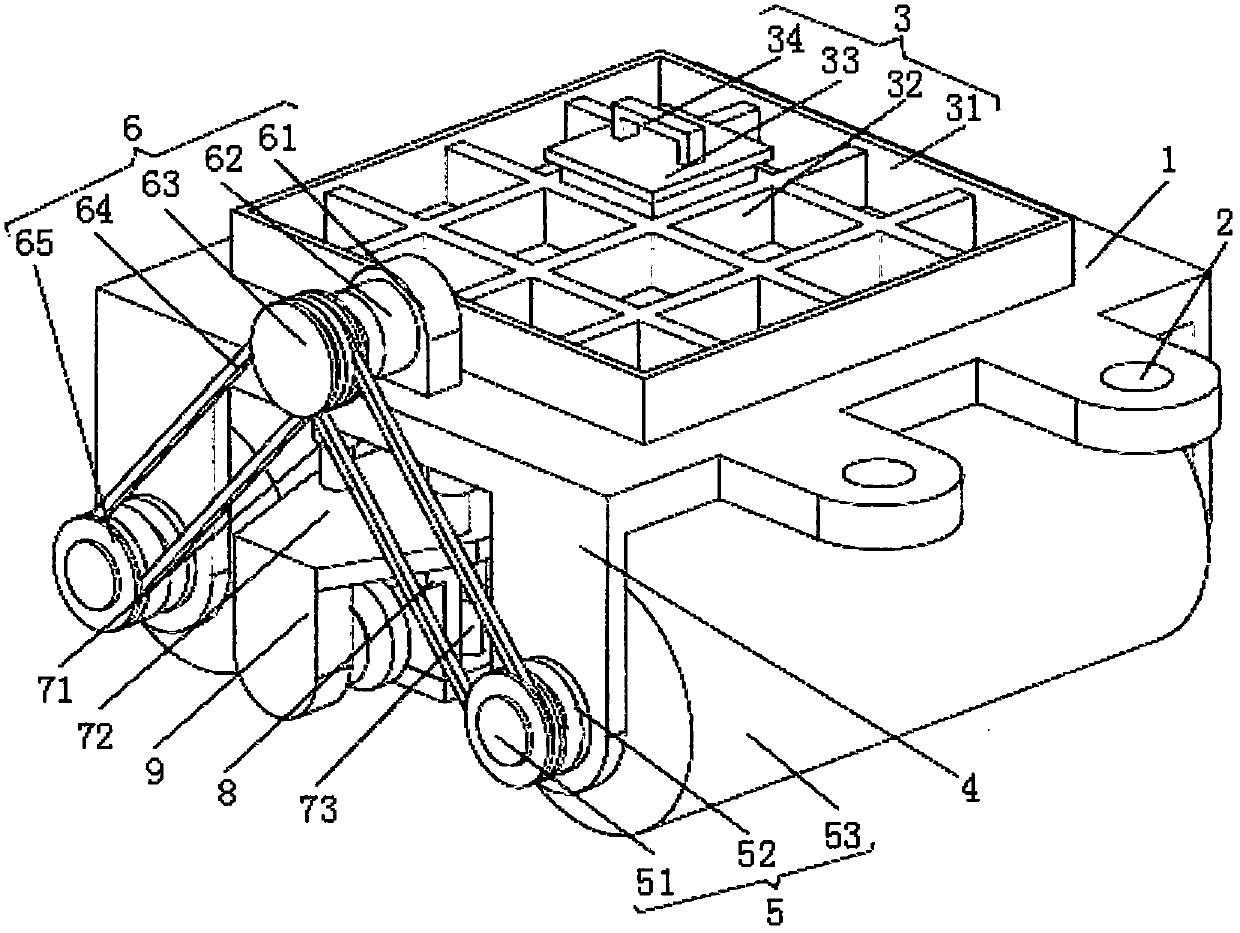

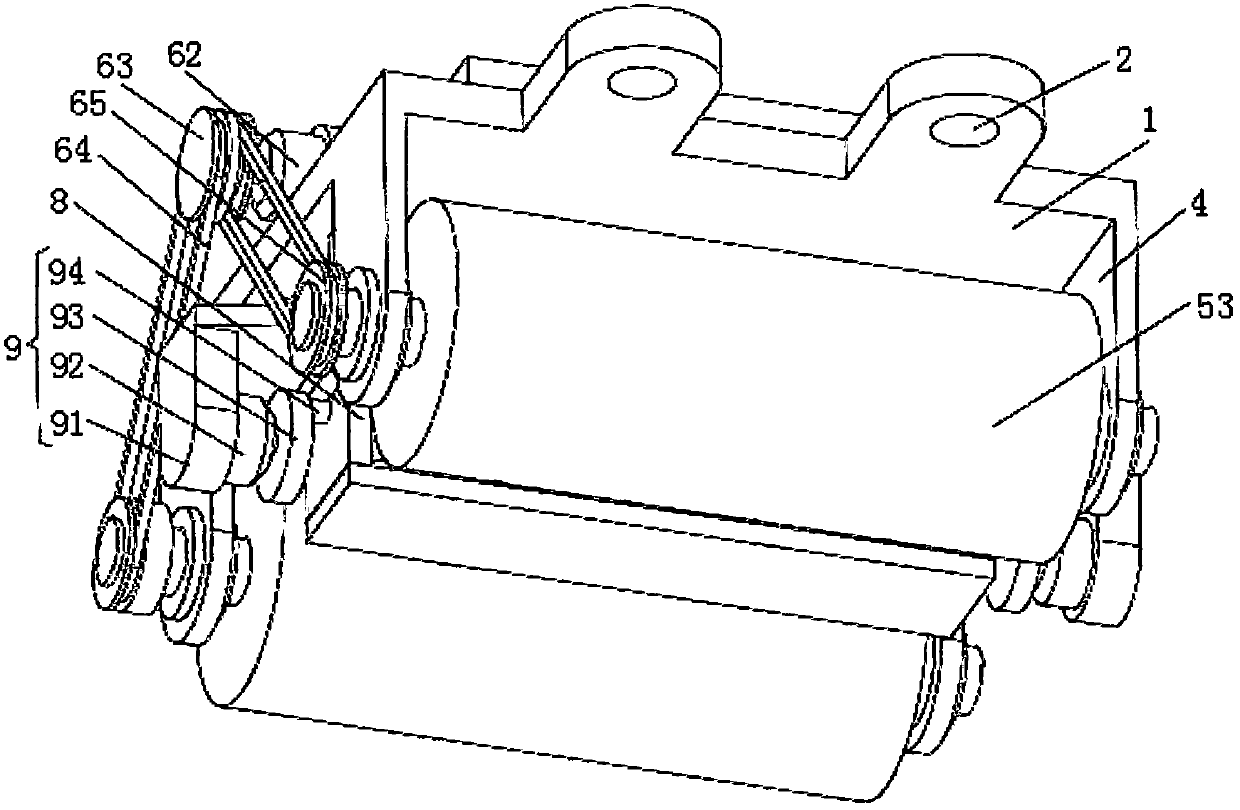

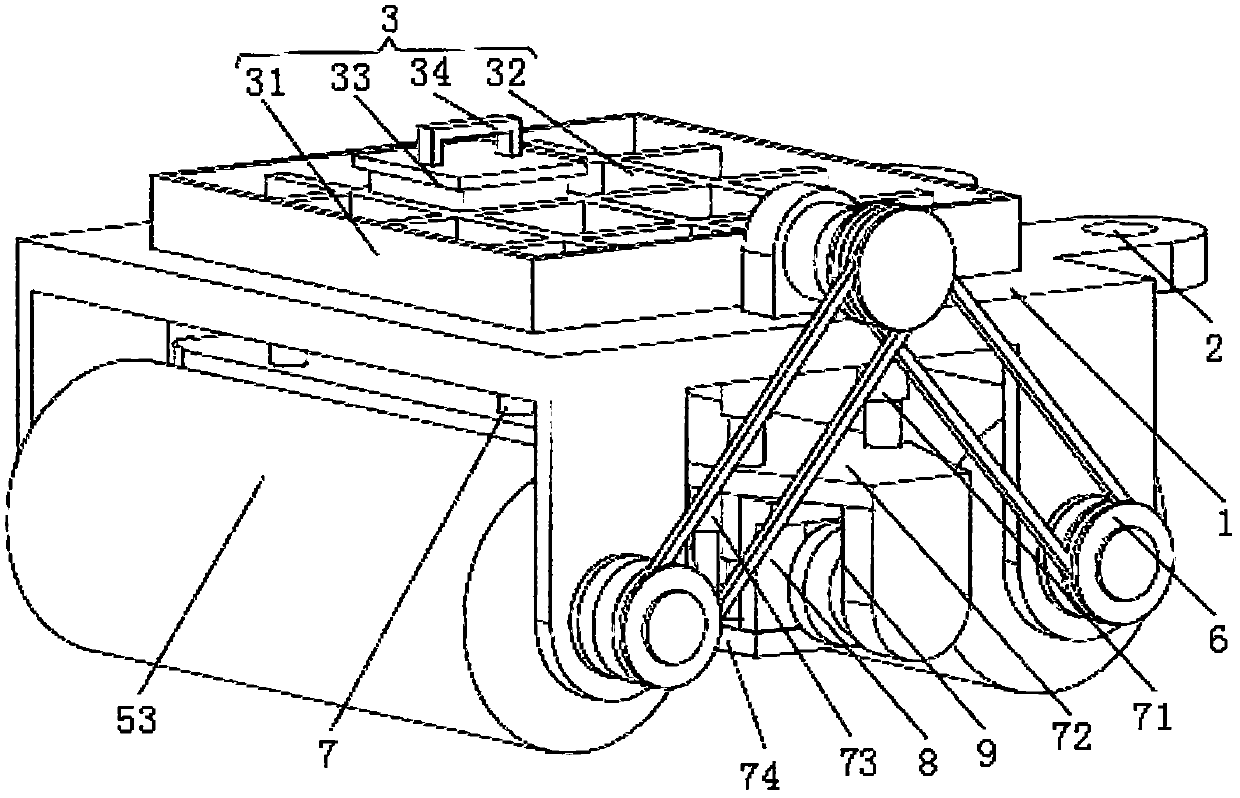

Bionic road roller steel wheel and operation method thereof

The invention discloses a bionic road roller steel wheel and an operation method thereof. The bionic road roller steel wheel comprises a steel wheel, a bionic compaction device, a fixed end cover, an electromagnetic positioning column and a polygon drawing prism. According to the bionic road roller steel wheel and the operation method thereof, the bionic compaction device carries out rough surface rolling on a rigid-flexible combined surface of cement-stabilized soil by using a bionic technology; and the steel wheel carries out plane compaction on a pavement. The bionic road roller steel wheel can be applicable to rolling of a plane and a rough surface at the same time, a user is greatly facilitated, the practical range is improved, and the bionic road roller steel wheel has the advantages of being simple in structure, convenient to disassemble and assemble, reasonable in setting and low in cost.

Owner:CHANGAN UNIV

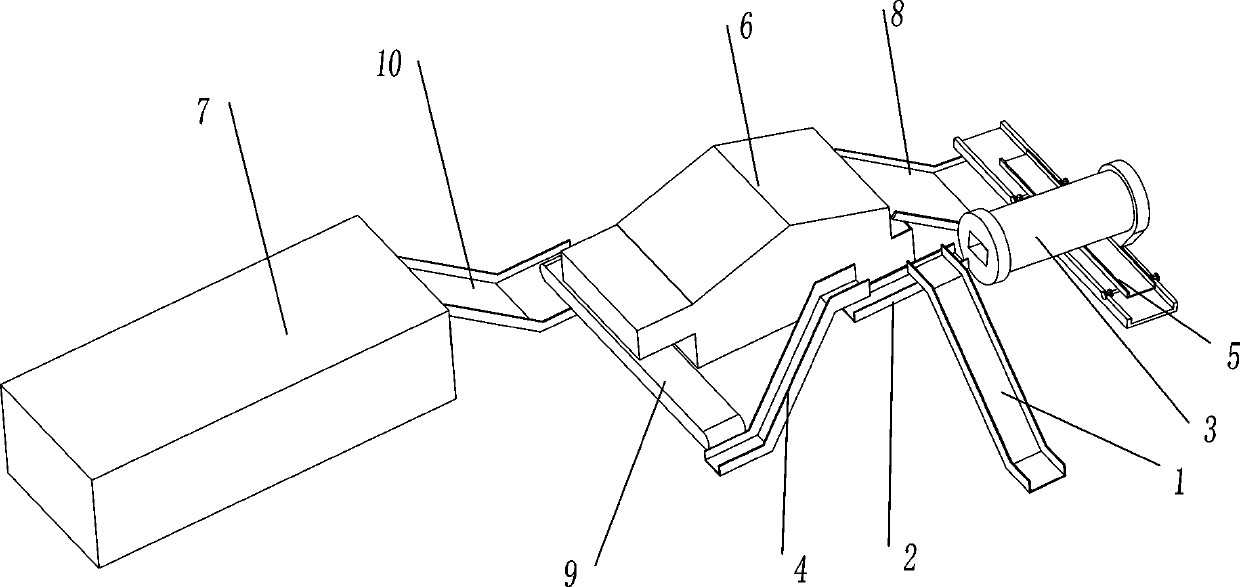

Rear-arranged hammering pressure device for road and bridge construction asphalt paver

The invention discloses a rear-arranged hammering pressure device for a road and bridge construction asphalt paver. The rear-arranged hammering pressure device comprises an installing plate. Two fixing rings arranged symmetrically are arranged at the right end of the installing plate. A balance weight device is arranged on the upper surface of the installing plate. A box body of the balance weightdevice is fixedly connected with the upper surface of the installing plate. Two sets of fixing plates arranged symmetrically are arranged on the side face of the installing plate. Two fixing plates are in each set. A rolling pressure device is arranged between the two fixing plates in each set. A first drive device is arranged at the front end of the upper surface of the installing plate. An auxiliary belt wheel of the first drive device is fixedly connected with the front ends of rotating shafts of the rolling pressure devices. A pressing device is arranged on the middle portion of the lowersurface of the installing plate. According to the rear-arranged hammering pressure device for the road and bridge construction asphalt paver, the hammering pressure device can be connected with the paver through the fixing rings, can carry out rolling pressure and hammering pressure on paved asphalt in time, can effectively improve the asphalt paving effect, and is easy to operate and convenientto use.

Owner:CHONGQING VOCATIONAL INST OF ENG

Method for constructing floor heating concrete back-filling layers

InactiveCN107299745AGuaranteed certaintyGuaranteed homogeneityFlooringRaw materialBuilding construction

The invention provides a method for constructing floor heating concrete back-filling layers. Compared with existing construction methods in the prior art, the method has the outstanding advantages that raw materials are classified, dry-mixed concrete is mechanically homogenized, watering is directly carried out after the dry-mixed concrete is uniformly paved, dry mixtures are easy to pave as compared with wet concrete mixtures, constructors wear soft-soled shoes, and accordingly floor heating coil pipes are hardly damaged in operation construction procedures by the aid of flat-end shovels; the completely paved dry concrete mixtures are watered by uniform watering equipment in watering procedures, the floor heating coil pipes are free of damage, and accordingly the durability can be guaranteed in follow-up use; field staffs, construction tools, the raw materials, the method and the like are reasonably and effectively planned, organized, coordinated, controlled and detected and are in excellent combination states, and accordingly the purpose of high-quality, efficient, low-consumption, balanced, safe and civilized production can be achieved.

Owner:四川本地人老秦新材料科技有限公司

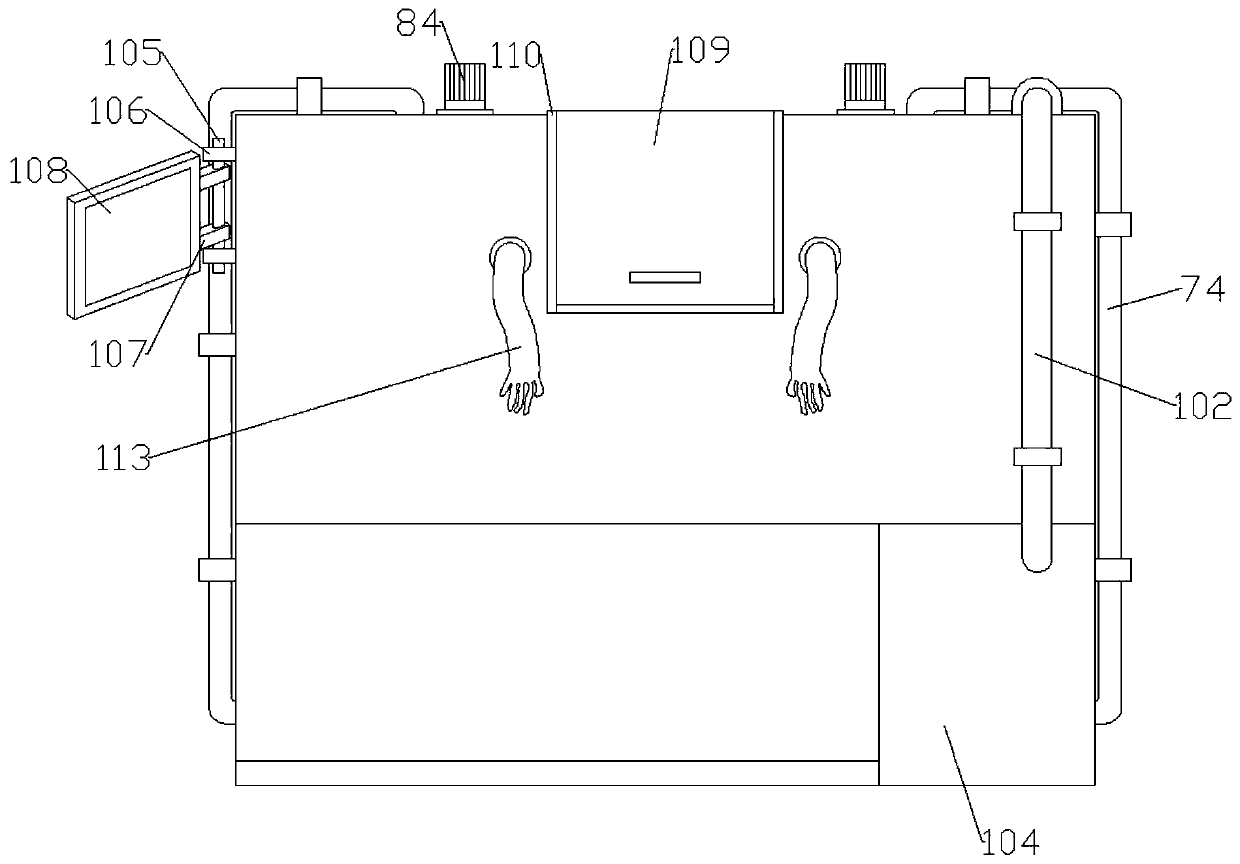

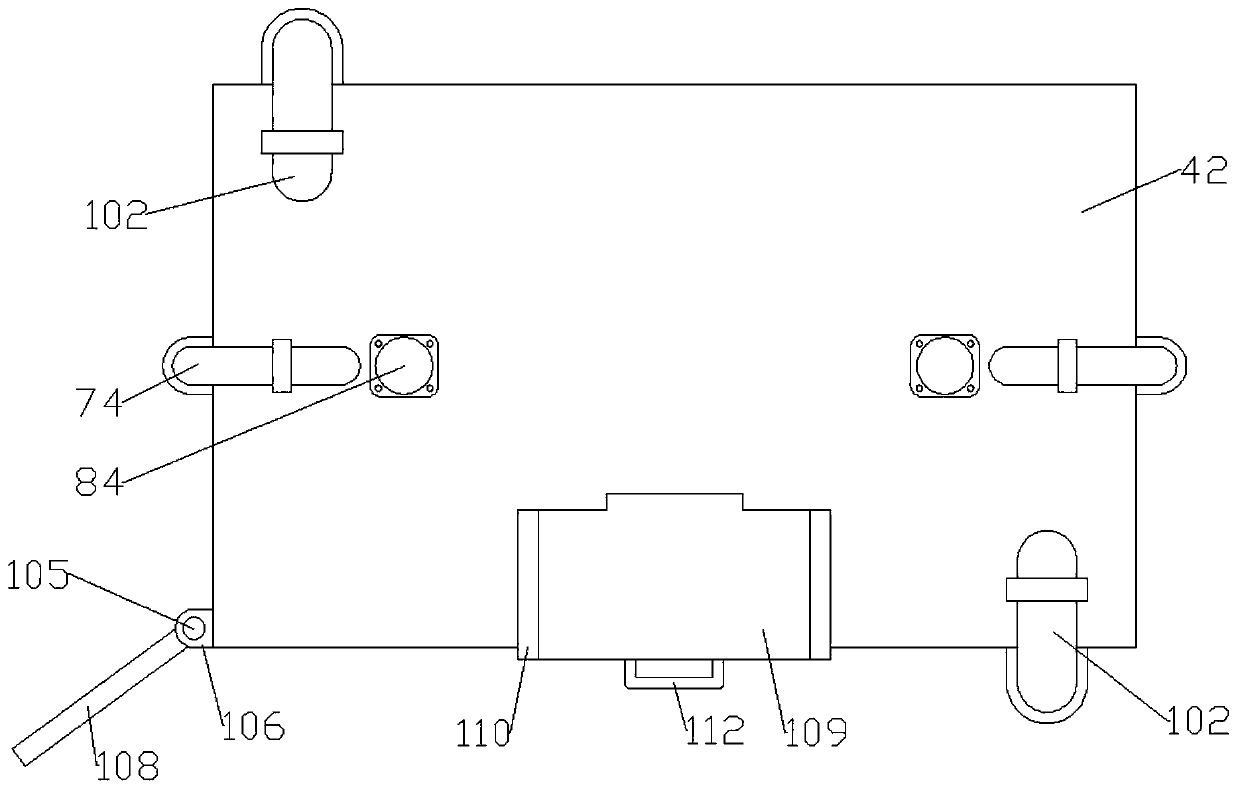

Production line and production method for green brick tea

ActiveCN109845844AReduce reproductionImprove stabilityPre-extraction tea treatmentProduction lineBrick

The invention relates to a production line for green brick tea. The production line comprises a feeding device, a vibration conveying device, a sprinkling device, a fermentation master batch adding device, a distributing device, a fermentation deblocking device and a drying device; the discharging hole of the feeding device is arranged right above the vibration conveying device, one side of the vibration conveying device is opposite to the discharging hole of the fermentation master batch adding device, and the other side is opposite to the feeding hole of the sprinkling device; the output endof the sprinkling device is positioned right above the distributing device, the distributing device is in transition connection with a first lifting conveyer belt, and the upper end of the lifting conveyer belt extends into the fermentation deblocking device; a positive and negative conveyer belt is arranged below the output end of the fermentation deblocking device, a discharge port at one end of the positive and negative conveyer belt is in transition connection with a second lifting conveyer belt, and the output end of the second lifting conveyer belt extends into the drying device. The production line for green brick tea provided by the invention can realize automatic production of green brick tea.

Owner:XINDING BIOLOGICAL SCI & TECH

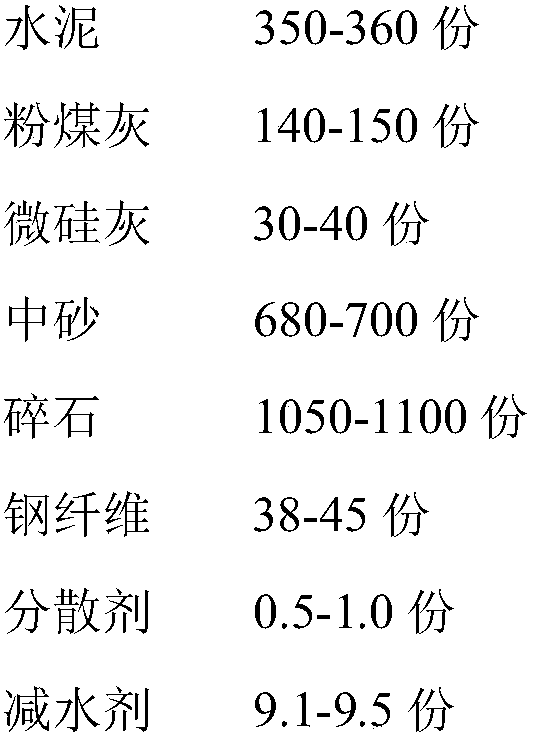

Medical device for medical image analysis

PendingCN109283687AGood for observation and analysisEasy to paveOptical elementsImage analysisMagnet

The invention discloses a medical device for medical image analysis. The medical device includes a light box; transparent sheets are arranged on two sides of the light box; illumination tubes are arranged on inner upper and lower ends of the transparent sheets; a concave groove is formed in an upper end of one side of the light box; a limiting plate is movably connected in the concave groove; oneside of the limiting plate is fixedly connected to a linkage rod; one end of the linkage rod is fixedly connected to a first clamping plate; T-shaped sliding grooves are formed in the lower end of oneside of the light box; T-shaped sliding blocks are movably connected in the T-shaped sliding grooves; the tops of the T-shaped sliding blocks are fixedly connected with a second clamping plate; magnets are arranged on the bottoms of the T-shaped sliding grooves; and a metal hose is arranged on the other side of the light box, and a flashlight is arranged on one end of the metal hose. The flashlight arranged on the back of the light box through the metal hose can locally irradiate the CT piece, and facilitates observation and analysis.

Owner:翟树校

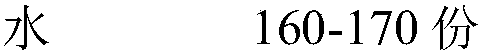

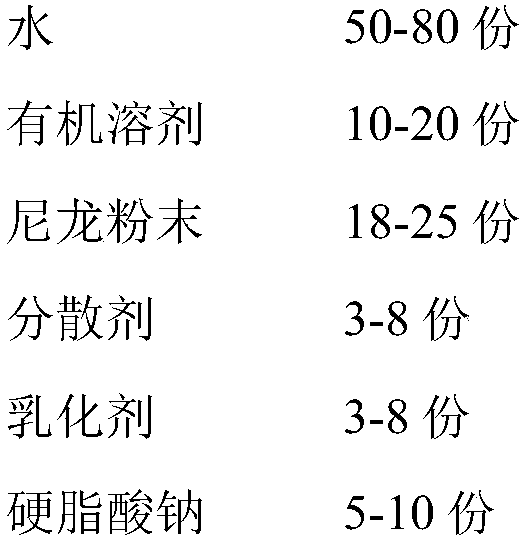

Preparation process of CF50 concrete

The invention relates to a preparation process of CF50 concrete. The CF50 concrete comprises the following components in parts by weight: 160 to 170 parts of water, 350 to 360 parts of cement, 140 to150 parts of coal ash, 30 to 40 parts of micro-silicon powder, 680 to 700 parts of medium sand, 1050 to 1100 parts of gravel, 38 to 45 parts of steel fiber, 0.5 to 1.0 part of dispersant and 9.1 to 9.5 parts of water-reducing agent, wherein the gravel comprises 700 to 750 parts of small gravel and 250 to 280 parts of big gravel, the grain size of the small gravel is 5 to 25 mm, and the grain sizeof the big gravel is 5 to 10 mm. In the scheme, adhesive adopts the cement, the coal ash and the micro-silicon powder, the gravel comprises big gravel and small gravel, the big gravel serves as aggregate, the small gravel is filled in the big gravel and is used for guaranteeing the structural strength of the concrete, the micro-silicon ash is used for enhancing the hardness of the concrete, the steel fiber is used for enhancing the toughness of the concrete, and the prepared concrete has good anti-cracking effect, is not liable to generate ash and has high structural strength.

Owner:成都精准混凝土有限公司

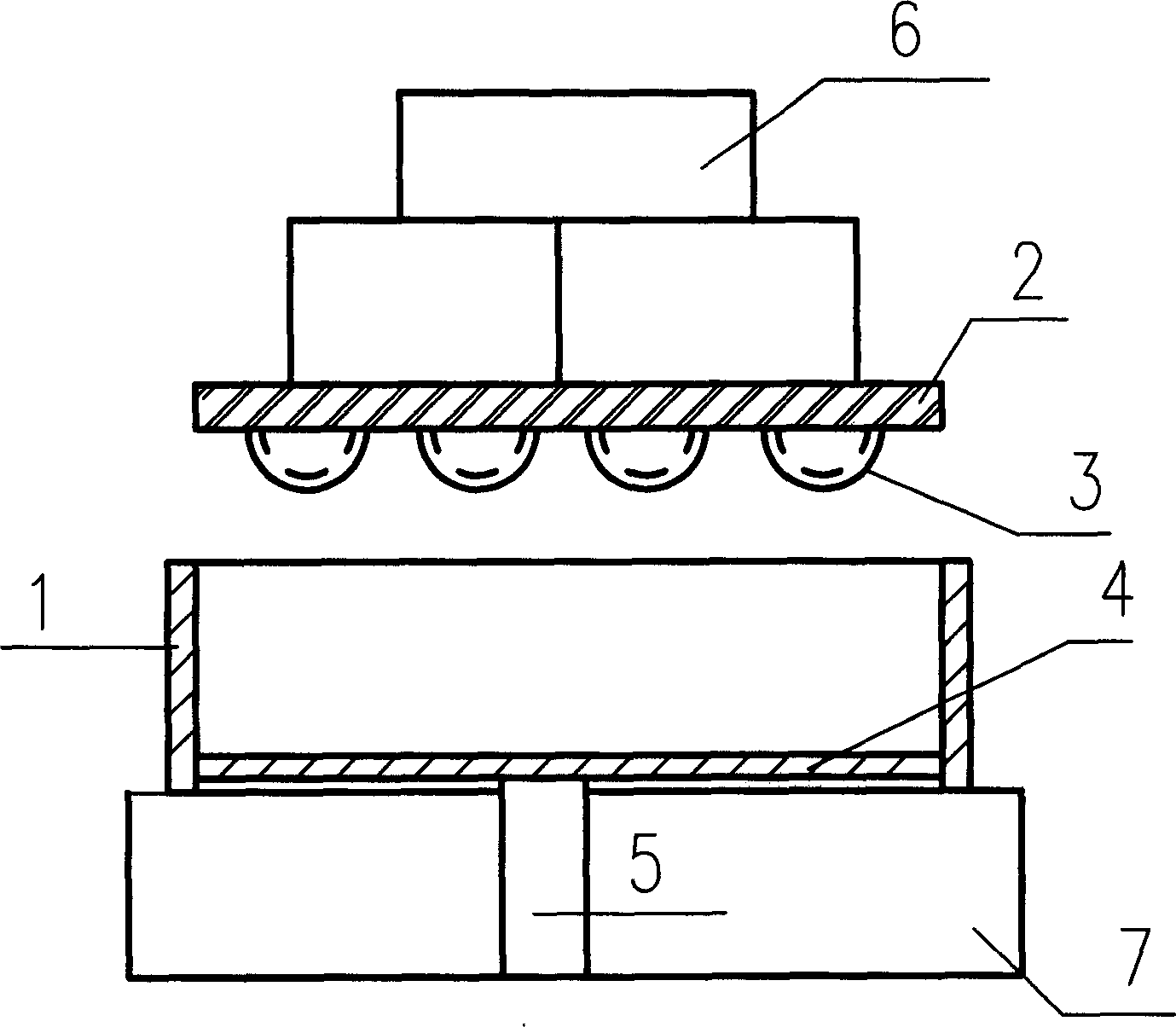

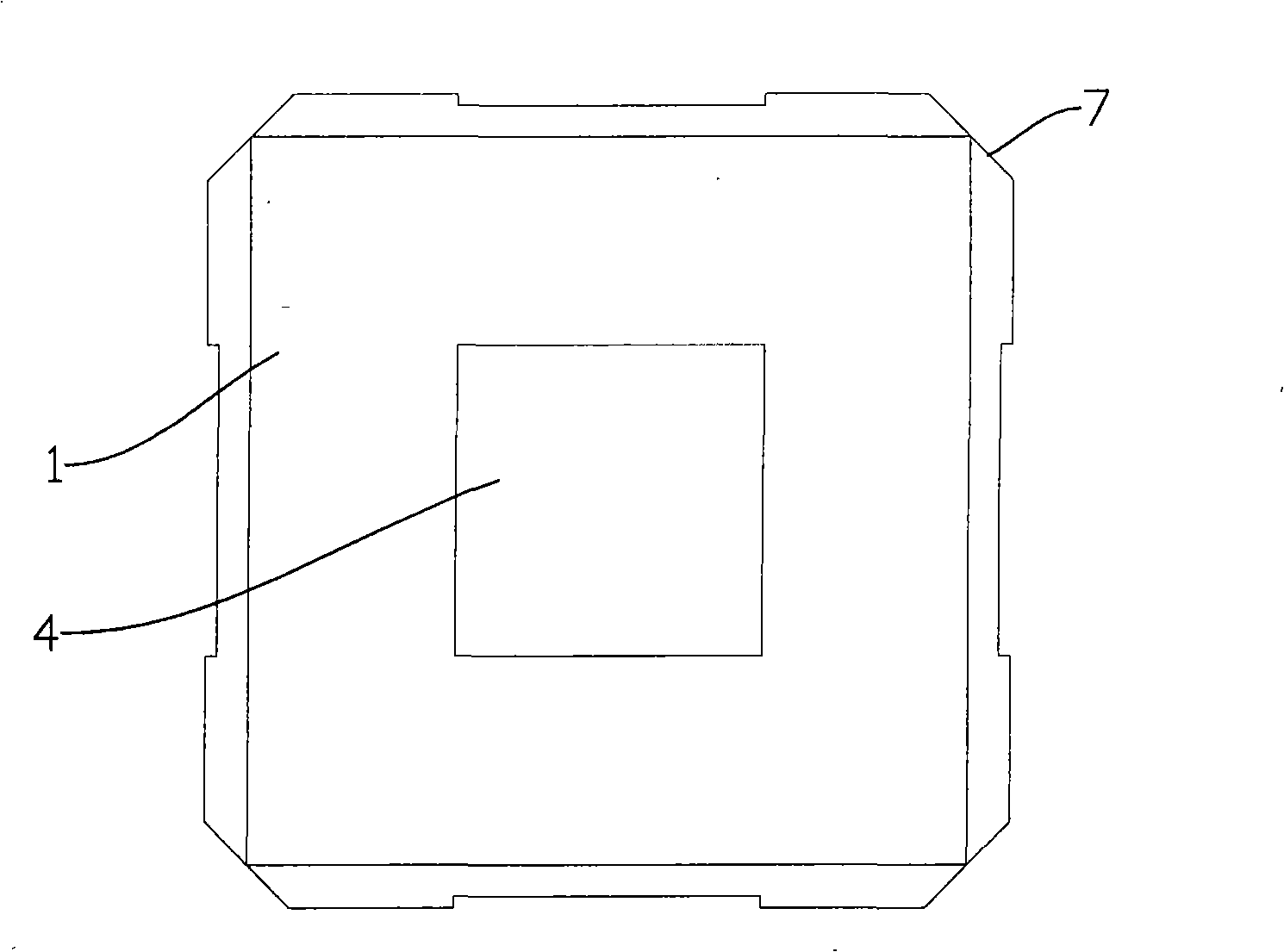

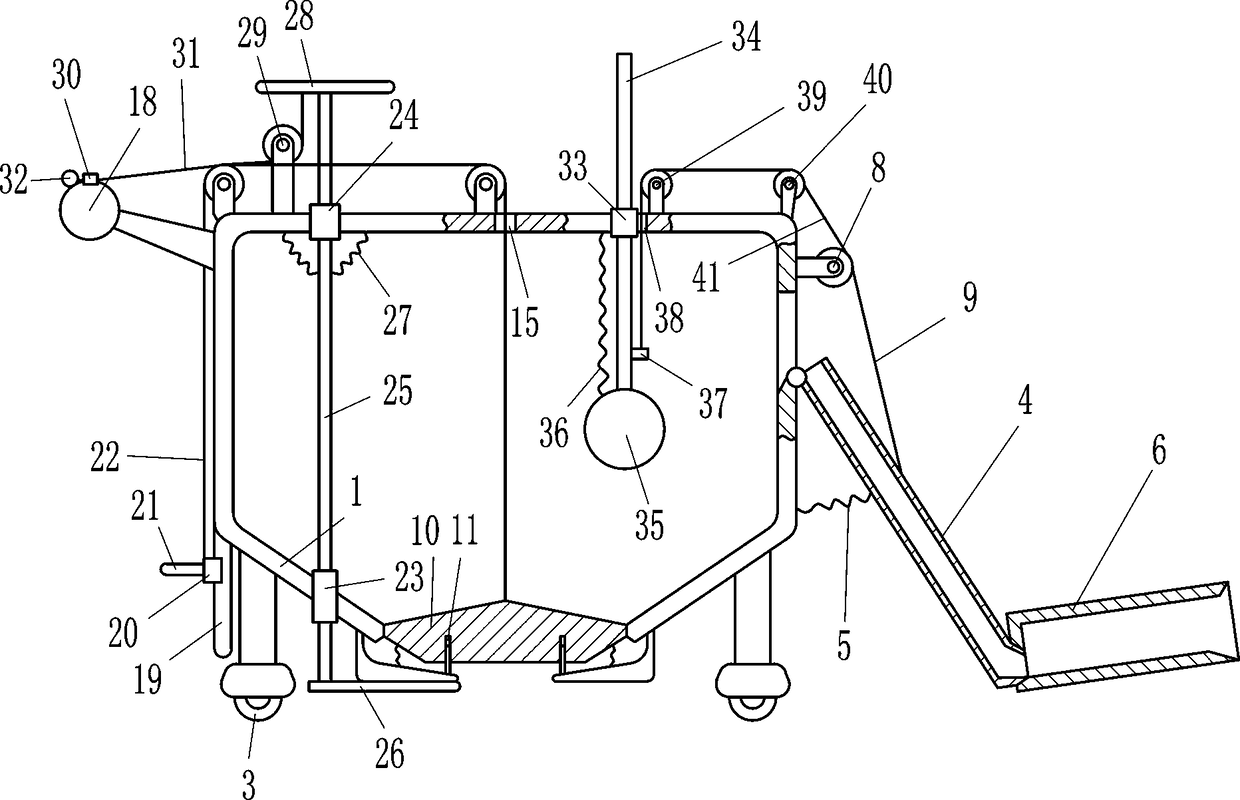

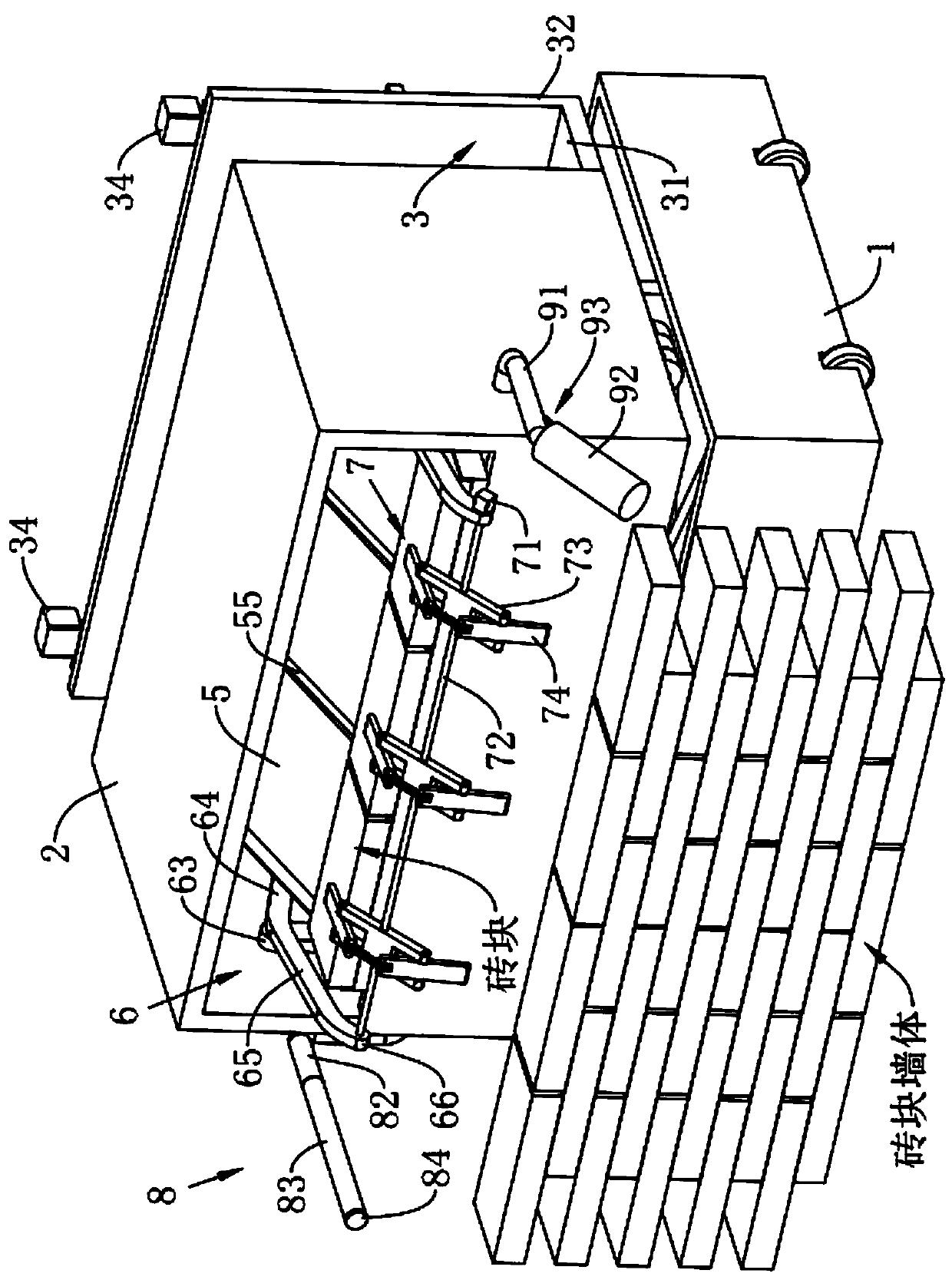

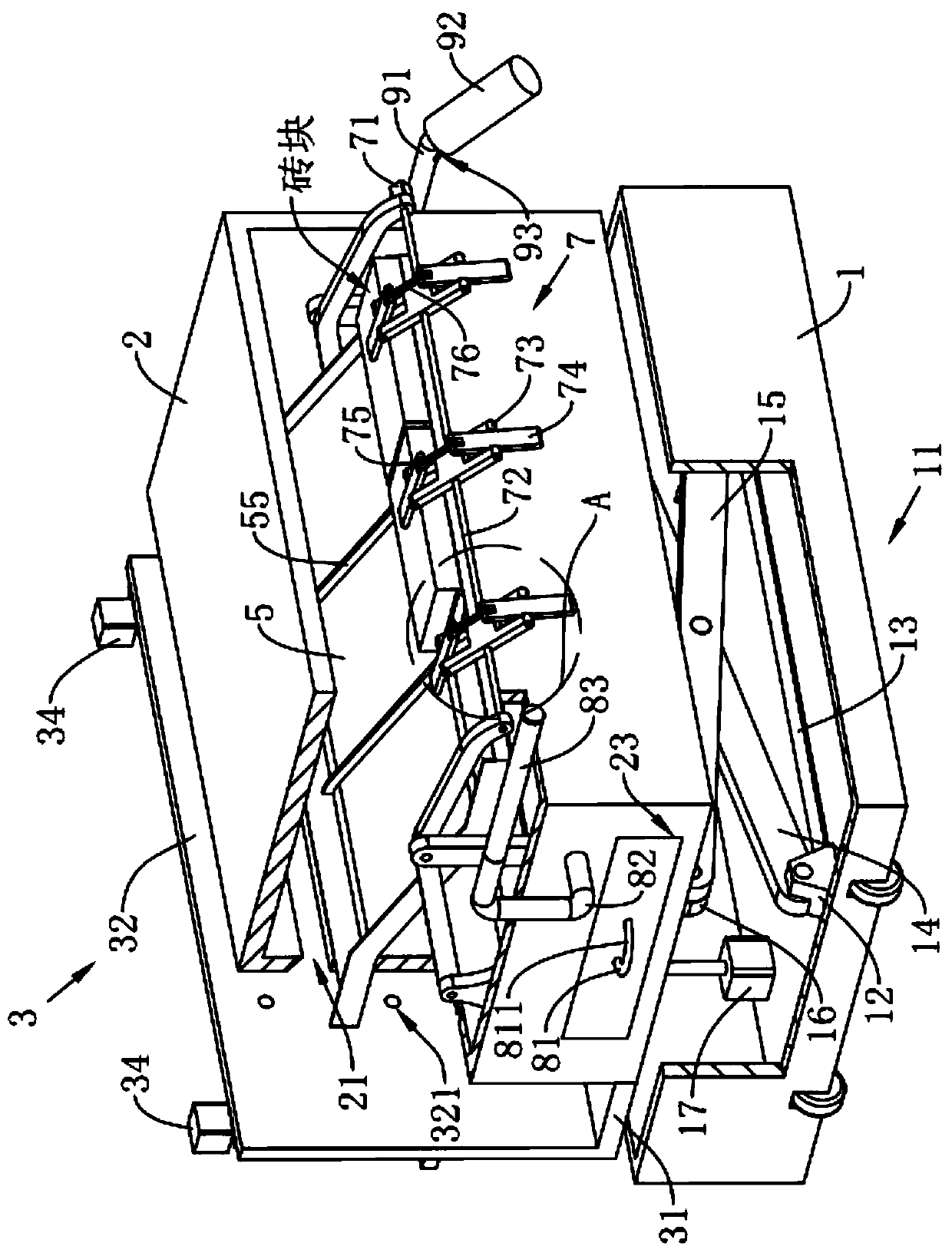

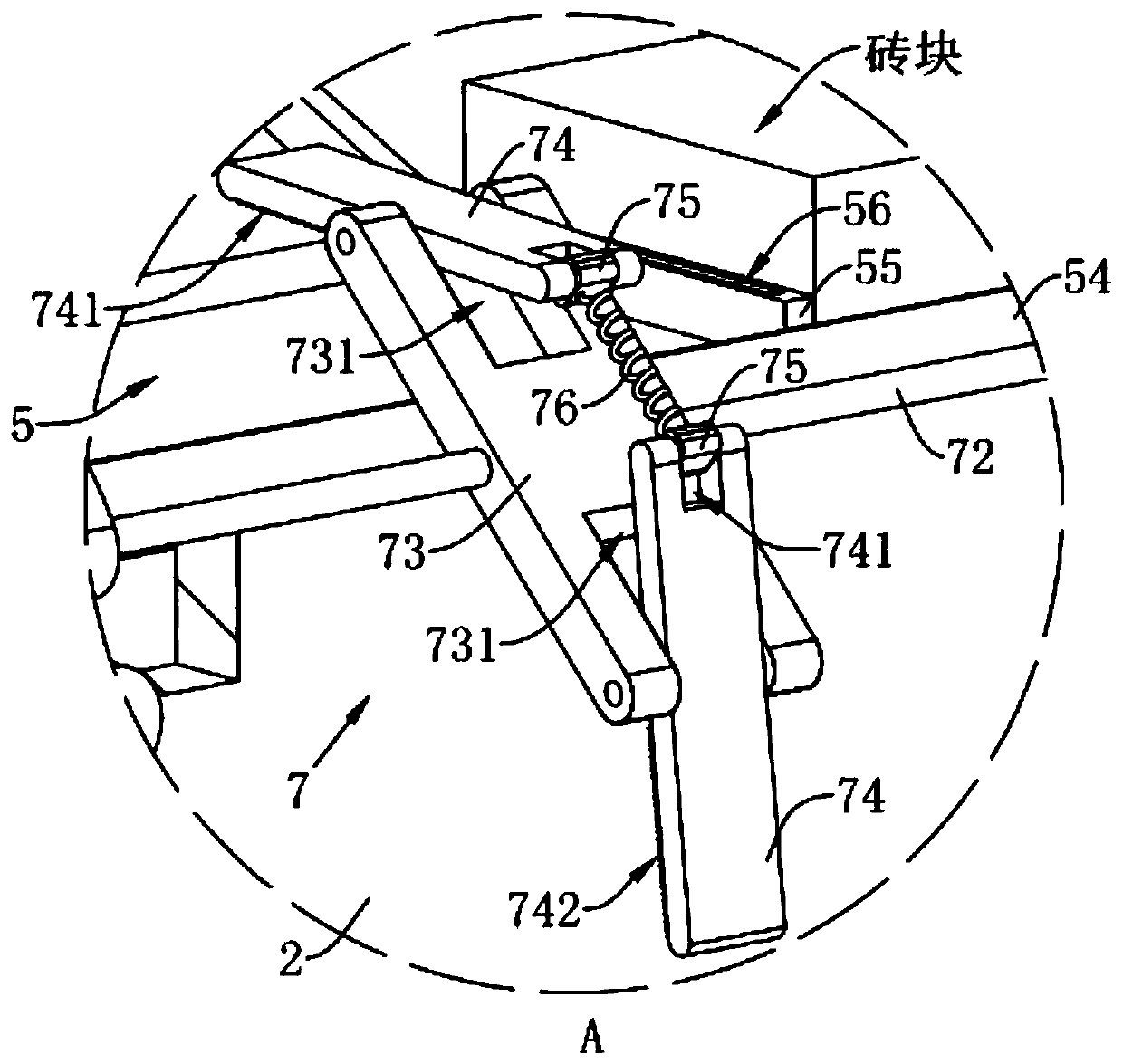

Wall bricklaying device

ActiveCN111535599AEasy to paveFacilitates laying and laying brickworkBuilding material handlingBrickEngineering

The invention discloses a wall bricklaying device. The wall bricklaying device comprises a moving vehicle body, wherein a shear fork mechanism is arranged on the top face of the moving vehicle body. Abarrel-type frame is arranged at the stretching-out end of the shear fork mechanism, one end of the barrel-type frame is open, the other end of the barrel-type frame is sealed, the open end of the barrel-type frame horizontally faces the side, perpendicular to the moving direction, of the moving vehicle body, and a feeding trough allowing bricks to pass and communicating with the interior of thebarrel-type frame is formed at the sealed end of the barrel-type frame. Lifting cylinders are arranged on the moving vehicle body, the stretching-out ends of the lifting cylinders are connected with acontaining frame, and the containing frame is provided with a pushing part. The pushing end of the pushing part penetrates through the containing frame and is arranged by facing the feeding trough. Afeeding guide plate right facing the feeding trough is arranged in the barrel-type frame. Connecting rod mechanisms are arranged in the barrel-type frame and are provided with multiple clamping partsused for clamping bricks on the feeding guide plate, and the connecting rod mechanisms drive the clamping parts to move towards the positions of bricks. The moving vehicle body is provided with a spraying device used for spraying mortar towards the bricklaying positions. Through the above arrangement, the wall bricklaying device has the advantage of replacing manpower so as to achieve intelligentbrick pavement and bricklaying.

Owner:广东中域建设工程有限公司

Nursing bellyband used after hepatobiliary surgery

InactiveCN109498275AEasy to control the degree of bendingNot easy to bendBreast bandagesPneumatic massageMagnetic tapeHand held

The invention discloses a nursing bellyband used after hepatobiliary surgery. The nursing bellyband comprises first magnetic tape pieces, a nursing cover and second magnetic tape pieces, three first magnetic tape pieces are uniformly arranged at each of two ends of the nursing cover transversely, three second magnetic tape pieces are longitudinally arranged on each of two sides of the nursing cover, a wavy airbag is arranged inside an internal groove, a handheld airbag is arranged at the other end of an air guide tube, and a cover is arranged at the top of the nursing cover. A medicine bag issqueezed through squeezing effect of the wavy airbag to enable the medicine bag to be fitted with an incision, so that contact between the medicine bag and skin is increased, and convenience is brought to flattening the medicine bag to maintain flatness of the medicine bag; the handheld airbag is slowly pressed to enable the wavy airbag to be in repeated contraction and expansion so as to massagethe incision; the nursing bellyband is convenient to use, convenience is brought to controlling bowing degree of a patient, and secondary damage caused by dragging of a wound is prevented.

Owner:王春侠

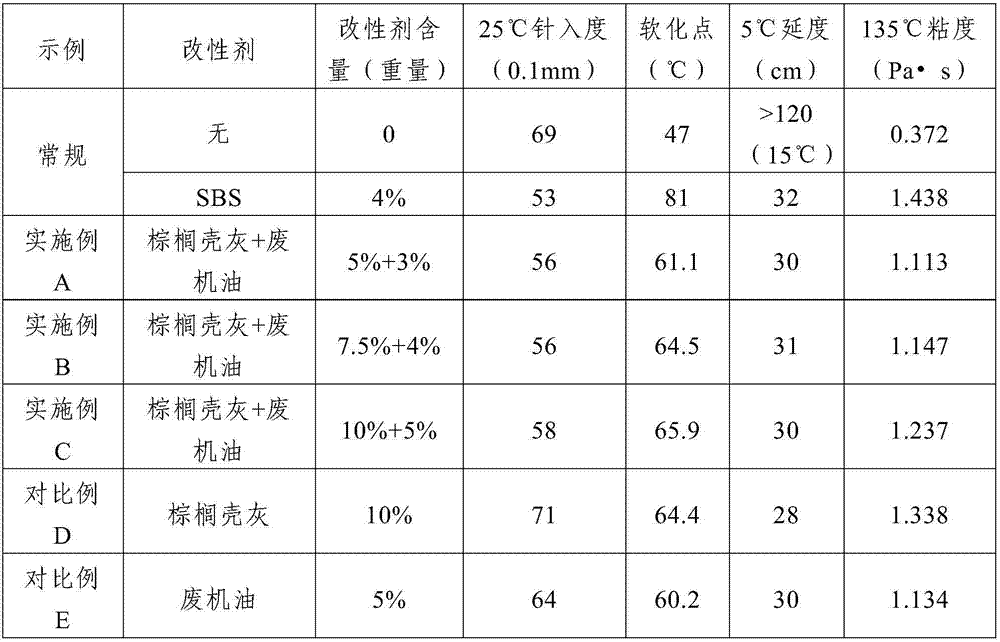

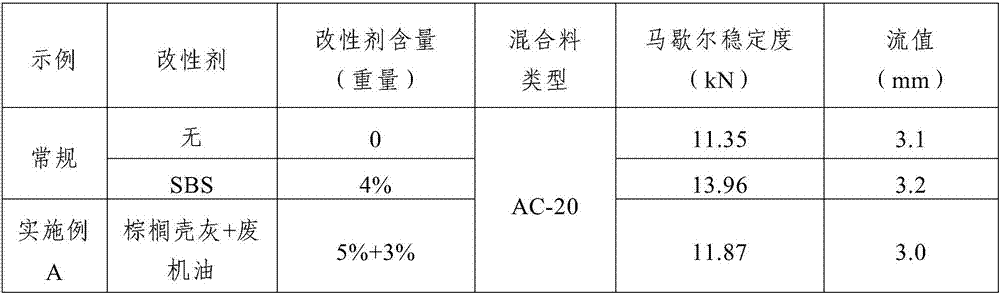

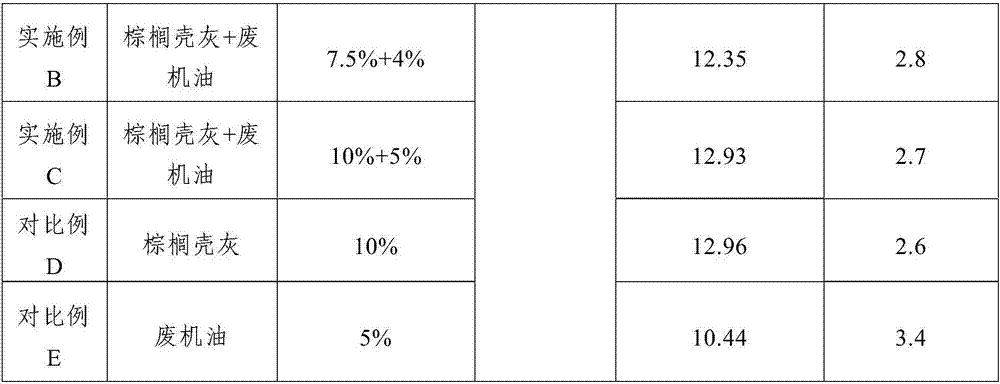

Modified asphalt

InactiveCN106916462AReduce in quantityImprove continuityBuilding insulationsSocial benefitsPalm fruit

Modified asphalt is provided. The modified asphalt includes matrix asphalt and a modifier. The modifier includes palm fruit shell ash and waste engine oil. The palm fruit shell ash is ash generated after palm fruit shell is combusted. The waste engine oil is engine oil wasted after vehicle maintenance. A large amount of palm fruit shell is adopted, thus providing a beneficial supplement for the flourishing palm oil industry at present, reducing pollution caused by secondary treatment of the palm fruit shell ash and the waste engine oil, reducing the fuel using amount during modified asphalt production, and meeting the social requirements of energy conservation and emission reduction at present. A construction process is convenient, the cost is low, and the effective utilization rate is increased. The modified asphalt can be widely used in highway and building projects, and has significant economic benefit and social benefit.

Owner:XIAN UNIV OF SCI & TECH

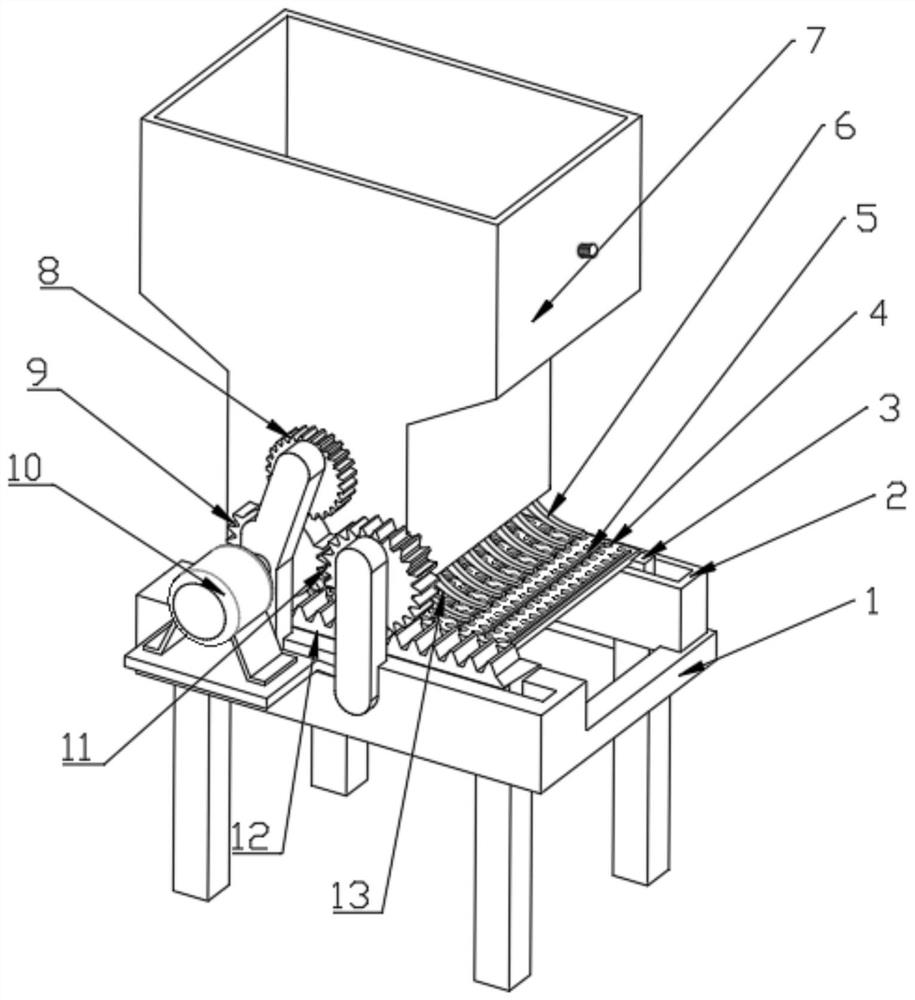

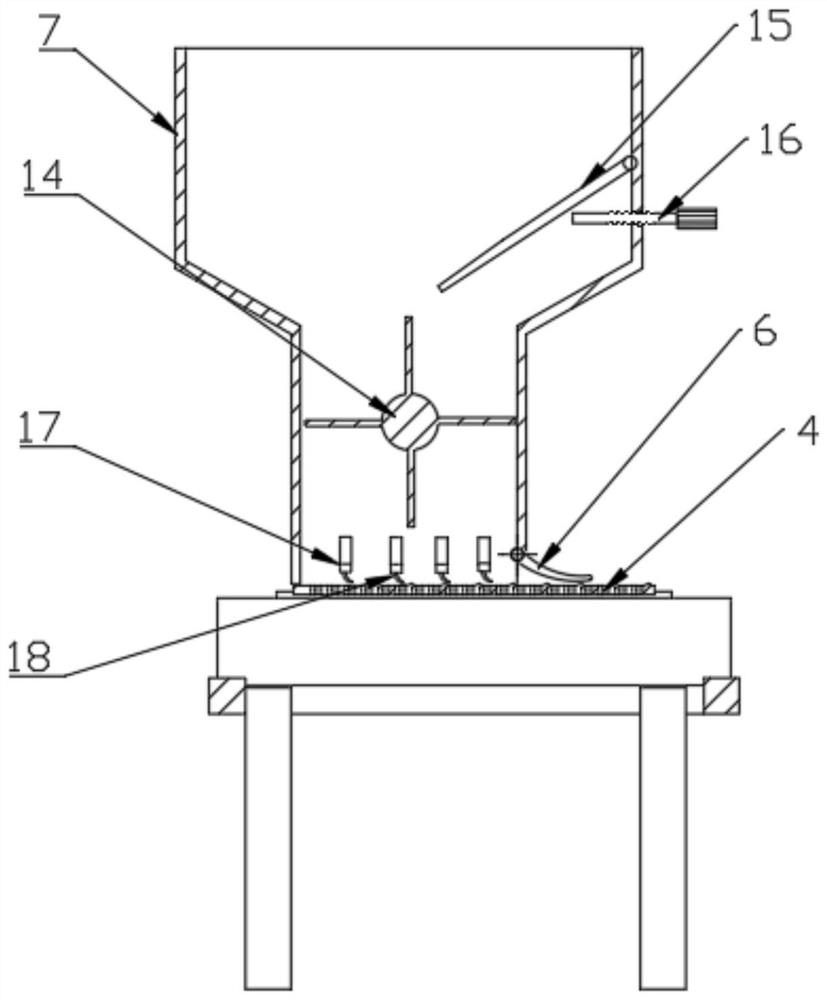

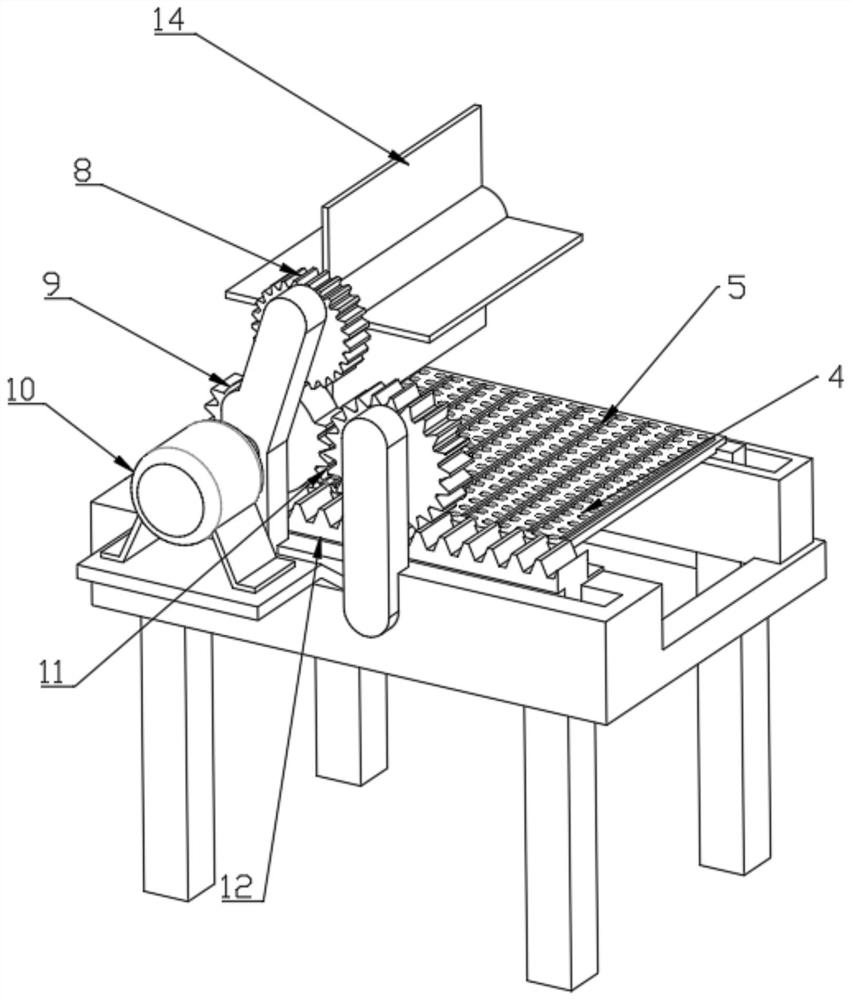

Concrete raw material screening device

The invention is applicable to the technical field of concrete, and provides a concrete raw material screening device. The screening device comprises a machine frame used for supporting and mounting,a hopper fixedly installed on the machine frame and used for containing concrete raw materials, a sieve plate slidably arranged on the machine frame below the hopper and used for sieving the concreteraw materials, a feeding roller rotationally arranged in the hopper and used for controlling feeding of the concrete raw materials, and a driving part connected with the feeding roller and the sieve plate through transmission parts and used for driving the feeding roller to rotate for feeding and driving the sieve plate to slide for screening, wherein the transmission parts comprise a first gear,an intermittent gear, a second gear and a rack, the rack is at least fixed to one end of the non-sliding side of the sieve plate, the first gear, the intermittent gear and the second gear are rotationally connected to the machine frame, and the second gear is meshed with the rack. The screening device has the advantages of simple structure, convenient operation, energy conservation, good synchronism, high screening efficiency and convenience in popularization and implementation.

Owner:李淑敏

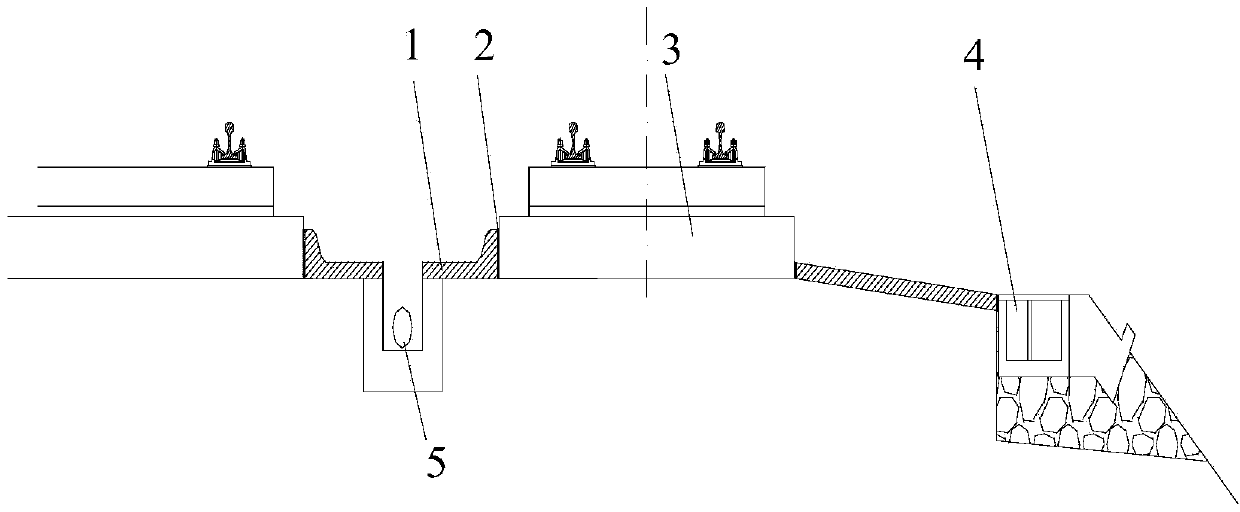

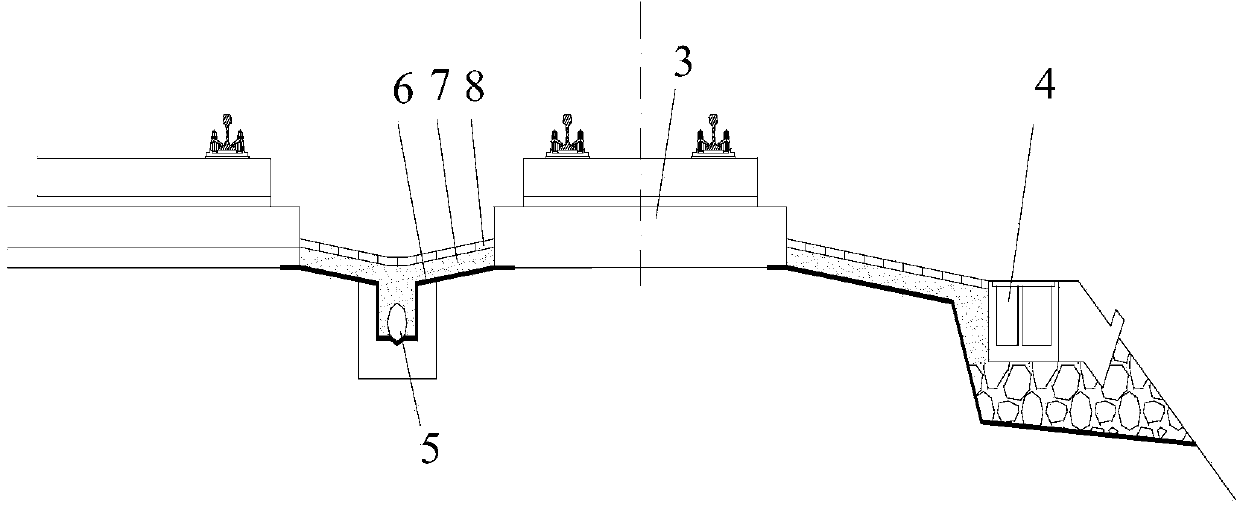

Ballastless track railroad roadbed surface water sealing layer structure

The invention discloses a ballastless track railroad roadbed surface water sealing layer structure which comprises a water-resisting layer, a prefabricated paved surface and a sand cushion. The sand cushion is arranged on the water-resisting layer, and the prefabricated paved surface is arranged on the sand cushion. Soil engineering seepage-proofing materials of two pieces of fabric and one film are adopted in the water-resisting layer, and the water-resisting layer is formed by combining the plastic thin film and the non-woven fabric. The roadbed surface water sealing layer structure is arranged on the inner side and the outer side of a track base, has transverse gradients and inclines towards the slanting underneath from the two sides of the track base. The water-resisting layer extends inwards to be below the track base and extends outwards to be outside a roadbed body, and surface water is made to flow out of a roadbed smoothly and is prevented from seeping into the roadbed. The water-resisting layer below the inner side line of the track base extends to a ditch between lines, and the water-resisting layer on the outer side of the track base extends to be below a cable groove outside the roadbed body. The ballastless track railroad roadbed surface water sealing layer structure solves the problem of leakage caused by the cracking and damage of a fiber concrete and bituminous concrete waterproof layer, adopted prefabricated paved surfaces can be prefabricated in factories, pavement is convenient, maintenance and repair are simple, construction cost is low, and new application prospects are revealed in ballastless track railroad roadbed projects.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

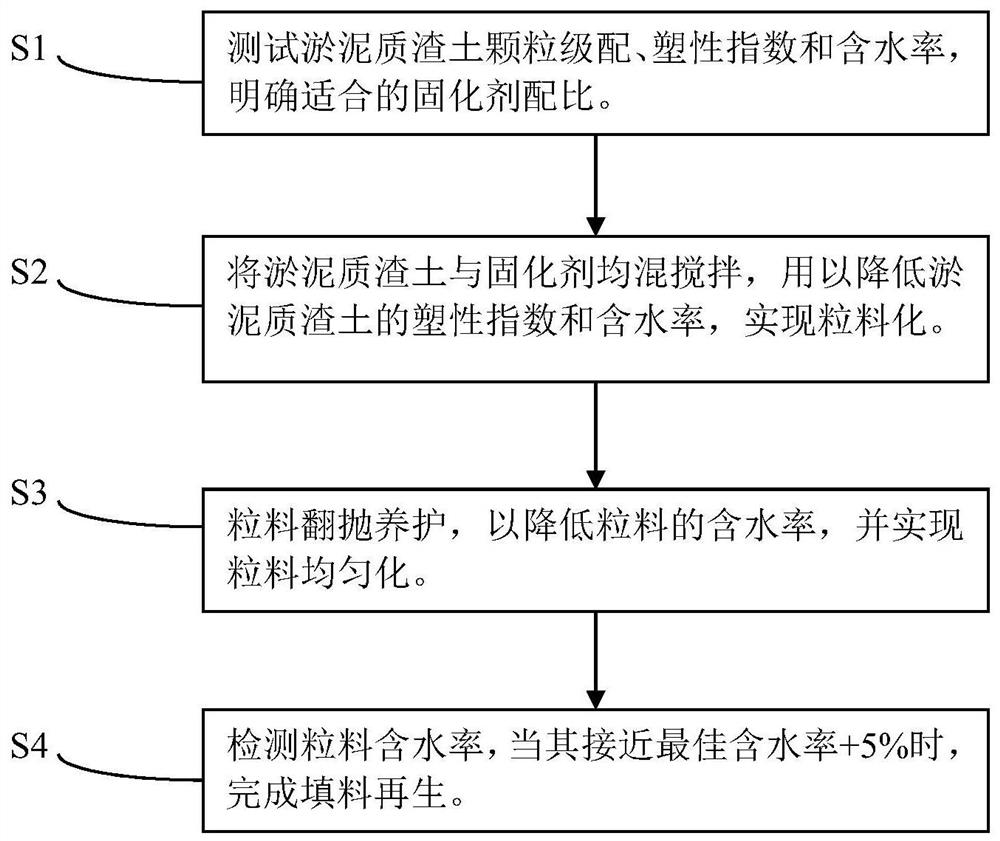

Production process for solidifying and regenerating roadbed filler by using mucky muck

InactiveCN113442291ASimple and efficient processEase of industrial applicationRoadwaysSolid waste managementRoad constructionPlastic property

The invention discloses a production process for solidifying and regenerating roadbed filler by using mucky muck. The production process comprises the following steps that the using amount of a curing agent is determined according to grain composition, plasticity index and water content of muck; the mucky muck is mixed with the curing agent to realize granulation; granules are turned, thrown and maintained to realize water reduction and homogenization of the granules; and the moisture content of the granules is detected, and when the moisture content of the granules is not higher than the optimal moisture content+5%, production of the regenerated roadbed filler is completed by taking the homogenized granules as the regenerated roadbed filler. According to the production process, the natural mucky muck can be directly solidified, pretreatment links such as drying and crushing or water distribution fluidization are not needed, the using amount of the curing agent is small, the treatment period is short, the regenerated filler is in the shape of loose and compactable powder which is appropriate in water content and viscosity, transfer and road construction operation are easy, secondary ash doping is not needed, the filler can be directly paved and rolled, and the roadbed bearing capacity requirement is met after compaction. The technological process is simple and efficient, and industrial application and large-scale popularization are easy.

Owner:ZHEJIANG UNIV +1

Corn seed processing equipment based on integration of various technologies

InactiveCN108848747AEasy to put inEasy to transportSievingDrying solid materials with heatUltimate tensile strengthComputer engineering

The invention discloses corn seed processing equipment based on integration of various technologies and relates to the technical field of corn seed processing equipment. The corn seed processing equipment based on the integration of the various technologies comprises a machine body, wherein two supporting legs are fixedly mounted at the bottoms of two side faces of the machine body; a feeding hopper is communicated with the left end of a top surface of the machine body; a first material fetching door is hinged to the bottom of a front surface of the machine body through a hinge; a second material fetching door is hinged to the top of the front surface of the machine body through a hinge. According to the corn seed processing equipment based on the integration of the various technologies, awashing device, an anti-blocking device, a drying device, a sieving device, a material conveying device, a material homogenization device and a blow-off device are matched to use, so that corn seedsare processed through various types of technological equipment in one step, and furthermore, the functionality of the corn seed processing equipment is enriched and the labor intensity of workers is alleviated; meanwhile, the working efficiency of the corn seed processing equipment is further improved.

Owner:张永春 +3

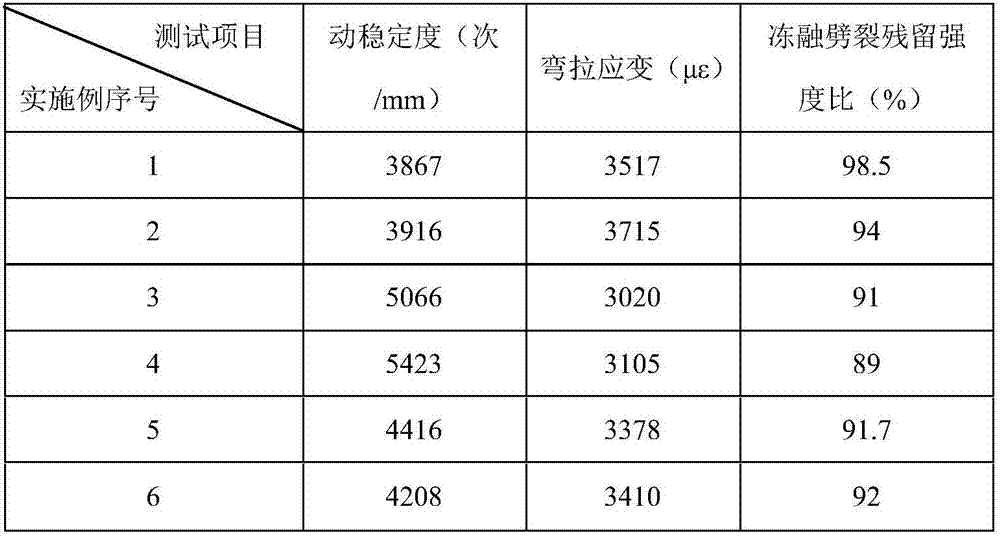

Preparation method of asphalt concrete warm mixing rutting and cracking resisting agent

The invention relates to a preparation method of an asphalt concrete warm mixing rutting and cracking resisting agent. The preparation method concretely comprises the following steps: fully mixing wax, resin and a cross-linking agent in a reaction kettle to obtain a modifying mixture; and adding a surfactant, a plasticizer and assistant to the modifying mixture, carrying out melt blending, and granulating the mixture through a granulating tower or a rotary belt condensation granulator to obtain the warm mixing rutting and cracking resisting agent. Compared with the prior art, the preparation method disclosed in the invention has the advantages of simplicity in operation, easiness in industrial generation, facilitation of reduction of the mixing temperature and the compacting temperature of asphalt concrete, reduction of the discharge of harmful gases, improvement of the moisture resistance, and high-temperature viscosity reducing and low-temperature viscosity increasing effects on asphalt; and the prepared warm mixing rutting and cracking resisting agent obviously improves the softening point, the ductility and the 60 DEG C viscosity of the asphalt, reduces the mixing and lying temperature, and improves the rutting resistance, the low-temperature cracking resistance and the water damage resistance of the asphalt concrete.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

High-strength asphalt mixture and preparation method thereof

The invention discloses a high-strength asphalt mixture and a preparation method thereof. The asphalt mixture comprises the components of elastic resin, waste rubber, rosin, diacetone alcohol, asbestos wool, a water reducer, paraffin, epoxy resin, stearamide, a curing agent, palmitic acid, an emulsifier, a fiber stabilizer, and silicon dioxide. The main method of a preparation process comprises: crushing and heating limestone and alkali granite, and then mixing the crushed materials with a premixed and preheated asphalt binding material for full reaction. The asphalt mixture has the characteristics of good toughness, high strength, water resistance, corrosion resistance, low toxicity and environmental friendliness, and can effectively prolong the service life of an asphalt pavement.

Owner:SICHUAN GUOXING POLYMER RESIN CO LTD

Fiber board and manufacturing method thereof

InactiveCN103437070ALess prone to mildewLess prone to wormsStuffed mattressesSpring mattressesHollow fibreFiber

The invention discloses a fiber board and a manufacturing method thereof. The fiber board comprises a first fiber layer and a second fiber layer, wherein both the top surface and the bottom surface of the second fiber layer are provided with a first fiber layer; the shapes of the radial projections of the first fiber layer and the second fiber layer are the same. The manufacturing method of the fiber board comprises the following steps: mixing and then loosening low-melting-point sheath-core compound fibers and regenerated three-dimensional hollow fibers to obtain first mixed fibers; mixing and loosening the low-melting-point sheath-core compound fibers and coconut fibers to obtain second mixed fibers; uniformly combing the first and second mixed fibers into bundles and then uniformly laying to obtain the first fiber layer and the second fiber layer respectively; laying the second fiber layer on the first fiber layer and covering the second fiber layer with the first fiber layer to obtain a primary fiber board; baking the primary fiber board at the temperature of 110-160 DEG C to obtain a mixed board; compressing and shaping the mixed board to obtain the fiber board. The fiber board does not go moldy and become wormy easily.

Owner:浏阳市南方椰棕厂

Road construction method

ActiveCN106120524AImprove waterproof performanceQuality improvementIn situ pavingsRoads maintainenceCrushed stoneRoad surface

The invention discloses a road construction method, and solves the problems that asphalt road surfaces are frequent in cracking, low in intensity and poor in stability because of non-standard construction of many regions. The road construction method is characterized by adopting the technical scheme comprising the following steps of (a), cleaning and levelling a road surface of a road requiring paving, and forming a roadbed for pond residues to fill and pave; (b), sequentially paving a first pond residue processing layer and a second pond residue processing layer; (c), grinding macadam materials to form a macadam cushion layer of which the crushing value is 30%, and paving the macadam cushion layer on the second pond residue processing layer; (d), paving a cement stabilizing crushed stone layer of which the cement content is 3-6%; (e), uniformly sprinkling petroleum asphalt of which the consumption is 1.2 Kg / m<2>, then sprinkling aggregates, and immediately grinding the aggregates by a road roller to form a lower sealing layer; and (f), paving an asphalt mixed material layer of which the void percentage is 3-6%. The road construction method disclosed by the invention has the advantages of being high in strength, not liable to crack and strong in durability.

Owner:天鸿建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com