Production process for solidifying and regenerating roadbed filler by using mucky muck

A technology of roadbed filler and production process, which is applied in the direction of roads, roads, and solid waste management, can solve the problems of large-scale consumption of muddy residue and shortage of roadbed filler resources, and achieves easy industrial application and large-scale promotion, Easy to transport and pave, simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

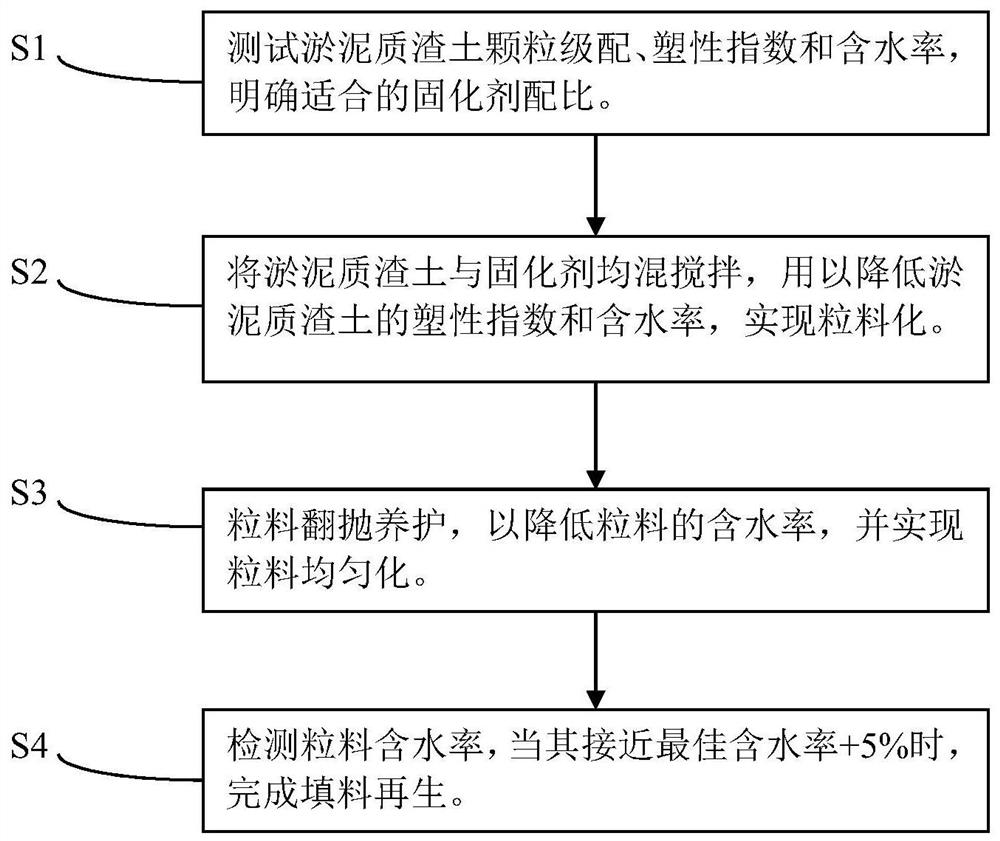

Method used

Image

Examples

Embodiment 1

[0036] (a) Take the muddy dregs for index test, the liquid limit of the muddy dregs is 46.0%, the plastic limit is 22.4%, the plasticity index is 23.6, the clay content is 33%, and the water content is 48.8%. According to the test Gained parameters, determine the amount of curing agent to be 6%;

[0037] (b) without pretreatment, the muddy dregs with a moisture content of 48.8% higher than the liquid limit value are uniformly mixed with a curing agent whose quality is 6% of the dregs quality, so as to reduce the plasticity index and Moisture content, to achieve granulation;

[0038] (c) Perform 7-day turning and throwing maintenance on the pellets to reduce the moisture content of the pellets and realize the homogenization of the pellets;

[0039] (d) The muddy slag is produced to solidify the recycled roadbed filler, which is immediately compacted as a specimen for the California load-carrying ratio test, and the strength test is carried out after immersion in water for 4 da...

Embodiment 2

[0042] (a) Taking muddy dregs for index test, the liquid limit of muddy dregs is 46.0%, the plastic limit is 22.4%, the plasticity index is 23.6, the clay content is 33%, and the water content is 54.4%. According to the test Obtained parameters, determine the amount of curing agent to be 10%;

[0043] (b) without pretreatment, the muddy dregs with a moisture content of 54.4% higher than the liquid limit value are homogeneously mixed with a solidifying agent whose quality is 10% of the dregs quality, so as to reduce the plasticity index and Moisture content, to achieve granulation;

[0044] (c) Perform 4-day turning and throwing maintenance on the pellets to reduce the moisture content of the pellets and realize the homogenization of the pellets;

[0045] (d) The muddy slag is produced to solidify the recycled roadbed filler, which is immediately compacted as a specimen for the California load-carrying ratio test, and the strength test is carried out after immersion in water f...

Embodiment 3

[0048] (a) Taking muddy dregs for index test, the liquid limit of muddy dregs is 41.5%, the plastic limit is 27.6%, the plasticity index is 13.8, the clay content is 19%, and the water content is 44.9%. According to the test Gained parameters, determine the amount of curing agent to be 8%;

[0049] (b) without pretreatment, the silty dregs with a moisture content of 41.5% higher than the liquid limit value are homogeneously mixed with a curing agent whose quality is 8% of the slag quality, so as to reduce the plasticity index and Moisture content, to achieve granulation;

[0050] (c) Perform 4-day turning and throwing maintenance on the pellets to reduce the moisture content of the pellets and realize the homogenization of the pellets;

[0051] (d) The muddy slag is produced to solidify the recycled roadbed filler, which is immediately compacted as a specimen for the California load-carrying ratio test, and the strength test is carried out after immersion in water for 4 days....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com