Patents

Literature

77results about How to "Appropriate moisture content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

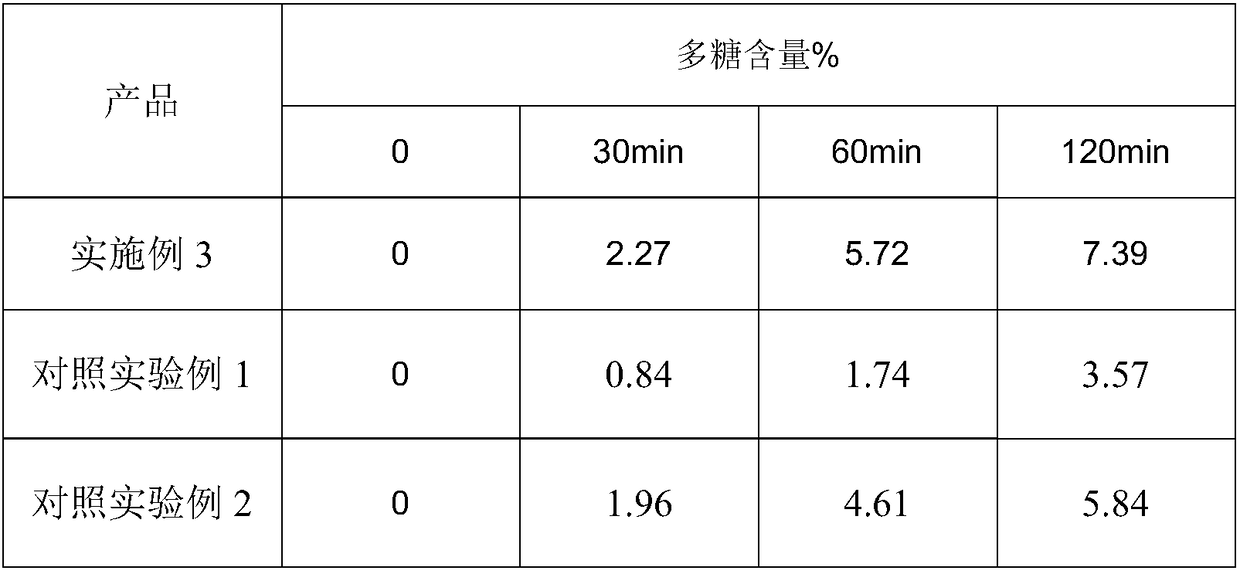

Mask liquid with multiple skin care effects and preparation method thereof

InactiveCN106074315AImprove moisturizing abilityAdjust water and oil balanceCosmetic preparationsToilet preparationsLong lastingWrinkle

The invention discloses mask liquid with multiple skin care effects and a preparation method thereof, aims at providing mask liquid which has effects of skin whitening, speckle removing, wrinkle smoothing, inflammation relieving and diminishing, long-lasting moisturizing and grease balancing, and belongs to the technical field of cosmetics. According to the technical scheme, the mask liquid is prepared from, by weight, 0.5%-3% of sericin, 3.011%-14.02% of a plant extract, 1.11%-8.35% of a moisturizer, 8%-15% of polyalcohol, 0.1%-1.5% of active peptides, 0.08%-0.15% of Carbomer, 0.08%-0.15% of triethanolamine, 0.02%-0.06% of disodium EDTA, 0.3%-0.5% of a preservative and the balance deionized water.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

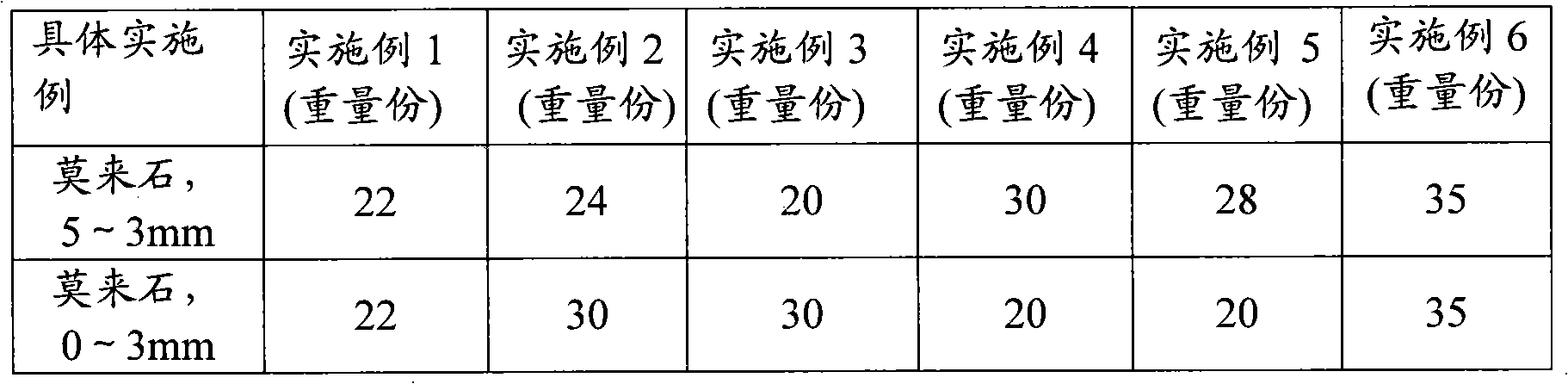

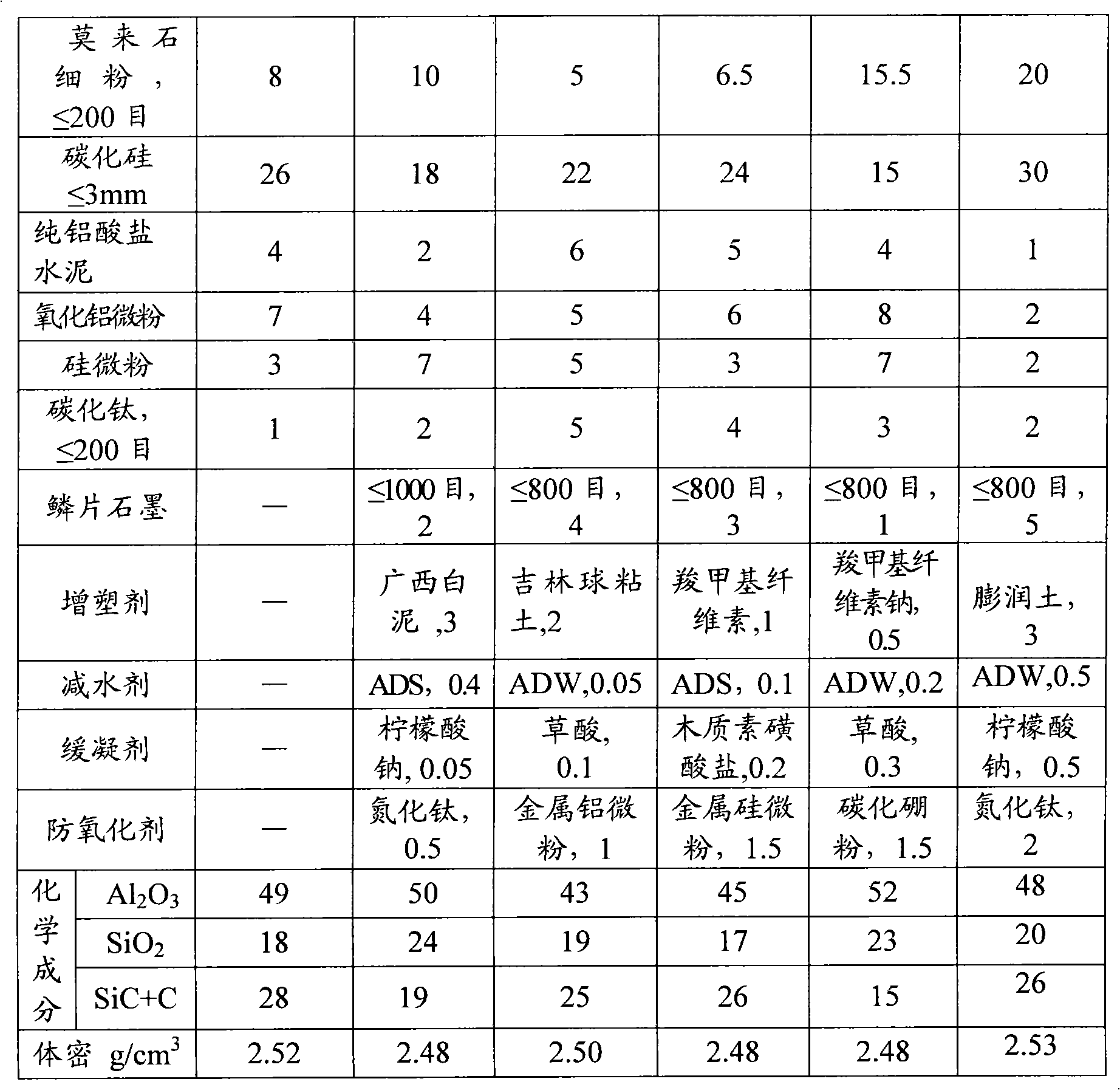

Torpedo can spouting material and spouting method thereof

ActiveCN102040386AImprove adhesion performanceImproved density and plasticityMelt-holding vesselsTitanium carbideChemical composition

The invention provides a torpedo can spouting material and a spouting method thereof. The torpedo can spouting material comprises the following components in parts by weight: 20-35 parts of mullite particles with the particle size of 3-5mm, 20-35 parts of mullite particles with the particle size of 0-3mm, 5-20 parts of mullite fine powder not greater than 200 meshes, 15-30 parts of silicon carbide with the particle size not greater than 3mm, 1-6 parts of pure aluminate cement, 2-8 parts of aluminum oxide micro powder not greater than 320 meshes, 2-7 parts of silicon micro powder and 1-5 parts of titanium carbide not greater than 200 meshes; and the torpedo can spouting material mainly comprises the following chemical components in percentage by weight: 40-65% of Al2O3, 15-25% of SiO2 and 15-30% of SiC+C. The invention also further provides the spouting method of the spouting material. The torpedo can spouting material provided by the invention has favorable corrosive resistance and antioxidation.

Owner:PUYANG REFRACTORIES GRP CO LTD

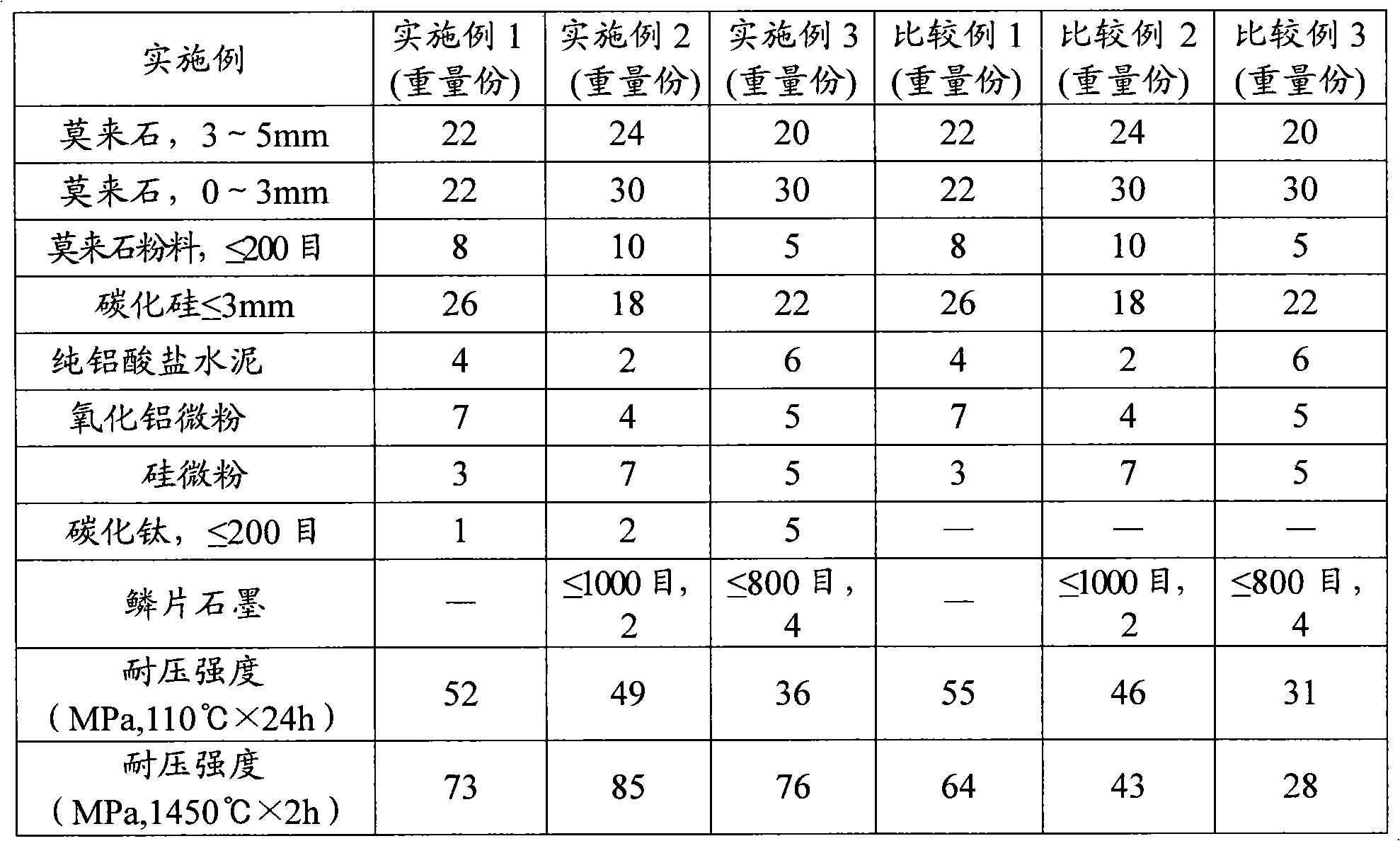

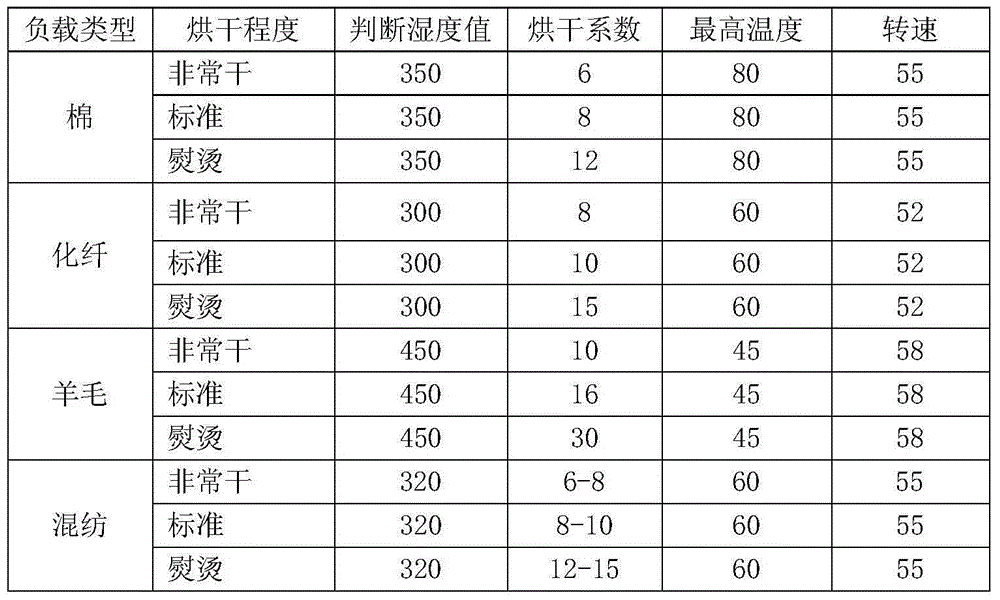

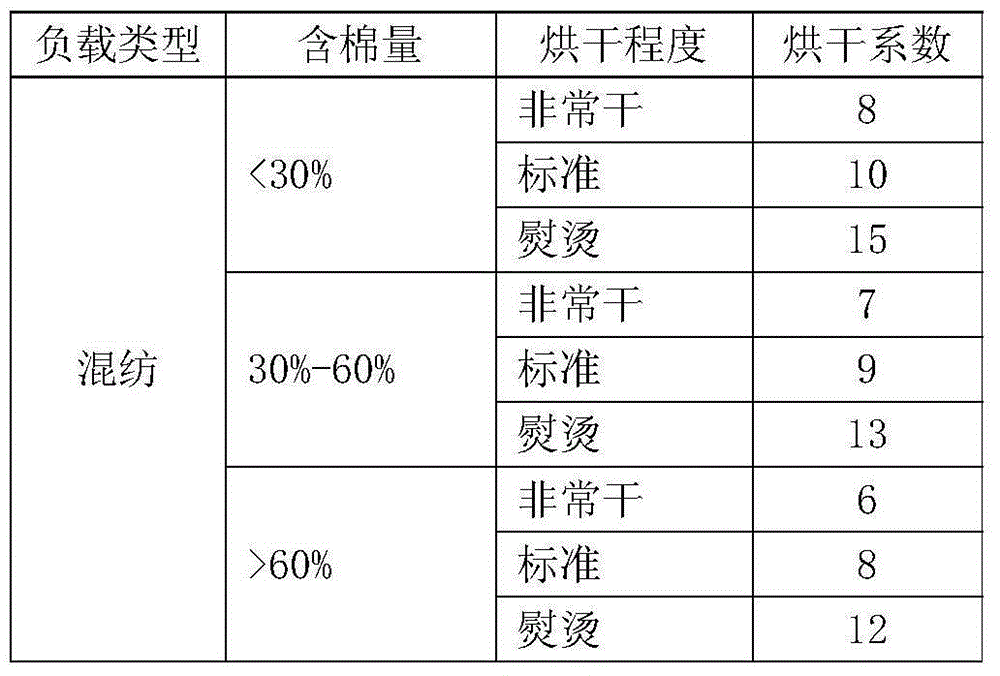

Clothes drying method and clothes dryer

ActiveCN106480685AImprove flatnessIncrease profitTextiles and paperLaundry driersProcess engineeringDrying time

The invention relates to the technical field of clothes drying equipment, in particular to a clothes drying method and a clothes dryer. The clothes drying method includes the steps: detecting types of load and determining drying coefficient according to the types of the load and drying degrees set by a user; during drying, detecting humidity value of the load, and when the humidity value reaches a set humidity threshold, determining drying time to be further needed according to the drying coefficient and time for reaching the humidity threshold. Through judgment of the types of the load, time for clothes drying is determined according to the types of the load, drying degrees and drying coefficient, therefore, flatness of dried clothes is improved, appropriate moisture content of the clothes after drying is achieved, problems about over drying or insufficient drying are solved, and utilization of energy sources is increased.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

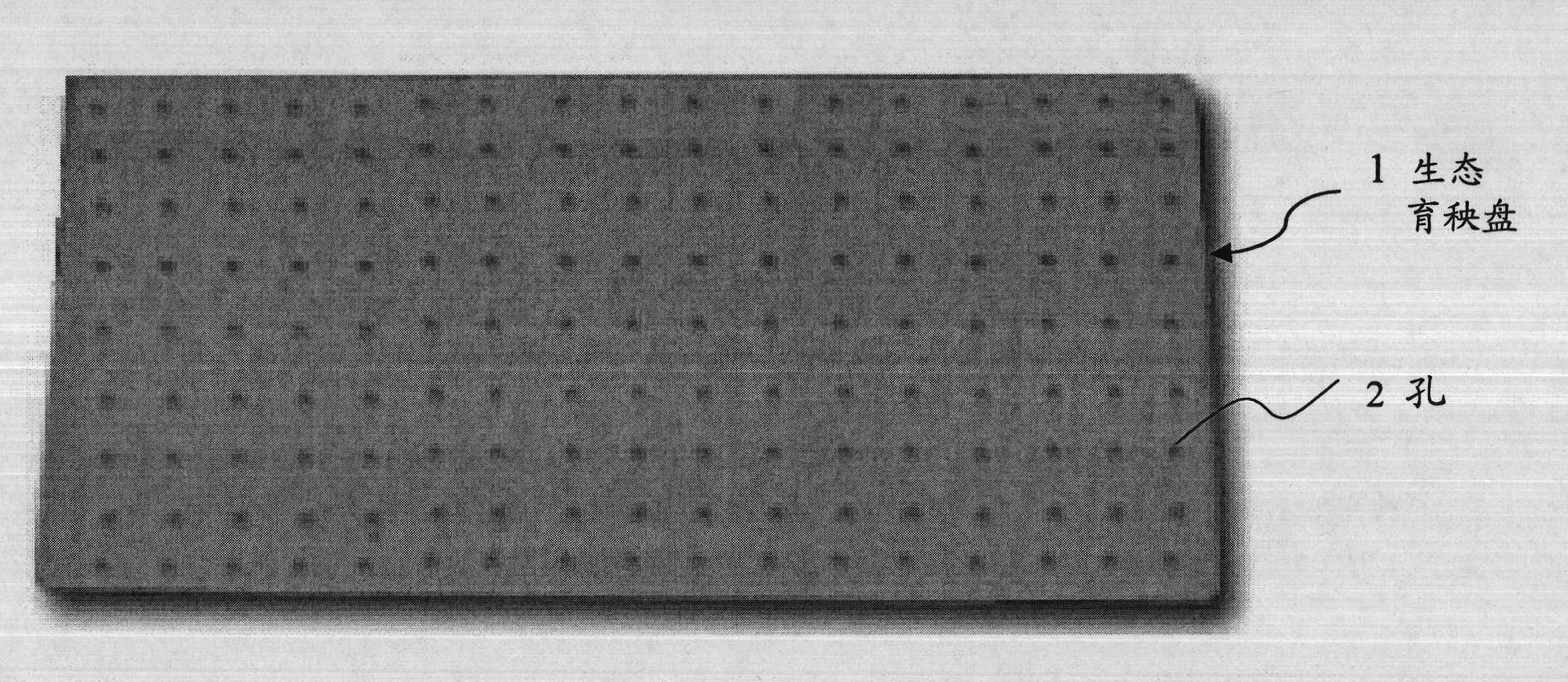

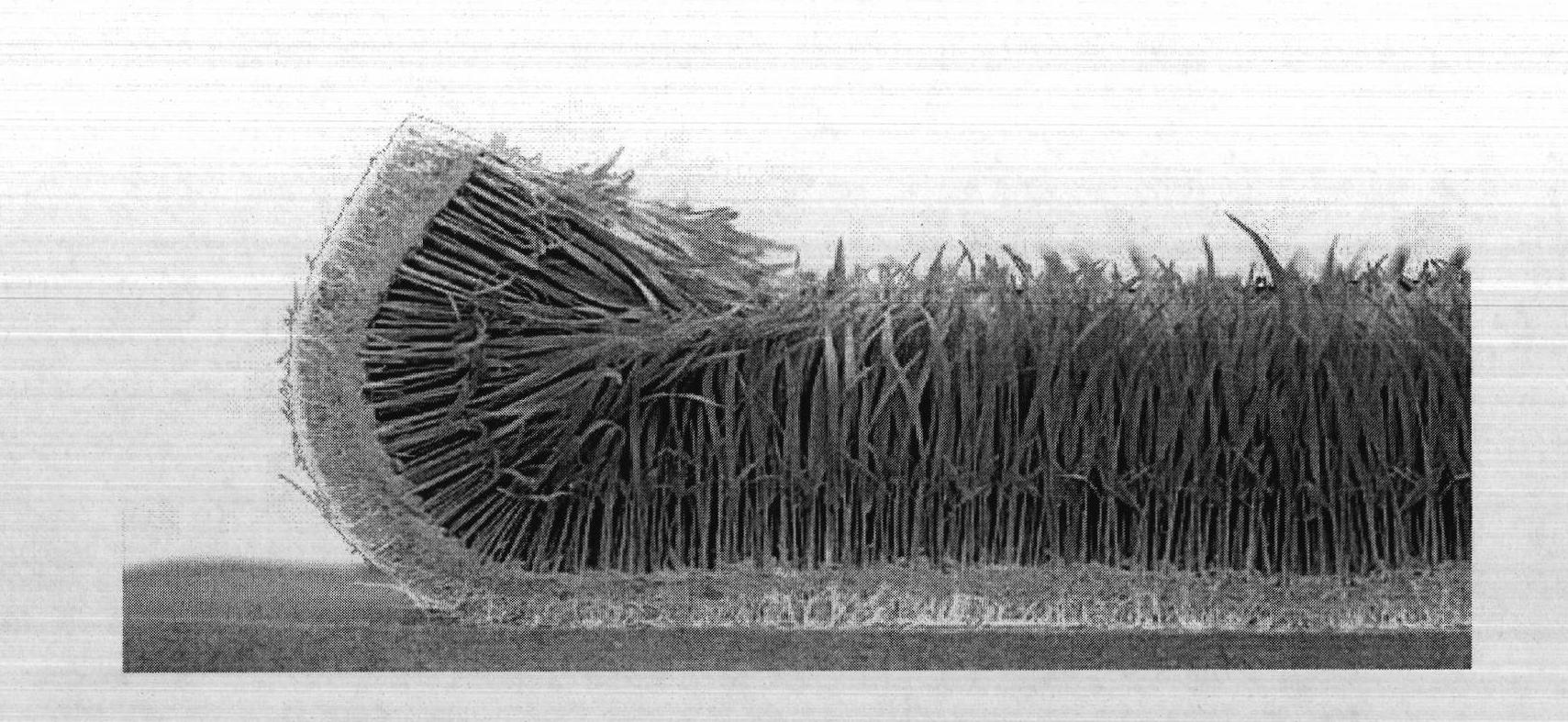

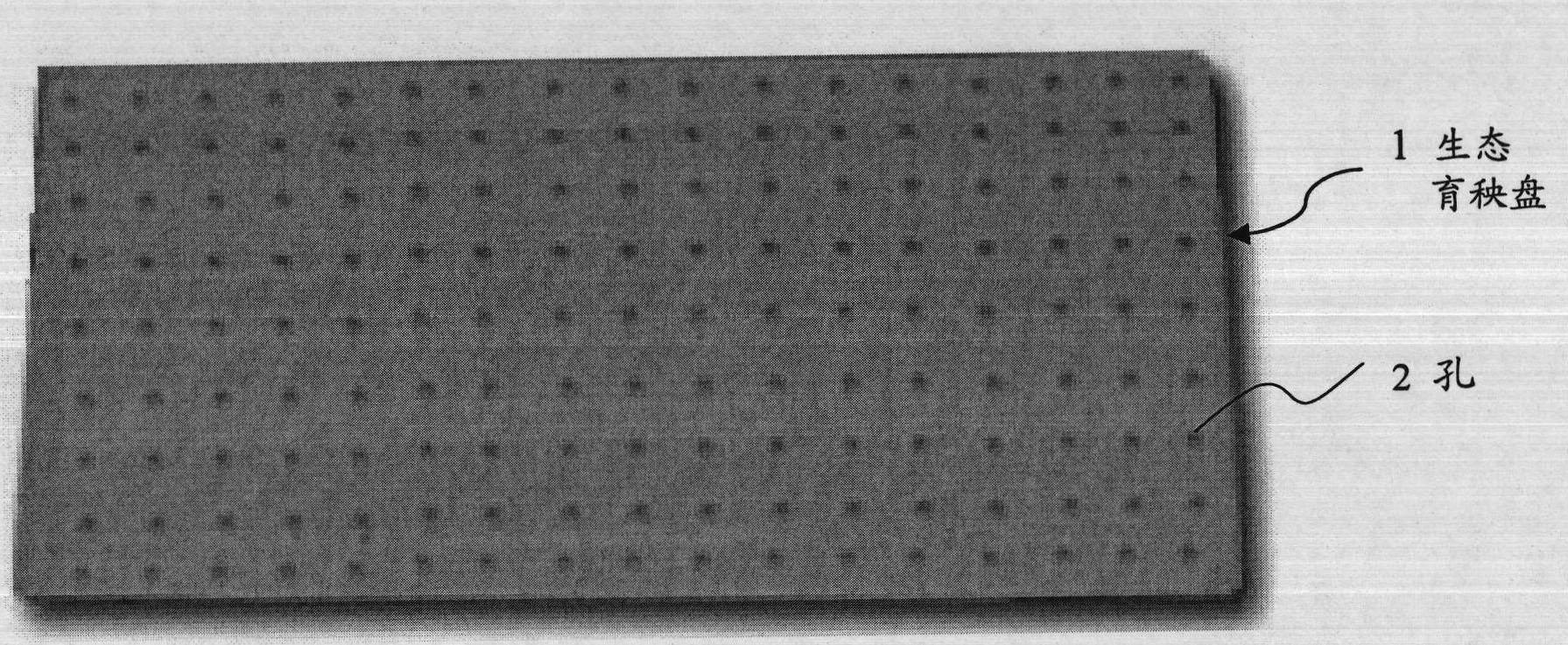

Ecological seedling tray and manufacturing method thereof

The invention provides an ecological seedling tray and a manufacturing method thereof. The ecological seedling tray comprises waste papers, expanded rice husks, and at least one selected from corn stalks and rice straws obtained by cutting, crushing, decomposing and fermenting operations. With respect to 100 wt% of the total weight of the waste papers and the expanded rice husks, the waste papers account for 20-35 wt%, the expanded rice husks account for 65-80 wt%, and the at least one selected from the corn stalks and the rice straws account for 25-35 wt%. By mixing them, shaping them according to the prescribed specification and drying them, the ecological seedling tray of the invention is obtained, which provides rich celluloses and nutrients and achieves improved water absorbability and permeability, so that seedlings take root and grow well. The ecological seedling tray of the invention allows easy control of the nutrients or water and eliminates barrier factors of successive plantation, thereby enhancing yield safety and mass production.

Owner:梁明俊

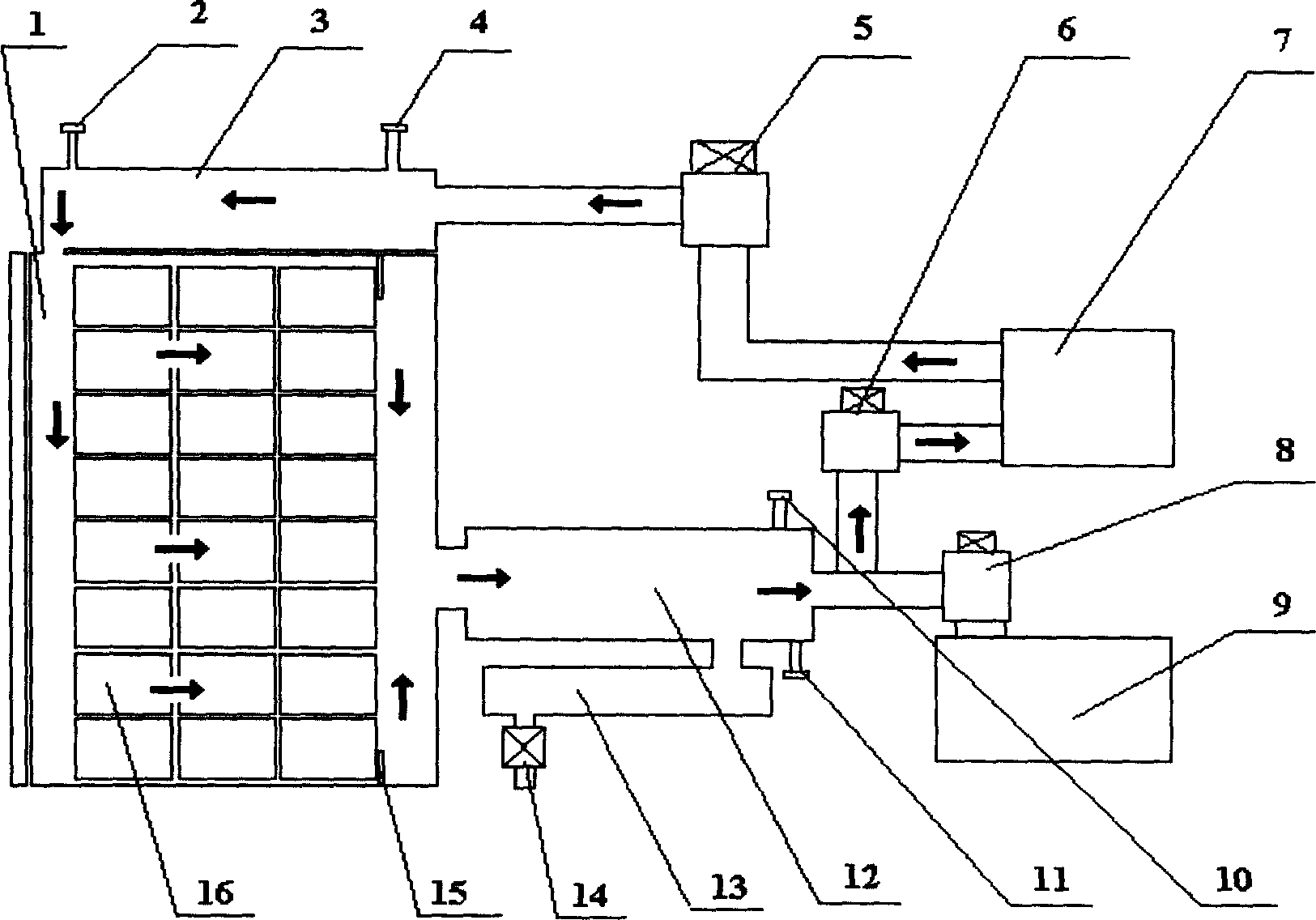

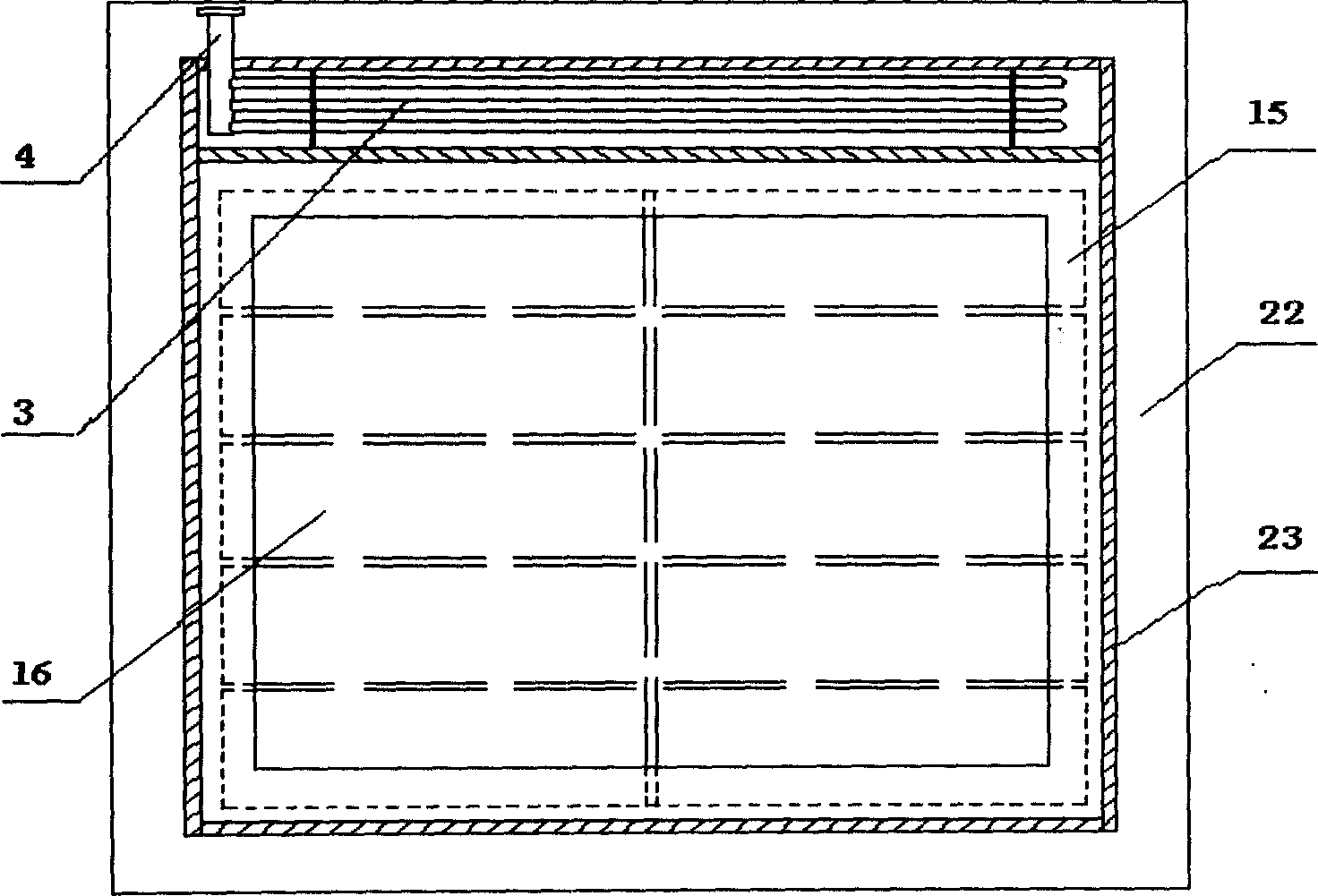

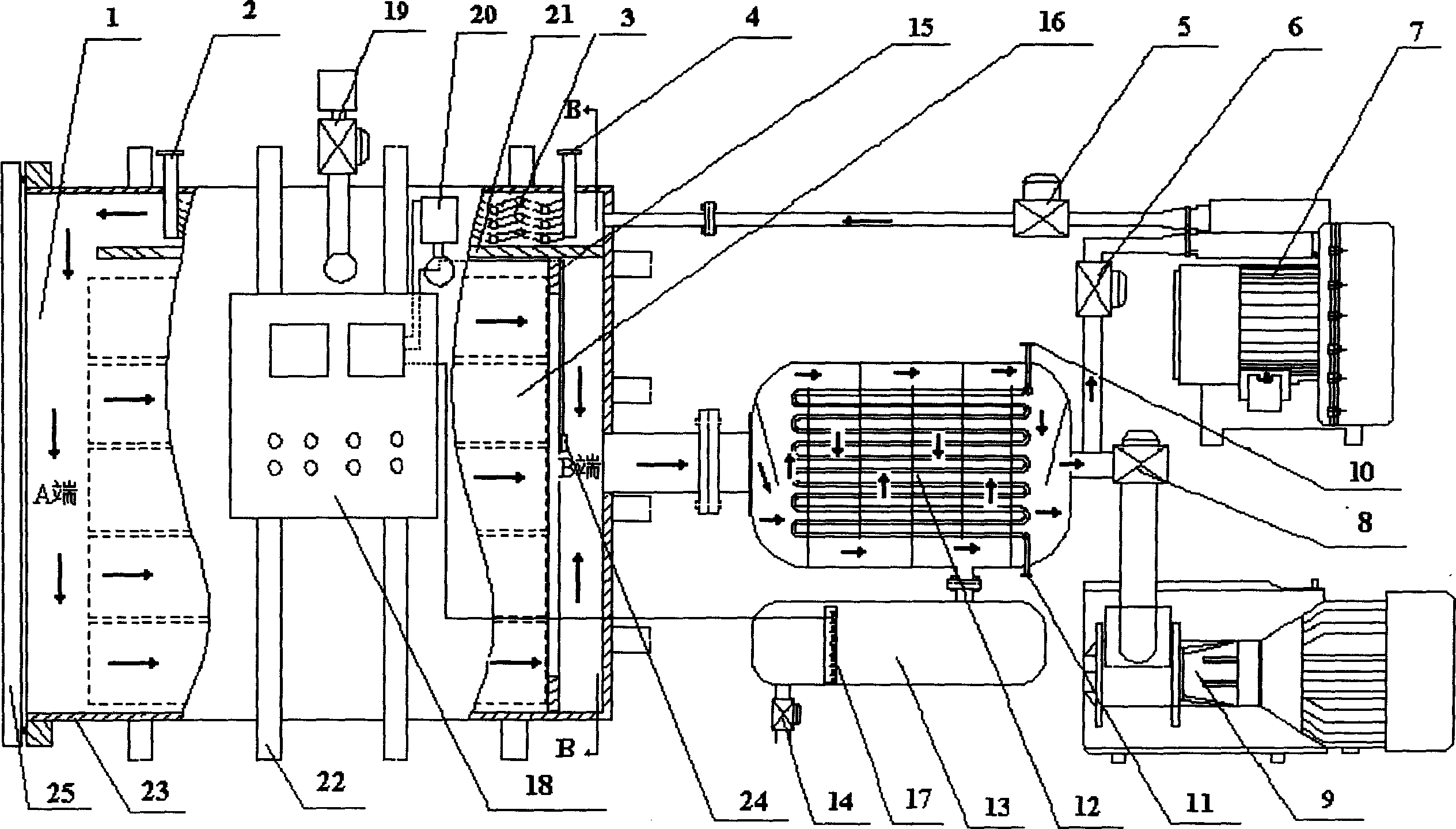

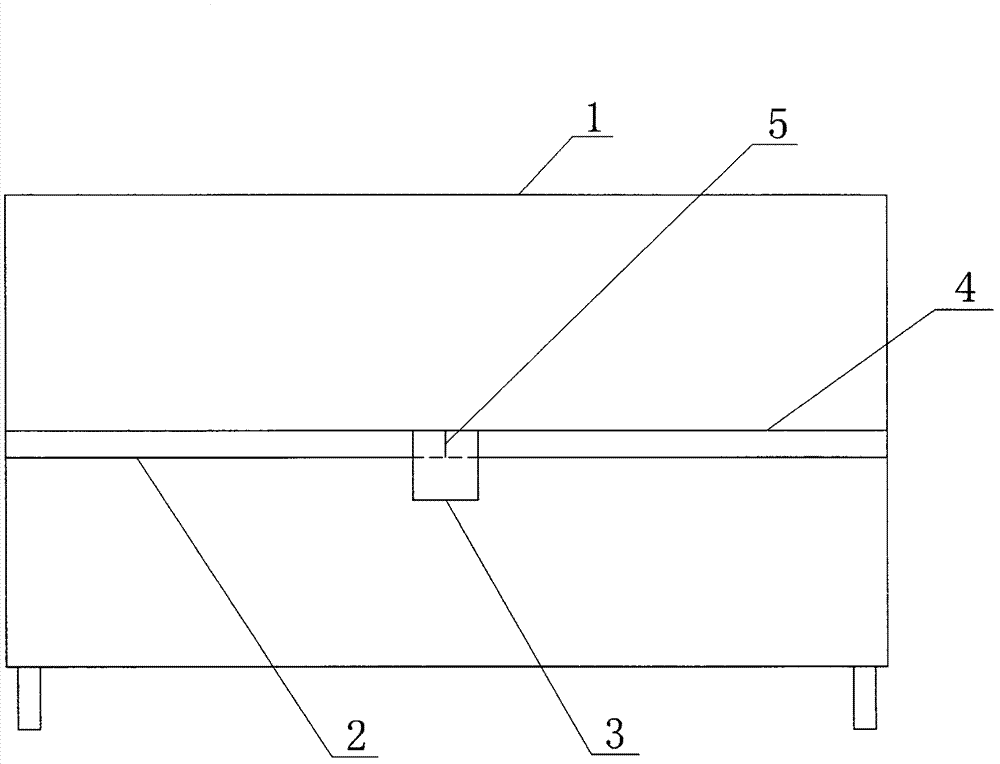

Edible fungus antistaling method and apparatus

InactiveCN1810131ANo pollutionDoes not damage appearanceFruits/vegetable preservation by freezing/coolingBiotechnologyContamination

Edible fungus antistaling method and apparatus are disclosed. The method includes dehumidifying fresh edible fungus with circulating wind inside a sealed vacuum processing chamber to reach set temperature and water content, and fast vacuum freezing to further eliminate water of edible fungus. The said method can maintain the metabolism of edible fungus and reach required temperature and water content of edible fungus without contamination and damage to look of edible fungus. The method and apparatus has low power consumption, results in homogeneous temperature and water content inside and outside the edible fungus, controls water content in edible fungus in 70-88 % and makes edible fungus capable of being preserved and transported at low temperature for long period.

Owner:上海大生泰保鲜设备有限公司

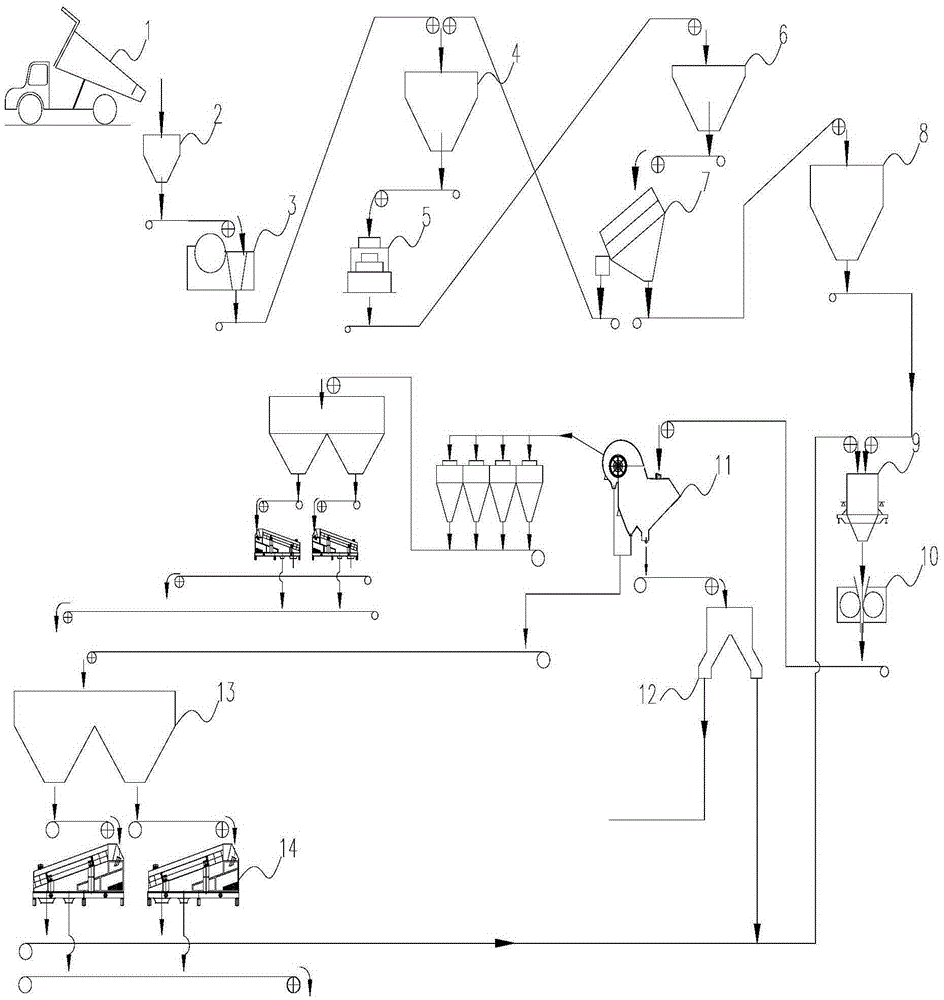

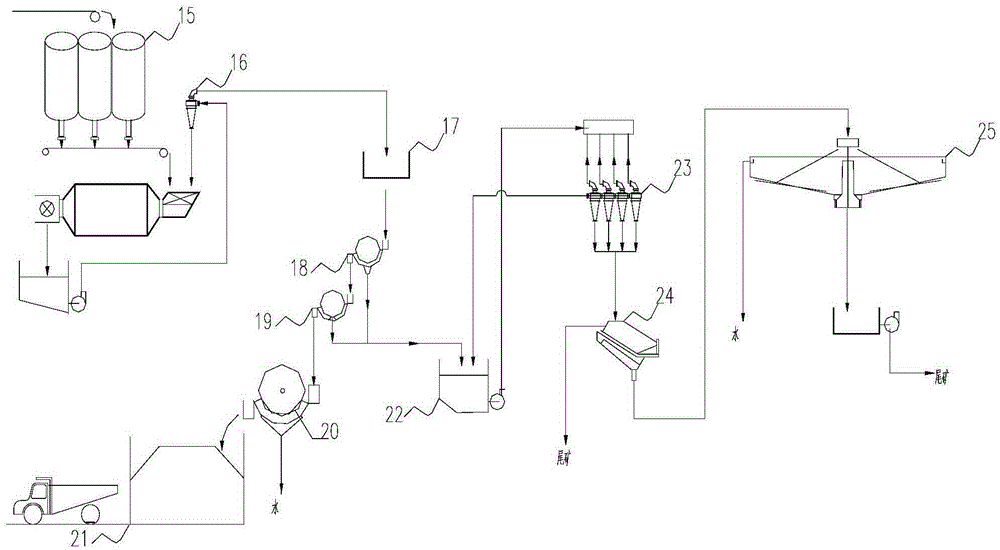

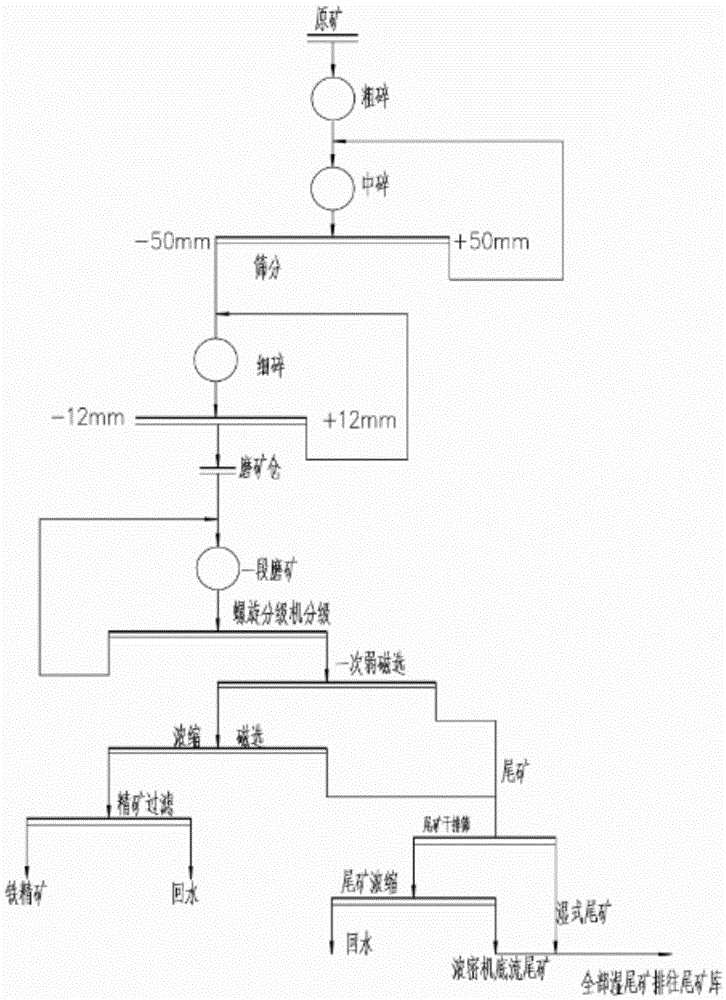

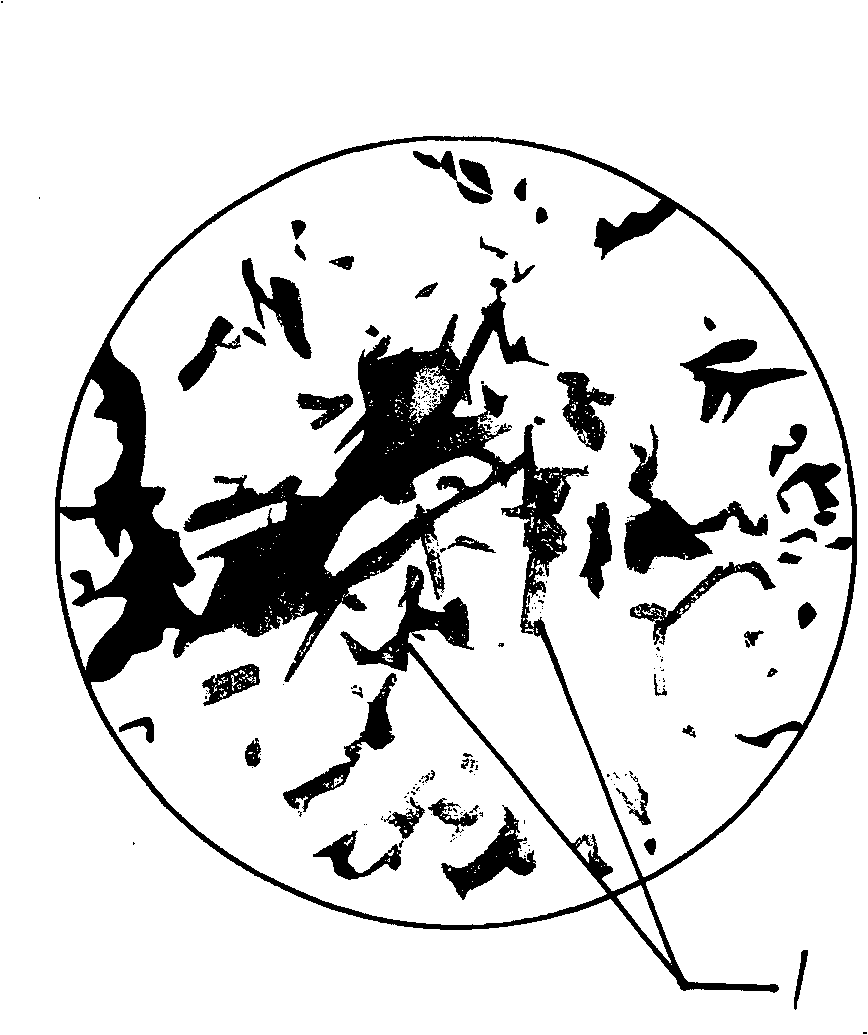

Mineral separation process and system for ultra-lean magnetite ore

ActiveCN105413842AReduce the cost of beneficiationReduce total beneficiation costMagnetic separationGrain treatmentsMagnetiteWet grinding

The invention provides a mineral separation process and system for an ultra-lean magnetite ore. The mineral separation process for the ultra-lean magnetite ore comprises the following steps of sequentially carrying out coarse crushing, intermediate crushing and fine crushing on a raw magnetite ore to obtain a fine-particle ore; carrying out dry magnetic separation on the fine-particle ore, and throwing tailings to obtain a dry concentrate; and carrying out wet grinding and separation on the dry concentrate. The dry pre-separation step is additionally arranged in the mineral separation process, so that the technical problems of high ore grinding and magnetic separation energy consumption, high cost, high mineral separation water consumption, tailing pond construction and the like are solved.

Owner:中冶沈勘工程技术有限公司

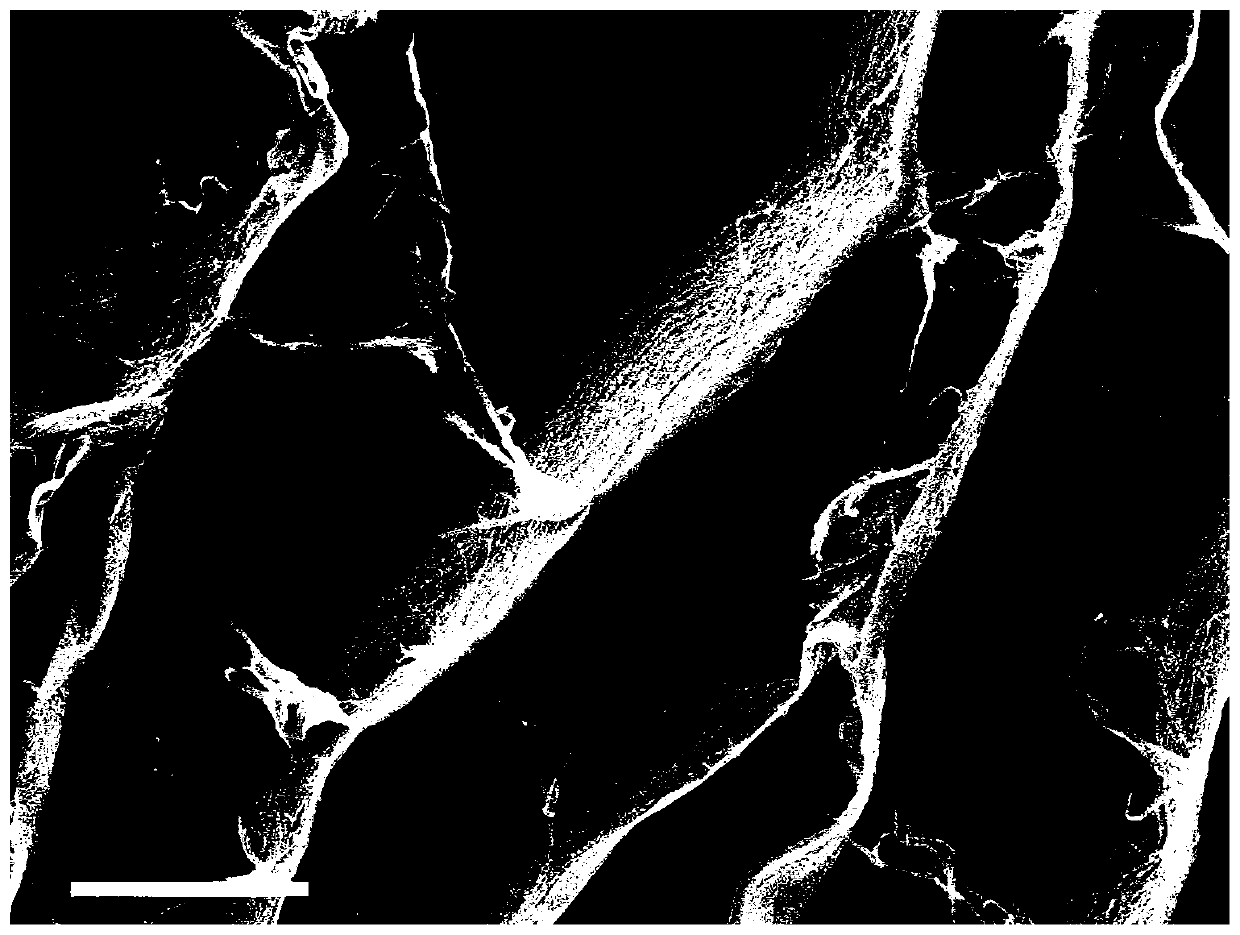

Thermoset plastics infiltration strengthened powdery plant fiber material and preparation method thereof

The invention relates to a powdery plant fiber material soaked and intensified by thermosetting plastic, and a preparation method thereof. The powdery plant fiber material is the raw material of a wood and plastic composite material. The plant fiber material disclosed by the invention comprises powdery plant fiber with more than 100 meshes in an amount of 100 parts, the thermosetting plastic in an amount of 2 to 30 parts, a curing agent adapted to the thermosetting plastic in an amount of 0.02 to 0.3 parts, a dispersant in an amount of 0.2 to 2 parts, and a lubricant in an amount of 0.2 to 2 parts. After the broken fiber surface and the interior of the powdery material of the powdery plant fiber are soaked with the thermosetting plastic, the prepared wood and plastic product not only has a high affinity for PVC, but also has better mechanical property compared with the prior wood and plastic product under the condition of equal loading. In addition, the prepared wood and plastic product has excellent anticorrosion property, humidity resistance, and high and low temperature resistance. The production of the powder is easy, convenient, and environment-friendly with low cost, thereby being easy to popularize and apply.

Owner:张国栋

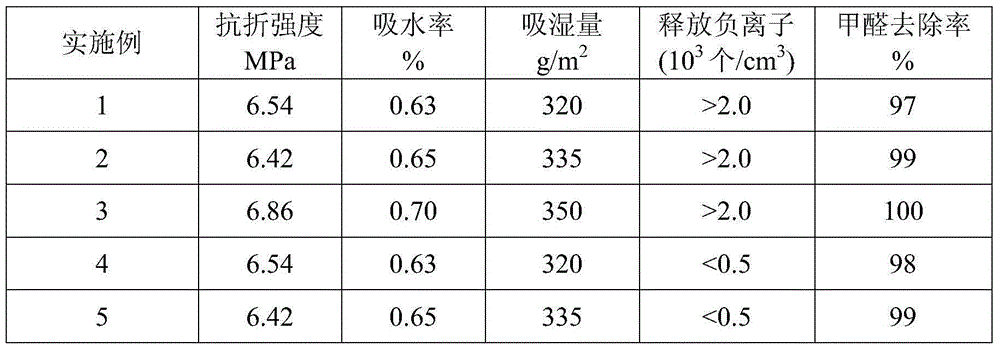

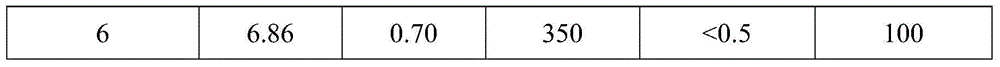

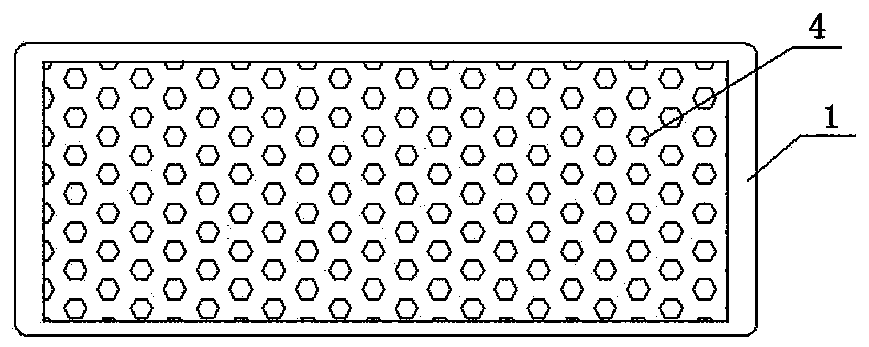

Diatomaceous earth breathing brick with high humidifying harm-reduction function and production method thereof

A diatomaceous earth breathing brick with a high humidifying harm-reduction function and a production method thereof are disclosed, through improvement of a formula, slurry with excellent performances can be prepared, a molding material is prepared by a spray granulation process, and the molding problem is overcome. The formula comprises, (wt%), 80%-90% of diatomaceous earth; 4%-14% of clay; 0.5%-1.5% of talc; 0.5%-1% of a ceramic body enhancer; 1%-2% of a ceramic sintering aid agent; 0.5%-1% of a superplasticizer; 0.5%-1.5% of nano titanium dioxide and 0.5%-1.5% of tourmaline powder. The production method is as follows: the raw materials are prepared into the slurry by adding of water, and by spray granulation, material distribution, molding and firing, the diatomaceous earth breathing brick with the high humidifying harm-reduction function is obtained. Compared with the prior art, the formula and the molding process are improved, the use amount of the diatomaceous earth is significantly increased, body cracking, deformation, stratification and other phenomena caused by inappropriate moisture content of raw materials, uneven material distribution and excessive local stress of a green body can be avoided, and the diatomaceous earth breathing brick has a higher humidifying harm-reduction function.

Owner:LIAONING SILICATE RES INST

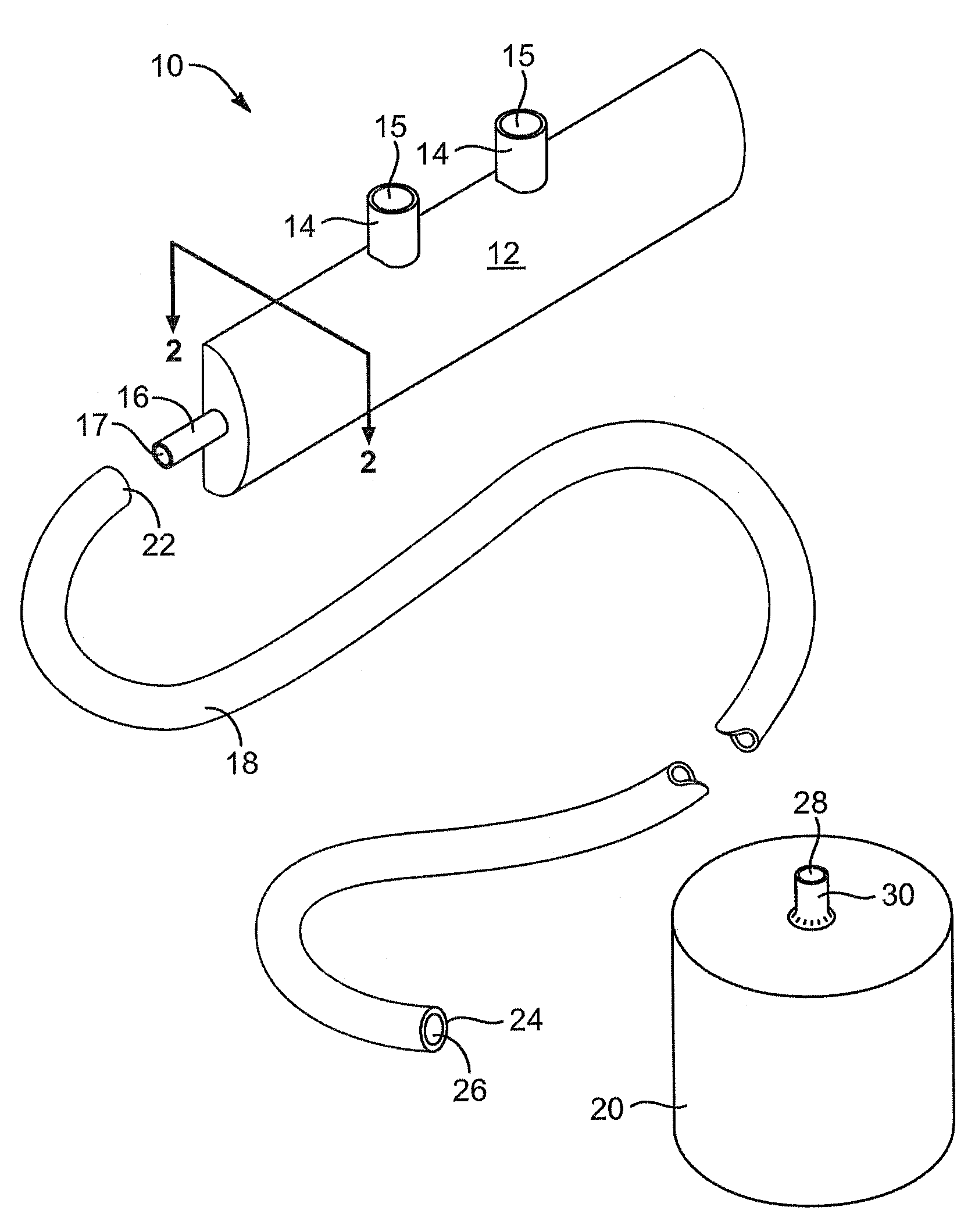

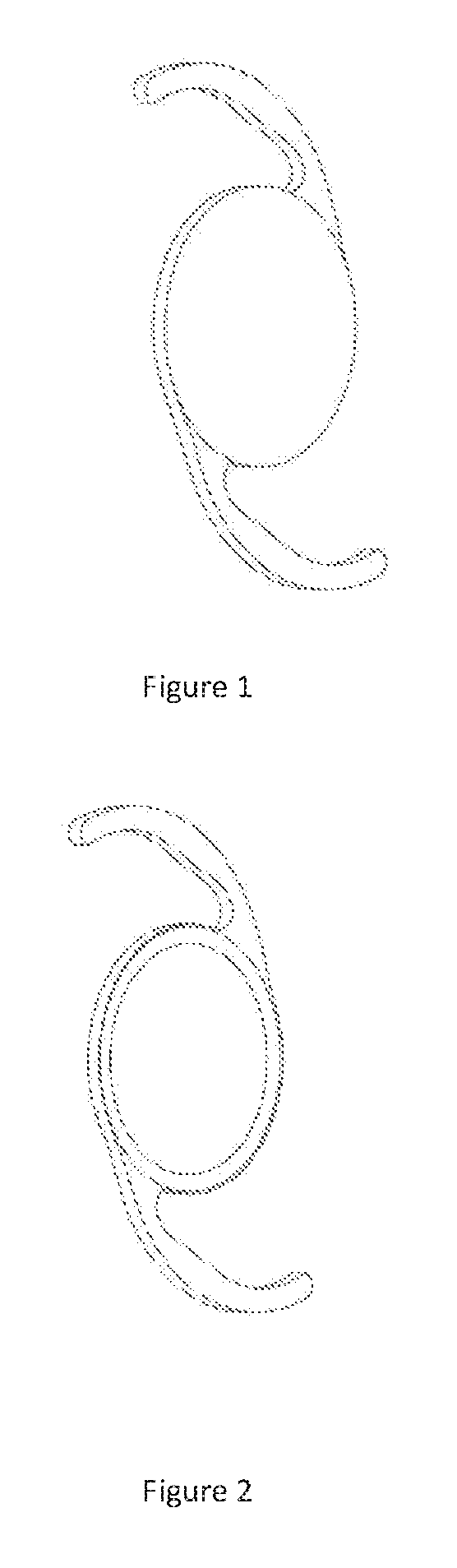

Nitric oxide reactor and distributor apparatus and method

ActiveUS20100018526A1Low rateEffective amountBiocideInorganic active ingredientsNostrilNitric oxide therapy

A reaction and distribution system may include a distributor securable near or in a path correspond to a breathing passage such as the nostrils or the mouth of a user for delivering nitric oxide therapy thereto. The distributor may contain an internal reactor for creating the nitric oxide from reactants. Alternative embodiments may rely on a line delivering nitric oxide to the distributor from a remote generator such as a cannister carried in a pocket or placed / at the bedside of a user.

Owner:SYK TECH LLC

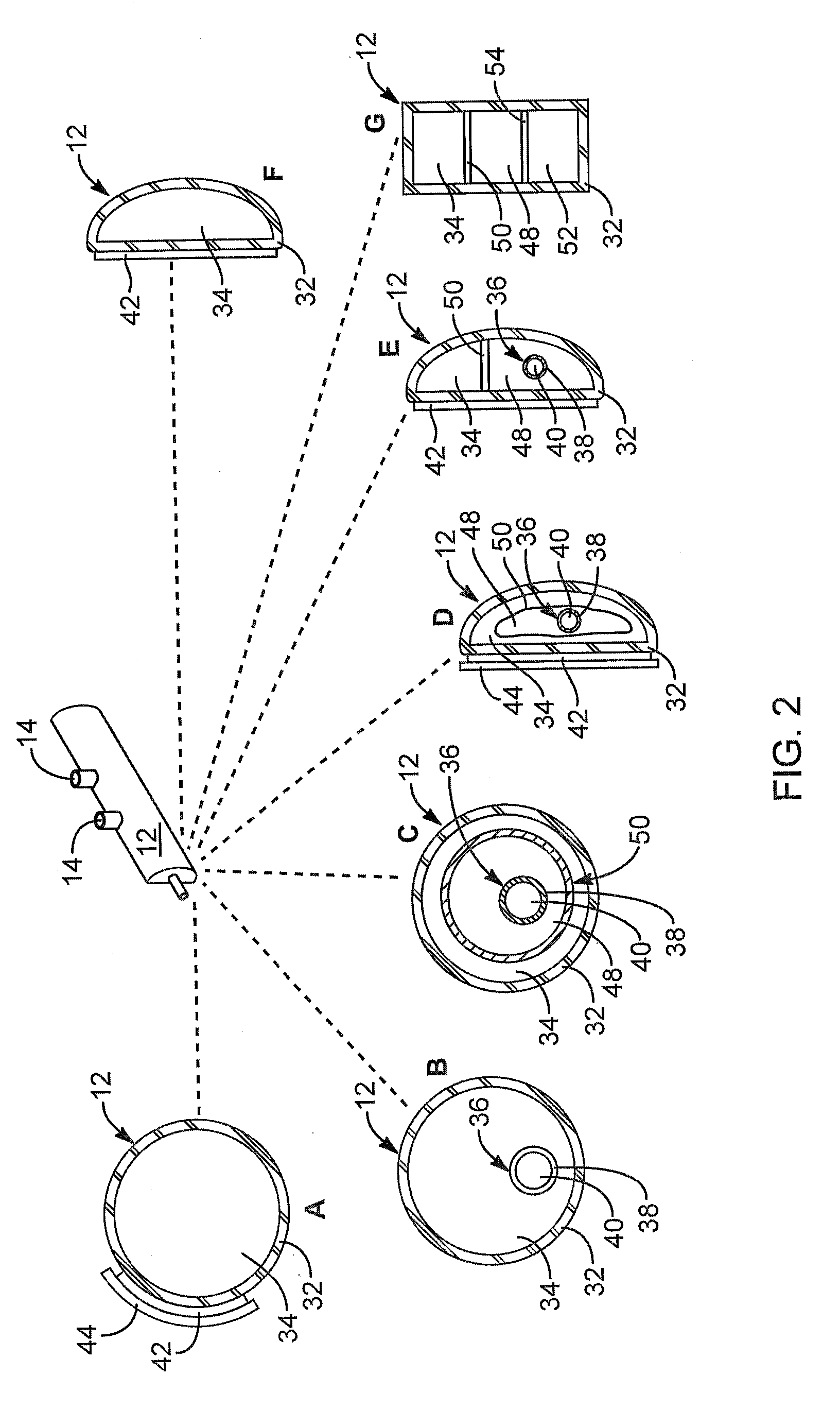

Compound feed for cow and its production technology

The invention discloses composite feed for dairy cow and consists of the following raw materials: straw of 20 to 28 parts by weight (calculated by dry matter), carrot of 0.8 to 1.2 parts by weight (calculated by dry matter), degradation bacteria of 500 to 1500 ml per ton straw (calculated by dry matter), brown sugar of 0.8 to 1.5 kg per ton straw (calculated by dry matter) and adequate water. After preparation, rubbing and crushing, mixing, spraying, compressing and baling, thin film packaging, sealing and fermentation, inspection and storage processes, compound feed favorite for dairy cow is produced. The invention feed has sourness and incense of silage and sweet and sourness of carrot and has high bacterial protein content, is rich in vitamin, meanwhile, having high nutritional value and good palatability, being eaten very fondly by dairy cow and other grazing animal, providing a good selection to dairy cow as picky eater from the most critical aspect, facilitating the preservation and transportation, providing the breeding of local dairy cow with high-quality functional roughage and having relatively low processing cost and broad market prospect.

Owner:河南花花牛集团牧业有限公司

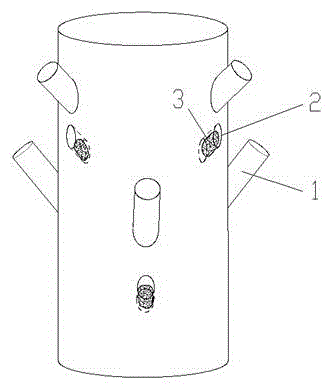

Citrus Bergamot combination landscape tree and cultivation method

InactiveCN104982181AImprove viewing valuePromote rapid growthGrowth substratesCulture mediaHorticultureBotany

The invention belongs to garden technology field, and particularly relates to a Citrus Bergamot combination landscape tree and the cultivation method. The method comprises the steps of making a hole that is 18-25cm in diameter and 20-23cm in depth and has a 45 degree angle with the branch at 30-35cm below the cut-off of the branch of the landscape tree; paving luffa cylindrical sponge in the hole and adding special composite culture material; transplanting the Citrus Bergamot sapling; after daily cultivation management, cultivating Citrus Bergamot landscape tree that has high ornamental value. The number of the hole of the whole landscape tree can be changed based on factors like number of the branches and model of the landscape tree.

Owner:湖北洲和生态农业产业发展股份有限公司

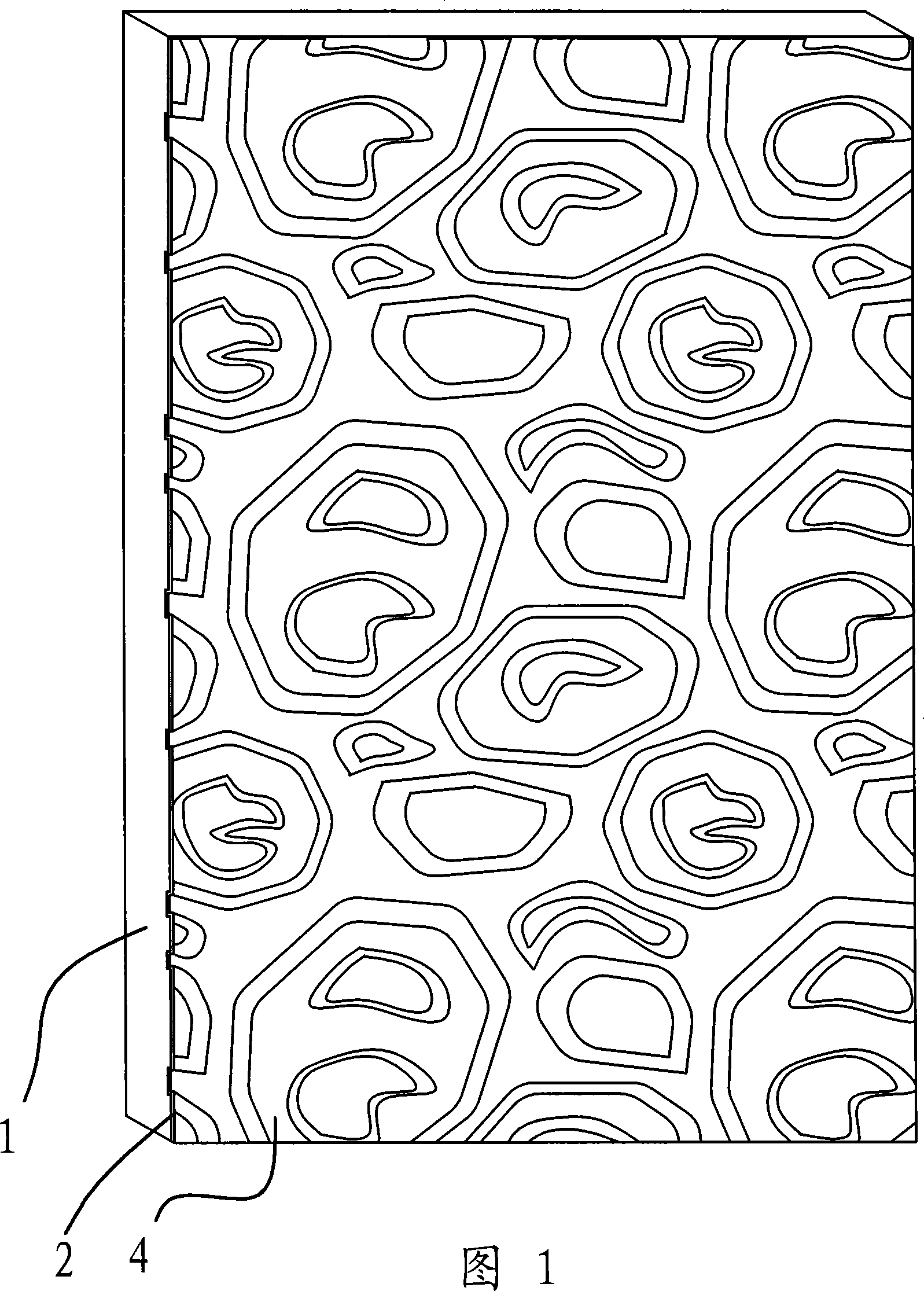

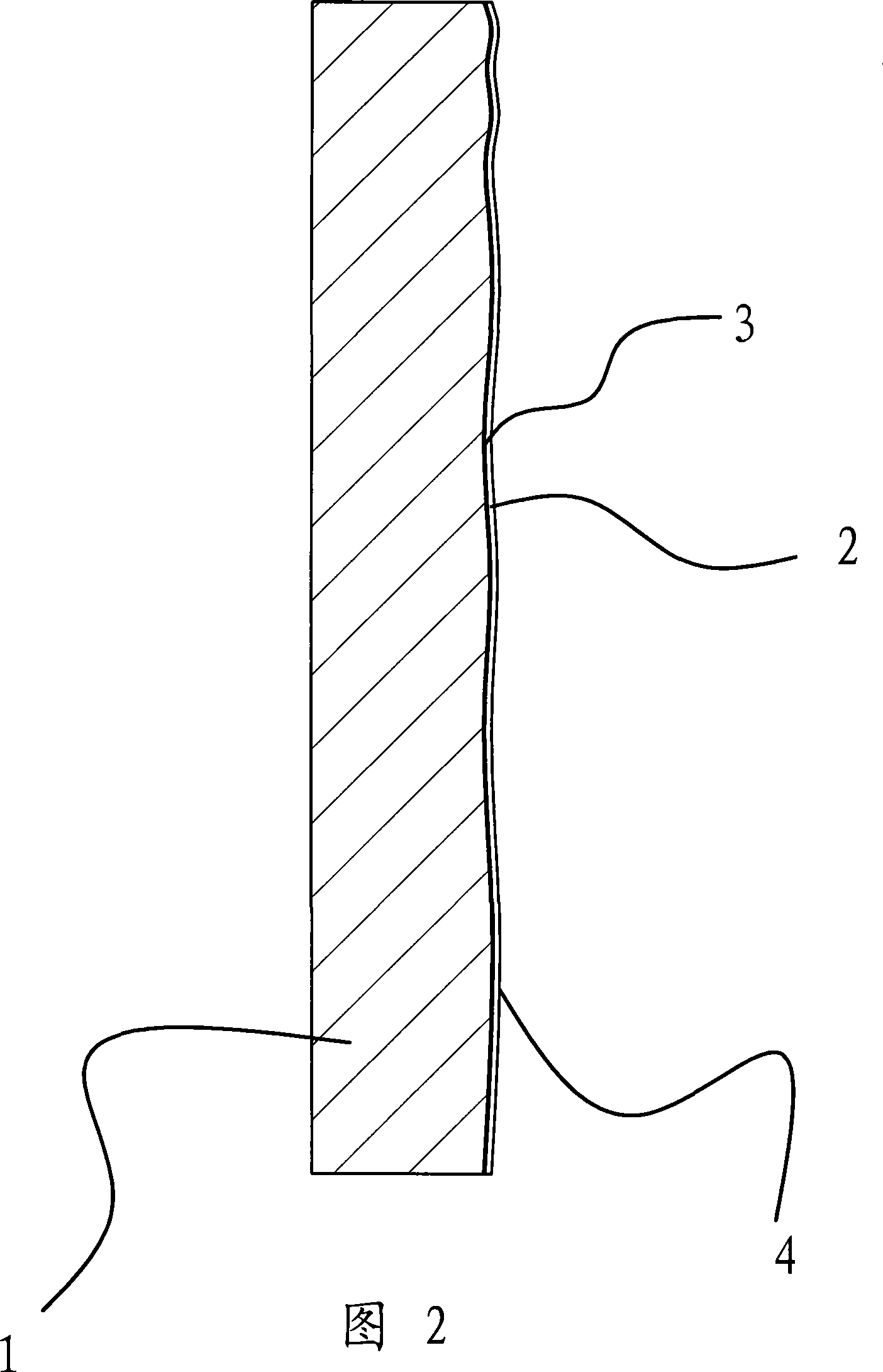

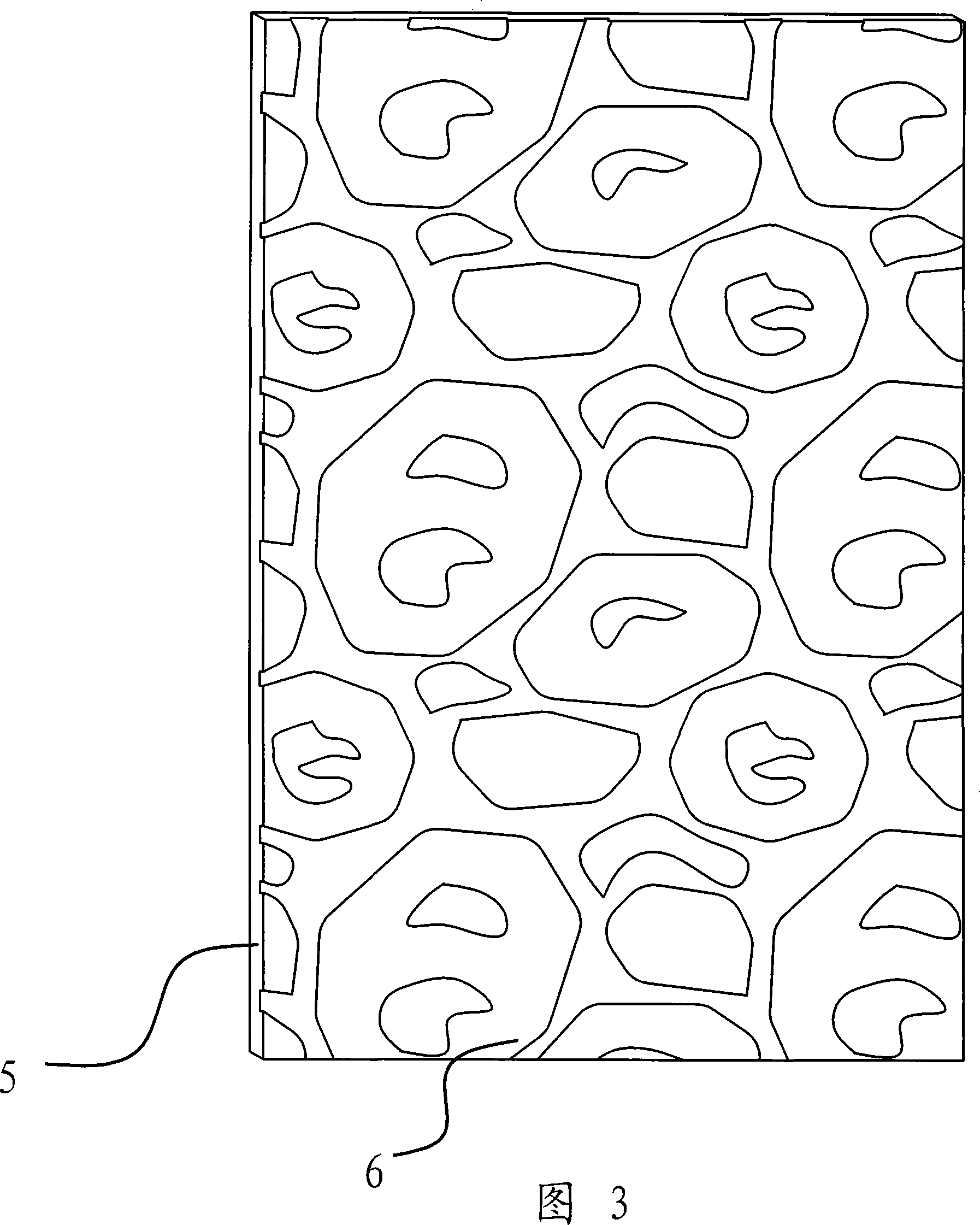

Method for manufacturing decoration sheet material with concave-convex surface

InactiveCN101195291AStrong three-dimensional senseImprove aestheticsLamination ancillary operationsLaminationCardboardEngineering

The invention provides a process for preparing decoration plates with concave-convex surfaces, which belongs to the technical field of materials. The invention resolves the problems that the surfaces of the existing sheets are not concave-convex, the exited cubic effect is not strong and the graceful property is poor. The process for preparing the decoration plates with concave-convex surfaces includes the steps of A gumming, B drying and C compressing, wherein the step of gumming comprises firstly selecting decoration sheets, then transferring the decoration sheets by a transferring machine and sinking the decoration sheets in hot-curing resin, enabling the right surfaces and back surfaces of the decoration sheets to be immerged in the hot-curing resin. The step of drying is realized by immerging the decoration sheets in a baking box to be precisely dried, wherein the drying temperature is 50 DEG C to 100 DEG C. In the step of compressing, flat distributing the precisely dried decoration sheets on a wood plate and compressing under a press through being transferred by the transferring machine at high temperature. Wood sheets produced by the process for preparing decoration plates with concave-convex surfaces has the advantages of fire resistance, moisture prevention, wear resistance, mar-proof property, high cubic effect and sound graceful property.

Owner:张纪元

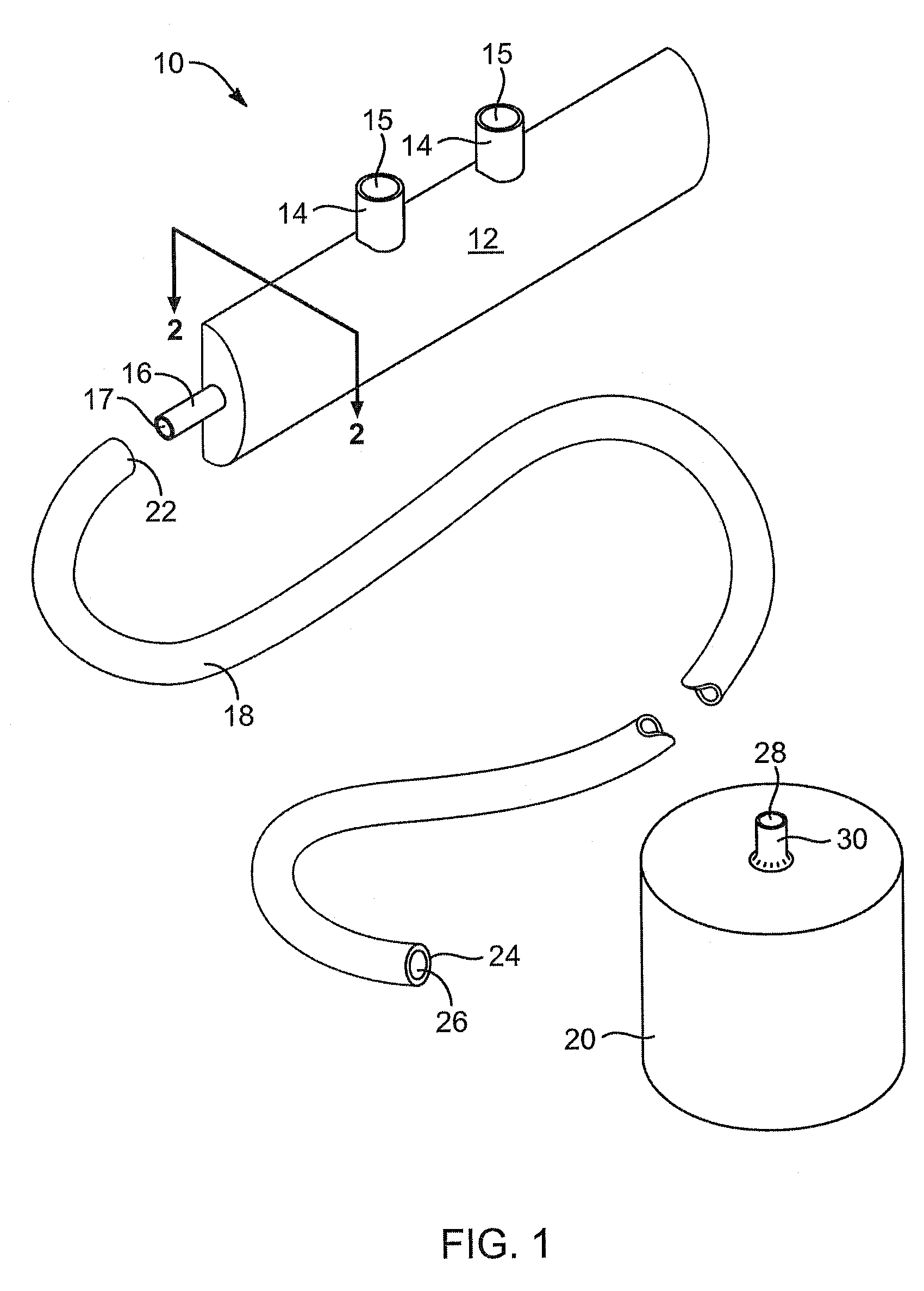

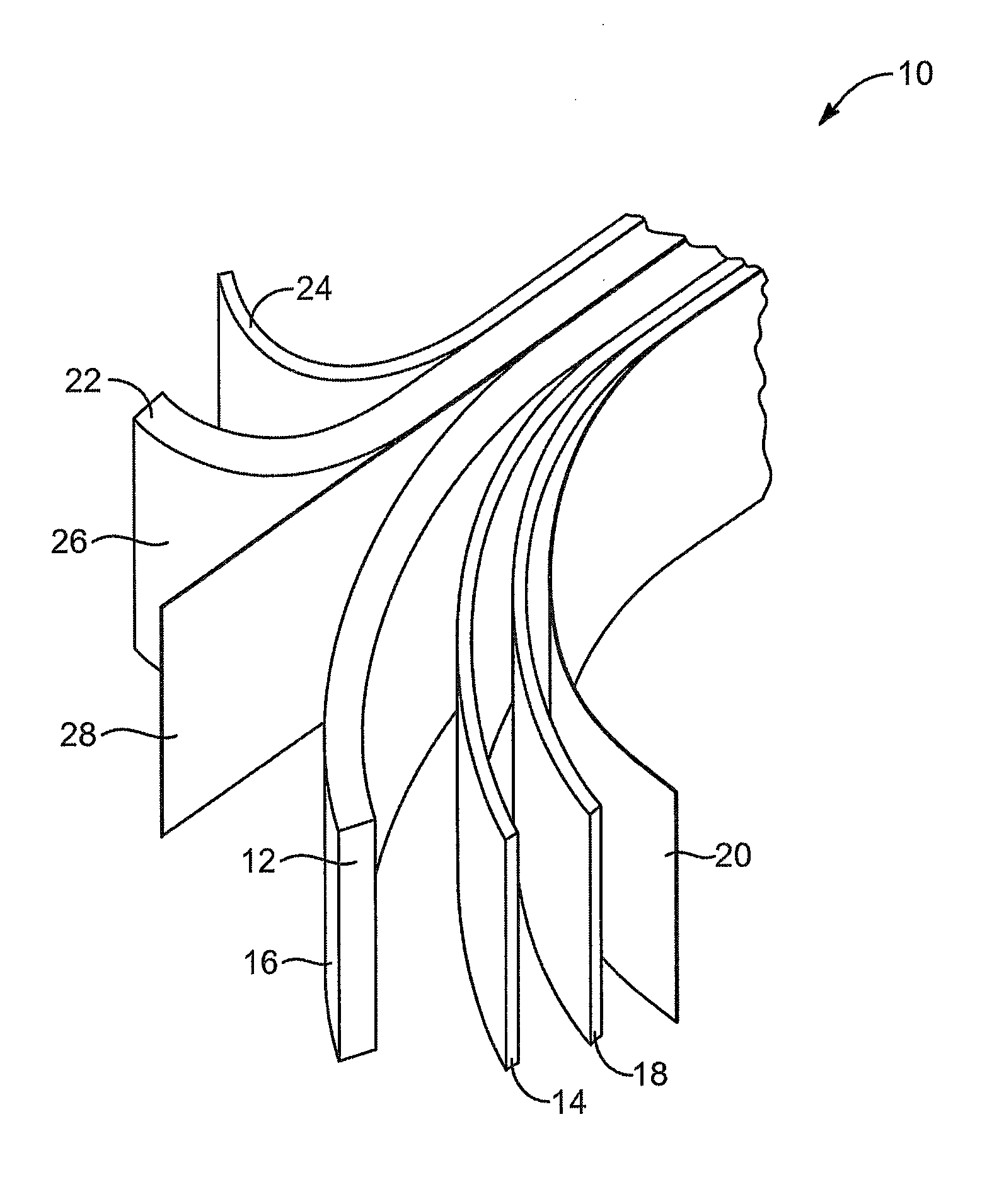

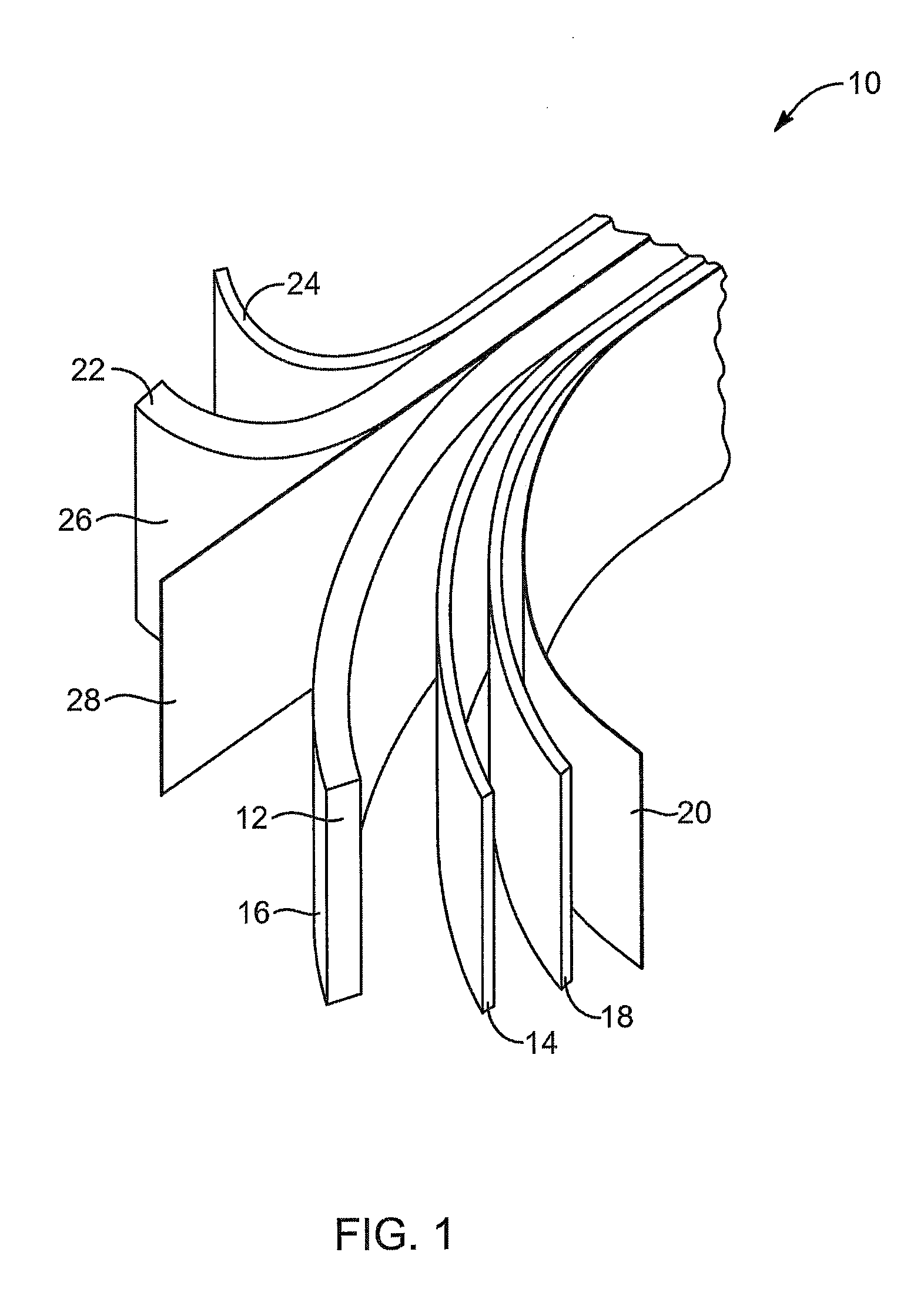

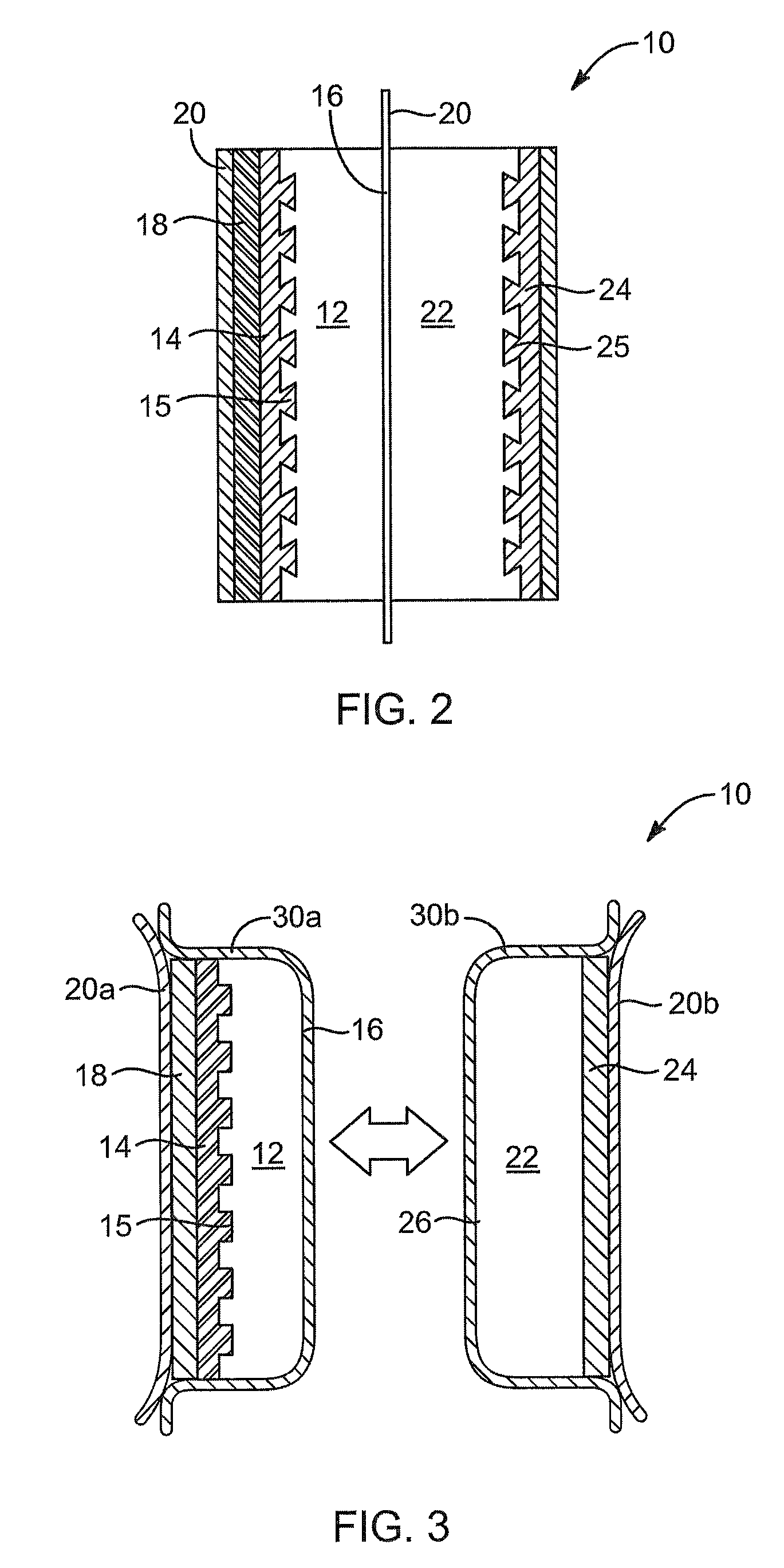

Nitric oxide gel apparatus and method

ActiveUS8720436B2Easy to disassembleSuitable degree of mechanical integrityBiocidePeptide/protein ingredientsNostrilNitric oxide

Gel strips containing reactants capable of reacting to form nitric oxide are maintained separate until application. Upon application, the gel strips are placed in contact with one another, and may mix, or operate by diffusion, to deliver nitric oxide directly to the stream of breathing air of a user. Adhesive strips bonded to a substrate supporting the gel strips may provide for securing the nitric oxide generator directly to an upper lip of a user for breathing the nitric oxide through the nostrils.

Owner:SYK TECH LLC

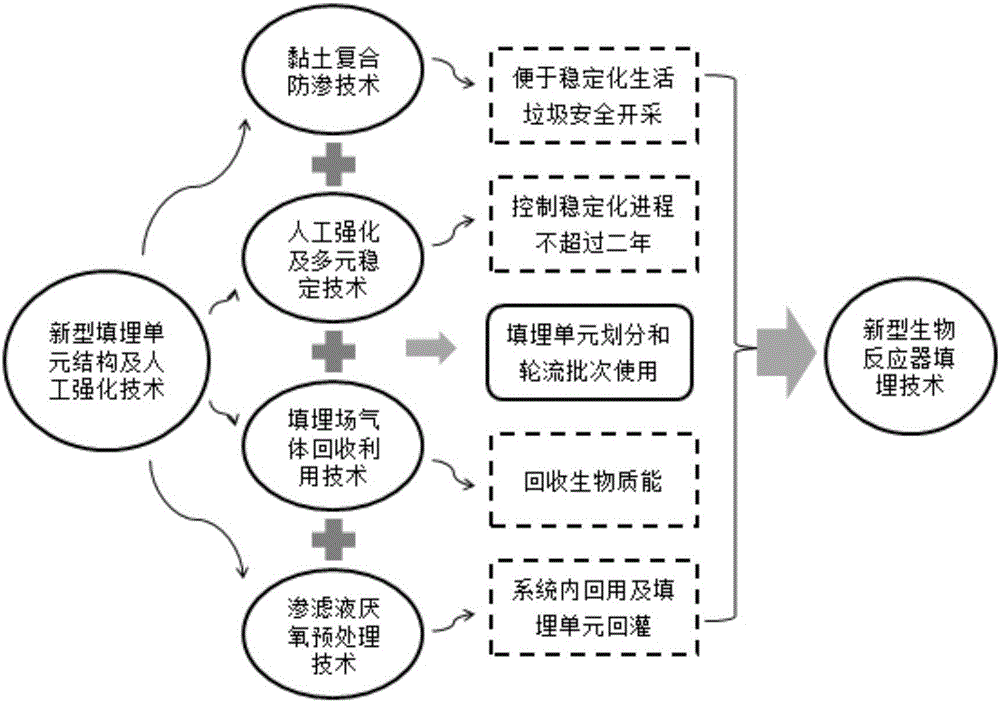

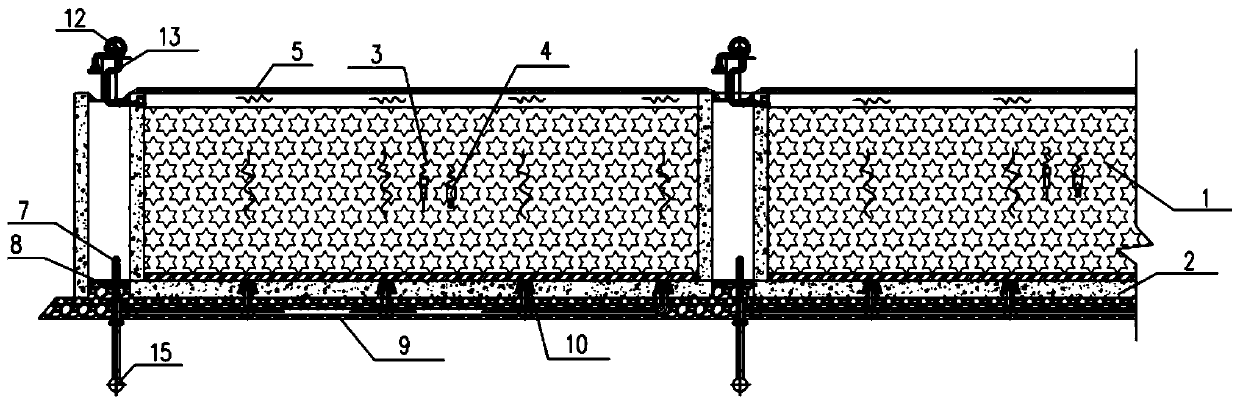

Circulating sustainable domestic waste landfill site and treatment method thereof

The invention discloses a circulating sustainable domestic waste landfill site and a treatment method thereof and belongs to the technical field of municipal domestic waste treatment and disposal. The circulating sustainable domestic waste landfill site comprises four treatment units, namely, the first unit, the second unit, the third unit and the fourth unit; the first unit is sequentially provided with a seepage-proofing lining, a rubble layer, a waste layer and a humus layer from the bottom to the top layer; vertically-upward central tube ventilating systems are arranged at mesh intersections in the first unit every other 10-20 m; the humus layer on the top layer of the first unit is covered with an HDPE geomembrane, and the HDPE geomembrane has excellent seepage-proofing and anti-corrosion performance and good chemical stability. The second unit, the third unit and the fourth unit are identical to the first unit, and all the units are sequentially at a landfilling stage, a stablizing stage and an exploitation stage according to the time sequence and are used alternately. The stabilizing degree of household waste is increased, and a circulating sustainable application of the landfill site is achieved.

Owner:NANJING UNIV +1

Method utilizing rice bran to bake meat product

The invention relates to a food processing method, and in particular relates to a method utilizing rice bran to bake a meat product. The method utilizes the rice bran to bake the meat product, and the baked meat product has an attractive appearance, bright color and luster, aromatic flavor, appropriate moisture content, appropriate hardness, no smoke taste to stimulate the throat and almost no polycyclic aromatic hydrocarbons such as benzopyrene and completely conforms to the national meat product standard. The processing method is simple, can carry out production of the four seasons, and is especially suitable for industrialization production of modern factories. Moreover, the same method can be used for processing various kinds of animal meat such as pork, beef, mutton, ass meat, beef tongue and the like and giblets.

Owner:湘潭市乡菜农副食品有限公司

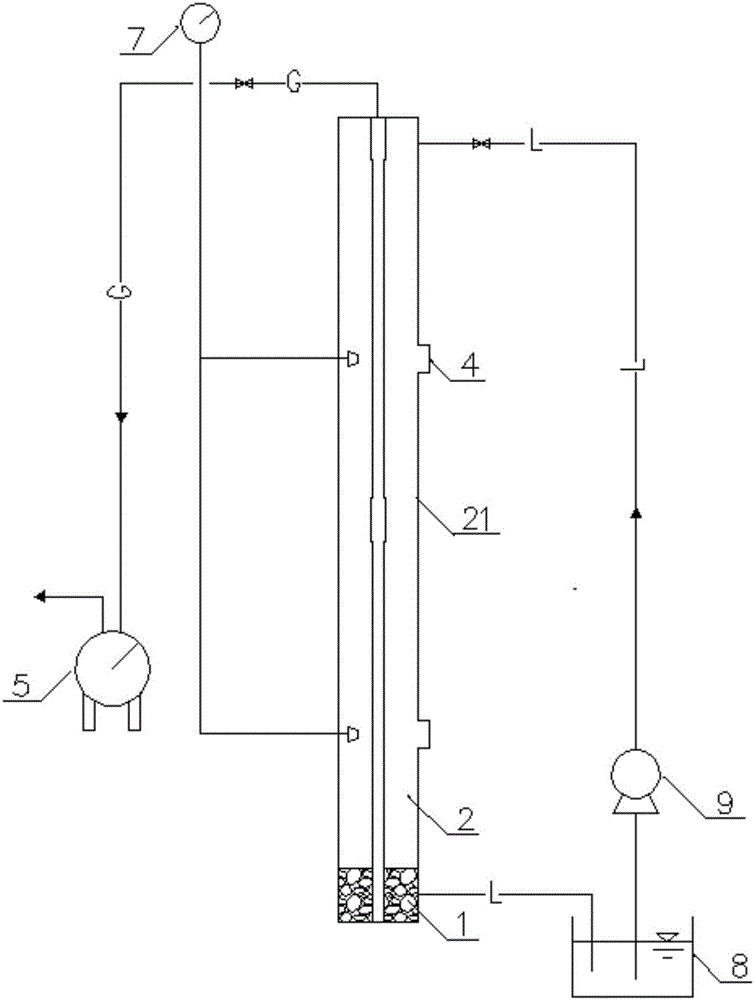

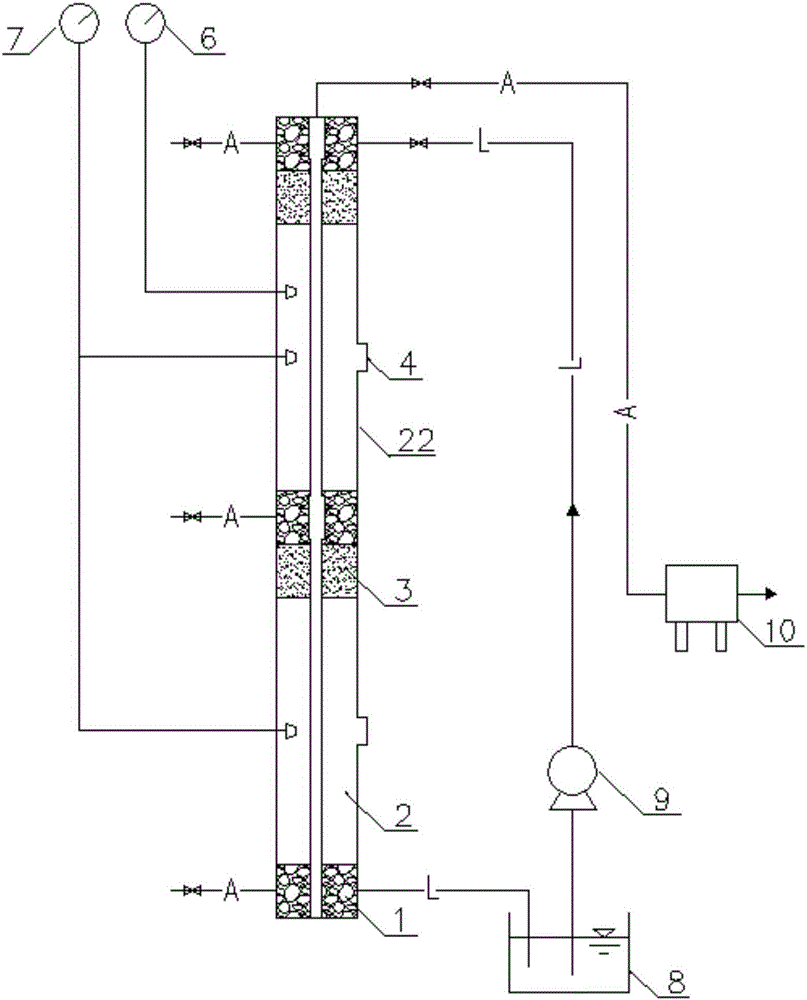

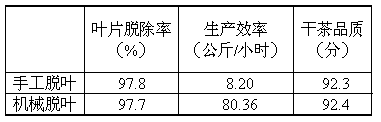

Full-automatic method for processing leaf-removed needle bud-shaped tea

ActiveCN103960381AAppropriate moisture contentMoisture content reachedPre-extraction tea treatmentHeat conductingBud

The invention discloses a full-automatic method for processing leaf-removed needle bud-shaped tea and belongs to the technical field of tea processing. The method comprises the following steps: tedding fresh leaves, deactivating enzyme, roasting, blowing tea pieces through a winnowing machine, performing primary softening treatment, tidying tea strips with hands, performing secondary softening treatment, performing secondary tea strip tidying treatment with hands, performing third-time softening treatment and roasting. The accurately controlled fresh leaves are tedded so as to obtain the most suitable fresh leaf enzyme-deactivated moisture content, the activity of fresh leaf enzymes is deactivated by contacting a heat-conducting roller for deactivation of enzymes, the moisture content of leaves needing to be removed in the fresh tea leaves is lower than the moisture content of buds needing to be preserved, the tea leaves immediately enter a needle-shaped tea roasting machine, the leaves needing to be removed are broken under the conditions of specific time, pressure and temperature and are blown by air, and the buds need to be kept perfectly; due to the dampening, softening and strip making process twice, straightness of tea buds can be preserved; and finally, due to roasting of a roasting unit, aroma of the tea leaves is generated, and the needed moisture content for refreshing the tea leaves is achieved.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

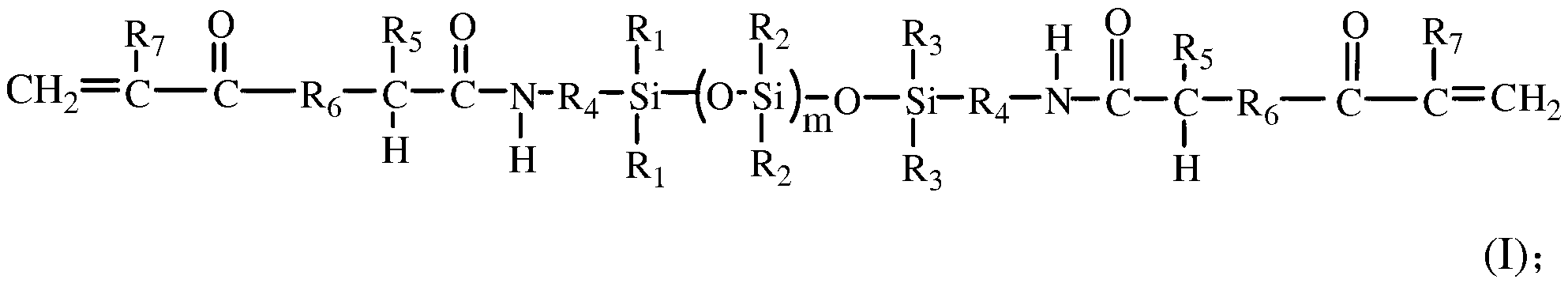

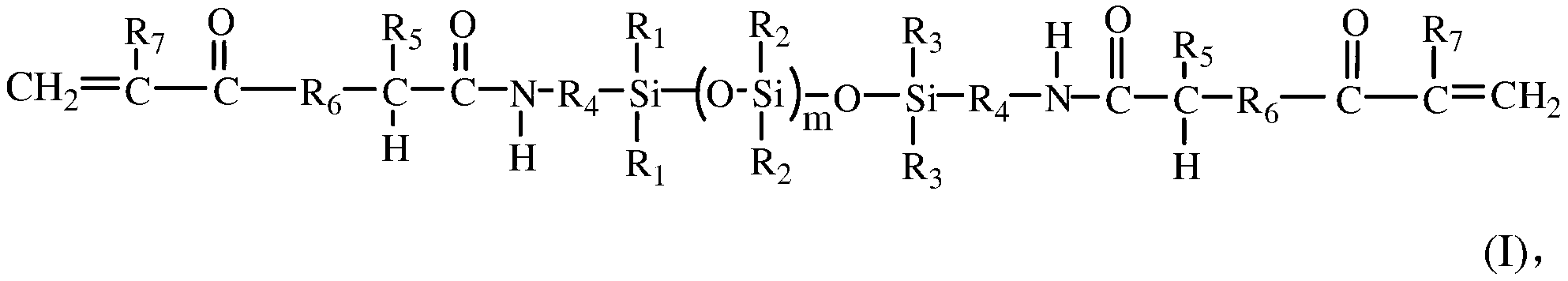

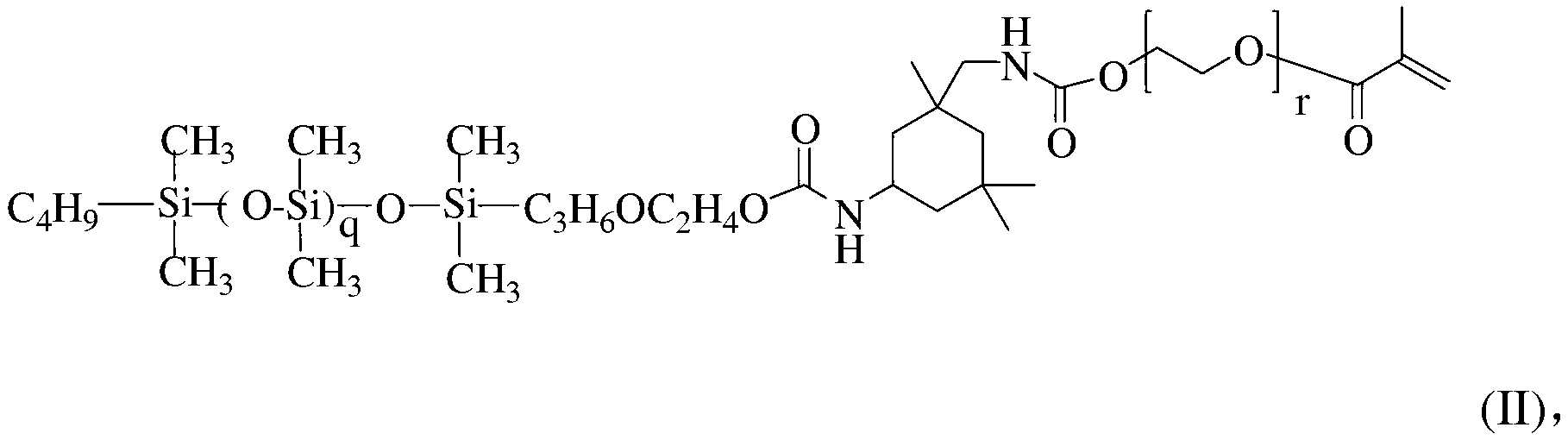

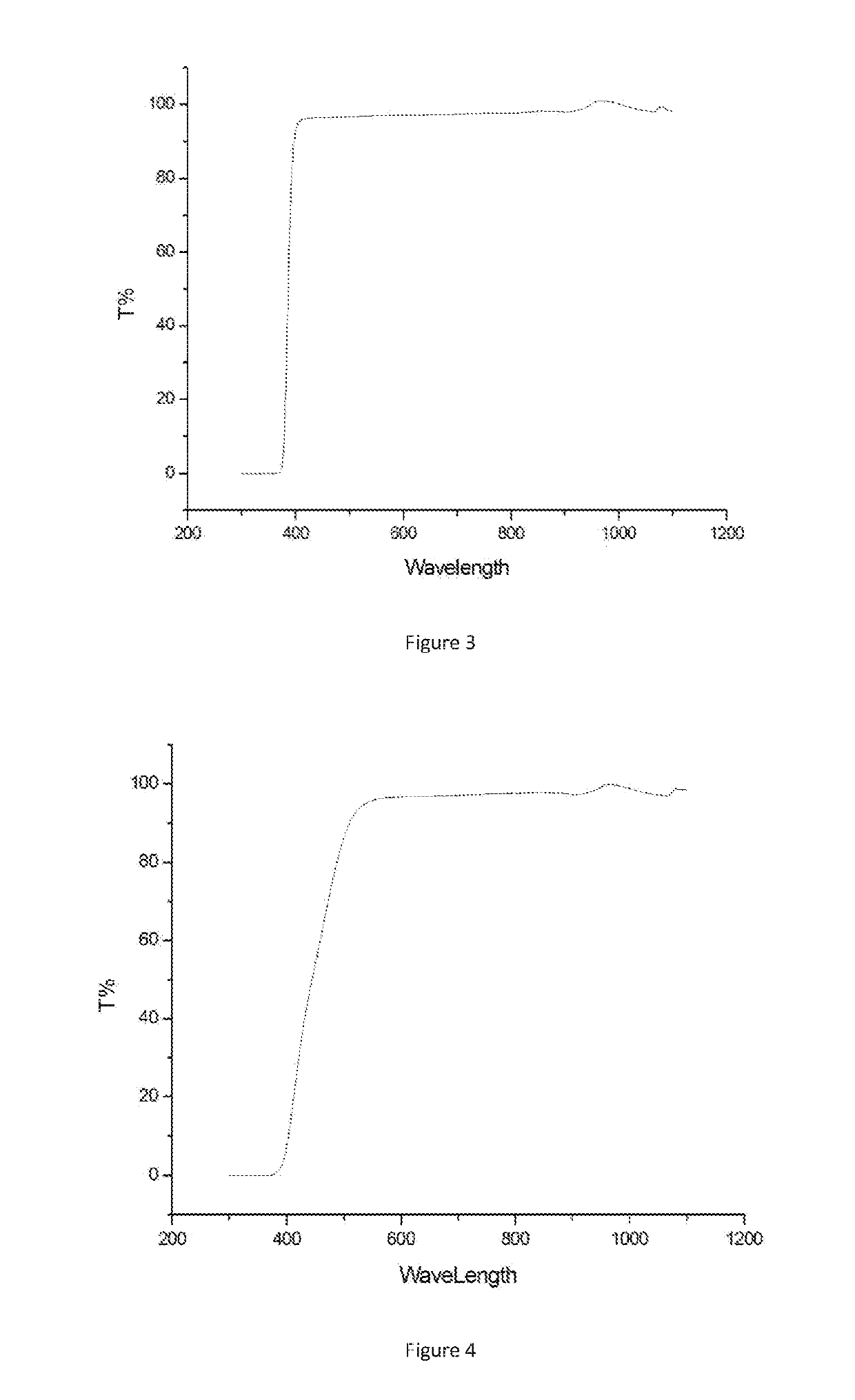

Contact lens material, contact lenses and method for manufacturing contact lenses

ActiveCN103224597AAppropriate moisture contentImprove wearing comfortOptical partsOptical elementsOxygenPermeation

The invention provides a contact lens material, a method for manufacturing contact lenses and the contact lenses manufactured with the method. The contact lens material, the contact lenses and the method for manufacturing the contact lenses are characterized by comprising a first siloxane tellurium polymer as shown in a chemical formula (1), namely the following chemical formula (1). Thus, the contact lenses made by the contact lens material have the advantages that an oxygen permeation rate (oxygen permeation coefficient DK) is high and a water content rate is moderate.

Owner:BENQ MATERIALS +1

Environment-friendly baking-free brick prepared from sludge and furnace slag and preparation method thereof

The invention discloses an environment-friendly baking-free brick prepared from sludge and furnace slag. Raw materials include: sludge, domestic incinerator slag, cement, a curing agent and water in amass ratio of (35-40): (10-15): (40-50): (5-10). The preparation method comprises the following steps: carrying out pyrohydrolysis and thermophilic anaerobic digestion treatment on raw sludge, and dehydrating to obtain dehydrated sludge; adding a deodorant into the dehydrated sludge, naturally deodorizing and airing, then crushing, sieving with a 100-mesh sieve to obtain sludge powder, and sieving the domestic incinerator slag with a 50-mesh sieve to obtain slag particles; and mixing the sludge powder and the slag particles with Portland cement, a curing agent and water, putting the obtainedmixture into a mold, performing extrusion and compression molding, and performing maintenance in air so as to obtain the environment-friendly baking-free brick. Waste sludge and furnace slag can be used as raw materials to prepare the environment-friendly baking-free brick which is stable in property, free of pollution and capable of meeting the strength requirement.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

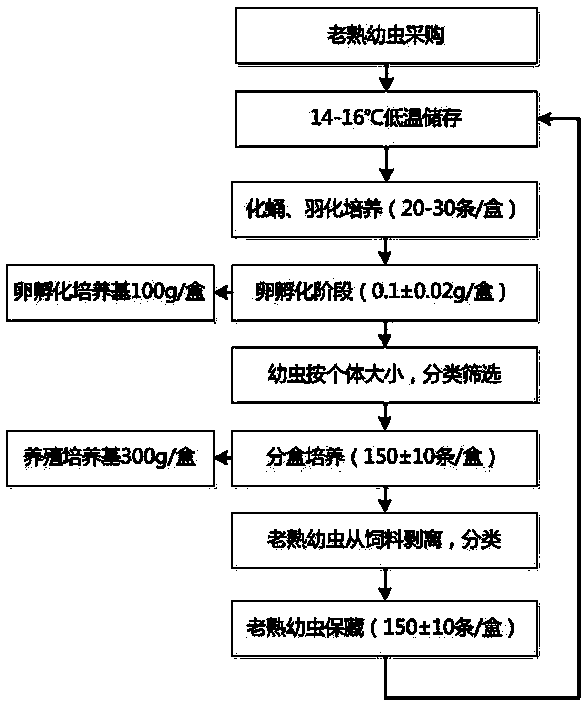

Standard breeding method for greater wax moth in laboratory

The invention discloses a standard breeding method for greater wax moth in a laboratory. Aged larvae with a fixed number are placed in a greater wax moth egg collecting box for carrying out pupation culture, and after adult emergence is completed, adults freely mate and lay eggs in the greater wax moth egg collecting box; egg pieces are collected for preservation at a low temperature; the egg pieces with a fixed mass are placed in larva breeding boxes for carrying out culture to a certain stage, wherein the mass of an incubation medium in each larva breeding box is constant; larvae with uniform sizes are screened and are put into the larva breeding boxes for carrying out culture, wherein the mass of a culture medium and the quantity of the larvae in each breeding box are constant, so thatthe growth rate of the larvae is basically consistent, the time for becoming aged larvae is basically consistent, the harvesting efficiency of the aged larvae and the feed utilization ratio are improved, and the harvested greater wax moth can be better applied to the fields of nematology study, pesticide development, bait processing and the like.

Owner:ZHENGZHOU IMMUNO BIOTECH

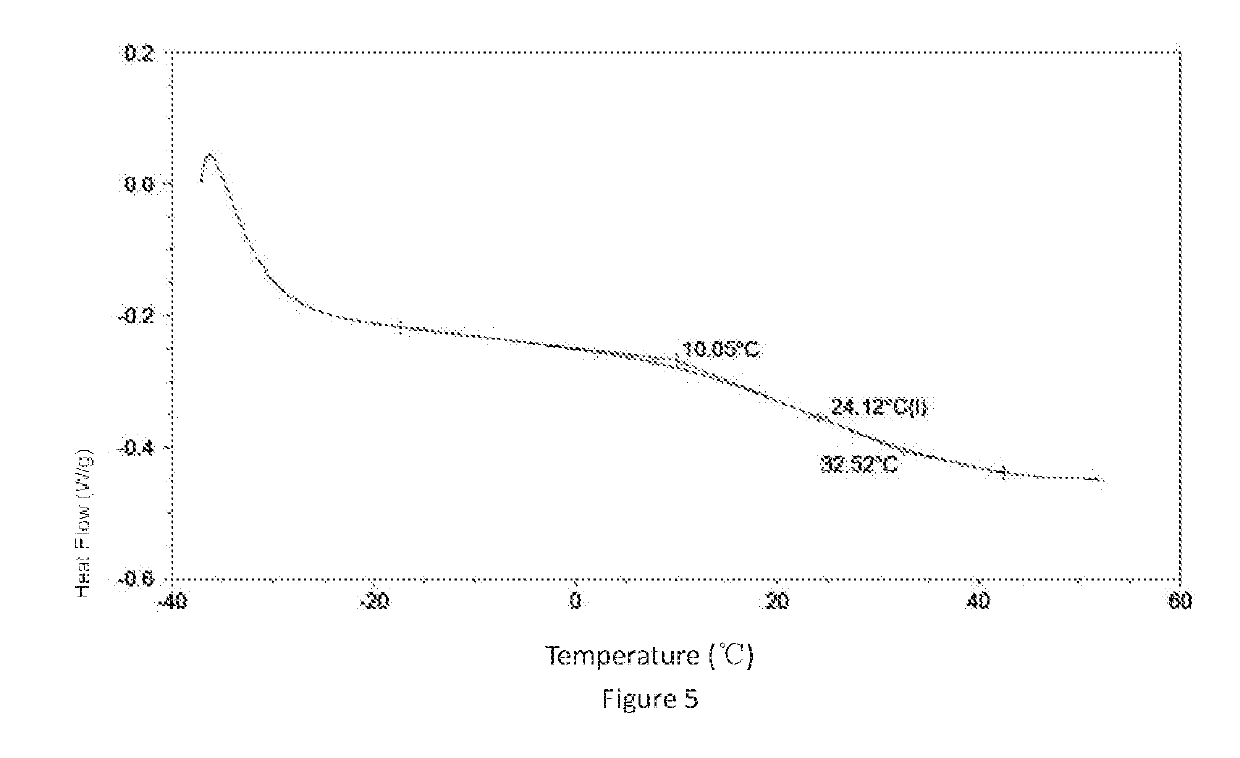

Materials for Preparing Intraocular Lens

ActiveUS20190314547A1Thin thicknessLow requirement of processing temperature and other conditionGogglesSurgeryIntraocular lensMedicine

The present invention relates to a material for preparing an intraocular lens. In particular, it relates to an ophthalmic medical material suitable for manufacture of micro-incision intraocular lens, having suitable water content and a suitable refractive index.

Owner:EYEBRIGHT MEDICAL TECH BEIJING

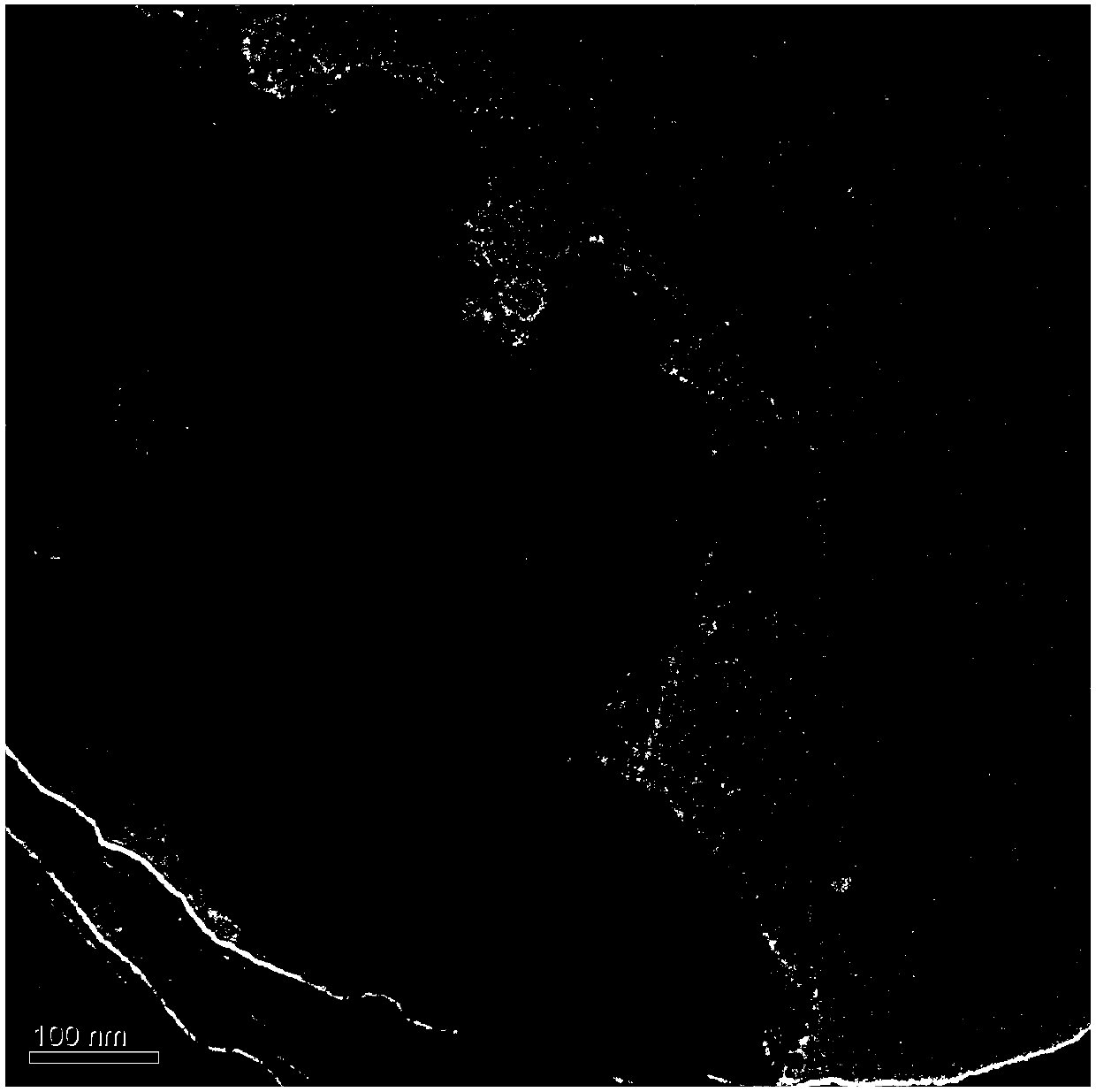

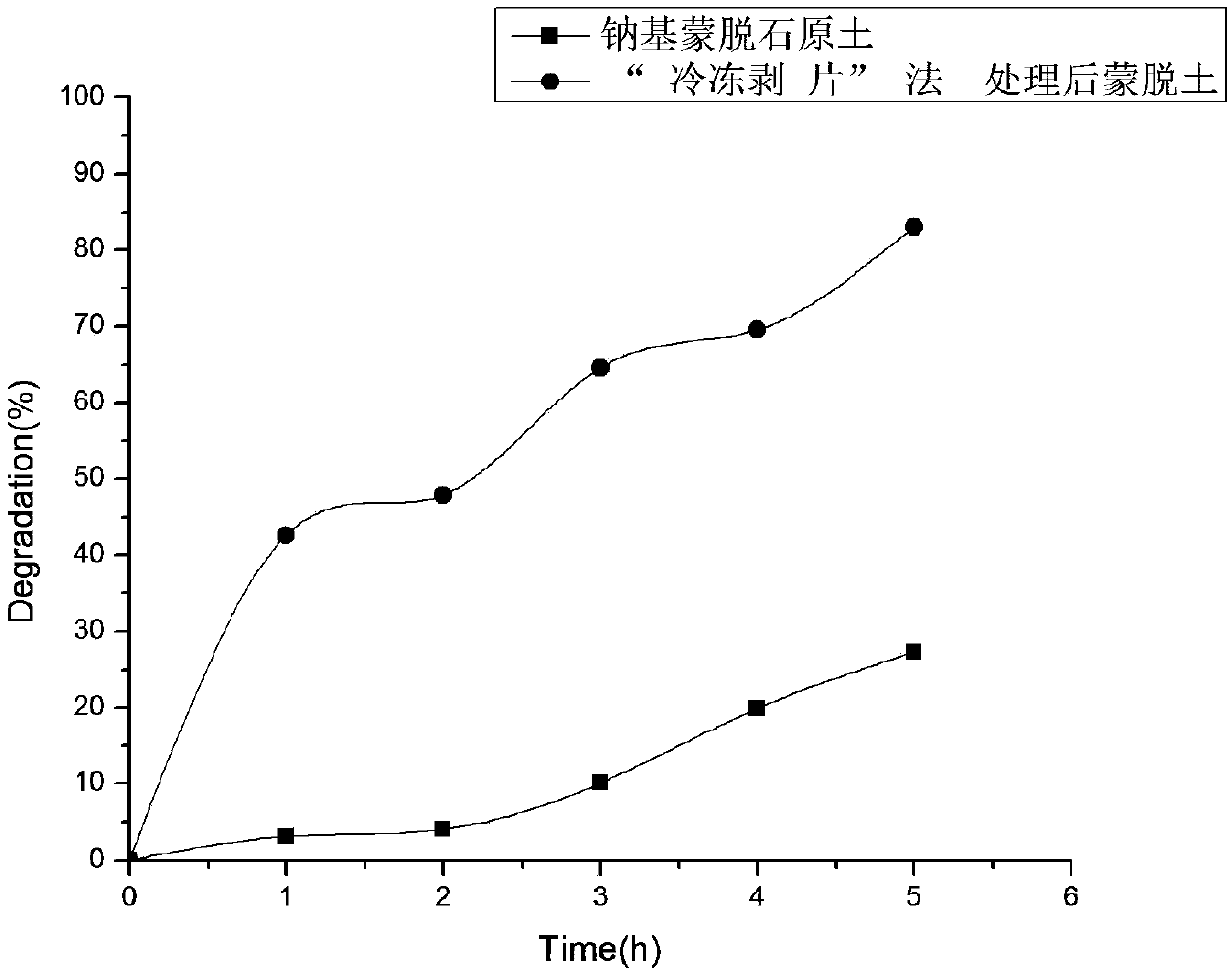

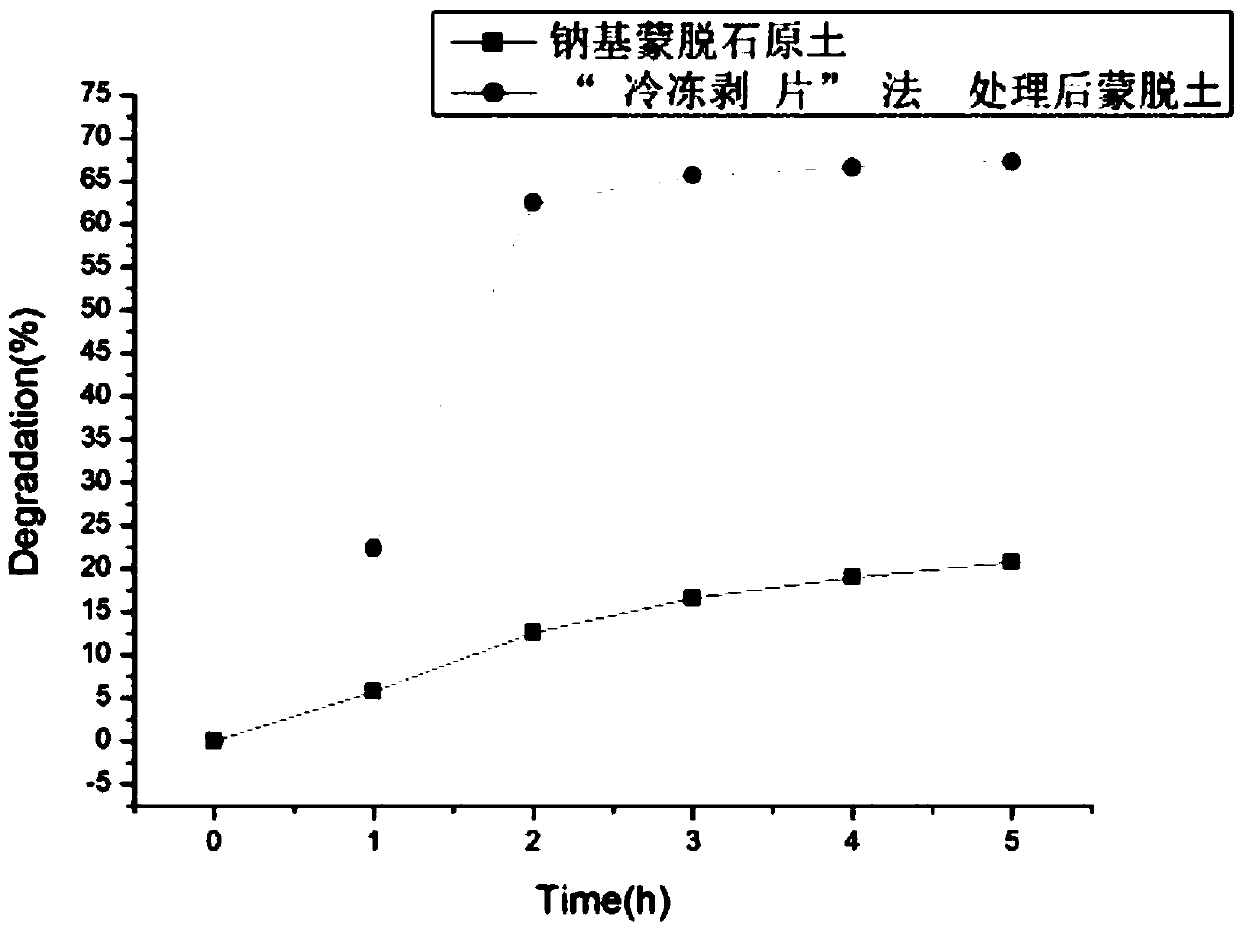

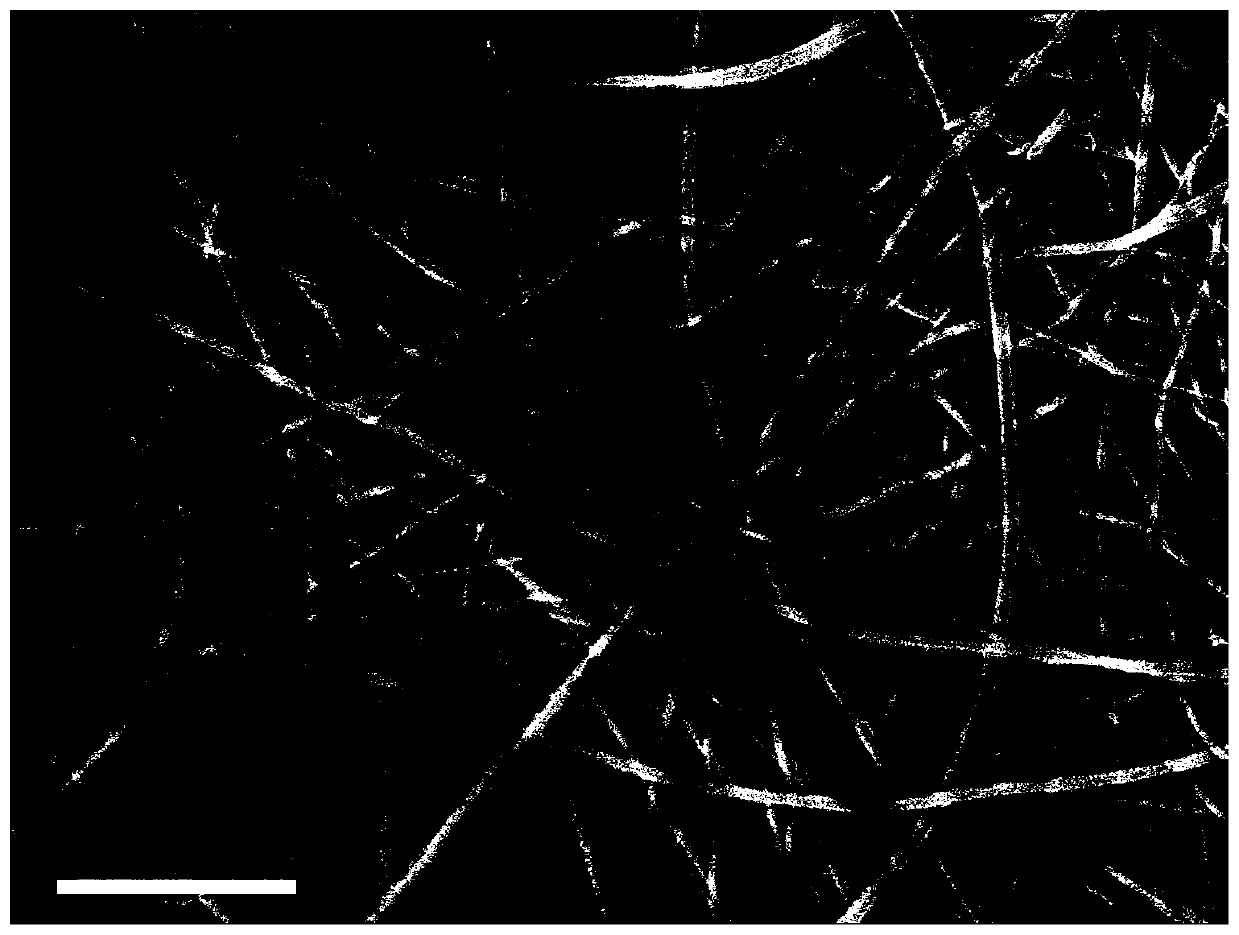

Preparation method of layered silicate mineral material based efficient adsorbent

InactiveCN107583601ALarge specific surface areaAvoid secondary pollutionOther chemical processesWater/sewage treatment by sorptionVacuum pumpingSorbent

The invention discloses a preparation method of a layered silicate mineral material based efficient adsorbent. The preparation method comprises steps as follows: layered silicate mineral is soaked inwater and is filtered after absorbing water sufficiently, and low-temperature drying is performed; freezing treatment is performed, and the temperature is reduced to zero DEG C or lower; an obtained material is put in a vacuum suction filter and subjected to vacuum pumping treatment; finally, the material is subjected to high-temperature drying treatment, and the layered silicate mineral materialbased efficient adsorbent is obtained. A freeze stripping method is a physical modification process performed under the condition that original interlayer spacing of the adsorbent is not changed, andother chemical modifiers are not needed; secondary pollution caused by the modification process is effectively avoided. A layered silicate mineral material is treated with the freeze stripping methodas a physical treatment method, so that the specific surface area of mineral can be increased, and the adsorption capacity of the mineral is greatly improved. Particularly, no chemical reagents are adopted for modification, and secondary pollution to the to-be-adsorbed material is avoided.

Owner:WUHAN UNIV OF TECH

Glazed low-temperature bright-red glaze and production process for ceramic products thereof

The invention relates to a glazed low-temperature bright-red glaze and a production process for ceramic products thereof, and belongs to the technical field of ceramics. The glazed low-temperature bright-red glaze is prepared by mixing 40 to 45 weight percent of bright-red pigment and 55 to 60 weight percent of low-temperature clinker, wherein the low-temperature clinker comprises the following components in percentage by weight: 1.2 to 2.4 percent of Li2O, 6.3 to 7.7 percent of KNaO, 43.1 to 46.2 percent of SiO2, 0.03 percent of Fe2O3, 4.9 to 6.9 percent of Al2O3, 4.9 to 5.6 percent of CaO, 27.2 to 28.9 percent of B2O3, 3.6 percent of SrO, 1.0 percent of ZrO and 1.2 to 1.6 percent of F. The production process for the ceramic products of the glazed low-temperature bright-red glaze comprises the following steps of: preparing the glaze, adding a deflocculating agent and water, mixing uniformly, performing ball milling, sieving, glazing, drying in the shade, and roasting. The technology is easy to implement; and the products have the characteristics of firm combination of blanks and the glaze, bright colors, high gloss and hardness, no toxin and the like.

Owner:潮州市波士发陶瓷制作有限公司

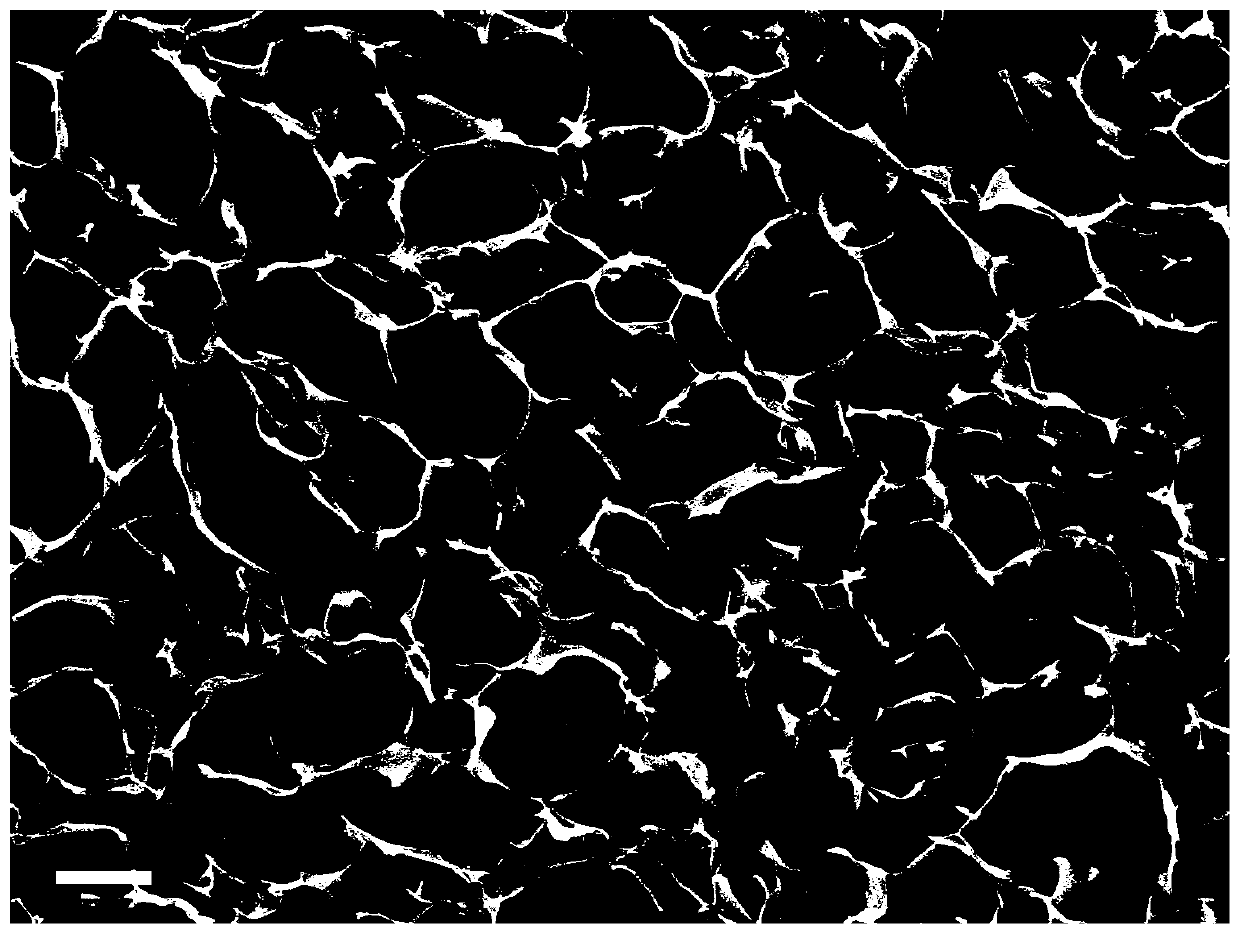

Nanofiber chitosan porous material and preparation method thereof

The invention discloses a nanofiber chitosan porous material and a preparation method thereof. The preparation method comprises the following steps: respectively preparing a chitosan solution and a polyvinyl alcohol-ethylene copolymer nanofiber suspension, uniformly mixing the chitosan solution and the polyvinyl alcohol-ethylene copolymer nanofiber suspension in proportion and freeze-drying to obtain the nanofiber chitosan porous material. With application of the method, the polyvinyl alcohol-ethylene copolymer nanofibers can be uniformly dispersed on the surface of the inner wall of the chitosan body, the problems that the traditional chitosan porous material is low in strength, prone to dissolution loss, short in service life and the like are solved, and the prepared porous material hasthe appropriate hot water dissolution loss rate, swelling rate, moisture content and compression strength so as to meet the requirements of practical application. The preparation method of the nanofiber chitosan porous material is simple and easy to implement and can meet industrial large-scale production; and the performance of the prepared porous material can be regulated and controlled by adjusting the ratio of the nanofibers to the chitosan so as to adapt to different application scenes, and the application range is wide.

Owner:WUHAN TEXTILE UNIV

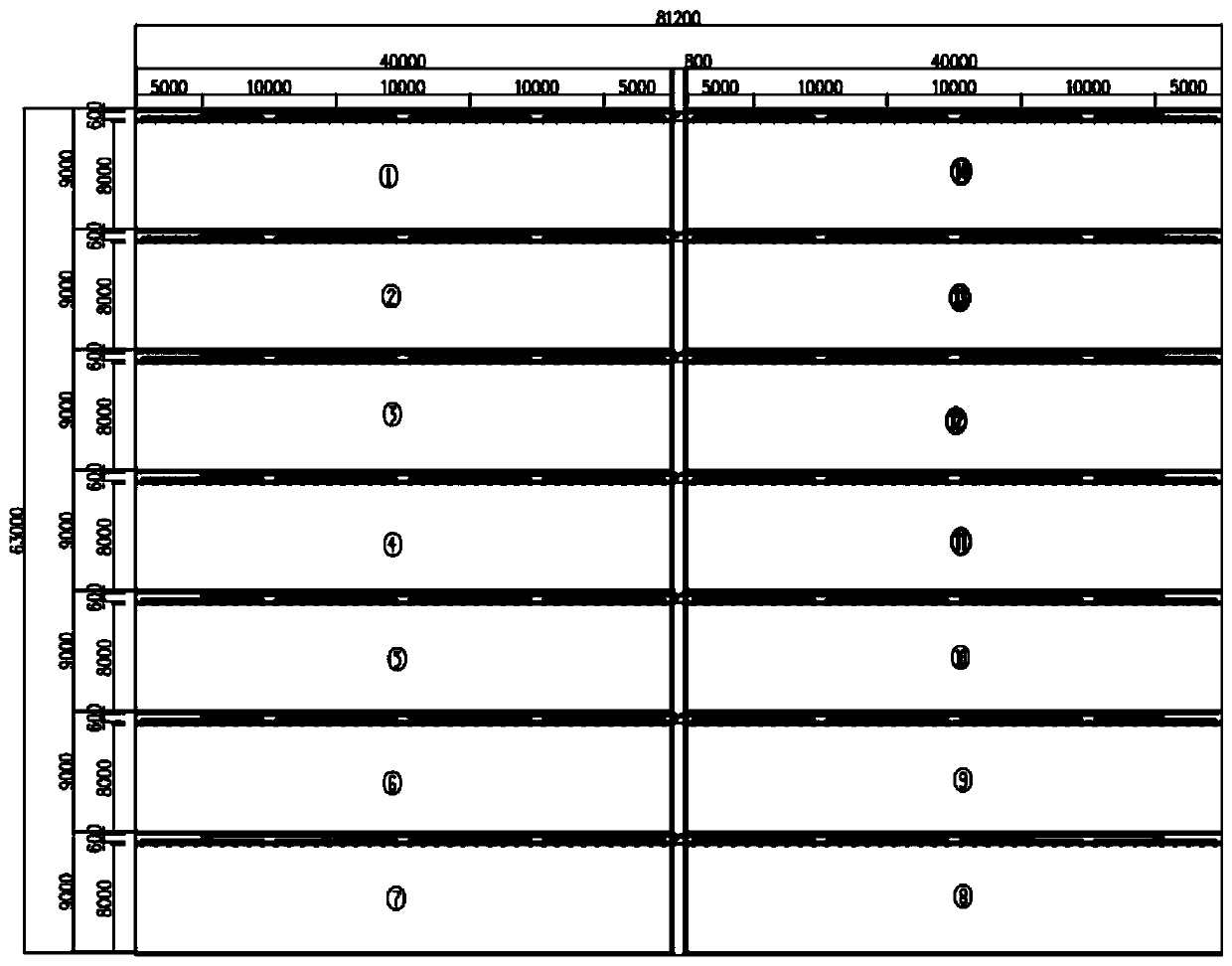

Method and system for treating garbage malodorous gas by humus soil aerobic fixed bed under multi-stage series stock household garbage sieve

ActiveCN111530268AAchieving balance control goalsAppropriate moisture contentDispersed particle separationAir quality improvementFixed bedEnvironmental engineering

The invention belongs to the field of waste gas treatment. The invention discloses a method and system for treating garbage malodorous gas by a humus soil aerobic fixed bed under a multi-stage seriesstock household garbage sieve. The method comprises the following steps: (1) enabling gas to enter a fixed bed from a gas inlet unit at the bottom of the fixed bed, exhausting the gas from the top after being treated by the fixed bed by sucking the top of the fixed bed, and carrying out treatment by uniformly preparing a stock garbage aged leachate from the top of the fixed bed, and (2) connectingthe exhausted gas to a bottom gas inlet unit of a next-stage fixed bed, treating by utilizing the multi-stage series-connected fixed beds in a sequencing batch alternating manner, and discharging after reaching the standard. According to the method disclosed by the invention, the treatment of three pollutants, namely the humus soil under the sieve, the aged leachate and the malodorous gas in thefixed bed is mutually combined, so that not only can wastes be treated by wastes, but also the three-in-one balance control target of three-phase pollution of water, solid and gas can be realized.

Owner:NANJING UNIV +1

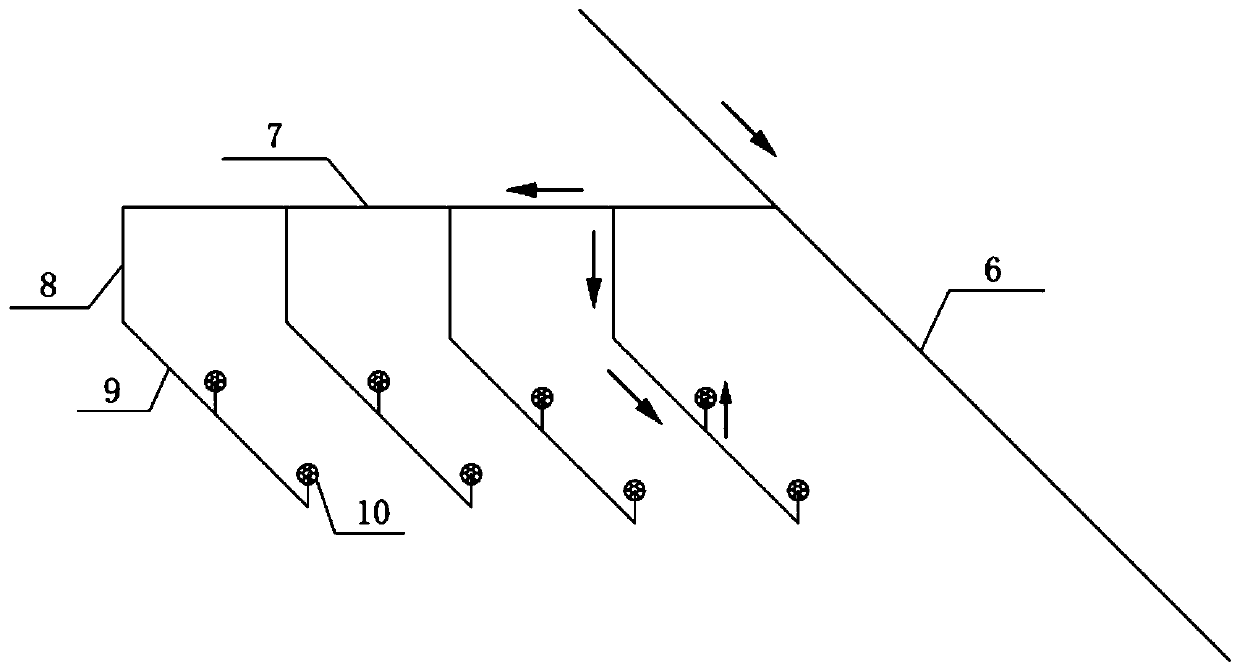

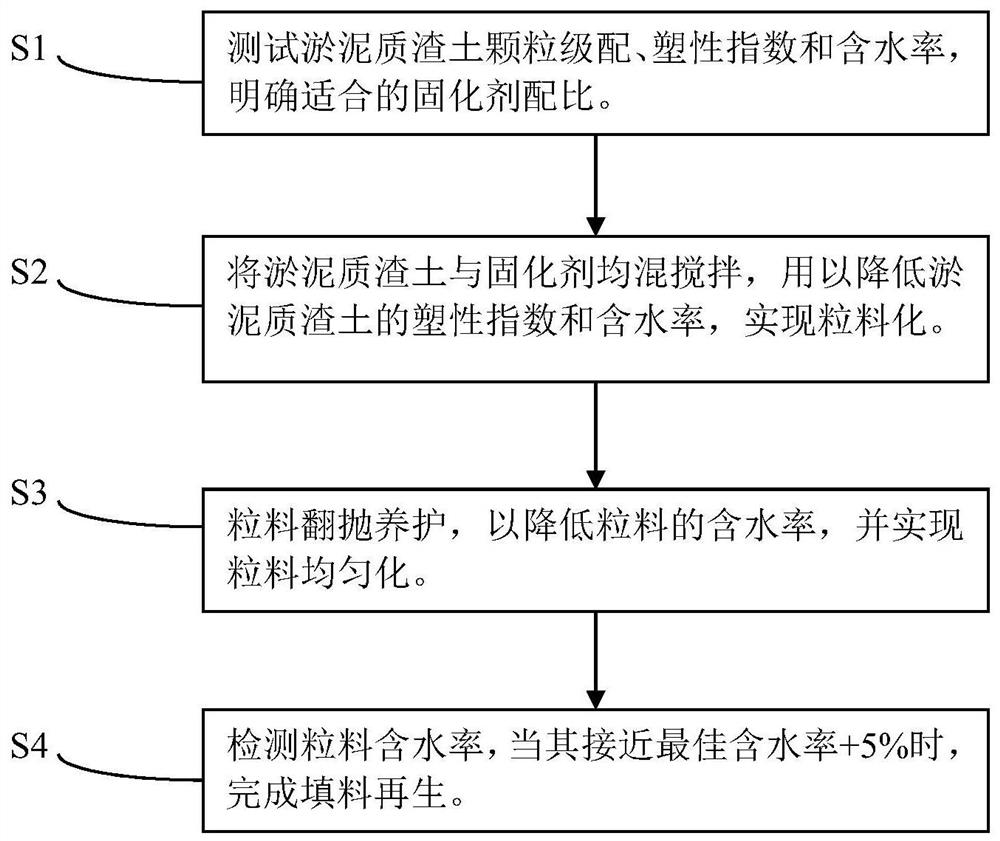

Production process for solidifying and regenerating roadbed filler by using mucky muck

InactiveCN113442291ASimple and efficient processEase of industrial applicationRoadwaysSolid waste managementRoad constructionPlastic property

The invention discloses a production process for solidifying and regenerating roadbed filler by using mucky muck. The production process comprises the following steps that the using amount of a curing agent is determined according to grain composition, plasticity index and water content of muck; the mucky muck is mixed with the curing agent to realize granulation; granules are turned, thrown and maintained to realize water reduction and homogenization of the granules; and the moisture content of the granules is detected, and when the moisture content of the granules is not higher than the optimal moisture content+5%, production of the regenerated roadbed filler is completed by taking the homogenized granules as the regenerated roadbed filler. According to the production process, the natural mucky muck can be directly solidified, pretreatment links such as drying and crushing or water distribution fluidization are not needed, the using amount of the curing agent is small, the treatment period is short, the regenerated filler is in the shape of loose and compactable powder which is appropriate in water content and viscosity, transfer and road construction operation are easy, secondary ash doping is not needed, the filler can be directly paved and rolled, and the roadbed bearing capacity requirement is met after compaction. The technological process is simple and efficient, and industrial application and large-scale popularization are easy.

Owner:ZHEJIANG UNIV +1

Chestnut tree planting method

InactiveCN106718560AEasy dischargeAppropriate moisture contentFertilising methodsCultivating equipmentsDistilled waterPollen

The invention discloses a chestnut tree planting method and relates to the technical field of planting. The chestnut tree planting method comprises the following steps: A, a planting pit is dug for planting a chestnut tree; B, a drainage trench is dug in the position taking the root of the chestnut tree as the center and 1-2 m away from the center, and a slope is formed from the soil at the root of the chestnut tree to the drainage trench; C, when the chestnut tree blooms, male flower pollen of large flowers is taken down and mixed with distilled water in a ratio being 1:2.5-3, and the mixture is sprayed to female flower pollen; D, surplus male flower pollen is cut off; E, a fertilization pit is dug in the position taking the root of the chestnut tree as the center and 0.3-0.5 m away from the center the pit is 3-5 cm deep, borax and urea are mixed in a ratio being 1-1.5:1, and the mixture is applied into the fertilization pit; F, weeds are spread on fertilizer and covered with soil. Compared with the prior art, the chestnut tree planting method solves the problems of smaller size and poorer taste of chestnuts fruited after chestnut tree planting.

Owner:韦界飞

Herbs dendrobii officinale mask product

InactiveCN108403558AGood moisturizing effectAppropriate moisture contentCosmetic preparationsToilet preparationsCelluloseComposite film

The invention provides a herba dendrobii officinale mask product. The herba dendrobii officinale mask product is prepared from 50 to 70 parts of herba dendrobii officinale extract, 15 to 25 parts of bighead atractylodes rhizome and rhizoma bletillae water extract, 15 to 30 parts of chitosan, and 10 to 15 parts of moisturizer. A preparation method comprises the following steps of selecting 10 to 20parts of chitosan, adding a 2% acetic acid solution, dissolving, directly flatly paving on a nonwoven cloth or an elastic fabric or a cellulose film, and drying under the vacuum condition until the water content is reduced to be 15% or lower, so as to obtain a composite film A; selecting 5 to 10 parts of atractylodes rhizome and rhizoma bletillae water extract, adding the water, dissolving, adding 30 to 40 parts of herba dendrobii officinale extract, then adding 10 to 15 parts of moisturizer, uniformly stirring, directly flatly paving on a release film, and drying under the vacuum condition until the water content is reduced to be 10 to 15%, so as to obtain a composite film B; selecting the residual atractylodes rhizome and rhizoma bletillae water extract, adding the water, dissolving, adding the residual herba dendrobii officinale extract, adding the left chitosan solution, uniformly stirring, directly pouring onto the composite film B, drying under the vacuum condition until the water content is reduced to be lower than 60 to 75%, overlapping with the chitosan surface of the composite film A, treating by ultrasonic waves for 10 to 30min, packaging under the vacuum condition, andstoring for further use.

Owner:江西轩斛生物科技有限公司

Display cabinet with humidification function

InactiveCN103082755AAppropriate moisture contentShow cabinetsShow shelvesTelecommunicationsDisplay cabinet

Disclosed is a display cabinet with a humidification function. A gap between a cabinet door and a separating board is utilized to form air returning space and air out space under the separating board. When a humidification device works, dry air above the separating board is inhaled through the air returning space, is blew into the air out space after being humidified, returns to space above the separating board through the gap between the cabinet door and the separating board and maintains proper water content.

Owner:赵建勋

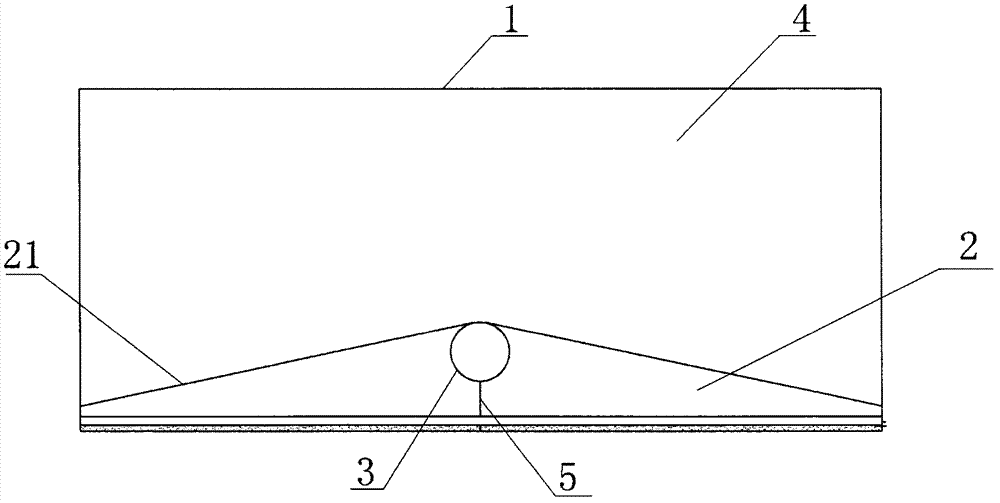

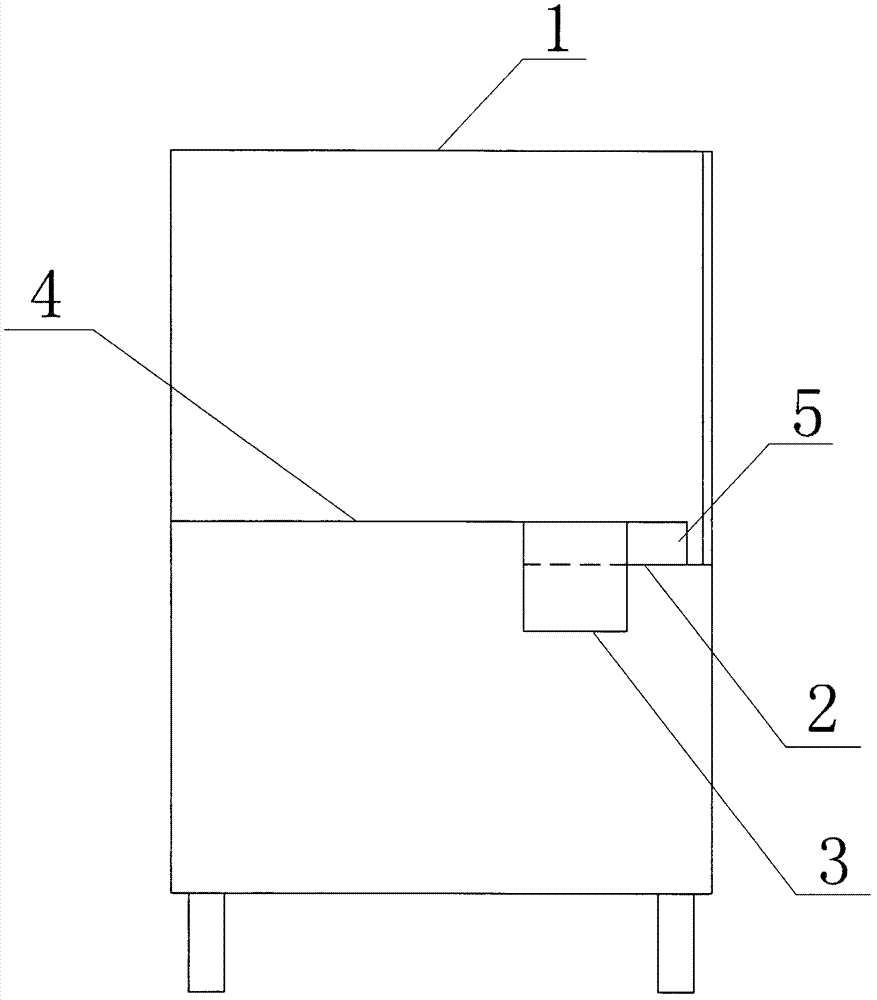

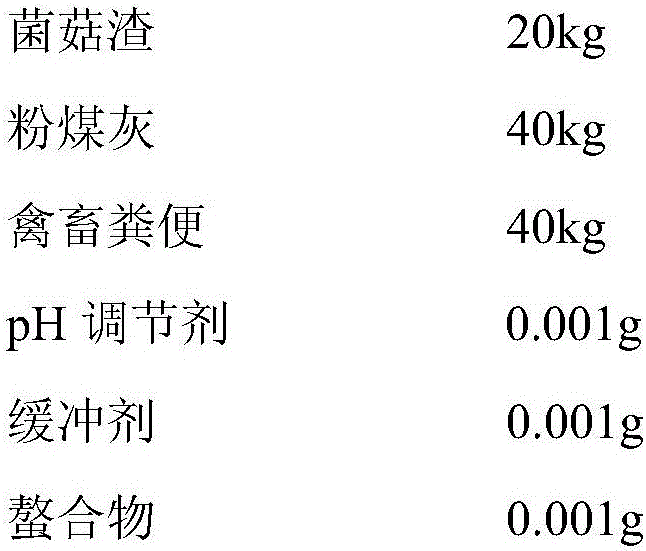

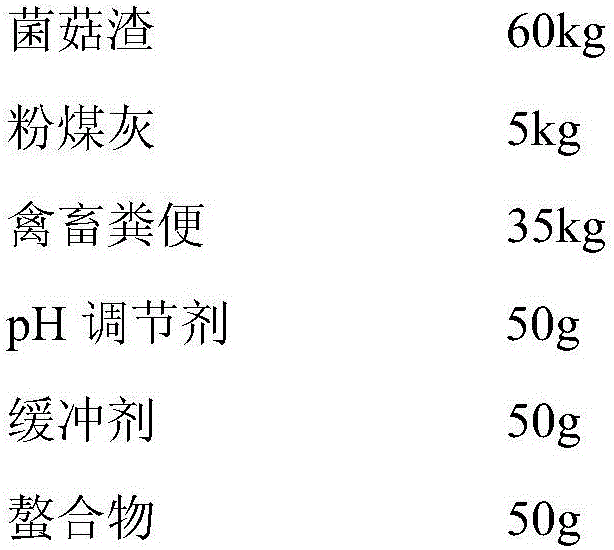

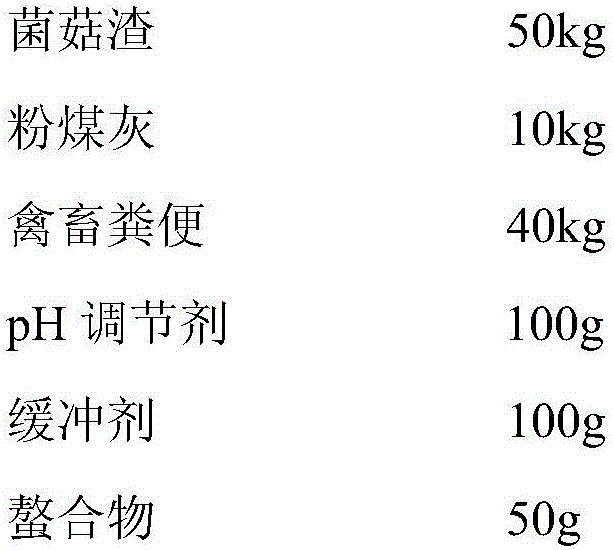

Mushroom residue-based artificial soil and synthesis method thereof

InactiveCN105948903AGuaranteed water retention and breathabilityLight textureExcrement fertilisersGrowth substratesPlant rootsFeces

The invention discloses a mushroom residue-based artificial soil. The mushroom residue-based artificial soil comprises mushroom residues, fly ash, animal dung, a pH regulator, a buffering agent and a chelate, wherein a mushroom residue, fly ash and animal dung mixture contains 20-60wt% of mushroom residues, 5-40wt% of fly ash and 15-40wt% of animal dung, and every ton of the mushroom residue, fly ash and animal dung mixture contains 0.01-1000g of the pH regulator, 0.01-1000g of the buffering agent and 0.01-500g of the chelate. The mushroom residues have light weight, the unit weights of the fly ash and the animal dung are large, and a ratio of the mushroom residues to the fly ash to the animal dung is controlled to make the unit weight of the artificial soil be similar to the unit weight of manure soil, so plant roots can be well fixed, the water holding permeability of soil is increased, water, fertilizers, air and other environment factors needed in the growth process of the plants are well coordinated, and a large amount of beneficial microorganisms in the mushroom residues increase the diversity of microorganisms in soil. The artificial soil has stable performances, is not affected by batches, seasons or regions, and keeps excellent application effects.

Owner:灌南县畜牧兽医站

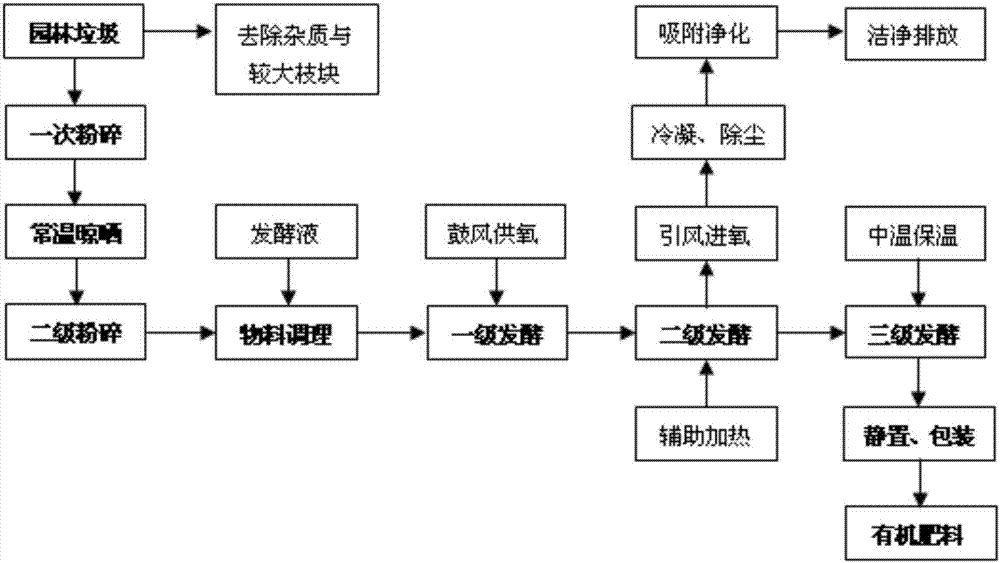

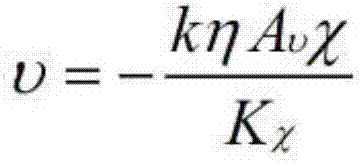

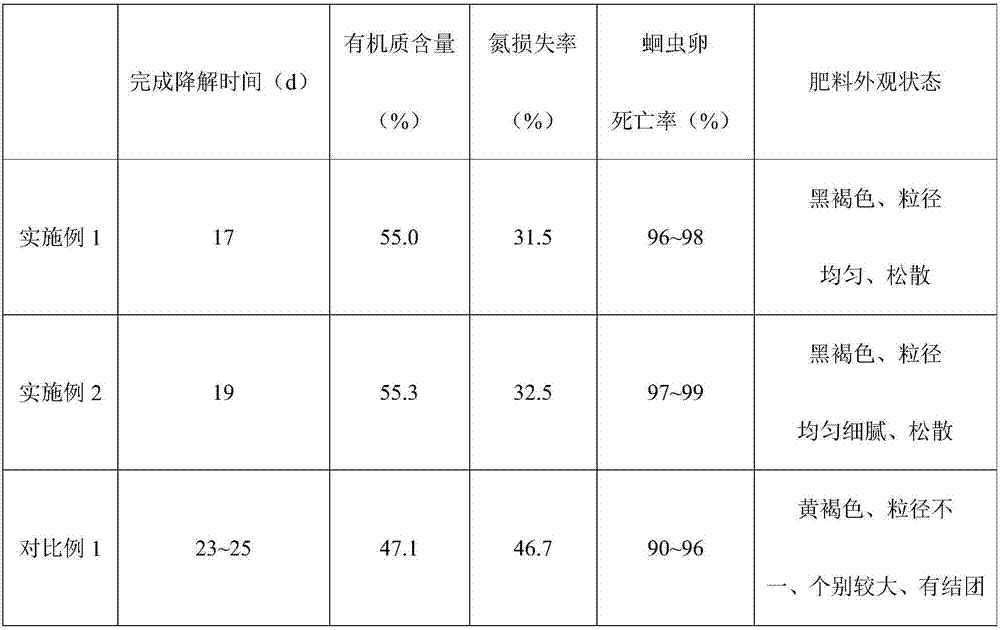

Garden waste lignin component fermentative degradation method

InactiveCN107188626AReduce volumeImprove decomposition rateBio-organic fraction processingBioloigcal waste fertilisersPre treatmentMushroom

The invention discloses a garden waste lignin component fermentative degradation method. The method includes the steps of: (1) crushing materials into materials with a particle size of 0.4-0.7cm; (2) placing the crushed materials into a first-stage fermentation area, adding a mushroom residue fermentation broth into the materials to keep the water content of the materials at 55%-65%, and conducting primary fermentation; (3) adding the mushroom residue fermentation broth into the materials subjected to primary fermentation, keeping the water content of the materials at 45%-55%, and then placing the materials in a second-stage fermentation area for secondary fermentation; and (4) putting the fermented materials subjected to secondary fermentation into a third-stage fermentation area for fermentation, thus finishing the whole fermentative degradation process. Directed at the characteristics of lignin in the materials, the method provided by the invention adopts physicochemical treatment method and biochemical treatment method for material pretreatment and material conditioning, and directed at the activity characteristics of bacteria, fungi, actinomycetes and other different dominant degrading floras at different temperature stages in the fermentative degradation process, realizes accurate condition control and efficient degradation of lignin.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com