Preparation method of layered silicate mineral material based efficient adsorbent

A layered silicate and mineral material technology, applied in the field of materials, can solve the problems of changing the interlayer and pore structure of minerals, high processing costs, cumbersome processes, etc., and achieve simple and environmentally friendly preparation process conditions, large adsorption capacity, and increased The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a layered silicate mineral material high-efficiency adsorbent, which comprises the following steps:

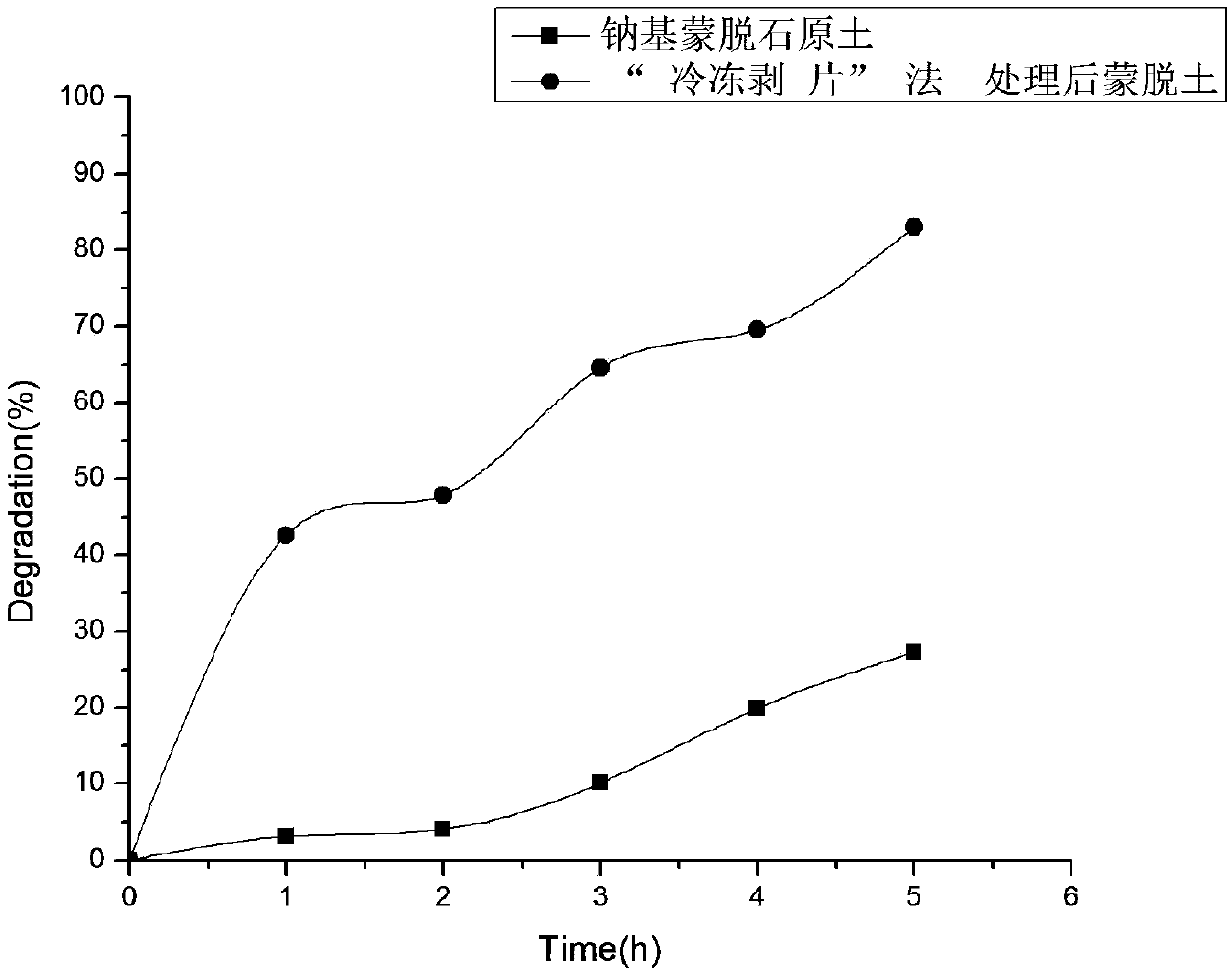

[0033] Using sodium montmorillonite as raw material, take 20g of sodium montmorillonite and put it in a beaker, pour 250ml of ultrapure water into it, place the beaker in a magnetic stirrer and stir for 10 hours at a low speed. Filter the soaked soil and bake in an oven at 60°C for 4 hours. Put the material in a steel cup, use 500ml liquid nitrogen to freeze for 1 hour, put the steel cup containing the material into a vacuum filter for 8 hours, take out the sample and place it in a drying oven for 2 hours at 120°C. The above steps of "soaking - low temperature drying - liquid nitrogen freezing - vacuuming - high temperature drying" were repeated twice to obtain the adsorbent.

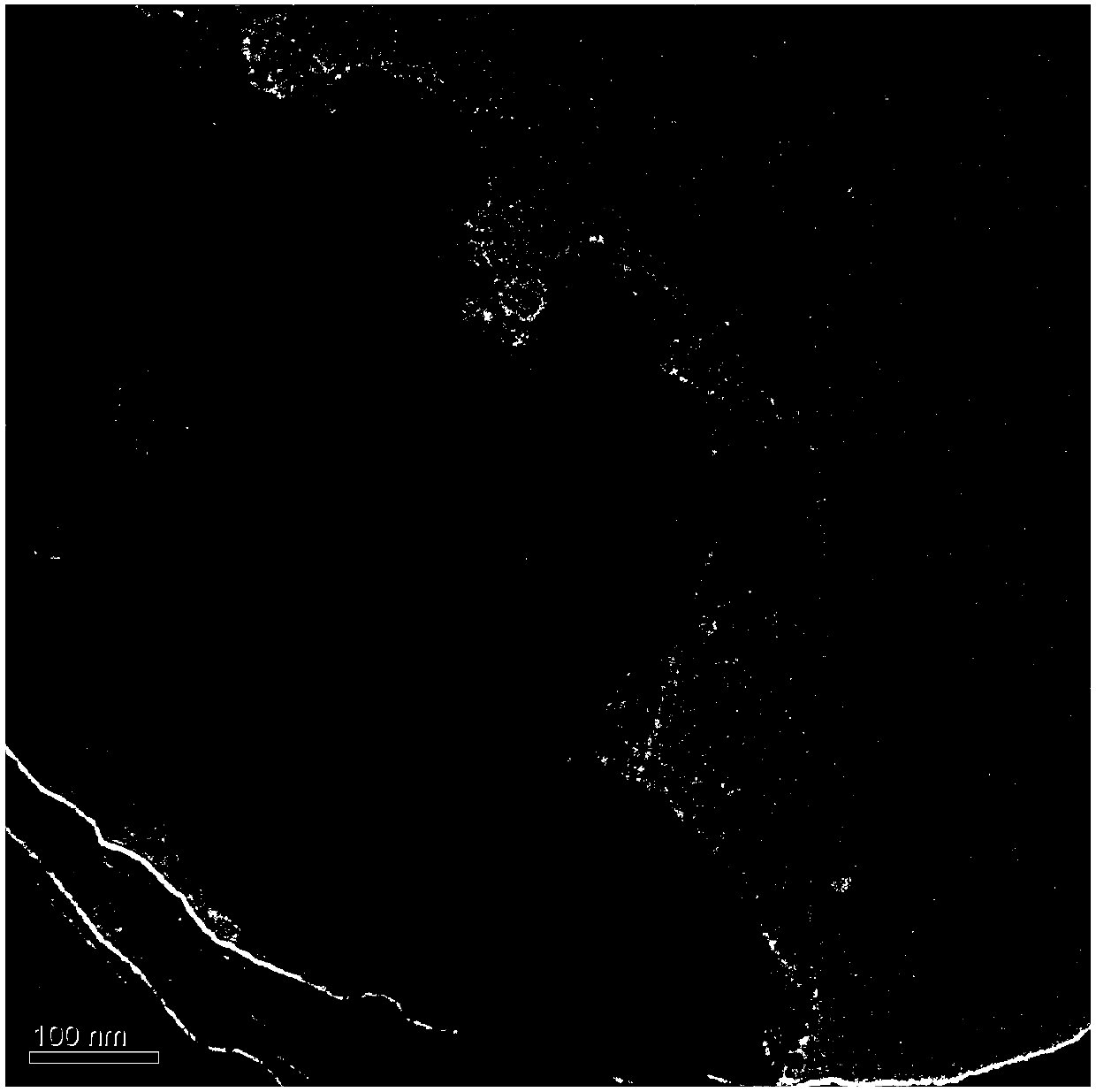

[0034] The adsorbent samples were analyzed by transmission electron microscopy, which proved that the lamellar structure of montmorillonite was peeled off, and a thin bloc...

Embodiment 2

[0037] A method for preparing a layered silicate mineral material high-efficiency adsorbent, which comprises the following steps:

[0038] Take 10g of sodium-based montmorillonite in a beaker, pour 250ml of ultrapure water into it, and place the beaker in a magnetic stirrer to stir at a low speed for 8 hours. Filter the soaked soil and bake in an oven at 50°C for 2.5 hours. Put the material in a steel cup, freeze it with 450ml of liquid nitrogen for 1 hour, put the steel cup containing the material into a vacuum filter for 4 hours, take out the sample and dry it in a drying oven at 120°C for 1 hour. The above steps of "soaking - low temperature drying - liquid nitrogen freezing - vacuuming - high temperature drying" were repeated once to obtain the adsorbent.

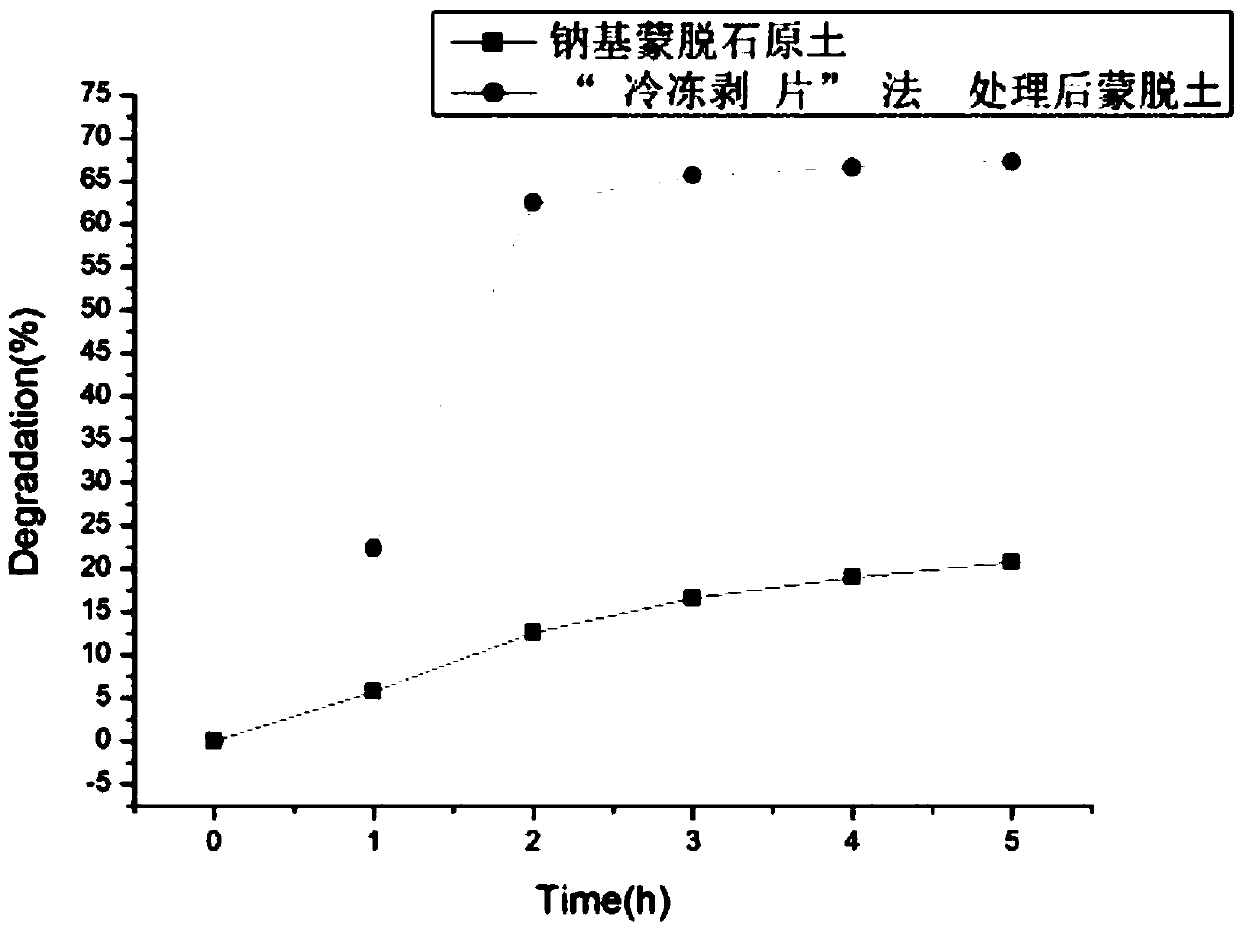

[0039] Prepare 40ml of 20mg / L rhodamine B solution, add 0.04g of the layered silicate mineral adsorbent obtained above under magnetic stirring, stir at room temperature for 5h, and record the adsorption rate of 67% (th...

Embodiment 3

[0041] A method for preparing a layered silicate mineral material high-efficiency adsorbent, which comprises the following steps:

[0042] Take 15g of sodium-based montmorillonite in a beaker, pour 250ml of ultrapure water into it, and place the beaker in a magnetic stirrer to stir at a low speed for 8 hours. Filter the soaked soil and bake in an oven at 80°C for 1.5h. Put the material in a steel cup, use 600ml liquid nitrogen to freeze for 1 hour, put the steel cup containing the material into a vacuum filter for 6 hours, take out the sample and dry it in a drying oven at 120°C for 2 hours. The above steps of "soaking - low temperature drying - liquid nitrogen freezing - vacuuming - high temperature drying" were repeated twice to obtain the adsorbent.

[0043] Prepare 40ml of 20mg / L thiamphenicol solution, add 0.04g of the layered silicate mineral adsorbent obtained above under magnetic stirring, stir at room temperature for 5h, and record an adsorption rate of 53% (the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com