Compound feed for cow and its production technology

A compound feed, dairy cow technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problem that the utilization rate of feed needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

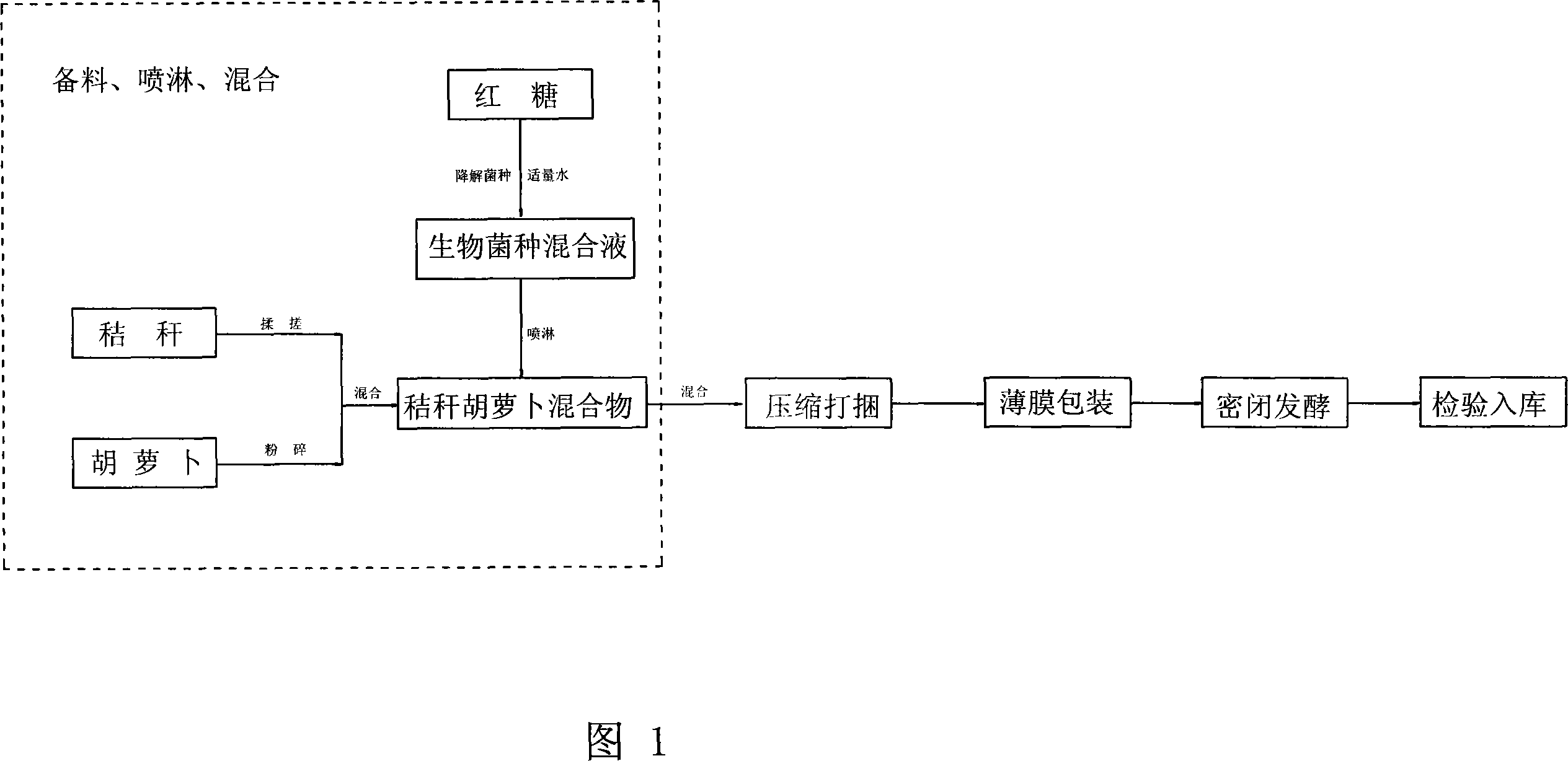

Method used

Image

Examples

Embodiment 1

[0050] 24 parts of rice straw (dry matter), 1 part of carrot (dry matter), 1000 ml / ton of straw (dry matter) of strain, 1.4kg / ton of brown sugar / ton of straw (dry matter).

[0051] After measurement: when the water content of rice straw is 20%, the water content of carrots is 90%.

[0052] Calculation of material ratio: the ratio of carrot is 1, then the ratio of straw is: 24*(1-90%) / (1-20%)=3. That is, straw (moisture content 20%):carrot (moisture content 90%)=3:1. The water content after the carrot and straw are mixed is (3*20%+1*90%) / (3+1)=37.5%.

[0053]Complementary water consumption calculation: the total water content of the product is required to be 50%, and when the material moisture content is 37.5%, the supplementary water consumption is 50%-37.5%=12.5%.

[0054] Preparation of biologically active bacteria solution: first put the biologically active bacteria into a small amount of 0.5% brown sugar solution at a temperature of 35-40°C, stir evenly, and revive for 1...

Embodiment 2

[0065] 28 parts of corn stalks (dry matter), 0.8 parts of carrots (dry matter), 800 ml / ton of straw (dry matter) of bacteria, 0.8 kg / ton of brown sugar / ton of straw (dry matter).

[0066] After measurement: when the water content of corn stalks is 40%, the water content of carrots is 88%.

[0067] Material ratio calculation: the ratio of carrots is 0.8 parts, then the ratio of straw is: 28*(1-88%) / (1-40%)=5.6. That is, straw (moisture content 40%):carrot (moisture content 88%)=5.6 / 0.8=7:1. The water content of carrots and straw after mixing is (7*40%+1*88%) / (7+1)=46%.

[0068] Complementary water consumption calculation: the total water content of the product is required to be 50%, and when the material moisture content is 46%, the supplementary water consumption is 50%-46%=4%.

[0069] Preparation of biologically active bacteria solution: first put the biologically active bacteria into a small amount of 0.5% brown sugar solution at a temperature of 35-40°C, stir evenly, and...

Embodiment 3

[0080] Wheat straw (dry matter) 20 parts, carrot (dry matter) 1.2 parts, strain 1500 ml / ton straw (dry matter), brown sugar 1kg / ton straw (dry matter).

[0081] After measurement: when the water content of wheat straw is 18%, the water content of carrot is 86%.

[0082] Material ratio calculation: the ratio of carrots is 1.2 parts, then the ratio of straw is: 20*(1-86%) / (1-18%)=3.4. That is, straw (moisture content 18%):carrot (moisture content 86%)=(3.4 / 1.2)=2.8:1. The water content after the carrots and straws are mixed is (2.8*18%+1*86%) / (2.8+1)=35.9%.

[0083] Complementary water consumption calculation: the total water content of the product is required to be 45%, and when the material moisture content is 35.9%, the supplementary water consumption is 45%-35.9%=9.1%.

[0084] Preparation of biologically active bacteria solution: first put the biologically active bacteria into a small amount of 0.5% brown sugar solution at a temperature of 35-40°C, stir evenly, and revive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com