Torpedo can spouting material and spouting method thereof

A technology of material injection and construction method, which is used in casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient injection material strength, high equipment requirements, complicated injection methods, etc., and achieves resistance to chemical corrosion. Excellent performance, good thermal shock resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

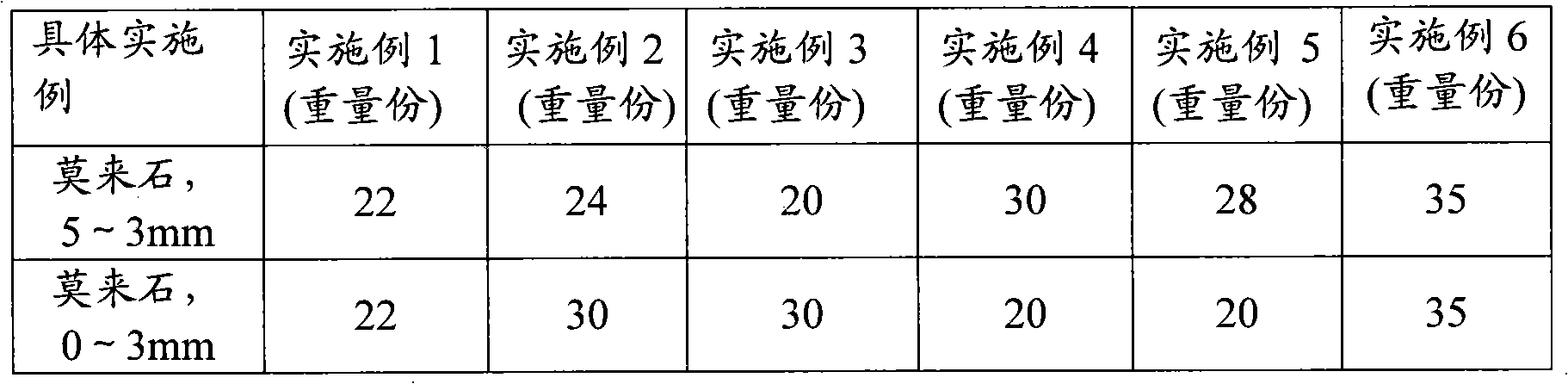

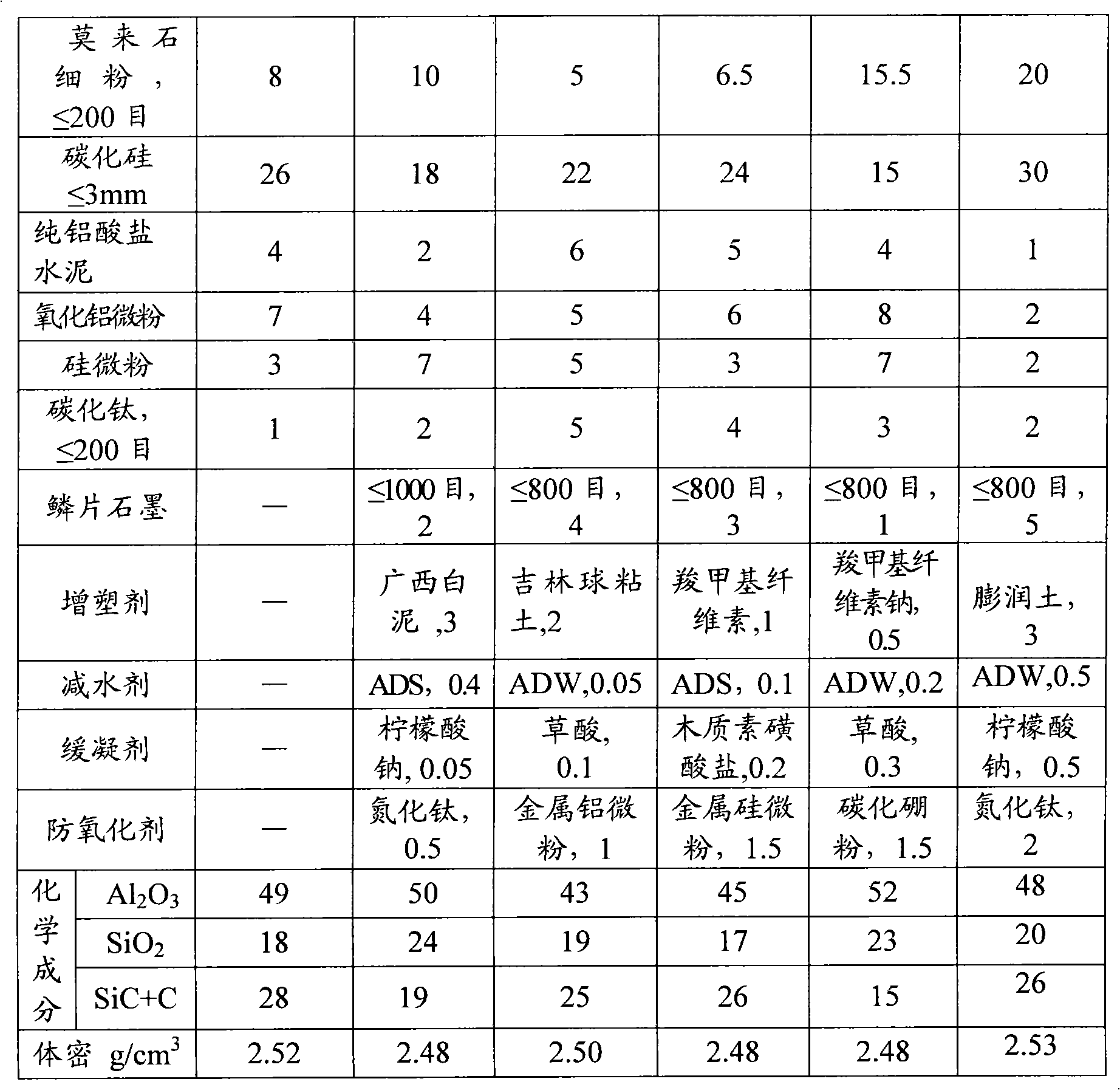

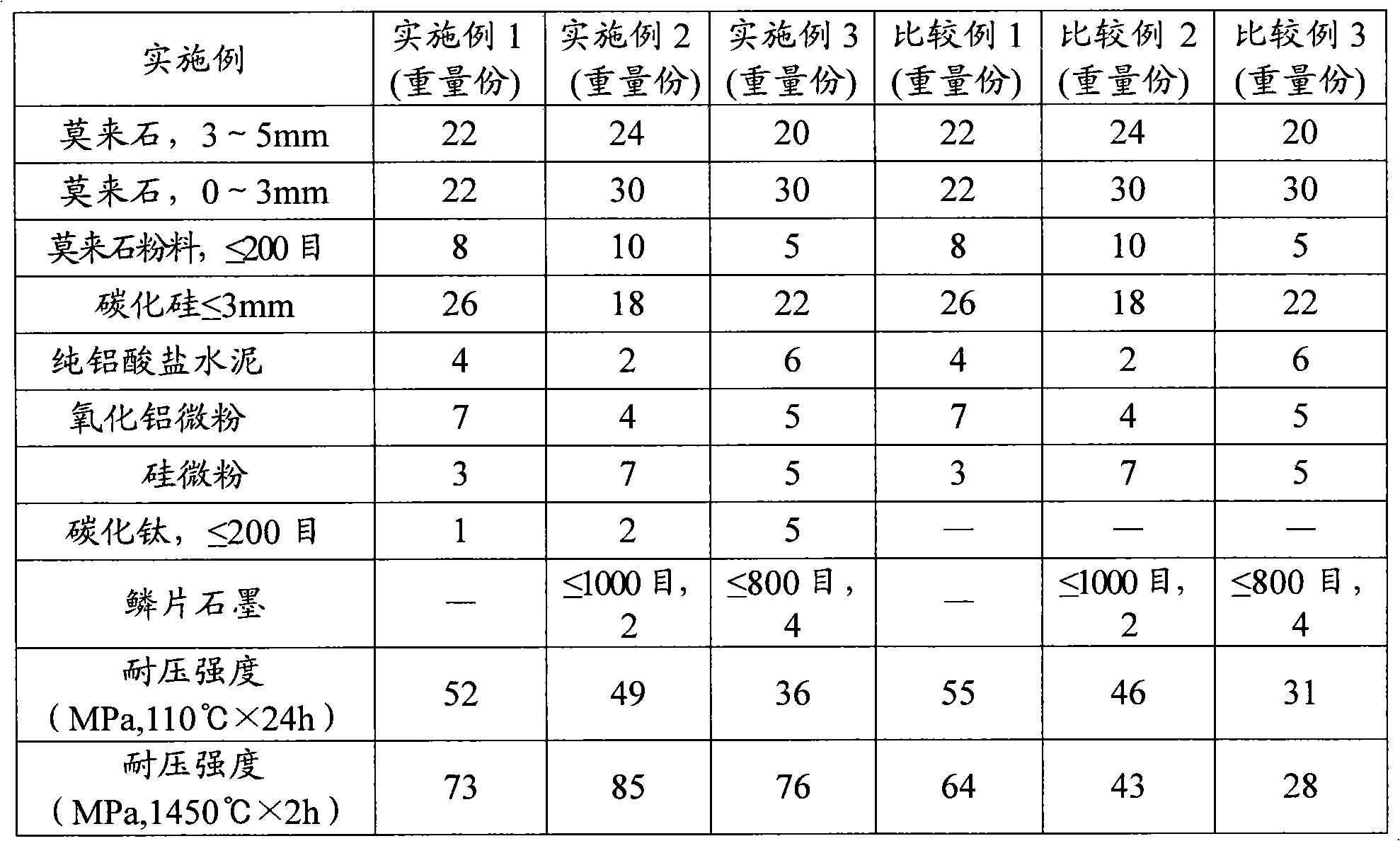

Examples

Embodiment 7

[0057] Adopt the injection material described in embodiment 1 to carry out injection, method is:

[0058] (1) Add water to the injection material, the addition of water is 6% of the weight of the injection material, and fully stir after adding water, so that the injection material becomes mud with certain fluidity;

[0059] (2) Using wet injection equipment, add a polyacrylamide aqueous solution with a concentration of 0.1wt% as a coagulant at the nozzle of the wet injection equipment, and use compressed air with a pressure of 0.2MPa to place the coagulant Blow into the injection material so that it is evenly mixed with the injection material in the spray gun and then injected to the surface to be sprayed, and the amount of coagulant mixed with the injection material is 1% of the weight of the injection material .

[0060] (3) Baking is performed after curing the sprayed surface.

[0061] The method for baking the sprayed surface is:

[0062] (1) When at room temperature, p...

Embodiment 8

[0067] Adopt the injection material described in embodiment 2 to carry out injection, method is:

[0068] (1) add water to the injection material and stir, the amount of water added accounts for 8% of the weight of the injection material, so that the injection material becomes mud with certain fluidity;

[0069] (2) use wet injection equipment, and add concentration at the outlet of described wet injection equipment and add the polyaluminum chloride aqueous solution that concentration is 20~30wt% as coagulant, and use the compressed air that pressure is 0.3MPa, the accelerator The coagulant is blown into the injection material, so that it is uniform with the injection material in the spray gun and finally injected to the surface to be sprayed. The amount of coagulant mixed with the injection material is 1.5% by weight of the injection material.

[0070] (3) Baking is carried out after curing the sprayed surface for 20 hours.

[0071] The method for baking the sprayed surface...

Embodiment 9

[0077] Adopt the injection material described in embodiment 3 to carry out injection, method is:

[0078] (1) Stir the injection material with water, the amount of water added accounts for 7% of the weight of the injection material, so that the injection material becomes mud with certain fluidity;

[0079] (2) Use wet injection equipment, and add sodium aluminate and potassium hydroxide composite aqueous solution as coagulant at the outlet of described wet injection equipment, and use the compressed air that pressure is 0.4MPa, coagulant is blown Into the injection material, make it uniform with the injection material in the spray gun, and then spray it to the surface to be sprayed. The amount of coagulation accelerator mixed with the injection material is 1.2% of the weight of the injection material; in the composite aqueous solution of sodium aluminate and potassium hydroxide, the molar ratio of sodium aluminate to potassium hydroxide is: 2:1.

[0080] (3) Baking is carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com