Patents

Literature

35results about How to "High softening point under load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

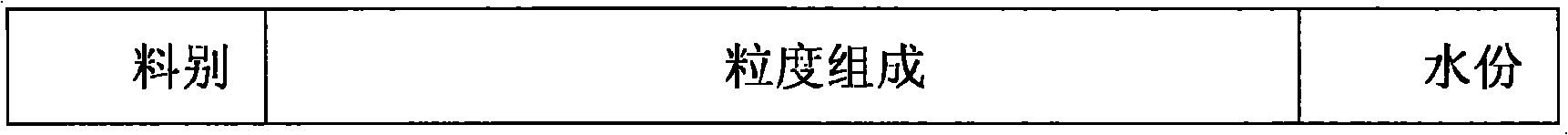

Dry type working liner material for erosion resistance continuous casting tundish

InactiveCN1800105AImprove high temperature strength and slag erosion resistanceExtended service lifeTundishOxide

The invention relates to an amorphous refractory; especially to an erosion resistance concast intermedium finish-go-home work sark. It uses magnetite as main raw material and the light-burned magnesium oxide, boric acid, silicon powder and aluminum powder as accelerator and the resin, starch gum and so on as insurance contract. It adds one or some kinds of chrome green, compound chrome-magnesite brick, magnesite-chrome brick. The raw material is that (wt%): the magnesite 5-1mm is 10-35%, 1-0.2mm is 10-35%, <=0.074mm is 20-40%, <=0.088mm admixture is 5-20%, <=0.088mm accelerator is 1-5%, starch gum is 5-12%. Each raw material has a certain quality technology index.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-crystal mullite-iolite high-temperature industrial ceramic and production method for same

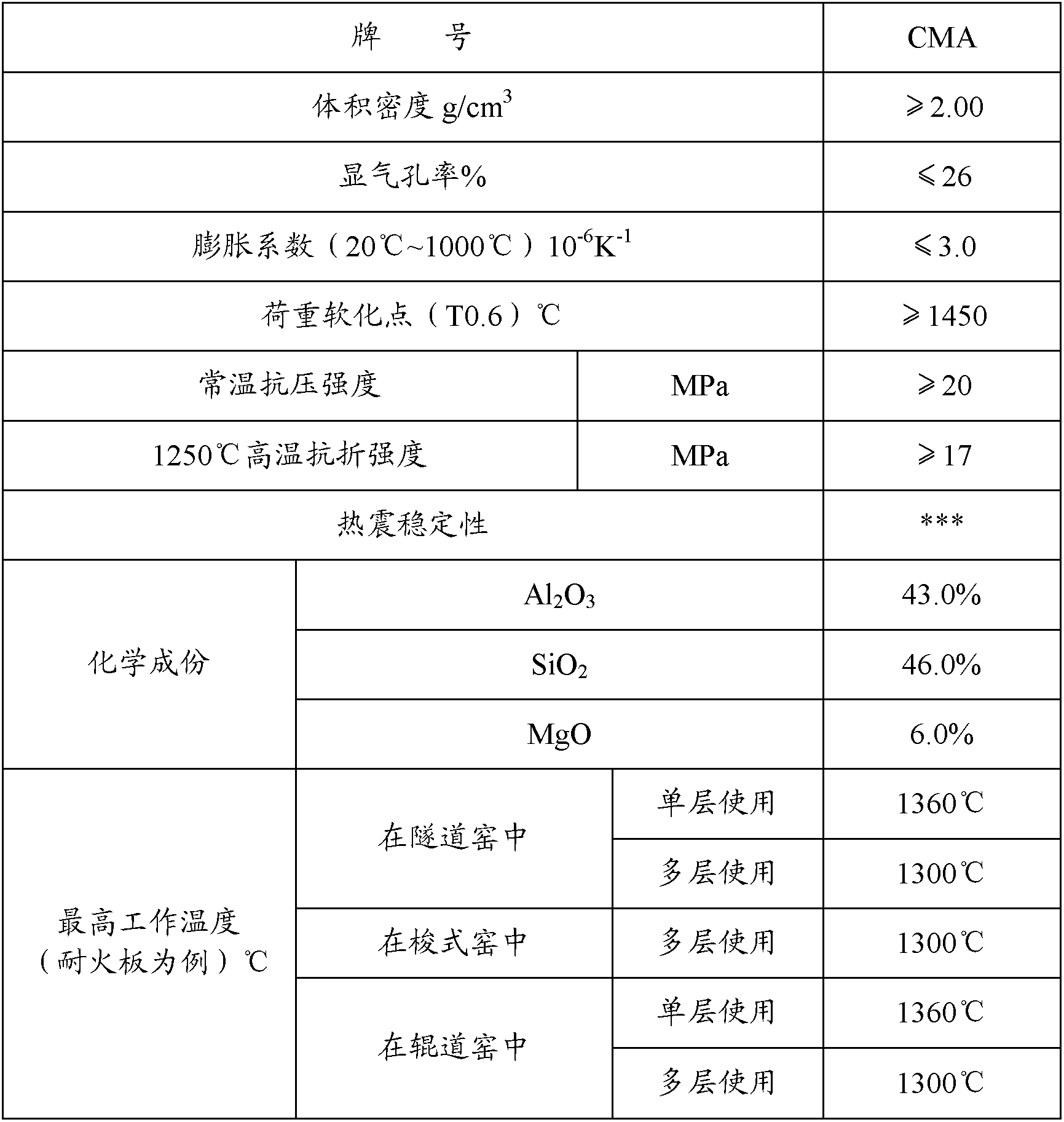

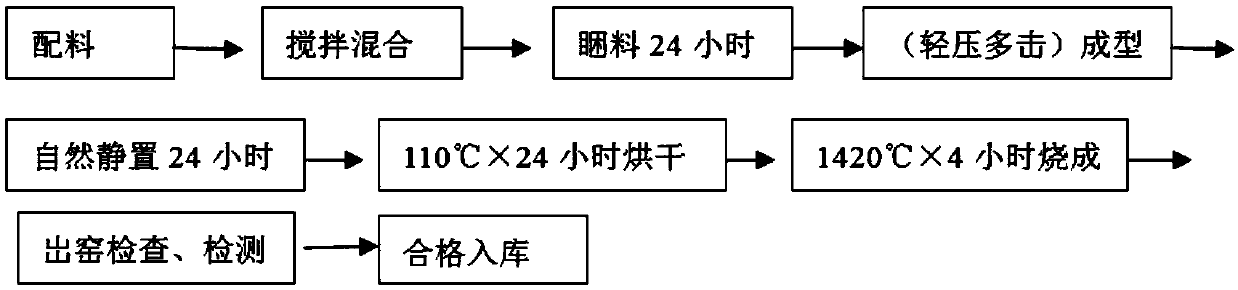

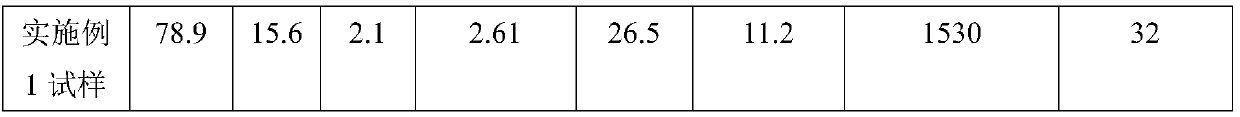

The invention relates to a high-crystal mullite-iolite high-temperature industrial ceramic and a production method for the same. Raw materials comprise, by weight, 40-80 parts of main crystal phase materials, 20-60 parts of combined composite substrate materials and an appropriate amount of composite microcrystal nucleating agent. A roasting process of the production method includes a two-stage constant-temperature roasting method and a two-stage composite crystallization synthetic reaction characteristic enhancing process, wherein the two-stage constant-temperature roasting method includes the steps of performing constant-temperature heat preservation for 10-15 hours at the temperature of 200 DEG C, and performing constant-temperature heat preservation for 10-15 hours at the temperature of 500 DEG C; and the two-stage composite crystallization synthetic reaction characteristic enhancing process includes the steps of sintering for 10-15 hours under the ordinary pressure and at the temperature ranging from 1100 DEG C to 1150 DEG C, and sintering for 20-25 hours under the ordinary pressure and at the temperature ranging from 1420 DEG C to 1430 DEG C. A refractory product produced bythe method has the advantages of excellent oxidation resistance, high refractoriness, high usage temperature, low thermal expansion coefficient, high compression strength, hypobarism, excellent heat stability, anti-strip performance and high high-temperature bending strength. The process of the method has the advantages of simple process, low cost and suitability for mass production, and is applicable to preparing kiln furniture, industrial ceramics and structural materials.

Owner:GUANGDONG REJINBAO NEW MATERIAL TECH +2

Waste sagger repairing coating and use method thereof

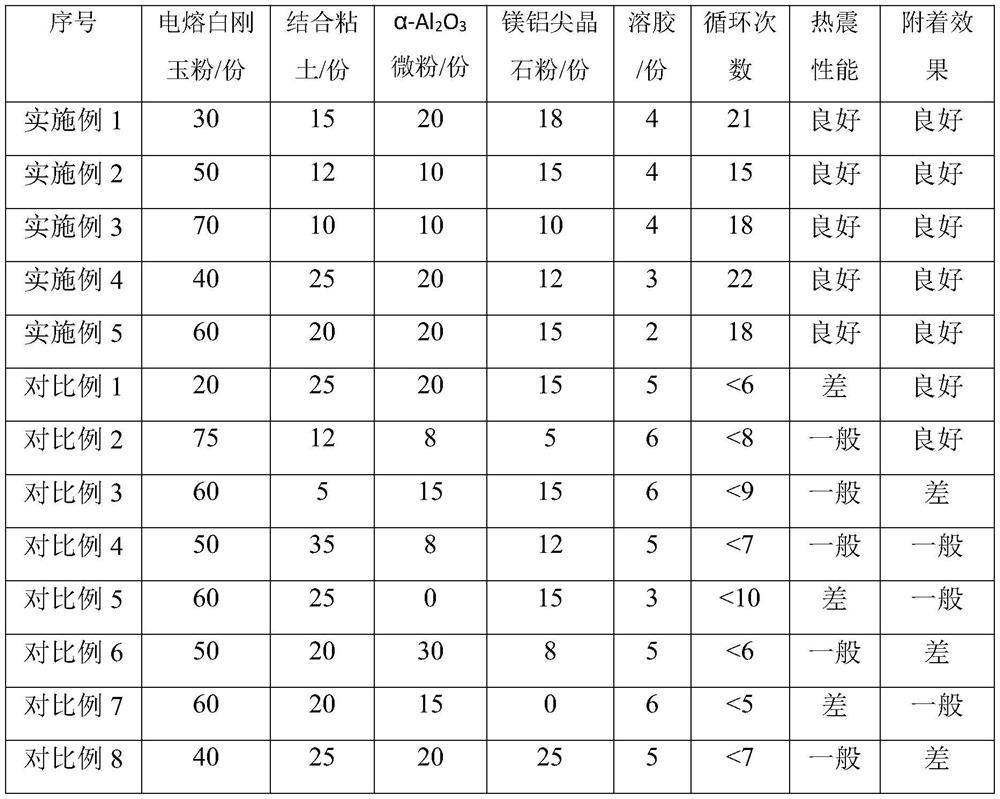

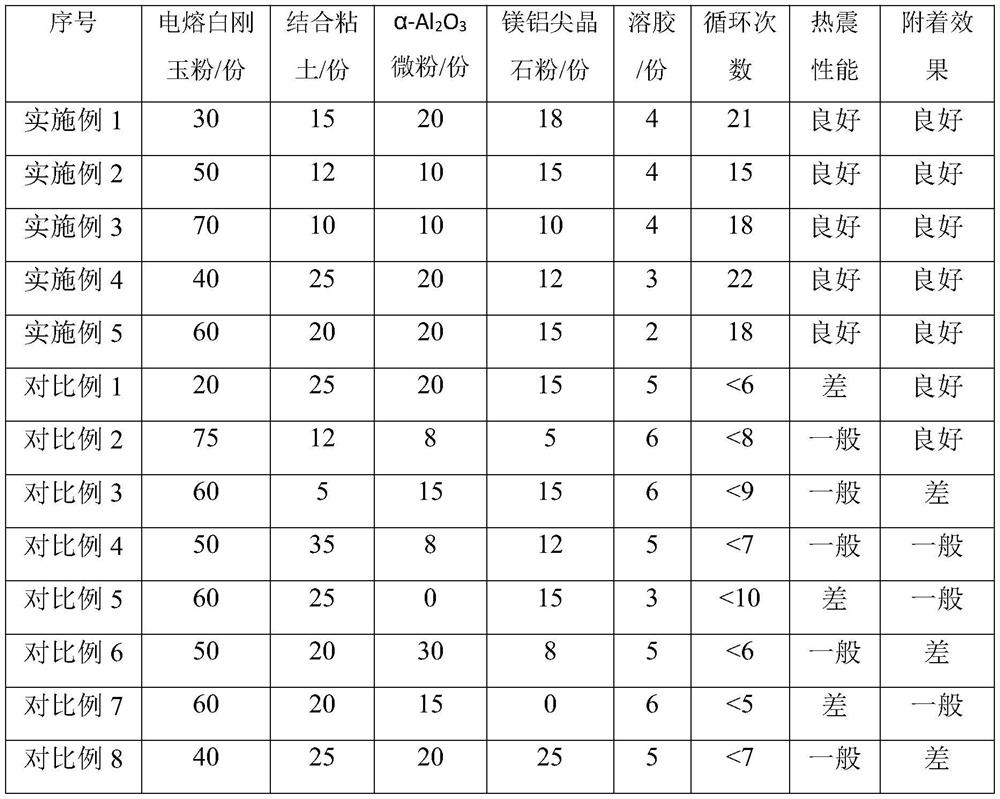

The invention provides waste sagger repairing coating and a use method thereof. The waste sagger repairing coating is prepared from the following raw material components in parts by weight: 30 to 70 parts of fused white corundum powder, 1 to 10 parts of mullite powder, 8 to 30 parts of binding clay, 0 to 5 parts of spodumene, 1 to 5 parts of zirconium oxide, 5 to 25 parts of alpha-Al2O3 micro powder, 1 to 20 parts of magnesium aluminate spinel powder, 2 to 8 parts of sol, 1 to 5 parts of a binding agent, 0.1 to 1 part of a water reducing agent and 16 to 22 parts of water. The using method of the waste sagger repairing coating comprises the steps of preparing the repairing coating, polishing a waste sagger and repairing the waste sagger to obtain a regenerated new sagger. The repaired waste saggar not only can be put into use again, but also is high in strength, high in corrosion resistance and good in thermal shock resistance. The recycling rate of the waste saggars is increased, and the problems of stacking difficulty and environmental pollution are reduced to a great extent.

Owner:CENT SOUTH UNIV

Metal-based aluminum-magnesium spinel sliding plate and preparation method thereof

PendingCN109160807AHigh mechanical strengthHigh softening point under loadSlide plateTemperature resistance

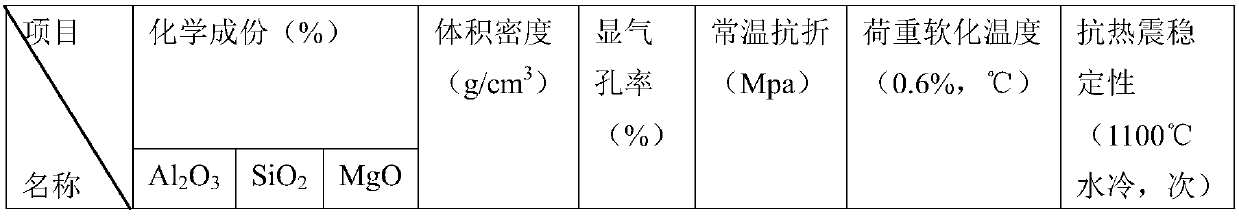

The invention discloses a metal-based aluminum-magnesium spinel sliding plate and a preparation method thereof. The metal-based aluminum-magnesium spinel sliding plate consists of a dry material and an additional binding agent; and the dry material comprises: high-purity corundum particles and fine powder, aluminum-magnesium spinel particles and fine powder, magnesia fine powder, alpha-Al2O3 finepowder and a metal powder additive. The specific preparation method comprises the following steps: firstly, taking the high-purity corundum fine powder, the magnesia fine powder, aluminum-magnesium spinel fine powder, the alpha-Al2O3 fine powder and the metal powder in the dry material to sufficiently mix so as to obtain pre-mixed powder; then taking the high-purity corundum particles and the aluminum-magnesium spinel particles to sufficiently mix, adding the binding agent into the mixed particles to remix, and then adding the pre-mixed powder into the mixture to carry out mixed milling; and carrying out ageing, forming, thermal treatment and impregnation on the obtained mixture, and then carrying out processes of drying, strapping, grinding and surface coating on the obtained semi-finished product so as to obtain the finished product. The invention provides the iron and steel smelting sliding plate which is safe and reliable and has high-temperature resistance, erosion resistance anda long service life; and the metal-based aluminum-magnesium spinel sliding plate is simple in preparation process, does not require a high temperature, and is low in production energy consumption andgood in operation environment.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

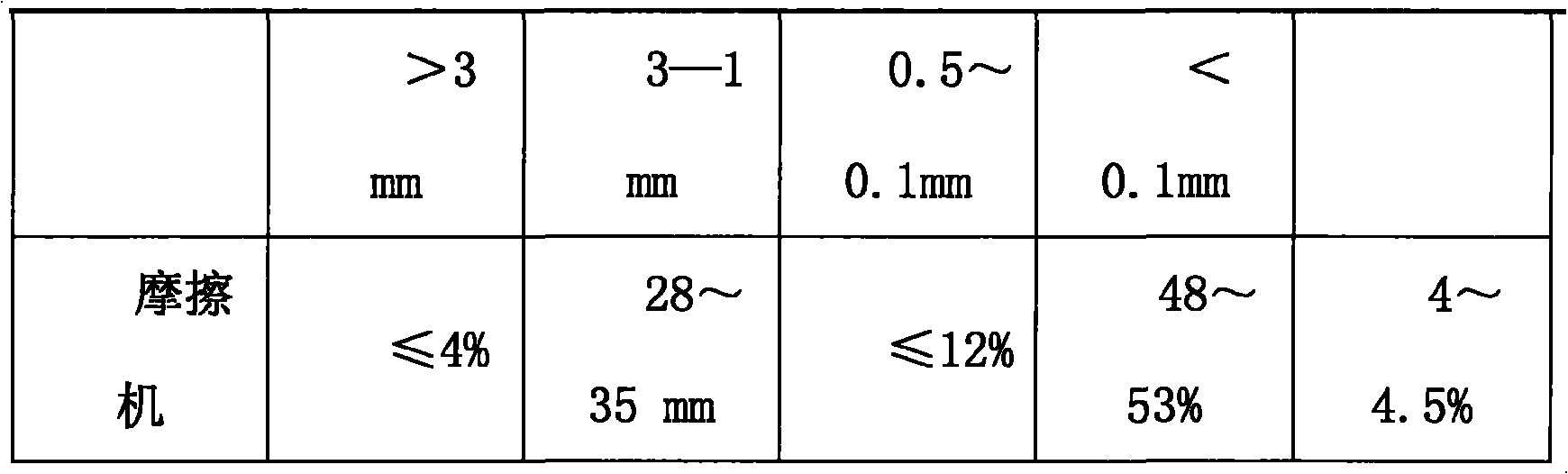

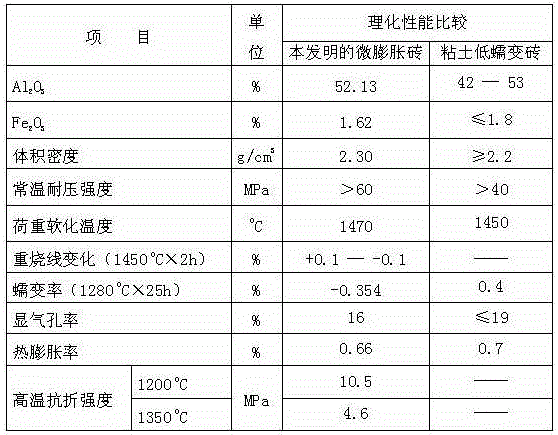

Micro-expansive brick for carbon anode baking furnace and preparation method thereof

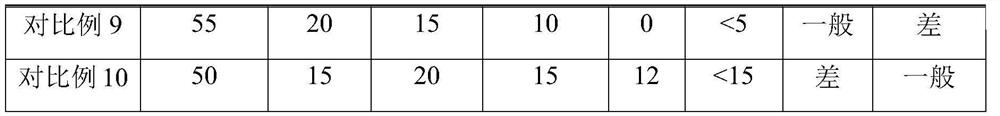

The invention discloses a micro-expansive brick for a carbon anode baking furnace and a preparation method thereof. The micro-expansive brick is prepared from the following components in percentage by weight: 6-8% of calcined bauxite clinker having the granularity of 3-5mm, 29-32% of calcined bauxite clinker having the granularity of 1-3mm, 15-20% of calcined flint clay clinker having the granularity of 0-1mm, 10-15% of Guangxi clay powder having the fineness less than or equal to 0.074mm, 14-15% of kyanite powder having the fineness less than or equal to 0.088mm, and 12-18% of calcined bauxite clinker powder having the fineness less than or equal to 0.088mm. The preparation method comprises the following steps: 1, crushing and screening the calcined bauxite clinker and the calcined flint clay clinker; 2, grinding the Guangxi clay, the kyanite and the calcined bauxite clinker; 3, mixing and stirring; 4, adding a paper pulp waste liquid and mixing; 5, pressing brick blanks; 6, drying and calcining to obtain the finished products. The prepared micro-expansive brick for the carbon anode baking furnace is low in creep rate, high in refractoriness under load, high in high-temperature bending strength and longer in service life, and therefore, the service life of the carbon anode baking furnace can be increased to the utmost extent and the maintenance cost can be reduced.

Owner:河南鑫诚耐火材料股份有限公司

Nitride bonded sandwich load bearing board and preparation method thereof

The invention relates to a nitride bonded sandwich load bearing board and a preparation method thereof, and belongs to the technical field of fireproof materials. The nitride bonded sandwich load bearing board comprises a mullite surface protection layer and a silicon nitride bonded silicon carbide middle layer, wherein the mullite surface protection layer is prepared from the following raw materials: mullite of which the coarseness is 0.2 to 1mm, mullite fine powder of which the particle size is 200 meshes, mullite of which the density is 325 meshes, clay and an organic bonding agent; the silicon nitride bonded silicon carbide middle layer is prepared from silicon carbide of which the coarseness is 1 to 3mm, silicon carbide of which the coarseness is 0.5 to 1, silicon carbide fine powder of which the coarsness is 0.5 to 1mm and the particle size is 325 meshes, silicon carbide ultrafine powder, the clay, metal silicon powder of which the particle size is 325 meshes and the organic bonding agent. According to the nitride bonded sandwich load bearing board disclosed by the invention, silicon nitride bonded silicon carbide is adopted as the middle layer, the high temperature bending strength of the silicon nitride bonded silicon carbide is high and is not reduced but increased under a high temperature, reaction between a magnetic material and the load bearing board is avoided during sintering of the magnetic material, and the service life of the load bearing board is indirectly prolonged.

Owner:宜兴市锦泰耐火材料有限公司

High-strength wear-resistant material for blast-furnace water slag flushing channel and preparation method of high-strength wear-resistant material

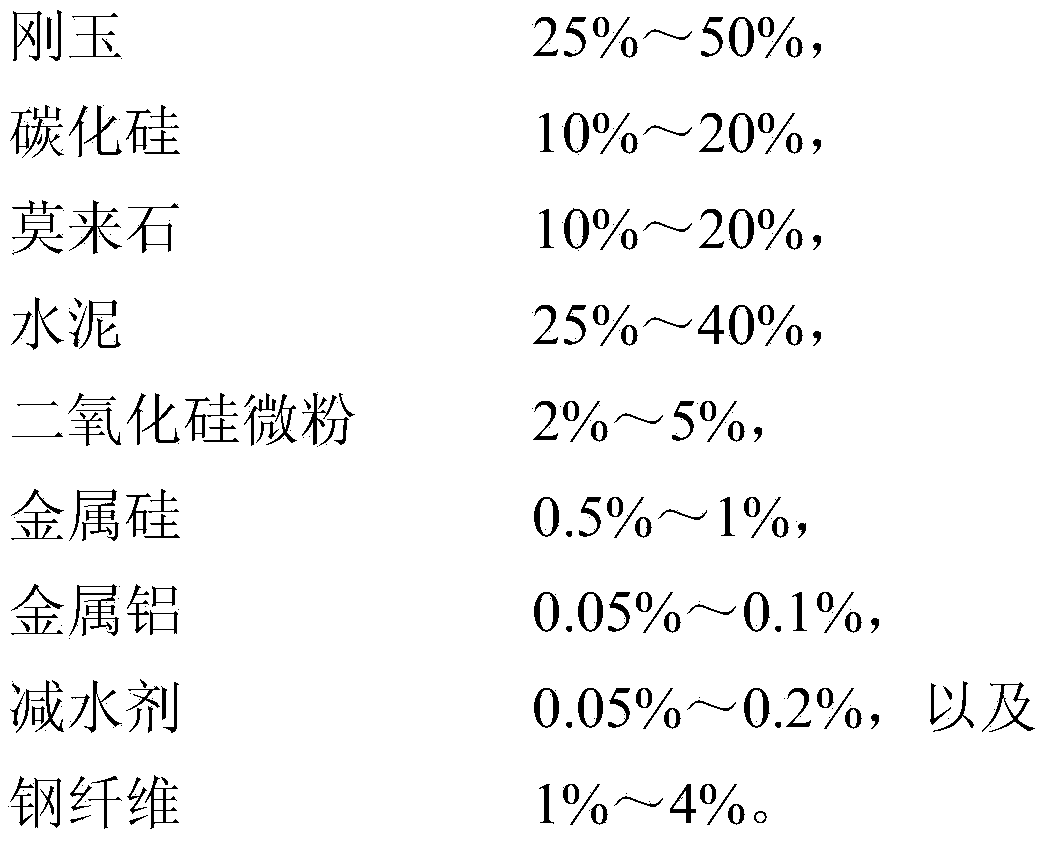

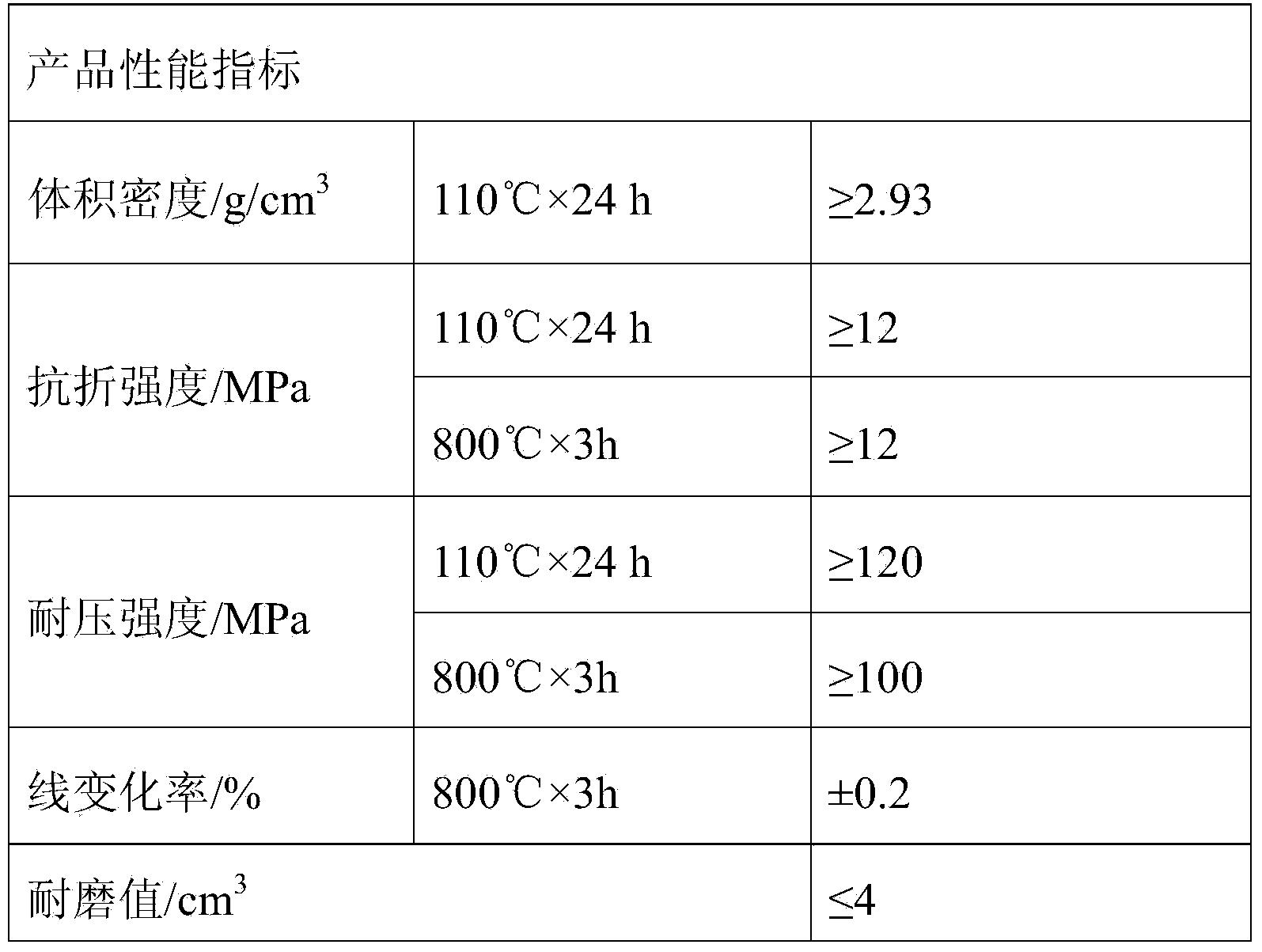

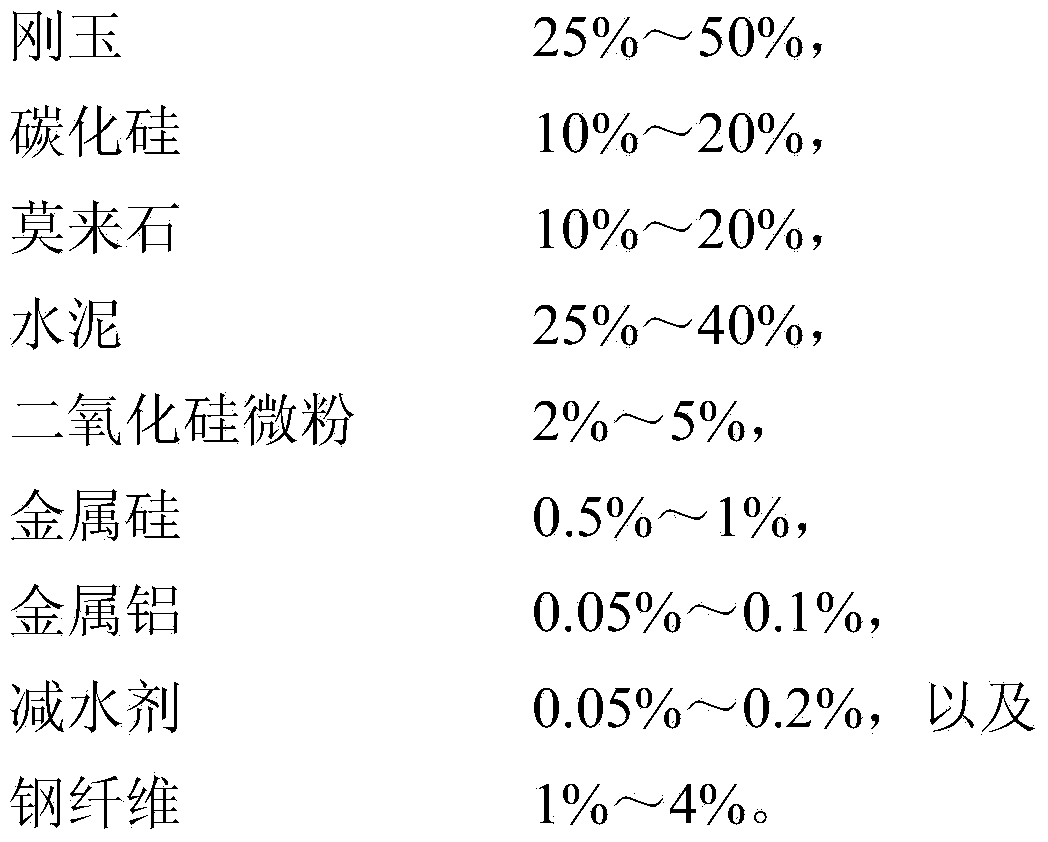

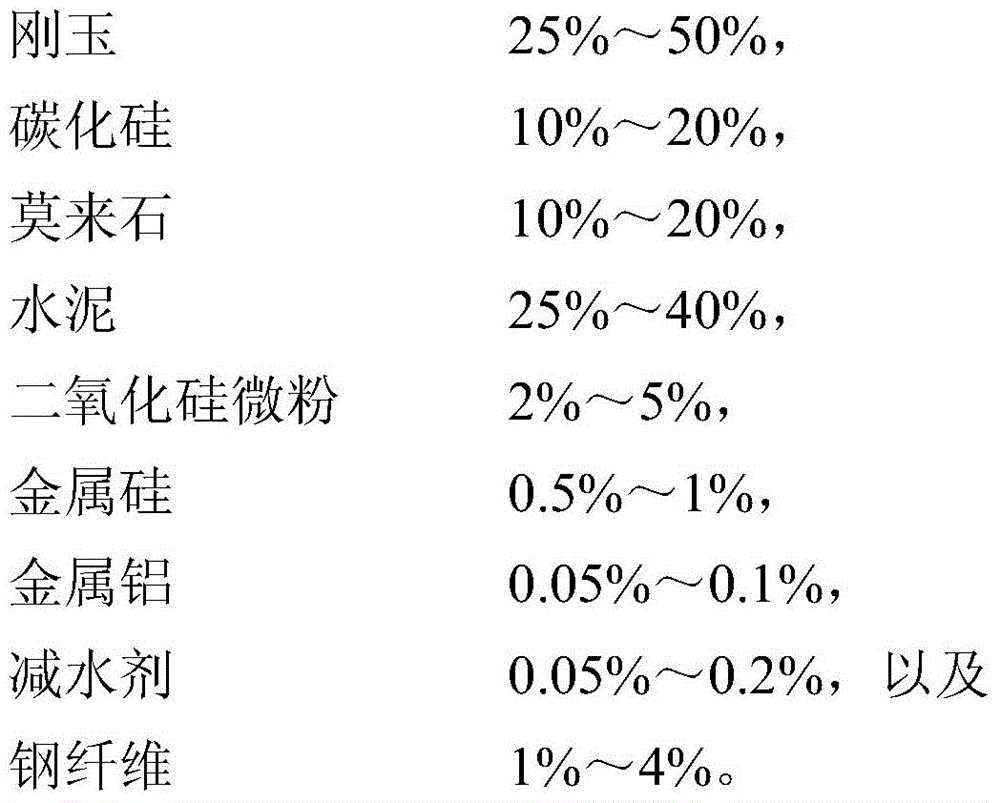

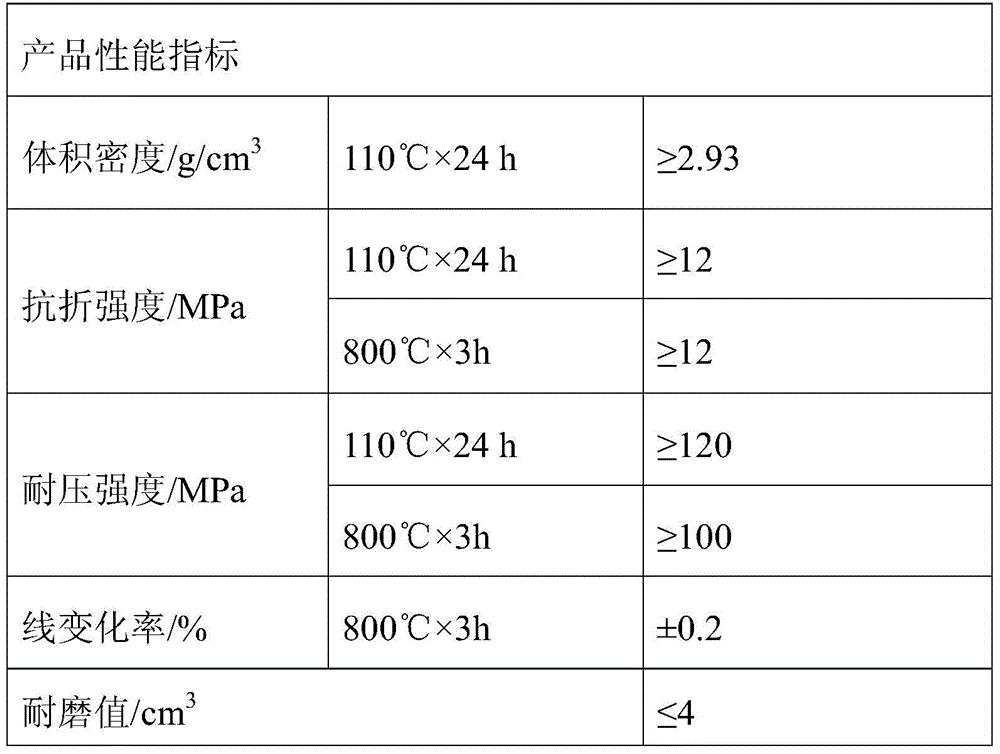

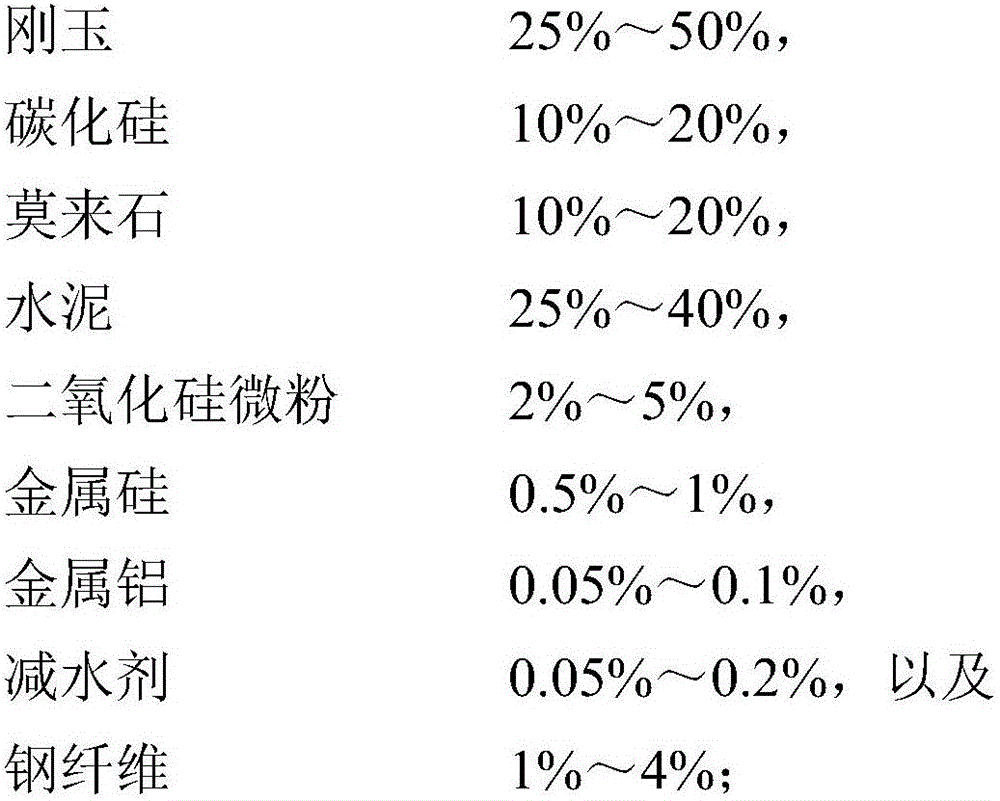

The invention provides a high-strength wear-resistant material for a blast-furnace water slag flushing channel and a preparation method of the high-strength wear-resistant material. The high-strength wear-resistant material for the blast-furnace water slag flushing channel comprises the following raw materials in percentage by weight: 25%-50% of corundum, 10%-20% of silicon carbide, 10%-20% of mullite, 25%-40% o cement, 2%-5% of silica micro-powder, 0.5%-1% of metallic silicon, 0.05%-0.1% of metallic aluminium, 0.05%-0.2% of a water reducing agent and 1%-4% of steel fiber. The high-strength wear-resistant material for the blast-furnace water slag flushing channel provided by the invention is high in applicable temperature, good in thermal shock resistance, good in abrasive resistance and long in service life.

Owner:CHINA JINGYE ENG +2

Silicon oxide heat storage ball

ActiveCN104119842AImproved thermal shock stabilityGood thermal shock resistanceHeat-exchange elementsOxidation resistantSilicon oxide

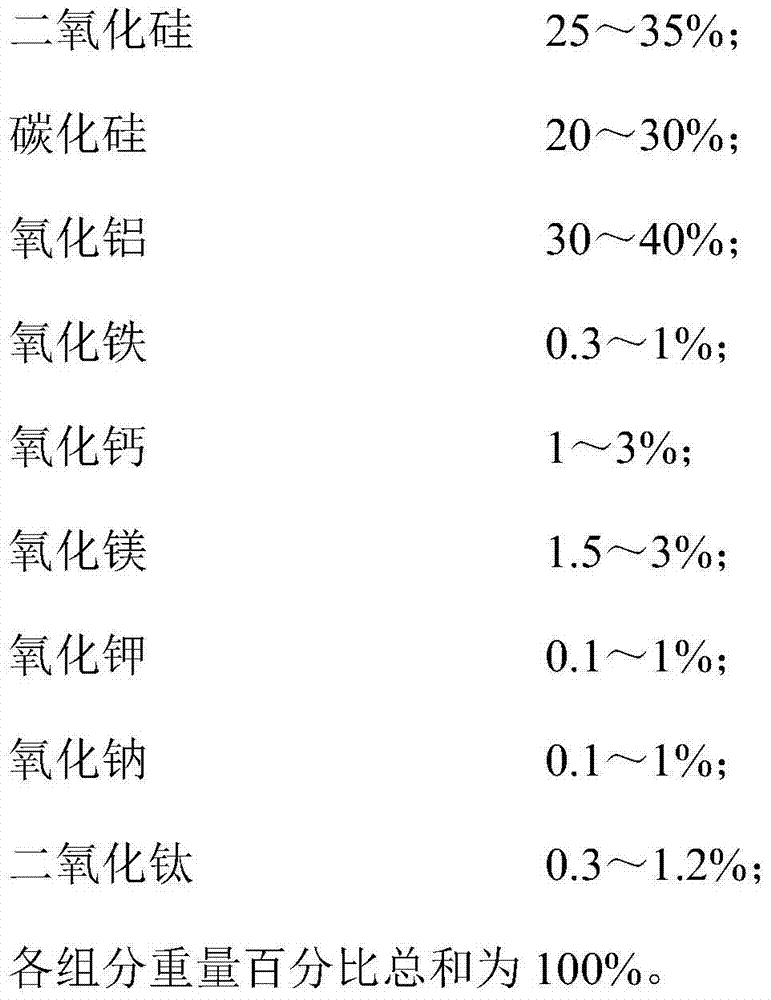

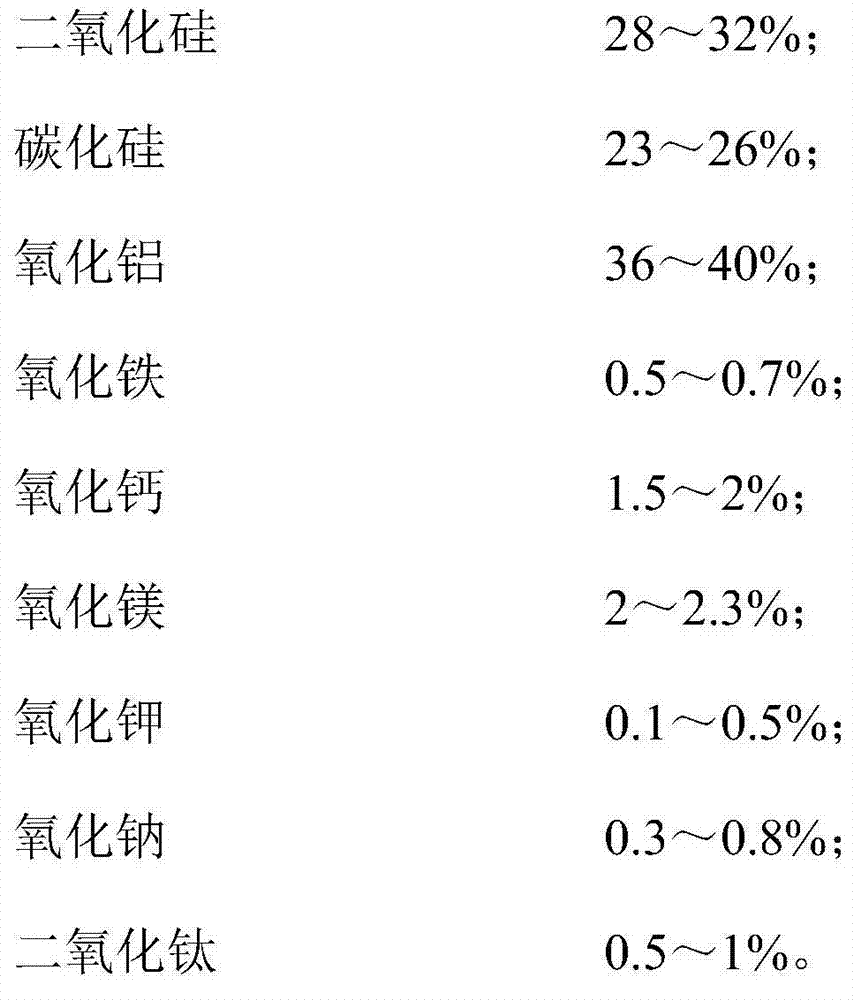

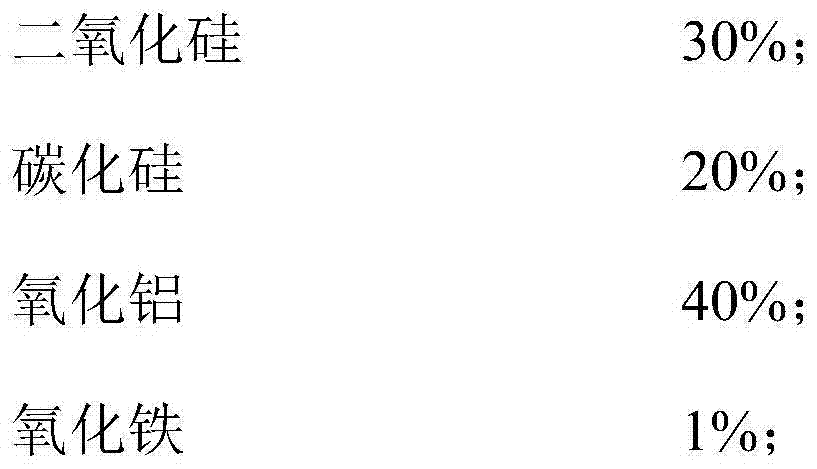

The invention discloses a silicon oxide heat storage ball which comprises the following components in percentage by weight: 25-35% of silicon dioxide, 20-30% of silicon carbide, 30-40% of aluminum oxide, 0.3-1% of ferric oxide, 1-3% of calcium oxide, 1.5-3% of magnesium oxide, 0.1-1% of potassium oxide, 0.1-1% of sodium oxide and 0.3-1.2% of titanium dioxide, totaling 100%. The silicon oxide heat storage ball disclosed by the invention has excellent performances of high density, high thermal shock resisting stability and high heat conductivity at the same time, has high strength, high hardness and good resistance to chemical corrosion and meanwhile has a good anti-oxidizing effect, so that the silicon oxide heat storage ball is particularly suitable for situations that the environment is harsh and a heat storage chamber is subjected to severe oxidation corrosion. The service life of the silicon oxide heat storage ball is 5-6 times longer than that of a heat storage body in the prior art.

Owner:长兴欧利雅磨具磨料厂

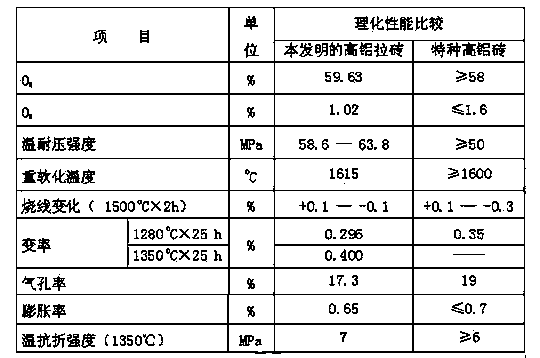

High-aluminum pull brick for carbon anode roasting furnace flame paths and preparation method thereof

The invention discloses a high-aluminum pull brick for carbon anode roasting furnace flame paths and a preparation method thereof. The high-aluminum pull brick for carbon anode roasting furnace flame paths is prepared by mixing, calcining and pressing calcined mullite, calcined high-aluminum bauxite, andalusite granules, alumina powder, Gangxi clay powder and andalusite fine powder. The preparation method comprises the following steps: 1. crushing and screening the calcined mullite and calcined high-aluminum bauxite; 2. selecting 10-16 wt% of alumina powder, 10-12 wt% of Gangxi clay powder and 15-21 wt% of andalusite fine powder, mixing and grinding; 3. mixing the co-ground powder with 8-12 wt% of calcined mullite, 17-23 wt% of calcined high-aluminum bauxite and 25-29 wt% of andalusite granules; 4. adding pulp waste, and compounding; 5. pressing to be green bricks; and 6. drying and calcining to obtain the finished product. The high-aluminum pull brick for carbon anode roasting furnace flame paths has the advantages of low creep rate, high refractoriness under load, favorable high-temperature folding strength and small physical dimension deformation, and can prolong the service life of the carbon anode roasting furnace and lower the maintenance cost.

Owner:河南鑫诚耐火材料股份有限公司

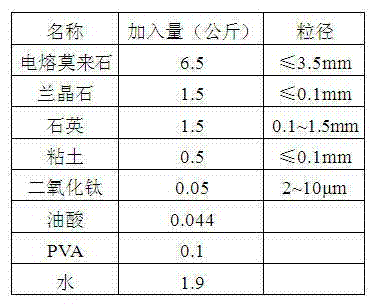

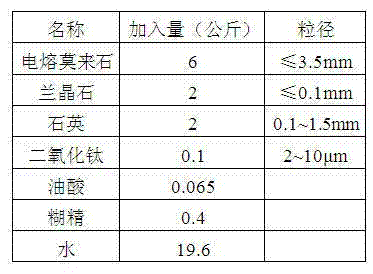

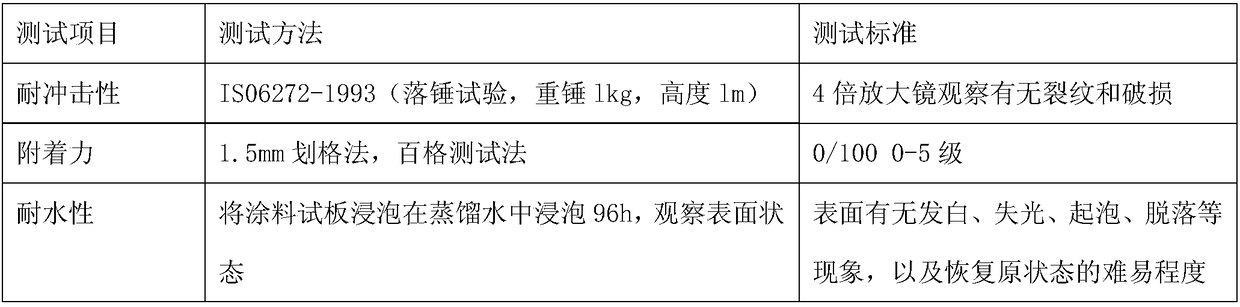

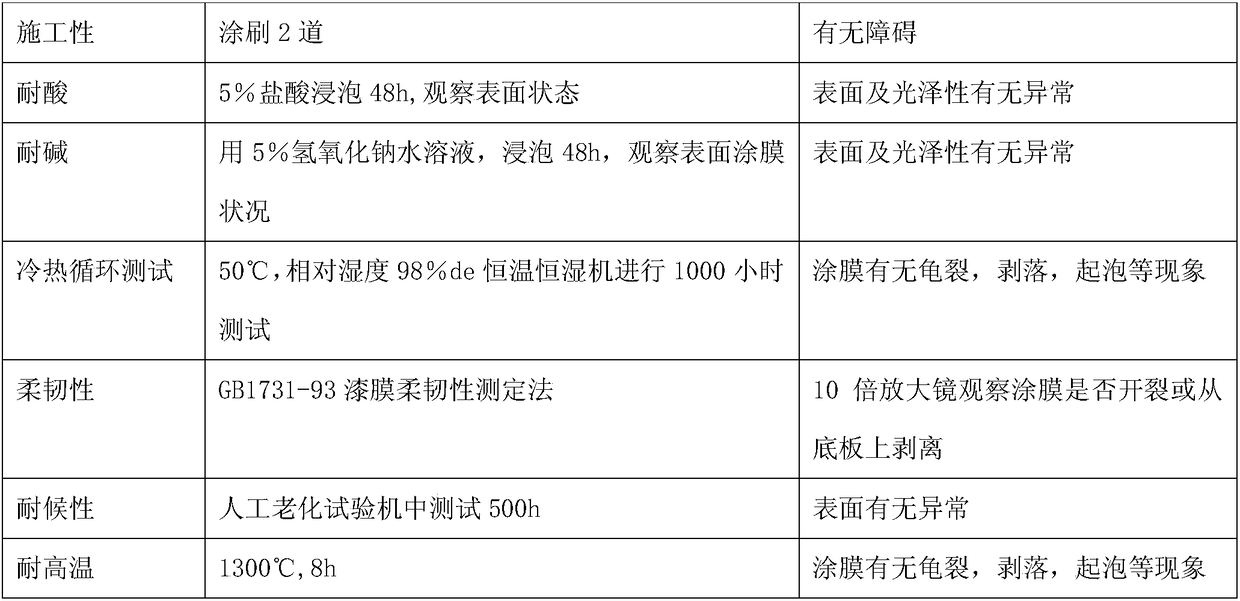

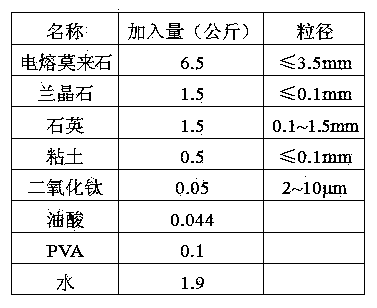

Electric cast mullite brick and preparation method thereof

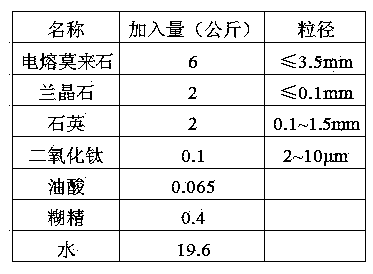

The invention relates to an electric cast mullite brick, which comprises the following raw materials with the granularity distribution in percentage by weight: 55 to 80 percent of electric cast mullite with the granularity distribution being smaller than or equal to 3.5mm, 10 to 20 percent of kyanite with the granularity distribution being smaller than or equal to 0.1mm, 10 to 20 percent of quartz with the granularity distribution being 0.1 to 1.5mm, 0 to 5 percent of clay with the granularity distribution being smaller than or equal to 0.1mm and 0 to 1 percent of titanium dioxide with the granularity distribution being 2 to 10mum. A preparation method of the electric cast mullite brick comprises the following steps that: crushing, sieving and magnetic separation are carried out; the kyanite, the quartz, the clay, the titanium dioxide and partial electric cast mullite are mixed with oleic acid and are subjected to ball milling to obtain ball milling materials; bonding agents are dissolved in water to be mixed with the rest electric cast mullite to obtain particle materials; the ball milling materials and the particle materials are mixed and are subjected to mixed milling, aging decaying and secondary mixing; green bricks are obtained through pressure forming, and the green bricks are dried and fired. The electric cast mullite brick and the preparation method have the advantages that the process is simple, the cost is low, the operability is high, and the obtained electric cast mullite brick body has high density, good acid resistance, high normal-temperature bending-resistant intensity and excellent thermal shock stability.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Method of improving high-temperature strength of integral alumina-based ceramic mold through chemical vapor infiltration

ActiveCN106083205AImprove high temperature strengthHigh temperature strengthCeramicwareChemical reactionSurface layer

The invention discloses a method of improving high-temperature strength of an integral alumina-based ceramic mold through chemical vapor infiltration, and belongs to the field of photocuring forming technology quick casting. The method includes the steps that 1, a resin mold is manufactured through the photocuring quick forming technology; 2, ceramic slurry is poured into a resin mold prototype of turbine blades through a gelcasting method to obtain a cast blank; 3, a porous alumina-based ceramic mold is obtained after vacuum freeze drying and ungrease treatment; 4, the alumina-based ceramic mold is subjected to chemical vapor infiltration, SiO2 generated after pyrolytic reaction of a silicon source precursor and matrix alumina react chemically to generate high-temperature strengthened phase mullite, the pore structure of the mold is filled with SiC generated through the pyrolytic reaction, a functional gradient material with the porosity gradually improved from the surface layer to the core part of the mold, and the porosity of the mold is reduced to improve the high-temperature strength of the mold. The method is reasonable in design and convenient to operate, and the high-temperature strength of the alumina-based ceramic mold is enhanced remarkably.

Owner:XI AN JIAOTONG UNIV

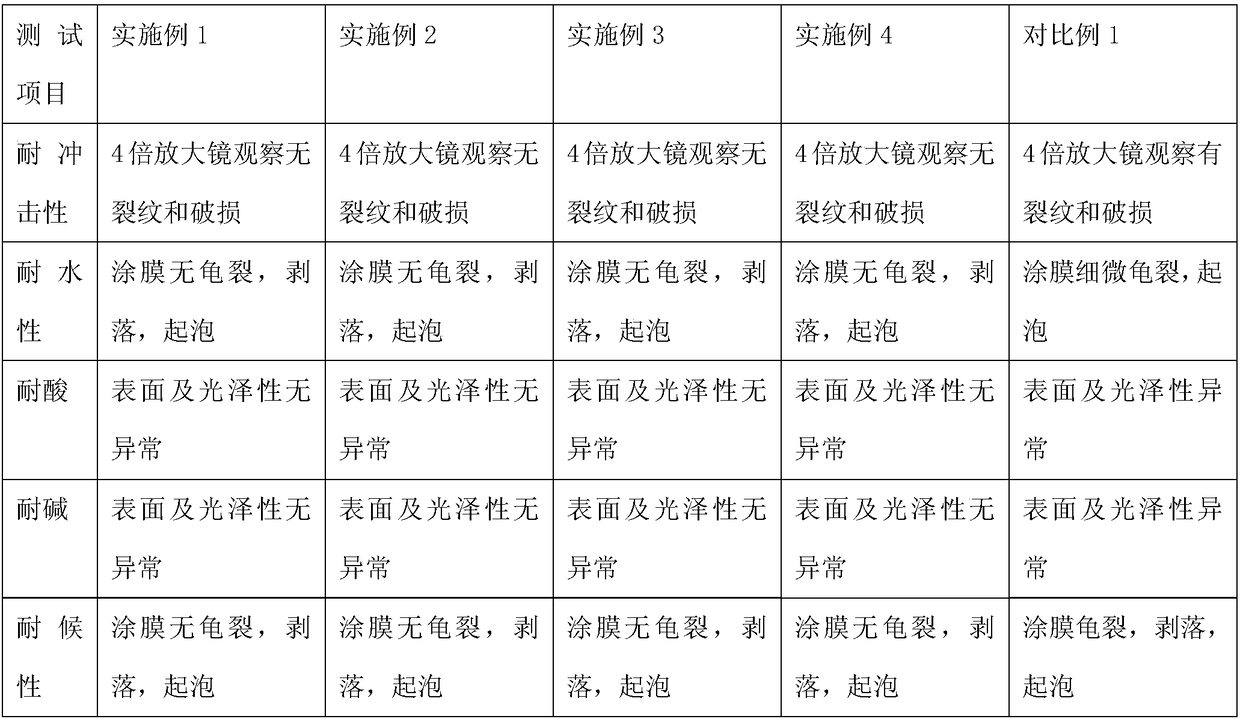

Weatherproof inorganic exterior wall coating based on graphene and mullite and preparation method thereof

ActiveCN109206948ADoes not fall offWaterproofFireproof paintsAntifouling/underwater paintsMulliteFire prevention

The invention relates to a weatherproof inorganic exterior wall coating based on graphene and mullite and a preparation method thereof, and belongs to the field of graphene-based wall inorganic coatings. The weatherproof inorganic exterior wall coating includes the following components by the mass percentage: 5-15% of mullite, 6-15% of perlite, 1-20% of graphene, 2-10% of vitrified micro-beads, 3-10% of sepiolite, 6-15% of albite, 5-18% of light calcium carbonate, 5-10% of bauxite, 2-8% of nano titanium dioxide, 10-15% of nano-silica sol, 20-30% of an auxiliary agent, and 3-6% of a pure acrylic emulsion. The coating has the advantages of strong bonding strength, simple construction and scouring resistance. At the same time, under high temperature conditions, a coating layer is not blistered and cracked or does not fall off, and plays the effects of water prevention, fire prevention, salt resistance, alkali resistance, heat insulation, heat preservation, corrosion prevention, rust prevention and aging resistance.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

High-strength abrasive brick for aviation garbage furnace

ActiveCN101303128APure white appearanceSmall sizeCasings/liningsIncinerator apparatusPorosityAviation

The invention discloses a brick with high strength abrasion performance and used in an aero garbage incinerator, composing of 25% to 37 % of 3 mm to 1 mm of mullite, 8% to 10 % of 1 mm to 0.1 mm of mullite, 23% to 25 % of mullite less than 0.1 mm, 10% to 12 % of 1 mm to 0.074 mm of brown fused alumina or white fused alumina, 10% to 12 % of brown fused alumina or white fused alumina less than 0.074 mm, 1% to 2% of micro powder of alpha-Al2O3 less than 5Mum, 1% to 2% of micro powder of silicon less than 1 mm and 10% to 12% of industrial phosphoric acid by mass percent, and has low porosity, good creep property and strong resistance to heat shock and corrosion, thereby being applicable to the abrasive backing of high-temperature industrial furnaces such as circulating fluidized bed and flame boiler, etc.

Owner:浙江圣奥耐火材料有限公司

Saggar for roller kiln for soft ferromagnet production and preparation method of saggar

InactiveCN109574644AImproved thermal shock stabilityHigh softening point under loadCharge supportsCeramicwareActivated Aluminum OxideAluminium oxide

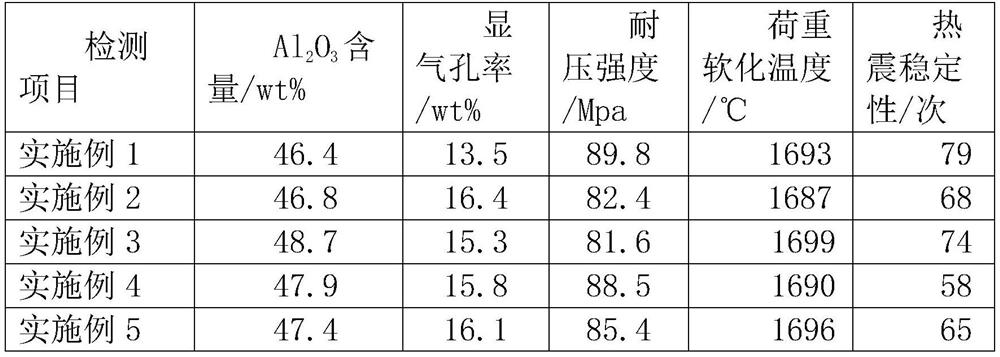

The invention discloses a saggar for a roller kiln for soft ferromagnet production and a preparation method of the saggar. The saggar is prepared from, by weight, 30-50 parts of sintered mullite, 10-20 parts of andalusite, 0.1-1 part of zirconium oxide fibers, 1-5 parts of kaolin, 15-25 parts of low-sodium aluminum oxide, 5-10 parts of activated aluminum oxide, 10-20 parts of aluminum-rich spinel,0.2-0.6 part of dextrin and 0.2-0.8 part of calcium lignosulfonate. The saggar is high in thermal shock resistance stability and high in refractoriness under load, the surface SiO2 content of the saggar can be reduced, and reaction between the saggar and soft ferromagnet is reduced; according to utilization in a soft ferromagnet calcining kiln, no adverse reaction is caused to products, deformation in a utilization process is avoided, and in a late utilization period, although small cracks probably occur, the saggar is high in integral strength and still can be used, and the service life is prolonged from 3 months to 5 months; in addition, the preparation method is simple, feasible and easy to implement.

Owner:无锡顺佳特种陶瓷有限公司

Preparation method of high-temperature volume-stable riser material

InactiveCN107010970AUniform expansionImproved thermal shock stabilityGlass making apparatusFilament/thread formingFiberThermal insulation

The invention discloses a preparation method of a high-temperature volume-stable riser material and belongs to the technical field of casting techniques. The method comprises the steps of firstly preparing a precursor sol from tetraethoxysilane and aluminum nitrate; preparing a spinning fiber from the precursor sol through an electrostatic spinning device and carrying out drying and calcining treatment to obtain a calcined modified mullite fiber; cleaning and airing magmatite, grinding, sieving, collecting magmatite powder, smelting and carrying out drawing treatment by using a glass rod to obtain molten magmatite silk, cooling to obtain a magmatite fiber; and carrying out mixed-grinding on the magmatite fiber, magnesium oxide and the calcined modified mullite fiber, mixing with magnesium chloride and carrying out sinter molding to obtain the high-temperature volume-stable riser material. The prepared riser material has the characteristics of being excellent in thermal insulation property, good in volume stability in a high-temperature state, stable in chemical property and convenient in aftertreatment, the yield of a cast part can be effectively improved and the mechanical property of the cast part can be improved.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

High-strength thermal-shock-resistant wear-resistant silicon mullite brick and production process thereof

InactiveCN112479693AHigh softening point under loadImprove thermal shock resistanceCeramicwareCarbide siliconBrick

The invention belongs to the technical field of silicon mullite bricks, and particularly relates to a high-strength thermal-shock-resistant wear-resistant silicon mullite brick and a production process thereof. The high-strength thermal-shock-resistant wear-resistant silicon mullite brick comprises 10-40wt% of natural sintered mullite particles; 5-40 wt% of andalusite particles; 3-20wt% of siliconcarbide particles; 3-15 wt% of andalusite fine powder; 3-10wt% of sillimanite fine powder; 3-6 wt% of Suzhou mud; 5-10 wt% of mullite fine powder; 5-15 wt% of silicon carbide powder; and 0.5-1.5 wt%of dextrin. The high-strength thermal-shock-resistant wear-resistant silicon mullite brick and the production process thereof have the effects of high refractoriness under load, low creep deformationand high thermal shock resistance.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Weather-resistant inorganic exterior wall paint based on graphene and mullite and preparation method thereof

ActiveCN109206948BDoes not fall offWaterproofFireproof paintsAntifouling/underwater paintsMulliteMaterials science

The invention relates to a weather-resistant inorganic exterior wall coating based on graphene and mullite and a preparation method thereof, and belongs to the field of inorganic wall coatings based on graphene. ~15%, graphene 1~20%, vitrified microbeads 2~10%, sepiolite 3~10%, albite 6~15%, light calcium carbonate 5~18%, bauxite 5~ 10%, nano-titanium dioxide 2-8%, nano-silica sol 10-15%, additives 20-30%, pure acrylic emulsion 3-6%. The coating has strong bonding strength, simple construction, and the coating is resistant to washing. At the same time, under high temperature conditions, the coating does not bubble, crack, or fall off, and has the functions of waterproof, fireproof, salt resistance, alkali resistance, heat insulation, anti-corrosion, anti-rust, and anti-aging.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

High-strength abrasive brick for aviation garbage furnace

ActiveCN101303128BPure white appearanceSmall sizeCasings/liningsIncinerator apparatusAviationPorosity

Owner:浙江圣奥耐火材料有限公司

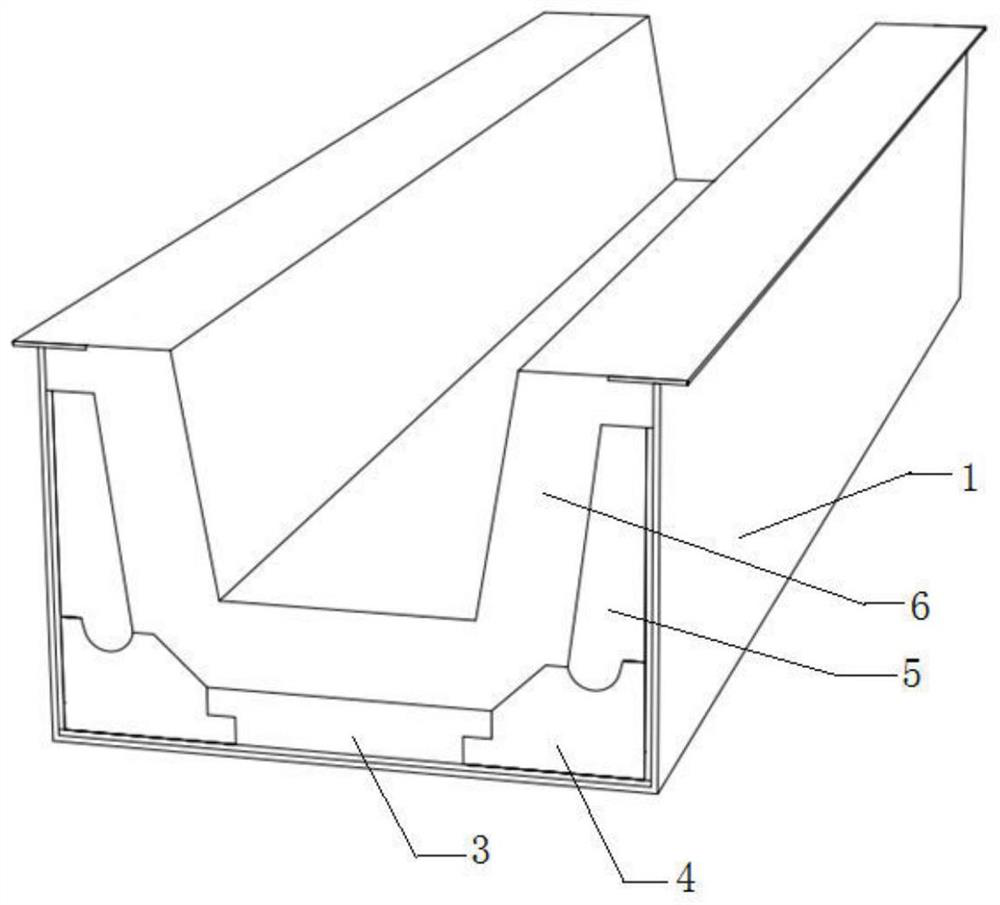

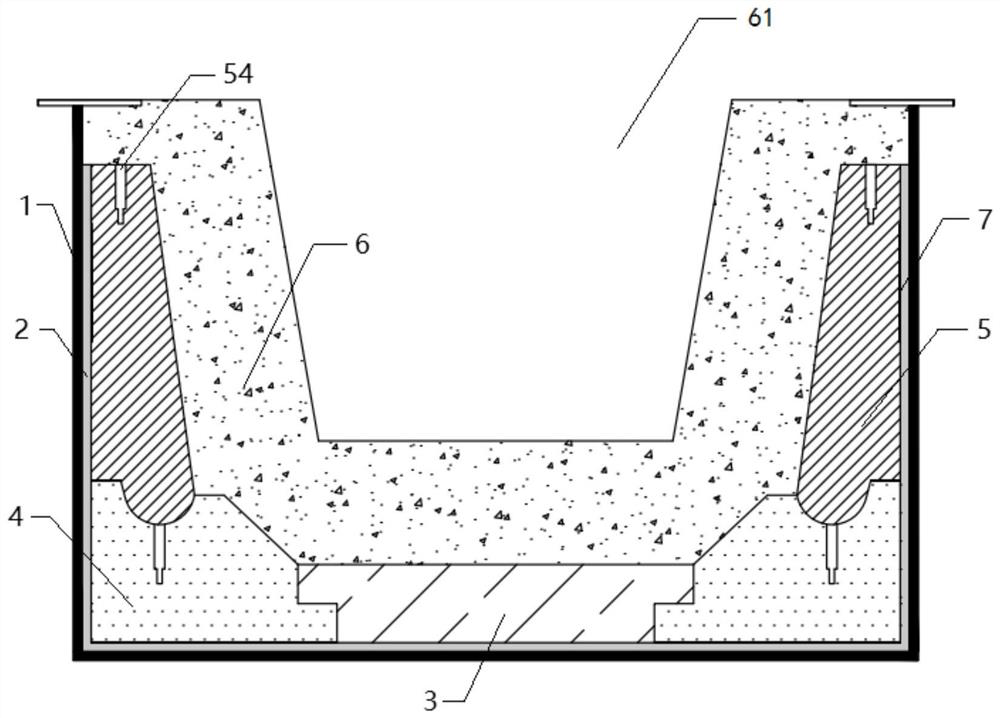

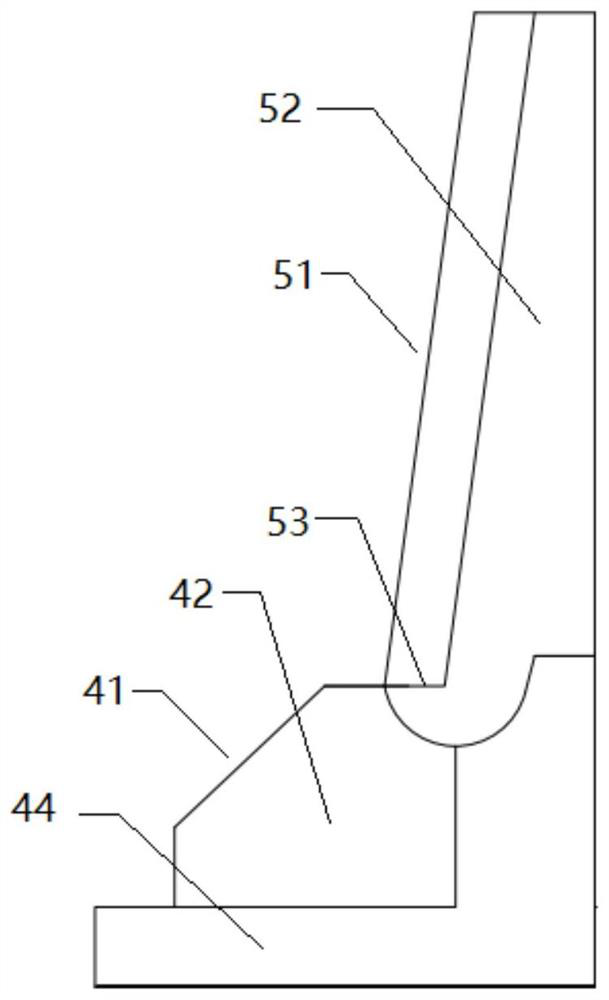

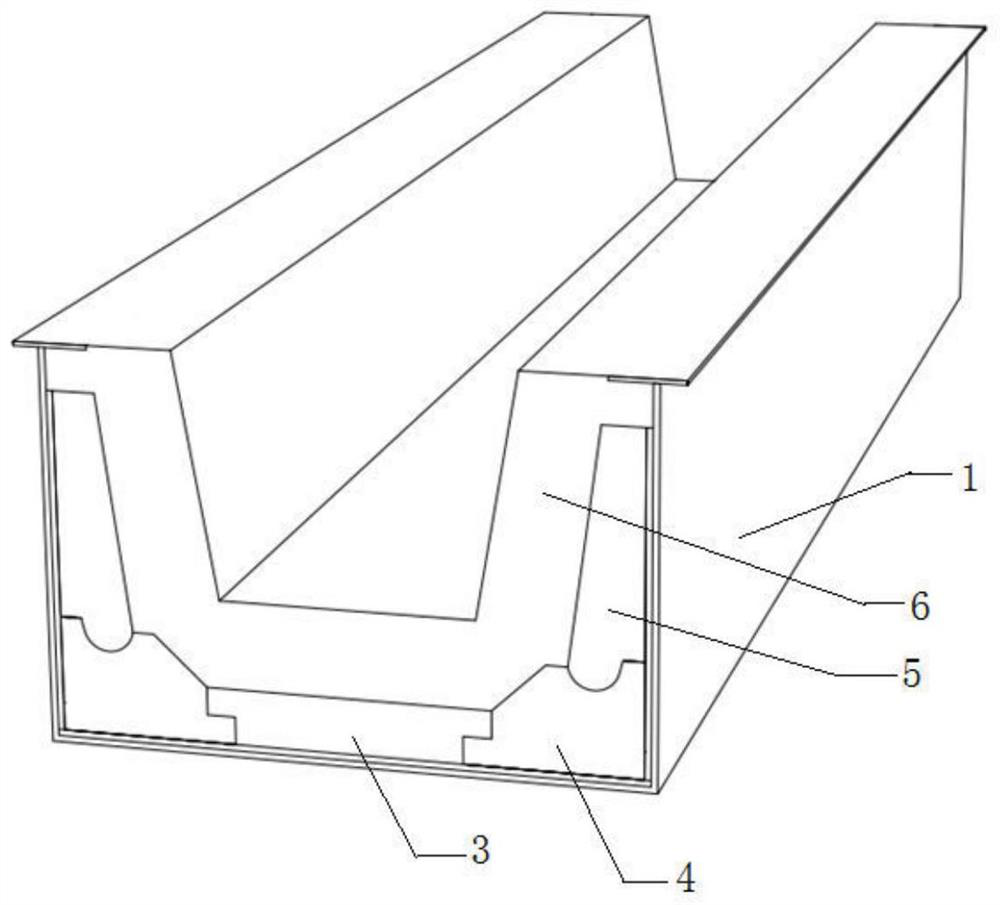

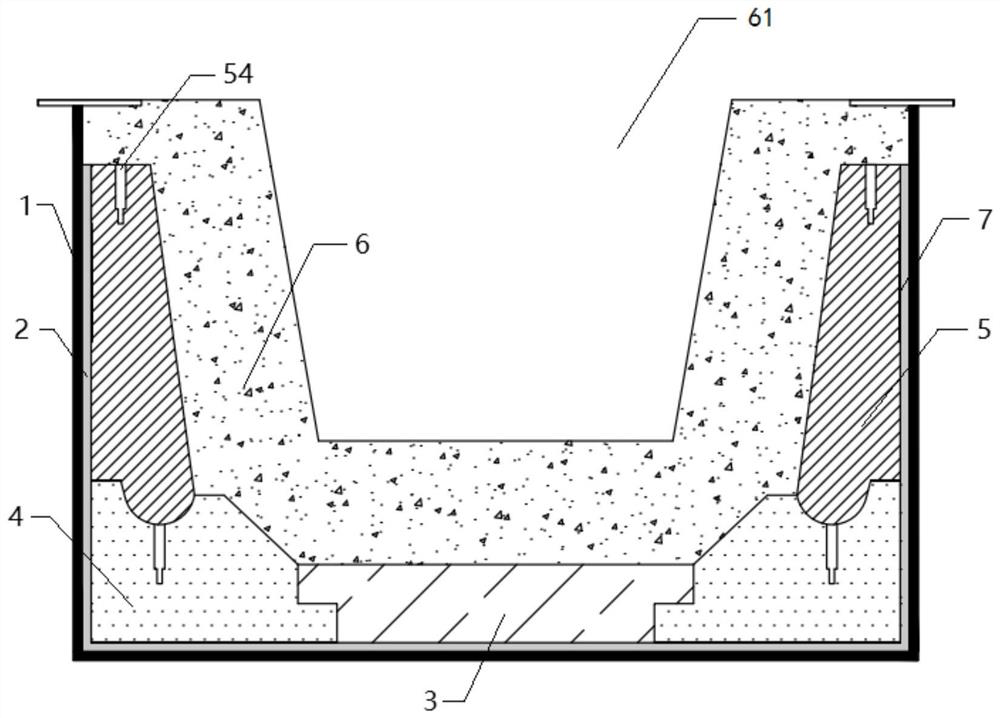

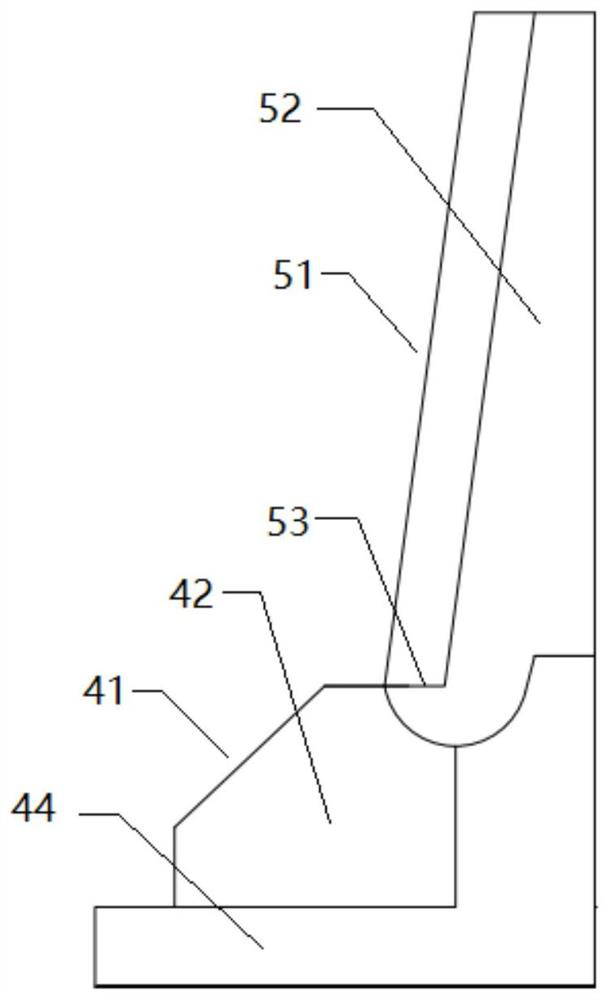

A new type of prefabricated iron ditch and its preparation method

ActiveCN112359157BIntuitive grasp of security statusMaster the security situationBlast furnace detailsCeramic shaping apparatusEngineeringStructural engineering

The invention discloses a new type of prefabricated iron trough, which comprises an outer steel shell, a permanent layer and a working layer arranged in the outer steel shell, the permanent layer includes a permanent pouring layer, a prefabricated base and a prefabricated side plate, and the working layer is arranged on the permanent pouring layer, In the space enclosed by the prefabricated base and the prefabricated side panels, the prefabricated side panels and the prefabricated base are plugged and fixed, the lower end of the prefabricated side panels is provided with arc-shaped protrusions, and the prefabricated base is provided with matching arc-shaped protrusions. Arc groove. The invention also discloses a method for preparing a novel prefabricated iron trough. The process of the invention is simple, and the prepared novel prefabricated iron trough can effectively block the molten material passing through the working layer, greatly reducing safety risks, and the replacement is convenient and time-consuming. During the process, the normal switching and use of the tap trough will not be affected at all.

Owner:YIXING REFRACTORY EQUIP & MATERIAL FACTORY +1

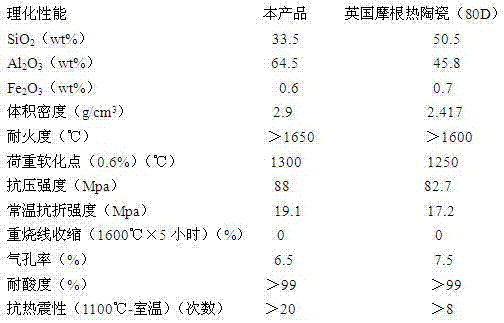

A kind of in-situ synthesis mullite whisker toughened 90 alumina ceramics and its preparation method

ActiveCN106167413BWiden the scope of selectionStimulating developmental effectsPolyvinyl alcoholAdhesive

The invention discloses a preparation method of an in-situ synthesized mullite whisker toughened 90 alumina ceramic. The method consists of: taking 85-95wt% of highly dispersed alpha-alumina powder and 5-15wt% of highly dispersed silicon dioxide powder as the raw materials, adopting aluminum fluoride trihydrate powder accounting for 4-18% of the weight of the raw materials and dry basis titanium dioxide accounting for 0.5-3% of the weight of the raw materials as the catalysts, mixing the raw materials with the catalysts, then using water as the medium to perform ball-milling so as to form an Al2O3-SiO2 precursor containing AlF3 and TiO2, then adding polyvinyl alcohol accounting for 1-3% of the weight of the raw materials to serve as the adhesive, conducting mixing, then employing spray drying process to perform granulation and ageing, then conducting isostatic pressing dry process forming, and performing high temperature firing so as to obtain the mullite whisker toughened 90 alumina ceramic. According to the invention, adding of expensive whiskers is unnecessary, a complicated dispersion process of additional adding of whiskers is omitted, also the preparation process is simple, the obtained whiskers have large length, high length-diameter ratio and uniform dispersion, and the method is suitable for industrial production.

Owner:江西省工业陶瓷工程技术研究中心

Novel prefabricated iron tap channel and preparation method thereof

ActiveCN112359157AReduce security risksImprove safety performanceCeramic shaping apparatusBlast furnace detailsStructural engineeringManufacturing engineering

The invention discloses a prefabricated iron tap channel. The novel prefabricated iron tap channel comprises an outer steel shell, a permanent layer and a working layer, wherein the permanent layer and the working layer are arranged in the outer steel shell, the permanent layer comprises a permanent pouring layer, a prefabricated base and prefabricated side plates, the working layer is arranged ina space defined by the permanent pouring layer, the prefabricated base and the prefabricated side plates, and the prefabricated side plates are fixedly connected with the prefabricated base in an inserted mode; arc-shaped protrusions are arranged at the lower ends of the prefabricated side plates, and arc-shaped grooves matched with the arc-shaped protrusions are formed in the prefabricated base.The invention further discloses a preparation method of the novel prefabricated iron tap channel. The preparation method is simple in process. The prepared novel prefabricated iron tap channel blocksmelts penetrating the working layer effectively, so that the safety risk is reduced greatly. The novel prefabricated iron tap channel is convenient to replace and short in time. Normal switching useof the iron tap channel is not affected completely in a maintenance repair process.

Owner:YIXING REFRACTORY EQUIP & MATERIAL FACTORY +1

Coating for oxygen lance of nonferrous smelting furnace

The invention discloses a coating for an oxygen lance of a nonferrous smelting furnace. The coating for the oxygen lance of the nonferrous smelting furnace consists of the following raw materials in percentage by weight: 5 to 15 percent of 3 to 5mm waste alumina-chrome bricks, 5 to 15 percent of 1 to 3mm waste alumina-chrome bricks, 5 to 15 percent of 3 to 5mm tabular corundum, 5 to 15 percent of 1 to 3mm tabular corundum, 40 to 50 percent of tabular corundum of less than 0.088mm, 8 to 15 percent of chromium oxide green of less than 0.044mm, 3 to 8 percent of pure calcium aluminate cement, 2.5 to 5 percent of alpha-Al2O3 micropowder of less than 0.044mm and 8 to 10 percent of bonding agent. The coating is small in thermal expansion coefficient difference and high in erosion scouring resistance and thermal shock stability, and the current situations of high oxidation rate and high erosion speed of the oxygen lance can be remarkably improved, so that the service life of the oxygen lance is greatly prolonged, and the comprehensive cost of the oxygen lance is lowered.

Owner:河南瑞泰耐火材料科技有限公司

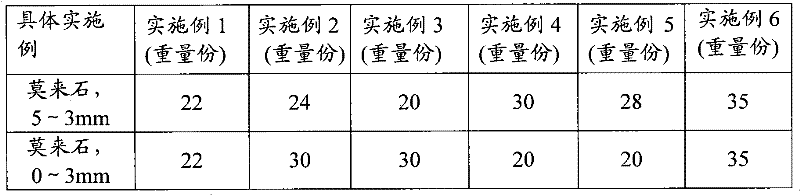

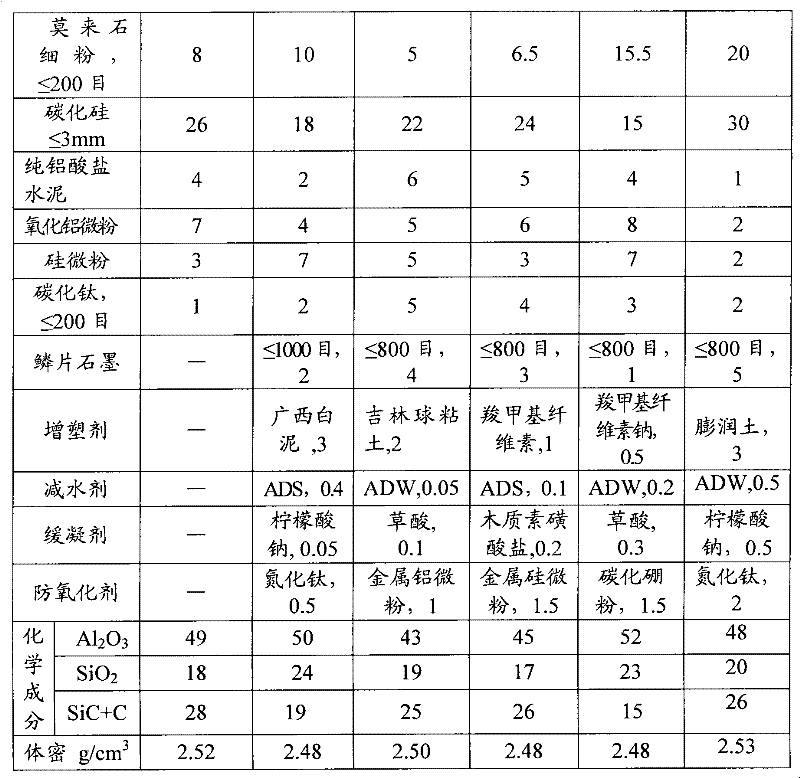

Torpedo can spouting material and spouting method thereof

ActiveCN102040386BHigh hardnessImprove thermal shock resistanceMelt-holding vesselsChemical compositionMullite

The invention provides a torpedo can spouting material and a spouting method thereof. The torpedo can spouting material comprises the following components in parts by weight: 20-35 parts of mullite particles with the particle size of 3-5mm, 20-35 parts of mullite particles with the particle size of 0-3mm, 5-20 parts of mullite fine powder not greater than 200 meshes, 15-30 parts of silicon carbide with the particle size not greater than 3mm, 1-6 parts of pure aluminate cement, 2-8 parts of aluminum oxide micro powder not greater than 320 meshes, 2-7 parts of silicon micro powder and 1-5 partsof titanium carbide not greater than 200 meshes; and the torpedo can spouting material mainly comprises the following chemical components in percentage by weight: 40-65% of Al2O3, 15-25% of SiO2 and 15-30% of SiC+C. The invention also further provides the spouting method of the spouting material. The torpedo can spouting material provided by the invention has favorable corrosive resistance and antioxidation.

Owner:PUYANG REFRACTORIES GRP CO LTD

High temperature ceramic fiber membrane microfiltration tube

ActiveCN107216134BHigh mechanical strengthImprove heat resistanceDispersed particle filtrationUltrafiltrationCelluloseFiber

The invention discloses a high temperature ceramic fiber membrane microfiltration tube which is prepared by the following steps: main materials mullite, alumina, titanium aluminum carbide, zirconium oxide, potassium feldspar and walnut shell powder are mixed in a kneader, carboxymethyl cellulose and vegetable oil are added for mixing, a blank is extruded and dried, fired at 1350 DEG C under heat insulation, and cooled to obtain a supporting tube body for standby use; zirconia aluminosilicate ceramic fiber, aluminum titanate, mullite, magnesium oxide, cerium oxide and feldspar are mixed evenly in kneader to obtain a mixture, and an additive is added into the mixture to obtain a film material to form a fiber membrane on the outer surface of the supporting tube body by high temperature firing. The high temperature ceramic fiber membrane microfiltration tube has high mechanical strength and thermal denaturation, membrane layer micro pore distribution is good, specific surface area is large, pore connectivity is good, filtering accuracy can reaches 0.1 mum, the service life is increased by more than 30%, the dust removal efficiency reaches 99.99%, and the dust concentration after filteration is less than 10mg / Nm3, and is far better than that of the national standard.

Owner:萍乡市三盈科技有限公司

Wear-resistant material for flushing slag ditch of high-strength blast furnace and preparation method thereof

The invention provides a high-strength wear-resistant material for a blast-furnace water slag flushing channel and a preparation method of the high-strength wear-resistant material. The high-strength wear-resistant material for the blast-furnace water slag flushing channel comprises the following raw materials in percentage by weight: 25%-50% of corundum, 10%-20% of silicon carbide, 10%-20% of mullite, 25%-40% o cement, 2%-5% of silica micro-powder, 0.5%-1% of metallic silicon, 0.05%-0.1% of metallic aluminium, 0.05%-0.2% of a water reducing agent and 1%-4% of steel fiber. The high-strength wear-resistant material for the blast-furnace water slag flushing channel provided by the invention is high in applicable temperature, good in thermal shock resistance, good in abrasive resistance and long in service life.

Owner:CHINA JINGYE ENG TECH CO LTD +2

A kind of waste and old sagger restoration paint and its application method

The invention provides a waste and old sagger restoration paint and a method for using the same. The waste and old sagger restoration paint comprises the following raw material components in parts by weight: 30-70 parts of fused white corundum powder, 1 part-70 parts of mullite powder 10 parts, bonded clay 8-30 parts, spodumene 0-5 parts, zirconia 1-5 parts, α-Al 2 o 3 5-25 parts of fine powder, 1-20 parts of magnesium aluminum spinel powder, 2-8 parts of sol, 1-5 parts of binder, 0.1-1 part of water reducing agent and 16-22 parts of water. The method for using the used sagger restoration paint includes preparing the repair paint, polishing the waste sagger and repairing the waste sagger to obtain a regenerated new sagger. The repaired waste saggers can not only be put into use again, but also have high strength, strong corrosion resistance and good thermal shock resistance. The invention improves the recycling rate of waste saggers, and largely reduces the problems of difficult stacking and environmental pollution.

Owner:CENT SOUTH UNIV

A kind of high-alumina drawn brick for carbon anode roasting furnace flue channel and preparation method thereof

The invention discloses a high-aluminum pull brick for carbon anode roasting furnace flame paths and a preparation method thereof. The high-aluminum pull brick for carbon anode roasting furnace flame paths is prepared by mixing, calcining and pressing calcined mullite, calcined high-aluminum bauxite, andalusite granules, alumina powder, Gangxi clay powder and andalusite fine powder. The preparation method comprises the following steps: 1. crushing and screening the calcined mullite and calcined high-aluminum bauxite; 2. selecting 10-16 wt% of alumina powder, 10-12 wt% of Gangxi clay powder and 15-21 wt% of andalusite fine powder, mixing and grinding; 3. mixing the co-ground powder with 8-12 wt% of calcined mullite, 17-23 wt% of calcined high-aluminum bauxite and 25-29 wt% of andalusite granules; 4. adding pulp waste, and compounding; 5. pressing to be green bricks; and 6. drying and calcining to obtain the finished product. The high-aluminum pull brick for carbon anode roasting furnace flame paths has the advantages of low creep rate, high refractoriness under load, favorable high-temperature folding strength and small physical dimension deformation, and can prolong the service life of the carbon anode roasting furnace and lower the maintenance cost.

Owner:河南鑫诚耐火材料股份有限公司

Electric cast mullite brick and preparation method thereof

The invention relates to an electric cast mullite brick, which comprises the following raw materials with the granularity distribution in percentage by weight: 55 to 80 percent of electric cast mullite with the granularity distribution being smaller than or equal to 3.5mm, 10 to 20 percent of kyanite with the granularity distribution being smaller than or equal to 0.1mm, 10 to 20 percent of quartz with the granularity distribution being 0.1 to 1.5mm, 0 to 5 percent of clay with the granularity distribution being smaller than or equal to 0.1mm and 0 to 1 percent of titanium dioxide with the granularity distribution being 2 to 10mum. A preparation method of the electric cast mullite brick comprises the following steps that: crushing, sieving and magnetic separation are carried out; the kyanite, the quartz, the clay, the titanium dioxide and partial electric cast mullite are mixed with oleic acid and are subjected to ball milling to obtain ball milling materials; bonding agents are dissolved in water to be mixed with the rest electric cast mullite to obtain particle materials; the ball milling materials and the particle materials are mixed and are subjected to mixed milling, aging decaying and secondary mixing; green bricks are obtained through pressure forming, and the green bricks are dried and fired. The electric cast mullite brick and the preparation method have the advantages that the process is simple, the cost is low, the operability is high, and the obtained electric cast mullite brick body has high density, good acid resistance, high normal-temperature bending-resistant intensity and excellent thermal shock stability.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Micro-expansion brick for carbon anode roasting furnace and preparation method thereof

Owner:河南鑫诚耐火材料股份有限公司

A method for improving the high temperature strength of monolithic alumina-based ceramic molds by chemical vapor infiltration

ActiveCN106083205BImprove high temperature strengthHigh temperature strengthCeramicwareChemical reactionSurface layer

The invention discloses a method of improving high-temperature strength of an integral alumina-based ceramic mold through chemical vapor infiltration, and belongs to the field of photocuring forming technology quick casting. The method includes the steps that 1, a resin mold is manufactured through the photocuring quick forming technology; 2, ceramic slurry is poured into a resin mold prototype of turbine blades through a gelcasting method to obtain a cast blank; 3, a porous alumina-based ceramic mold is obtained after vacuum freeze drying and ungrease treatment; 4, the alumina-based ceramic mold is subjected to chemical vapor infiltration, SiO2 generated after pyrolytic reaction of a silicon source precursor and matrix alumina react chemically to generate high-temperature strengthened phase mullite, the pore structure of the mold is filled with SiC generated through the pyrolytic reaction, a functional gradient material with the porosity gradually improved from the surface layer to the core part of the mold, and the porosity of the mold is reduced to improve the high-temperature strength of the mold. The method is reasonable in design and convenient to operate, and the high-temperature strength of the alumina-based ceramic mold is enhanced remarkably.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com