Wear-resistant material for flushing slag ditch of high-strength blast furnace and preparation method thereof

A wear-resistant material and blast furnace technology, applied in the field of industrial building materials, can solve the problems of insufficient wear resistance, poor thermal shock resistance, low bulk density, etc., and achieve good impact resistance, good wear resistance, and high bulk density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

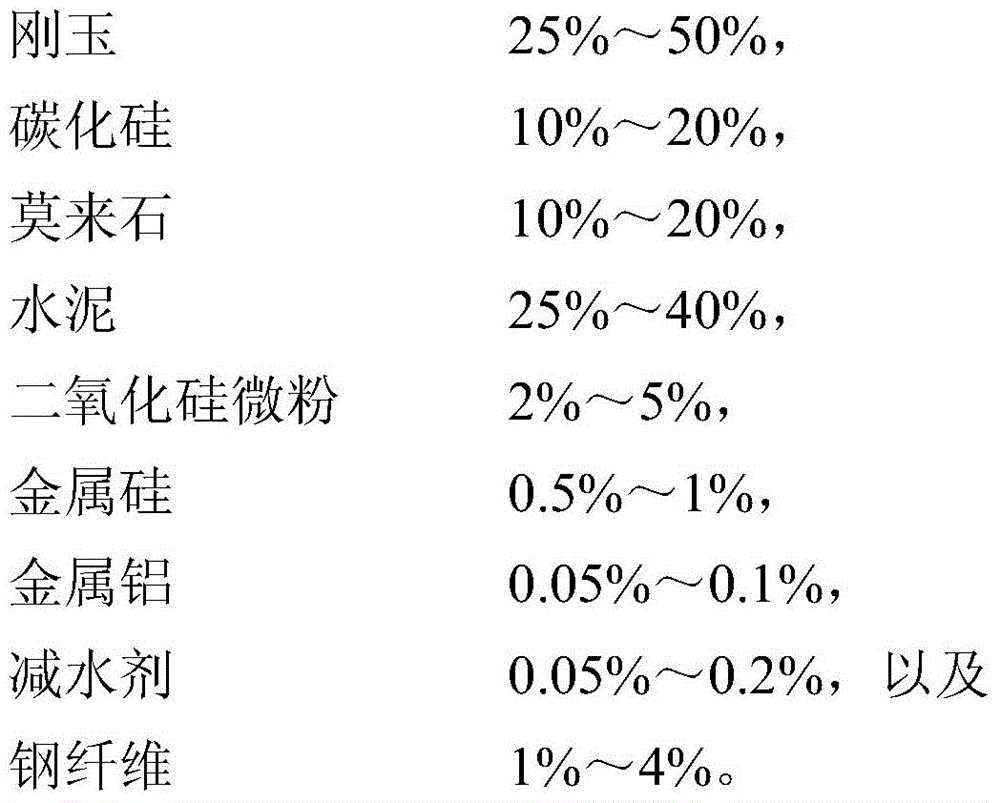

Embodiment 1

[0035] The raw material composition of wear-resistant materials for high-strength blast furnace flushing slag ditch is as follows: by weight percentage, brown corundum 38%; silicon carbide 10%; mullite 15.3%; cement 30%; silicon dioxide micropowder 2%; metal silicon 0.5% ; Aluminum 0.05%; Water reducing agent 0.15%; Steel fiber 4%.

[0036] The preparation method is as follows: put cement, silicon dioxide micropowder, metal silicon, metal aluminum, and water reducing agent into the DSH-1 type double-helix conical mixer according to the above weight percentage and stir evenly to prepare premixed powder; then, premixed powder , brown corundum, silicon carbide, mullite, and steel fiber are put into the JW-350 type forced mixer according to the above weight percentage and stirred evenly, and the wear-resistant material for high-strength blast furnace flushing slag ditch can be obtained.

Embodiment 2

[0038] The raw material composition of wear-resistant materials for high-strength blast furnace flushing slag ditch is as follows: by weight percentage, brown corundum 32.5%; silicon carbide 20%; mullite 10.3%; cement 30%; silicon dioxide micropowder 2%; metal silicon 1% ; Aluminum 0.05%; Water reducing agent 0.15%; Steel fiber 4%.

[0039] The preparation method is the same as in Example 1 to prepare the wear-resistant material for blast furnace flushing slag ditch.

Embodiment 3

[0041] The raw material composition of wear-resistant materials for high-strength blast furnace flushing slag ditch is as follows: by weight percentage, brown corundum 38%; silicon carbide 15%; mullite 10.3%; cement 30%; silica micropowder 2%; metal silicon 0.5% ; Aluminum 0.05%; Water reducing agent 0.15%; Steel fiber 4%.

[0042] The preparation method is the same as in Example 1 to prepare the wear-resistant material for blast furnace flushing slag ditch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com