A kind of high-alumina drawn brick for carbon anode roasting furnace flue channel and preparation method thereof

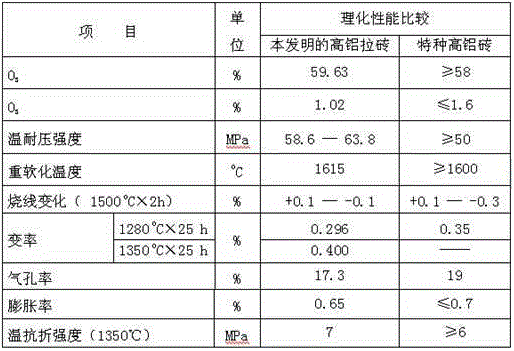

A carbon anode and furnace fire channel technology is applied in the field of high-alumina drawn bricks for carbon anode roasting furnace fire channels and their preparation, which can solve the problems of high creep rate, low high-temperature flexural strength, deformation of external dimensions, etc. of high-alumina drawn bricks problems, to achieve the effect of high high temperature flexural strength, low creep rate, and small deformation of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. After crushing calcined mullite and calcined high-alumina bauxite, sieve them into a particle size of 1-3mm; after crushing andalusite, sieve them into a particle size of 0-1mm;

[0026] 2. Select alumina powder with a mass percentage of 10%, Guangxi clay powder with a mass percentage of 10% and andalusite fine powder with a mass percentage of 16% to mix, and grind into a co-milled powder with a fineness of ≤0.088mm;

[0027] 3. Combine the co-milled powder with calcined mullite with a mass percentage of 12% and a particle size of 1-3mm, calcined high-alumina bauxite with a mass percentage of 23% and a particle size of 1-3mm, a mass percentage of 29%, and a particle size of 0-1mm andalusite particles are mixed to make a mixture;

[0028] 4. Add pulp waste liquid in a ratio of 100:1 to the mass ratio of the mixture, and knead for 10 minutes to make a kneading mud;

[0029] 5. Use a 315T pneumatic press to press the mixed mud into a density > 2.75g / cm 3 adobe;

[00...

Embodiment 2

[0032] 1. After crushing calcined mullite and calcined high-alumina bauxite, sieve them into a particle size of 1-3mm; after crushing andalusite, sieve them into a particle size of 0-1mm;

[0033] 2. Select alumina powder with a mass percentage of 16%, Guangxi clay powder with a mass percentage of 12% and andalusite fine powder with a mass percentage of 21% to mix, and grind into a co-milled powder with a fineness of ≤0.088mm;

[0034] 3. Combine the co-milled powder with calcined mullite with a mass percentage of 8% and a particle size of 1-3mm, calcined high-alumina bauxite with a mass percentage of 17% and a particle size of 1-3mm, a mass percentage of 26%, and a particle size of 0-1mm andalusite particles are mixed to make a mixture;

[0035] 4. Add pulp waste liquid according to the mass ratio of 100:2 to the mixture, and mix for 15 minutes to make mixed mud;

[0036] 5. Use a 315T pneumatic press to press the mixed mud into a density > 2.75g / cm 3 adobe;

[0037] 6. Th...

Embodiment 3

[0039] 1. After crushing calcined mullite and calcined high-alumina bauxite, sieve them into a particle size of 1-3mm; after crushing andalusite, sieve them into a particle size of 0-1mm;

[0040] 2. Select alumina powder with a mass percentage of 14%, Guangxi clay powder with a mass percentage of 12% and andalusite fine powder with a mass percentage of 21%, and grind them into a co-milled powder with a fineness of ≤0.088mm;

[0041] 3. Combine the co-milled powder with calcined mullite with a mass percentage of 11% and a particle size of 1-3mm, calcined high-alumina bauxite with a mass percentage of 17% and a particle size of 1-3mm, a mass percentage of 25%, and a particle size of 0-1mm andalusite particles are mixed to make a mixture;

[0042] 4. Add pulp waste liquid according to the mass ratio of 100:1.5 to the mixture, and knead for 12 minutes to make a kneading mud;

[0043] 5. Use a 315T pneumatic press to press the mixed mud into a density > 2.75g / cm 3 adobe;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com