Micro-expansion brick for carbon anode roasting furnace and preparation method thereof

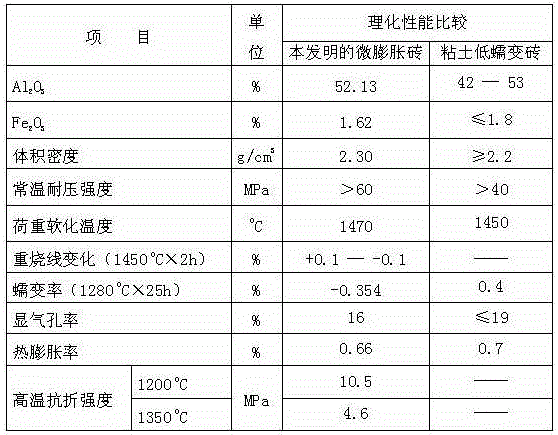

A carbon anode and roasting furnace technology, which is applied in the field of micro-expanded bricks for carbon anode roasting furnace and its preparation field, can solve the problems of inability to realize mechanized furnace operation, unsatisfactory overall strength of fire channel wall, and increase furnace maintenance cost, etc. The effect of thermal shock resistance, high temperature flexural strength, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The calcined bauxite clinker is crushed and sieved into clinker with a particle size of 1-3mm and 3-5mm; the calcined coke clinker is crushed and sieved into clinker with a particle size of 0-1mm;

[0025] 2. Grind Guangxi clay into a fine powder with a fineness of ≤0.074mm, and grind kyanite and calcined bauxite clinker into a fine powder with a fineness of ≤0.088mm;

[0026] 3. Select 6% of calcined bauxite clinker with a particle size of 3-5mm, 29% of calcined bauxite clinker with a particle size of 1-3mm, 20% of calcined coke clinker with a particle size of 0-1mm, and fineness 12% of Guangxi clay powder with a fineness of ≤0.074mm, 15% of kyanite powder with a fineness of ≤0.088mm, and 18% of calcined bauxite clinker powder with a fineness of ≤0.088mm are mixed and stirred to make a mixture;

[0027] 4. Add pulp waste liquid and water according to the mass ratio of 100:1 to the mixture, and mix for 10 minutes to make a mixed mud;

[0028] 5. Use a 315T pneumatic...

Embodiment 2

[0031] 1. The calcined bauxite clinker is crushed and sieved into clinker with a particle size of 1-3mm and 3-5mm; the calcined coke clinker is crushed and sieved into clinker with a particle size of 0-1mm;

[0032] 2. Grind Guangxi clay into a fine powder with a fineness of ≤0.074mm, and grind kyanite and calcined bauxite clinker into a fine powder with a fineness of ≤0.088mm;

[0033] 3. Select 7% of calcined bauxite clinker with a particle size of 3-5mm, 30% of calcined bauxite clinker with a particle size of 1-3mm, 18% of calcined coke clinker with a particle size of 0-1mm, and fineness 15% of Guangxi clay powder with a fineness of ≤0.074mm, 14% of kyanite powder with a fineness of ≤0.088mm, and 16% of calcined bauxite clinker powder with a fineness of ≤0.088mm, mixed and stirred to make a mixture;

[0034] 4. Add pulp waste liquid and water in a ratio of 100:2 to the mass of the mixture, and mix for 15 minutes to make a mixed slurry;

[0035] 5. Use a 315T pneumatic pres...

Embodiment 3

[0038] 1. The calcined bauxite clinker is crushed and screened into clinker with a particle size of 1-3mm and 3-5mm; the calcined coke clinker is crushed and screened into clinker with a particle size of 0-1mm;

[0039] 2. Grind Guangxi clay into a fine powder with a fineness of ≤0.074mm, and grind kyanite and calcined bauxite clinker into a fine powder with a fineness of ≤0.088mm;

[0040] 3. Select 8% of calcined bauxite clinker with a particle size of 3-5mm, 32% of calcined bauxite clinker with a particle size of 1-3mm, 15% of calcined coke clinker with a particle size of 0-1mm, and fineness 13% of Guangxi clay powder with a fineness of ≤0.074mm, 14% of kyanite powder with a fineness of ≤0.088mm, and 18% of calcined bauxite clinker powder with a fineness of ≤0.088mm, mixed and stirred to make a mixture;

[0041] 4. Add pulp waste liquid and water according to the mass ratio of 100:1.5 to the mixture, and mix for 12 minutes to make a mixed mud;

[0042] 5. Use a 315T pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com