Patents

Literature

50results about How to "Low creep rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

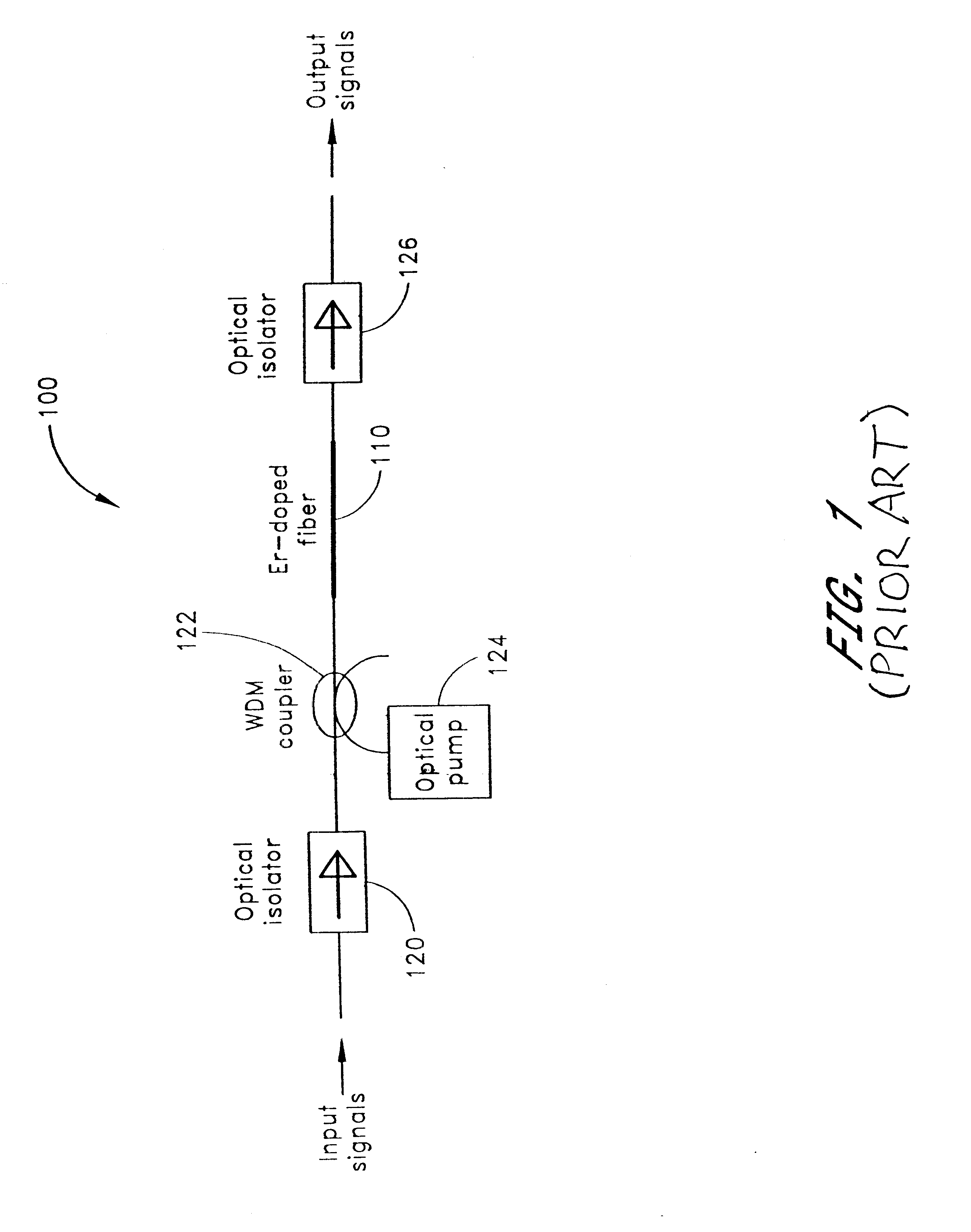

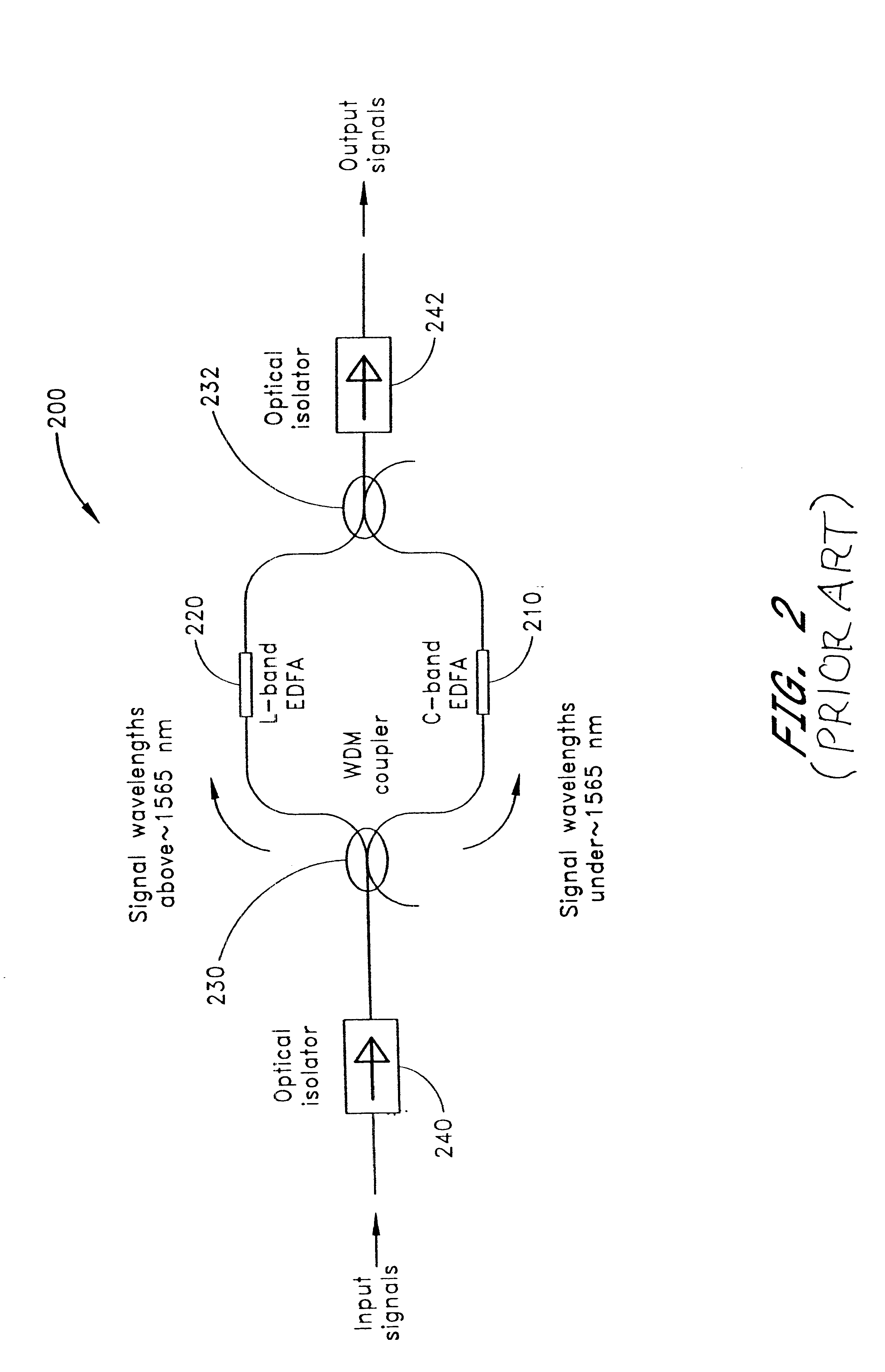

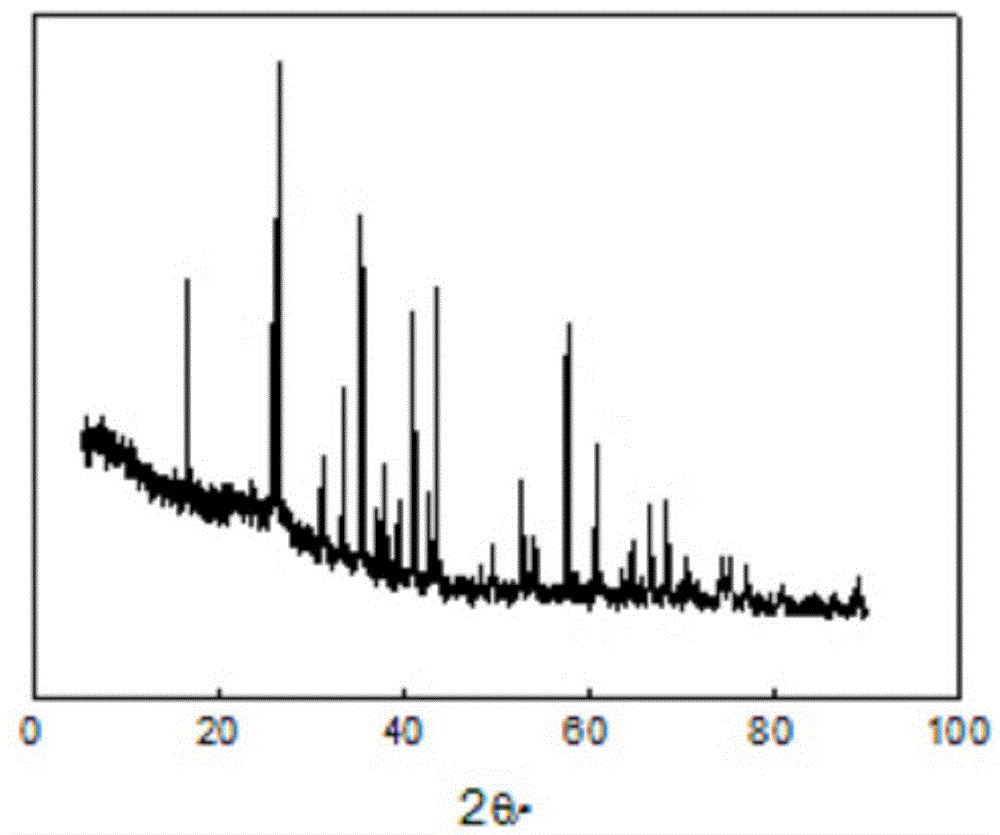

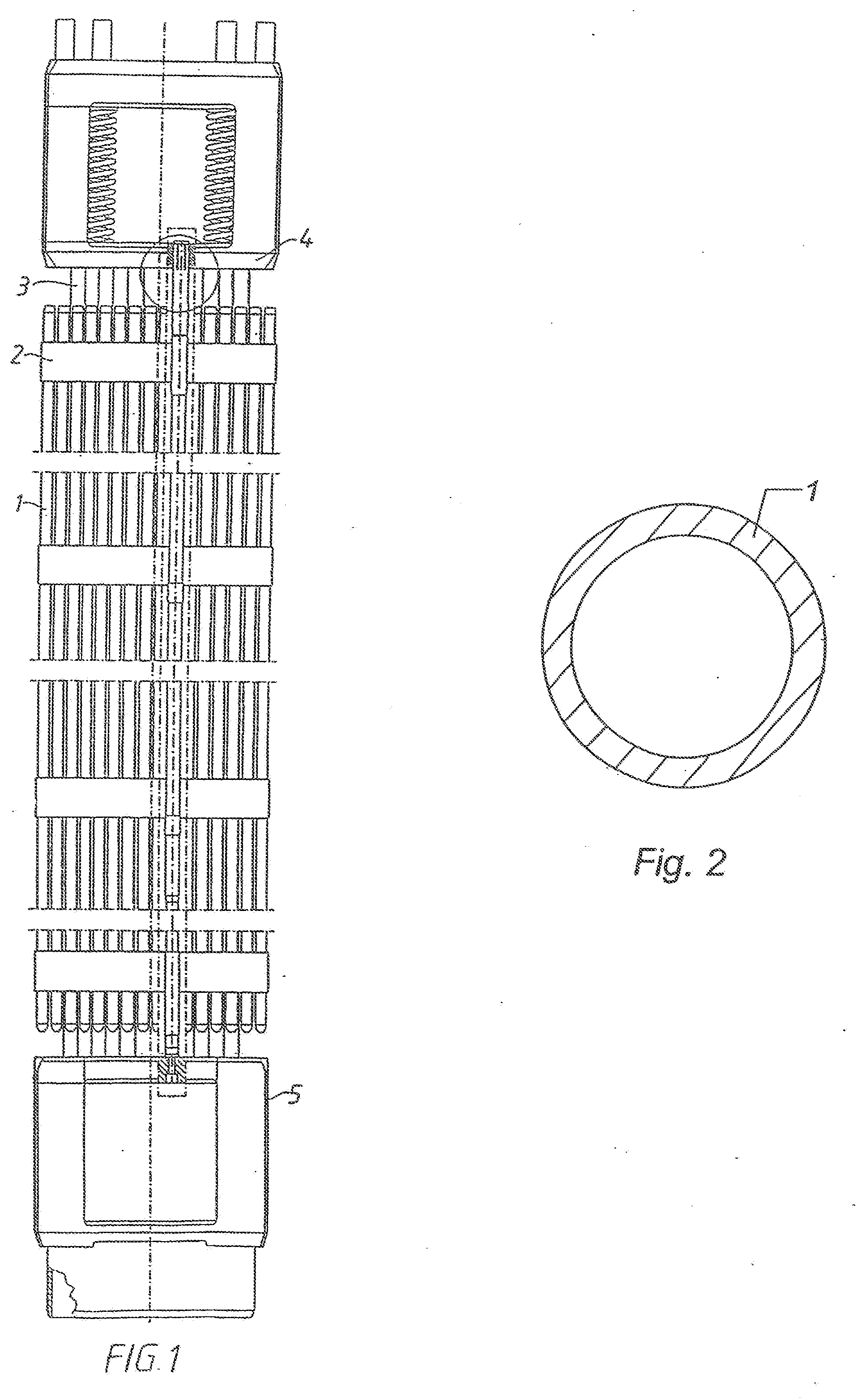

Method of amplifying optical signals using doped materials with extremely broad bandwidths

InactiveUS6490081B1Eliminate chemical pollutionIncreased formationActive medium materialFibre transmissionErbium dopingRare earth

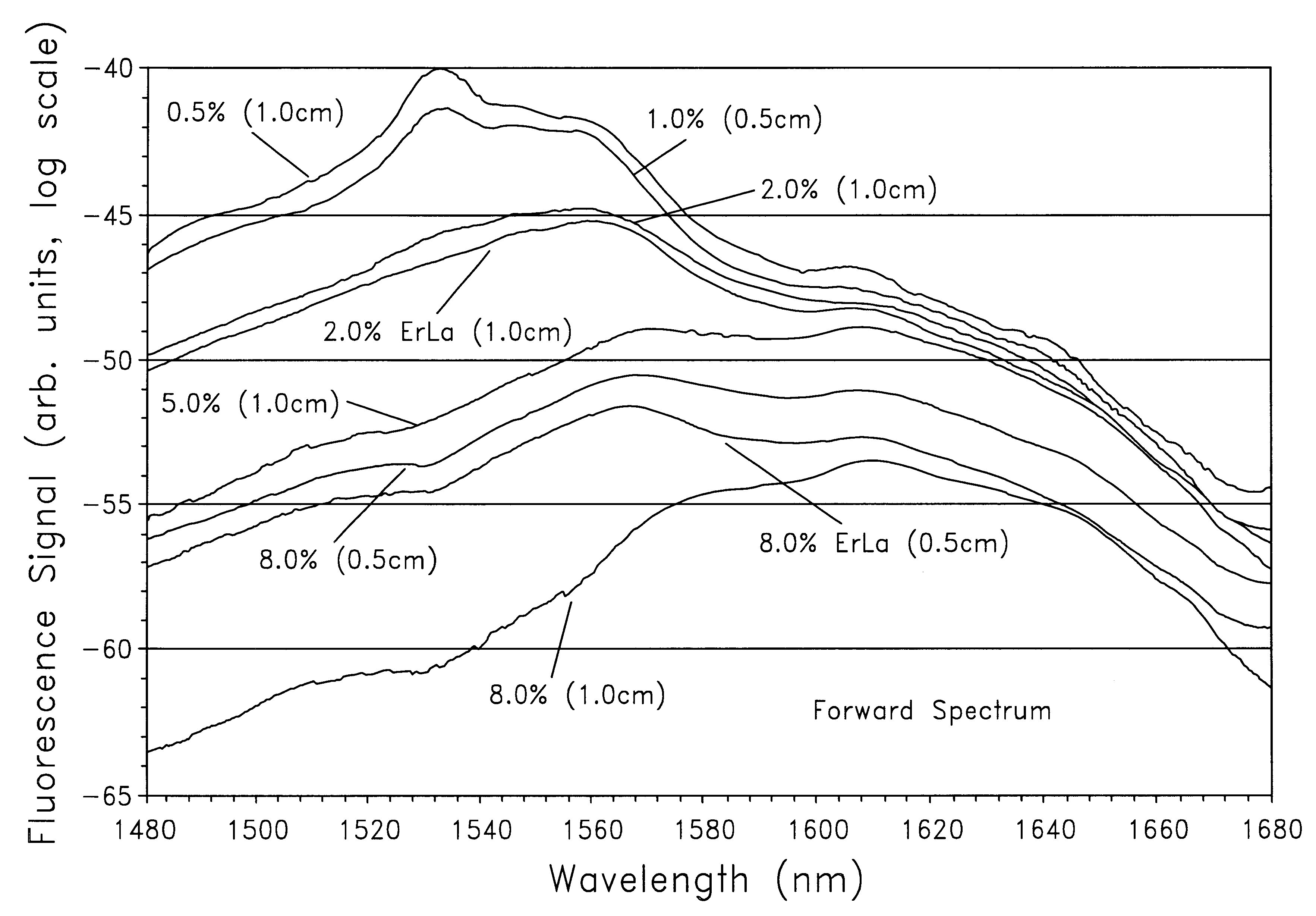

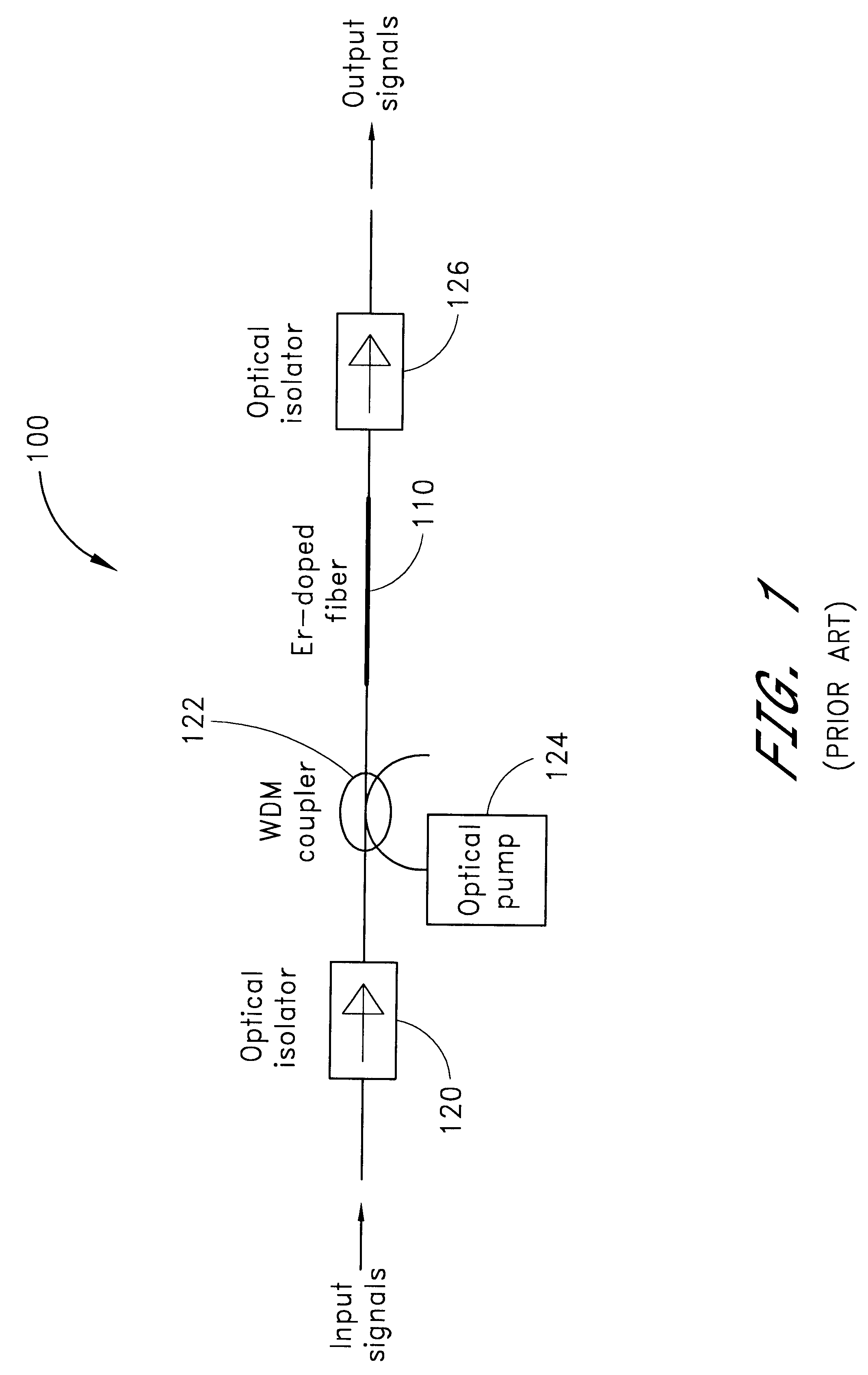

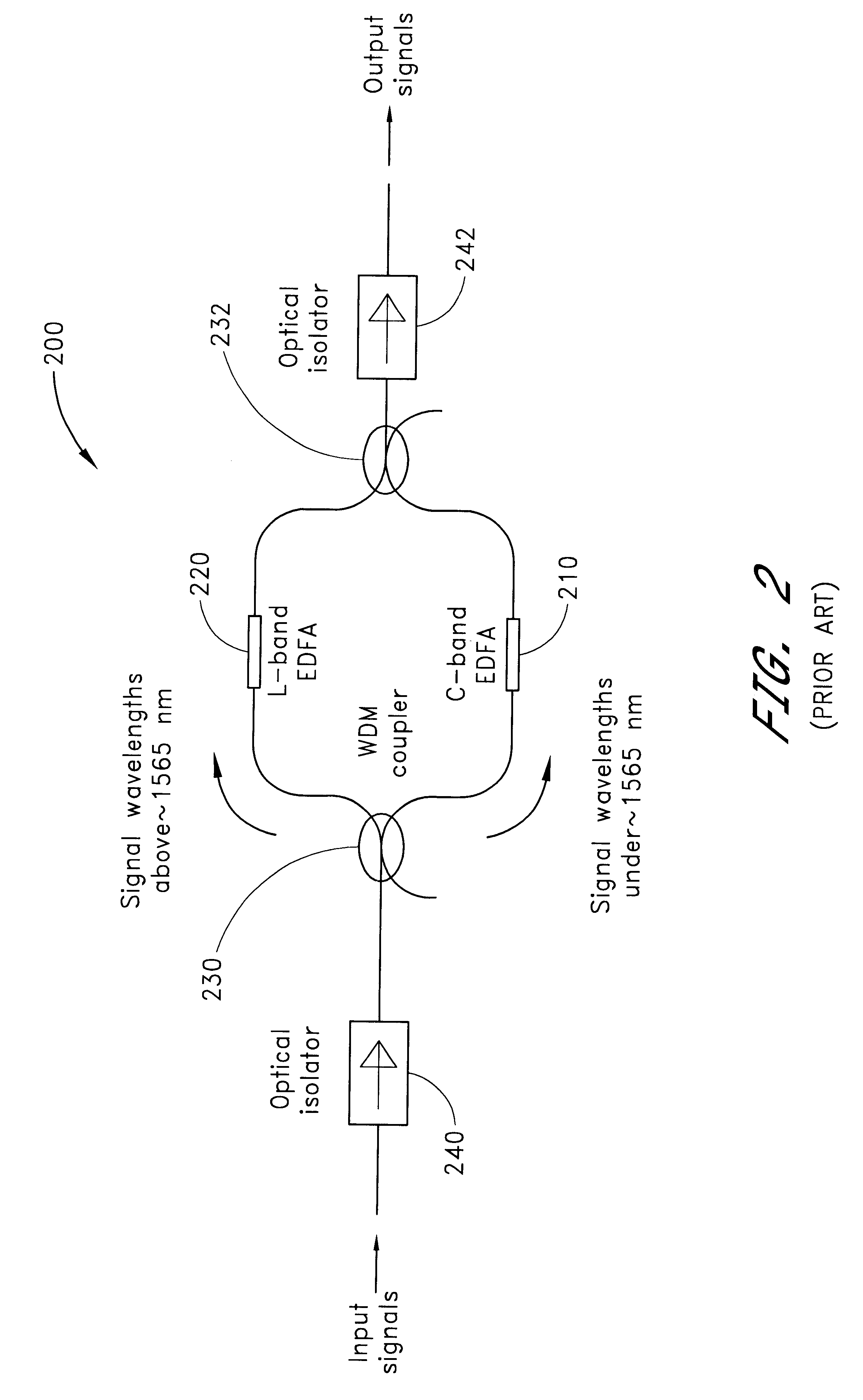

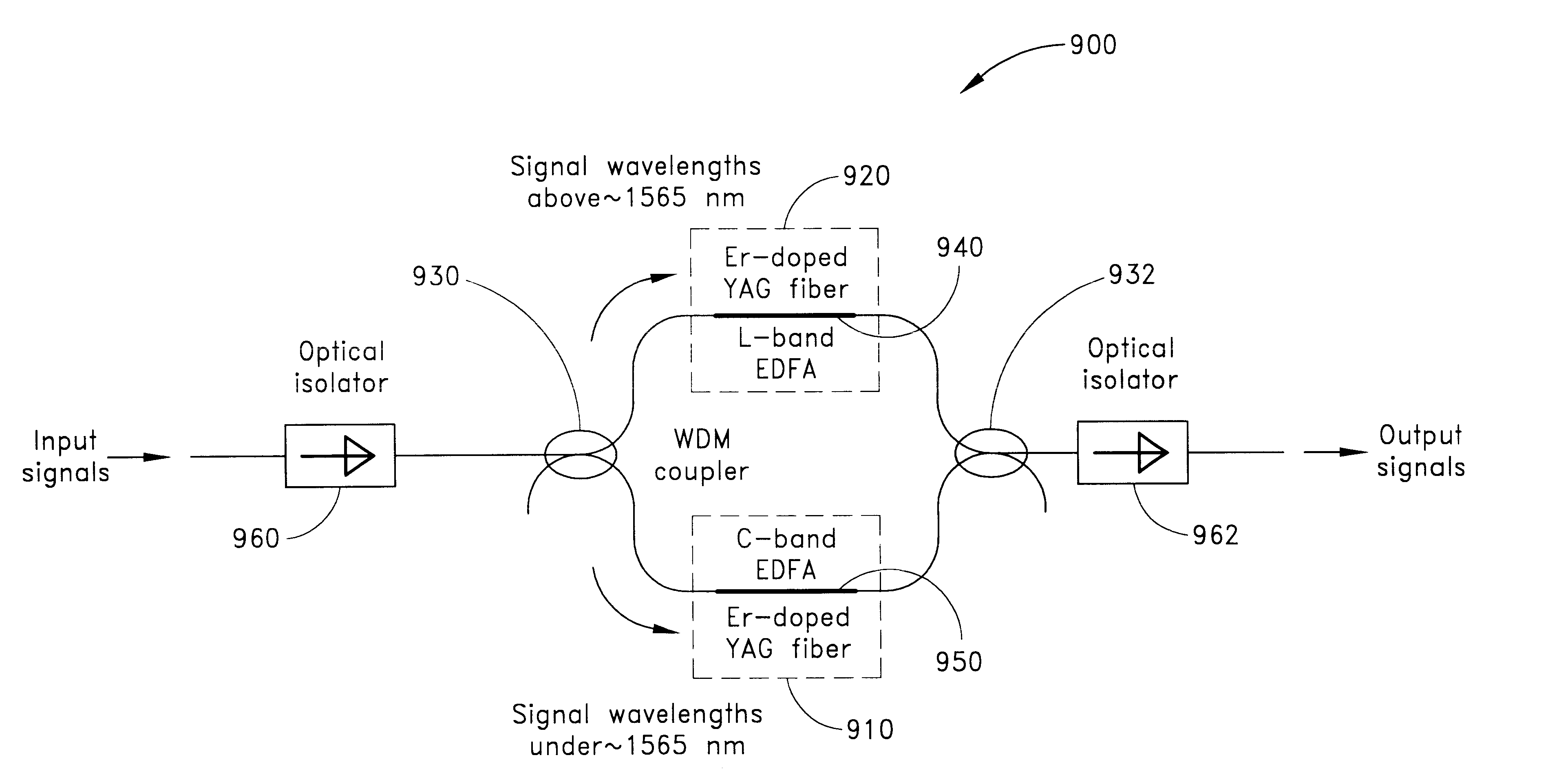

In a method of amplifying optical input signals over a wide bandwidth, the optical input signals are applied to an optical waveguide made from a rare-earth-doped amorphous material (e.g., erbium-doped yttrium aluminum oxide material). The optical input signals include optical signals having wavelengths over a range of at least 80 nanometers, and, preferably, over a range of at least 160 nanometers. Pump light is applied to the optical waveguide to cause the waveguide to provide optical gain to the optical input signals. The optical gain causes the optical signals to be amplified within the waveguide to provide amplified optical signals over the extended 80-160-nanometer range, including, in particular, optical signals having wavelengths at one end of the range and optical signals having wavelengths at a second end or the range.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method of amplifying optical signals using erbium-doped materials with extremely broad bandwidths

InactiveUS6469825B1Eliminate chemical pollutionIncreased formationActive medium materialFibre transmissionRare earthErbium doping

In a method of amplifying optical input signals over a wide bandwidth, the optical input signals are applied to an optical waveguide made from a rare-earth-doped amorphous yttrium aluminum oxide material (e.g., erbium-doped yttrium aluminum oxide material). The optical input signals include optical signals having wavelengths shorter than 1,520 nanometers and optical signals having wavelengths longer than 1,610 nanometers. Preferably, the wavelengths range from as short as approximately 1,480 nanometers to as long as approximately 1,650 nanometers. Pump light is applied to the optical waveguide to cause the waveguide to provide optical gain to the optical input signals. The optical gain causes the optical signals to be amplified within the waveguide to provide amplified optical signals over the extended range from approximately 1,480 nanometers to approximately 1,650 nanometers, including, in particular, optical signals having wavelengths shorter than 1,520 nanometers and optical signals having wavelengths longer than 1,610 nanometers. Alternatively, the wavelengths of the optical input signals may be in the range from approximately 1,480 nanometers to approximately 1,565 nanometers. As a further alternative, the wavelengths of the optical input signals may be in the range from approximately 1,565 nanometers to approximately 1,650 nanometers.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

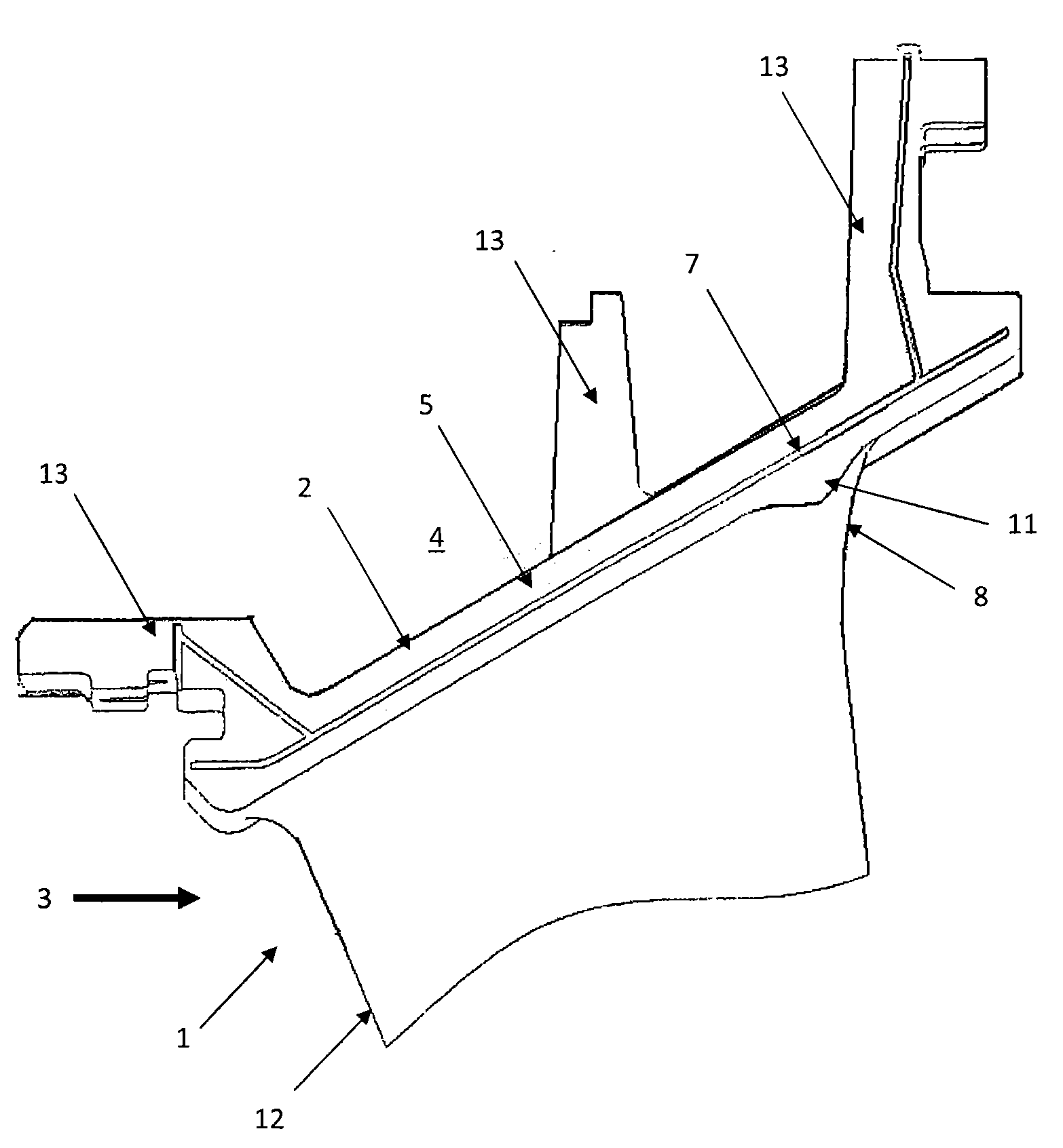

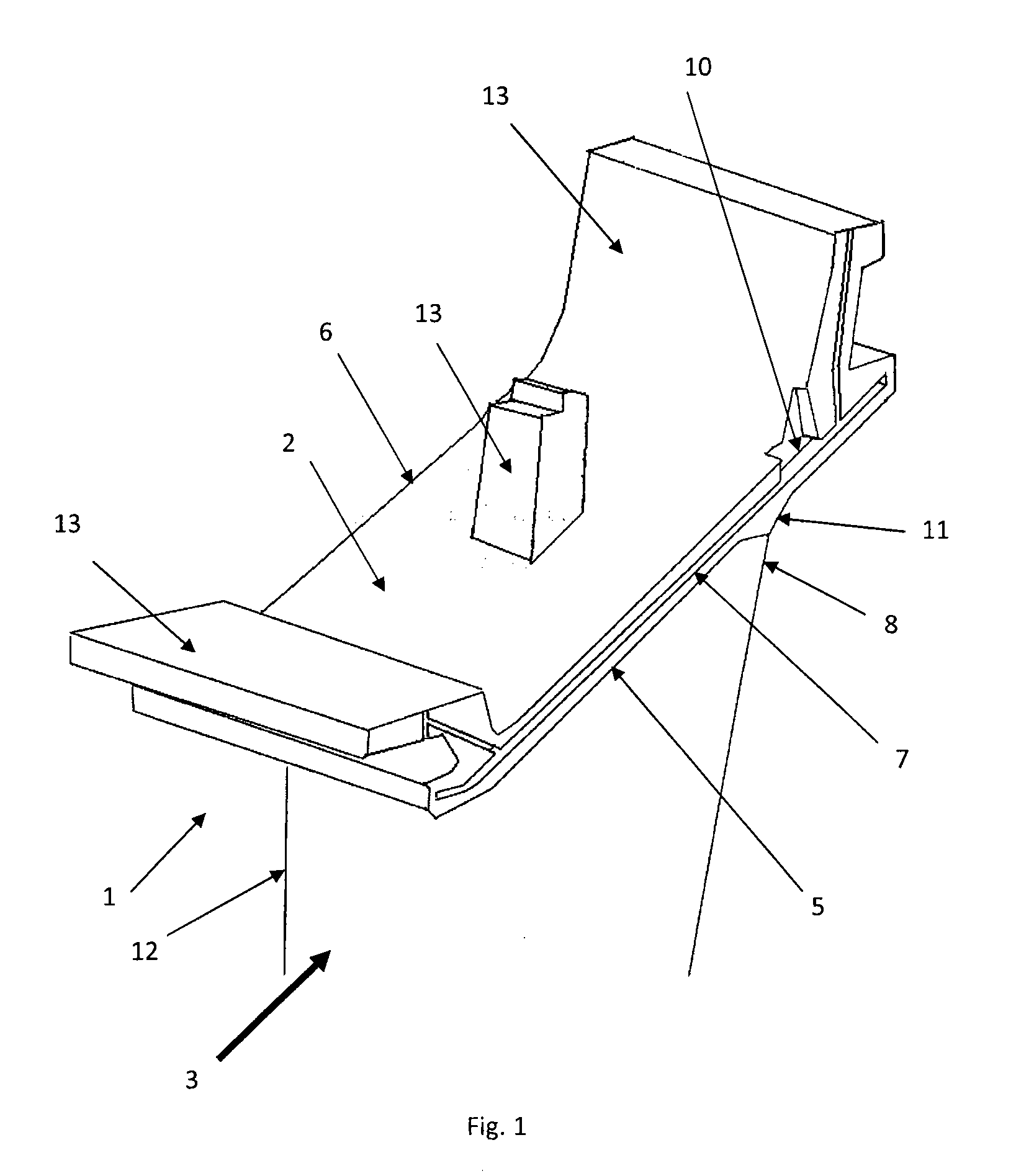

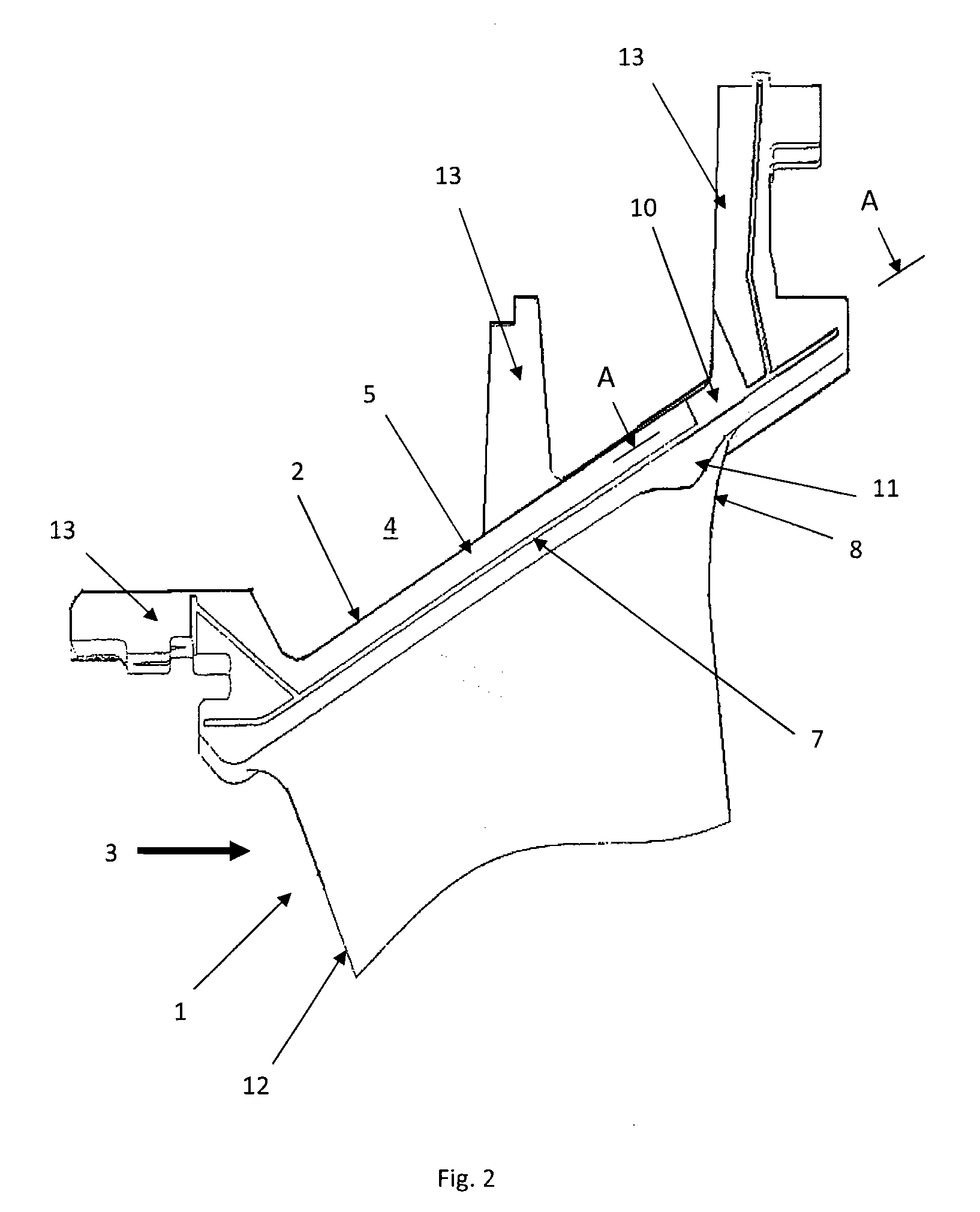

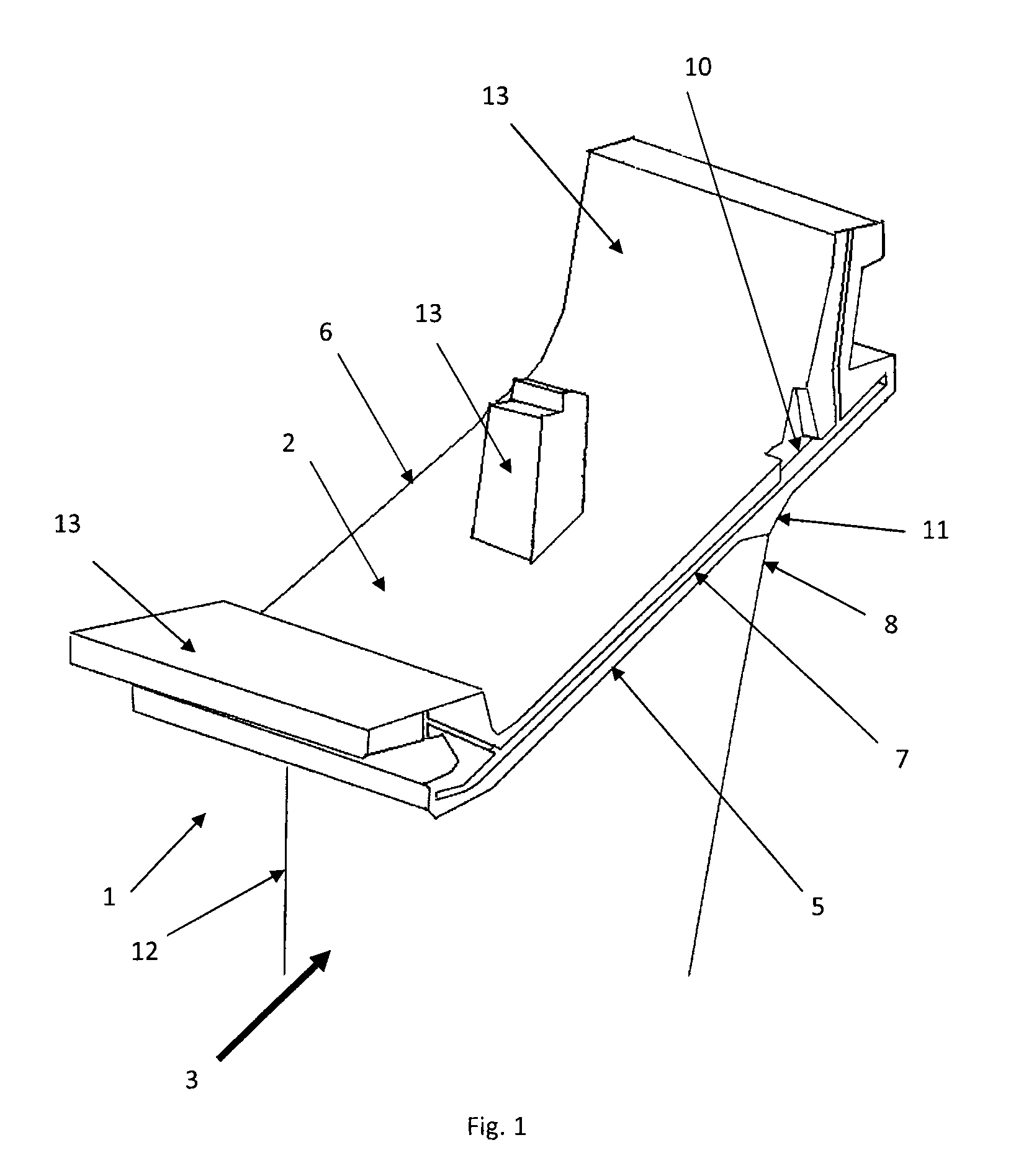

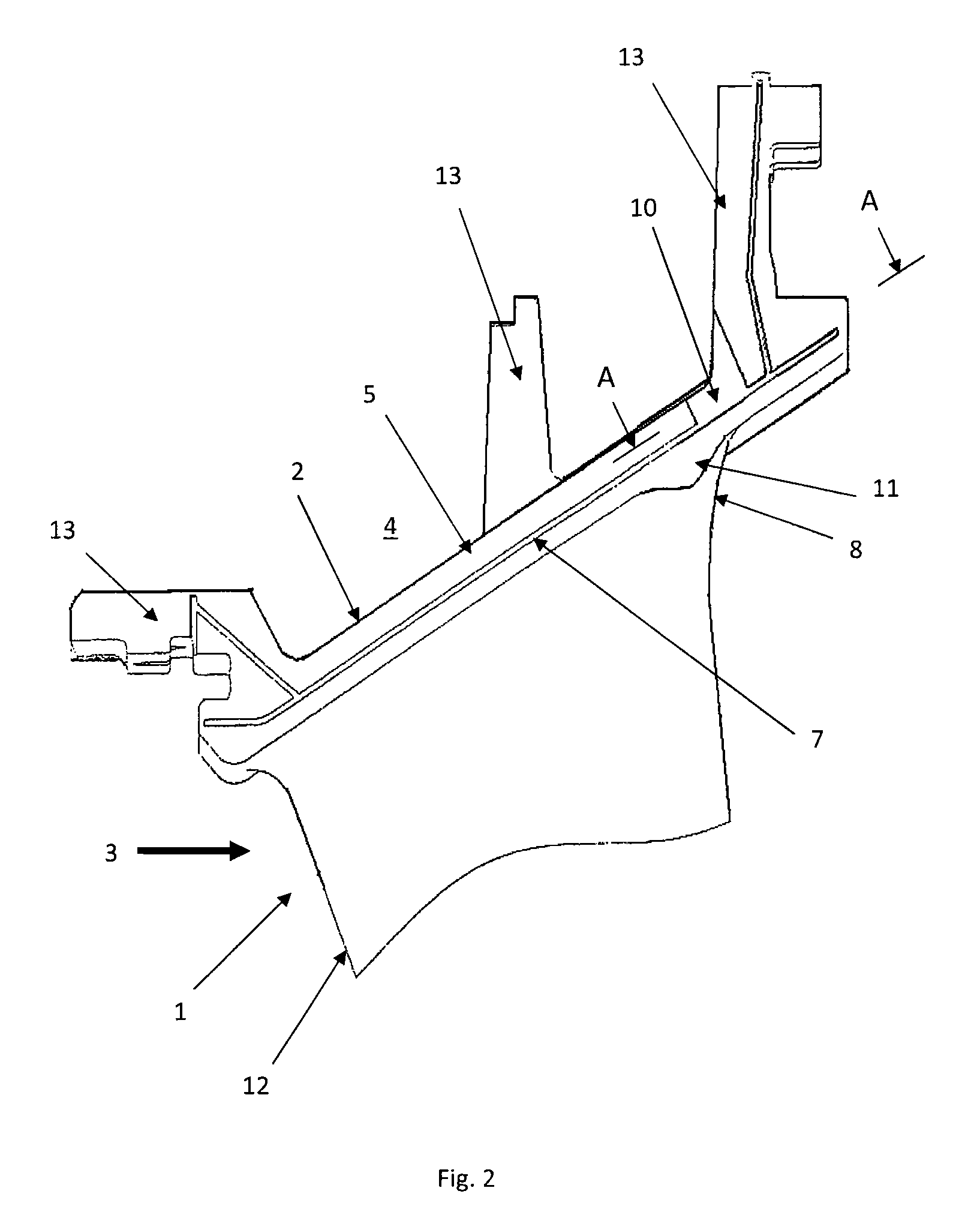

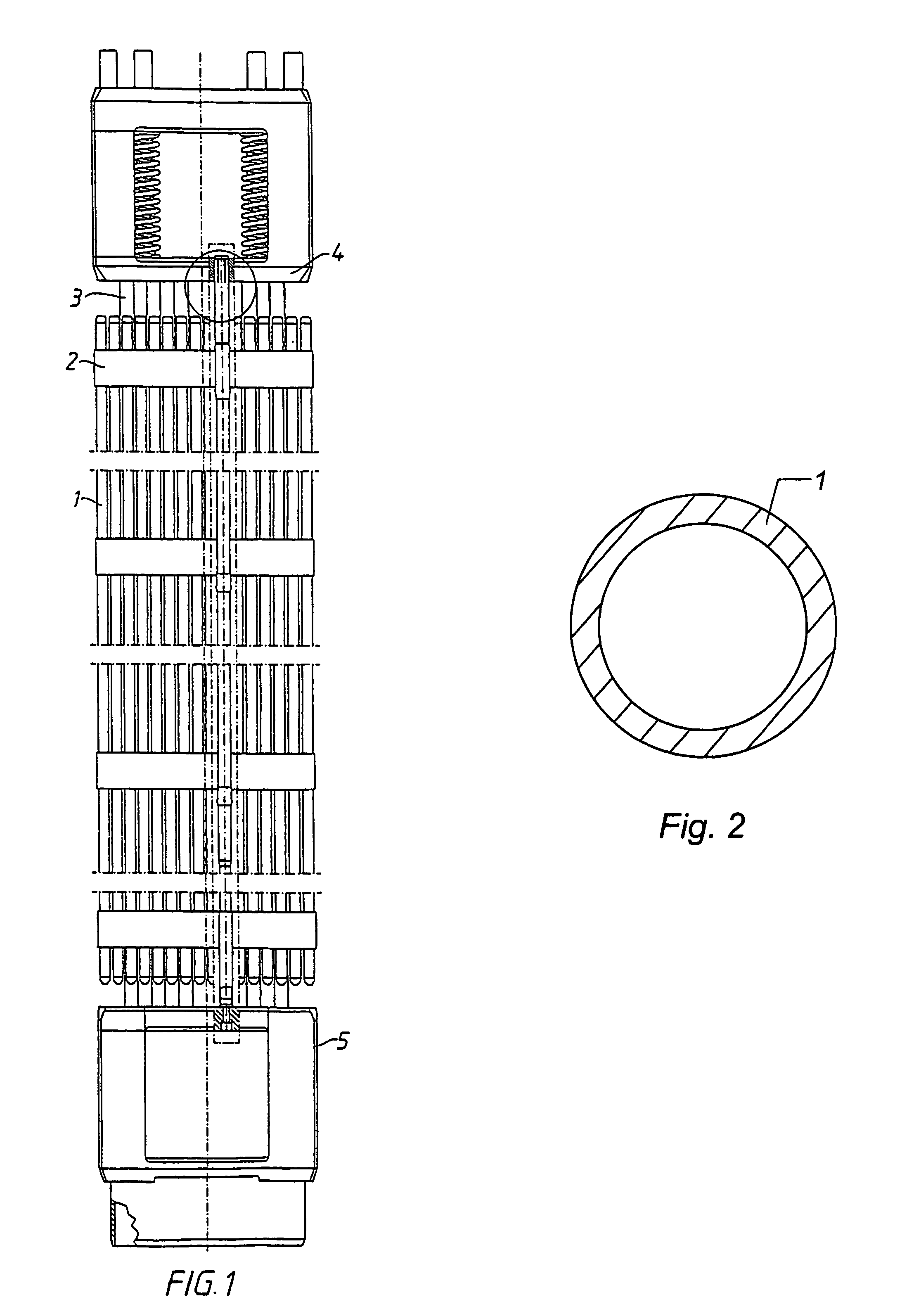

Stator vane for a gas turbine engine

InactiveUS20100150710A1Reduce stress concentrationLow cycle fatigueEngine manufacturePump componentsLeading edgeEngineering

A guide vane for a gas turbine includes a vane body having a leading edge and a trailing edge and a shroud extending at least between the leading edge and the trailing edge. The shroud has a first side wall and a second side wall extending essentially radially and in a longitudinal direction of the gas turbine. The first side wall has a groove disposed in a region of the trailing edge extending in a longitudinal direction of the shroud and is configured to receive a sealing plate. The first side wall also has a clearance extending from the groove in a region of the trailing edge, wherein a depth of the clearance in a circumferential direction of the gas turbine is equal to a depth of the groove, and wherein a width of the clearance in the longitudinal direction of the shroud is between one to three times the depth of the clearance.

Owner:GENERAL ELECTRIC TECH GMBH

Gas turbine and method for reducing bucket tip shroud creep rate

A bucket tip shroud in a gas turbine includes a seal rail having a cutter tooth at one end. Bucket tip shroud creep rate can be reduced by removing the cutter tooth from the bucket tip shroud seal rail after use or with a pre-groove honeycomb shroud. Preferably, the remaining geometry matches a geometry of the seal rail within a predetermined tolerance.

Owner:GENERAL ELECTRIC CO

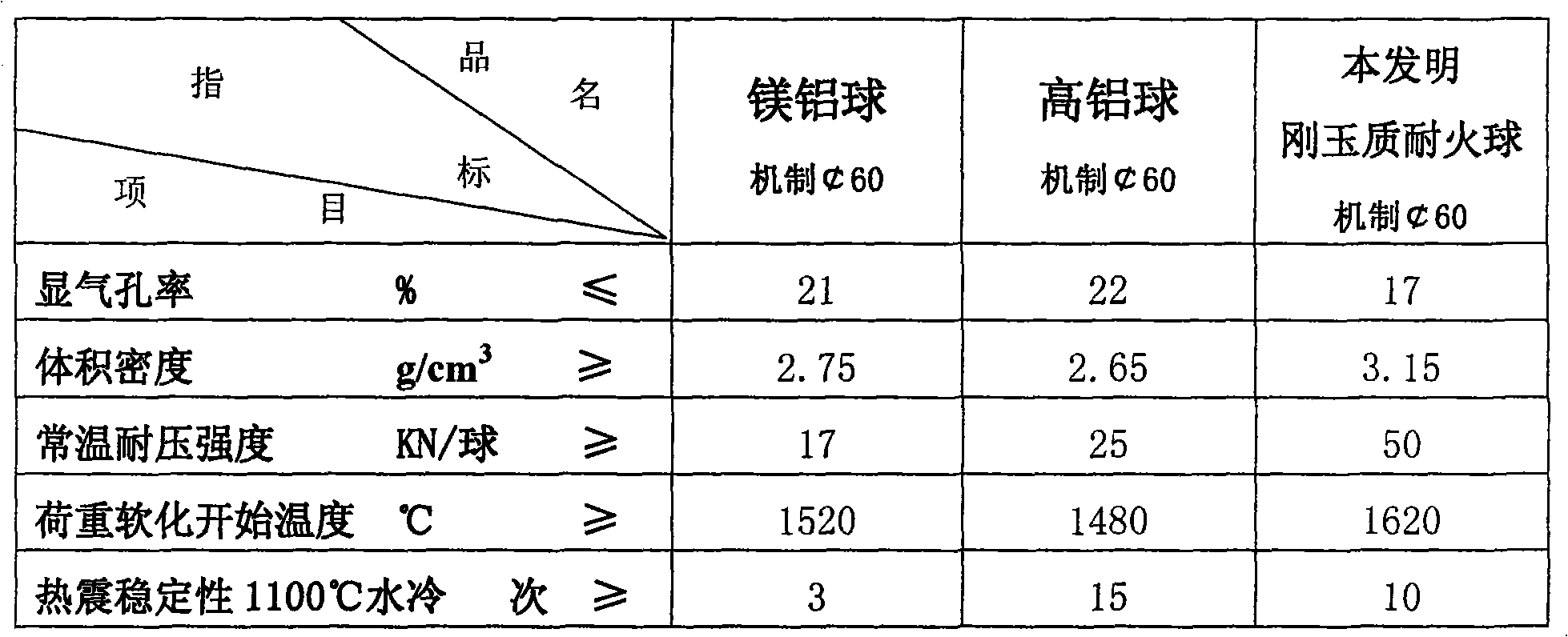

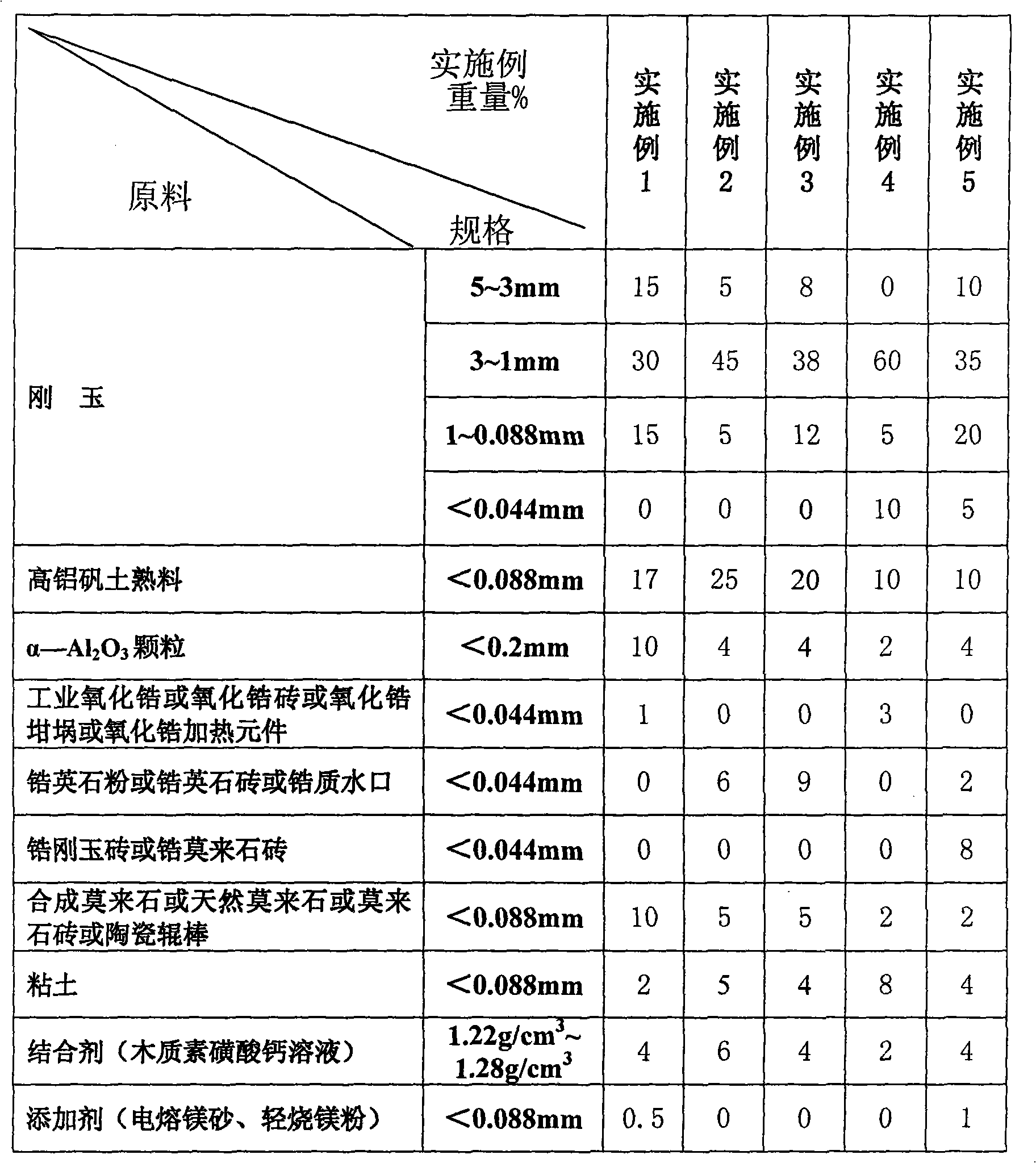

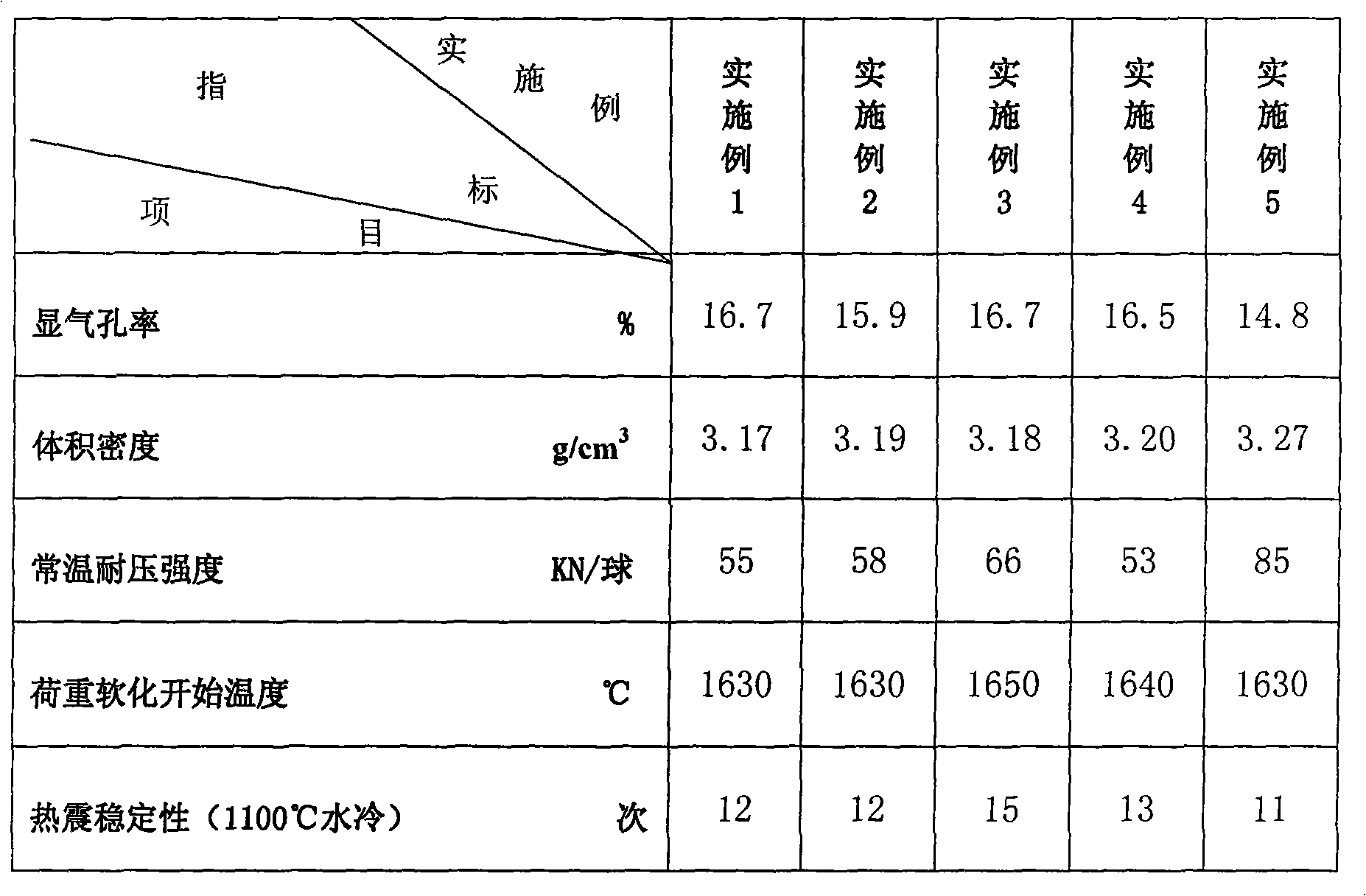

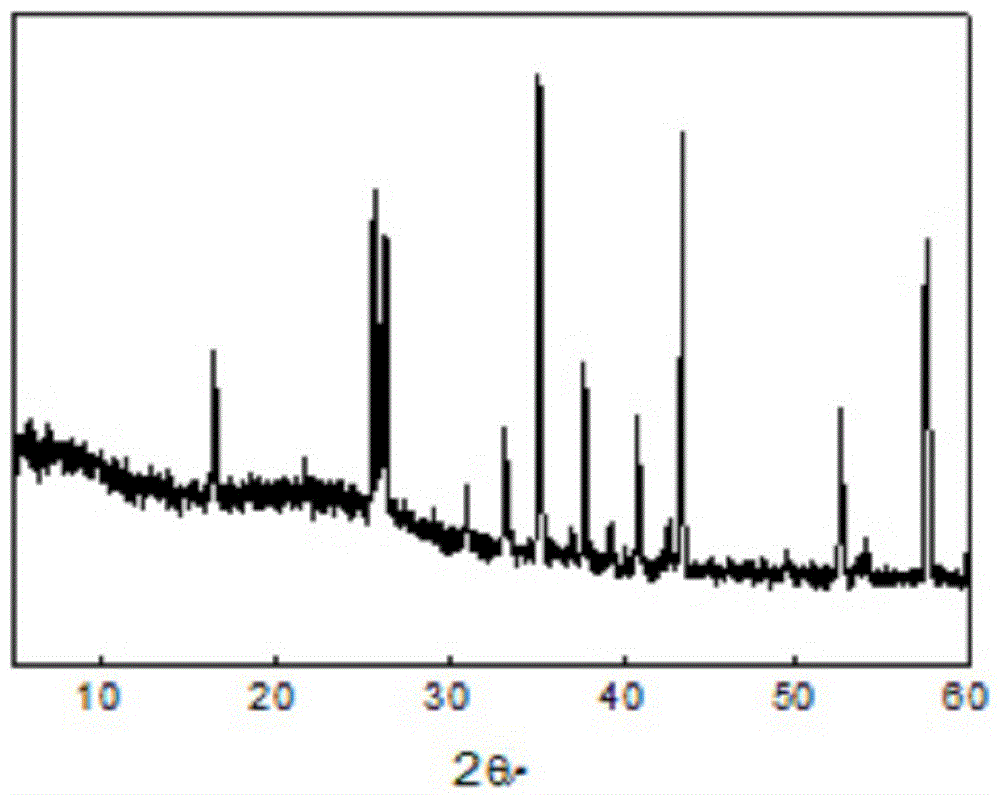

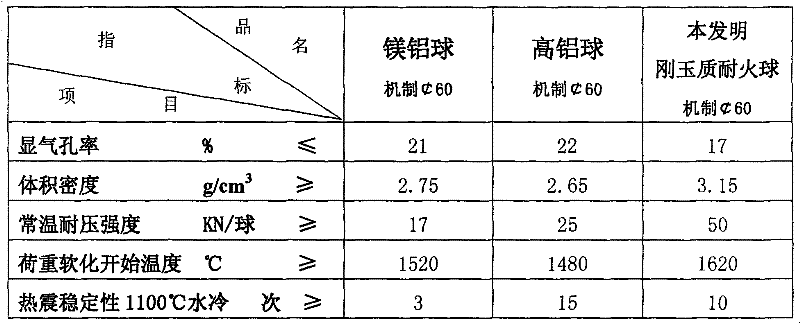

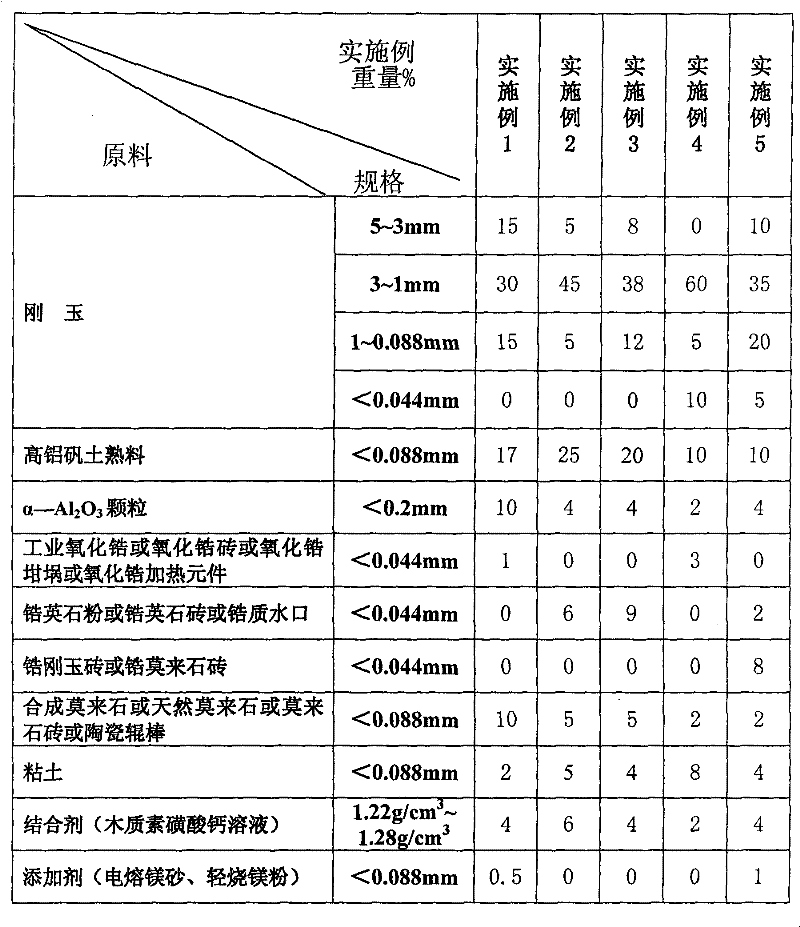

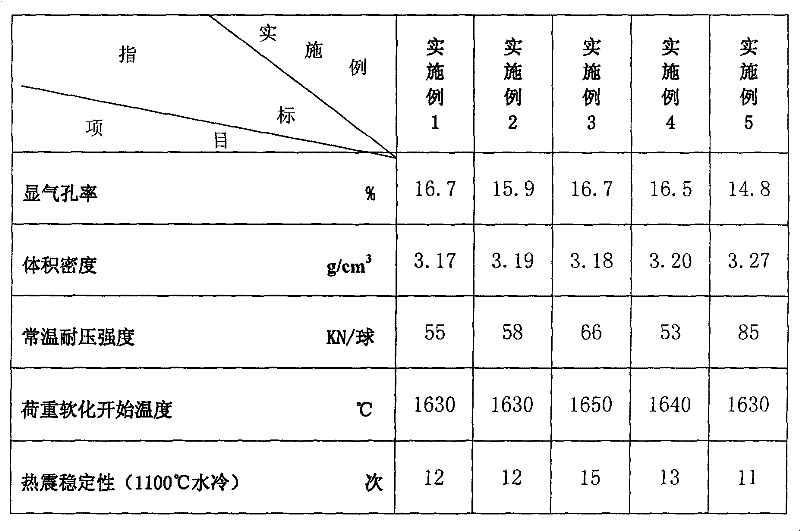

Corundum fireproof ball used for ball-type hot-blast stove and preparation method thereof

InactiveCN101555151AImprove thermal shock resistanceIncrease heat capacityBrick-hot blast stovesHot blastAluminium

A corundum fireproof ball used for a ball-type hot-blast stove and a preparation method thereof are characterized in that the corundum fireproof ball comprises the following main materials, adhesive and additive, wherein the main materials comprises the following raw materials by weight percentage: 0-15% of corundum (granularity of 5-3mm), 30-60% of corundum (granularity of 3-1mm), 5-30% of corundum (granularity of 1-0.088mm), 0-10% of corundum (granularity less than 0.044mm), 10-25% of bauxite chamotte (granularity less than 0.088mm), 2-10% of Alpha-Al2O3 grain, 1-10% of zirconia-contained material, 2-8% of clay and 2-10% of mullite or materials containing mullite which is taken as main phase; the adding amount of the adhesive is 1-6% of the weight of the main materials; and the adding amount of the additive is 0-1% of the weight of the main materials. The preparation method comprises the following steps of ageing mixture, back-rolling, pressing and molding, drying billet, and sintering in a tunnel kiln and the sintering temperature is within 1450-1600 DEG C.

Owner:巩义市金岭耐火材料有限公司

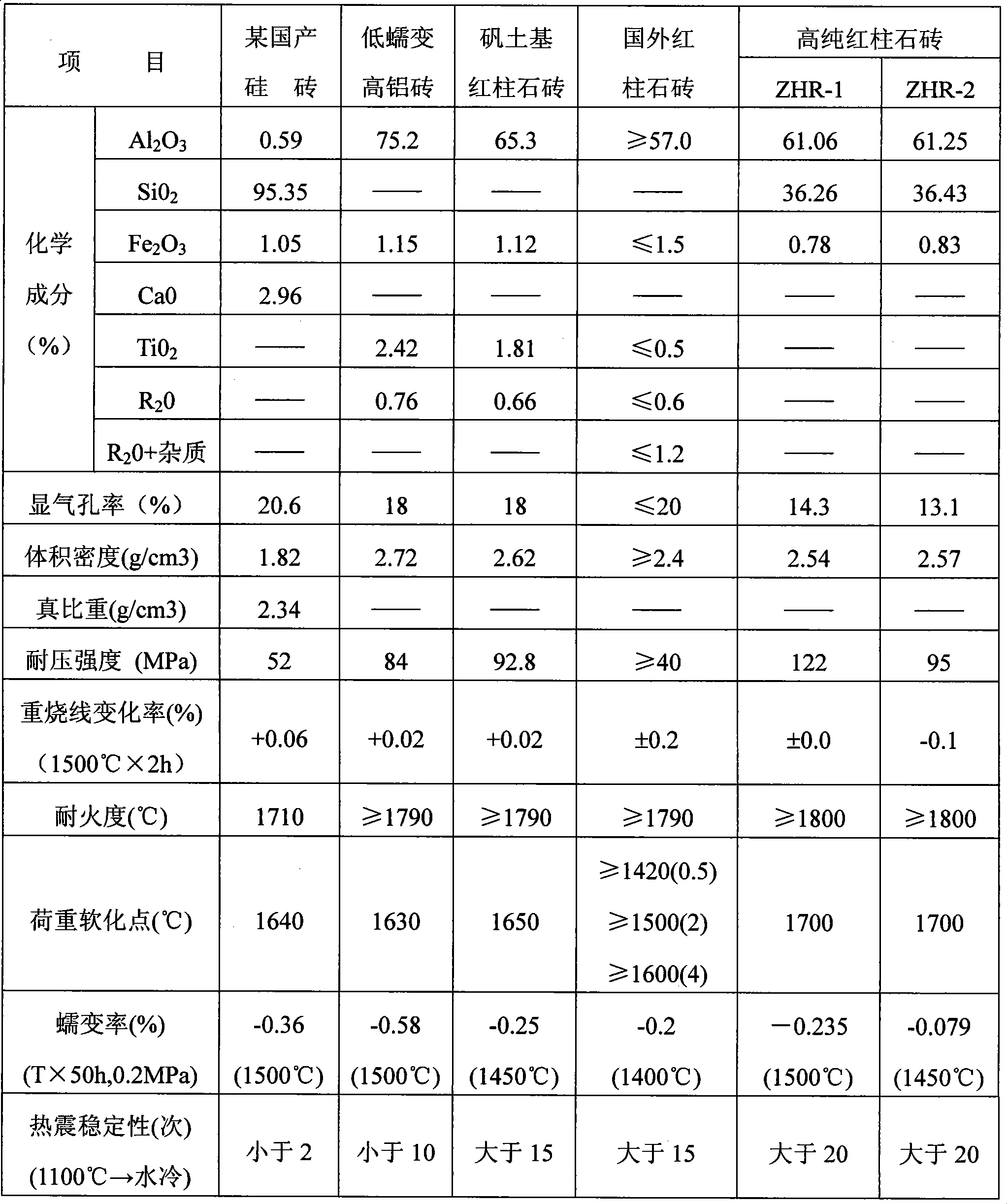

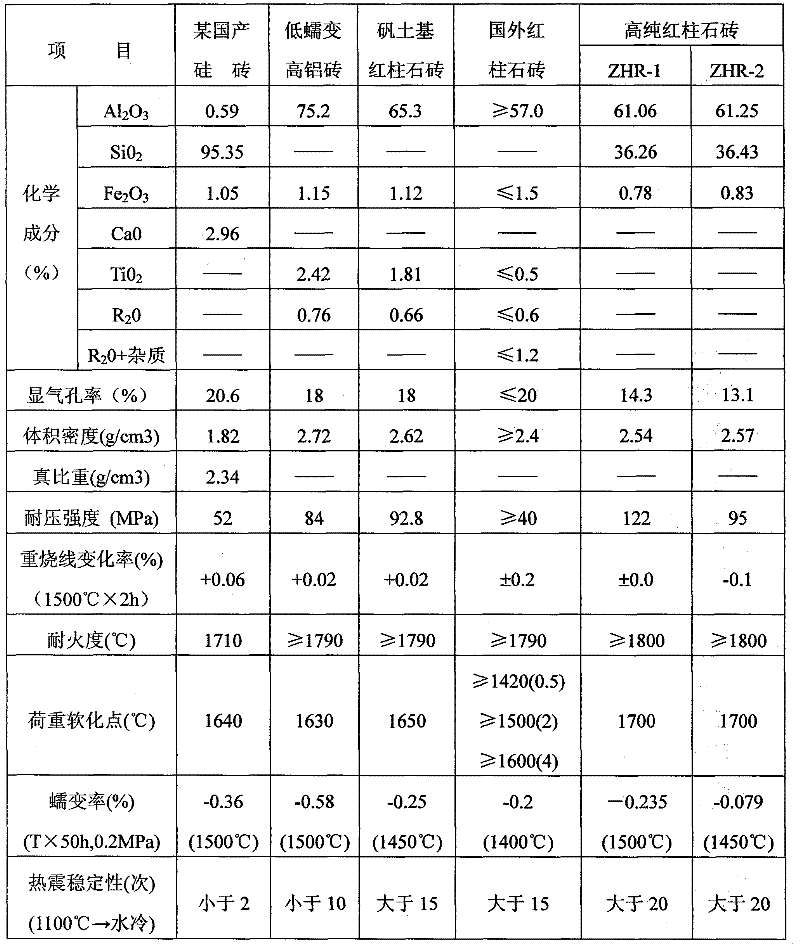

High purity andalusite brick for high blast temperature and long time type hot blast stove and preparation method thereof

The invention discloses a high pure andalusite brick for an air heating furnace with high blast temperature and long service life, and a preparation method thereof. The high pure andalusite brick is prepared by the following steps: andalusite, sillimanite sand, activated alumina powder and kaolin are taken as raw materials, andalusite powder, the activated alumina powder and kaolin powder which have the raw material particle size of between 0.088 and 0 mm are premixed into powder first, then the remaining particle materials, sulphite liquor and the prepared powder are mixed evenly to produce pug, the produced pug is pressed into a green brick, and the green brick is transferred into a high-temperature tunnel kiln for calcination to obtain a product. As a refractory material of a large-scale air heating furnace, the product has low creep rate and good thermal shock stability during use, and can apparently improve the blast temperature and the service life of the air heating furnace, thereby saving a large amount of maintenance cost and energy-saving cost for iron and steel users, and obtaining remarkable social and economical benefits.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

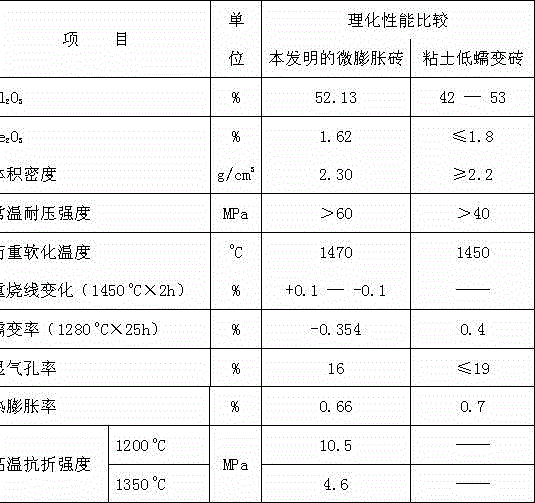

Micro-expansive brick for carbon anode baking furnace and preparation method thereof

The invention discloses a micro-expansive brick for a carbon anode baking furnace and a preparation method thereof. The micro-expansive brick is prepared from the following components in percentage by weight: 6-8% of calcined bauxite clinker having the granularity of 3-5mm, 29-32% of calcined bauxite clinker having the granularity of 1-3mm, 15-20% of calcined flint clay clinker having the granularity of 0-1mm, 10-15% of Guangxi clay powder having the fineness less than or equal to 0.074mm, 14-15% of kyanite powder having the fineness less than or equal to 0.088mm, and 12-18% of calcined bauxite clinker powder having the fineness less than or equal to 0.088mm. The preparation method comprises the following steps: 1, crushing and screening the calcined bauxite clinker and the calcined flint clay clinker; 2, grinding the Guangxi clay, the kyanite and the calcined bauxite clinker; 3, mixing and stirring; 4, adding a paper pulp waste liquid and mixing; 5, pressing brick blanks; 6, drying and calcining to obtain the finished products. The prepared micro-expansive brick for the carbon anode baking furnace is low in creep rate, high in refractoriness under load, high in high-temperature bending strength and longer in service life, and therefore, the service life of the carbon anode baking furnace can be increased to the utmost extent and the maintenance cost can be reduced.

Owner:河南鑫诚耐火材料股份有限公司

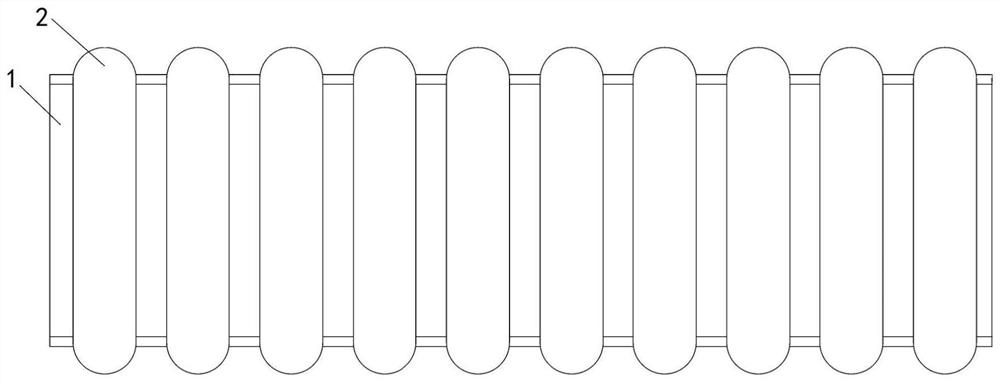

High-ring-stiffness internal rib-reinforced corrugated pipe and preparation method thereof

The invention relates to a high-ring-stiffness internal rib-reinforced corrugated pipe. The high-ring-stiffness internal rib-reinforced corrugated pipe is prepared by extruding and shaping outer materials and inner materials with an extruder, wherein the outer materials is composed of, by weight part, 85-100 parts of high-density polyethylene, 15-25 parts of polypropylene, 5-15 parts of filler, 1-2 parts of bulking agent and 1-3 parts of color masterbatch; the inner materials is composed of 85-100 parts of high-density polyethylene, 15-25 parts of polypropylene, 1-2 parts of bulking agent and1-3 parts of color masterbatch. Compared with the prior art, the high-ring-stiffness internal rib-reinforced corrugated pipe is higher in ring stiffness, light in weigh per meter and capable of greatly reducing the costs of raw materials.

Owner:湖北盈禄塑胶制品有限公司

Breeding Nuclear Fuel Mixture Using Metallic Thorium

InactiveUS20110299645A1Creep rate of be reduceSuperior performanceFuel elementsConversion outside reactor/acceleratorsPlutonium dioxideNuclear power plant

Disclosed is a breeding nuclear fuel mixture including metallic thorium useable in a nuclear power plant, prepared by mixing uranium dioxide (UO2) or plutonium dioxide (PuO2) having ceramic properties with metallic thorium (Th), in order to enable thorium breeding by neutrons released during nuclear fission of U or Pu and conversion of the bred thorium into a novel nuclear fissile material, i.e., U-233, thereby ensuring continuous nuclear fission. The foregoing nuclear fuel mixture may be burned at a reactor core of a nuclear power plant through thorium breeding over a long period of time. Therefore, when the inventive breeding nuclear fuel mixture is employed in a nuclear power plant, utilization of the nuclear power plant may be increased while maximizing conservation of limited uranium resources.

Owner:KOREA ATOMIC ENERGY RES INST +1

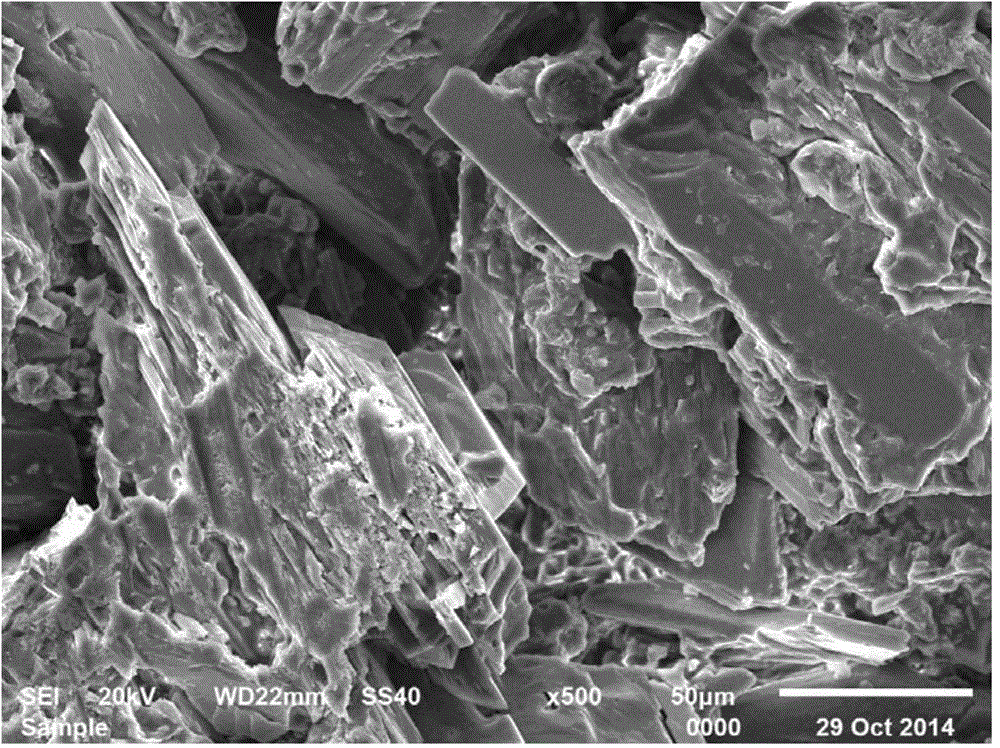

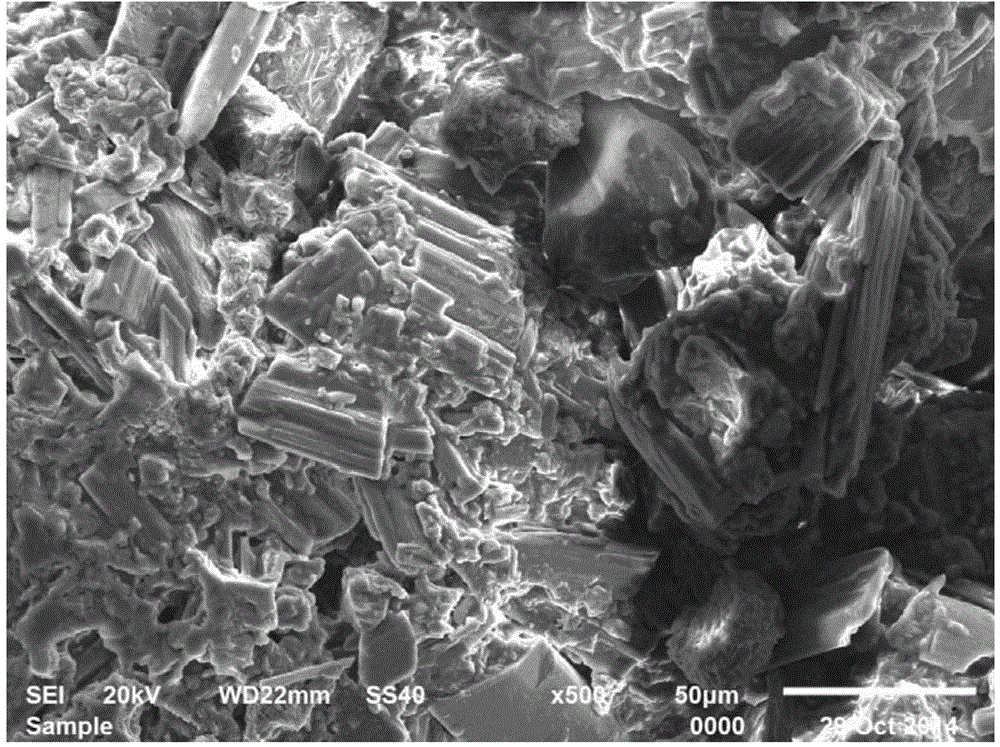

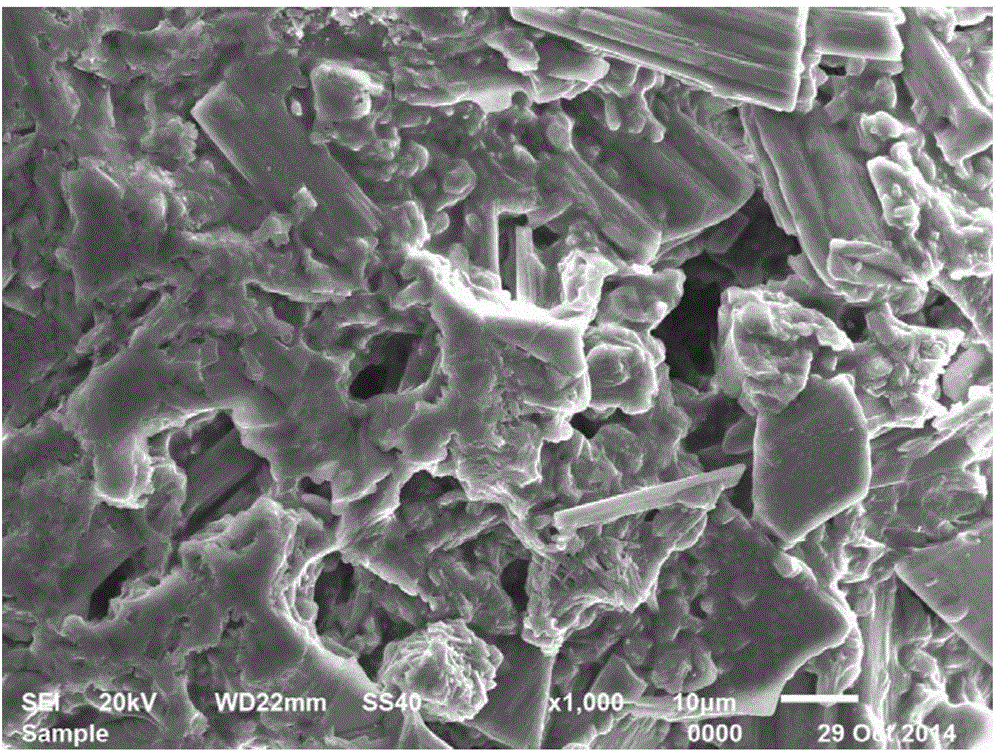

Fireproof material, preparation method thereof and fireproof brick

The invention provides a fireproof material. The fireproof material is prepared from the following components in percentage by mass: 48-62 percent of andalusite, 20-35 percent of sillimanite, 4-8 percent of aluminum oxide, 5-15 percent of corundum, 2-6 percent of combined clay, 1-3 percent of silica powder, 0.5-1.5 percent of paper pulp powder and 0.1-0.3 percent of a water reducing agent. In the fireproof material prepared from the high-purity andalusite and sillimanite, the high-purity corundum and the high-purity aluminum oxide are also added for strengthening a base material so that a main crystal phase mullite in the base material is columnar, long column-shaped or needle-shaped and a special network structure is formed; meanwhile, the needle-column-shaped mullite in the base material forms an interlaced network structure with the andalusite and the sillimanite, so the fireproof material disclosed by the invention is extremely good in thermal shock resistance and stability, relatively high in refractoriness under load (higher than 1700 DEG C) and relatively low in creep rate (0.125%). The invention also provides a preparation method of the fireproof material and a fireproof brick.

Owner:HUNAN XIANGGANG RUITAI TECH

High-aluminum pull brick for carbon anode roasting furnace flame paths and preparation method thereof

The invention discloses a high-aluminum pull brick for carbon anode roasting furnace flame paths and a preparation method thereof. The high-aluminum pull brick for carbon anode roasting furnace flame paths is prepared by mixing, calcining and pressing calcined mullite, calcined high-aluminum bauxite, andalusite granules, alumina powder, Gangxi clay powder and andalusite fine powder. The preparation method comprises the following steps: 1. crushing and screening the calcined mullite and calcined high-aluminum bauxite; 2. selecting 10-16 wt% of alumina powder, 10-12 wt% of Gangxi clay powder and 15-21 wt% of andalusite fine powder, mixing and grinding; 3. mixing the co-ground powder with 8-12 wt% of calcined mullite, 17-23 wt% of calcined high-aluminum bauxite and 25-29 wt% of andalusite granules; 4. adding pulp waste, and compounding; 5. pressing to be green bricks; and 6. drying and calcining to obtain the finished product. The high-aluminum pull brick for carbon anode roasting furnace flame paths has the advantages of low creep rate, high refractoriness under load, favorable high-temperature folding strength and small physical dimension deformation, and can prolong the service life of the carbon anode roasting furnace and lower the maintenance cost.

Owner:河南鑫诚耐火材料股份有限公司

Stator vane for a gas turbine engine

InactiveUS8152454B2Reduce stress concentrationLow cycle fatigueEngine manufacturePump componentsLeading edgeEngineering

A guide vane for a gas turbine includes a vane body having a leading edge and a trailing edge and a shroud extending at least between the leading edge and the trailing edge. The shroud has a first side wall and a second side wall extending essentially radially and in a longitudinal direction of the gas turbine. The first side wall has a groove disposed in a region of the trailing edge extending in a longitudinal direction of the shroud and is configured to receive a sealing plate. The first side wall also has a clearance extending from the groove in a region of the trailing edge, wherein a depth of the clearance in a circumferential direction of the gas turbine is equal to a depth of the groove, and wherein a width of the clearance in the longitudinal direction of the shroud is between one to three times the depth of the clearance.

Owner:GENERAL ELECTRIC TECH GMBH

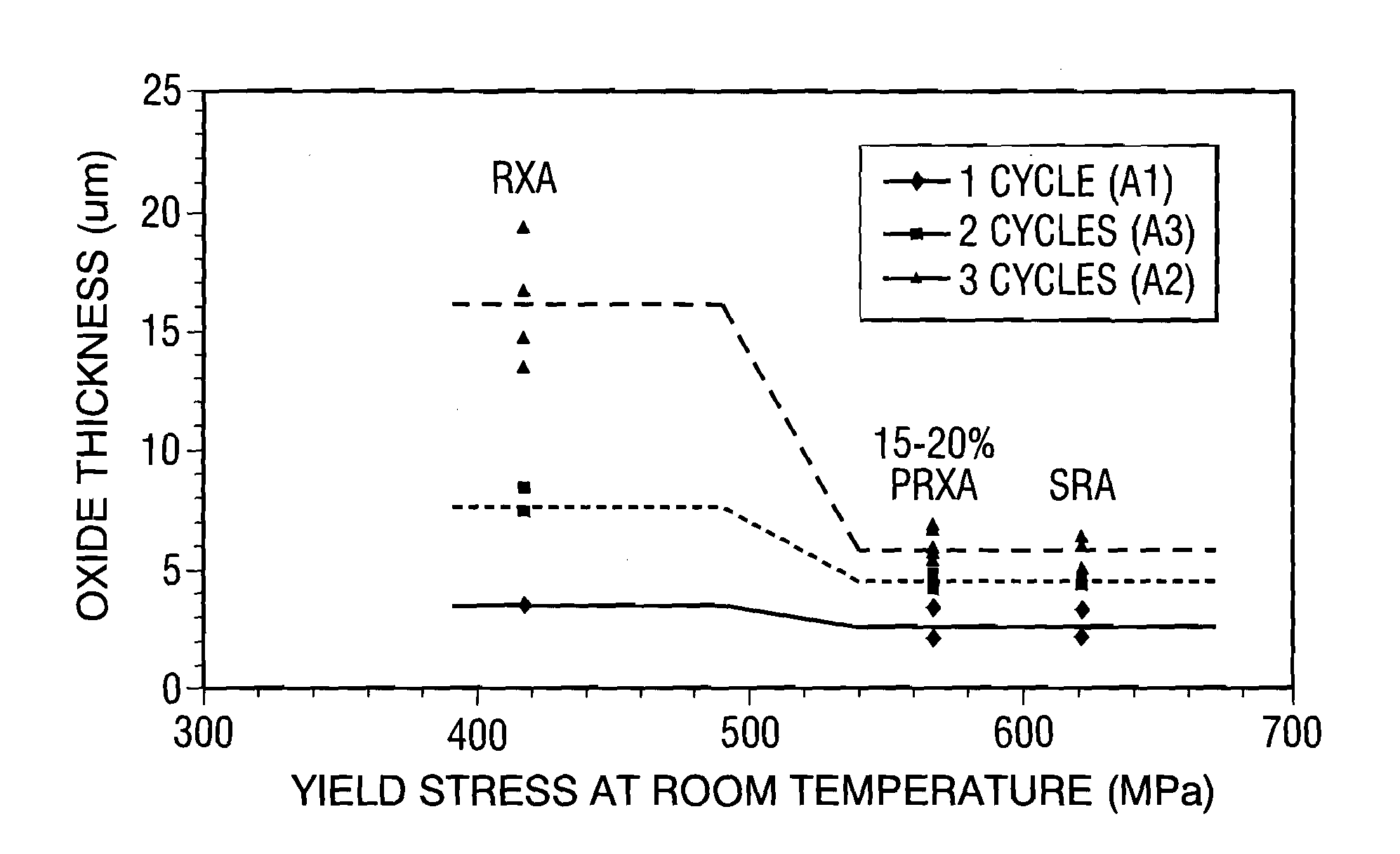

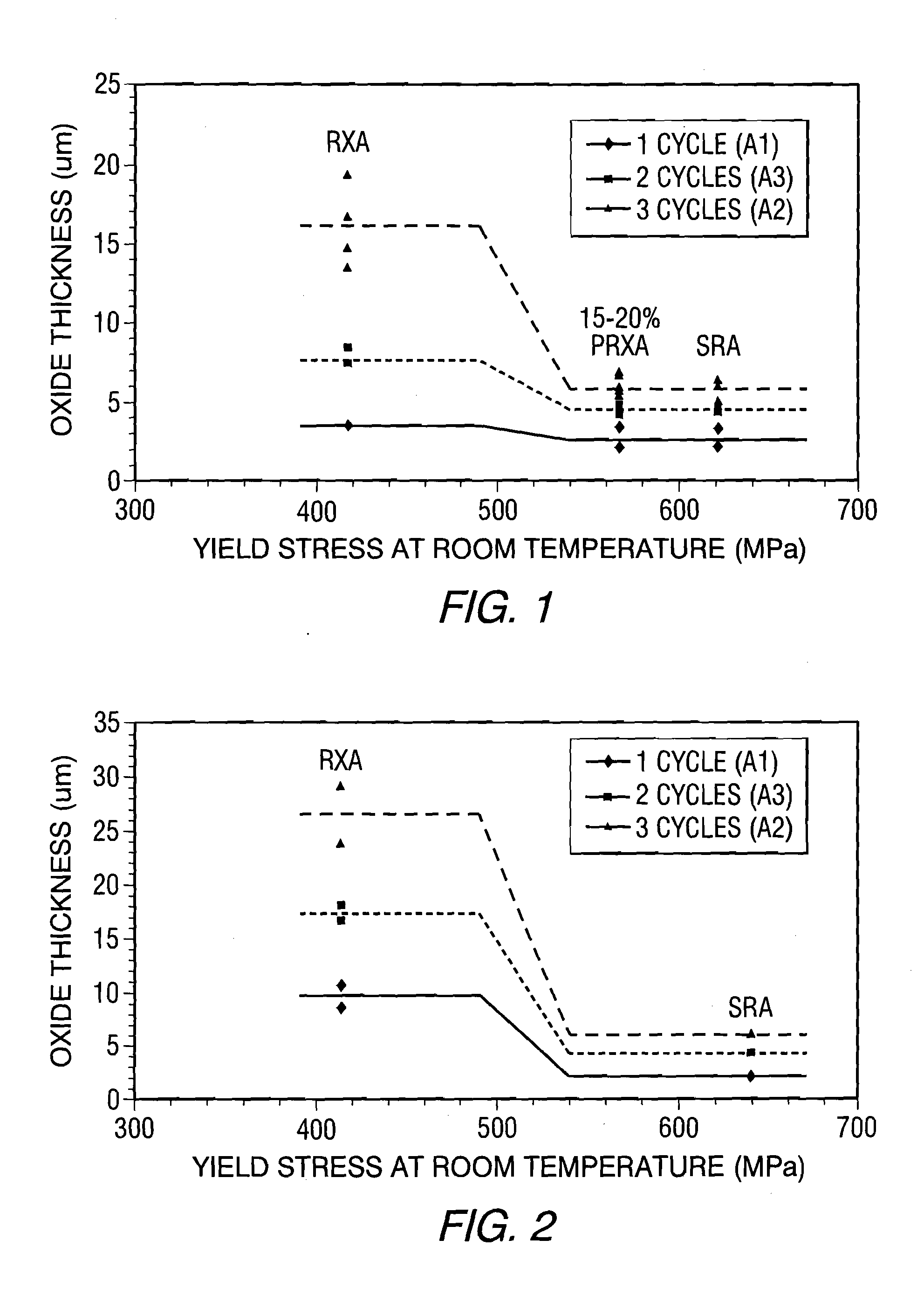

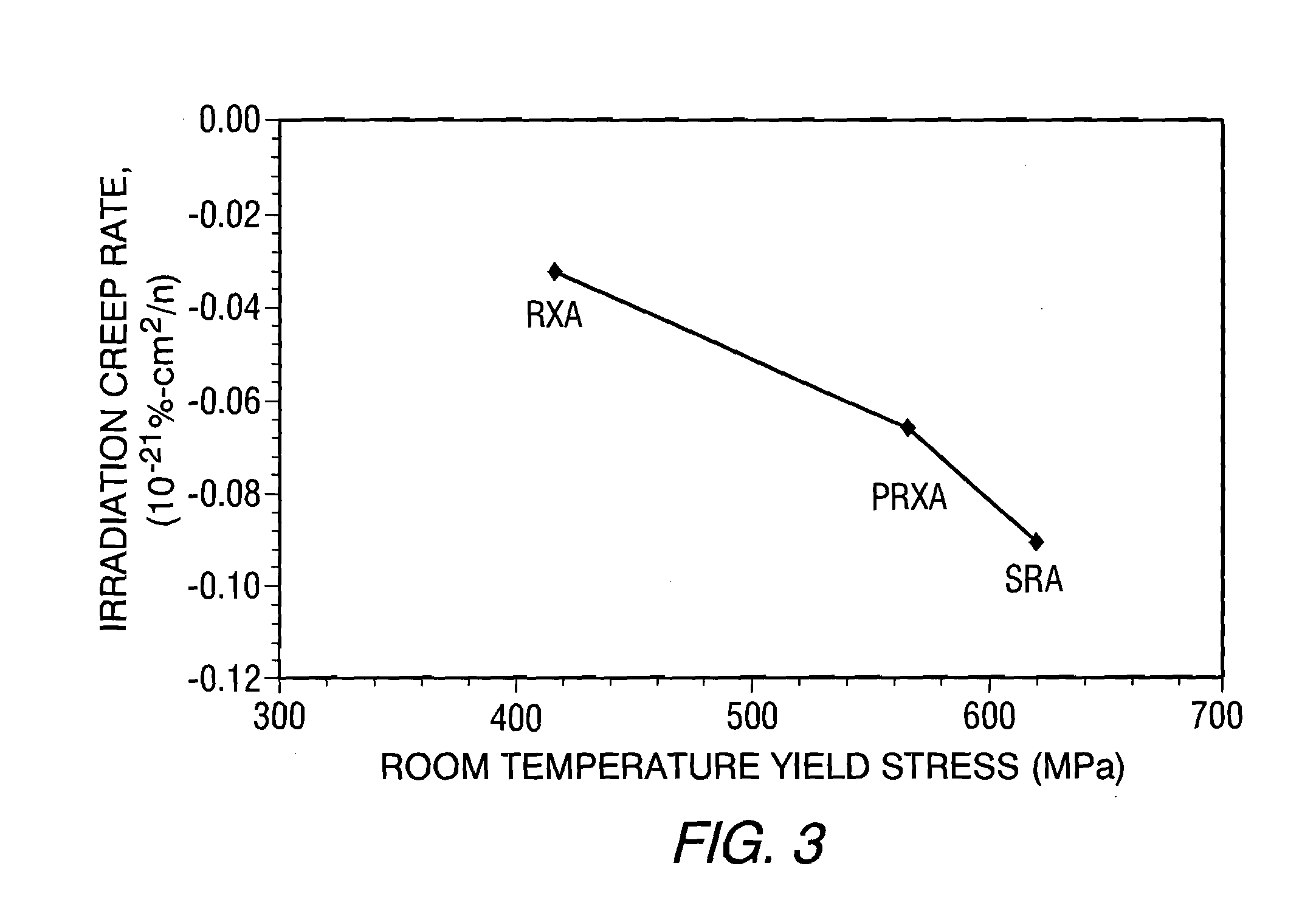

Zirconium alloys with improved corrosion/creep resistance due to final heat treatments

ActiveUS20110293466A1Reduced intermediate anneal temperatureImprove corrosion resistanceNuclear energy generationReactor fuel elementsNiobiumCopper

Articles, such as tubing or strips, which have excellent corrosion resistance to water or steam at elevated temperatures, are produced from alloys having 0.2 to 1.5 weight percent niobium, 0.01 to 0.6 weight percent iron, and optionally additional alloy elements selected from the group consisting of tin, chromium, copper, vanadium, and nickel with the balance at least 97 weight percent zirconium, including impurities, where a necessary final heat treatment includes one of i) a SRA or PRXA (15-20% RXA) final heat treatment, or ii) a PRXA (80-95% RXA) or RXA final heat treatment.

Owner:WESTINGHOUSE ELECTRIC CORP

Low creep brick production method by using alumina tailings and fly ash

The present invention particularly relates to a low creep brick production method by using alumina tailings and fly ash. In the prior art, alumina tailings and fly ash can not be adopted to replace alumina clinker, kyanite, andalusite and mullite to produce a low creep brick. With the present invention, the problem in the prior art is solved. The low creep brick production method specifically comprises: carrying out mixing processing molding on alumina tailings and fly ash, carrying out high temperature sintering homogenization, crushing to form a processing aggregate, taking the processing aggregate, matching the processing aggregate and alumina tailing crude ore fine powder, adding a binder, carrying out blank production and drying, carrying out high temperature sintering, and finally processing into the low creep clay brick product. The low creep brick produced by the production method has a good use performance, and has advantages of good thermal shock stability, low creep rate, long service life and the like compared with the similar products.

Owner:孝义市和中兴矿产有限公司

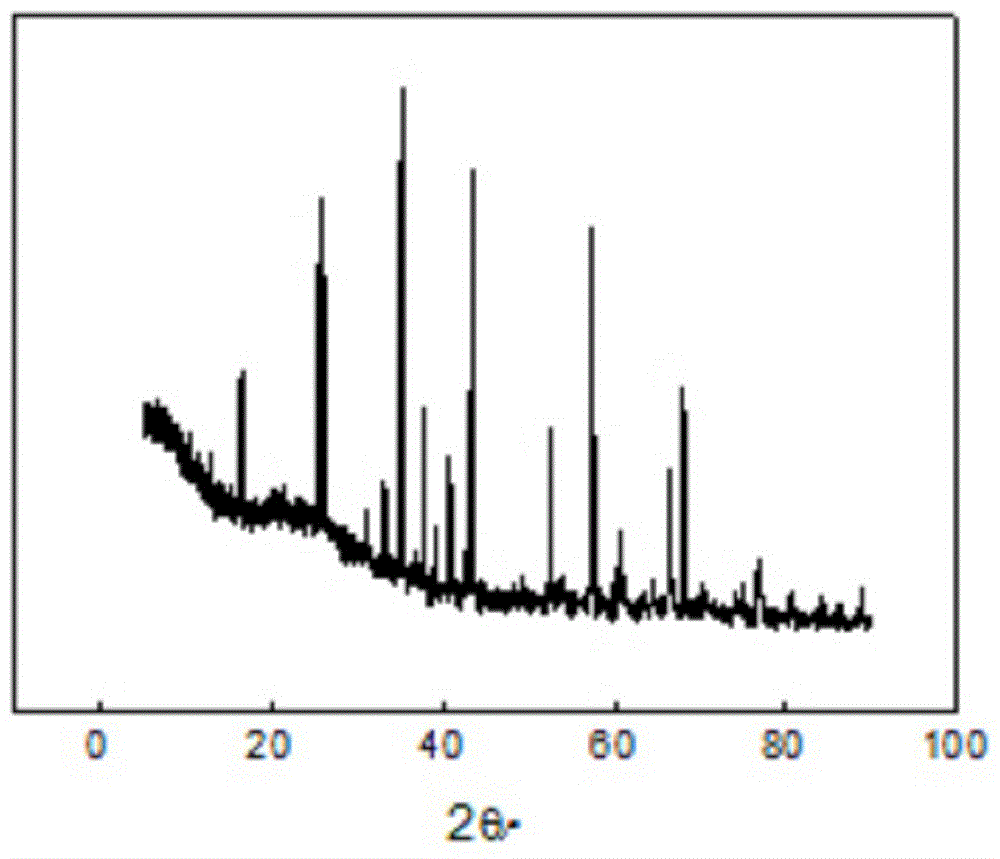

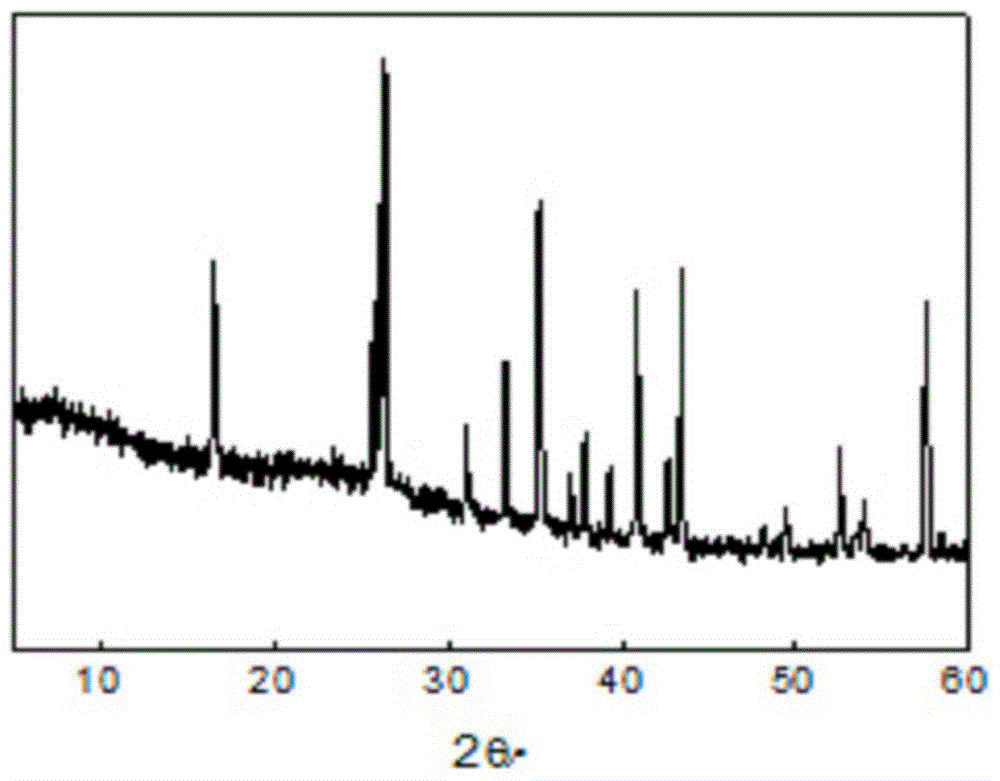

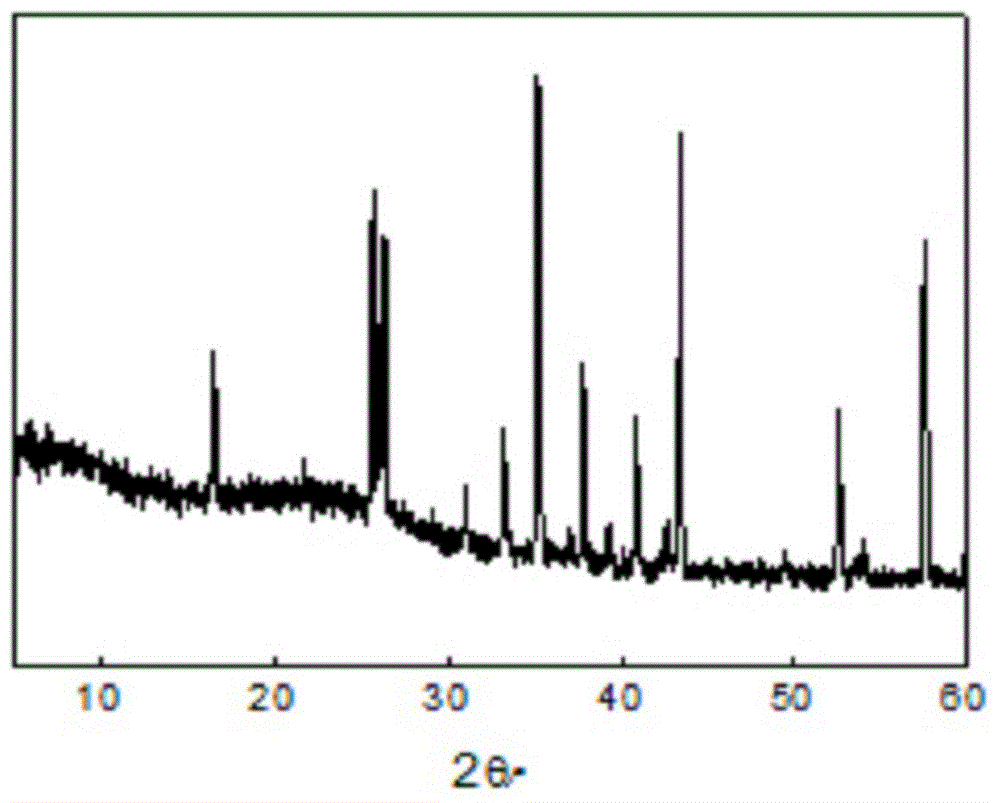

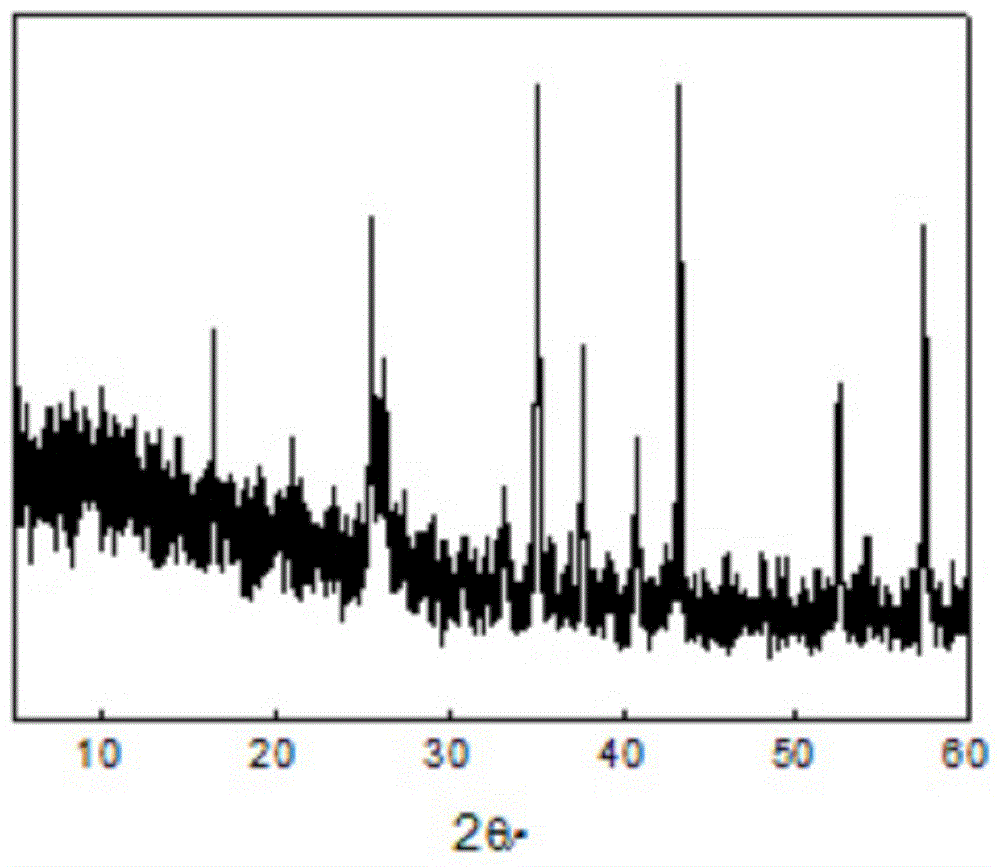

Porous mullite-corundum ceramics preparation method

The invention relates to a porous mullite-corundum ceramics preparation method. The method takes bauxitic clay and diatomite as raw materials, then employs steps of wet grinding, filtering, drying and stirring, and additionally adds a binder, a dispersant, a foam stabilizer and a foaming agent, and finally the product is molded, dried and sintered to obtain the porous mullite-corundum ceramics. The method has the characteristics of simple process, short production period, high efficiency, stable product quality, and low cost. The porous mullite-corundum ceramics material can be prepared according to the requirement, and has good industrial utilization prospect.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

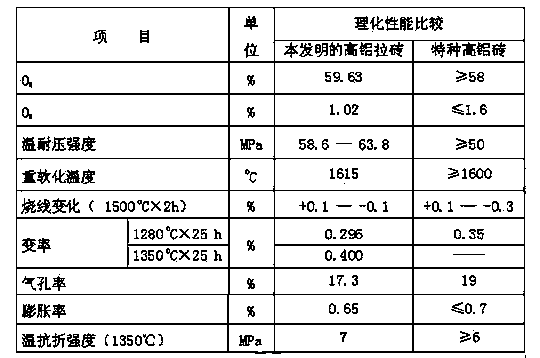

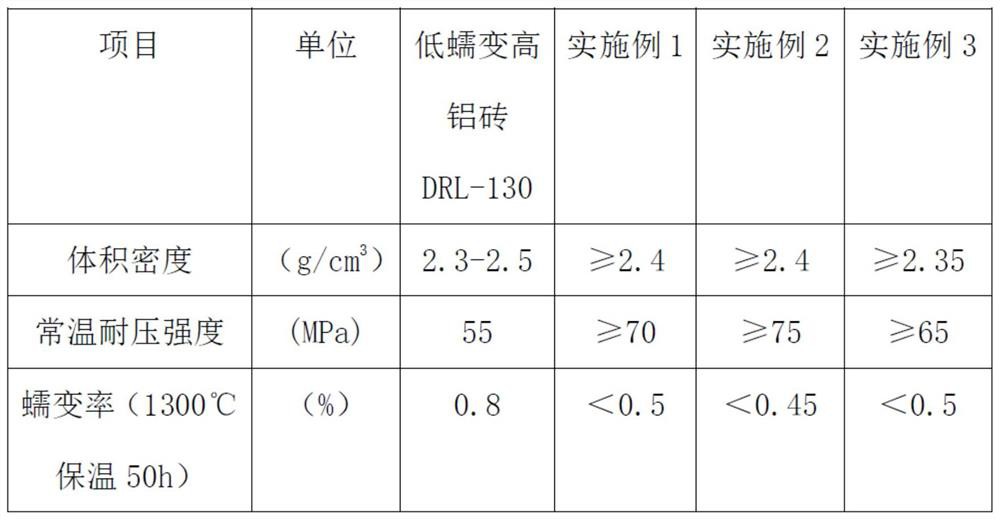

Low-creep high-alumina brick and preparation method thereof

The invention relates to a low-creep high-alumina brick and a preparation method thereof. The low-creep high-alumina brick comprises the following raw materials in parts by weight: 50-60 parts of high-alumina material, 5-20 parts of high-alumina powder, 5-20 parts of alumina powder, 0-20 parts of sillimanite powder, 5-20 parts of andalusite powder and 5-15 parts of Guangxi white mud. The method comprises: mixing and uniformly stirring the high-aluminum material, the high-aluminum powder, the aluminum oxide powder, the sillimanite powder and the andalusite powder in proportion, adding a properamount of water, stirring for 10 minutes, adding the Guangxi white mud, and mixing and stirring for 10 minutes, and after the mixed pug is pressed and formed, drying and sintering to obtain a finishedproduct. The low-creep high-alumina brick has the advantages of high compressive strength and low creep, and the preparation method is simple, low in cost and convenient for batch production.

Owner:郑州凯翔耐火材料有限公司

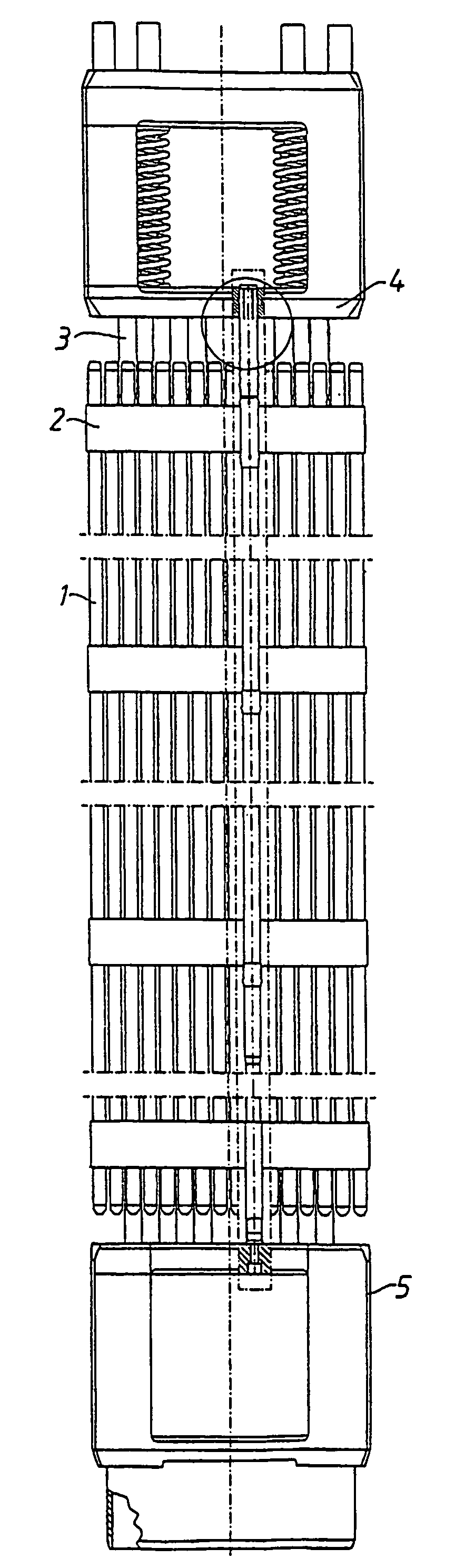

Method, use and device concerning cladding tubes for nuclear fuel and a fuel assembly for a nuclear pressure water reactor

ActiveUS7473329B2Improve resistance to damageReduce riskOptical rangefindersNuclear energy generationPressurized water reactorNiobium

A method of producing a cladding tube for nuclear fuel for a nuclear pressure water reactor includes forming a tube which at least principally consists of a cylindrical tube component of a zirconium-based alloy, where the alloying element, except for zirconium, which has the highest content in the alloy is niobium, wherein the niobium content in weight percent is between about 0.5 and about 2.4 and wherein no alloying element, except for zirconium and niobum, in the alloy, has a content which exceeds about 0.2 weight percent. The cladding tube is then annealed such that the tube component is partly but not completely recrystallized. The degree of recrystallization in the tube component is higher than about 40% and lower than about 95%. A fuel assembly for a nuclear pressure water reactor also has a plurality of such cladding tubes.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

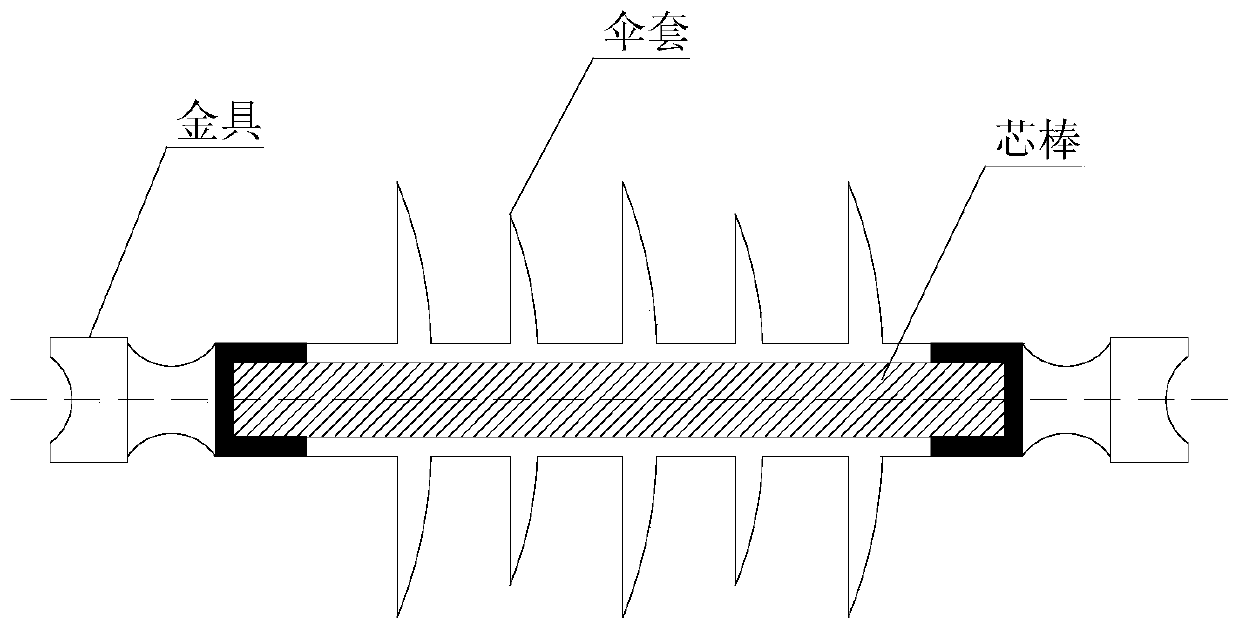

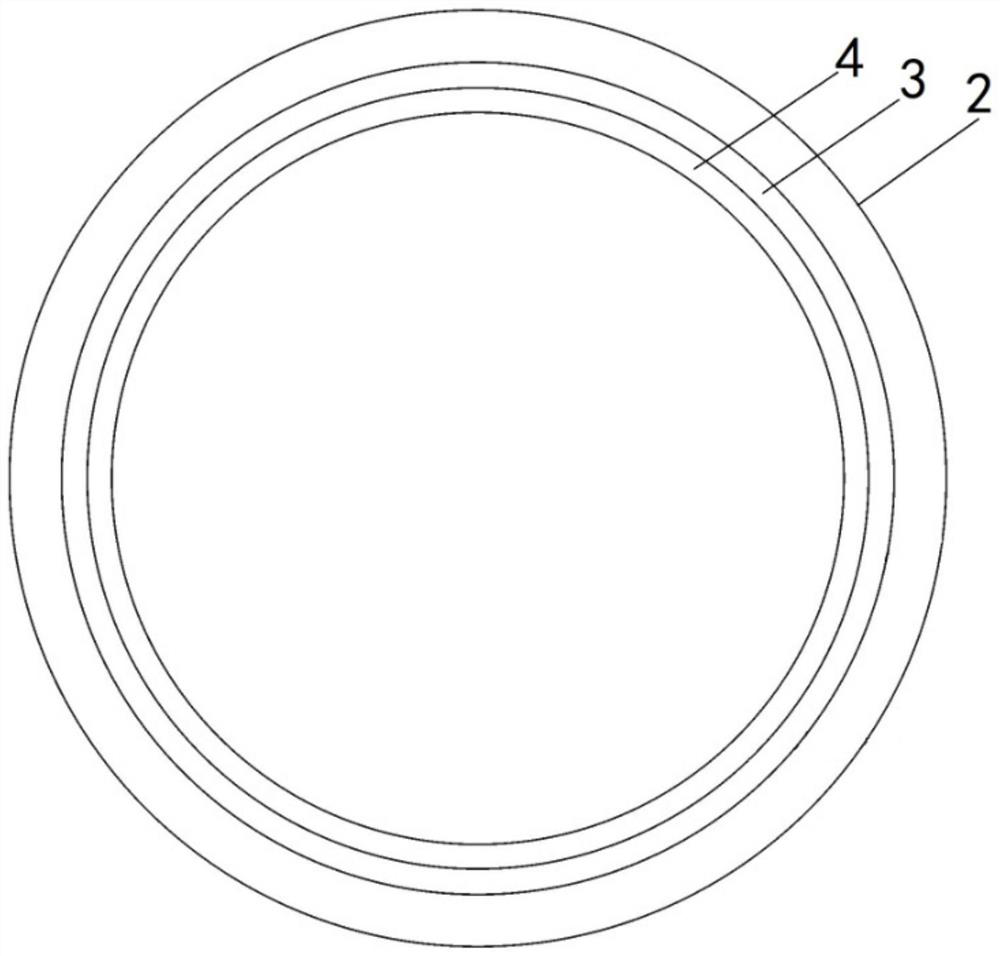

Basalt fiber insulator core rod

The invention provides a basalt fiber insulator core rod. The core rod comprises basalt fibers, high-temperature-resistant resin and a curing agent, wherein the core rod is formed by adopting a pultrusion process, the section of the core rod is round or similar to a circle, the volume fraction of the basalt fiber is 65-75%, the volume fraction of the high-temperature-resistant resin is 20-40%, andthe volume fraction of the curing agent is 5-10%. According to the basalt fiber insulator core rod, the tensile strength is 1200-1500 MPa, the bending strength is 1200-1400 MPa, the mechanical strength is high, the requirement of the electric power industry for a large-diameter high-strength core rod is met, meanwhile, the structure is reliable, the performance is stable, the safe operation margin is large, flashover, breakdown and pollution flashover accidents are avoided, and safe operation of a line is guaranteed. Besides, the basalt fiber insulator core rod is high in temperature resistance and insulating property, the requirements of high-voltage and extra-high-voltage circuits for large-diameter high-strength core rods are met, and the increasingly-developed requirements of the power industry are met.

Owner:衡水瑞纤新材料科技有限公司

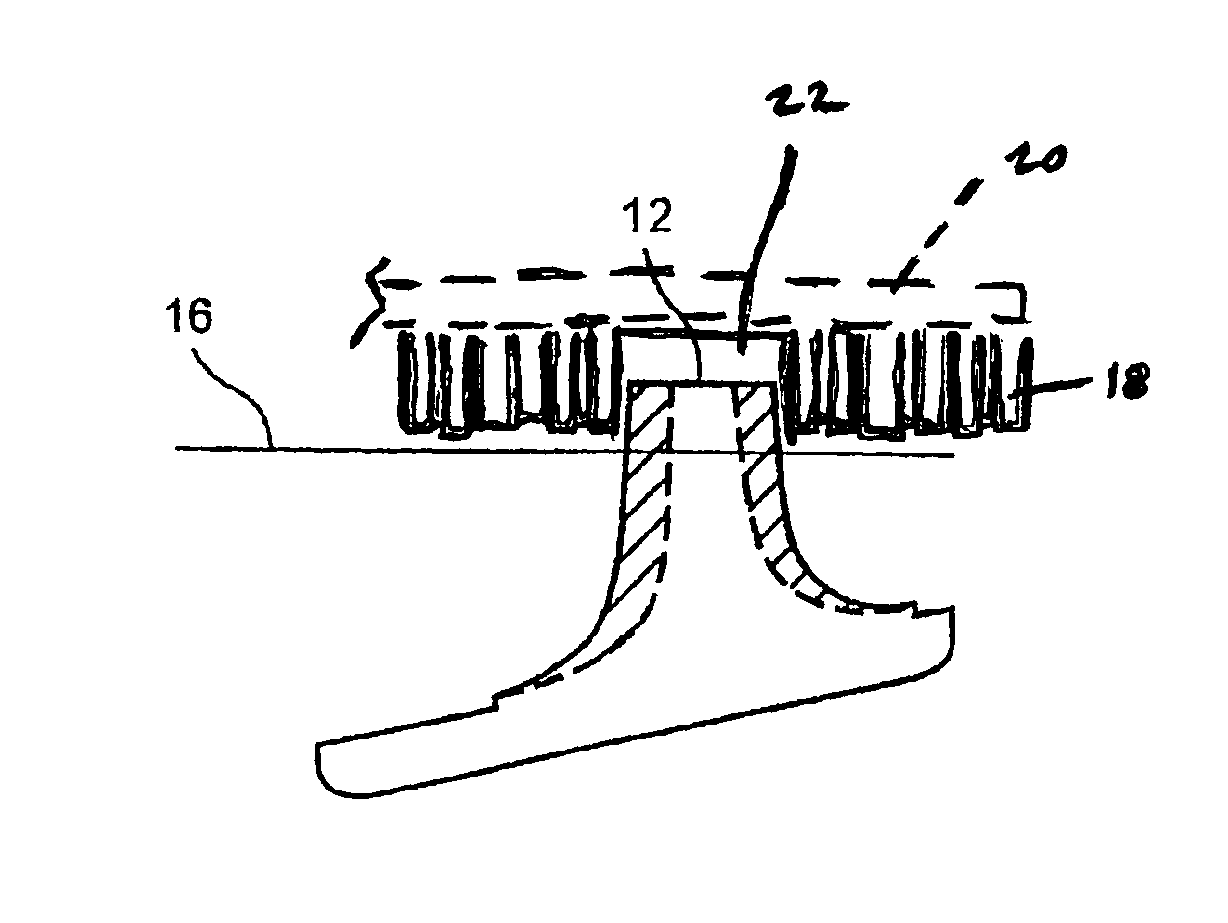

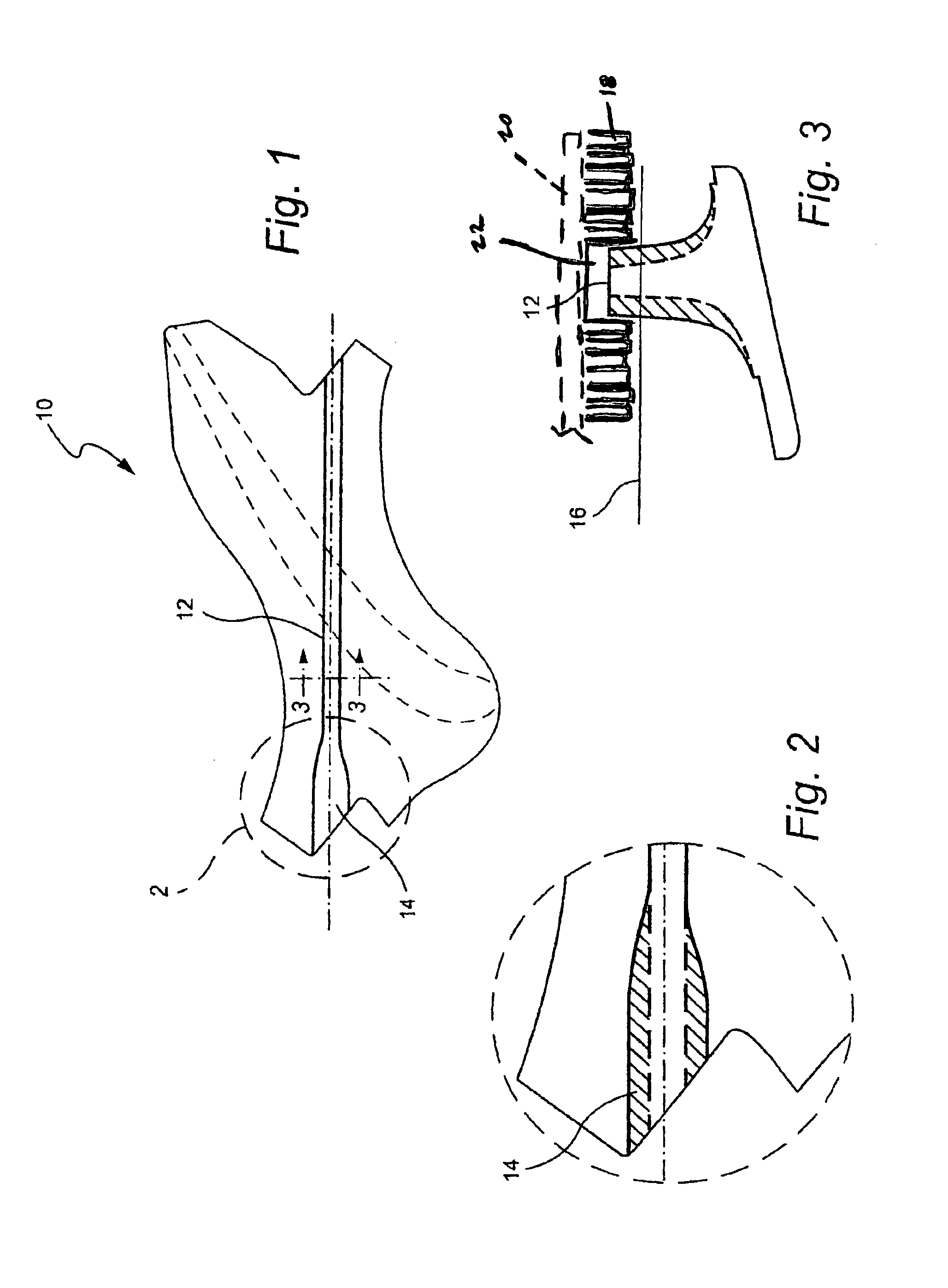

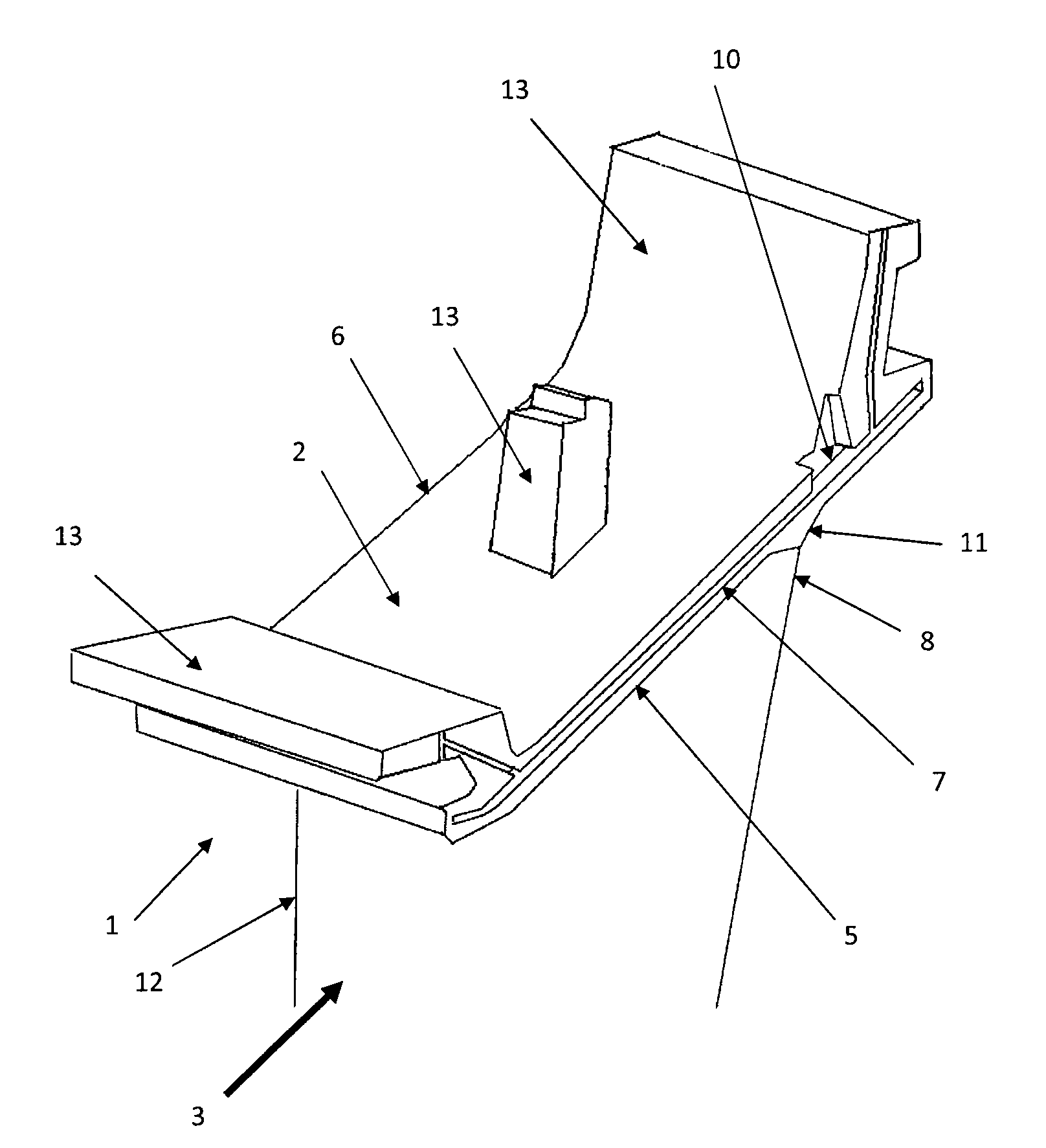

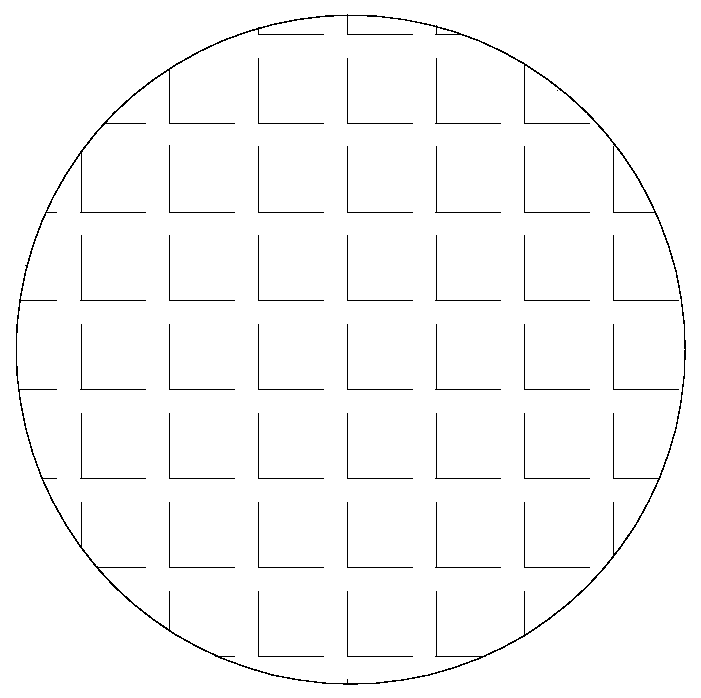

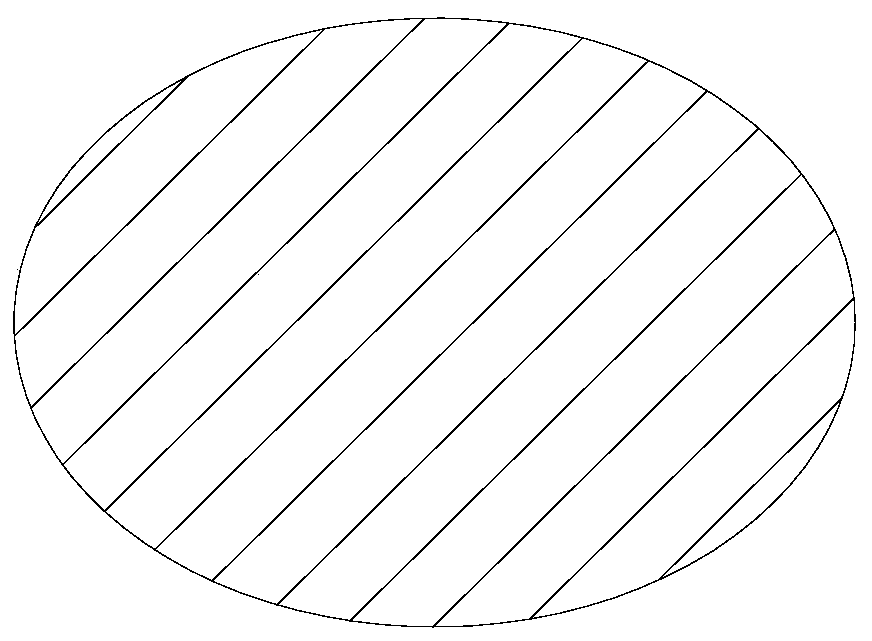

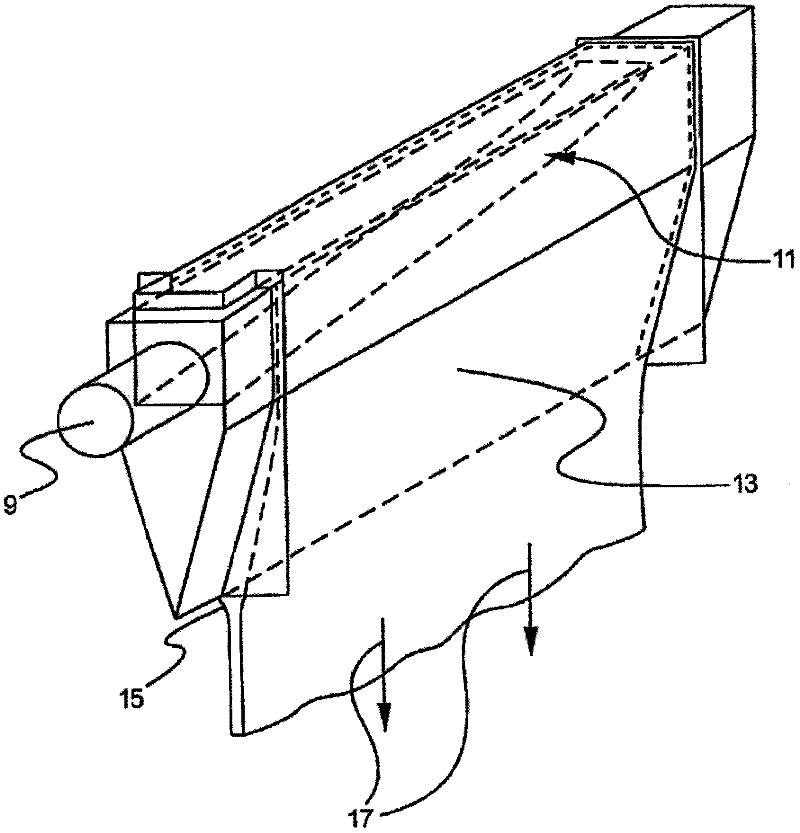

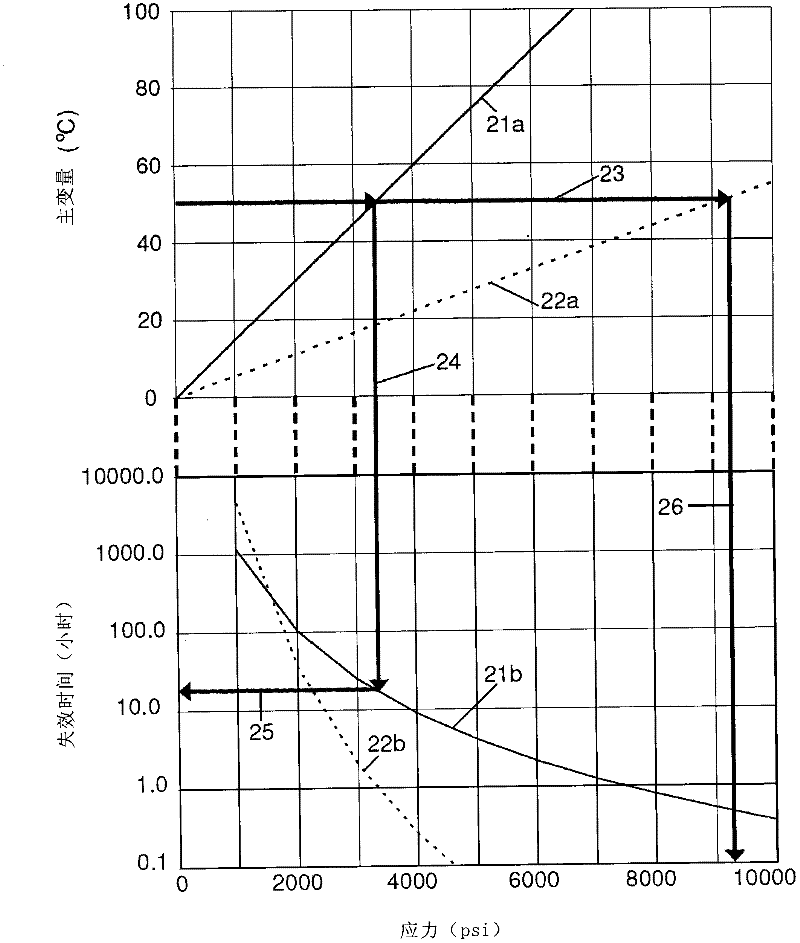

High static fatigue alumina isospipes

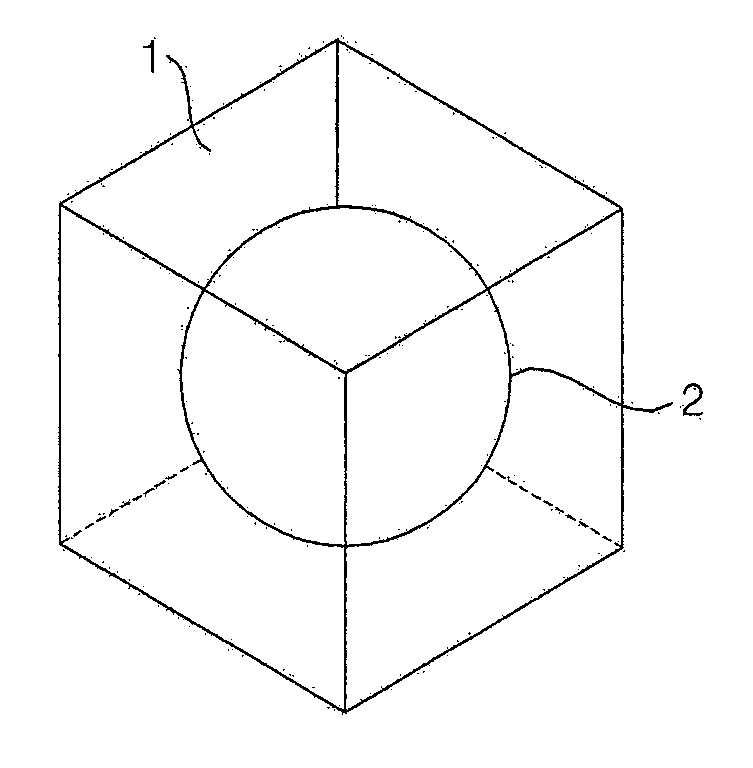

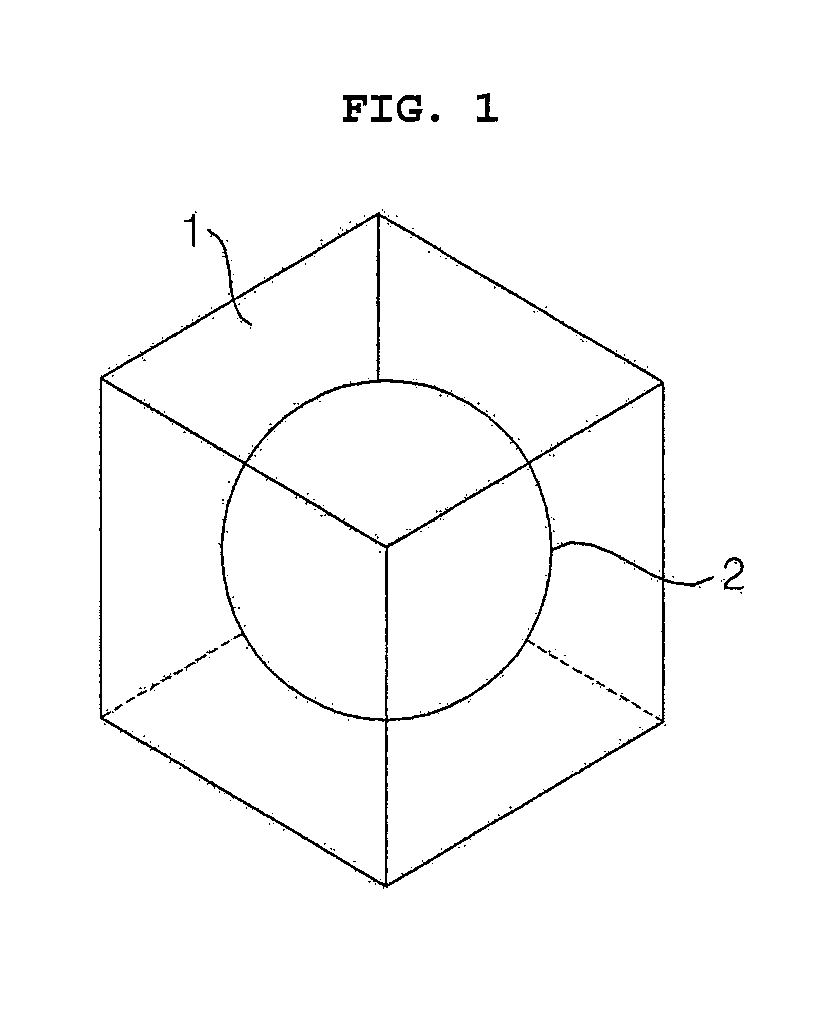

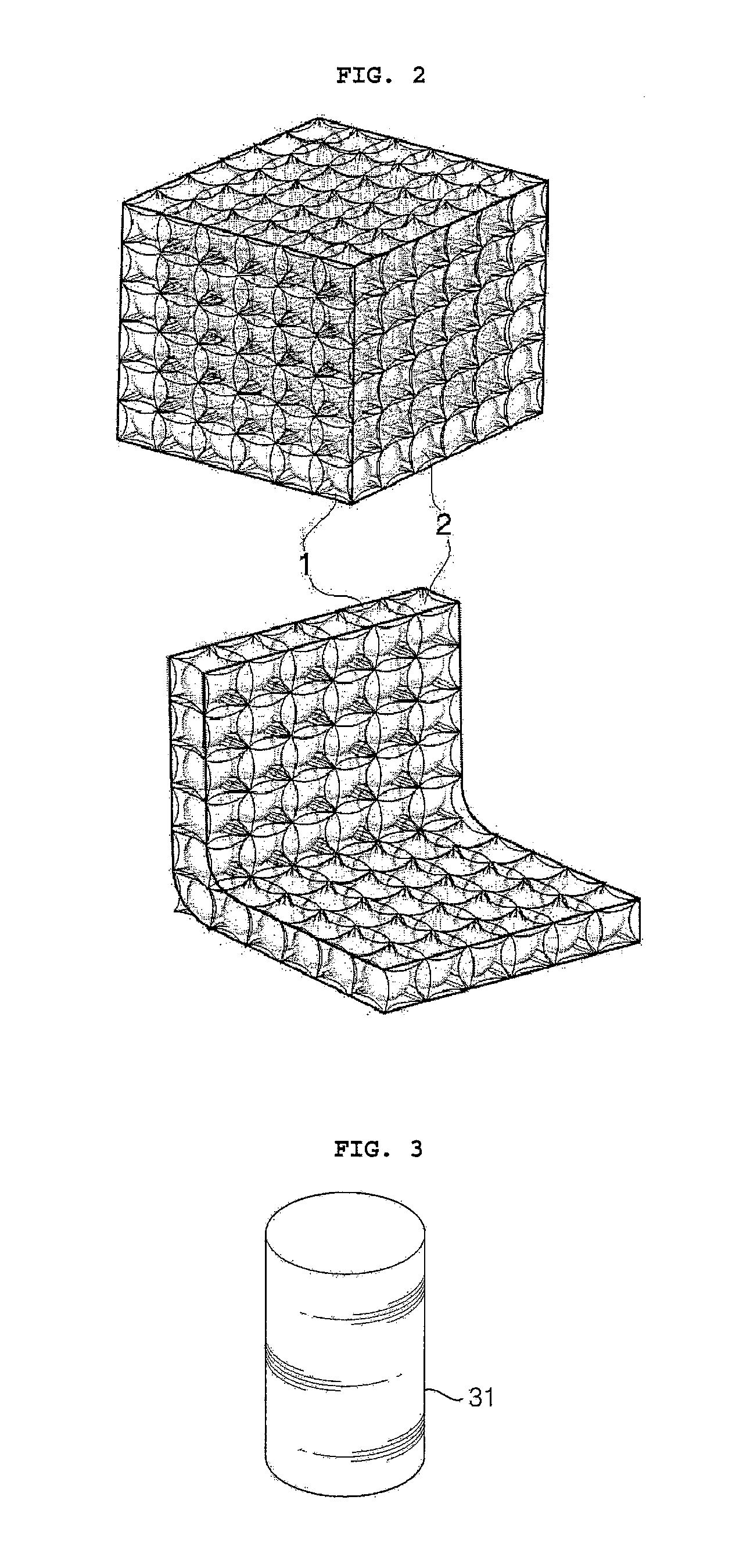

ActiveCN102442760AReduce volume fractionWill not affect the replacementGlass forming apparatusGlass-ceramicGlass sheet

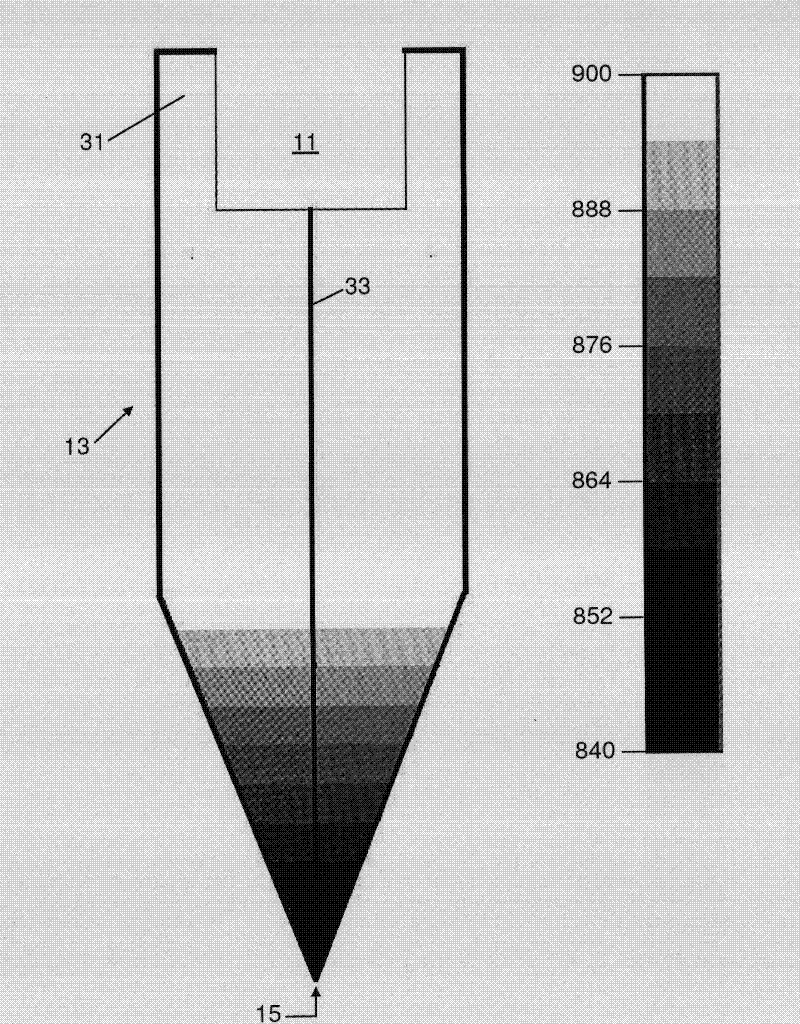

Isopipes (13) for making a glass or a glass-ceramic using a fusion process are provided. The isopipes are made from an alumina material which has a higher static fatigue than existing alumina materials intended for use as isopipes. In particular, the alumina materials have times-to-failure (static fatigues) of greater than one hour at 1200 DEG C at an applied stress of 10,000 psi. These high levels of static fatigue allow alumina isopipes to replace zircon isopipes in the manufacture of high performance glass sheets by the fusion process, including glass sheets which are incompatible with zircon isopipes but compatible with alumina isopipes, e.g., chip and scratch resistant glass sheets which have high alkali contents.

Owner:CORNING INC

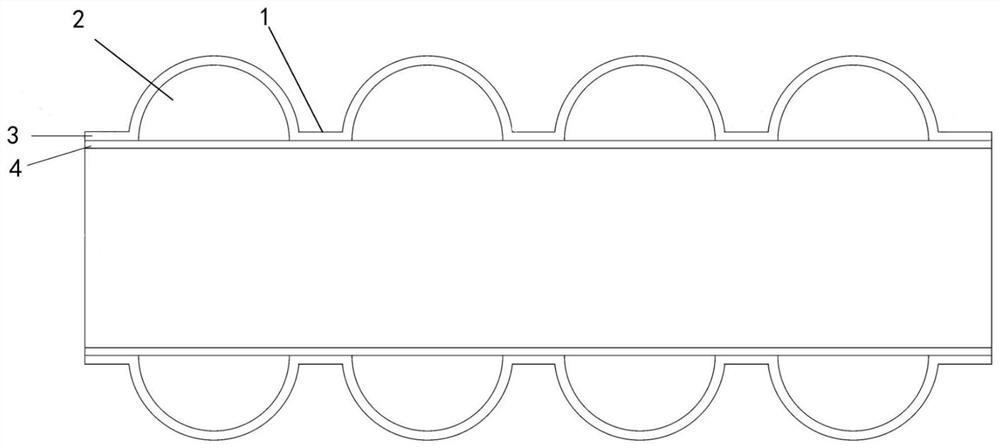

Glass microsphere and glass fiber composite reinforced corrugated pipe and production method thereof

PendingCN113418129ASimple moldingGood visual appearanceElongated constructional elementsThermal insulationSmooth surface

The invention discloses a glass microsphere and glass fiber composite reinforced corrugated pipe and a production method of the glass microsphere and glass fiber composite reinforced corrugated pipe. A pipe body comprises an inner wall and an outer wall. The outer wall comprises wave crest sections and wave trough sections, wherein the wave crest sections and the wave trough sections are regularly spaced in sequence. The inner wall is formed by a smooth pipe body layer. A composite reinforced material of the outer wall contains glass microspheres and glass fibers. The production method of the glass microsphere and glass fiber composite reinforced corrugated pipe comprises the steps that the hollow glass microspheres and the chopped glass fibers are added into the composite reinforced material of the outer wall, and the color of the inner wall and the color of the outer wall are distinguished. The superfine glass microspheres in the corrugated pipe contain gas, are of a hollow structure, have the advantages of low heat conductivity coefficient, light weight, smooth surface and the like, and can be used for preparing pipes with good thermal insulation and mechanical properties. The glass fibers in the corrugated pipe have the advantages of high tensile strength, good heat resistance, heat insulation, sound insulation, flame retardance, acid and alkali resistance, excellent insulativity and the like, and can be used for preparing the heat-resistant, acid-resistant, alkali-resistant and high-strength pipes.

Owner:河南金铨塑业有限公司

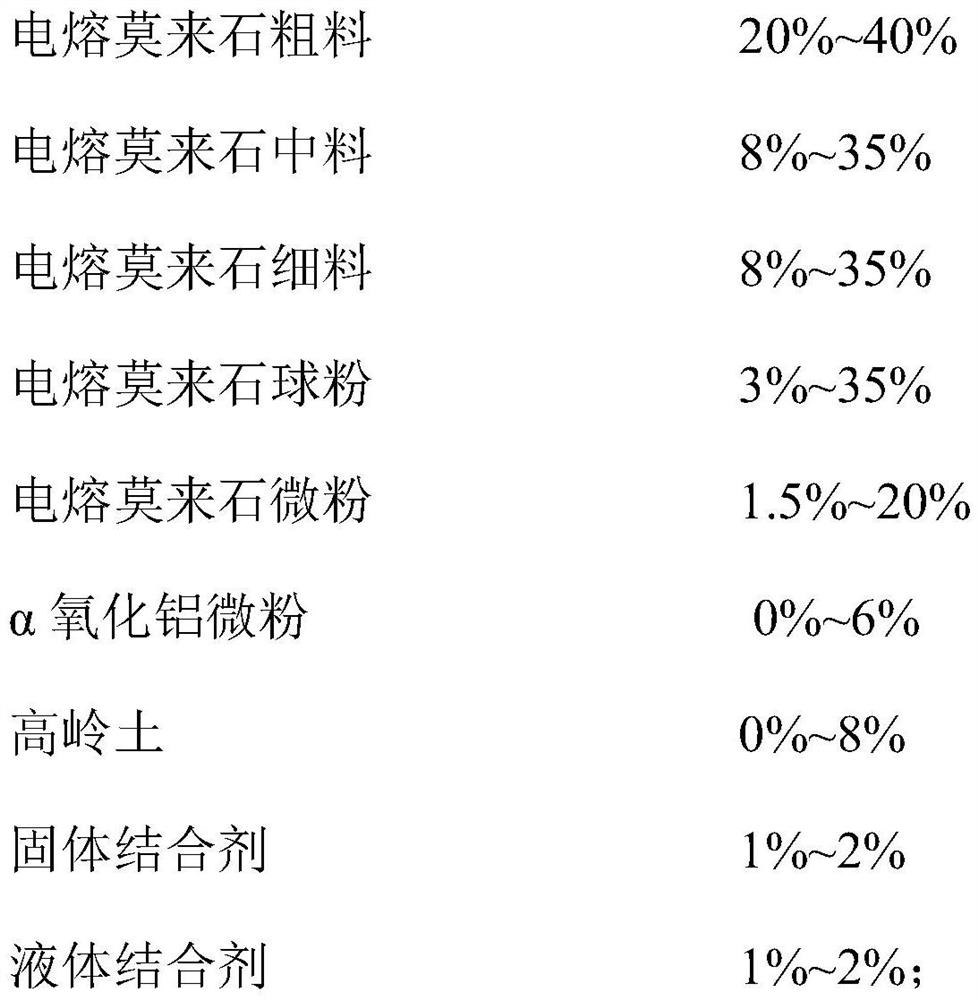

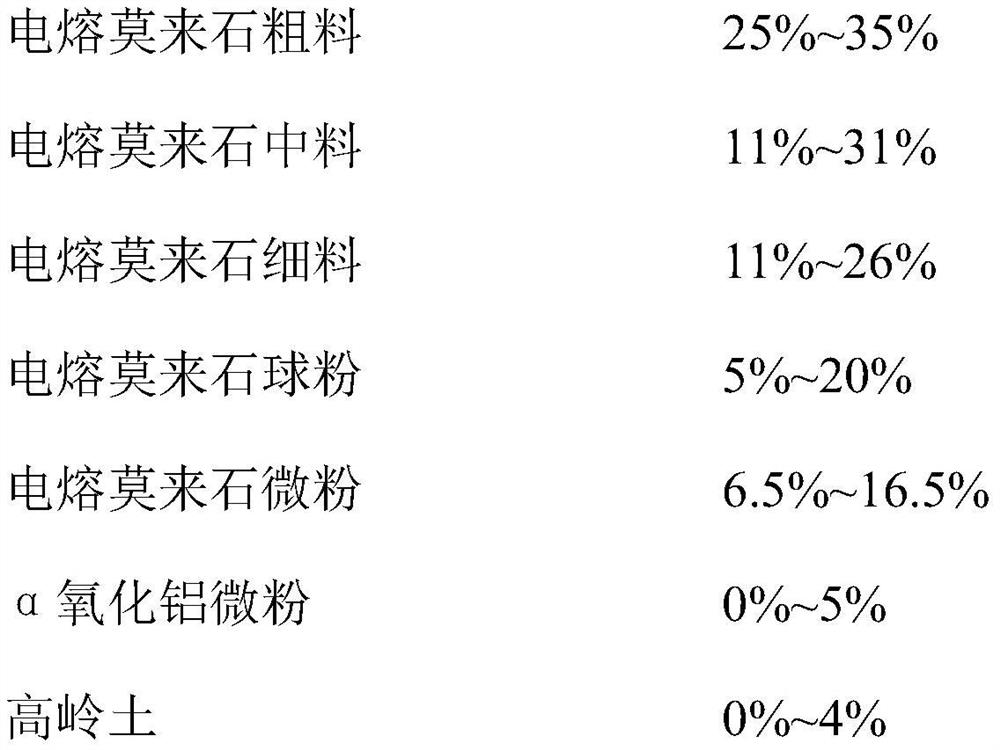

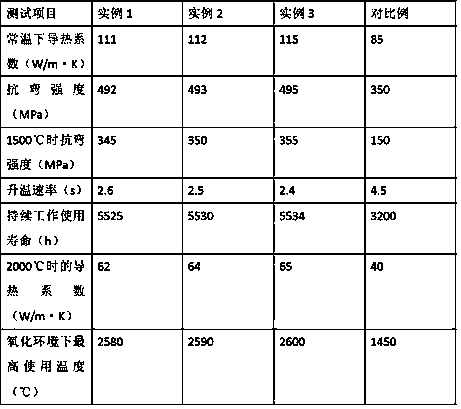

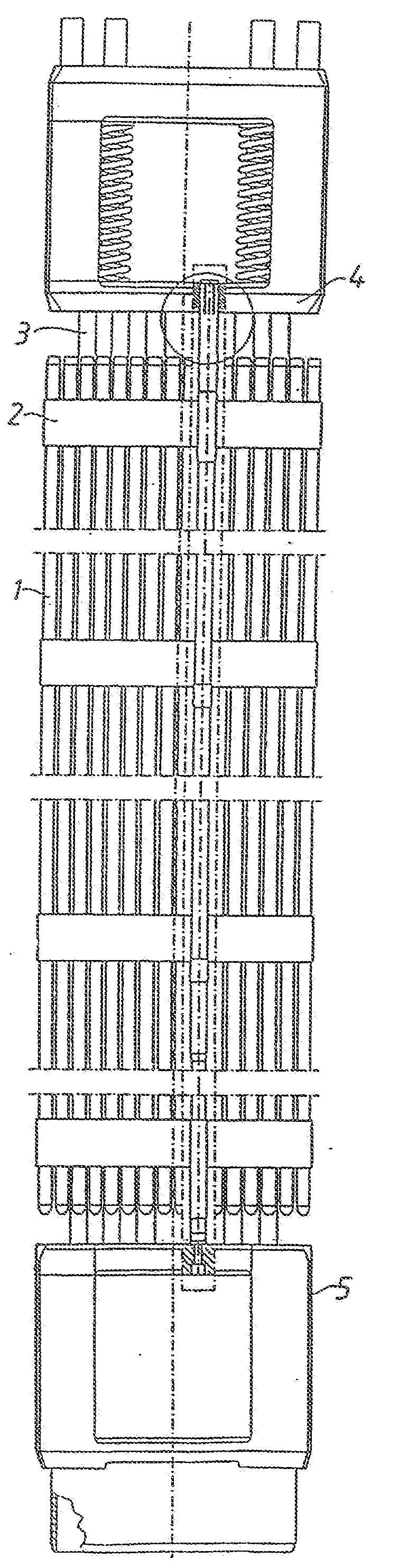

Resintered fused mullite brick and preparation method and application thereof

PendingCN112341221AOptimizing particle size distribution combined with sintering processReduce contentBrickKaolin clay

The invention discloses a resintered fused mullite brick and a preparation method and application thereof. The resintered fused mullite brick comprises the following raw materials in percentage by weight: 20-40% of fused mullite coarse material, 8-35% of fused mullite medium material, 8-35% of fused mullite fine material, 3-35% of fused mullite ball powder, 1.5-20% of fused mullite micro powder, 0-6% of alpha alumina micro powder, 0%-8% of kaolin, 1%-2% of a solid binding agent and 1%-2% of a liquid binding agent; the resintered fused mullite brick has characteristics of low porosity, good quality and prolonged service life, and further has low creep rate at a high temperature.

Owner:广州市白云区石井特种耐火材料厂

Preparation method of superhigh-temperature anti-oxidative ceramic heating unit

InactiveCN108503358AWith high temperature oxidation resistanceHigh resistivityHeat conductingRare earth

The invention discloses a preparation method of a superhigh-temperature anti-oxidative ceramic heating unit and belongs to the technical field of heating unit preparation. The ceramic heating unit isdivided into an inner layer and an outer layer, and graphite is taken as a doping component for the inner layer of the heating unit, so that heat conducting capacity of the inner layer of the heatingunit is improved; by means of added rare-earth metal, electrical resistivity and high-temperature strength of ceramics can be improved, ceramic crystal grains are refined, and creep rate can be reduced. According to the preparation method, molybdenum and silicon in molybdenum disilicide are bonded through metallic bonds, silicon is bonded through covalent bonds, molybdenum disilicide is tetragonalcrystal, when the temperature of a heating element is higher than 1700 DEG C, an SiO2 protecting film can be formed, can be condensed at the melting point of 1710 DEG C and is fused with SiO2 to formmolten drops, and the inner layer of the heating unit is covered, so that highly conductive substances such as graphite and the like are protected from being oxidized; furthermore, by means of synergistic effect of mutual filling of silicon carbide and bentonite, the prepared ceramic material has good mechanical properties at superhigh-temperature and has broad application prospect.

Owner:田秋珍

Method, use and device concerning cladding tubes for nuclear fuel and a fuel assembly for a nuclear pressure water reactor

InactiveUS20090060115A1Improve resistance to damageReduce riskOptical rangefindersFuel elementsNiobiumPressurized water reactor

A method of producing a cladding tube for nuclear fuel for a nuclear pressure water reactor includes forming a tube which at least principally consists of a cylindrical tube component of a zirconium-based alloy, where the alloying element, except for zirconium, which has the highest content in the alloy is niobium, wherein the niobium content in weight percent is between about 0.5 and about 2.4 and wherein no alloying element, except for zirconium and niobium, in the alloy, has a content which exceeds about 0.2 weight percent. The cladding tube is then annealed such that the tube component is partly but not completely recrystallized. The degree of recrystallization in the tube component is higher than about 40% and lower than about 95%. A fuel assembly for a nuclear pressure water reactor also has a plurality of such cladding tubes.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

High purity andalusite brick for high blast temperature and preparation method thereof

The invention discloses a high pure andalusite brick for an air heating furnace with high blast temperature and long service life, and a preparation method thereof. The high pure andalusite brick is prepared by the following steps: andalusite, sillimanite sand, activated alumina powder and kaolin are taken as raw materials, andalusite powder, the activated alumina powder and kaolin powder which have the raw material particle size of between 0.088 and 0 mm are premixed into powder first, then the remaining particle materials, sulphite liquor and the prepared powder are mixed evenly to produce pug, the produced pug is pressed into a green brick, and the green brick is transferred into a high-temperature tunnel kiln for calcination to obtain a product. As a refractory material of a large-scale air heating furnace, the product has low creep rate and good thermal shock stability during use, and can apparently improve the blast temperature and the service life of the air heating furnace, thereby saving a large amount of maintenance cost and energy-saving cost for iron and steel users, and obtaining remarkable social and economical benefits.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

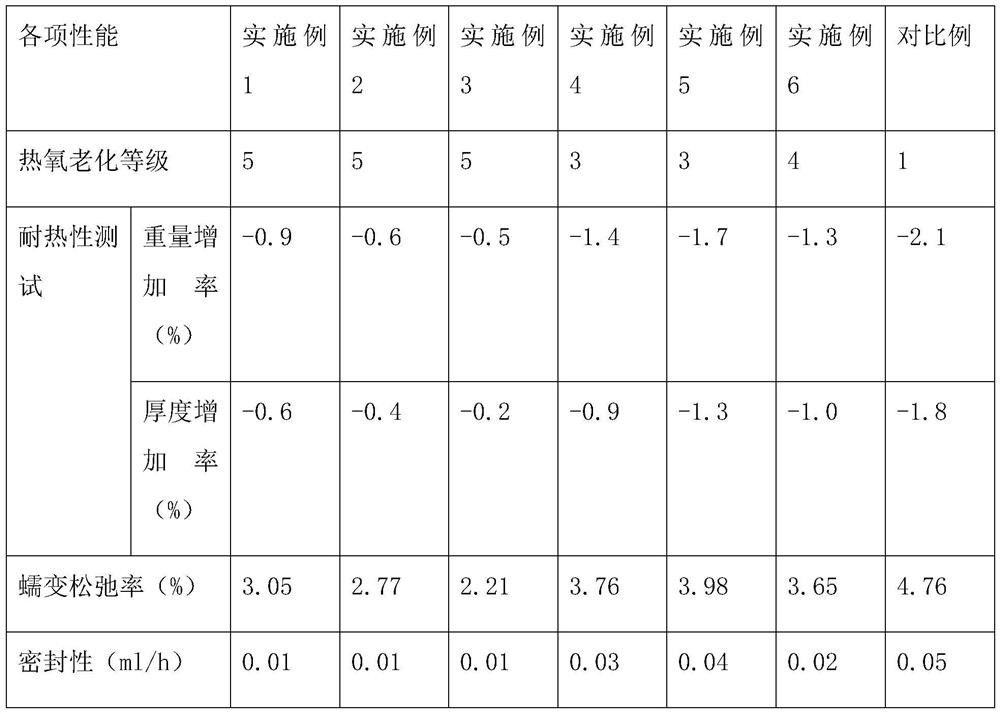

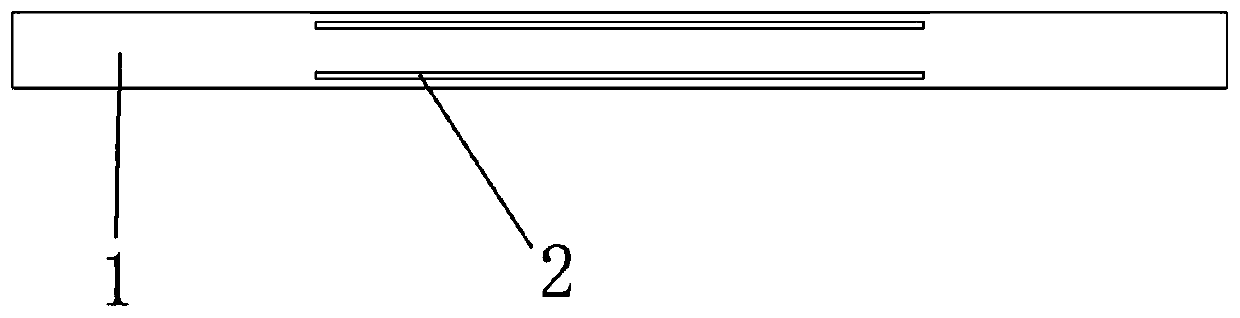

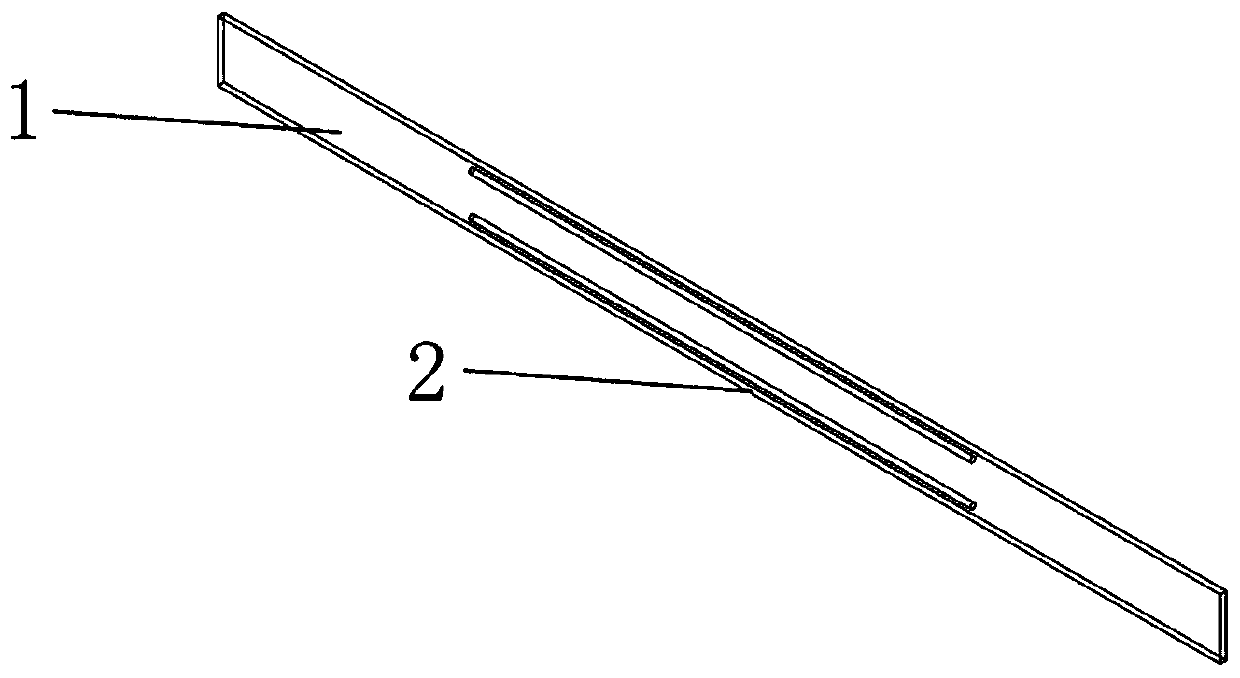

High-temperature-resistant low-creep sealing plate and preparation process thereof

InactiveCN112662236AIncrease frictionInhibit sheddingEngine sealsConjugated diene hydrocarbon coatingsBinding forceMetallic substrate

The invention discloses a high-temperature-resistant low-creep sealing plate and a preparation process thereof. The sealing plate comprises a metal base material, and rubber layers coating the upper surface and the lower surface of the modified metal base material, wherein the rubber layers are obtained by airing a rubber mixture. The prepared sealing plate combines the high strength of the metal base material and the high elasticity and compressibility of the rubber layer, and is low in weight, high in sealing performance, excellent in thermal oxidation resistance, high in binding force between the metal base material and the rubber layer, low in creep relaxation rate, wide in application range and high in sealing performance, and peeling and stripping cannot occur even if the sealing plate works in a high-temperature environment for a long time, the application range is wide, and the practicality is high.

Owner:JIANGSU SEALSTARS SEALING TECH CO LTD

Preparation method of porous mullite-corundum perovskite loaded La1-xKxCo0.7Fe0.3O3 material

The invention relates to a preparation method of porous mullite-corundum perovskite loaded La1-xKxCo0.7Fe0.3O3 (x is equal to 0.2 to 0.8). The preparation method comprises the following steps: preparing a porous mullite-corundum material by taking bauxite and diatomite as raw materials through carrying out wet milling, filtering, drying and stirring, additionally adding a binding agent, a dispersant, a foam stabilizer and a foaming agent, and molding, drying and sintering; then loading perovskite on a porous mullite-corundum carrier by adopting a vacuum impregnation and calcining method to prepare a porous mullite-corundum perovskite loaded La1-xKxCo0.7Fe0.3O3 material. The preparation method has the characteristics of simple process, short production period, high efficiency, stable product quality, low cost and the like; the porous mullite-corundum perovskite loaded La1-xKxCo0.7Fe0.3O3 material can be produced and prepared according to requirements and the preparation method has a relatively good industrial utilization prospect.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Posterior sclera reinforcing structure capable of developing under nuclear magnetic resonance

ActiveCN111249034AEase of evaluationConvenient for postoperative reviewEye implantsNMR - Nuclear magnetic resonanceBiocompatibility

The invention provides a posterior sclera reinforcing structure capable of developing under nuclear magnetic resonance. The structure comprises a main body structure and a developing structure, the developing structure is arranged on the main body structure and is integrated with the main body structure, the developing structure is a hollow structure, the outer shell wall of the developing structure is waterproof, the inner cavity of the developing structure is filled with a developing agent capable of developing under nuclear magnetic resonance, the developing agent is used for easily observing the form and the position of the main body structure under nuclear magnetic resonance, and therefore postoperative review and examination are facilitated, and medical staff can conveniently evaluate the operation effect. The material disclosed by the invention is good in biocompatibility, proper in elasticity and tensile strength and not easy to absorb, so that the operation effect is effectivefor a long time, and the requirements of posterior sclera reinforcement treatment are met.

Owner:许寅聪 +1

A corundum refractory ball for a ball-type hot blast stove and its preparation method

InactiveCN101555151BImprove dispersion uniformityReduce porosityBrick-hot blast stovesTunnel kilnPolymer science

A corundum refractory ball for a spherical hot blast stove and a preparation method thereof, characterized in that: the corundum refractory ball includes the following main ingredients, binders and additives; wherein the main ingredients include the following raw materials in weight percentages: 0-15% of corundum with a particle size of 5-3mm, 30-60% of corundum with a particle size of 3-1mm, 5-30% of corundum with a particle size of 1-0.088mm, 0-10% of corundum with a particle size of less than 0.044mm, and 0-10% of corundum with a particle size of less than 0.088mm High alumina bauxite clinker 10-25%, α-Al2O3 particles 2-10%, zirconia-containing material 1-10%, clay 2-8%, mullite or mullite-containing main phase material 2-10% %; the added amount of the binder is 1-6% of the weight of the main material; the added amount of the additive is 0-1% of the weight of the main material. The preparation method of the present invention adopts trapping, back-rolling, machine-pressing, drying the green body, and then firing in a tunnel kiln at a firing temperature of 1450°C to 1600°C.

Owner:巩义市金岭耐火材料有限公司

A kind of preparation method of low-creep anti-crack silica brick

The invention relates to a low-creeping and anti-cracking silicon brick preparation method, and belongs to the technical field of silicon brick preparation. The low-creeping and anti-cracking silicon brick preparation method comprises: preparing a mixing slurry from peat moss and lichen, infiltrating the mixing slurry into the pores of silica rock during a constant temperature culture process, and freezing with liquid nitrogen to ice the liquid in the pores, wherein the volume is increased to produce pressure, such that the pores of the silica rock are widened and deepened; carrying out microwave thawing, wherein the slurry deep enters the interior of the silica rock along the expanded pores so as to corrode the silica rock; freezing again, and crushing to crack up the silica rock; making the silica rock absorb a saturated calcium hydroxide solution at a low temperature; carrying out ultrasonic dispersion; at a high temperature, reducing the solubility of calcium hydroxide, and precipitating on the surface of the silica rock; and drying, mixing with peach gum and the like, and carrying out high temperature firing to obtain the product. According to the present invention, the prepared low-creeping and anti-cracking silicon brick has excellent creep resistance under the high temperature condition, has a starting refractoriness under load of 1700-1800 DEG C, has refractoriness of more than 1750 DEG C, and has broad application prospect.

Owner:YIXING KAIDA REFRACTORY MATERIALS CO LTD

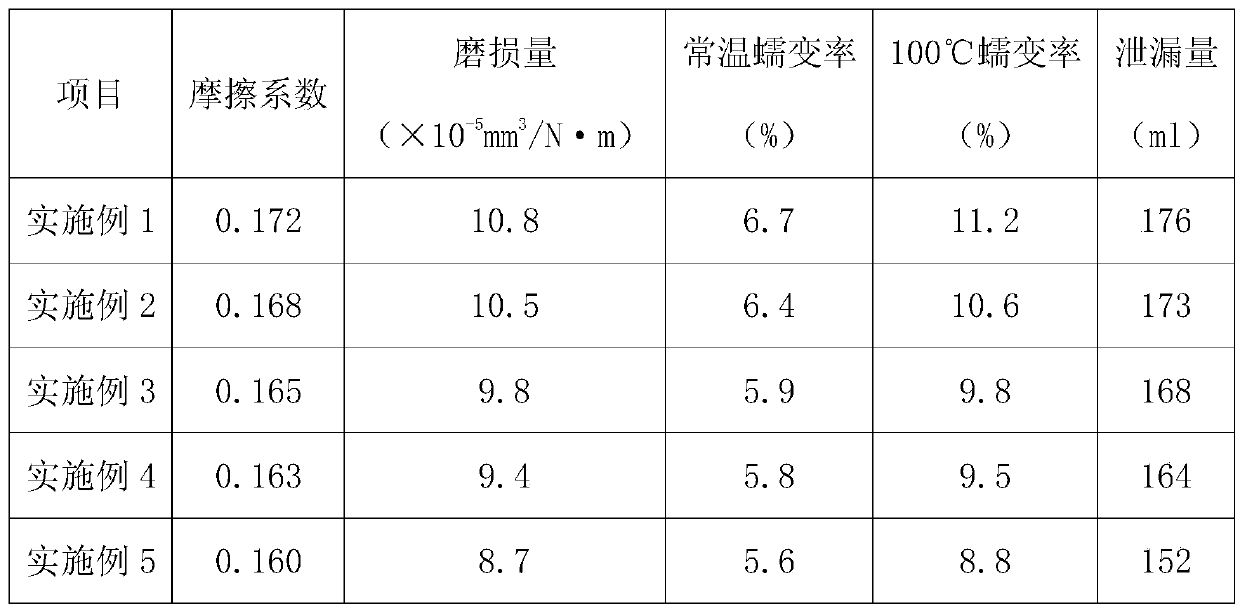

Polytetrafluoroethylene composite material for mechanical seal and preparation method of polytetrafluoroethylene composite material for mechanical seal

InactiveCN105504613AReduce coefficient of frictionReduce wearOther chemical processesVehicle sealing arrangementsVinyl etherCreep rate

The invention discloses a polytetrafluoroethylene composite material for mechanical seal and a preparation method of the polytetrafluoroethylene composite material for mechanical seal. The polytetrafluoroethylene composite material is prepared from, by weight, 48-55 parts of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer, 22-35 parts of polybutadiene, 2-6 parts of chlorinated polyethylene, 1.5-2.2 parts of polyacrylonitrile-based carbon fiber, 0.8-1.5 parts of polytetrafluoroethylene micropowder, 1.2-1.6 parts of antioxidant DNP, 0.5-0.8 part of stearic acid, 5-8 parts of fire retardant, 0.6-0.9 part of assistant crosslinker, 2.2-2.6 parts of plasticizer and 0.8-1.2 parts of bismuth oxide by mixing, granulating, extrusion molding, radiation crosslinking and post processing. The polytetrafluoroethylene composite material is low in friction coefficient, abrasion loss and creep rate and has excellent abrasion resistance and long service life. Compared with a traditional polytetrafluoroethylene seal ring made by mould pressing, a seal ring made of the polytetrafluoroethylene composite material has the advantages of remarkable leakage reduction and promising application prospect.

Owner:桐乡市搏腾贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com