High purity andalusite brick for high blast temperature and long time type hot blast stove and preparation method thereof

A long-life, hot-blast stove technology, applied in the field of refractory materials, can solve the problems of creep resistance and thermal shock resistance that cannot meet the requirements of hot-blast stoves, differences in the quality of mullite bricks, and materials that are no longer suitable. Effects of complete mulliteization, low apparent porosity, reduction in material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

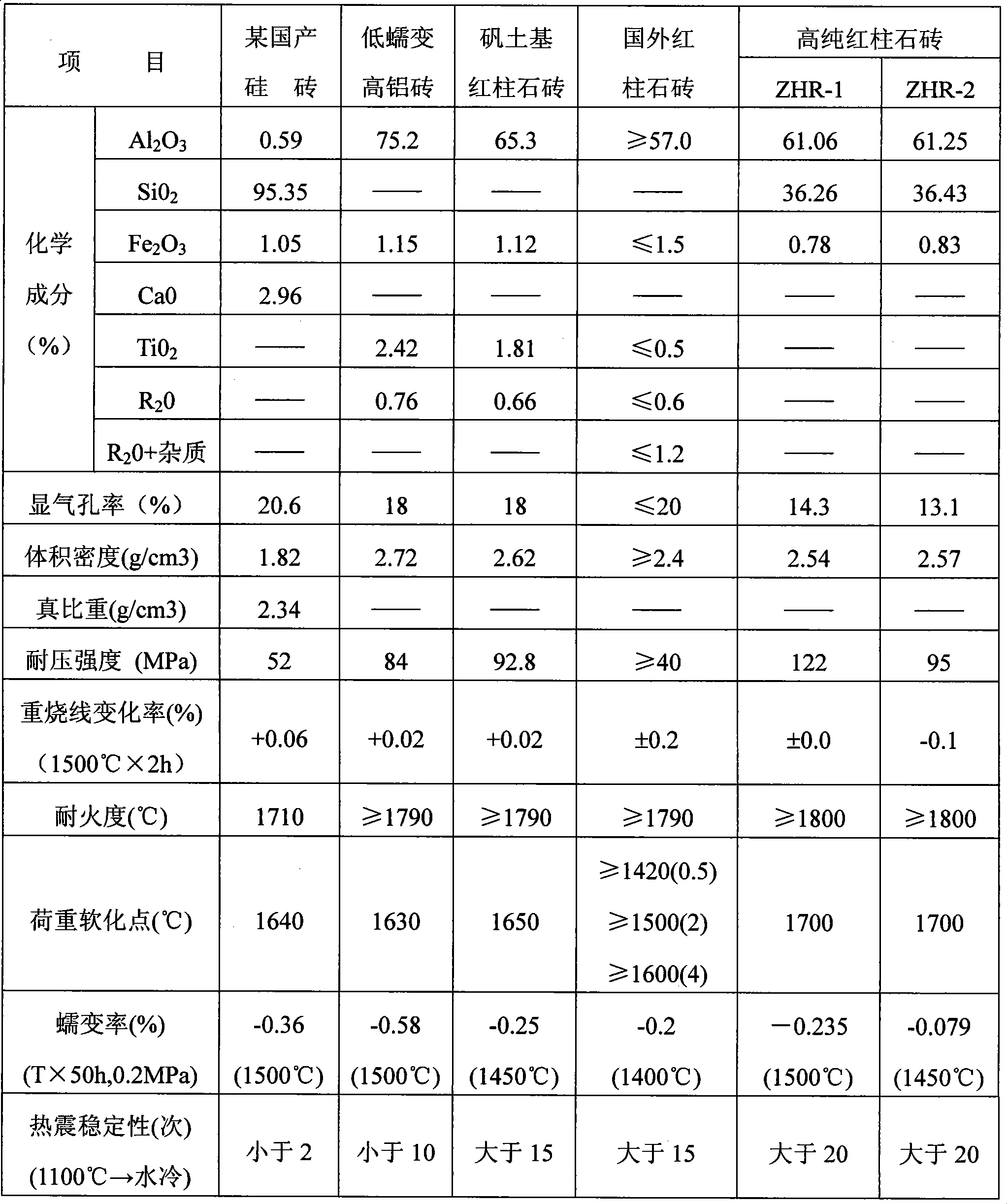

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A high-purity andalusite brick used in a high-wind temperature, long-life hot blast stove and its preparation method

[0041] The ingredients of high-purity andalusite bricks used in high-temperature and long-life hot blast stoves are:

[0042] 50% andalusite with a particle size of 3.5-1mm, 5% andalusite with a particle size of 1-0mm, 25% andalusite with a particle size of 0.088-0mm, 10% activated alumina powder, 5% sillimanite sand and 5% Suzhou kaolin.

[0043] Preparation method of high-purity andalusite bricks used in high-temperature, long-life hot blast stoves:

[0044] The method includes the following detailed steps:

[0045] a. Weigh various raw materials according to the ingredients of high-purity andalusite bricks above, and pre-mix the powder part, namely andalusite powder with a particle size of 0.088-0mm, activated alumina powder and Suzhou kaolin powder, and the pre-mixing time is 30-50 minutes , mixed evenly to make powder;

[0046] b. Fir...

Embodiment 2

[0050] Embodiment two: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0051] The ingredients of high-purity andalusite bricks used in high-temperature and long-life hot blast stoves are:

[0052] 40% andalusite with a particle size of 3.5-1mm, 15% andalusite with a particle size of 1-0mm, 20% andalusite with a particle size of 0.088-0mm, 8% activated alumina powder, 7% sillimanite sand and 10% Suzhou kaolin.

[0053] Preparation method of high-purity andalusite brick:

[0054] The total amount of pulp waste liquid added in step b accounts for 4% of the total raw material amount of high-purity andalusite bricks;

[0055] In the step c, a vibratory press machine is used to press into adobe;

[0056] In step d, the total drying time is 22 hours from the inlet temperature of the drying kiln being ≤70°C to the outlet temperature being 150°C±10°C;

[0057] In step e, it takes 34 hours to raise the temperature from normal temp...

Embodiment 3

[0058] Embodiment three: basically the same as embodiment one, the similarity is no longer described, and the difference is:

[0059] The ingredients of high-purity andalusite bricks used in high-temperature and long-life hot blast stoves are:

[0060] 48% andalusite with a particle size of 3.5-1mm, 10% andalusite with a particle size of 1-0mm, 22% andalusite with a particle size of 0.088-0mm, 9% activated alumina powder, 9% sillimanite sand and 2% Suzhou kaolin.

[0061] Preparation method of high-purity andalusite brick:

[0062] The total amount of pulp waste liquid added in step b accounts for 5% of the total raw material amount of high-purity andalusite bricks;

[0063] In step d, the total drying time is 18 hours from the inlet temperature of the drying kiln being ≤70°C to the outlet temperature being 150°C±10°C;

[0064] In step e, it takes 30 hours to raise the temperature from normal temperature to the firing temperature of 1580°C, and it takes 30 hours to raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com