Corundum fireproof ball used for ball-type hot-blast stove and preparation method thereof

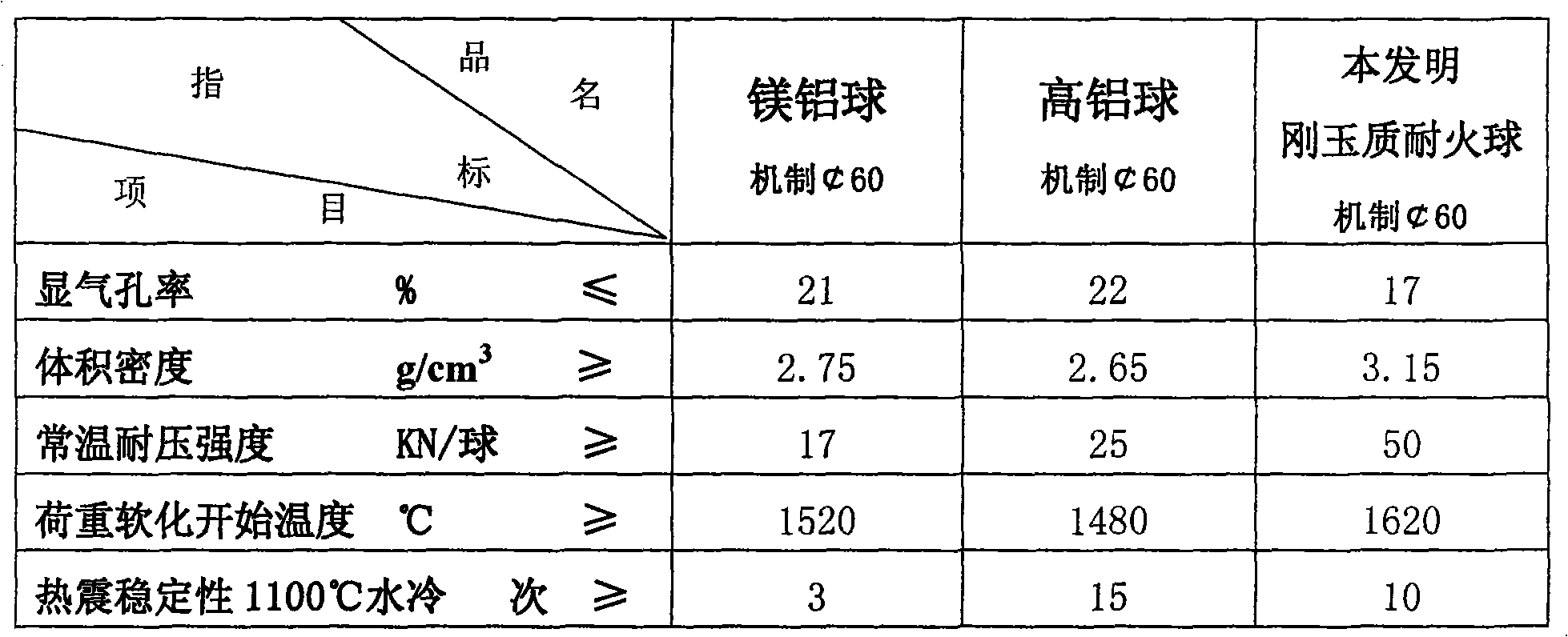

A corundum, refractory ball technology, used in brick blast furnaces and other directions, can solve the problems of short ball changing cycle, low strength of magnesium-aluminum balls, poor thermal shock resistance, etc. The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

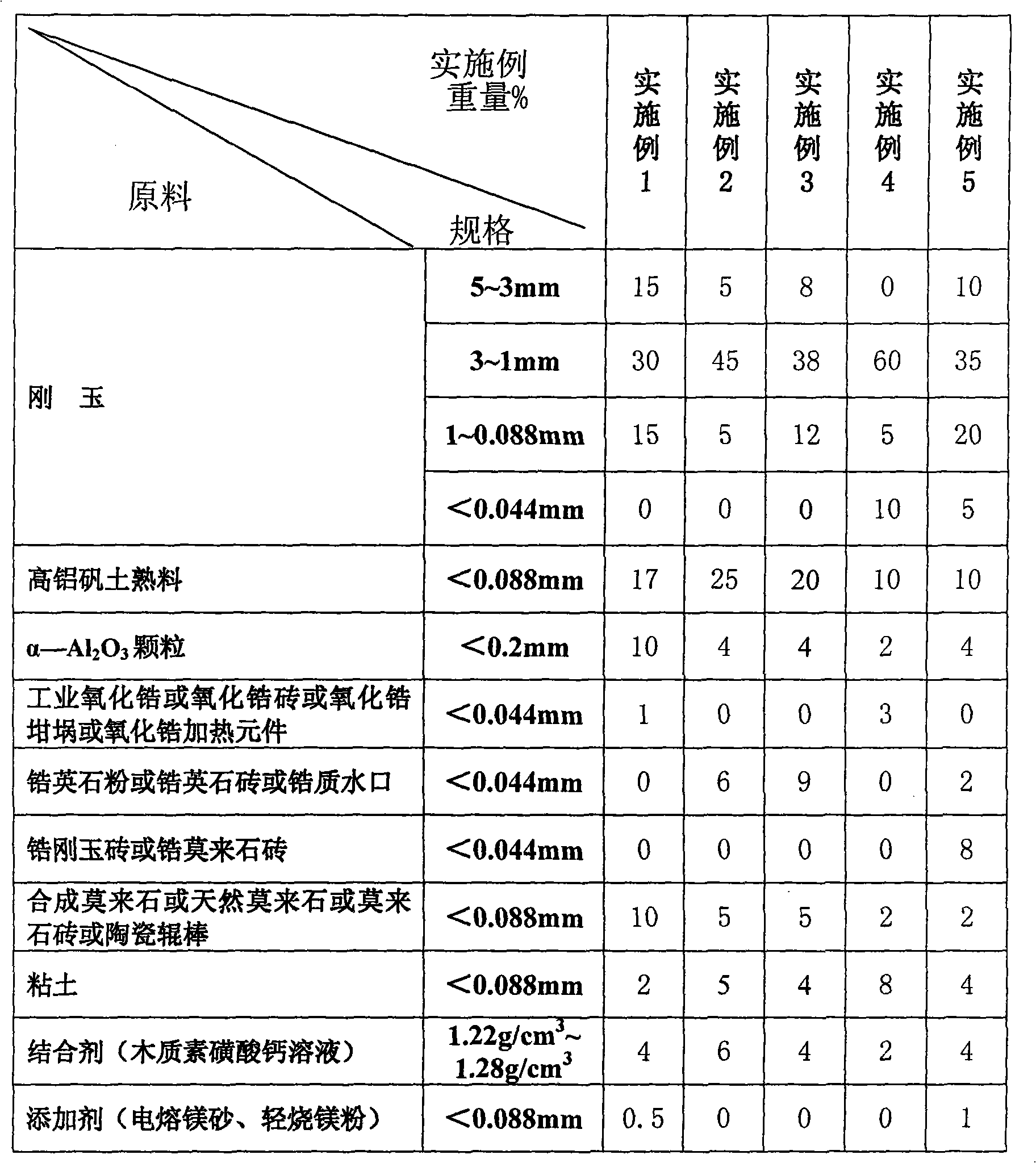

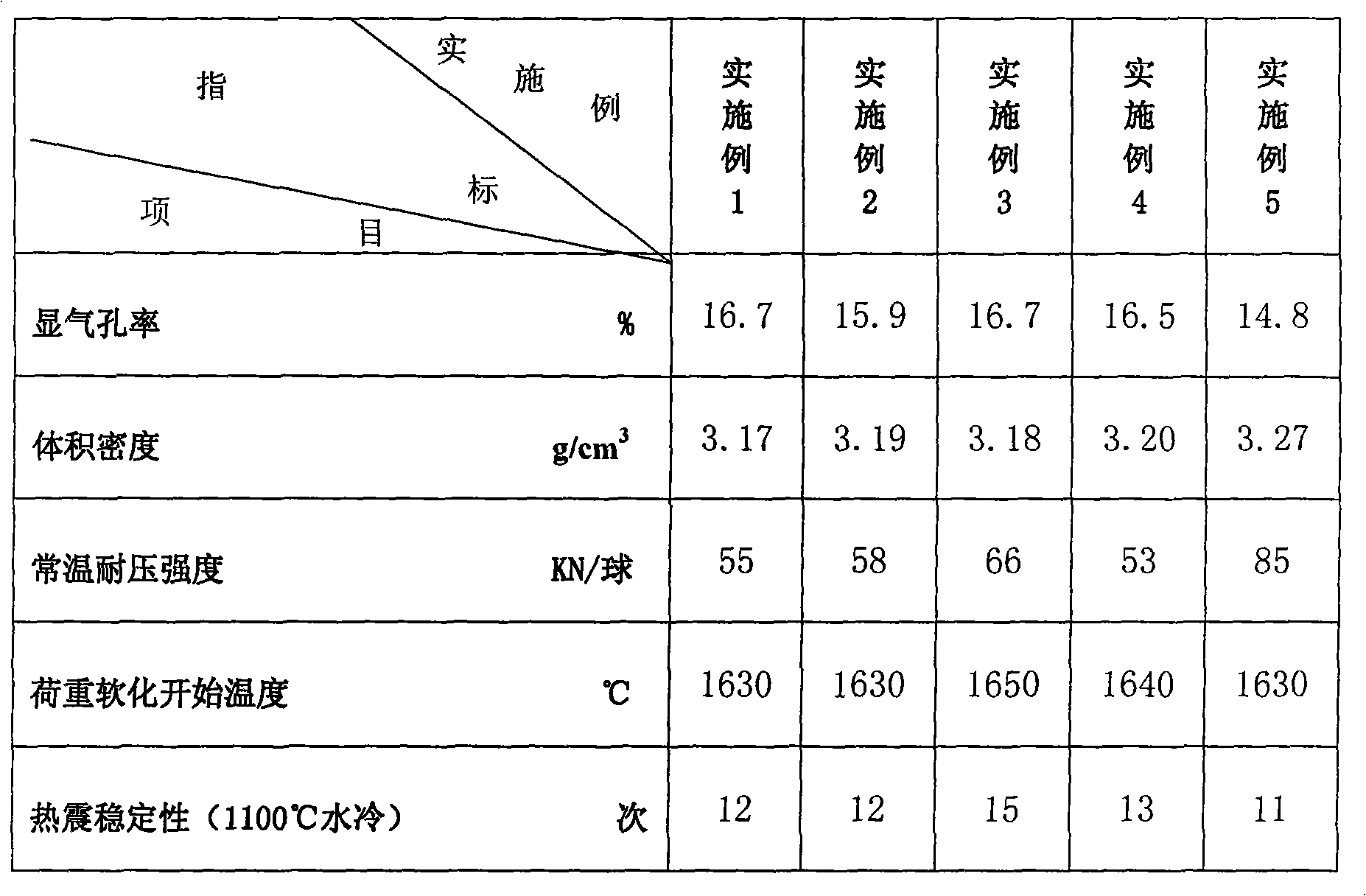

Examples

Embodiment 1

[0030]a. Weigh α-Al with a particle size of less than 0.2 mm according to the raw materials, specifications, and weight percentages corresponding to Example 1 in Attached Table 2 2 o 3 Granules, zirconia-containing materials with a particle size of less than 0.044mm, and additives with a particle size of less than 0.088mm (either fused magnesia or lightly burned magnesia powder or a combination of the two), are prepared by dry co-milling into a particle size of all Fine powder less than 0.02mm (500 mesh) (the inner lining of the ball mill adopted in the method of joint mixing and grinding is a corundum ceramic grinding lining brick, and the ceramic grinding medium ball is a corundum ceramic grinding medium ball or a zirconia ceramic grinding medium Balls, including corundum ceramic grinding lining bricks and corundum ceramic grinding media balls AI 2 o 3 The content of ≥95%, zirconia ceramic grinding media ball ZrO 2 The content of ≥94%. ),spare;

[0031] b. High alumina ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com