Patents

Literature

83results about How to "High compressive strength at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature creep resistant mullite-cordierite product and preparation method thereof

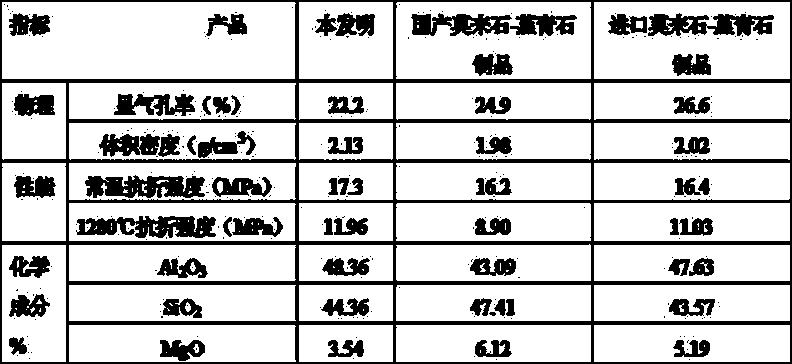

The invention relates to a high temperature refractory material, and specifically relates to a high temperature creep resistant mullite-cordierite product and a preparation method thereof. The product is prepared from the main raw materials of sintered mullite, cordierite, white corundum, fused quartz, kyanite, alumina micro powder, bentonite micro powder, slaked talcum micro powder and kaolin by the steps of mixing, mixture ageing, forming-drying and final high-temperature firing. By adopting scientific mixing proportion and graduation, and using a resonable production method, the high temperature creep resistant mullite-cordierite product provided by the invention is prepared. Compared with other products, the high temperature creep resistant mullite-cordierite product provided by the invention has the advantages of low apparent porosity, high volume density, good creep resistance, excellent thermal shock resistance, long service life, and on the like, and is mainly suitable for moderate temperature material sintering, such as sintering of cobaltous oxide and ferric aluminum phosphate raw materials for automotive batteries in chemical industry.

Owner:长兴宏业高科高温耐火材料有限公司

Mafic-magnalium compound spinel brick and preparation method thereof

InactiveCN102020479AHigh softening temperature under loadIncrease temperatureBrickPhysical chemistry

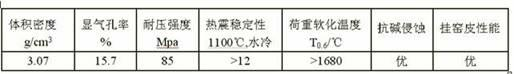

The invention relates to a mafic-magnalium compound spinel brick and a preparation method thereof. The raw materials comprise 20-55% of high iron magnesia sand with granularity of 5-3mm, 10-45% of high iron magnesia sand with granularity of less than 2mm, 20-45% of high iron magnesia sand with granularity of less than 0.088mm, 4-35% of magnalium spinel with granularity of not more than 5mm, and 2-4% of bonding agent. The preparation method comprises the following steps of: weighing the raw materials, wet milling, shaping, drying and sintering; drying the brick blank for 8-24h at the temperature of 110-160 DEG C; heating to the temperature of 1600-1700 DEG C; warming for 3-12h at the temperature of 1600-1700 DEG C and taking out. The product comprises the main components of 73-95% of MgO, 3-15% of Al2O3 and 2-12% of Fe2O3. The mafic-magnalium compound spinel brick has good product performance, high load softening temperature, high pressure resistance intensity, good thermal shaking stability and good alkali corrosion resistance, and is an ideal material for cement kiln high temperature belts. The mafic-magnalium compound spinel brick can substitute the current magnesia-chromite fire-proof material and is a new environmentally-friendly alkali fire-proof material.

Owner:河南瑞泰耐火材料科技有限公司

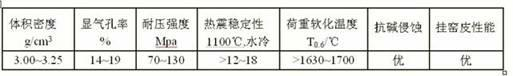

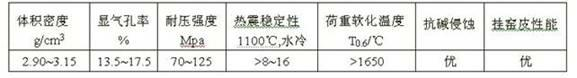

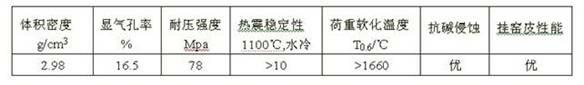

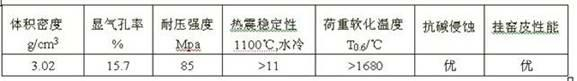

Pleonaste-hercynite bricks and preparation method thereof

The invention relates to pleonaste-hercynite bricks and a preparation method thereof. The pleonaste-hercynite bricks are prepared from the following raw materials in percentage by weight: 55 to 98 percent of high-iron magnesia with a particle size of less than or equal to 5 millimeters, 2 to 45 percent of hercynite with a particle size of less than or equal to 5 millimeters and 2 to 4 percent of binding agent. The preparation method comprises: weighing raw materials; rolling wet materials; forming; drying; firing; drying the fired bricks at 110 to 160 DEG C for 8 to 24 hours; heating the bricks to 1,550 to 1,700 DEG C; keeping the temperature for 3 to 15 hours; and taking the bricks out of kiln. The pleonaste-hercynite bricks have high performance, high refractoiness under load, high thermal shock resistance, high alkaline corrosion resistance and high kiln-crust sticking performance, are free from hydration and easy to transport, are ideal materials for the high-temperature zone of acement kiln and can be used in place of the conventional magchrome refractory material.

Owner:河南瑞泰耐火材料科技有限公司

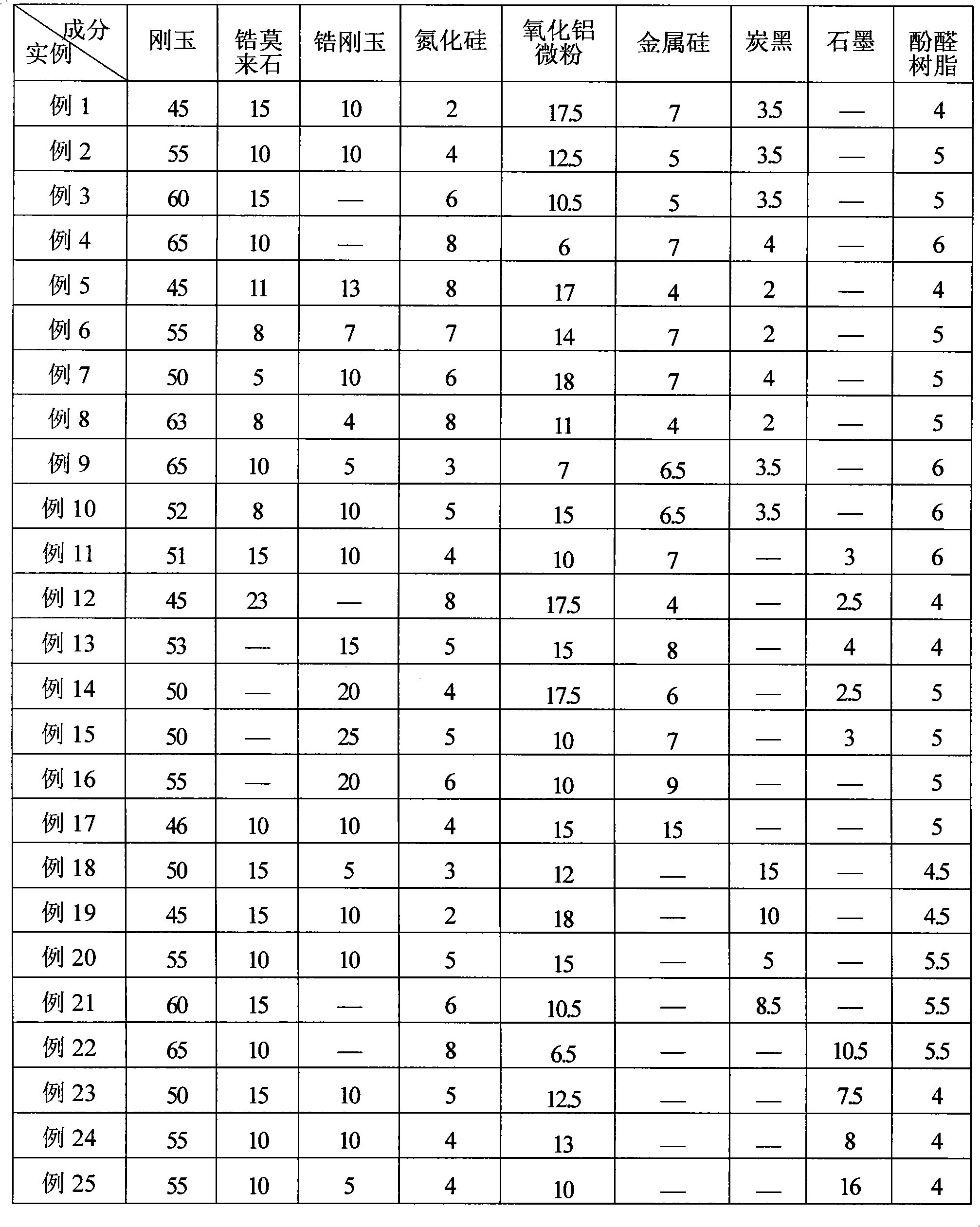

Slide plate refractory with silicon nitride added and production method thereof

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powder and a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Fireproof product for cement rotary kiln transition belt

InactiveCN1919797AImprove performanceHigh compressive strength at room temperatureCement rotary kilnCoesite

The invention discloses a fireproof composition product of cement rotary kiln transmitting belt through dried method, which comprises the following parts: 50-79% alumina clinker aggregate with Al2O3 not less than 90% and bulk density not less than 3.0g / cm3, 5-20% silicon carbide, 3-15% clay with Al2O3 not less than 32%, 3-15% alumina, wherein the silicon carbide, clay and alumina are added at 0.1-10mm fined powder pattern, which possesses 63-75% Al2O3,8-32.5% SiO2 and 4.5-19% SiC for sintered components.

Owner:YIXING REFRACTORY EQUIP & MATERIAL FACTORY

Graphite base heatproof and heat insulating material and production technique thereof

InactiveCN101391878AGood heat insulation effectHigh compressive strength at room temperatureThermal insulationPetrochemical

The invention discloses a graphite-based temperature-resistant thermal insulation material and a production technology thereof. The material comprises the following components: 15-30wt percent of graphite powder, 18-28wt percent of sepiolite, 8-15wt percent of inorganic foaming agent, 5-20wt percent of inorganic adhesive, 6.4-32wt percent of high-quality cement, and other auxiliary agents as the rest; and the insulation material is obtained by stirring and mixing, molding, and curing. The invention also provides the production technology of the graphite-based temperature-resistant thermal insulation material, one is that after stirring, mixing and molding, the raw materials are naturally dried or dried and cured by using a drying oven; and the other is that after stirring, mixing and molding, the raw materials are sintered and cured. The invention has easily obtained raw materials with low price, simple production technology, convenient operation, good high-temperature resistant and thermal insulating performance of products, light weight, large mechanical strength and low thermal conductivity coefficient, and can be widely used in the fields of construction, petrochemical industry, metallurgy, and the like.

Owner:晟茂(青岛)先进材料有限公司

Preparation method of magnesium aluminate spinel brick

ActiveCN105837229AHigh compressive strength at room temperatureImproved thermal shock stabilityMagnesium AluminatePelletizing

The invention provides a preparation method of a magnesium aluminate spinel brick, wherein the preparation method comprises the specific steps: A, mixing evenly magnesia particles, a corundum fine powder and a binder, then granulating, carrying out heat treatment, and screening to obtain a material A and a material B; B, mixing a magnesia fine powder, a corundum fine powder, a magnesium aluminate spinel fine powder and a binder evenly, carrying out heat treatment, then crushing and screening to obtain a material C and a material D; C, mixing evenly the material A, the material B, the material C, the material D, a magnesium aluminate spinel fine powder, a magnesia fine powder, a corundum fine powder and a binder, and then carrying out heat treatment, to obtain the magnesium aluminate spinel brick. The method is beneficial for close contact of all kinds of raw material particles, but also makes full use of structural characteristics of materials at different temperatures; the prepared magnesium aluminate spinel brick has excellent characteristics of high room-temperature compressive strength, high thermal shock stability, high load softening temperature, and low reburning line change rate.

Owner:江苏诺明高温材料股份有限公司

Method for manufacturing silicon mullite brick by adopting bauxite tailings

The present invention particularly relates to a method for manufacturing a silicon mullite brick by adopting bauxite tailings so as to solve a problem of high raw material cost of the existing silicon mullite brick. According to the method for manufacturing the silicon mullite brick by adopting bauxite tailings, bauxite tailings is adopted to replace mullite with expensive cost to be adopted as a main raw material, and is matched with silicon carbide and other materials, and high-pressure molding and medium temperature firing are performed to obtain the silicon mullite brick. The method has characteristics of comprehensive resource utilization, energy saving and environmental protection. The obtained silicon mullite brick has advantages of high compressive strength at a room temperature and low cost, wherein a compressive strength of the product achieves 115-137 MPa, thermal shock resistance under a 1100 DEG C water cooling condition achieves 60-110 times, room temperature wear resistance achieves 9-13 cm<3>, and content, bulk density, apparent porosity, and refractoriness under load of alumina are higher than the national standards.

Owner:孝义市和中兴矿产有限公司

MgO-MA unburned brick for RH refining furnace and preparation method of MgO-MA unburned brick

The invention relates to an MgO-MA unburned brick for an RH refining furnace and a preparation method of the MgO-MA unburned brick. According to the technical scheme, the MgO-MA unburned brick is prepared from the following raw materials in percentage by weight: 1-6wt% of silicon oxynitride fine powder, 10-30wt% of fused magnesite powder, 10-25wt% of magnesium aluminate spinel fine powder, 1-6wt% of aluminite powder and 1-5% of silica powder as matrix materials, and 50-65wt% of fused magnesite particles as an aggregate. The method comprises the steps of firstly mixing the matrix materials in a roller ball mill to obtain matrix fine powder; carrying out dry mixing on the aggregate in a mixing mill, adding phenolic resin which is 1-6wt% of the sum of the aggregate and the matrix powder and carrying out wet mixing; finally adding the matrix fine powder, mulling and ageing under a sealed condition; and carrying out mechanical pressing on the aged material to prepare the MgO-MA unburned brick for the RH refining furnace. The MgO-MA unburned brick is simple in synthesis process, energy-saving, environment-friendly and low in production cost; and the prepared MgO-MA unburned brick for the RH refining furnace has excellent apparent porosity, room-temperature breaking strength, room-temperature compression strength, high-temperature breaking strength and thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

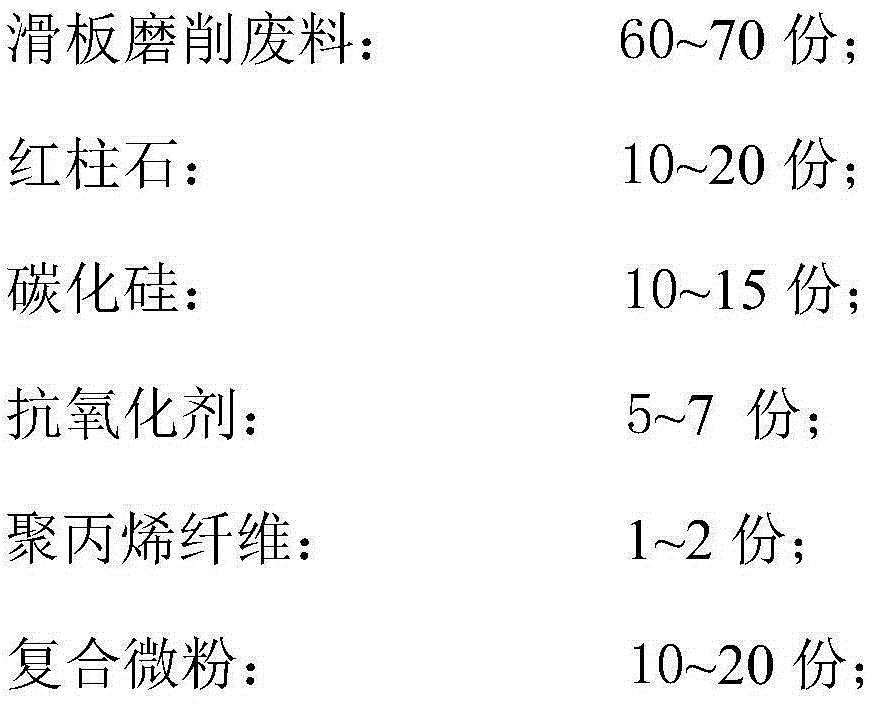

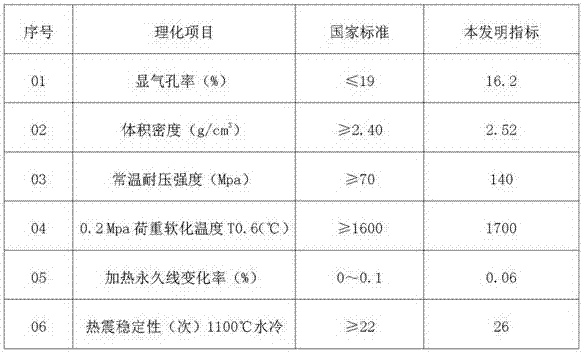

Regenerative iron runner castable

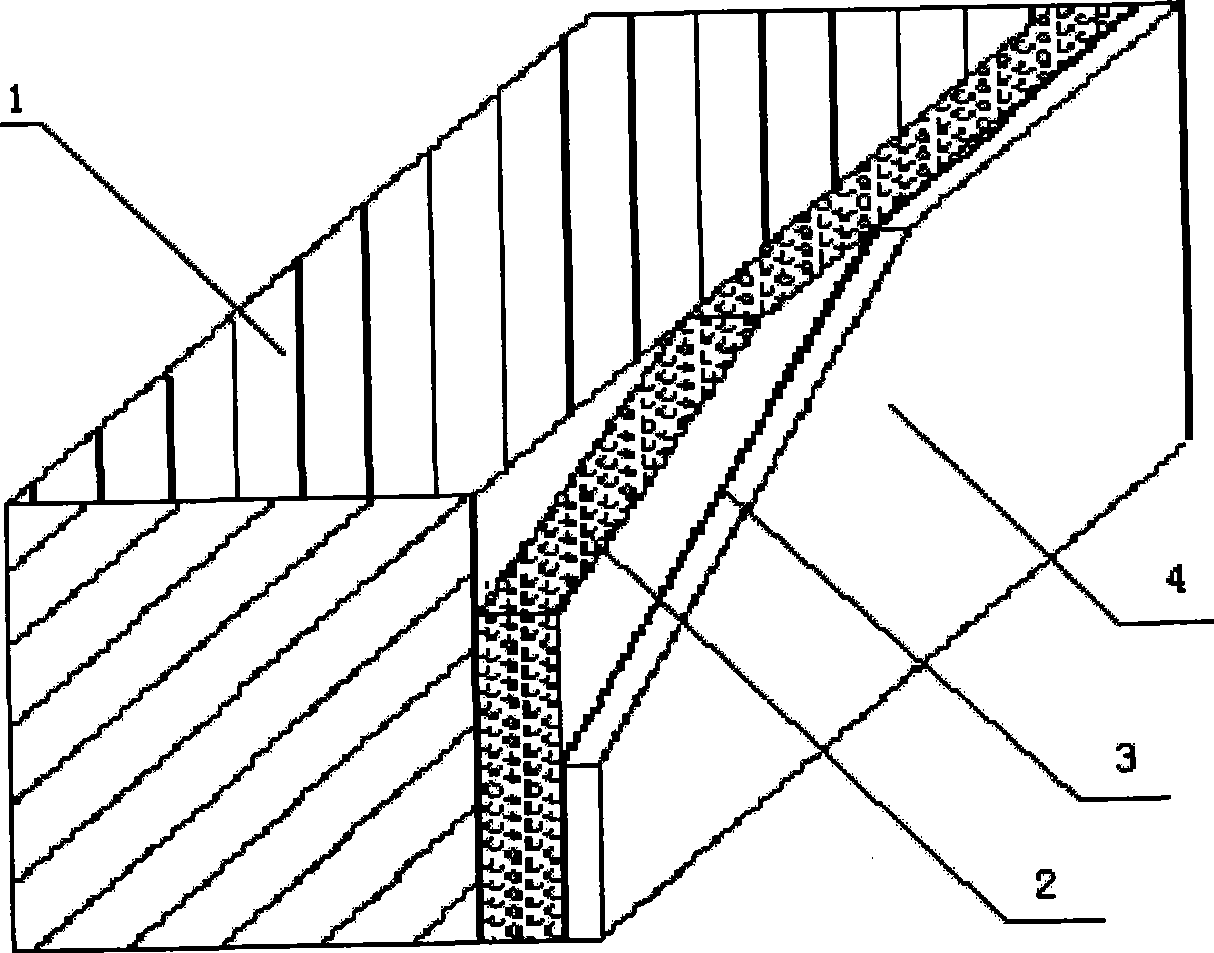

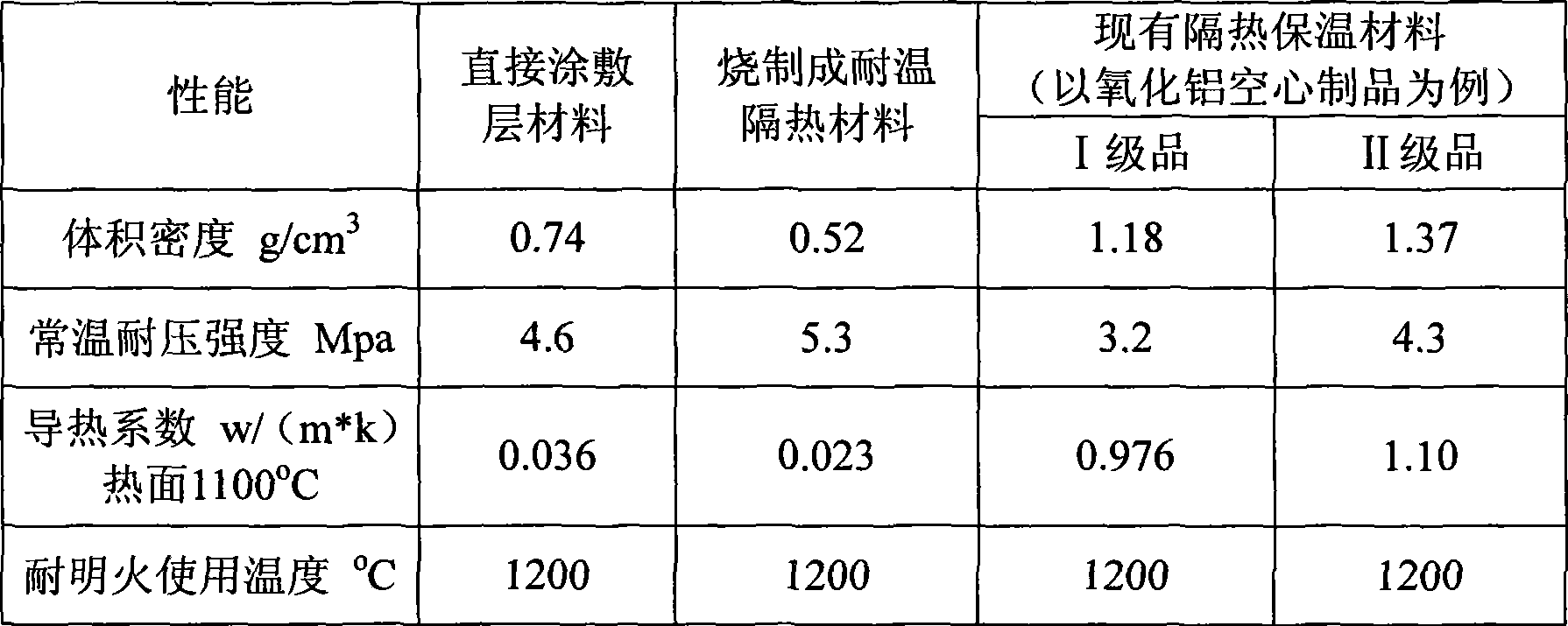

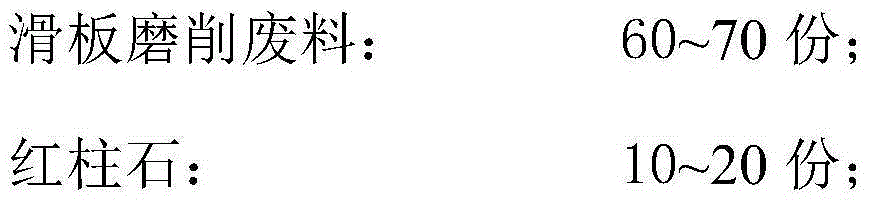

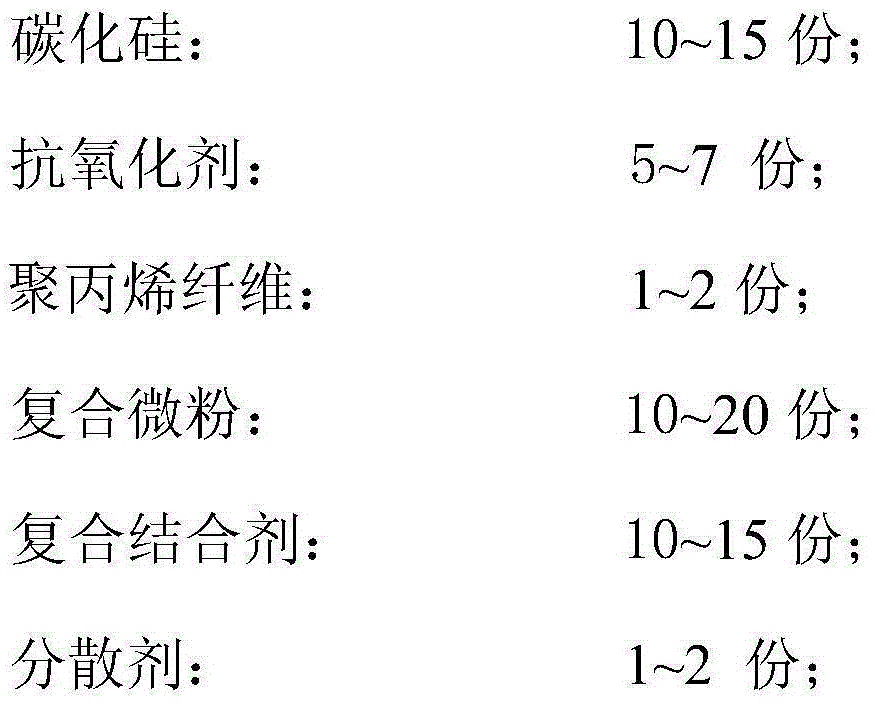

The invention discloses a regenerative iron runner castable. The iron runner castable with low cost is manufactured by utilizing cheap skateboard grinding waste materials of which main components include corundum, high-alumina bauxite and carbon materials, so that the apparent porosity of the iron runner castable is obviously reduced, the volume density and the rupture strength are increased, and the slag resistant performance is enhanced. Compound silicon sol-sodium polyacrylate in the iron runner castable is used as a binding agent, so that the iron runner castable forms a large quantity of meshy mullite crystals in different shapes at high temperature, the meshy mullite crystals are scattered in structures, so that the high-temperature rupture strength is increased, the cold crushing strength of the iron runner castable is enhanced, and the construction performance is improved. The performance of the regenerative iron runner castable is flat with that of an existing iron runner castable, the price is only 85% of the existing iron runner castable, and the regenerative iron runner castable meets the development requirements of clean production and circular economy.

Owner:长兴云峰炉料有限公司

Mullite fire resistant insulation products and preparation method thereof

A mullite refractory thermal insulation product takes mullite powder, industrial alumina powder and kyanite powder as main materials and takes white wool soil and combustible substances as auxiliary materials, and the mullite refractory thermal insulation product is formed by adding water, mixing, shaping and sintering. The parts by weight of various raw materials are: 12 to 16 parts of mullite powder, 20 to 30 parts of industrial alumina powder, 10 to 18 parts of kyanite powder, 32 to 40 parts of white wool soil, 8 to 12 parts of combustible substances and 80 to 90 parts of water. Al2O3 in the mullite powder is more than 55 percent by weight, Fe2O3 is less than 1 percent by weight, the particle size is not more than 180 meshes; the Al2O3 in the industrial alumina powder is more than 99 percent by weight, the particle size is not more than 180 meshes; the Al2O3 in the kyanite powder is more than 58 percent by weight, the Fe2O3 is less than 1 percent by weight, the particle size is not more than 120 meshes; the Al2O3 in the white wool soil is more than 35 percent by weight, the Fe2O3 is less than 1.5 percent by weight, the particle size is not more than 180 meshes; the combustible substances are polystyrene and / or sawdust with the particle size of less than 1mm. The specific gravity of the product is 0.5 to 0.6g / cm<3>. The product has super-lightweight, low thermal conductivity, high re-burning and can be directly contacted with flame.

Owner:徐进清

Multifiber reinforced magnesia-alumina-carbon refractory material and preparation process thereof

The invention relates to a multifiber reinforced magnesia-alumina-carbon refractory material and a preparation process thereof. A refractory brick is prepared from the following raw materials in percentages by weight: 8 to 10% of A-grade dead-burnt magnesia fine powder, 5 to 7% of B-grade dead-burnt magnesia fine powder, 19 to 22% of C-grade dead-burnt magnesia fine powder, 11 to 13% of D-grade dead-burnt magnesia fine powder, 8 to 10% of E-grade dead-burnt magnesia fine powder, 15 to 18% of F-grade dead-burnt magnesia fine powder, 7 to 8% of a binder A, 5.5 to 7.5% of a binder B, 1.3 to 1.7% of a binder C, 6 to 8% of metal aluminum powder and 0.3 to 0.5% of an additive. According to the invention, products and raw materials are safe and non-toxic, and may not cause harmful effects to users and the environment; good physical properties and wide application prospects in the fields of metallurgy and steelmaking are realized; the refractory material is improved in mechanical properties of the substrate thereof by mixed application of dead-burnt magnesia fine powder with different particles sizes, and is superior to a substrate material prepared from the dead-burnt magnesia fine powder with single particle size; the fiber structure greatly improves the mechanical properties of the material; meanwhile, carbon is difficult to be diffused into molten steel after carbon nanotube fiber is formed, so the pollution of the refractory materials to the molten steel is greatly reduced.

Owner:营口宏远耐火材料有限公司

Aluminum carbon castable with graphite microspheres as carbon source and preparation method thereof

The invention relates to an aluminum carbon castable with graphite microspheres as the carbon source and a preparation method thereof. The technical scheme includes: adopting 40-70wt% of brown fused alumina, 15-35wt% of silicon carbide, 3-15wt% of active alpha-alumina micropowder, 1-7wt% of silicon powder, 1-7wt% of graphite microspheres and 2-6wt% of calcium aluminate cement as the raw materials,performing mixing, then adding polycarboxylic acid accounting for 0.1-0.3wt% of the raw materials, and stirring the substances evenly, thus obtaining the aluminum carbon castable with graphite microspheres as the carbon source. Detection indicates that: the flow value is 210-240cm; the volume density is 2.85-3.10g / cm<3>; the ambient compressive strength is 41.5-47.7MPa; the normal temperature flexural strength is 6.5-10.6MPa; and the apparent porosity is 10.5-14%. After 1450DEG C / 3h treatment, the flexural compressive strength, oxidation resistance and thermal shock stability are significantly improved. The aluminum carbon castable with graphite microspheres as the carbon source prepared by the method provided by the invention not only has good fluidity, but also has greatly improved flexural compressive strength, oxidation resistance and thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

Carbon-free brick binding agent adding method

ActiveCN101190551AIncrease the proportionHigh bonding strengthMixing operation control apparatusCeramic shaping apparatusBrickMagnesium salt

The invention discloses a method of adding carbonless brick binding material. The carbonless brick magnesium salt complex binding material is magnesium salt. The invention is characterized in that the invention adopts the compound addition of solid magnesium salt and magnesium salt solution. The adding amount of the solid magnesium salt is 0.5%-2% of that of the carbonless brick raw material while the adding amount of the magnesium salt solution is 3%-5% of that of the carbonless brick raw material. The technique process is as follows: first, adding carbonless brick particles into an edge runner wet mill, then, solid magnesium salt is added into the edge runner wet mill to be dryly mixed for 1-2 minutes to lead the solid magnesium salt to be uniformly distributed in the particles; adding in the magnesium salt solution with the amount of 3%-5% of the mixing material amount, and wet mixing is carried out for 1-2 minutes, then a mixing roll with a roller is adopted for mixing; putting powder material in and discharging is carried out after 8-13 minutes of wet mixing, finally, shaping by pressure and drying the half finished product under the temperature of 160-200 DEG C for more than 36 hours. Because the invention adds solid magnesium salt on the base of adding magnesium salt solution in the rolling mixture, the binding material concentration is enhanced. The method of adding complex binding material is simple in operation and low in cost, which enhances the quality of product and has wide popularization value.

Owner:鞍山钢铁集团耐火材料有限公司

High temperature nanometer non-burning slide plate and processing technique thereof

ActiveCN106986619AImprove high temperature performanceImprove antioxidant capacitySlide plateEngineering

The invention relates to a high temperature nanometer non-burning slide plate and a processing technique thereof. By applying a method for shaping for many times, namely, a primary shaped slide plate is prepared firstly, and then slide plates in line of dimension requirement are shaped through gradually expanding outwards for several times on this basis; the slide plate is integrated structure. By applying the method of shaping for many times and the progressive way, the slide plate is more compactly pressed, and the primary shaping dimension is big; thus the primary shaped slide plate is not easy to deform and damage even through being pressed during the secondary shaping; meanwhile, the slide plate is provided with a reinforcing pipe to provide stress load during the pressing process, thus the shaping quality of the slide plate is further guaranteed; meanwhile, the reinforcing pipe is further arranged to be a hollow pipe, thus the reinforcing pipe can play a certain bearing effect during the secondary shaping and the third shaping; the reinforcing pipe also can be deformed and compactly inlaid in the groove for being pressed, thus the shaping quality and compact consistence of the slide plate are guaranteed.

Owner:JIANGSU YUEZHAN NEW MATERIALS

High-temperature sillimanite brick and production method thereof

The invention discloses a high-temperature sillimanite brick which is prepared from the following raw materials in parts by weight: 5 to 10 parts of andalusite, 10 to 25 parts of zirconite, 10 to 25 parts of mullite, 20 to 35 parts of acid-pickled sillimanite, 10 to 25 parts of alumina powder and 10 to 25 parts of binding clay, wherein mass ratio of a particle material to a fine powder material of the mullite is 3 to 7. A production method of the high-temperature sillimanite brick comprises the technological steps of mixing and grinding raw materials, ageing materials and regrinding materials, compression moulding, sintering to obtain a finished product and the like. After compression moulding, a green brick is sintered in a high-temperature tunnel kiln in temperature of 1450 to 1500 DEG C under thermal insulation for 10 to 12 hours, a green brick finished product is taken out of the kiln after being naturally cooled for 48 to 52 hours, and the high-temperature sillimanite brick can be obtained. According to the high-temperature sillimanite brick disclosed by the invention, ingredients of the zirconite, the andalusite , the mullite and the like are added into the acid-pickled sillimanite, so that the service life of the high-temperature sillimanite brick in a high-temperature melting furnace is prolonged, and the phenomena that the high-temperature sillimanite brick cracks and peels off in a using process are avoided.

Owner:辉县市东方耐火材料有限公司

Corundum mullite multiphase gradient material for heat recovery coke oven door

ActiveCN111153708AHigh flexural strength at room temperatureHigh compressive strength at room temperatureEnergy inputCoke oven doors/closuresSilica fumeThermal shock

The invention relates to a corundum mullite multiphase gradient material for a heat recovery coke oven door. The preparation method comprises the following steps: fully premixing corundum aggregate, flint clay aggregate, high-alumina cement, silica fume, alumina powder, fine bauxite powder and fine flint clay powder used as raw materials; adding water accounting for 5-10% of the mass of the raw materials as a binding agent, and continuing stirring; putting the mixture into a mold for vibration pouring; performing demoulding after a sample is cured in the mold; then, drying the cured castable under the condition of 100 DEG C to 150 DEG C; and finally, calcining the dried castable at a high temperature of 1500-1600 DEG C for 2-6 hours to obtain the corundum-mullite multiphase gradient material for a heat recovery coke oven door. According to the invention, the characteristics of the precast block fired by two different castables are effectively combined, so that the normal-temperature mechanical strength and thermal shock resistance stability of the material are improved while the cost is reduced.

Owner:UNIV OF SCI & TECH LIAONING

Manufacture process of immersive elongated-nozzle zirconia flow control

The invention provides a manufacture process of an immersive elongated-nozzle zirconia flow control, comprising the following steps: 1), mixing and grinding raw materials; 2), making the materials into blanks; 3), firing; 4) preparing particles; 5), removing iron; 6), preparing powder; 7), mixing semi-finished products; 8), granulating; 9), forming under high pressure; 10), drying; 11) charging into a kiln; 12), sintering at high temperature; 13) emptying the kiln; 14), inspecting and packaging to obtain finished products. The immersive elongated-nozzle zirconia flow control manufactured by using the process has high normal-temperature pressure resistance, good thermal shock stability and good scour resistance, zirconium product cracks are effectively reduced, product quality is guaranteed, and the life of each product is prolonged.

Owner:TAICANG HONGDA JUNMENG NEW MATERIAL

Silicon carbide powder and preparation method thereof

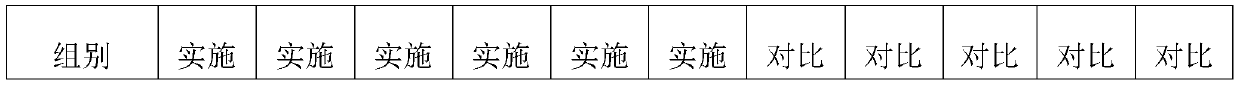

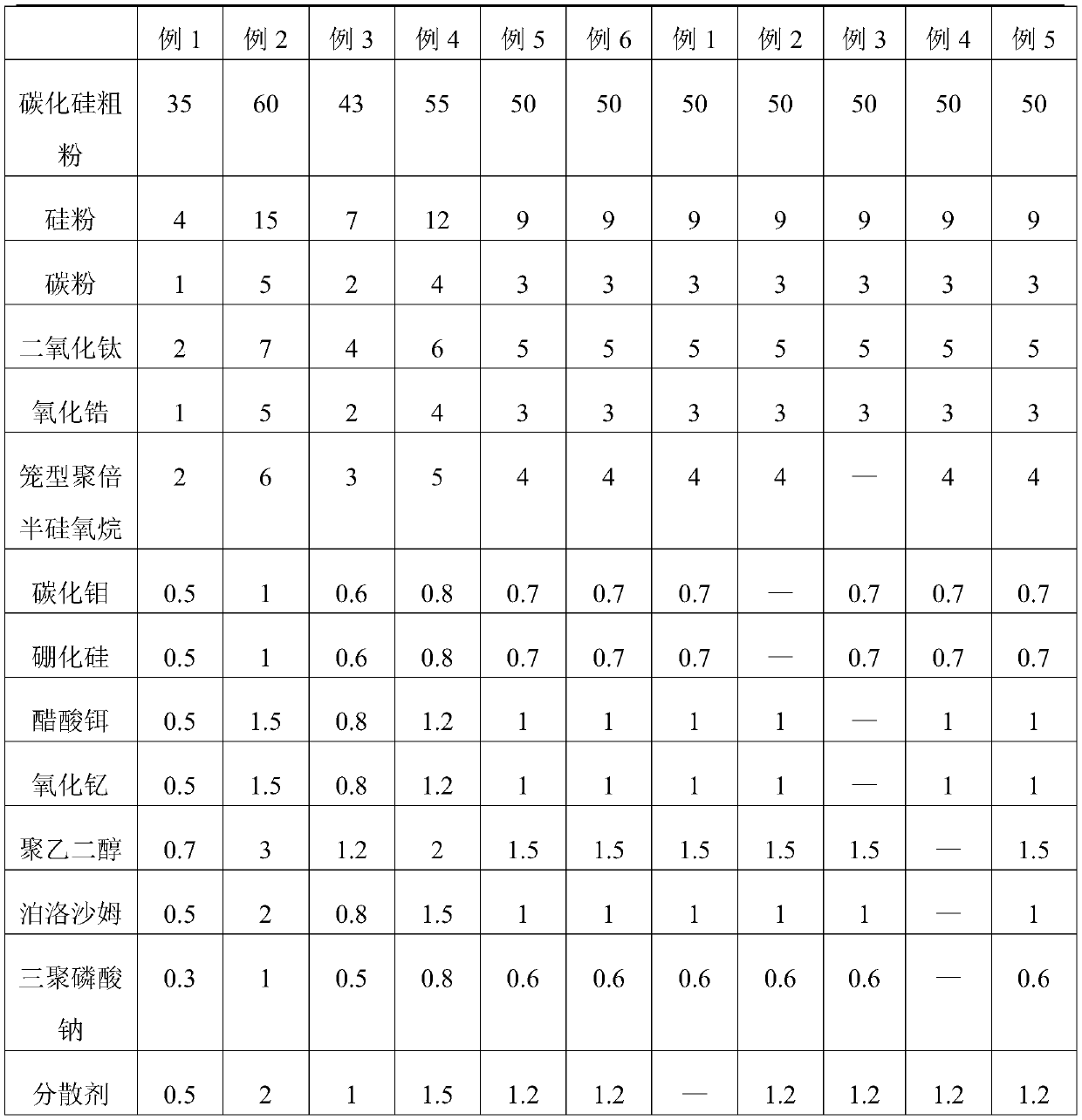

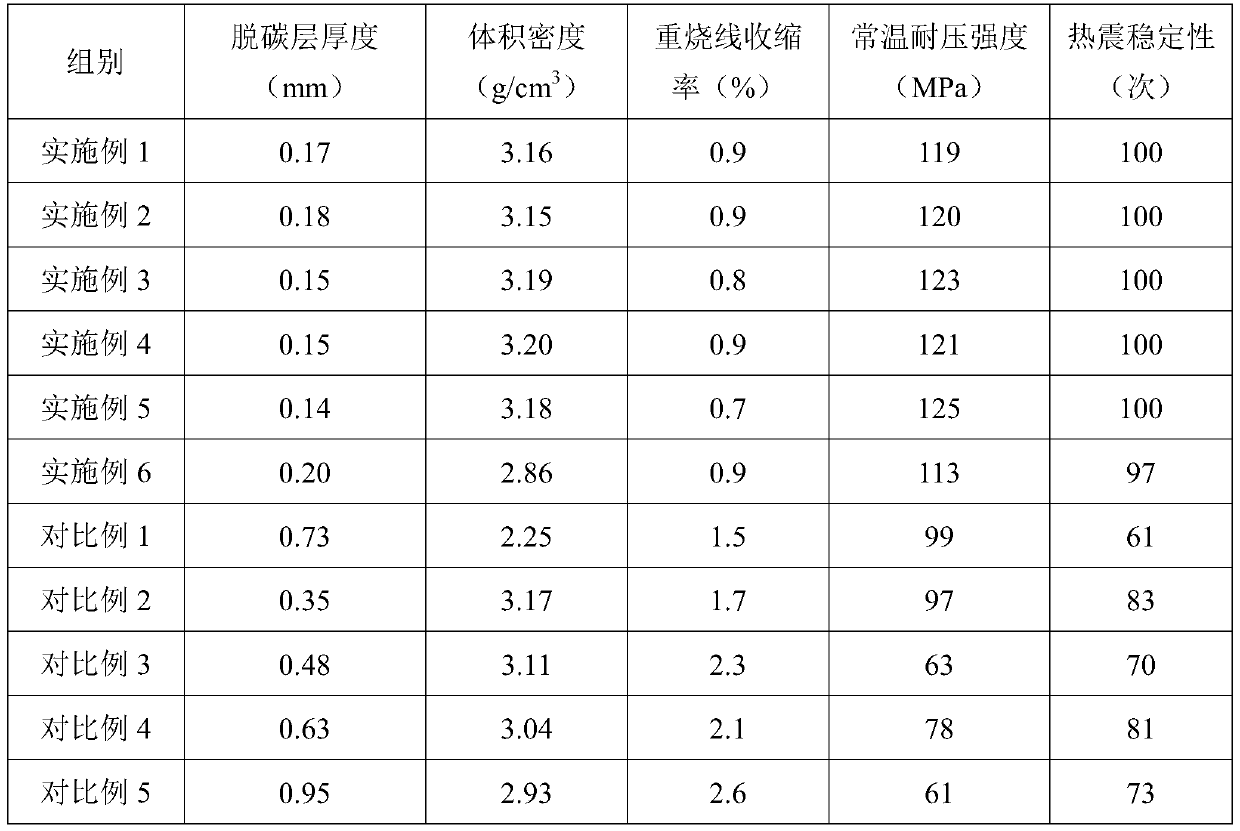

The invention belongs to the technical field of refractory materials, and provides silicon carbide powder and a preparation method thereof. The silicon carbide powder includes, by weight, 35-60 partsof silicon carbide coarse powder; 4-15 parts of silica fume, 1-5 parts of carbon powder, 2-7 parts of titanium dioxide, 1-5 parts of zirconium oxide, 2 to 6 parts of polyhedral oligomeric silsesquioxane, 0.5-1 part of molybdenum carbide, 0.5-1 part of silicon boride, 0.5-1.5 parts of erbium acetate, 0.5-1.5 parts of yttrium oxide, 0.7-3 parts of polyethylene glycol, 0.5-2 parts of poloxamer, 0.3-1part of sodium tripolyphosphate and 0.5-2 parts of a dispersing agent. In the preparation method, a step-by-step mixing and twice ball milling combined manner is adopted. Through the technical scheme, the problems of low strength and poor thermal shock stability of a silicon carbide plate caused by easy agglomeration when the silicon carbide plate is fired by the silicon carbide powder in the prior art are solved.

Owner:唐山市瑞兆碳化硅制品有限公司

Fire, wear and acid resistant clinkery brick and preparation method thereof

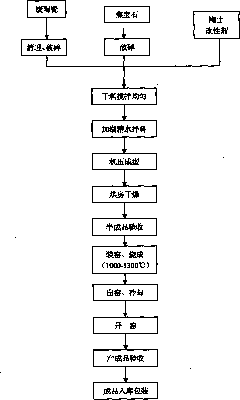

The invention discloses a fire, wear and acid resistant clinkery brick which comprises 30 to 55 percent of waste ceramics, 20 to 45 percent of flint clay, 5 to 15 percent of clay, and 5 to 15 percent of modifier. The preparation method comprises the following steps that: the waste ceramics is cleared and crushed into 0.01 to 5mm grain size, the flint clay is crushed into 0.01 to 5mm grain size, and the clay and the modifier are ground into the granularity with 0.01 to 0.074 grain size; and then the dry materials are dry mixed uniformly, dextrin water topping which is 2 to 5 percent of the total weight of the dry materials is added in, pressed, formed, dried and fried for 3 to 8h at the high temperature of 1000 to 1300DEG C; and the materials are drawn and cooled, and a finished product is obtained after the acceptance is past. The invention has the advantages of high pressure resistant strength at normal temperature, smooth product surface, small friction coefficient, low wear rate, good thermal shock resistance, excellent corrosion resistance, low cost and one-step success of coke investment. As estimated, the service life of a coke cooling bench is prolonged by more than 3 times and is expected to be more than 10 years.

Owner:宜兴市丁山耐火器材有限公司

CMA cement bonded MgO-MA unfired bricks and preparation method thereof

The invention discloses CMA cement bonded MgO-MA unfired bricks and a preparation method thereof. The unfired bricks are prepared by taking 2-5wt% of silicon oxynitride fine powder, 5-20wt% of fused magnesite fine powder, 8-20wt% of magnesium aluminum spinel fine powder, 1-5wt% of aluminum powder, 1-5wt% of silicon powder and 1-10wt% of CMA cement as substrate materials, and using 50-65wt% of fused magnesite particles as aggregate. The preparation method comprises the steps of putting all the substrate materials into a roller ball mill, and mixing for 3-5 minutes to obtain substrate fine powder; putting the aggregate into a mixer, then adding the substrate fine powder, and dry-blending for 3-5 minutes; after that, adding water for wet mixing to obtain mixed pug, wherein the adding amount of the water is 1-10wt% of the total mass of the aggregate and the substrate fine powder; finally, mechanically pressing the mixed pug for molding under the condition of 100-250MPa to obtain the CMA cement bonded MgO-MA unfired bricks. The preparation method provided by the invention is simple, energy-saving, environmentally friendly and low in production cost; the unfired bricks are low in apparent porosity, high in breaking strength at the room temperature, high in compressive strength at the room temperature, high in breaking strength at the high temperature, and good in slag resistance andthermal shock resistance.

Owner:瑞泰马钢新材料科技有限公司

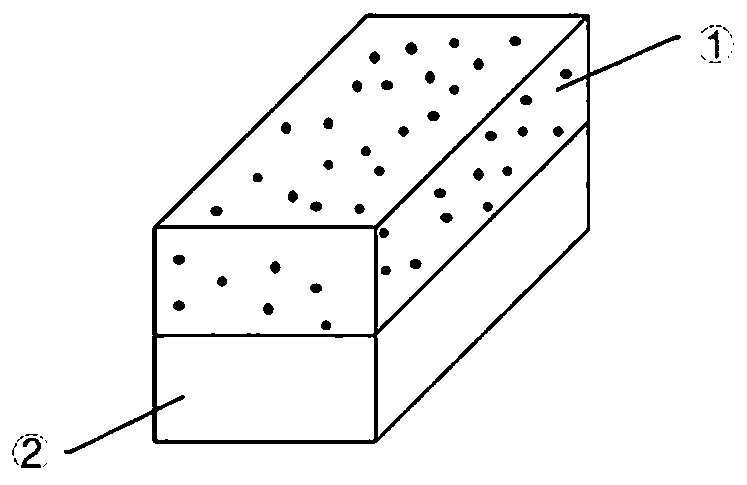

Multiphase gradient furnace door brick of box-type resistance furnace and manufacturing method

PendingCN111205068AHigh compressive strength at room temperatureSmall bulk densityFurnace componentsFurnace typesGrogElectric furnaces

The invention relates to a multiphase gradient furnace door brick of a box-type resistance furnace and a manufacturing method. Aluminum oxide hollow spheres, aluminum oxide powder, a light clinker, plastic clay and a foaming agent are used as raw materials, a box-type resistance furnace multiphase gradient furnace door green brick body is obtained through mixing, forming and drying, finally, the green brick body is placed in a high-temperature electric furnace to be sintered, the sintering temperature is 1200-1350 DEG C, and heat preservation is conducted for 2-6 hours. Characteristics of twodifferent castables are effectively combined, and on the basis of high temperature resistance, mechanical properties and thermal shock resistance stability of the furnace door brick are improved.

Owner:UNIV OF SCI & TECH LIAONING

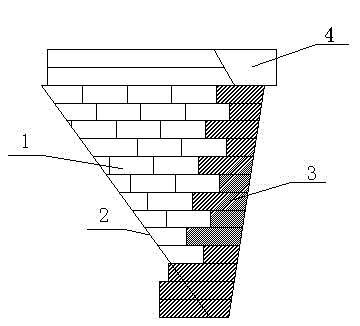

Improvement method for laying of corbel pillar bricks of coke dry quenching furnace

InactiveCN105482831AExtended service lifeHigh compressive strength at room temperatureCoke quenchingCoke oven brickworkQuenchingImprovement methods

The invention relates to an improvement method for laying of corbel pillar bricks of a coke dry quenching furnace. The improvement method is characterized by comprising the following steps of: a, investigation and analysis of the breakage of the corbel pillar bricks of the coke dry quenching furnace; and b, laying improvement of the corbel pillar bricks of the coke dry quenching furnace: (1) material improvement of the corbel pillar bricks of the coke dry quenching furnace and (2) laying structure improvement of the corbel pillar bricks of the coke dry quenching furnace. The improvement method for the laying of the corbel pillar bricks of the coke dry quenching furnace, disclosed by the invention, has the advantages that the difficult problem that the corbel pillar bricks of the coke dry quenching furnace are frequent to break, the service life of the corbel pillar bricks is prolonged, the room-temperature pressure-resistant strength is high, the high-temperature rupture strength is high, the engineering cost is reduced, and the production time of the coke dry quenching furnace is prolonged.

Owner:MCC5 GROUP CORP SHANGHAI

Siliceous refractory material and preparation method thereof

InactiveCN110483076AHigh compressive strength at room temperatureIncrease temperatureSodium carboxymethylcelluloseOrganic acid

The invention provides a siliceous refractory material and a preparation method thereof and relates to the field of refractory materials. The siliceous refractory material is prepared from the following raw materials: high-purity silicon powder, quartz, quartz sand, silica sand, clay, glass fibers, plant fibers, a polyvinyl alcohol aqueous solution, a carboxymethyl cellulose aqueous solution, a water reducing agent, an organic acid and a proper amount of water. The preparation method of the siliceous refractory material comprises the steps of blank preparation, blank forming and drying and blank high-temperature calcination. The glass fibers and the plant fibers are added, so the normal-temperature compressive strength of the refractory material is improved, the product is high in load deformation starting temperature, high in refractoriness and stable in size, the product further has good high-temperature resistance, erosion resistance, thermal shock resistance and abrasion resistance, the heat dissipation loss of the product is reduced, the service life of a sintering furnace is prolonged, and the requirement for economic benefits is met.

Owner:浙江卡斯特科技有限公司

AZC (alumina-zirconia-chromium sesquioxide) lattice brick, manufacturing method of AZC lattice brick and heat accumulation chamber built of AZC lattice brick

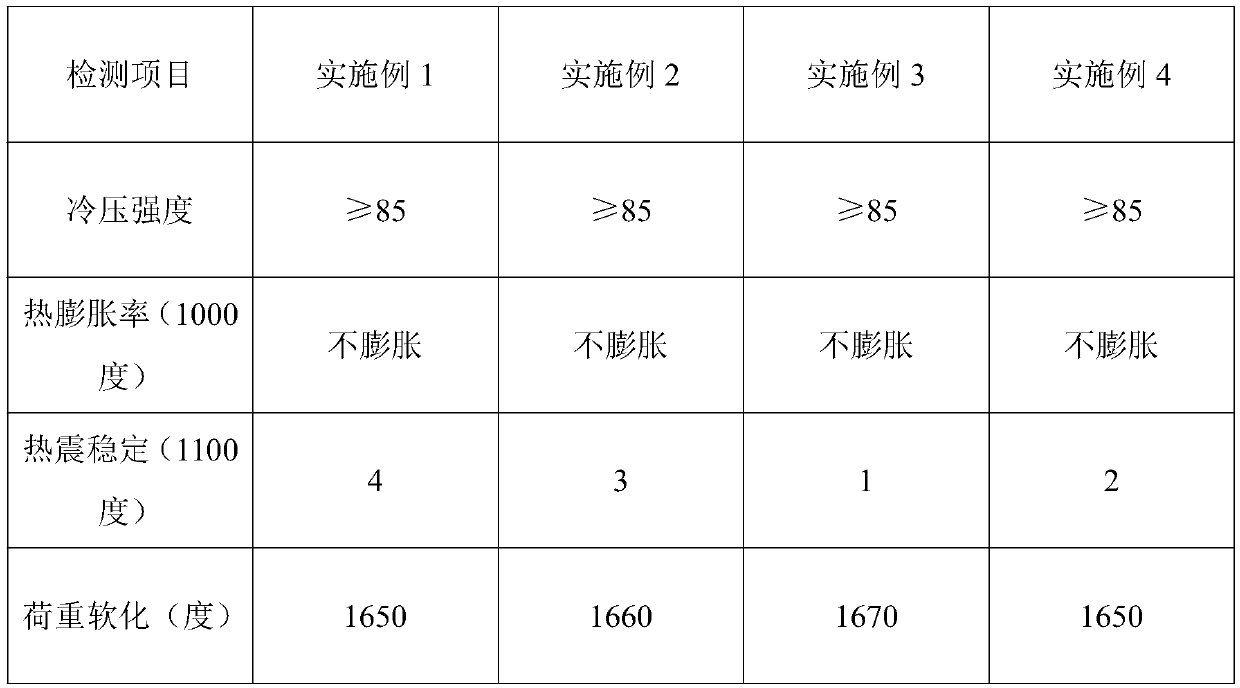

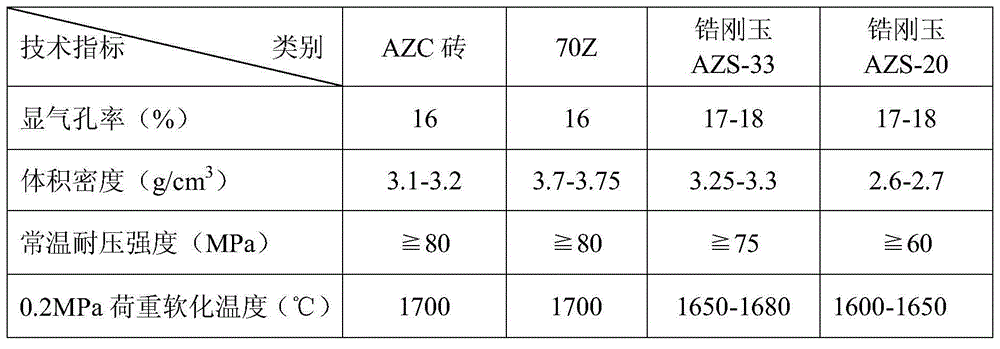

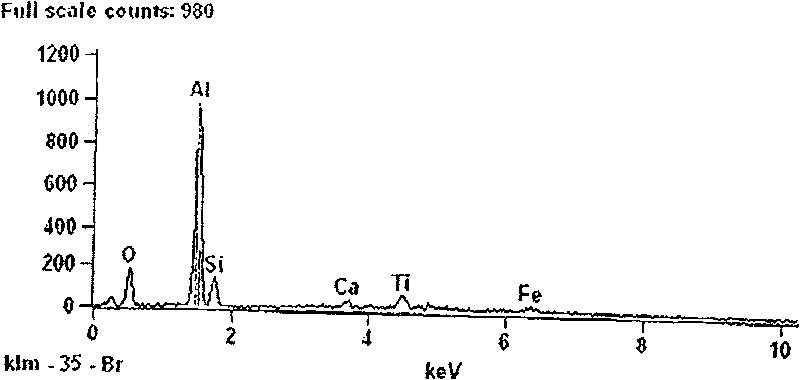

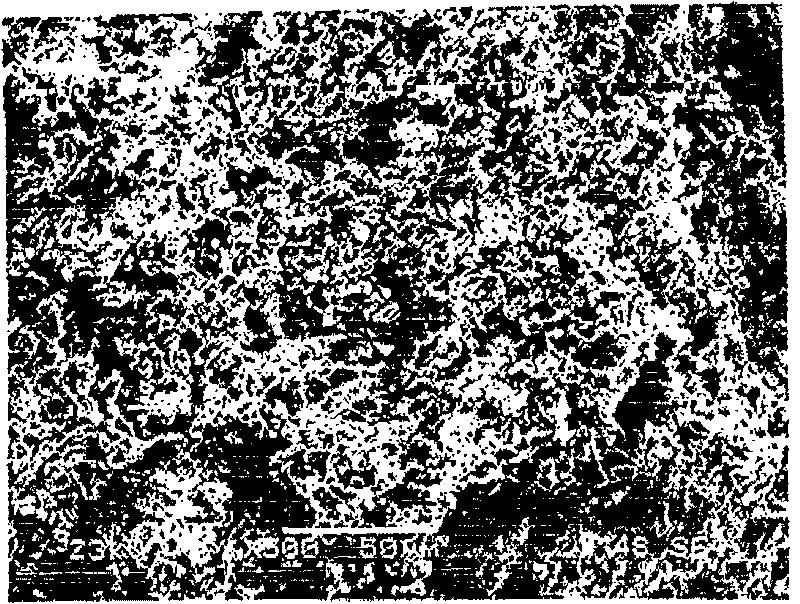

ActiveCN104692628ALow apparent porosityHigh bulk densityGlass furnace apparatusChromium sesquioxideBrick

The invention discloses an AZC (alumina-zirconia-chromium sesquioxide) lattice brick, a manufacturing method of the AZC lattice brick and a heat accumulation chamber built of the AZC lattice brick. The AZC lattice brick is manufactured from the following components in percentage by weight: 70-75% of alumina, 7-12% of zirconia, 6-10% of chromium sesquioxide and 9-12% of aluminum phosphate, wherein the chromium sesquioxide is prepared by calcining waste chromium sesquioxide twice, and the chromium sesquioxide has a particle size of more than 6,000 meshes. The AZC lattice brick has quite low apparent porosity, high bulk density, high compression strength at normal temperature and high refractoriness under the load of 0.2MPa. External substances (harmful gases generated during the combustion of petroleum coke) can be prevented from intruding into the AZC lattice brick so that the organizational structures of refractory materials can be kept intact. In addition, the AZC lattice brick has strong capacity of resisting the erosion of harmful gases generated during the combustion of petroleum coke and has good creep resistance.

Owner:江苏中正耐火材料有限公司

Micro-pore mullite lightweight aggregate and preparation method thereof

The invention relates to the field of refractory materials, particularly to a microporous mullite light aggregate and a production method thereof, and solves the problems of the prior art, such as large volume density, poor compression strength and fire resistance, high heat conductivity, large pore size and non-uniform pore distribution. The light aggregate is made from bauxite, coal gangue, sawdust and petroleum coke. The production method comprises the following steps: crushing raw materials respectively, mixing thoroughly, adding water 80-85% the total weight of the raw materials, wet-milling, filtering with a screen mesh, molding under 6-8 MPa, drying at 180-200 DEG C for 65-75 h, calcining at 1400-1450 DEG C for 9-10 days, crushing, and sieving to obtain mullite light aggregate. Theproduct has the advantages of high porosity, less volume density, small average pore size, small heat conductivity, high compression strength and good fire resistance. The product is widely used as heat-insulating material or directly used in work lining and roof of various industrial furnaces such as heating furnace.

Owner:孝义市京山耐火材料有限公司

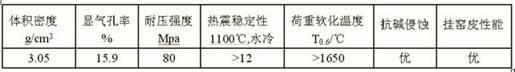

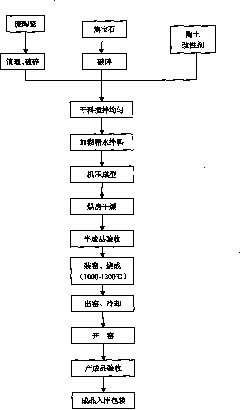

Technological process for preparation of converter sliding plate inlaid zirconium product

The invention discloses a technological process for preparation of converter sliding plate inlaid zirconium product. The technological process comprises the following steps of: mixing and milling raw materials; blanking by using the raw materials; sintering; deironing; preparing powder; mixing; pelleting; mechanical pressing and drying; cellaring; high-temperature sintering; taking out from cellar; inspection; packaging, and obtaining the finished product. Basic magnesium carbonate and iridium oxide added in the technological process provided by the invention can enhance the stability of zirconia, and consequentially, the normal temperature compression strength, the thermal shock stability and the scouring resistance of the product are improved remarkably. The accessory added during the mixing process guarantees the formation density and the blank strength, the product shrinkage is controlled to be 3-10%, the product shrinking percentage can be regulated by regulation on the dosage of the powder and the magnesium-zirconium powder, moreover, unnecessary impurities are eliminated in the technology, cracking of zirconium product is reduced effectively, and the quality of product is guaranteed.

Owner:TAICANG HONGDA JUNMENG NEW MATERIAL

Preparation method and use method of modified magnesian unfired product binding agent

The invention discloses a preparation method and a use method of a modified magnesian unfired product binding agent, and the preparation method comprises the following steps: adding ferrocene into anhydrous phenolic resin to obtain the modified magnesian unfired product binding agent; taking the modified magnesian unfired product binding agent which accounts for 3-5% of the total weight of the aggregate and the powder of the magnesian unfired product; and carrying out hot mixing, molding under the pressure intensity of 150-350MPa, and carrying out reduction gas heat treatment at 1650 DEG C for4h. The anhydrous phenolic resin is modified, so that the inherent advantages of high viscosity, high carbonization residual carbon content and high product strength of the binding agent are ensured;according to the method, the carbon nanostructure is formed in the carbonization process, the organic grid structure is synthesized in situ at the heat treatment temperature, crystalline carbon graphite with very high oxidation resistance is formed in the carbonization process, the carbon nanostructure is formed in the medium-temperature reducing atmosphere, the strength and the heat stability ofthe magnesium unfired product are further enhanced, and the method has practical significance in production and preparation of the magnesium unfired product.

Owner:LUOYANG INST OF SCI & TECH

Barium zirconate/magnesium oxide composite ceramic material and preparation method thereof

The invention relates to a barium zirconate / magnesium oxide composite ceramic material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: mixing a barium source and a zirconium source, carrying out dry ball milling, carrying out heat preservation at 1200-1500 DEG C, carrying out furnace cooling, and crushing to obtain pre-sintered barium zirconate powder; mixing the pre-sintered barium zirconate powder and the fused magnesia fine powder to obtain a mixture I; and mixing the fused magnesite particles I and the fused magnesite particles II to obtain a mixture II. And mixing the mixture I and the mixture II to obtain the barium zirconate / magnesium oxide composite ceramic powder. And carrying out mechanical pressing, heating the barium zirconate / magnesium oxide composite ceramic green body to 1500-1600 DEG C under the conditions of air atmosphere and normal pressure, and carrying out heat preservation for 3-5 hours to obtain the barium zirconate / magnesium oxide composite ceramic material. The preparation method is simple in process, short in production period, low in cost and environment-friendly, and the prepared barium zirconate / magnesium oxide composite ceramic material is high in normal-temperature compression strength and low in normal-temperature heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

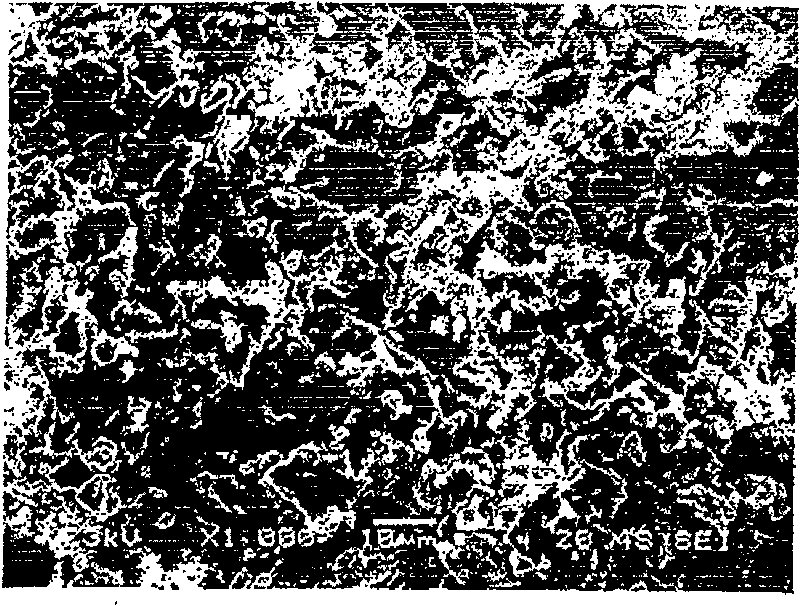

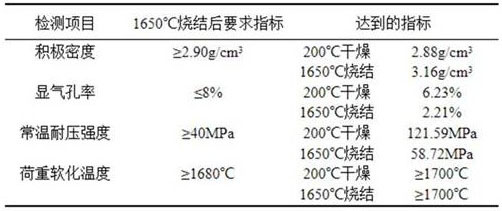

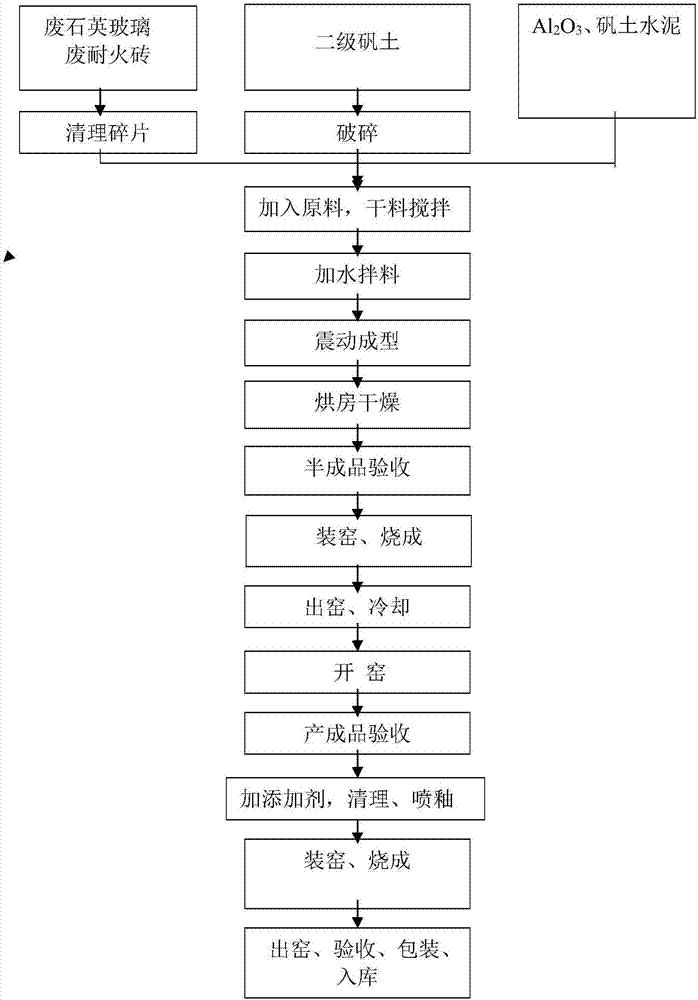

Pouring glazed tile used for oversized coke oven of specific structure and preparation method thereof

The invention discloses a pouring glazed tile used for an oversized coke oven of a specific structure. The pouring glazed tile comprises the following components: secondary alumina, alumina cement, alumina, additives, water, waste quartz glass and waste refractory bricks, wherein the total weight of the waste quartz glass and the waste refractory bricks accounts for not more than 40% of the totalweight of all the components, and the additives comprise spodumene, potassium feldspar, quartz, clay, alumina and water. The invention also discloses a preparation method of the energy-saving and environment-friendly glazed tile. The glazed tile obtained by adopting the preparation method can not produce bubbles, fly glaze or fall off at high temperature of 1300 DEG C, a smooth glaze layer is realized, and expansion coefficient of the glaze layer is close to that of a biscuit firing billet, so that the biscuit firing billet and the glaze layer are basically consistent in thermal expansion andshrinkage, the billet and the glaze layer are free of cracks, thermal expansion coefficient of the overall product is consistent, and thermal expansion problem of the glaze layer and the biscuit firing billet is solved.

Owner:宜兴市丁山耐火器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com