Slide plate refractory with silicon nitride added and production method thereof

A technology of refractory materials and silicon nitride, which is applied in the field of sliding refractory materials added with silicon nitride, can solve problems such as not being able to meet the requirements of use, and achieve the effects of improving oxidation resistance, increasing density, and improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

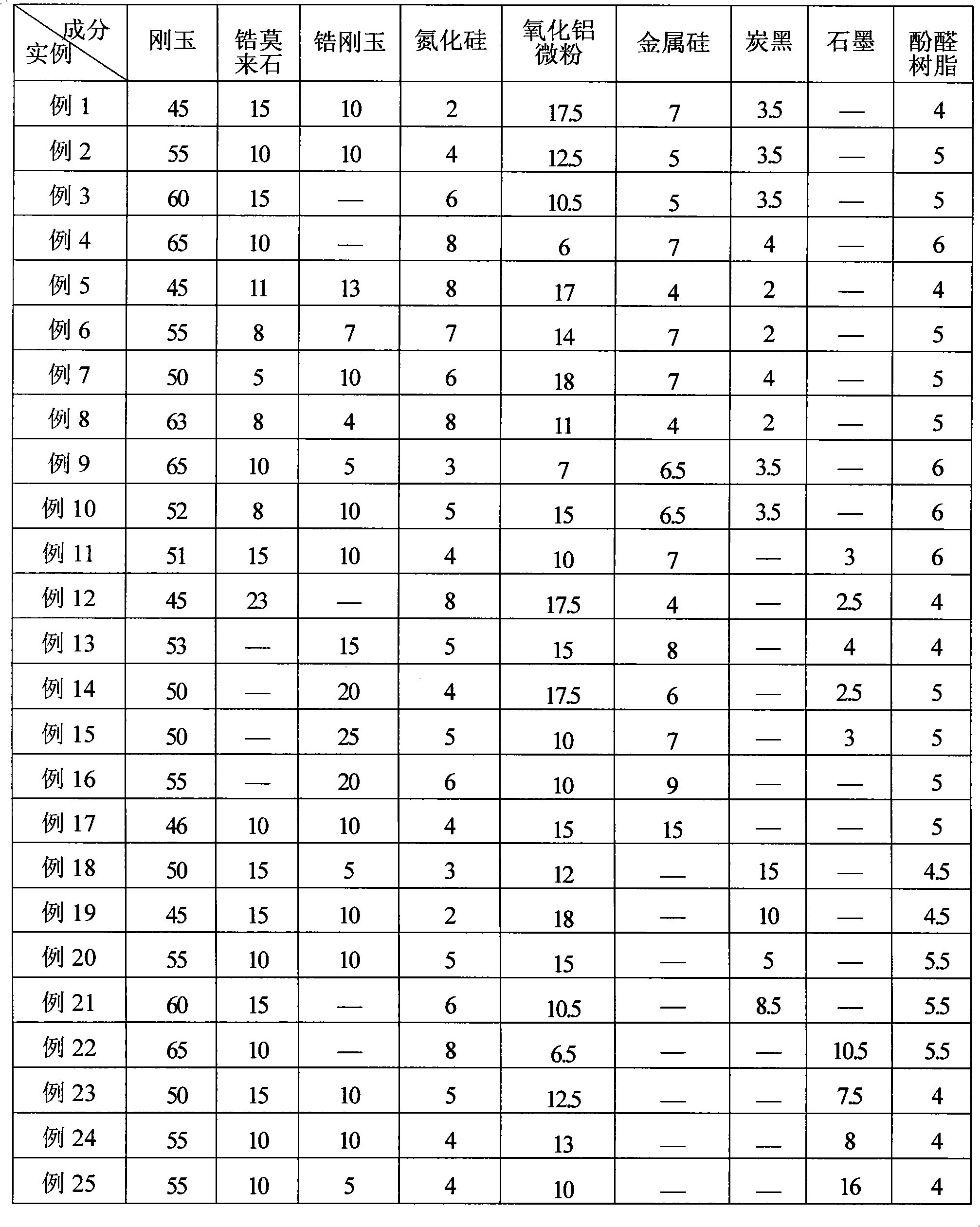

Examples

Embodiment 1

[0017] Example 1: A sliding plate refractory material added with silicon nitride, the composition is shown in Table 1 by weight percentage, that is, the raw material composition is: 45% corundum, 15% zirconium mullite, 10% zirconium corundum, 2 % of silicon nitride, 3.5% of carbon black, 7% of metal silicon, 17.5% of alumina micropowder, plus 4% of phenolic resin binder. The phenolic resin is a thermosetting resin.

[0018] During production, first weigh the raw materials according to the proportion, mix them evenly, and get the mud material through mixing, then press and form it through a friction press, dry it at 200±10°C for 8 hours, and then burn it under a nitrogen atmosphere at 1300°C; After hooping, grinding and coating, the Al with silicon nitride added in the present invention can be made. 2 o 3 -ZrO 2 -Si 3 N 4 -C skateboard.

[0019] The mixing is carried out in two steps. First, the powder in the raw material is put into a kneader and mixed evenly to obtain a...

Embodiment 2

[0022] Embodiment 2: The composition is shown in Table 1, which is basically the same as Embodiment 1, the difference being:

[0023] During production, the raw materials are first weighed according to the proportion, mixed evenly, and mud is obtained through mixing, and then pressurized and formed by a friction press, dried at 200±10°C for 6 hours, and then fired at 1250°C under a nitrogen atmosphere. After hooping, grinding and coating, the Al with silicon nitride added is formed. 2 o 3 -ZrO 2 -Si 3 N 4 -C skateboard.

[0024] The obtained product has an apparent porosity of 2%, a normal-temperature compressive strength of 161MPa, and a high-temperature flexural strength of 29MPa. Its oxidation resistance and erosion resistance are excellent, and its thermal shock resistance is good.

Embodiment 3

[0025] Embodiment 3: The composition is shown in Table 1, which is basically the same as that of Embodiment 1, except that:

[0026] During production, the raw materials are first weighed according to the proportion, mixed evenly, and mud is obtained through mixing, and then pressurized by a friction press, dried at 200±10°C for 9 hours, and then fired at 1350°C under a nitrogen atmosphere. After hooping, grinding and coating, the Al with silicon nitride added is formed. 2 o 3 -ZrO 2 -Si 3 N 4 -C skateboard.

[0027] The obtained product has an apparent porosity of 3%, a normal temperature compressive strength of 176MPa, a high temperature flexural strength of 30MPa, and excellent oxidation resistance, erosion resistance and thermal shock resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com