High temperature creep resistant mullite-cordierite product and preparation method thereof

A cordierite and creep-resistant technology, applied in the field of high-temperature refractories, can solve the problems of low high-temperature creep resistance, and achieve the effects of reducing porosity, good thermal shock resistance, and strengthening sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

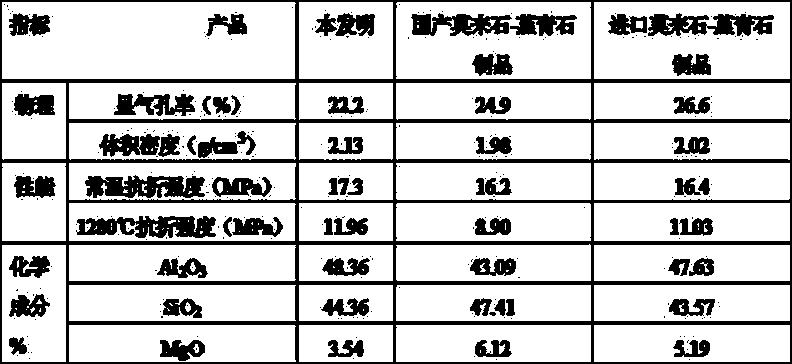

Image

Examples

Embodiment 1

[0047] The main raw materials are formulated according to the following proportions by weight:

[0048]Sintered mullite M70: 10 parts of sintered mullite with a particle size of 0.1-1mm

[0049] Sintered mullite M45: 5 parts of sintered mullite with particle size less than 0.089mm

[0050] 5 parts of sintered mullite with a particle size of 0.5-1 mm

[0051] 5 parts of sintered mullite with a particle size of 1-1.5 mm

[0052] 10 parts of cordierite with a particle size of 0.1-1 mm

[0053] 8 parts of cordierite with a particle size of 1-3mm

[0054] 8 parts of white corundum

[0055] Fused silica 4.35 parts

[0056] Kyanite 10 parts

[0057] 10 parts of alumina micropowder

[0058] Bentonite powder 1.6 parts

[0059] 8 parts cooked talc micropowder

[0060] 15 parts kaolin

[0061] Add 0.05 part of binder agent sulfurous acid pulp waste liquid, the specific process steps are as follows:

[0062] 1) Mixing: Put the raw materials in a ...

Embodiment 2

[0067] The main raw materials are formulated according to the following proportions by weight:

[0068] Sintered mullite M70: 12 parts of sintered mullite with a particle size of 0.1-1mm

[0069] Sintered mullite M45: 6 parts of sintered mullite with particle size less than 0.089mm

[0070] 6 parts of sintered mullite with a particle size of 0.5-1mm

[0071] 8 parts of sintered mullite with a particle size of 1-1.5mm

[0072] 12 parts of cordierite with a particle size of 0.1-1mm

[0073] 10 parts of cordierite with a particle size of 1-3mm

[0074] 12 parts of white corundum

[0075] Fused silica 2.77 parts

[0076] Kyanite 5 parts

[0077] 7 parts of alumina micropowder

[0078] Bentonite powder 1.2 parts

[0079] 6 parts cooked talc micropowder

[0080] 12 parts kaolin

[0081] Add 0.03 part of binding agent hydroxymethyl cellulose, and the specific process steps are as follows:

[0082] 1) Mixing: Put the raw materials in a vertic...

Embodiment 3

[0087] The main raw materials are formulated according to the following proportions by weight:

[0088] Sintered mullite M70: 8 parts of sintered mullite with a particle size of 0.1-1mm

[0089] Sintered mullite M45: 4 parts of sintered mullite with particle size less than 0.089mm

[0090] 4 parts of sintered mullite with a particle size of 0.5-1 mm

[0091] 6 parts of sintered mullite with a particle size of 1-1.5mm

[0092] 9 parts of cordierite with a particle size of 0.1-1mm

[0093] 7 parts of cordierite with a particle size of 1-3mm

[0094] 5 parts of white corundum

[0095] Fused silica 5.75 parts

[0096] Kyanite 12 parts

[0097] 12 parts of alumina micropowder

[0098] 2.2 parts of bentonite micropowder

[0099] 8 parts cooked talc micropowder

[0100] Kaolin 17 parts

[0101] Add 0.05 part of binder dextrin, and the specific process steps are as follows:

[0102] 1) Mixing: Put the raw materials in a vertical stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com