High-performance magnesia calcia brick and preparation method thereof

A high-performance magnesia-calcium brick and magnesia-calcium sand technology, applied in the field of refractory materials, can solve the problems of weak slag erosion resistance and high apparent porosity of magnesia-calcium bricks, and achieve improved hydration resistance, bulk density, and other parameters Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

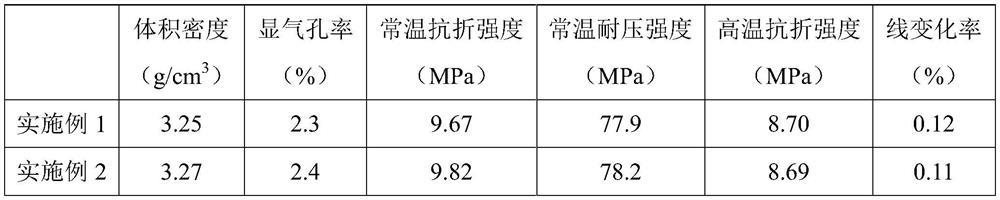

Embodiment 1

[0037] The high-performance magnesia-calcium brick of this embodiment includes the following raw materials in parts by weight:

[0038] Magnesia calcium sand: 55 parts,

[0039] Magnesia: 30 parts,

[0040] Anhydrous binder: 3 parts,

[0041] Medium temperature sintering aid: 5 parts;

[0042] Wherein said anhydrous binder comprises urotropine, o-phenylphenol, propylene carbonate,

[0043] The weight ratio between the urotropine, the o-phenylphenol and the propylene carbonate is 1:4:2;

[0044] Wherein the medium temperature sintering aids include sodium borate, lithium feldspar, paraffin, zirconia,

[0045] The weight ratio among the sodium borate, the lithium feldspar, the paraffin and the zirconium dioxide is 2:3:1:4.

[0046] In the above-mentioned high-performance magnesia-calcium brick, the particle size of the magnesia-calcium sand is 200 mesh; the particle size of the magnesia is 200 mesh.

[0047] In the above-mentioned high-performance magnesia-calcium bricks, ...

Embodiment 2

[0059] The high-performance magnesia-calcium brick of this embodiment includes the following raw materials in parts by weight:

[0060] Magnesia calcium sand: 70 parts,

[0061] Magnesia: 20 parts,

[0062] Anhydrous binder: 5 parts,

[0063] Medium temperature sintering aid: 3 parts;

[0064] Wherein said anhydrous binder comprises urotropine, o-phenylphenol, propylene carbonate,

[0065] The weight ratio between the urotropine, the o-phenylphenol and the propylene carbonate is 1:4:2;

[0066] Wherein the medium temperature sintering aids include sodium borate, lithium feldspar, paraffin, zirconia,

[0067] The weight ratio among the sodium borate, the lithium feldspar, the paraffin and the zirconium dioxide is 2:3:1:4.

[0068] In the above-mentioned high-performance magnesia-calcium brick, the particle size of the magnesia-calcium sand is 200 mesh; the particle size of the magnesia is 200 mesh.

[0069] In the above-mentioned high-performance magnesia-calcium bricks, th...

Embodiment 3

[0081] The high-performance magnesia-calcium brick of this embodiment includes the following raw materials in parts by weight:

[0082] Magnesia calcium sand: 62 parts,

[0083] Magnesia: 25 parts,

[0084] Anhydrous binder: 4 parts,

[0085] Medium temperature sintering aid: 4 parts;

[0086] Wherein said anhydrous binder comprises urotropine, o-phenylphenol, propylene carbonate,

[0087] The weight ratio between the urotropine, the o-phenylphenol and the propylene carbonate is 1:4:2;

[0088] Wherein the medium temperature sintering aids include sodium borate, lithium feldspar, paraffin, zirconia,

[0089] The weight ratio among the sodium borate, the lithium feldspar, the paraffin and the zirconium dioxide is 2:3:1:4.

[0090] In the above-mentioned high-performance magnesia-calcium brick, the particle size of the magnesia-calcium sand is 200 mesh; the particle size of the magnesia is 200 mesh.

[0091] In the above-mentioned high-performance magnesia-calcium bricks, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com