Geo polymer base composite material double pole plate and its preparing method

A composite material and geopolymer technology, used in fuel cells, battery electrodes, fuel cell components, etc., can solve the problems of immature composite bipolar plate technology, low mechanical strength and bending strength, and metal bipolar plate density. Large and other problems, to achieve the effect of light weight, good electrical conductivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

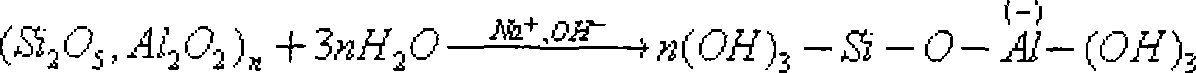

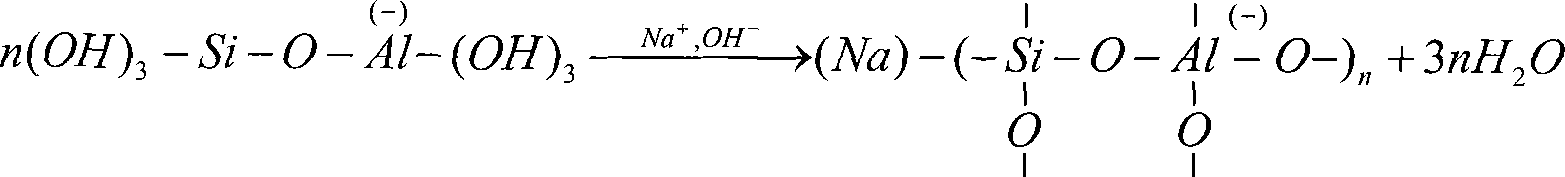

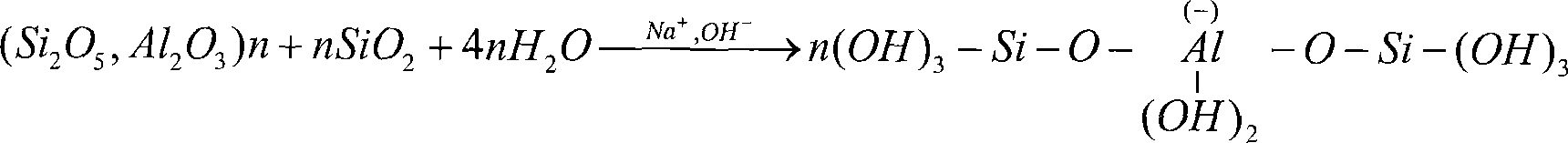

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing a geopolymer-based composite bipolar plate, comprising the steps of:

[0065] 1) Select 4 groups of raw materials (number 1-4) according to Table 7. The metakaolin is commercially available coal series kaolin or pure kaolin, which is calcined at a high temperature of 600-850°C. The purity of the graphite is more than or equal to 99.85 wt%, and the fineness is less than 90 μm. The length of the carbon fiber is less than 4mm, and the diameter is less than 0.2mm.

[0066] 2) Fully stir the metakaolin and the conductive material with a JJ-5 cement mortar mixer, and mix evenly to obtain a powder; add the water glass solution to the uniformly mixed powder, and then fully stir to obtain a slurry;

[0067] 3) After the slurry is fully stirred by the JJ-5 cement mortar mixer, it is injected into a metal mold (bipolar plate forming mold) with a reverse gas flow channel, hot-pressed at 120-180°C for 15 minutes, and demolded. After demoulding, put it under...

Embodiment 2

[0074] A method for preparing a geopolymer-based composite bipolar plate, comprising the steps of:

[0075] 1) According to Table 9, select 12 groups of raw materials (serial numbers 1-12, correspondingly make 12 bipolar plates). The metakaolin is commercially available coal series kaolin or pure kaolin, which is calcined at a high temperature of 600-850°C. The purity of the graphite is more than or equal to 99.85 wt%, and the fineness is less than 90 μm. The length of the carbon fiber is less than 4mm, and the diameter is less than 0.2mm.

[0076] 2) Fully stir the metakaolin and the conductive material with a JJ-5 cement mortar mixer, and mix evenly to obtain a powder; add the water glass solution to the uniformly mixed powder, and then fully stir to obtain a slurry;

[0077] 3) After the slurry is fully stirred by the JJ-5 cement mortar mixer, it is injected into a metal mold with a reverse gas flow channel (the bipolar plate forming is implemented according to the existi...

Embodiment 3

[0081] A method for preparing a geopolymer-based composite bipolar plate, comprising the steps of:

[0082] 1) According to graphite dosage is 20% of metakaolin quality, and carbon fiber dosage is 10% of metakaolin quality; The mass ratio of water glass solution and metakaolin and conductive material is 0.4: 1 selects metakaolin, graphite, carbon fiber and water The raw material of glass solution, wherein the conductive material is composed of graphite and carbon fiber; the metakaolin is obtained by calcining coal series kaolin sold on the market at a high temperature of 600°C; the modulus of the water glass solution is m=2.8, Baumé Be=35; the purity of the graphite is ≥99.85wt%, and the fineness is less than 90 μm; the length of the carbon fiber is less than 4mm, and the diameter is less than 0.2mm;

[0083] 2) Fully stir the metakaolin and the conductive material with a JJ-5 cement mortar mixer, and mix evenly to obtain a powder; add the water glass solution to the uniformly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com