Patents

Literature

311 results about "Grog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grog, also known as firesand and chamotte, is a raw material for making ceramics. It has a high percentage of silica and alumina. It is normally available as a powder or chippings, and is an important ingredient in Coade stone.

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Iolite cellular ceramic and preparation method

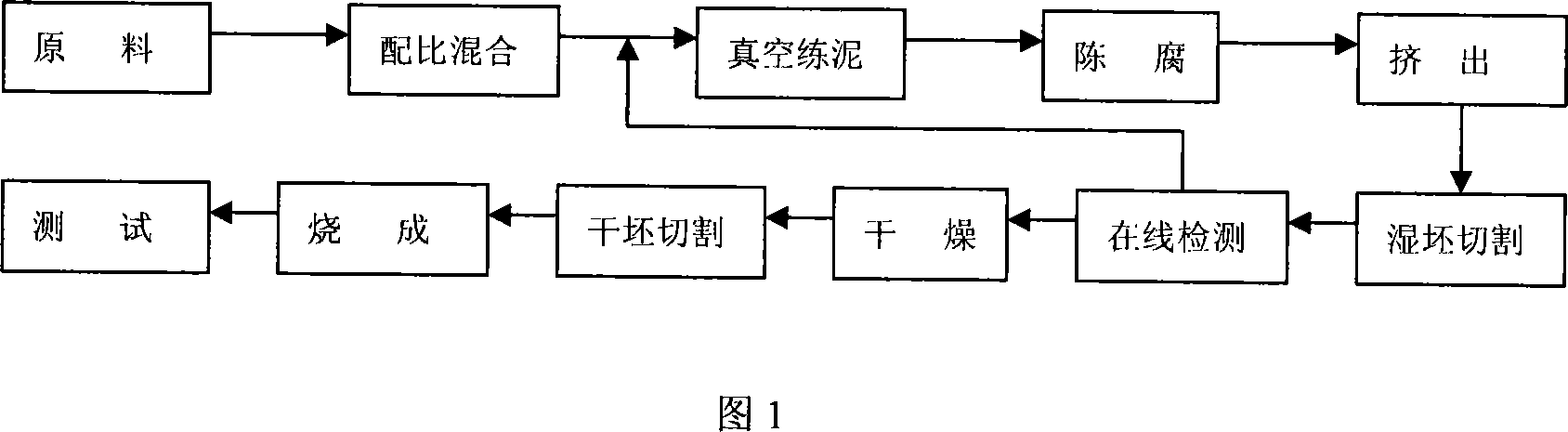

A high-porosity thin-wall cordierite-type cellular ceramics is prepared proportionally from LiO2, talc, kaolinite, calcined kaolinite, alpha-AlO, aluminum hydroxide, silicon powder, solid adhesive, and the liquid organic additive prepared from water, propanetriol, liquid adhesive, surfactant and lubricant. Its preparing process is also disclosed.

Owner:JIANGSU GAOCHUN CERAMICS +1

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

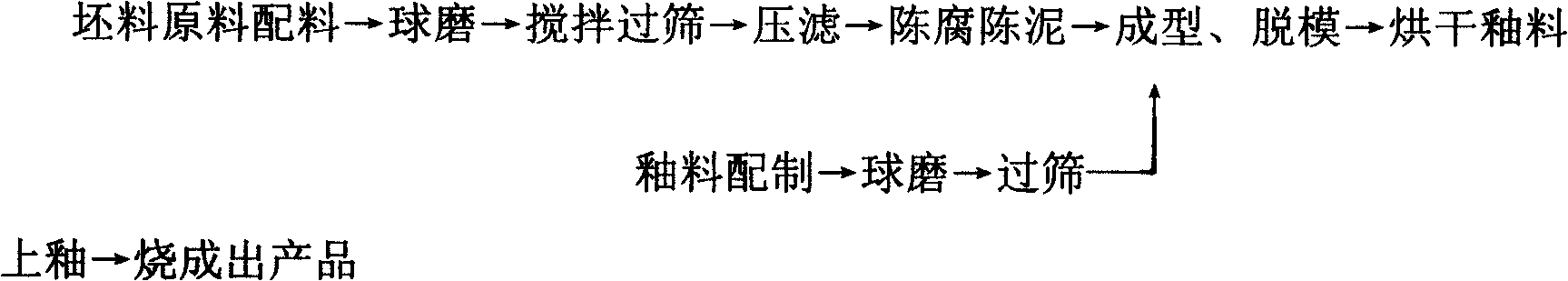

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Anchoring grouting material as well as preparation method and application thereof

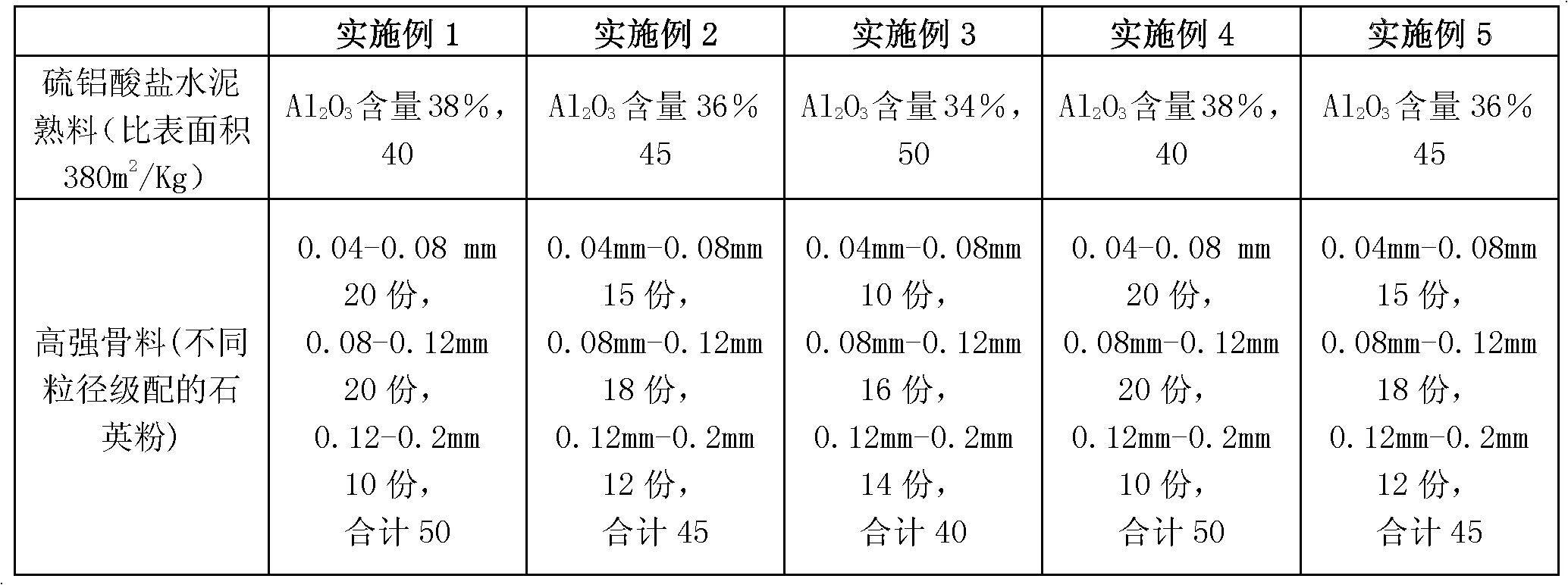

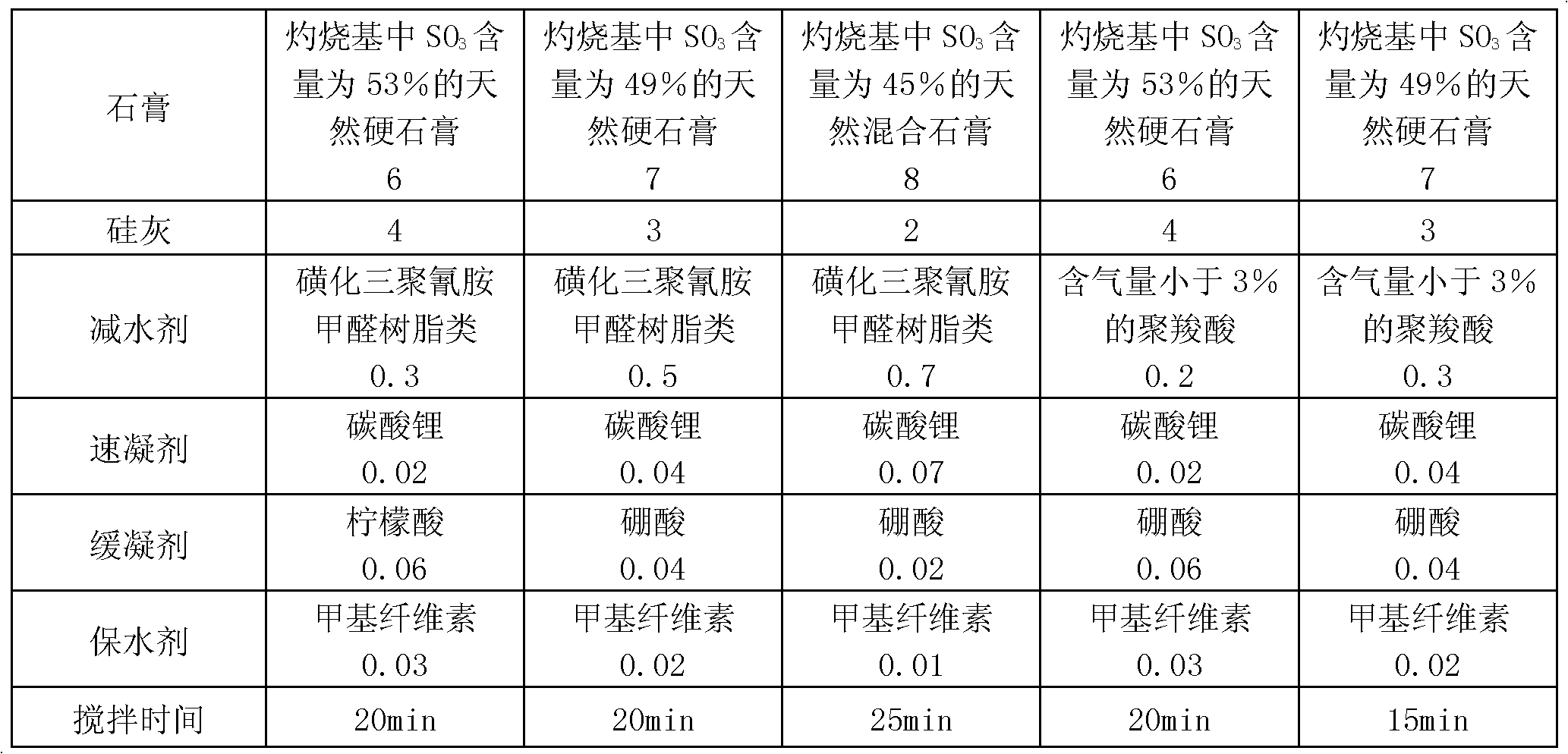

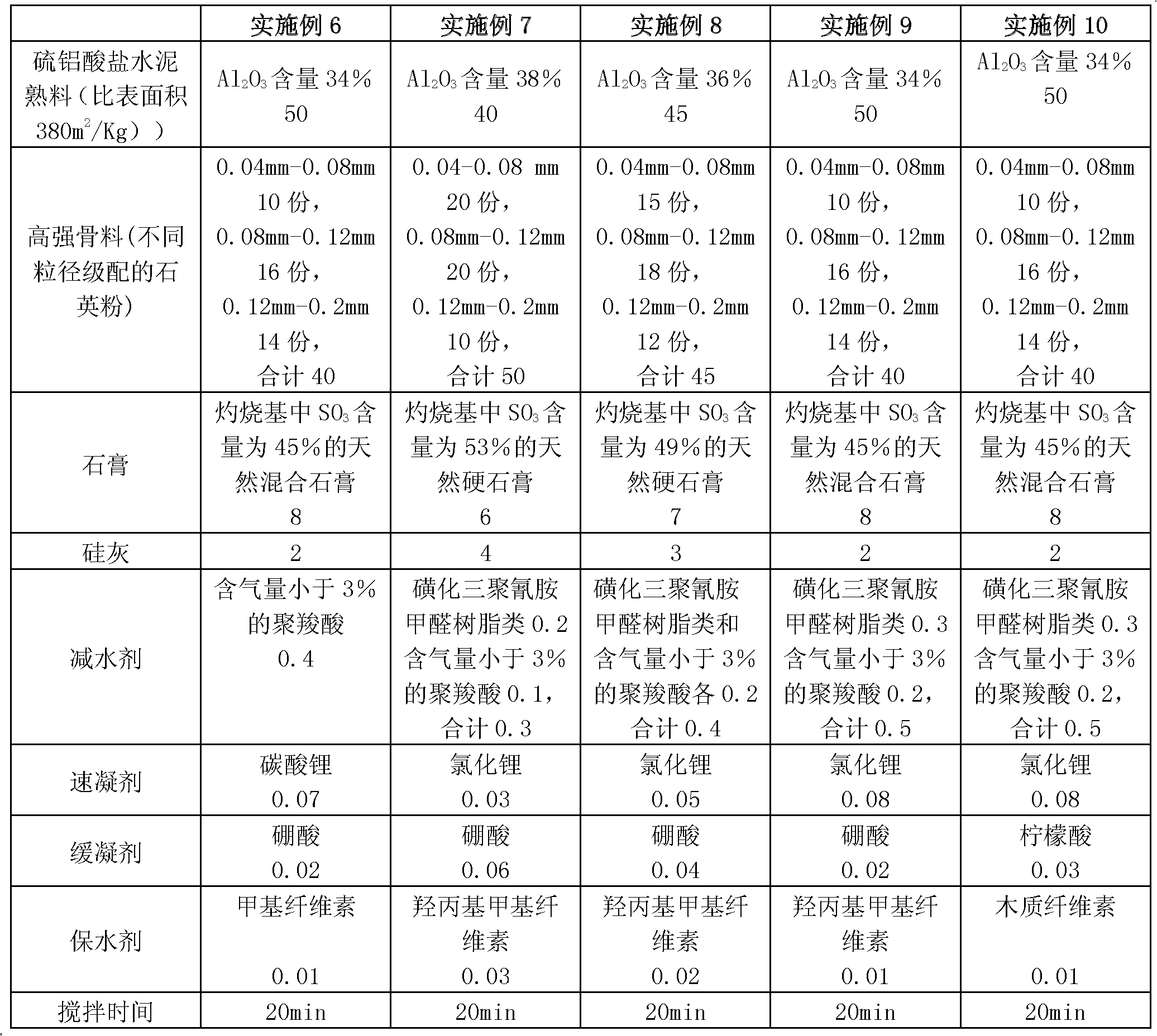

The invention discloses an anchoring grouting material as well as a preparation method and an application of the anchoring grouting material. The raw material reciple of the anchoring grouting material comprises the following ingredients in parts by weight: 40 to 50 parts of special clinkers, 40 to 50 parts of high-intensity aggregate, 6 to 8 parts of gypsum, 2 to 4 parts of silicon ash, 0.2 to 0.7 part of water reducing agents, 0.02 to 0.08 part of setting accelerators, 0.02 to 0.06 part of setting retarders and 0.01 to 0.03 part of water-retaining agents. Detection results show that the initial flow rate of the materials is smaller than 20 seconds in the low temperature state of -20 DEG C to 0 DEG C, the flow rate after 20 seconds is smaller than 30 seconds, the pressure resistant intensity in 3 hours is greater than 20MPa, in addition, the pressure resistant intensity in 3 days is higher than 50MPa, the limit expansion rate in 7 days is greater than 0.01 percent, the micro expansion performance is realized, in addition, the viscosity is low, the permeability is good, a good reinforcing effect is also realized on a soil layer, the anchoring grouting material can be used for anchoring anchor cables or anchor rods in underground support protection engineering such as subway, tunnels and the like in low-temperature environment (in winter), and application prospects are wide.

Owner:CNBM ZHONGYAN TECH +1

Ceramic Al203SiC refractory and preparation method thereof

A refractory ceramic Al2O3-SiC brick with high strength and low porosity is prepared through proportionally mixing high-Al alumine, white corundum, brown corundum, industrial silicon carbide, andalusite, ceramic additive, adhesive and water, stirring or grinding, die pressing, drying at 60-110 deg.C for 12-24 hr or natural drying, and calcining at 1400-1470 deg.C.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

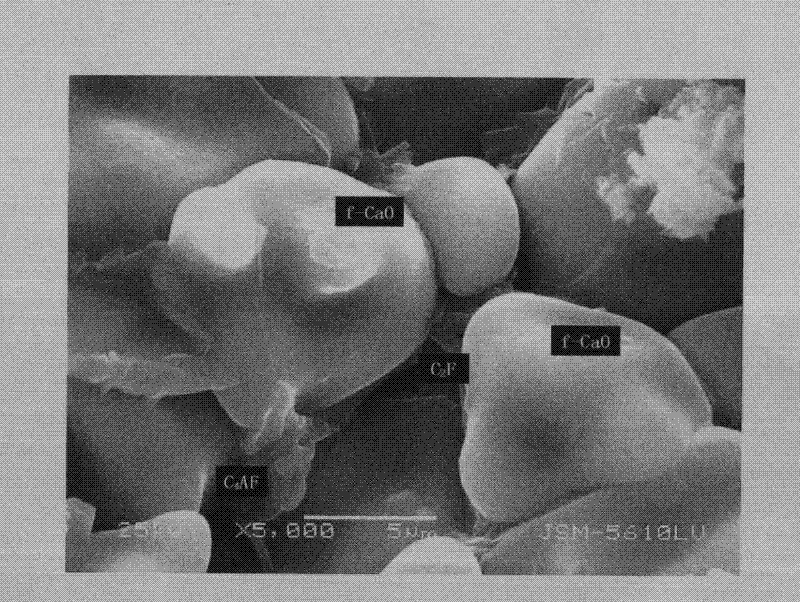

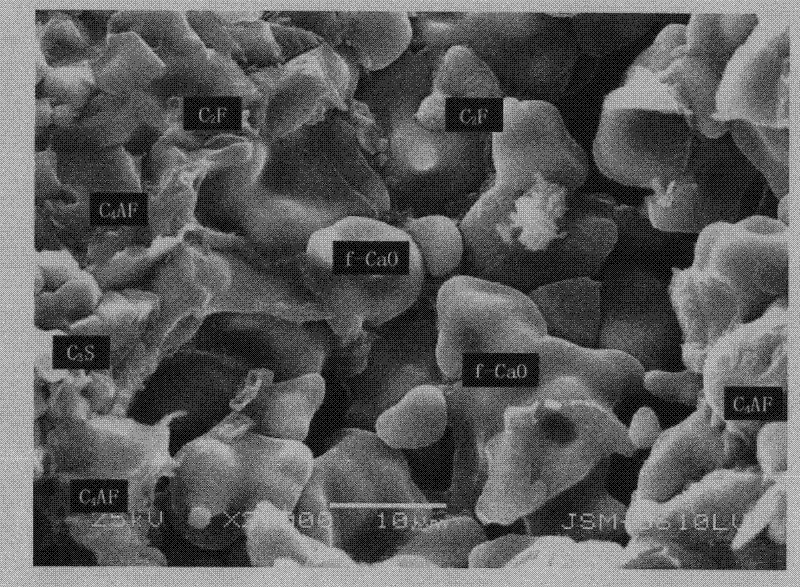

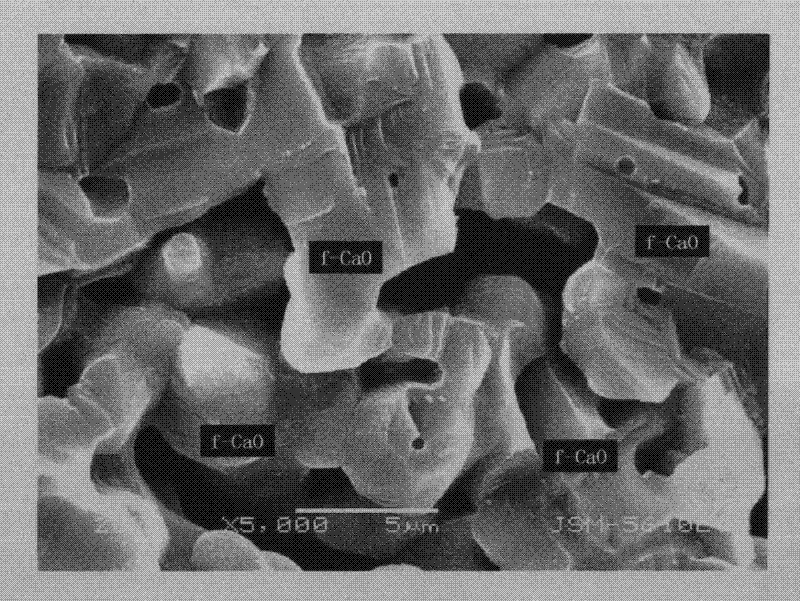

Expanding clinker, expanding agent, concrete and preparation method of expanding clinker

The invention relates to expanding clinker. The expanding clinker is formed by mixing and calcining raw materials of lime stone and iron powder, wherein in the raw materials, the calcium carbonate content based on the calcium oxide (CaO) content is 48 to 53 weight percent; the ferric oxide (Fe2O3) content is 1 to 5 weight percent; and the weight percentage is based on the total weight of the lime stone and the iron powder. The invention also relates to an expanding agent containing the expanding clinker and a preparation method of the expanding clinker. The invention further relates to an expanding agent containing the expanding clinker or the expanding agent provided by the invention.

Owner:武汉三源特种建材有限责任公司

Light refractory castable material for heat insulation lining of cast steel plate (CPS) furnace roller

The invention discloses a light refractory castable material for a heat insulation lining of a cast steel plate (CPS) furnace roller. The light refractory castable material comprises the following components by weight percent: 40-50% of light mullite bone material, 5-8% of flint clay with a particle size of 0.1-1mm, 5-7% of kyanite powder, 6-9% of first-class bauxite chamotte with a particle sizeof less than or equal to 180 meshes, 7-9% of silicon micro powder, 5-8% of alpha-Al2O3 micro powder, 10-18% of bauxite cement, 1-4% of refractory fiber, 1-1.5% of spodumene, 0.05-0.154% of sodium hexametaphosphate, 0.05-0.15% of organic water reducing agent, 0.04-0.07% of organic silane coupling agent and 0.013-0.06% of defoaming agent. The refractory castable material has the characteristics of light volume weight, strong high temperature resistance, good mechanical property, good heat insulation property and excellent thermal shock stability performance.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Composite magnesia alumina spinel/Sialon ceramic material and its prepn process

The present invention relates to one kind of composite magnesia-alumina spinel / Sialon ceramic material and its preparation process. The technological scheme is that the materials including alumina ash 25-95 wt%, fine magnesia powder 0.1-2 wt%, fine bauxite chamotte 0.5-55 wt%, fine silicon powder 0-30 wt%, fine aluminum powder 0-10 wt% and fine SiO2 powder 0-50 wt%, are prepared into the composite magnesia-alumina spinel / Sialon ceramic material through mixing, forming into biscuit, sintering in nitrogen atmosphere first at 1000-1100 deg.c for 0.5-5 hr, then at 1300-1350 deg.c reached in the rate of 2-5 deg.c / min for 1-6 hr and finally at 1360-1500 deg.c reached in the rate of 2-5 deg.c / min for 2-10 hr, and naturally cooling to room temperature in nitrogen atmosphere. The present invention has waste alumina ash as main material, environment friendship and low production cost.

Owner:WUHAN UNIV OF SCI & TECH

Forsterite bakie coating material and method for making same

InactiveCN101117464AImprove high temperature resistanceLow priceFireproof paintsMelt-holding vesselsFiberOlivine

The present invention relates to a refractory coating for forsterite tundish and the preparation method thereof. The technical scheme adopted is that: 20-50 wt percent of forsterite sand, 25-55 wt percent of forsterite clinker, 15-30 wt percent of magnesia powder, 5-15 wt percent of magnesia-calcium sand powder are mixed with 1-5 wt percent of clay, which are coupled with 0-0.5 wt percent of organic fiber of the above ingredients, 0.5-2.0 wt percent of sodium hexametaphosphate and 0.3-1.0 wt percent of sodium tripolyphosphate, and then the present invention is prepared through the mixing of a mixer; when the present invention is in use, the present invention is added with water and stirred. The present invention takes forsterite as base material, and the products prepared is characterized in good high-temperature resistance, low cost, no pollution to molten steel, good durability, no adverse effect to human body and convenient use.

Owner:WUHAN UNIV OF SCI & TECH

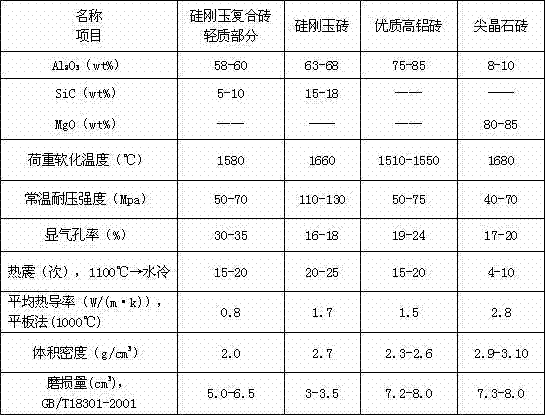

Low-heat conductance silicon corundum brick material and silicon corundum composite brick made of same

The invention relates to a low-heat conductance silicon corundum brick material and a silicon corundum composite brick made of the same, and belongs to the technical field of refractory materials. The low-heat conductance silicon corundum brick material comprises a liquid bonding agent and the following solid raw materials in parts by weight: 38-45 parts of bauxite chamotte granules with the content of Al2O3 of more than or equal to 87 percent by weight, 15-20 parts of silicon carbide powder with the content of SiC of more than or equal to 90 percent by weight and the content of free carbon of not less than 5 percent, 8-13 parts of electric smelting white corundum powder with the Al2O3 content of more than or equal to 99 percent by weight, 6-8 parts of andalusite powder with the Al2O3 content of more than or equal to 55 percent by weight, 3-5 parts of SiO2 ultramicro powder with SiO2 content of more than or equal to 95 percent by weight, 0.5-1 part of monatomic silicon ultramicro powder, 0.5-1 part of monatomic aluminum ultramicro powder, 3-5 parts of floating beads with the Al2O3 content of more than or equal to 30 percent by weight and the SiO2 content of more than or equal to 50 percent by weight and 8-10 parts of soft refractory clay with the Al2O3 content of more than or equal to 30 percent by weight. The silicon corundum composite brick made of the low-heat conductance silicon corundum brick material is obtained by carrying out double-surface mechanical pressing and burning on two materials, namely the low-heat conductance silicon corundum brick material and a heavy brick material. When the silicon corundum composite brick provided by the invention is used for building the transitional zone of a cement rotary kiln, the mean temperature of a cylinder body is low and is only 186 DEG C.

Owner:ZHENGZHOU ZHONGBEN KILN MATERIALS

Mullite light insulating brick and preparation method thereof

The invention relates to a mullite light insulating brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps of: by taking the following components by weight percent as raw materials: 30-40 wt% of a flint clay clinker, 20-30wt% of a clay clinker, 20-32wt% of kyanite micro-powder, 2-8 wt% of p-aluminum oxide micro-powder, 1-6wt% of light-burnt calcium oxide and 0.5-2wt% of silicon dioxide micro-powder, adding 20wt% of water and 0.5-2wt% of a water reducing agent, mixing and preparing a slurry; then, adding 0.1-0.5wt% of a foaming agent to prepare foams, stirring, adding 0.5-2 wt% of a gel, 0.1-1wt% of a thermosetting water-soluble high molecular compound and 0.5-2.5wt% of an accelerating agent, stirring, pouring, and molding; and finally, drying for 4-9 hours in a temperature of 30-50 DEG C, demolding, baking for 10-20 hours in a temperature of 60-120 DEG C, and preserving a temperature of 1350-1500 DEG C for 2-12 hours to obtain the mullite light insulating brick. The preparation method is short in de-molding time, short in drying period and environment-friendly; and the product is small in air hole size, uniform in air hole distribution, high in strength, low in volume density and low in heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

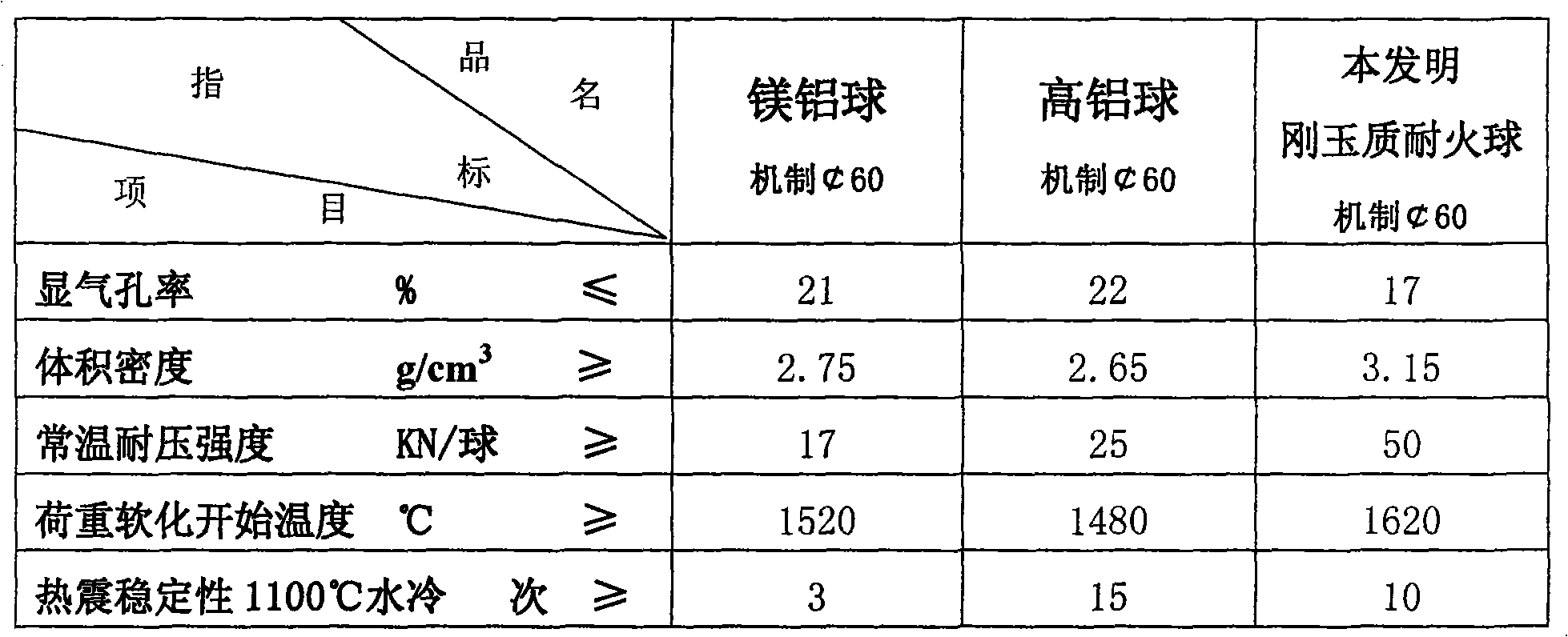

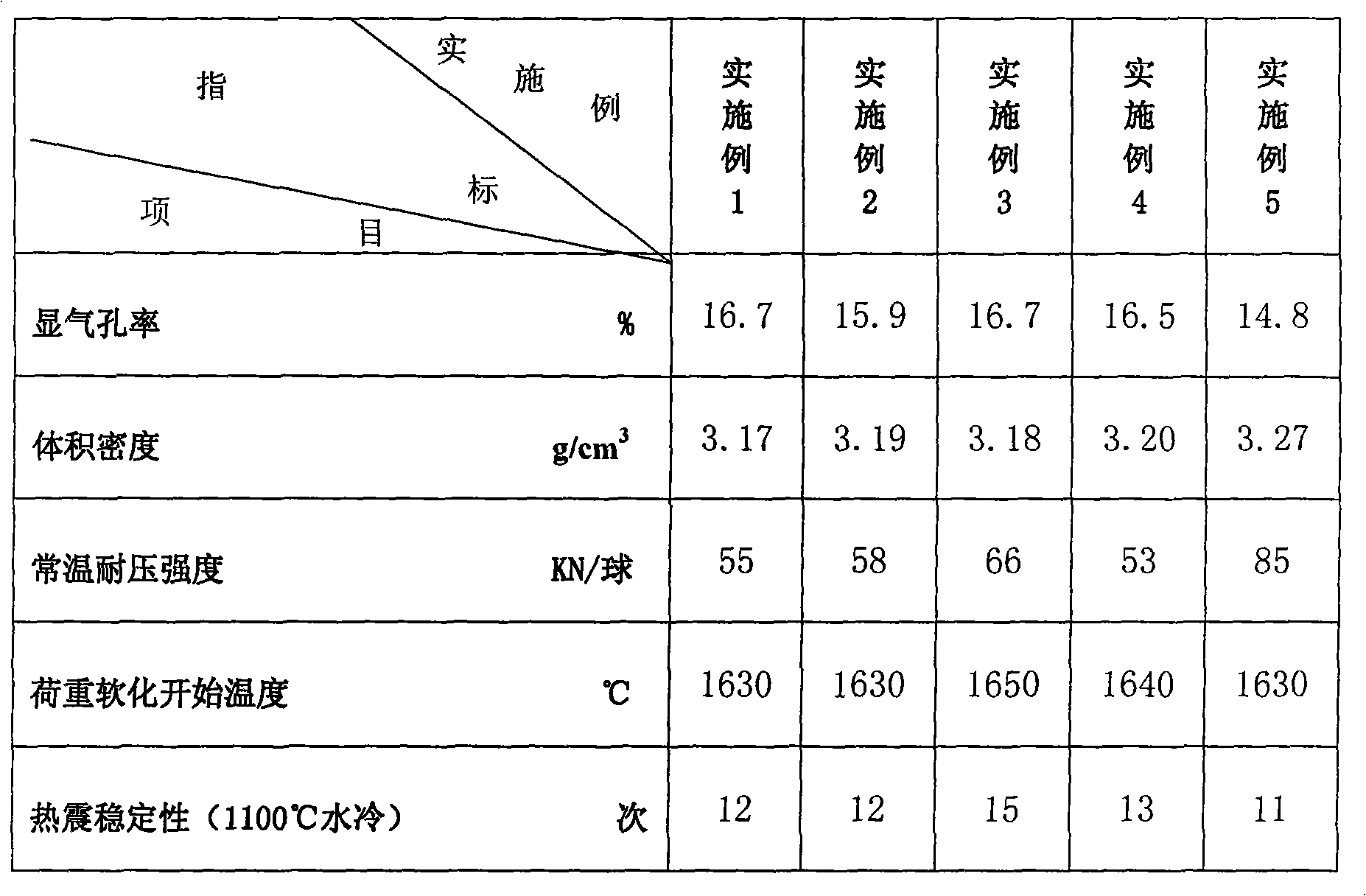

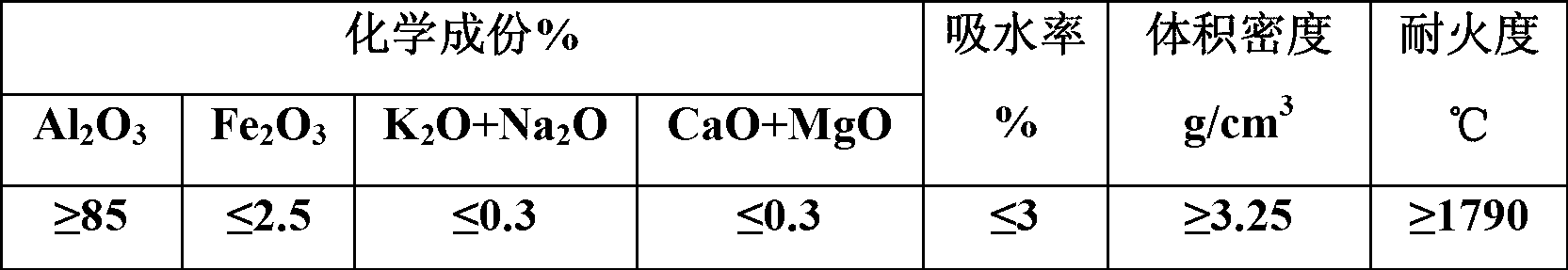

Corundum fireproof ball used for ball-type hot-blast stove and preparation method thereof

InactiveCN101555151AImprove thermal shock resistanceIncrease heat capacityBrick-hot blast stovesHot blastAluminium

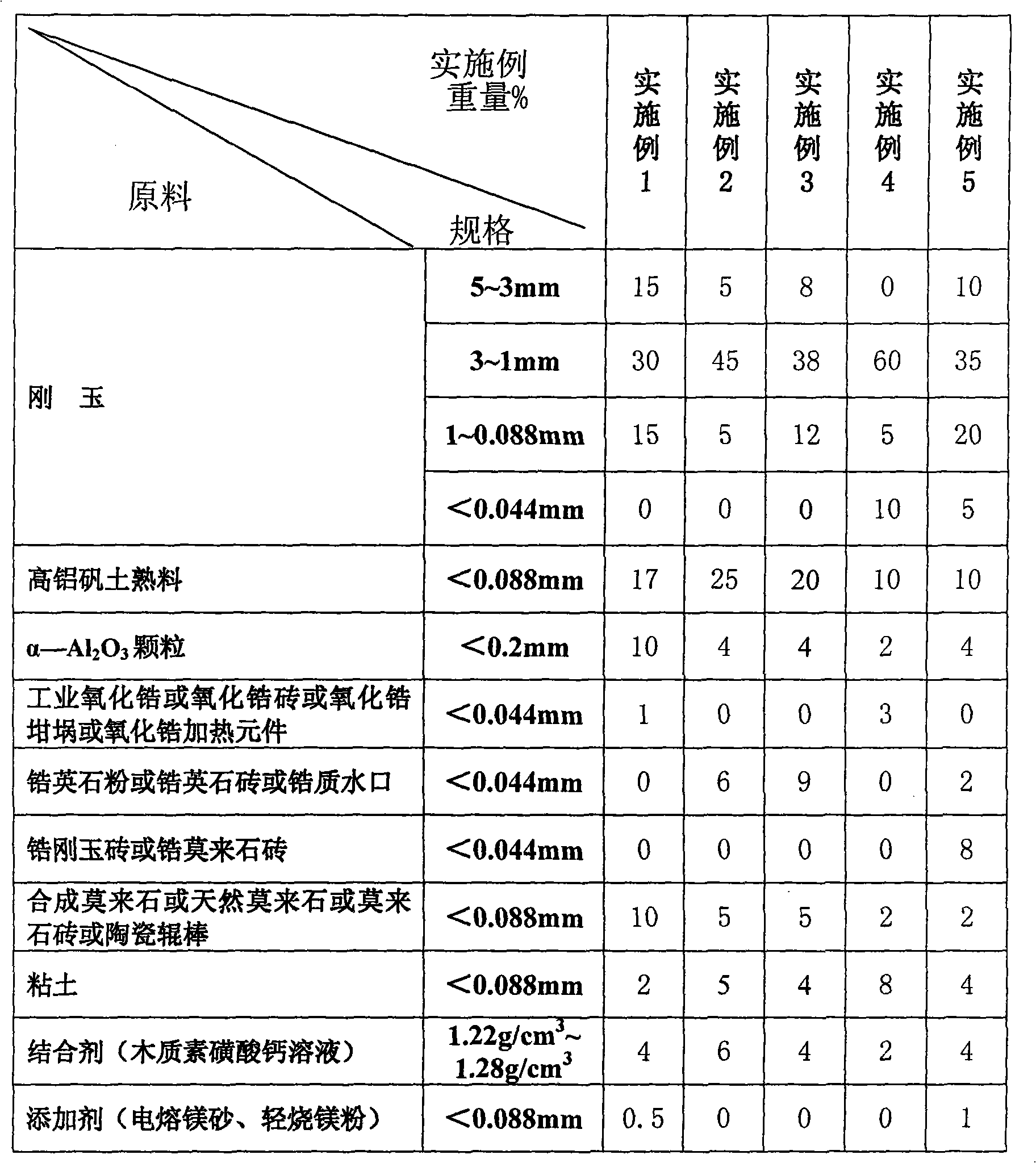

A corundum fireproof ball used for a ball-type hot-blast stove and a preparation method thereof are characterized in that the corundum fireproof ball comprises the following main materials, adhesive and additive, wherein the main materials comprises the following raw materials by weight percentage: 0-15% of corundum (granularity of 5-3mm), 30-60% of corundum (granularity of 3-1mm), 5-30% of corundum (granularity of 1-0.088mm), 0-10% of corundum (granularity less than 0.044mm), 10-25% of bauxite chamotte (granularity less than 0.088mm), 2-10% of Alpha-Al2O3 grain, 1-10% of zirconia-contained material, 2-8% of clay and 2-10% of mullite or materials containing mullite which is taken as main phase; the adding amount of the adhesive is 1-6% of the weight of the main materials; and the adding amount of the additive is 0-1% of the weight of the main materials. The preparation method comprises the following steps of ageing mixture, back-rolling, pressing and molding, drying billet, and sintering in a tunnel kiln and the sintering temperature is within 1450-1600 DEG C.

Owner:巩义市金岭耐火材料有限公司

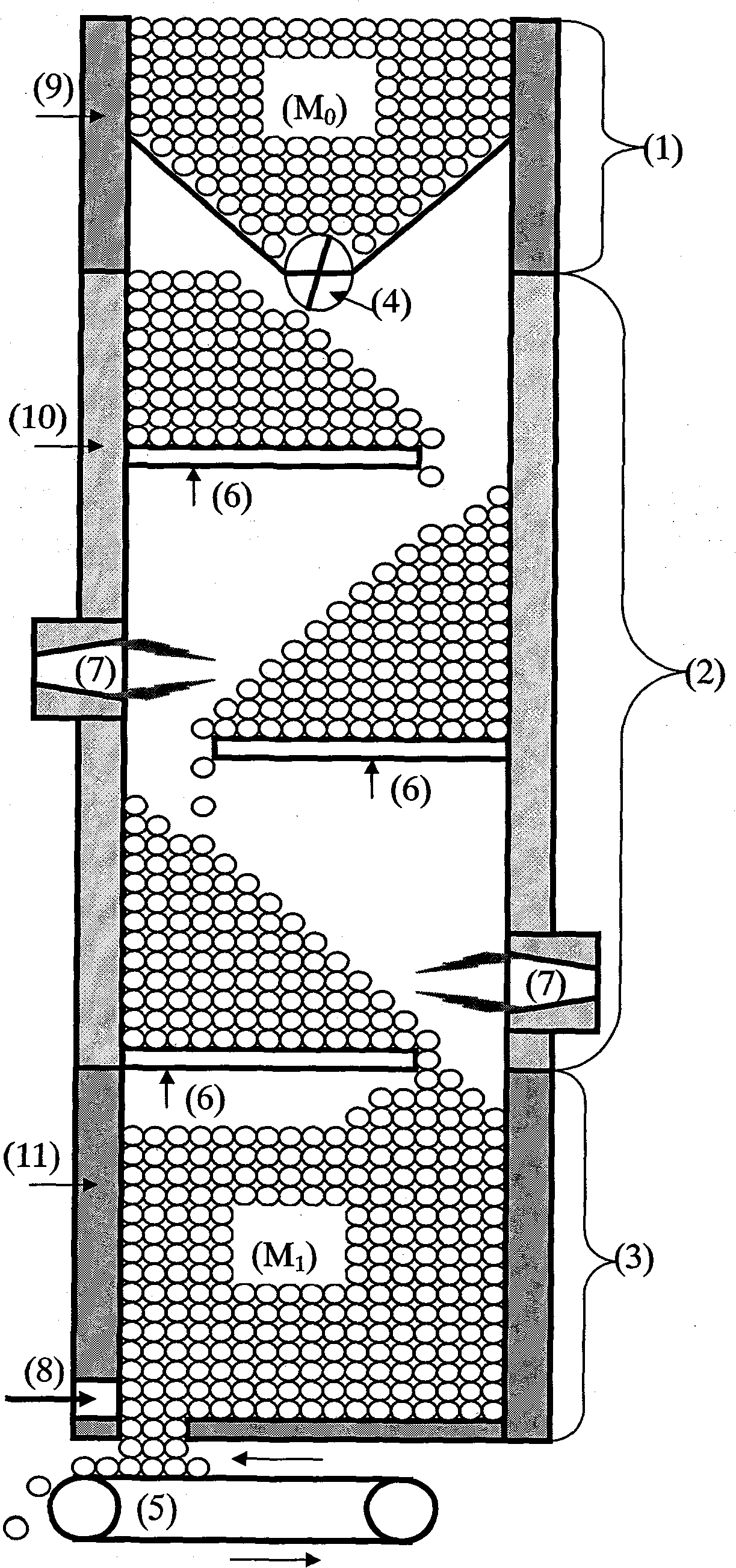

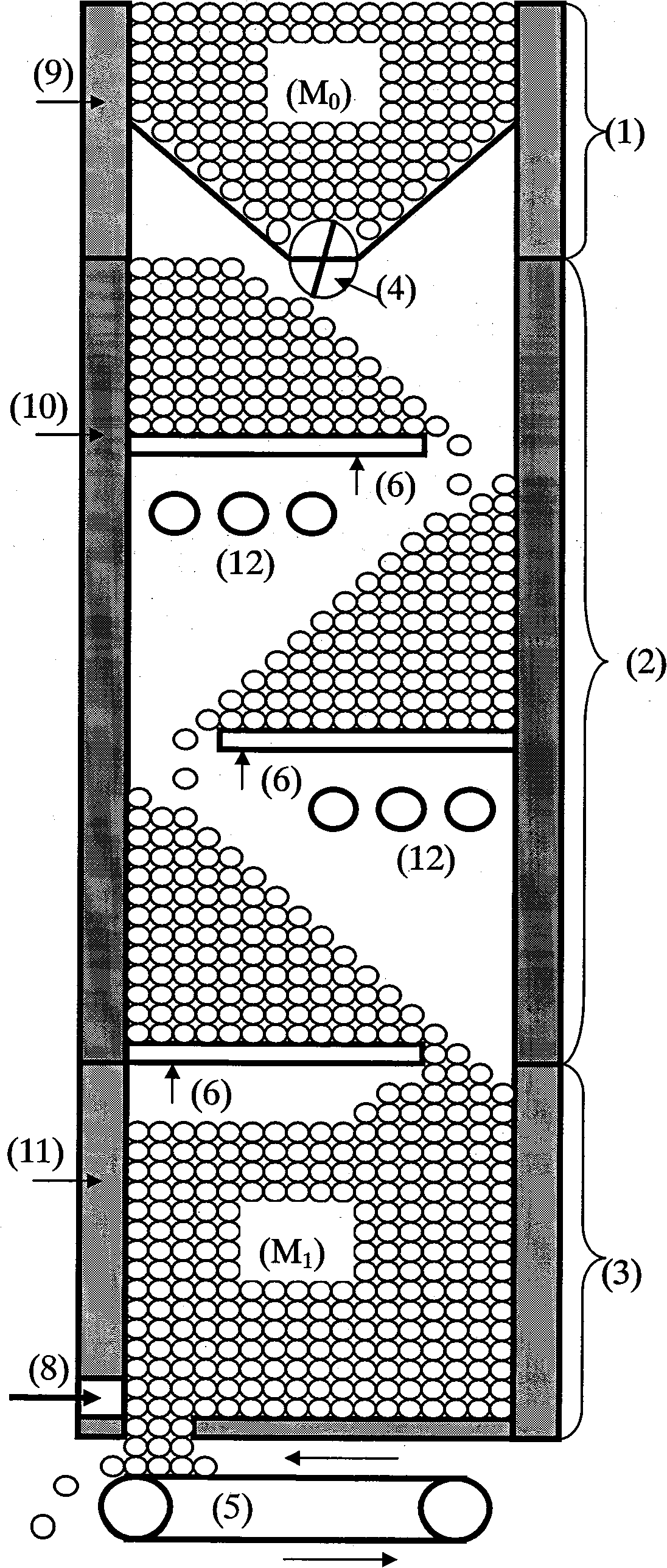

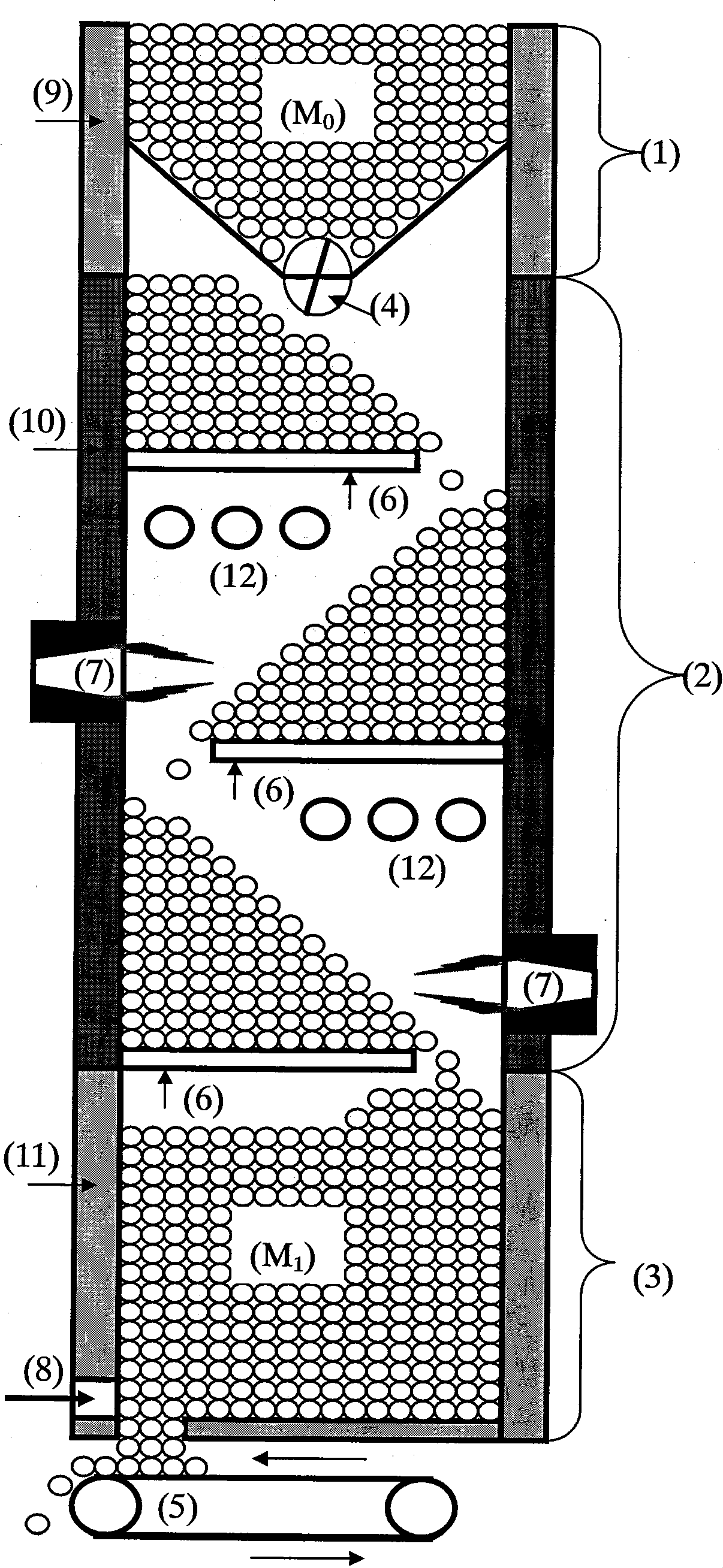

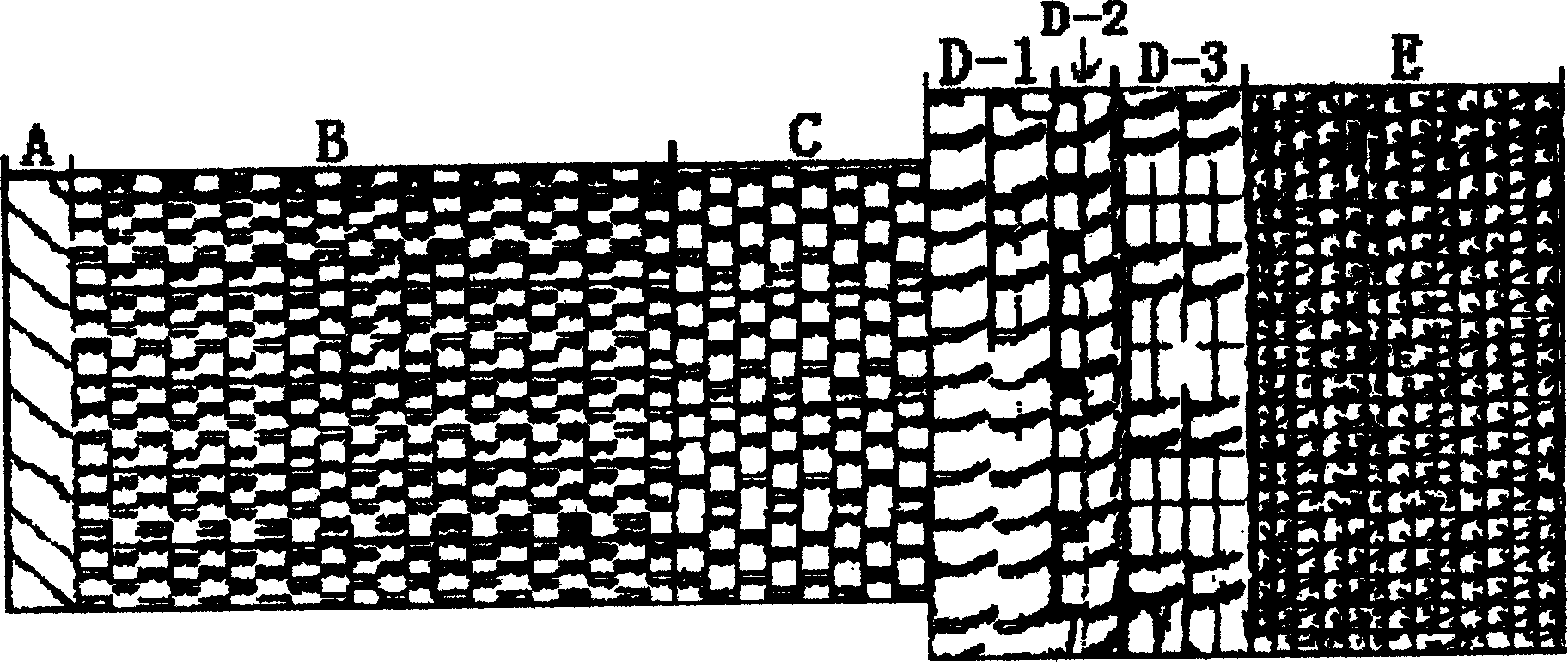

Stepped furnace

The invention provides a vertical kiln that is used for treatment on solid material, such as combination reaction, decomposition reaction, reaction between the solid material and gas, and sintering and compacting of the solid material or melting of the solid material into high-temperature liquid. The stepped furnace consists of an upper silo, a feeding mechanism, a step furnace, step plates, a bottom silo and a discharging mechanism; furthermore, a gas inlet and a gas outlet are arranged at the lower parts of the bottom silo and the top silo; the step plates in the stepped furnace can be staggered mutually in horizontal direction so that the step root is always connected with two furnace walls that are arranged in parallel and the step edge is always away from the two furnace walls by a certain distance; the step plates are away from one another by a certain distance in vertical direction; furthermore, the vertical distance from the step edge to the next step surface can meet the flowing of the material and can also have certain free space height. The vertical kiln can replace vertical reaction towers, vertical thermal decomposition furnaces, light-burning furnaces, clinker sintering furnaces, melting furnaces and special metallurgical smelting furnaces. Compared with the traditional vertical kiln, the vertical kiln in the invention has the characteristics of good material processing quality, high uniformity, and good energy-saving and consumption-reducing effect, and having no pollution to environment.

Owner:蒋明学

Production method of electric smelting zircon corundum brick

The invention relates to a production method of an electric smelting zircon corundum brick, which can solve the problem that over-length, over-width or over-thin or disproportionate brick materials are big in molding difficulties, low in finished product ratio and complex in productive technology. The production method is characterized in that raw materials by weight are 30-50% clinker and 50-70%raw batch. The clinker evenly mixed and made by materials by weight of 1.3-1.6% sodium oxide, 32-33% zirconia, 14-16% monox and 50-52.5%, the raw batch comprises raw materials by weight of 22-50% zircon sand, 38-67% calcine alumina powder, 6-20% desilicication zirconium and 1-3% soda ash. The raw materials are melted, oxygen is blew in a melting process, melted feed liquid is poured into a mould for molding for 10 minutes, an iron rod is communicated with the position at the upper 2 / 3 portion of the mould for discharging air, and then the brick is cooled and taken out. The production method is unique in process, simple in operation and convenient, and is an innovation on the production method of the electric smelting zircon corundum brick.

Owner:郑州远东耐火材料有限公司

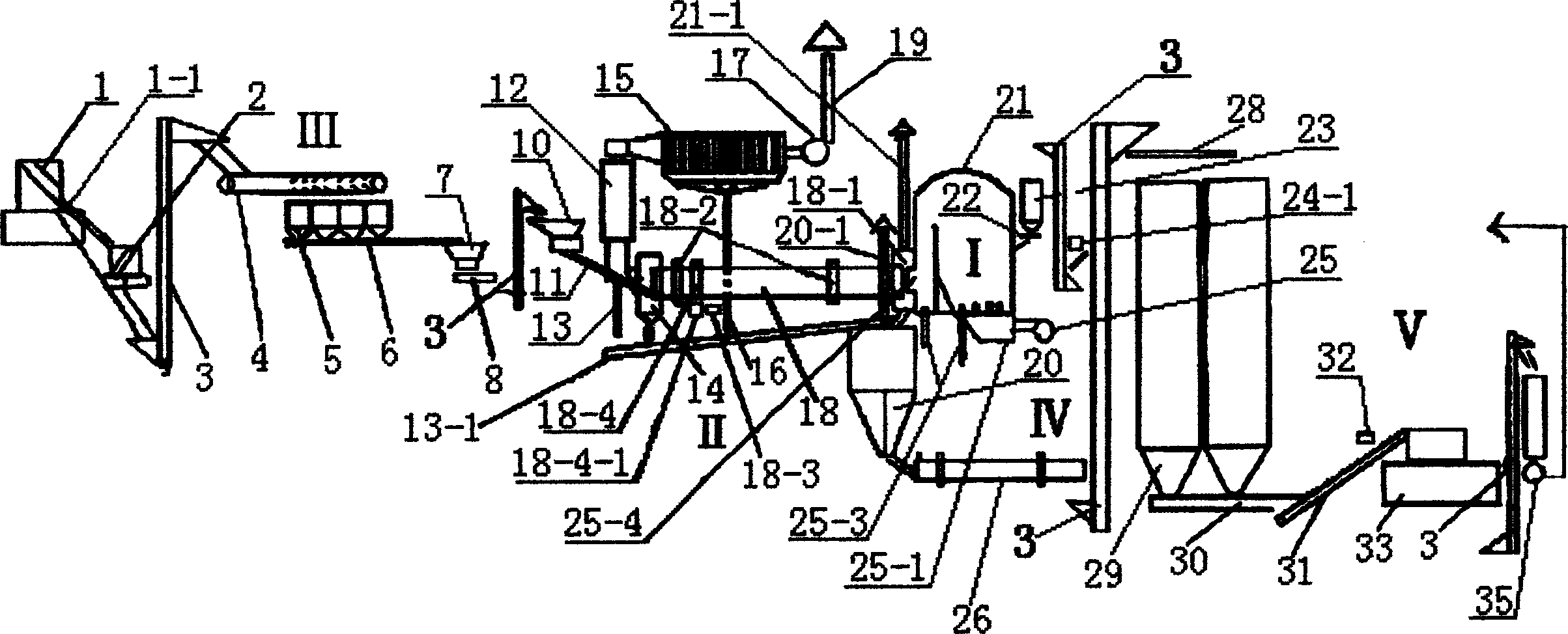

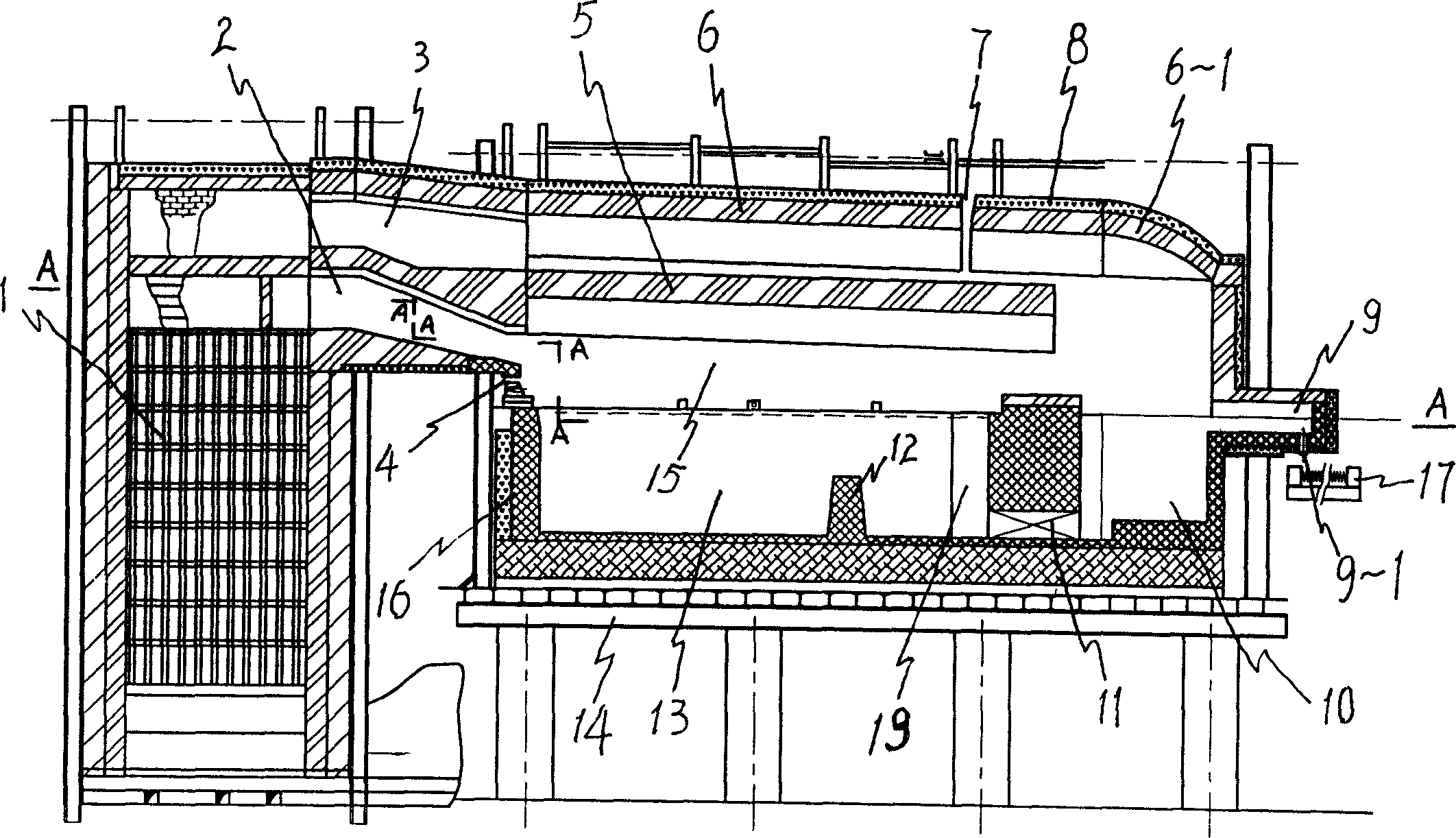

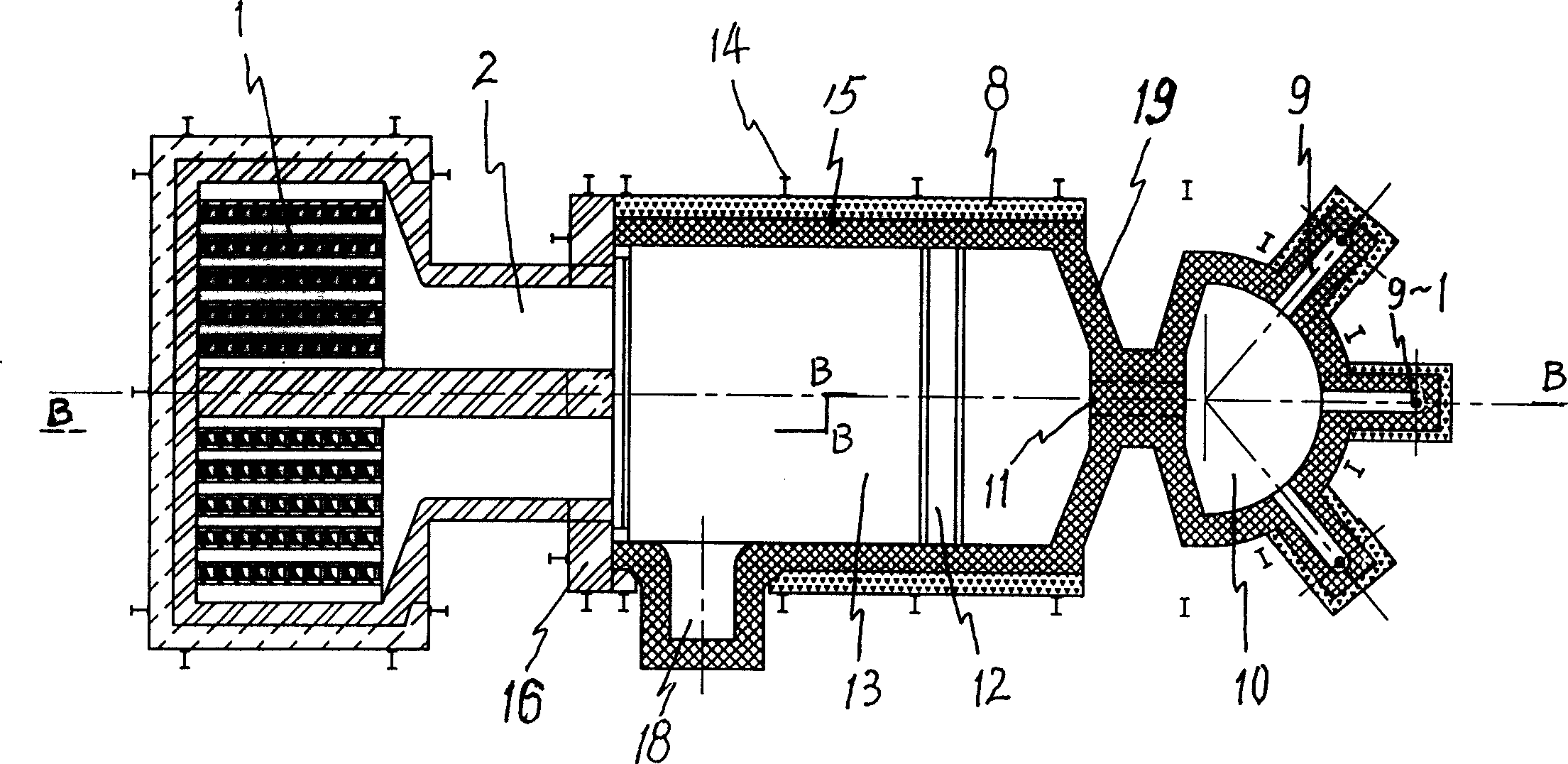

Magnesia calcining boiling furnace rotary kiln method and apparatus

The present invention relates to magnesia calcining boiling furnace rotary kiln method and apparatus. The magnesia calcining process includes feeding material from the high end of the rotary kiln, producing hot fume in the coal-burning boiling furnace, making the fume flow from the low end of the rotary kiln to the high end for counter flow type heat exchange with material inside the rotary kiln, exhausting fume and dust in the high end of the rotary kiln and recovering useful dust material, producing chamotte in sealed bin via high temperature radiation heating, and tempering the over burnt material. The apparatus consists of boiling furnace system for producing and supplying hot fume, calcining rotary kiln system, material feeding system, dust collecting system, and chamotte conveying, storing, ageing and cooling system. The present invention has the advantages of good coal adaptability, high heat efficiency, low cost, low power consumption, high yield, etc.

Owner:王全祥

Castable refractory for high-precision aluminum alloy melt external refining and using method

The invention discloses a refractory castable material for external refining of a high refined aluminum alloy liquid, which consists of aggregate, powder and an additive, wherein the aggregate consists of bauxite chamotte and sub-white corundum; the powder consists of alpha-Al2O3, sub-white corundum powder, CA70 pure calcium aluminate cement, titanium pigment and barium sulfate; and the additive consists of sodium hexametaphosphate and water. The refractory castable material overcomes the defects in the prior art that the refractory castable material can be glued with the aluminum alloy liquid at a high temperature and impurities such as silicon and iron in refractory materials can be released into the aluminum alloy liquid, and can guarantee that refractory linings cannot be cracked, do not increase silicon and iron, are not glued with aluminum during external refining of the high refined aluminum alloy liquid, and have cheap price, convenient use and large applicable range.

Owner:成都蜀冶新材料有限责任公司

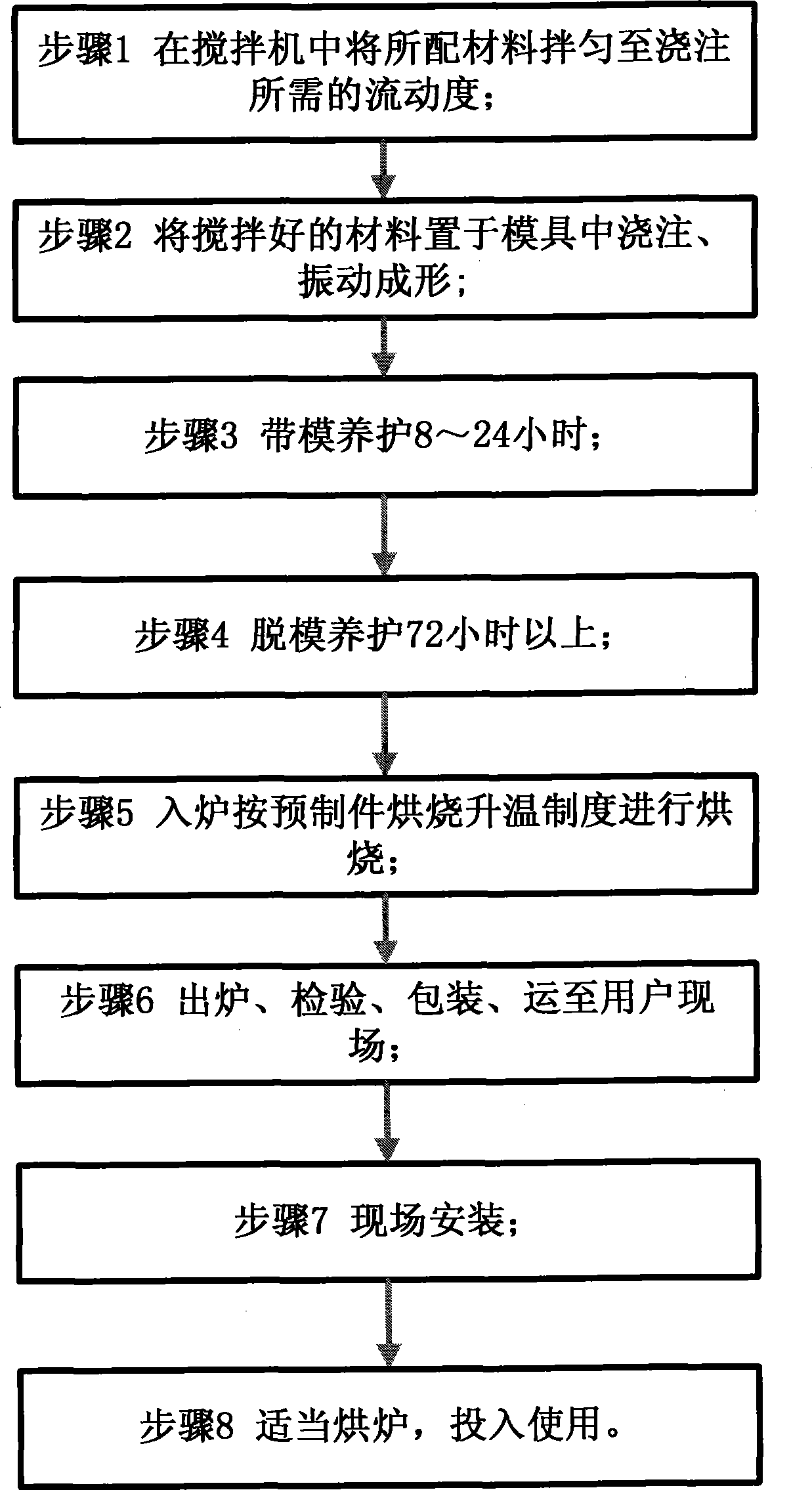

Poured material for foundry ladle bottom and its pouring process and mold

The present invention is poured material for foundry ladle bottom and its pouring process and mold. The poured material consists of high grade alumina clinker, white alundum, fine alumina powder, magnesite sand clinker and fine silica powder. The pouring process includes the following steps: cleaning and mounting mold, smearing grease, mixing the material in a stirrer, pouring, curing and demolding. The present invention has even poured thickness, compact structure, high strength at high temperature and high heat shock stability.

Owner:CHEMIAL PLANT GANGCHENG ENTERPRISE GENERAL PANZHIHUA IRON & STEEL GROUP

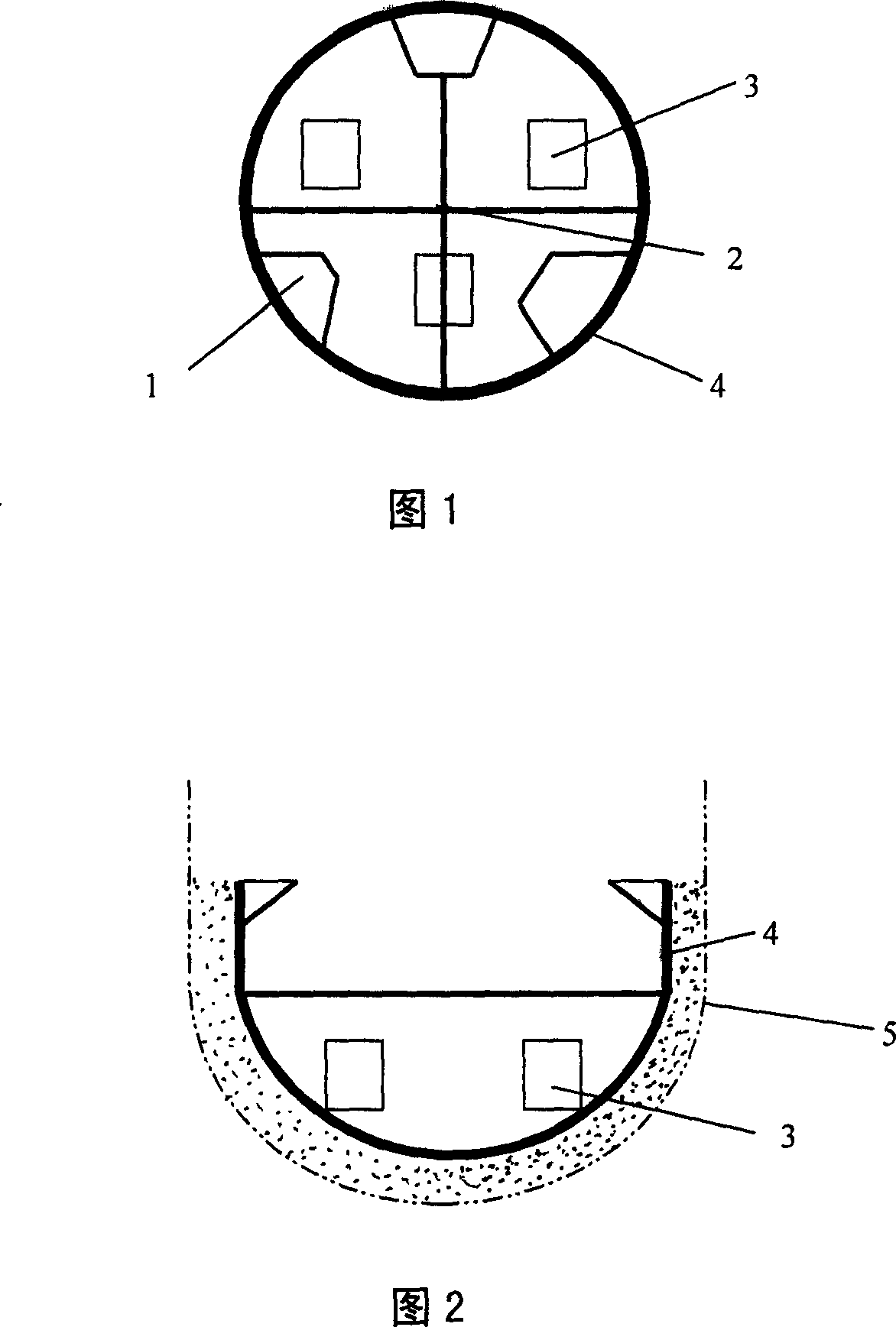

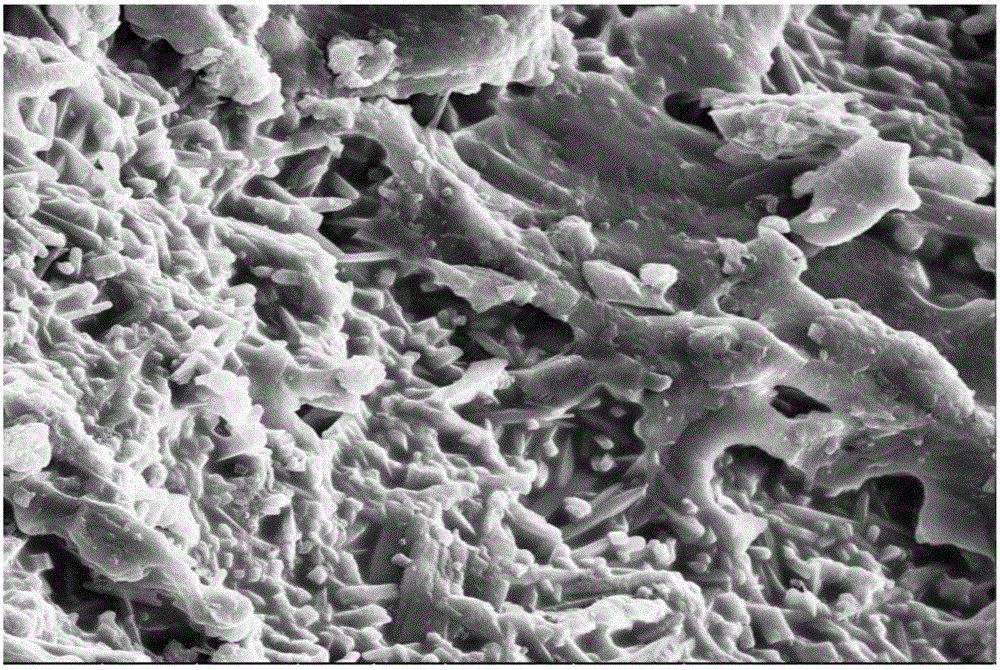

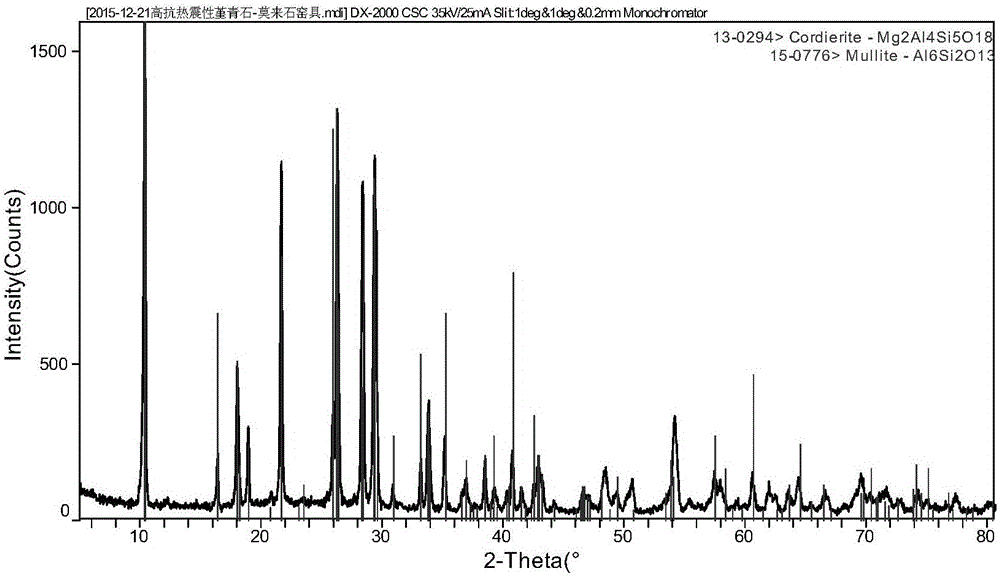

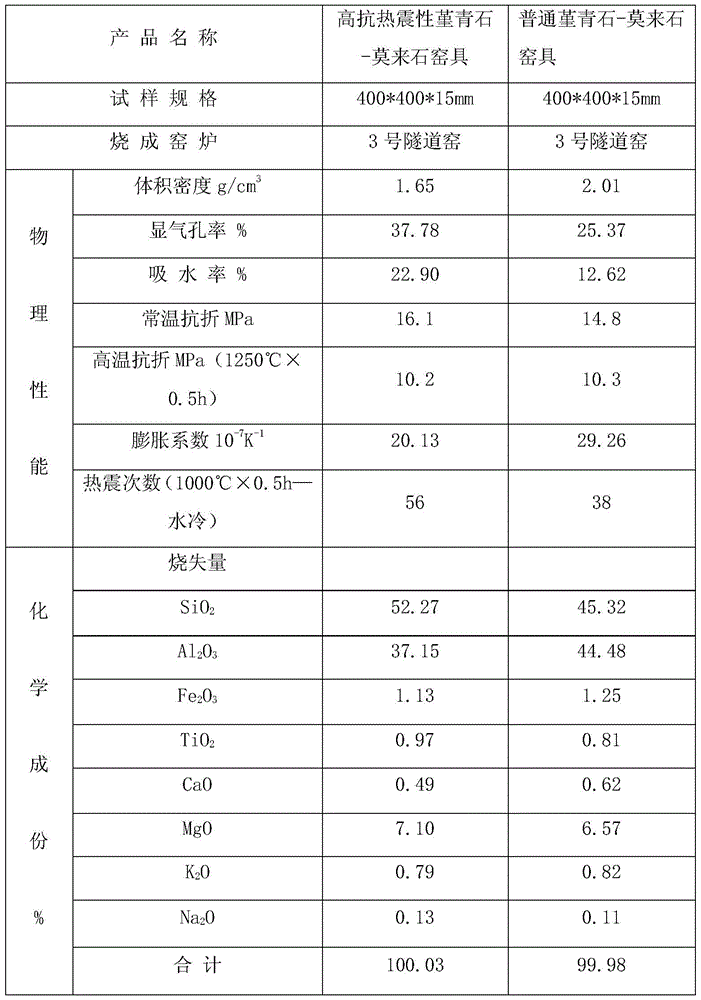

Cordierite-mullite kiln furniture material with high thermal shock resistance

InactiveCN105669244AImprove thermal shock resistanceImprove high temperature resistanceCeramicwareExpansion factorCordierite

The invention relates to a cordierite-mullite kiln furniture material with high thermal shock resistance and belongs to the field of the kiln furniture material. According to the kiln furniture material, floating beads, cordierite clinker, cordierite-mullite waste blanks, chamotte clay and wood meal are taken as aggregate, talc, aluminum oxide and clay are taken as a substrate material, a solid substance of the kiln furniture material is prepared from the aggregate, the substrate material and an additive yellow dextrin, water is added to the solid substance and is stirred, and a mixture is formed. After optimization, the requirement that the final composition is consistent with the composition of the cordierite-mullite kiln furniture material in the market is met, and the firing temperatures also keep consistent; the material has the advantages that the expansion factor is low, the number of thermal shock times is large, the volume density is low and the strength is high, and the material is suitable for being used as the excellent cordierite-mullite kiln furniture material with high thermal shock resistance.

Owner:天津创导热材料有限公司

Fused zirconia corundum low-seepage brick production method

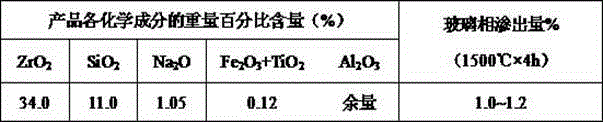

The invention relates to a fused zirconia corundum low-seepage brick production method which can effectively reduce seepage amount of a fused zirconia corundum brick glass phase. According to the technical scheme of the fused zirconia corundum low-seepage brick production method, a raw material is prepared by evenly mixing, by weight, 20-30% of clinker and 70-80% of raw meal, wherein the clinker is prepared by evenly mixing, by weight, 1.3-1.6% of sodium oxide (Na2O), 32-33% of zirconium oxide (ZrO2), 14-16% of silicon dioxide (SiO2) and 50-52.5% of aluminum oxide (Al2O3); the raw meal is prepared by evenly mixing, by weight, 15-30% of zircon sand, 50-77% of forged alumina powder, 7-18% of desilicated zirconia and 1-2% of sodium carbonate (Na2CO3). According to a produced fused zirconia corundum low-seepage brick, the seepage amount of the glass phase under the condition of 1500 DEG C*4 h is reduced to 1.2%, and accordingly chemical replacement between the brick and high-temperature glass melt in use is reduced, erosive damage to a material is reduced, and the service life of the fused zirconia corundum brick is greatly prolonged.

Owner:郑州远东耐火材料有限公司

Microporous high-penetration-resistance high-aluminum casting material, and preparation method and application method thereof

The invention discloses a microporous high-penetration-resistance high-aluminum casting material, and a preparation method and an application method thereof. The casting material is prepared from the following components in parts by weight: 51-95 parts of aggregate, 23.5-41.5 parts of powder, 3-6 parts of composite dewetting agent and 0.02-0.4 part of composite water reducing agent, wherein the aggregate is superfine bauxite chamotte; and the powder contains 180-mesh superfine bauxite fine powder, 800-mesh superfine bauxite fine powder, CA-70 cement, alpha-Al2O3 micro powder and SiO2 micro powder. A lining cast by the microporous high-penetration-resistance high-aluminum casting material provided by the invention is low in porosity, small in pore size of air pores and high in resistance to aluminum alloy liquid-state or vapor-state element penetration and corrosion; the aluminum alloy melt penetration resistance is improved; the mechanical strength is high, the high-temperature volume is stable, and the thermal shock resistance is favorable; and nodulation and bulge phenomena at the three-phase juncture can be effectively avoided.

Owner:贵阳联合高温材料有限公司

Neutral lining of medium-frequency induction furnace for smelting of sintered neodymium-iron-boron permanent-magnet material

InactiveCN103693983AHigh temperature strengthImprove fire resistanceLinings repairGrogInduction furnace

The invention relates to a neutral lining of a medium-frequency induction furnace for smelting of a sintered neodymium-iron-boron permanent-magnet material, which is manufactured through the following steps: proportionally mixing high-alumina bauxite chamotte used as a main raw material and added magnesia powder and admixture, uniformly stirring, ramming and baking. The neutral lining obtained by the invention has the characteristics of high refractoriness, excellent chemical property stability and volume stability, favorable thermal shock resistance, convenient and quick furnace building process, short furnace baking time, long furnace life, low comprehensive cost and the like.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

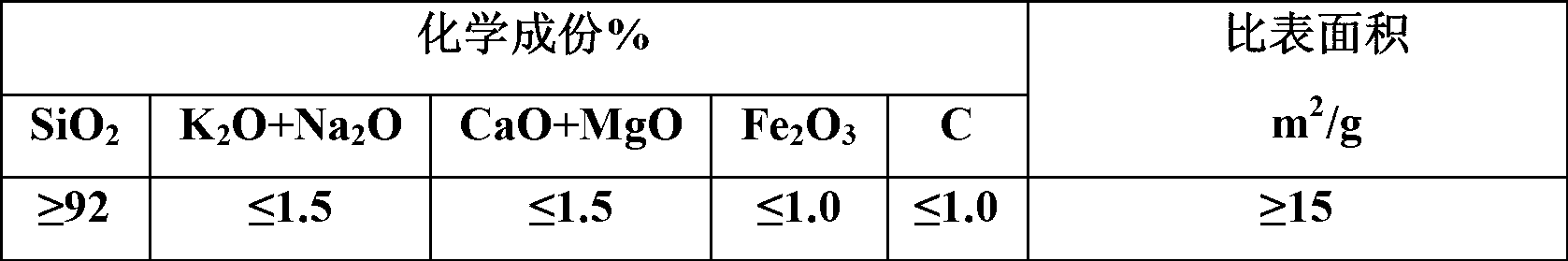

Method for fabricating alkali proof glassbeads and siln for production

InactiveCN1562835AIncrease temperatureStable temperatureGlass furnace apparatusGlass shaping apparatusGlass ballMelting tank

In the invention, quartz, sand, zircon sand, titanis schorl, calcite, fluorite, potassium nitrate, soda ash and some other chamotte are used as raw and auxiliary to high-zirconia alkali-resisting glass ball by melting, cooling, clearing, ball-making and annealing, the double-arch furnace melting glass liquid includes heat exchange cell, inside and outside big arches, small furnace, gas ejector, flue pipe, anocelia, front and back facewall, dog-hole, clearing tank and feed entrance. Melting tank made by non-contraction cavities electric smelted corundum brick and qualified silicon brick and double-arch lining or building body are used by said furnace.

Owner:自贡市宏洋新型材料制品有限公司

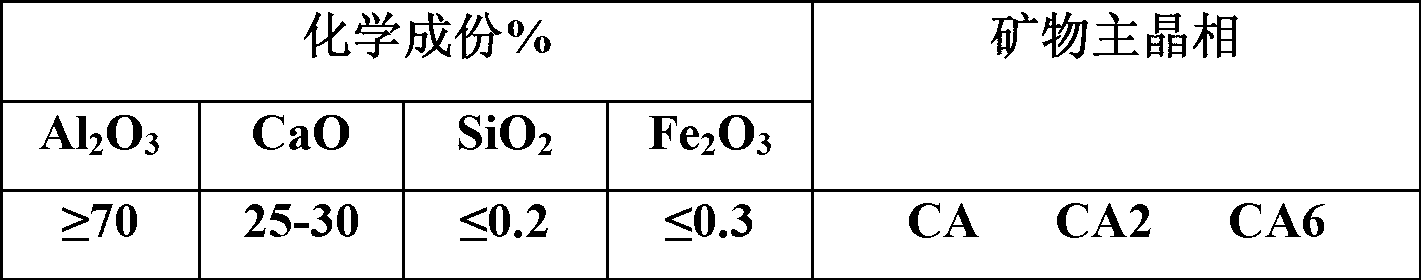

Compact CA2-CA6 composite phase lightweight fire-proof clinker and preparation method thereof

The invention relates to a compact CA2-CA6 composite phase lightweight fire-proof clinker and a preparation method thereof, wherein the components comprise, by weight, 77.2-84.6% of Al2O3, 11.4-20.8% of CaO, and 2.0-4.0% of MnO, the relative density is 91.3-95.2%, and the apparent porosity is 2.6-3.8%. The preparation method comprises: (1) respectively carrying out fine grinding on bauxite and limestone, and mixing; (2) pressing the mixed material into green pellets, and carrying out first calcination to produce the clinker; (3) carrying out fine grinding on the clinker, adding manganous oxide micro-powder, and pressing into pellets; and (4) carrying out second calcination. According to the present invention, the manganous oxide micro-powder is adopted as the sintering promoting agent, and manganous oxide solid is dissolved into the CA2 and CA6 crystal phase during the calcination process to form the solid solution, such that the occurrence of the lattice distortion of the CA2 and CA6 phase is promoted, the activity is improved, and the sintering and compacting behavior of the CA2-CA6 composite phase lightweight fire-proof clinker is effectively promoted so as to obtain the compact CA2-CA6 composite phase lightweight fire-proof clinker under the conditions of the low two calcination temperatures and the short thermal insulation time.

Owner:LIAONING INST OF SCI & TECH

Mullite silicon carbide composite brick with low thermal conductivity and preparation method thereof

The invention discloses a mullite silicon carbide composite brick with low thermal conductivity and a preparation method thereof. The composite brick is prepared from the following raw materials in percentage by weight: 20 to 60 percent of mullite homogenized grogs, 20 to 45 percent of bauxite chamotte, 10 to 20 parts of silicon carbide, 5 to 15 parts of alumina hollow ball, 3 to 8 parts of Guangxi white clay, and with the addition of waste paper pulp accounting for 2 to 5 percent of the total weight of the raw materials. The preparation method comprises the steps that firstly mixing and grinding are performed on all the materials; the obtained mixture is subjected to compression moulding to obtain a green brick; the obtained green brick is subjected to drying, sintering, finally cooling and taking out of a kiln so as to obtain a product. According to the composite brick disclosed by the invention, the difficulties of rotary kiln cylinder body deformation caused by higher thermal conductivity causing the high temperature of the cylinder body and energy waste can be solved. The mullite silicon carbide composite brick disclosed by the invention has the characteristics of low heat conduction, thermostability, anti-erosion, anti-scouring and the like, and is used for multiple rotary kilns in China, which proves that the using effect is good.

Owner:TONGDA REFRACTORY TECH CO LTD +1

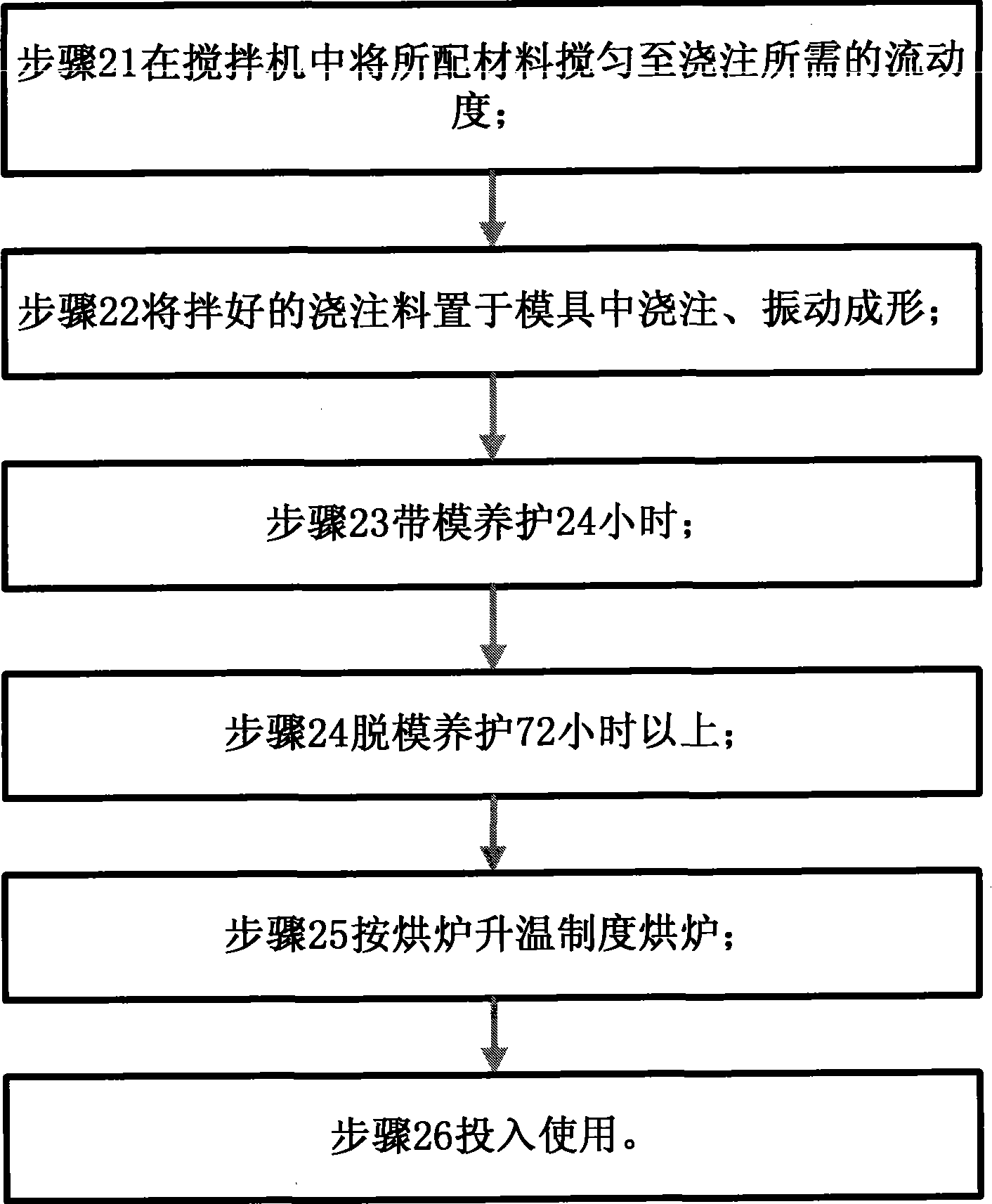

Method for preparing compound lining material of blast furnace

The invention belongs to the field of fireproof materials and relates to a method for preparing a novel compound lining material used in a blast furnace, in particular to a method for preparing a nonmetal compound lining material used in a furnace body of the blast furnace. The method comprises the following steps: using high-aluminum alumina chamotte, carborundum, metallic silicon powder, silicon ash and artificial graphite as main raw materials, using CA50 fireproof cement as a bonding agent, adding a right amount of admixture, and after mixing and smelting, injecting pulp into a relevant mould for moulding, curing for days and then stripping and baking to obtain the Al2O3-SiC-C compound lining material. The method is favorable to constructing special-shaped brick furnace linings at the weak positions of the furnace body, such as special-shaped edges, corners, holes and the like and enhancing the construction quality, and the whole furnace lining which has no seam after being poured and has uniform structure can not generate looseness and penetrating seams when being heated and used; the method prolongs the service life of the furnace lining, provides superior thermal insulation performance to the furnace body and obviously enhances the effect of energy saving. The compound lining material prepared by using the invention can be widely applied to the furnace abdomen, the furnace waist and the lower part of the furnace body of a smelting blast furnace.

Owner:UNIV OF SCI & TECH BEIJING

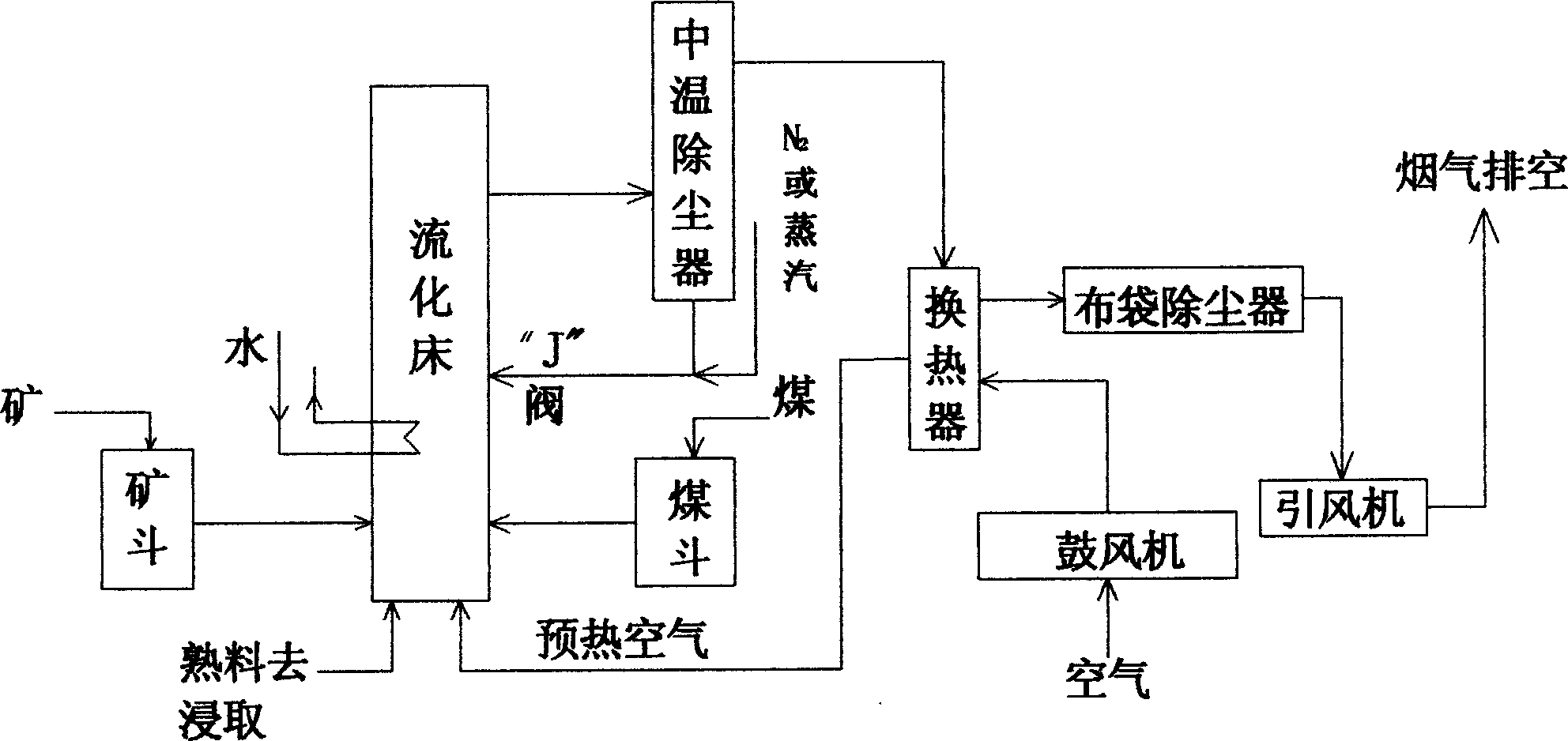

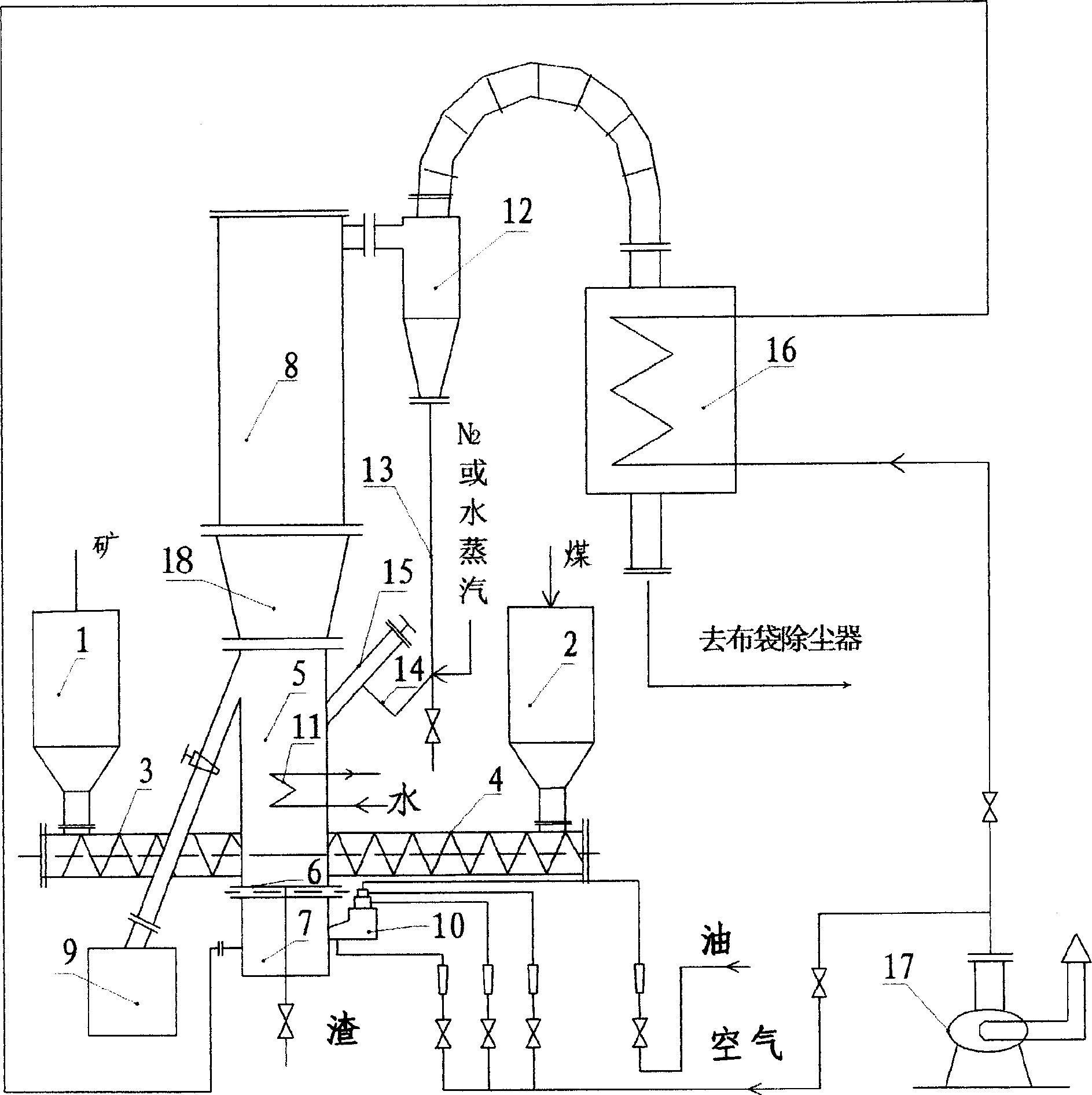

Circulating fluidized bed mineral reducing roasting device and reducing roasting method

The present invention relates to apparatus and process of reducing and roasting inorganic mineral in circular fluidized bed. The reducing and roasting process includes feeding the pretreated ore and coal material into the fluidizing section of the roasting furnace; providing burning air with the blower via the air chest and grid plate to the fluidizing section of the roasting furnace; collecting the flyash with the medium temperature insulating deduster from the exhaust of the roasting furnace and returning the flyash via the vertical pipe, the J-valve and the returning pipe to the fluidized bed; heat exchange of the exhaust from the medium temperature insulating deduster in the gas-gas heat exchanger to lower the temperature to 110-150 deg.c and further dedusting in bag deduster before exhausting; and discharging the roasted material via the side overflow pipe to the chamotte storage.

Owner:南京东大能源环保科技有限公司

Method for manufacturing high-alumina-quality high-temperature crucible pot

The invention provides a method for preparing a high alumina heat resistant crucible, relating to a method for preparing the high alumina ceramic crucible which is applied to experiment manufacturing processes such as the high temperature sintering and high temperature chemical synthesis. The method is characterized by comprising the following steps that: raw materials of alumyte grog refractory,alpha-Al2O3, Suzhou clay, carborundum, cooked pencil stone, zirconite, an appropriate amount of a caking agent of Arabian gum dry powder are subject to matching, grinding and watering to prepare slurry; after the casting process, the proximate matter is dried and calcined so that the high alumina heat resistant crucible is prepared. The high alumina heat resistant crucible has good chemical stability, good thermal physics properties such as the heat-resistant stability and the quake-resistance stability, long service life and easy popularization in industry.

Owner:中铝矿业有限公司 +1

Cast ceramsites as well as manufacture method and application thereof

ActiveCN107324781AReduce manufacturing costRaw materials are cheap and easy to getFoundry mouldsFoundry coresExpanded clay aggregateThermal expansion

The invention provides cast ceramsites as well as a manufacture method and application thereof. In the method, bauxite clinker, kaolin and bauxite are used as raw materials; not only are the raw materials easy and convenient to obtain, but also a preparation process is simple, the energy consumption is low, the production efficiency is high and environmental protection treatment on production wastes is easy, so that the cost can be effectively reduced. At the same time, the cast ceramsites disclosed by the invention have high refractoriness, high strength, low thermal expansion coefficient and high repetitive utilization rate, not only meet the requirement of casting, but also can effectively reduce the casting cost.

Owner:HANDAN SHENGHUO CERAMIC PROPPANT CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com