Anchoring grouting material as well as preparation method and application thereof

A grouting material and anchoring technology are applied in the fields of anchoring grouting materials, anchoring grouting materials and their preparation, and can solve problems such as failure to meet the requirements of anchoring and grouting in supporting engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the above-mentioned anchoring grouting material, comprising the following steps:

[0038] 1) Take the raw materials according to the above-mentioned raw material formula;

[0039] 2) Mix the water-retaining agent, gypsum, silica fume, water-reducing agent, quick-setting agent and retarder with a mixer first, then put in the rest of the materials, and mix them with a mixer to obtain the anchoring grouting material.

[0040] The purpose of mixing water retaining agent, gypsum, silica fume, water reducer, accelerator and retarder first is to prevent uneven mixing of a small amount of components directly into a large number of components, and reduce the adhesion of a small amount of components in the production process. The possibility of damage caused by the inner wall of the equipment.

[0041] The stirring time in the step 2) is preferably 15-25 minutes. Too long time will cause stratification of components with...

Embodiment 1-10

[0045] Embodiment 1-10 Preparation of anchoring grouting material

[0046] The preparation method of anchoring grouting material of the present invention, comprises the following steps:

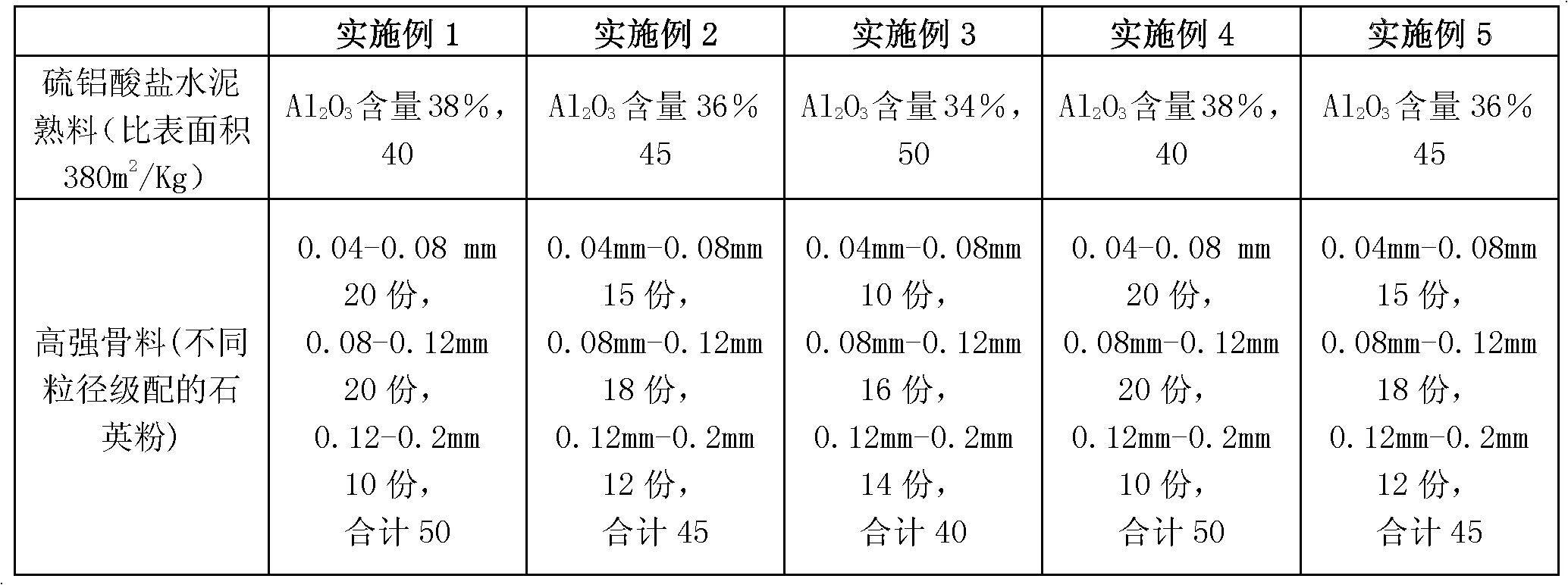

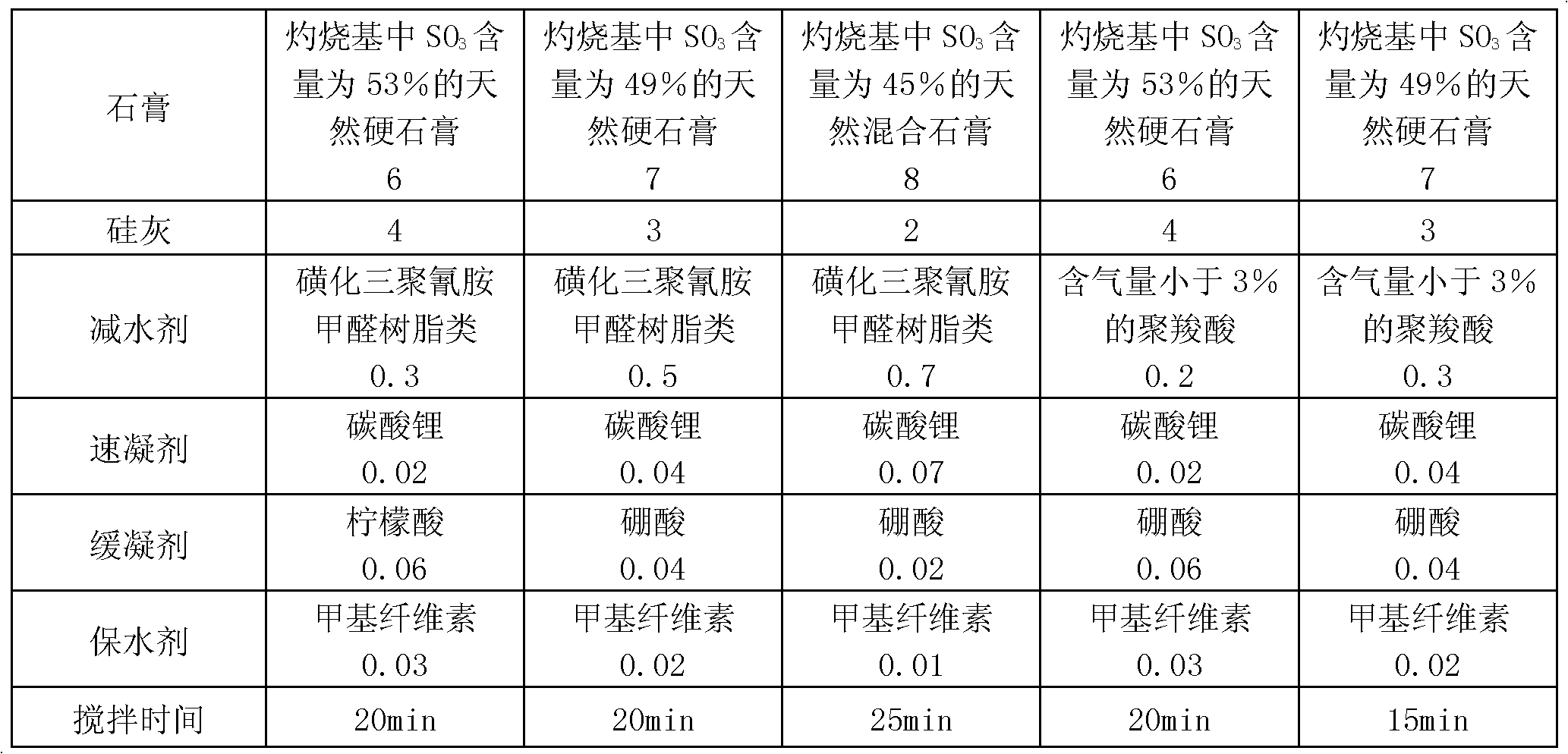

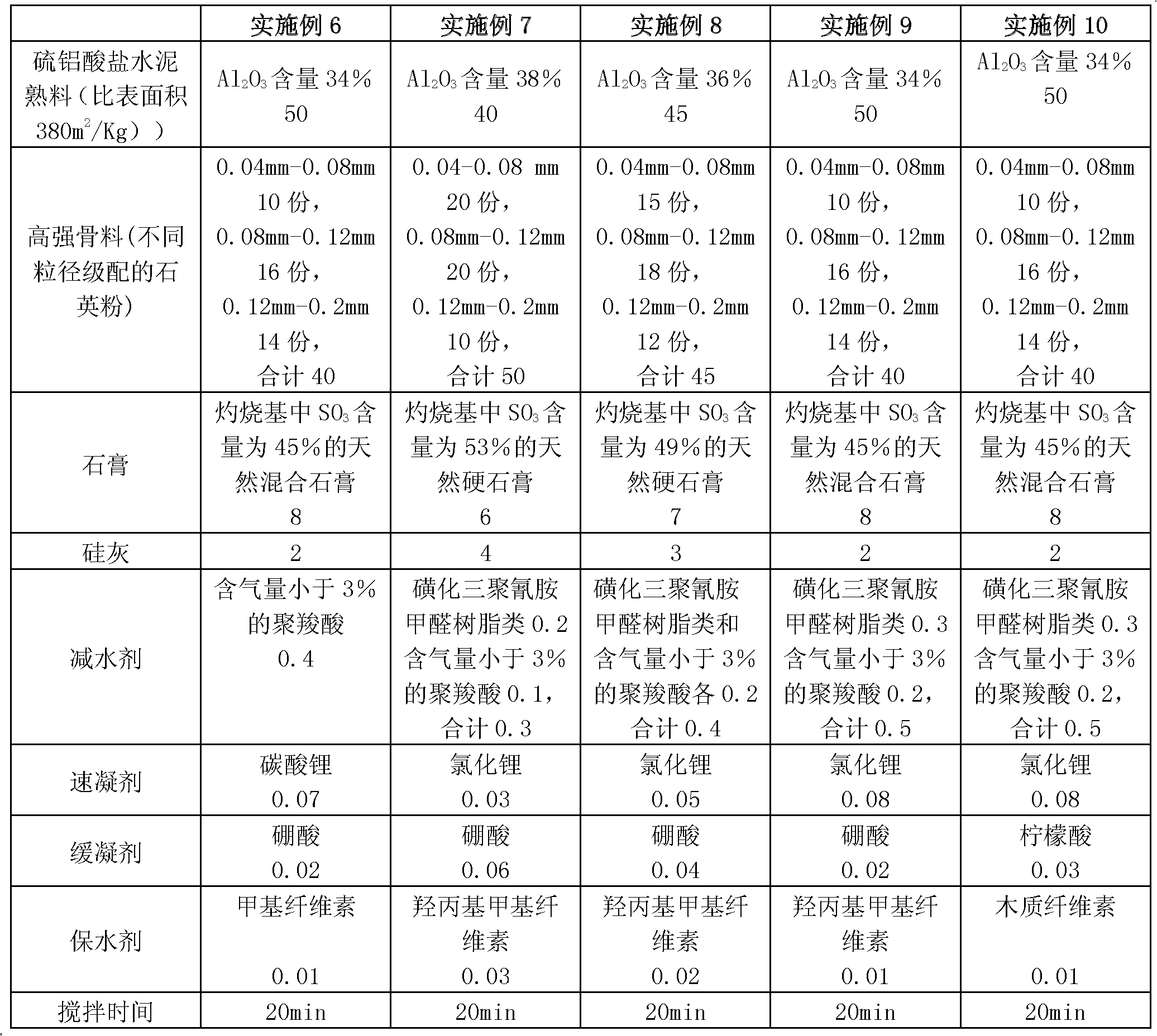

[0047]1) Take the raw materials by weighing the raw material formula shown in Table 1;

[0048] 2) First mix gypsum, silica fume, water reducer, accelerator, retarder and water retention agent with a small mixer, then put in the rest of the materials, and stir for 15-25 minutes with a gravity-free mixer to obtain anchor grouting Material. The main parameters in the preparation methods of Examples 1-10 are shown in Table 1.

[0049] The formula of table 1 embodiment 1-10 anchoring grouting material and the main parameter of preparation method (formulation unit: parts by weight)

[0050]

[0051]

[0052]

[0053] The measurement unit of parts by weight can be kilogram or its multiple values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com