Magnesia calcining boiling furnace rotary kiln method and apparatus

A technology for calcination of magnesia and rotary kiln, which is applied in the field of calcination of magnesia in fluidized fluidized furnace rotary kiln, can solve the problems of inability to calcine high-quality active magnesia and multiphase magnesia, single internal structure, poor coal adaptability, etc., and achieve low cost, Easy to operate and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

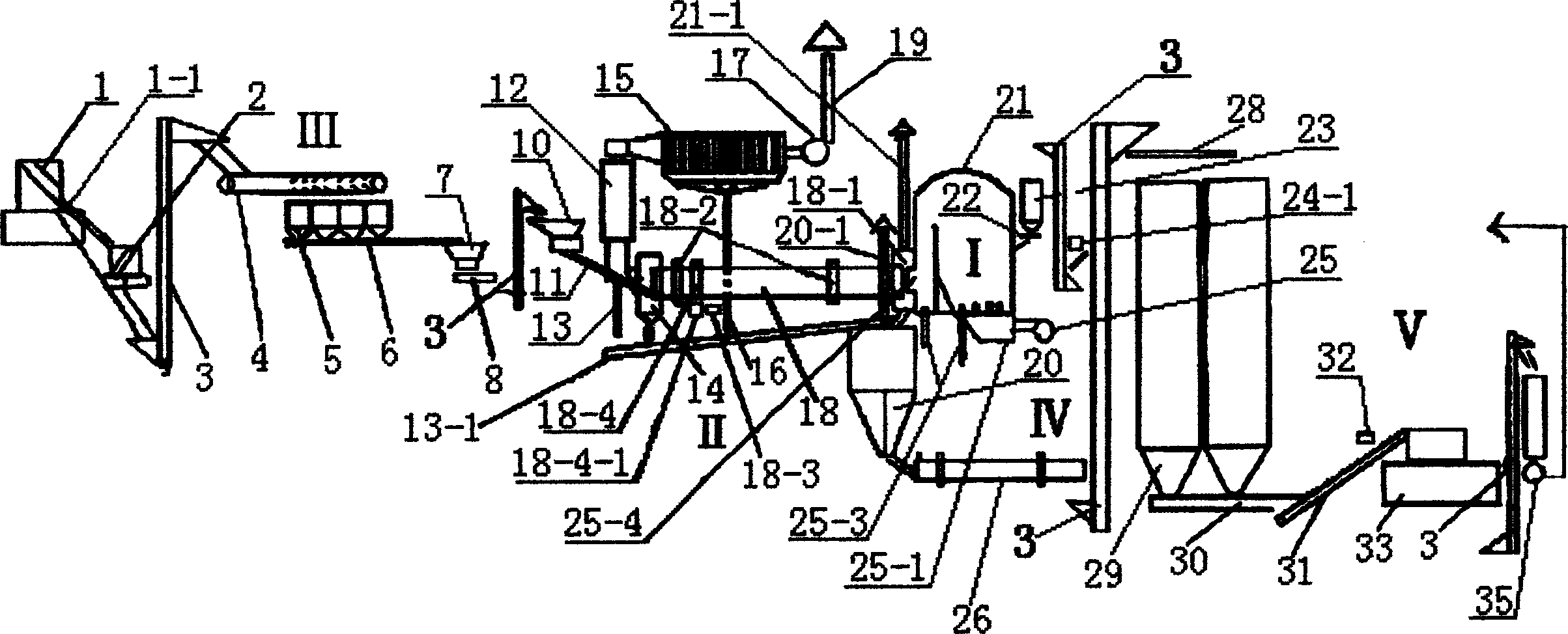

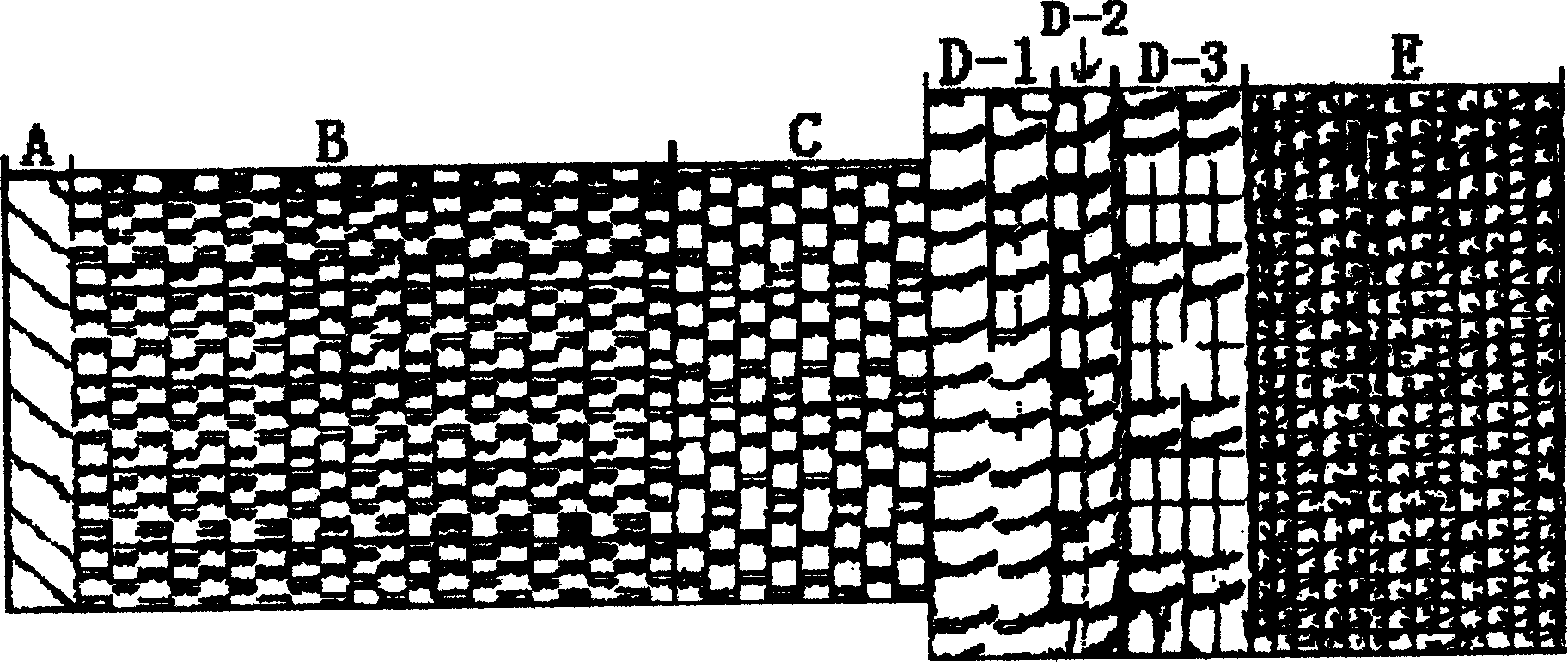

[0032]The method for calcining magnesium oxide in a fluidized fluidized furnace rotary kiln of the present invention is that mineral raw materials such as magnesite and gypsum are crushed by a jaw crusher, screened by a vibrating screen, crushed by a jaw crusher and homogenized by a multi-grid raw material homogenization bin. The material with a particle size of ≤30mm enters from the high end of the rotary kiln and discharges from the low end, and the hot flue gas generated by the coal-fired fluidized fluidized furnace enters from the low end and discharges from the high end of the rotary kiln. During this period, it experienced four kinds of thermal effects: conduction, convection, radiation and smoldering; the dust and flue gas discharged from the high-end rotary kiln are sent to the conveyor through the useful material and dust recovered by the dust collection equipment, and the flue gas discharged from the dust collection equipment is The fan and flue gas are exhausted from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com