Knitting circular weft knitting machine

A technology for knitting circular weft machines and needle cylinders, applied in knitting, textiles and papermaking, etc. It can solve the problems of unsatisfactory treatment of flying flocs, large space occupation, and wind blowing, so as to prevent flying flocs from adhering to the conveyor belt. The yarn device is installed, the blowing is uniform, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

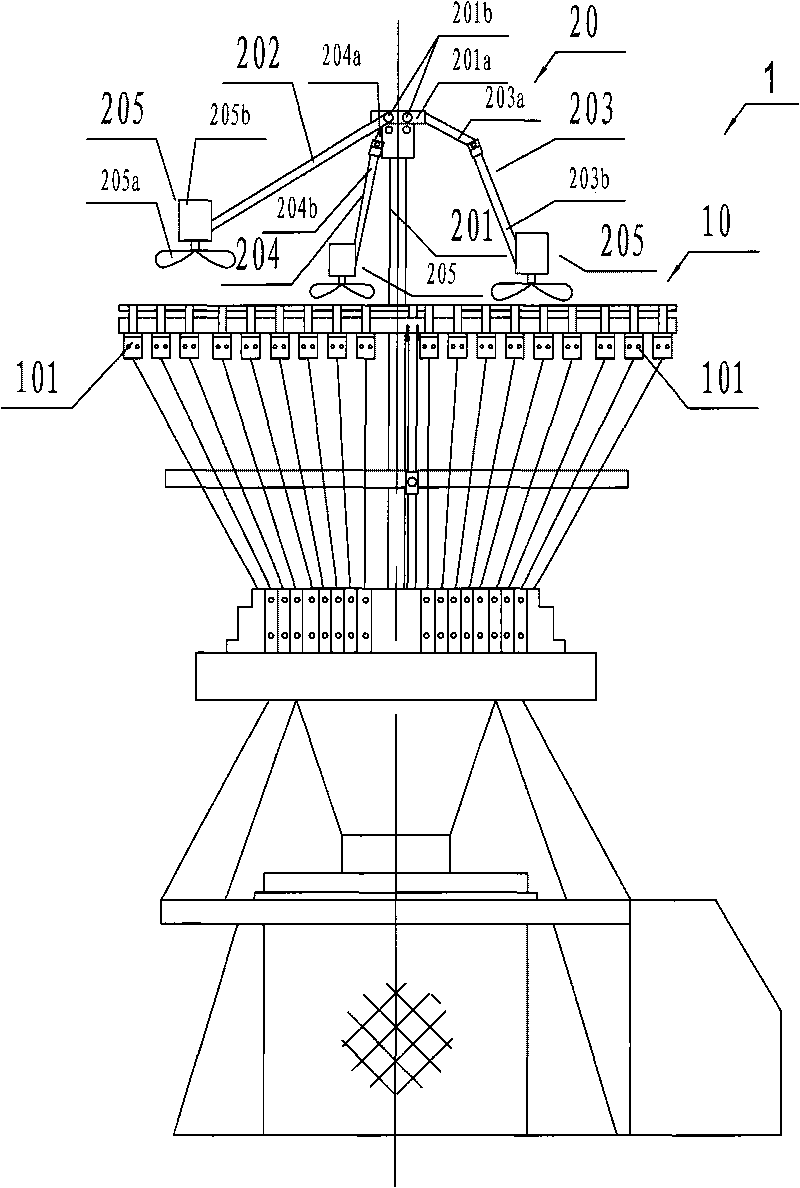

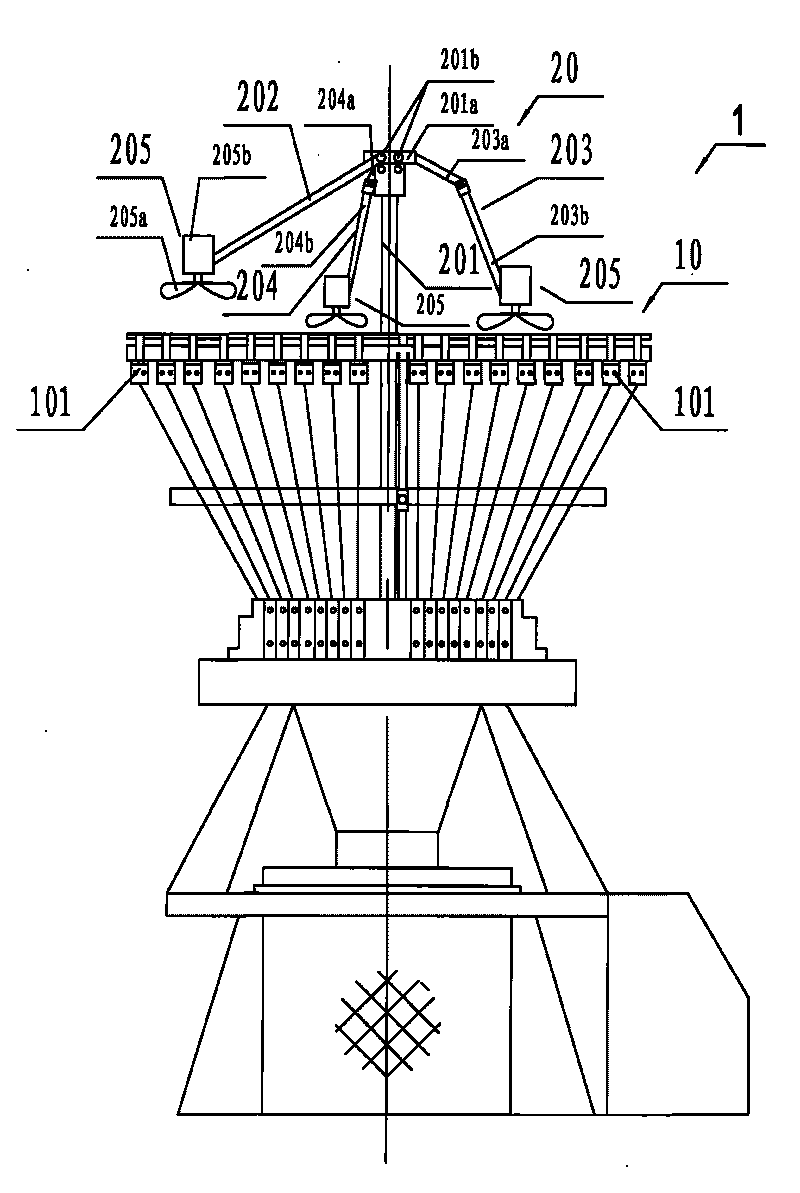

[0017] figure 1 It is a structural schematic diagram of the circular knitting machine of the present invention. As shown in the figure, the present invention provides a circular knitting machine 1, which is used for knitting yarns into double-sided fabrics, and the knitting is completed by needle cylinders (not shown in the figure).

[0018] The circular knitting machine 1 includes a yarn feeding device 10 and a blowing device 20 . The yarn feeding device 10 is used as the yarn feeding device of the circular knitting machine 1, and it is mainly composed of a plurality of yarn feeding devices 101 located on the top of the circular knitting machine 1 and distributed around the circumference.

[0019] The blowing device 20 includes a rotating rod 201, an A bracket 202, a B bracket 203, a C bracket 204, an electric fan unit 205, and a driving source for the rotating rod (not shown in the figure). The rotating rod 201 is located at the center of the circular knitting machine 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com