Patents

Literature

39results about How to "Improve calcination quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

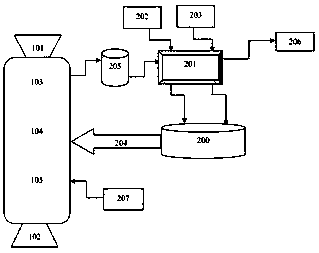

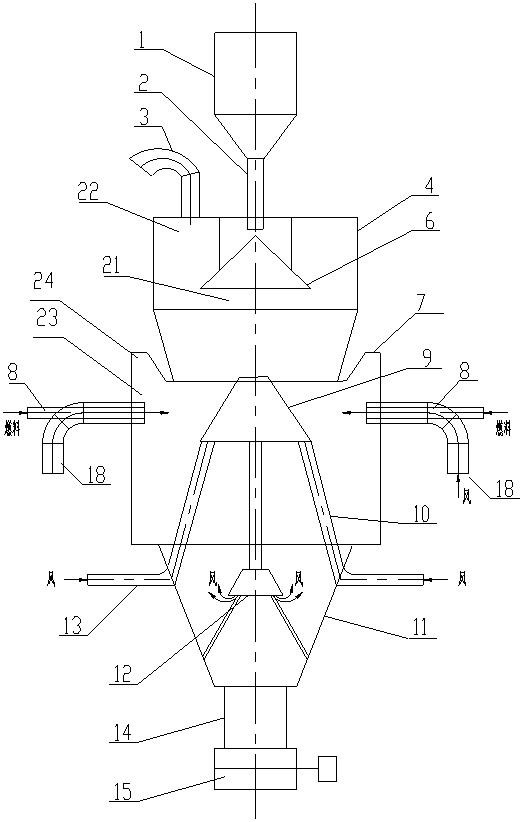

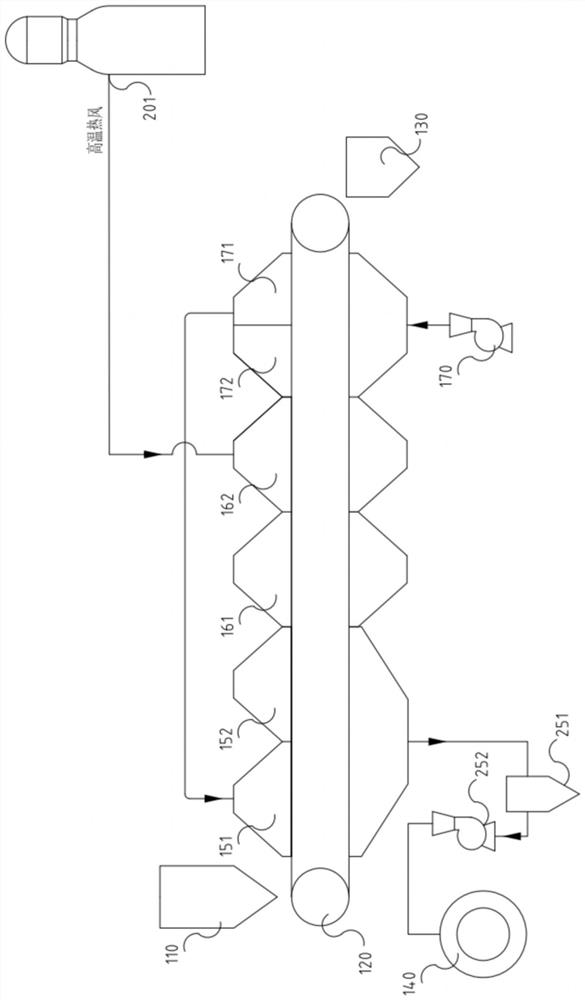

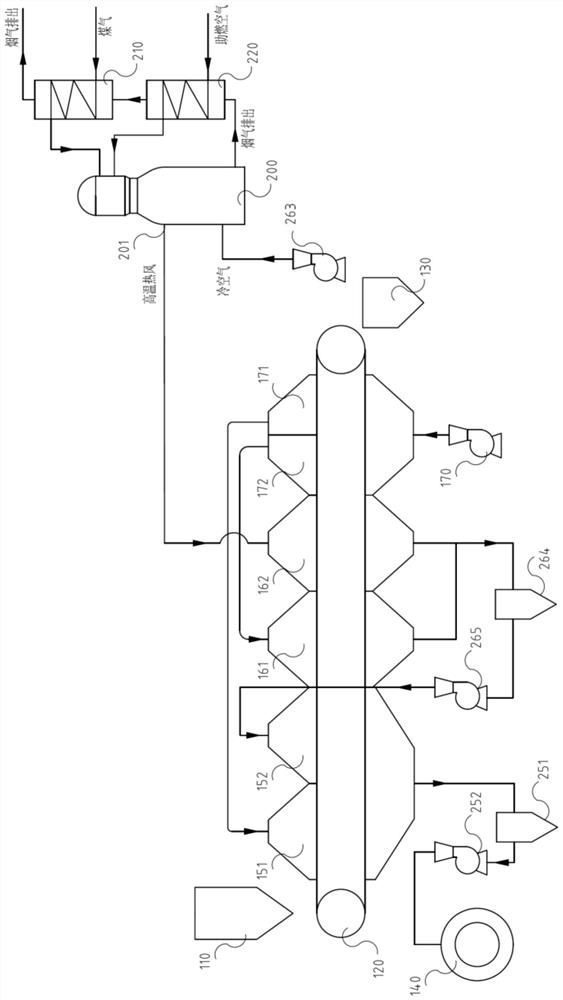

Lime kiln device adopting circulating hot air

The invention relates to a lime kiln device adopting circulating hot air and a production method for industrial lime. According to the lime kiln device adopting the circulating hot air and the production method for the industrial lime, in the preparation process of the lime, limestone is calcined by using the circulating hot air, the calcined waste circulating hot air is used for preheating limestone ore, and the preheated waste circulating hot air is cooled, is subjected to dust removal, then is conveyed to a regenerative heating furnace set, is heated to a set calcining temperature and thenis sent back to a lime kiln system for calcining. The lime kiln device adopting the circulating hot air and the production method for the industrial lime have the advantages that the limestone is calcined by using the circulating hot air, so that the quality of the lime can be remarkably improved, the yield of the lime can be increased, the productivity can be improved, and high-purity CO2 can beconveniently recycled; and the lime kiln system adopts the regenerative heating furnace set for heating, a lime kiln is not provided with a burner system, regenerative heating furnaces can utilizes low-heating-value blast furnace gas as fuel, and therefore the structure of a kiln body can be conveniently simplified, and the operation cost of the lime kiln can be lowered.

Owner:王长春 +3

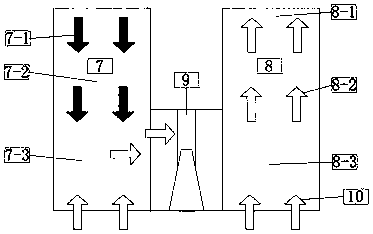

Magnesia calcining boiling furnace rotary kiln method and apparatus

The present invention relates to magnesia calcining boiling furnace rotary kiln method and apparatus. The magnesia calcining process includes feeding material from the high end of the rotary kiln, producing hot fume in the coal-burning boiling furnace, making the fume flow from the low end of the rotary kiln to the high end for counter flow type heat exchange with material inside the rotary kiln, exhausting fume and dust in the high end of the rotary kiln and recovering useful dust material, producing chamotte in sealed bin via high temperature radiation heating, and tempering the over burnt material. The apparatus consists of boiling furnace system for producing and supplying hot fume, calcining rotary kiln system, material feeding system, dust collecting system, and chamotte conveying, storing, ageing and cooling system. The present invention has the advantages of good coal adaptability, high heat efficiency, low cost, low power consumption, high yield, etc.

Owner:王全祥

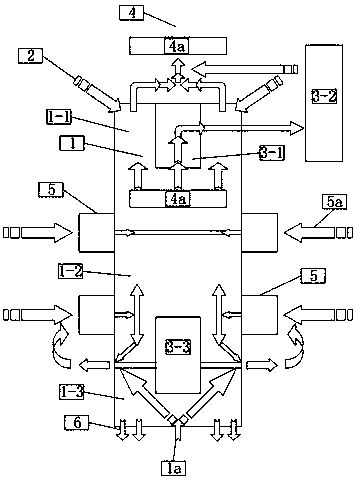

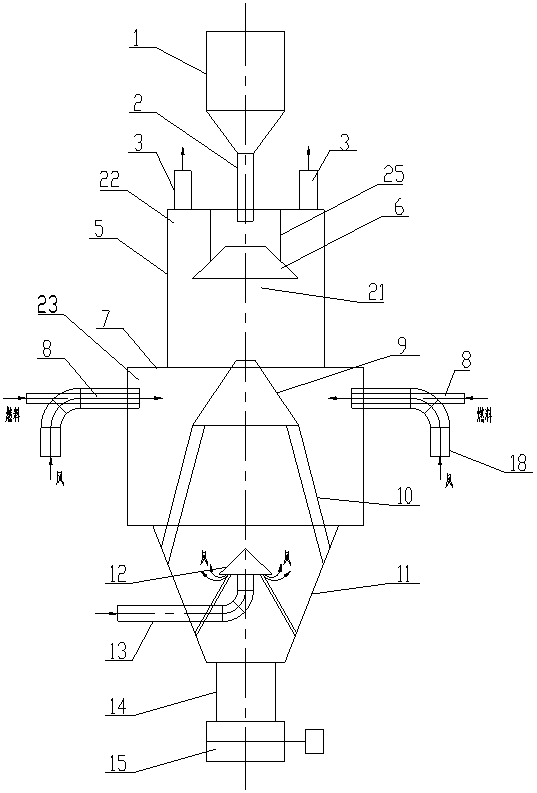

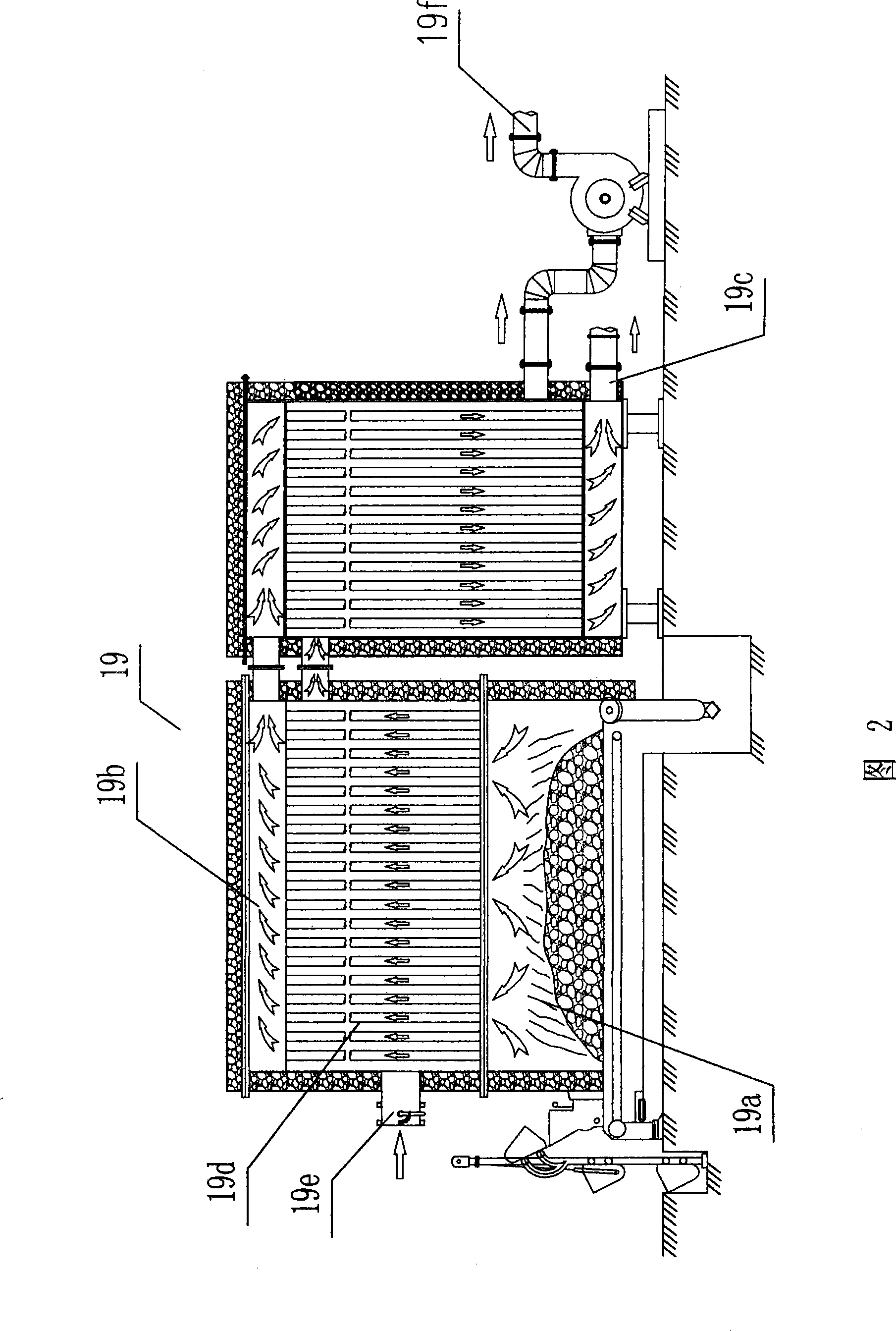

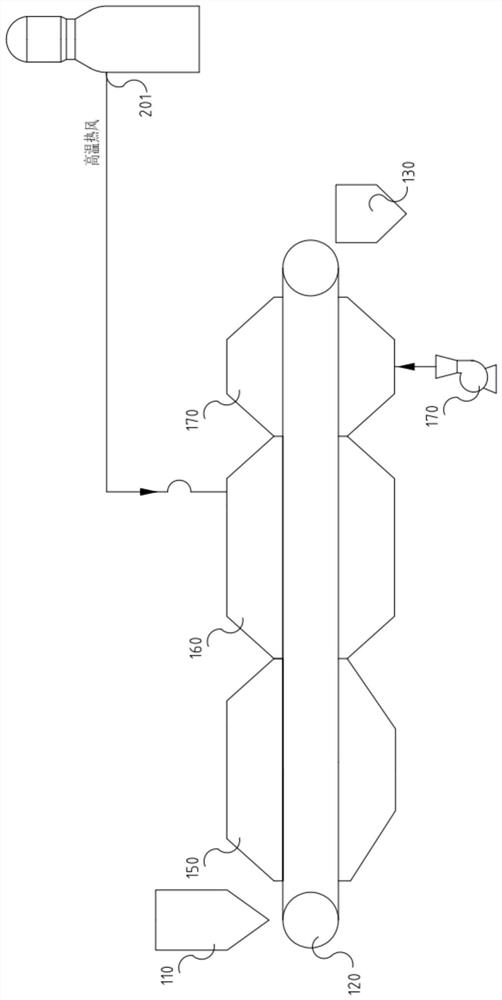

Lime kiln device with application of hot-air

The invention relates to a lime kiln device with hot-air calcination and a method for producing lime by the utilization of the lime kiln device. When preparing lime, hot air generated from a combustion apparatus outside a kiln is used for calcination of limestone; waste hot air used after the calcination is used for preheating of the limestone mineral aggregate; the waste hot air used after preheating is discharged out of the kiln body, and then undergoes dedusting and finally used for preheating of coal gas and oxidizing air. Through the use of hot air for calcination of limestone, lime quality can be remarkably improved, lime yield is raised, and productivity is enhanced. The lime kiln proposed by the invention is not provided with a burner system, and the hot air for high temperature calcination is from a combustion furnace device outside the kiln. Blast-furnace gas can be used as a fuel for the combustion furnace device, and hot flue gas generated by the combustion device can be used as the hot air. Thereby, the kiln structure is simplified, and operating cost of the lime kiln is reduced.

Owner:王长春 +2

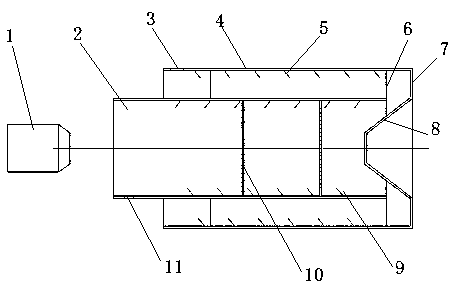

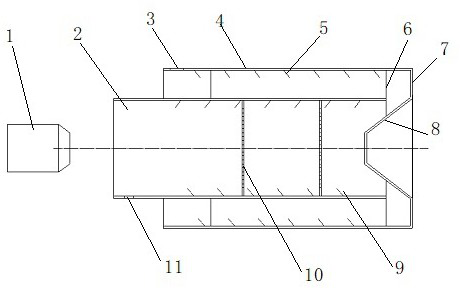

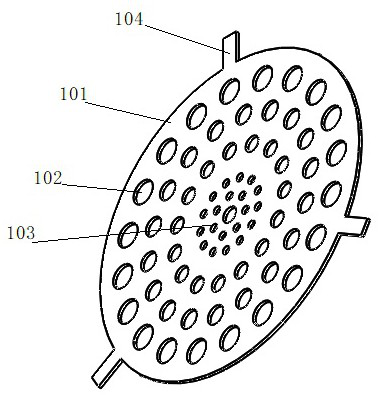

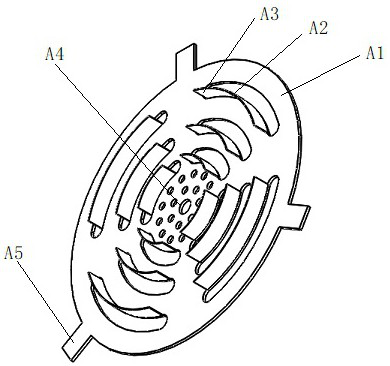

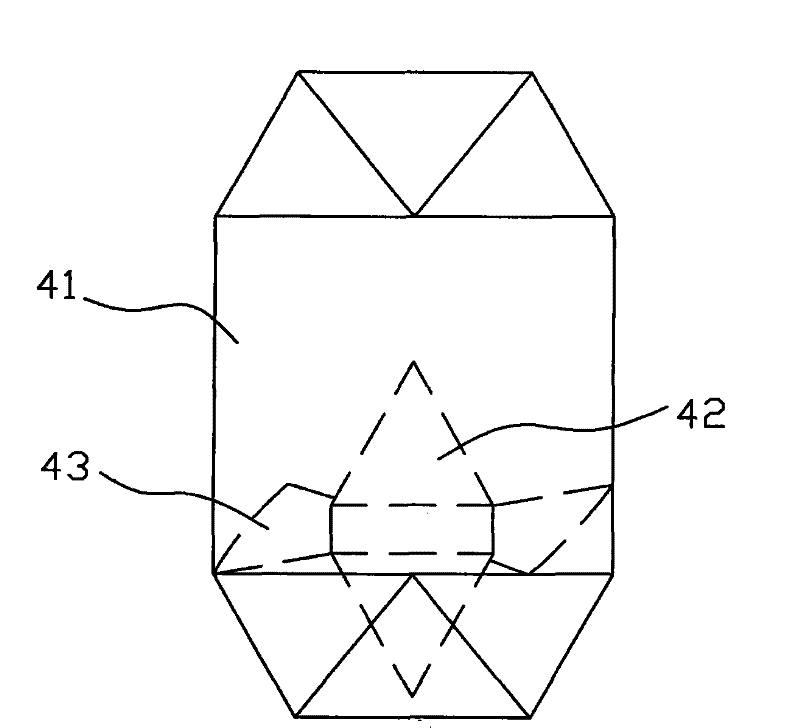

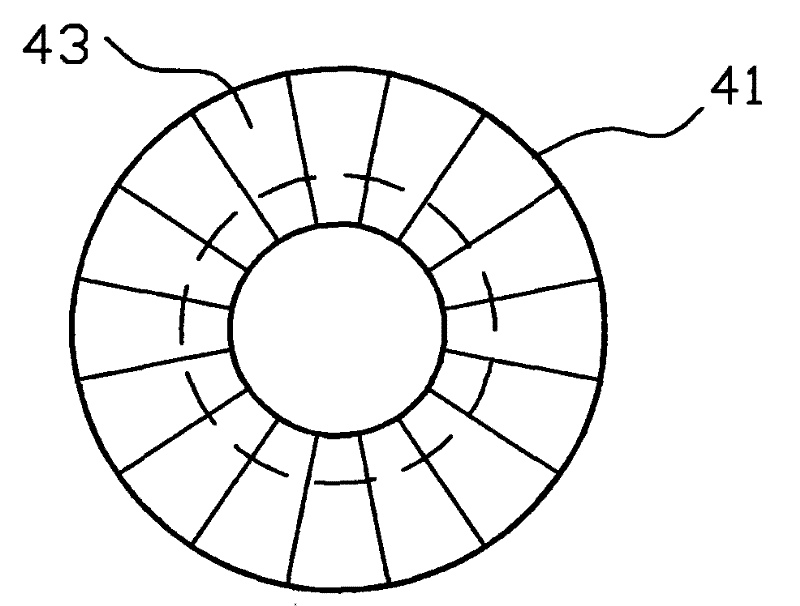

Phosphogypsum calciner

A phosphogypsum calciner belongs to the field of phosphogypsum calcinations. The phosphogypsum calciner includes a fire spitting furnace, an inner cylinder, a material inlet, an outer cylinder, an outer cylinder material pushing plate, an inner and outer cylinder connecting piece, an outer cylinder tail end, a conical body, an inner cylinder material pushing plate, a pressure equalizing device anda material outlet; the fire spitting furnace is a coal spraying furnace or a gas-fired fire spraying furnace, and is mounted at the material outlet of the inner cylinder, and the fire spraying direction of the fire spitting furnace is locate at the material discharging end of the inner cylinder; the inner cylinder is arranged in the outer cylinder and is coaxial with the outer cylinder, and the outer wall of the inner cylinder is fixedly connected with the outer cylinder through the inner and outer cylinder connecting piece; and the material inlet is arranged in the outer cylinder, is locatedat one end of the fire spitting furnace, and penetrates through the wall thickness of the outer cylinder. The phosphogypsum calciner has the characteristics of keeping of the balance of airflow in the inner cylinder, uniformity in heating of the calcined material, realization of movement of the calcined material tending to be smooth, and improvement of the production efficiency and the calcination quality.

Owner:ZHENGZHOU SUNDY BUILDING TECH

Process for producing molybdenum trioxide through spiral flow fluidized calcination

InactiveCN101798116ALarge specific surface areaRapid responseMolybdenum oxides/hydroxidesAutomatic controlLeaching rate

The invention discloses a process for producing molybdenum trioxide through spiral flow fluidized calcination. The process mainly comprises the following steps of: preheating molybdenum concentrate to make the materials in a gas-solid mixed state; conveying the preheat molybdenum concentrate to a fluidized rotary calciner to make the gas-solid mixed ratio in the calciner to be 40: 0.5-1 and temperature to be 50 to 800 DEG C; allowing the calcined smoke to enter an air-cooled heat exchanger to cool the smoke to below 300 DEG C; and collecting dust by using a cloth bag to perform gas-solid separation to recycle the calcined sand. Due to the process, the molybdenum metal grade reaches over 60 percent and the recovery rate reaches 99.5 percent after the molybdenum concentrate is calcined. Compared with the convention calcination, the process has more complete oxidation so as to be beneficial for producing molybdate and improve leaching rate and recovery rate. The process is performed in a fully-sealed system and has the advantages of high recovery rate, environmental friendliness, convenient automatic control, simpliness, little time consumption, low energy consumption, good calcining quality, improvement on production efficiency and reduction in labor intensity of operators.

Owner:江西省鼎力金属有限公司

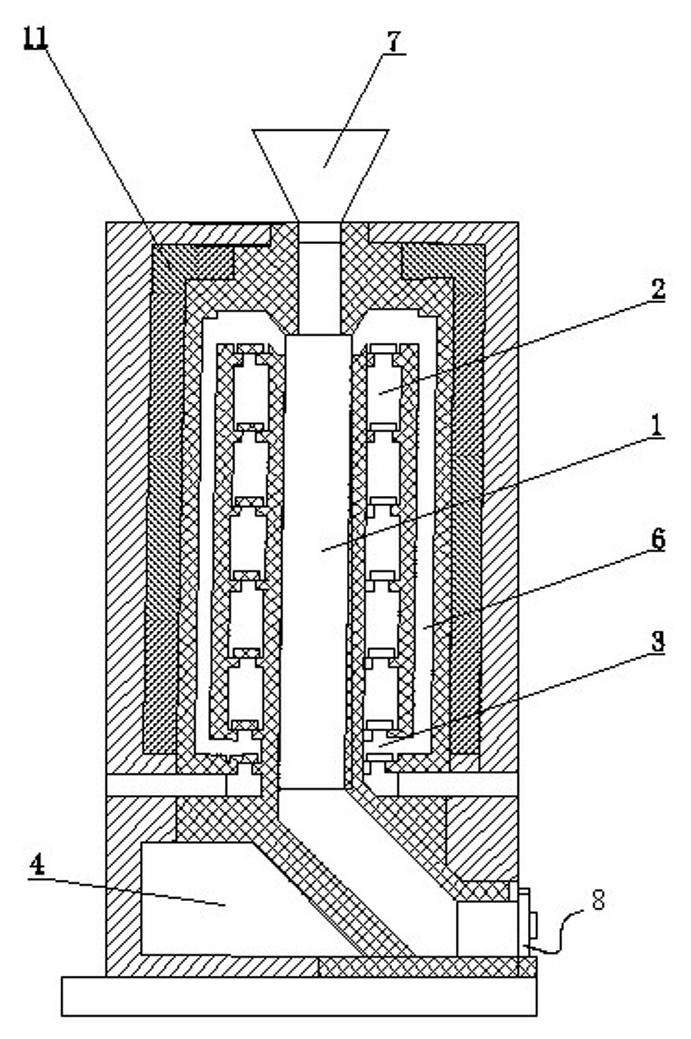

Industrial calcination shaft kiln

PendingCN108088236AEqual temperatureEasy to achieve uniform temperature requirementsControl devices for furnacesVertical furnacesCombustionPulp and paper industry

The invention discloses an industrial calcination shaft kiln. According to the industrial calcination shaft kiln, gas, liquid or power are taken as fuel, the calcination temperature is more even, theproduct quality is better, energy conservation and environmental protection are achieved, the automation degree is high, and massive or granular or ball-shaped materials can be calcined. The industrial calcination shaft kiln comprises a cylinder body, a material adding device used for adding materials to the interior of the cylinder body and an exhaust device used for exhausting tail gas are arranged on the upper portion of the cylinder body; a combustion-supporting wind device used for sending combustion-supporting wind to the interior of the cylinder body and an unloading device used for discharging the material in the cylinder body are arranged on the lower portion of the cylinder body, at least a sudden-changed section is arranged at the position, between the material adding device andthe combustion-supporting wind device, of the cylinder body, the size of the part, on the upper portion of the sudden-changed section, of an inner cavity of the cylinder body is small in the horizontal direction, the size of the part, on the lower portion of the sudden-changed section, of the inner cavity of the cylinder body is large in the horizontal direction, and when the materials flow downwards in the cylinder body, a cavity which the materials cannot reach naturally is formed on the lower portion of the sudden-changed section; and an outlet of a combustion nozzle in a fuel combustion device communicates with the cavity, and materials are sprayed out from the combustion nozzle.

Owner:NANJING SUYE CALCIUM IND TECH

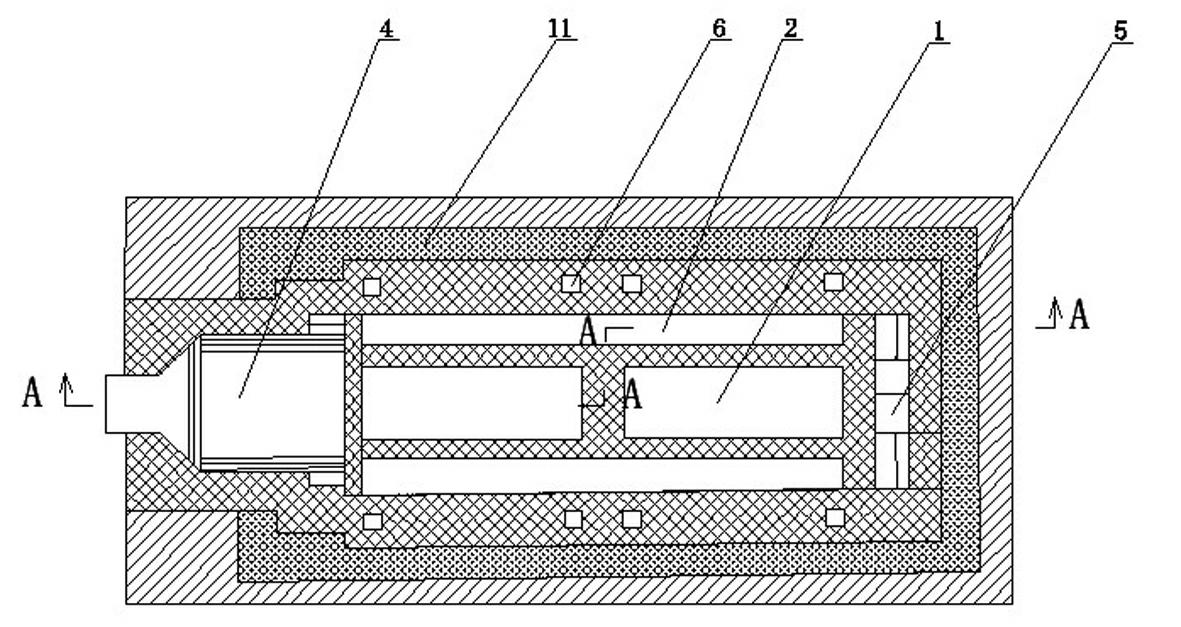

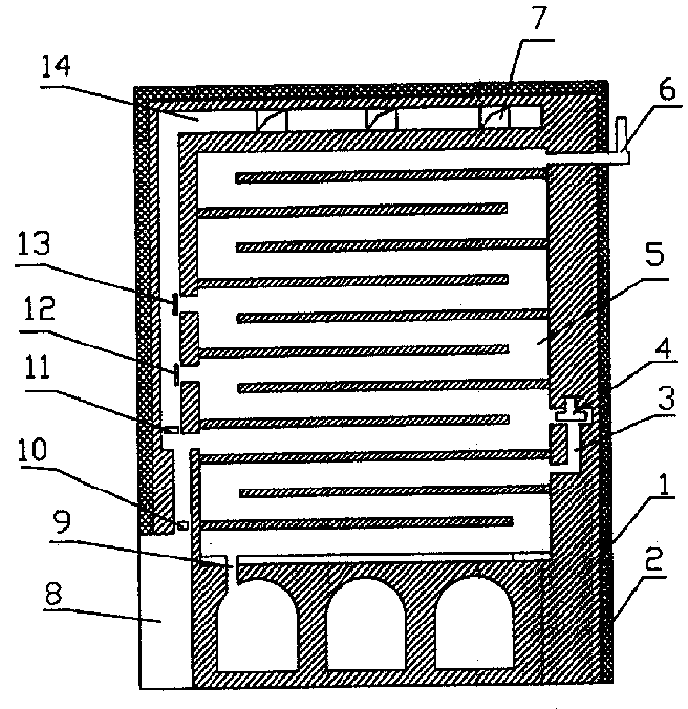

Pot-type calcining furnace

InactiveCN102538455AExpensive to manufactureSimple structureCombustion processCrucible furnacesFlueProcess engineering

The invention discloses a pot-type calcining furnace. The pot-type calcining furnace consists of two calcining pots which are vertically arranged right and left, a combustion chamber, heating fire ways, air ways, volatilizing subways, a flue, feeding systems and discharging systems, wherein the heating fire ways are arranged on the front sides and the back sides of the calcining pots; inlets of the heating fire ways are connected with the combustion chamber, and outlets of the heating fire ways are communicated with the flue; the volatilizing subways are arranged on the peripheries of the heating fire ways; inlets of the volatilizing subways are connected with volatile discharging ports which are formed on the upper parts of the calcining pots, and outlets of the volatilizing subways are communicated with the heating fire ways; and the air ways are arranged below the heating fire ways and are communicated with the volatilizing subways. The pot-type calcining furnace is simple in structure; volatiles decomposed from raw materials are discharged from the discharging ports on the upper parts of the calcining pots, are mixed with air and pre-heated by the heating fire ways, enter the heating fire ways, and are fully combusted and utilized; the heat efficiency of the whole pot-type calcining furnace is high; the production continuity is high; and the production efficiency is high.

Owner:许继忠

Method for calcining titanium dioxide through expansion drying technique

A method for calcining titanium dioxide through an expansion drying technique comprises a feeding step and a calcining step, wherein a metatitanic acid material subjected to filter pressing and expansion drying and with the moisture content of 10-15% is conveyed into a rotary kiln to be calcined; the calcining in the rotary kiln is divided into three stages, each stage accounts for one third of the whole length of the rotary kiln, the temperature of the first stage is controlled to be 500-700 DEG C and the standing time is 1.5-2 hours, the temperature of the second stage is controlled to be 700-850 DEG C and the standing time is 1.5-2 hours, the temperature of the third stage is controlled to be 850-950 DEG C and the standing time is 2-2.5 hours. In the method for calcining the titanium dioxide, a heat source required for expansion drying can be provided by high temperature flue gas of the kiln tail of the rotary kiln, and the rotating speed of the rotary kiln is kept at 0.25-0.33 revolutions per minute. The calcining method provided by the invention can increase the productivity, decrease the energy consumption, and also improve the calcining quality of a product.

Owner:GUANGXI JINMAO TITANIUM

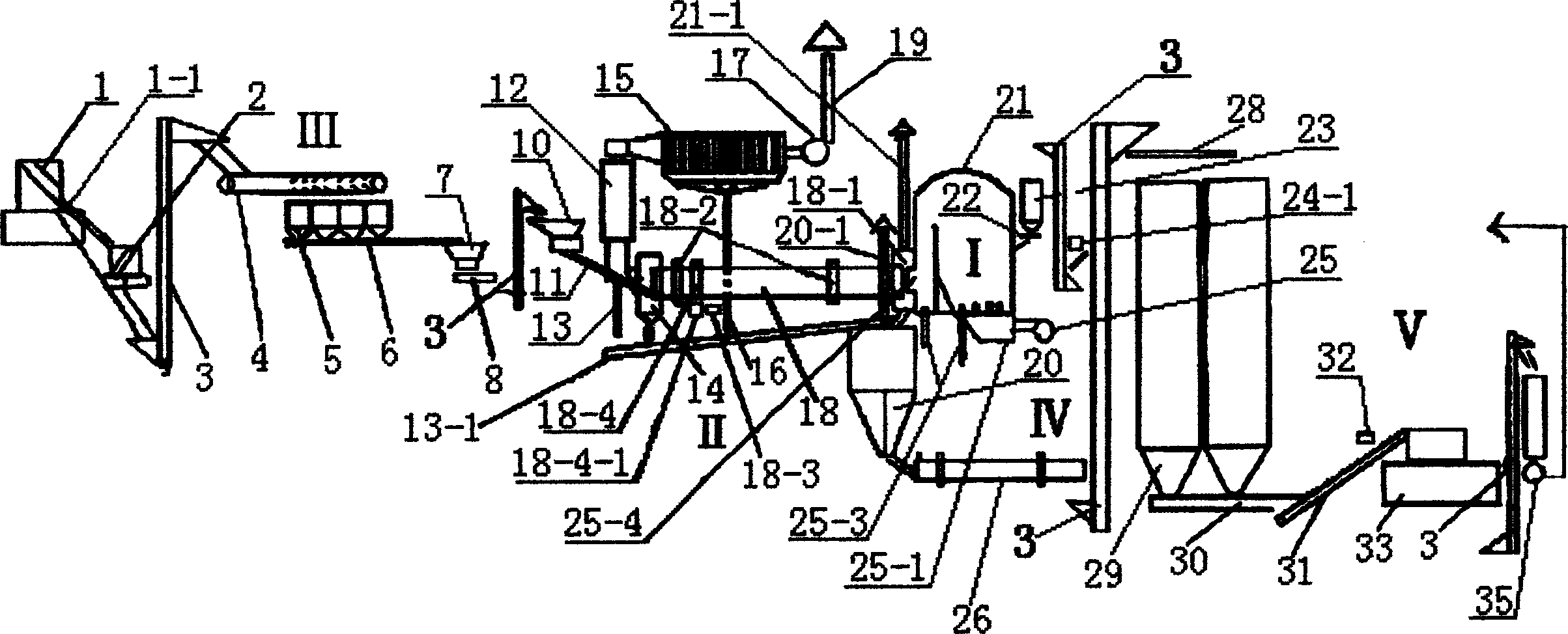

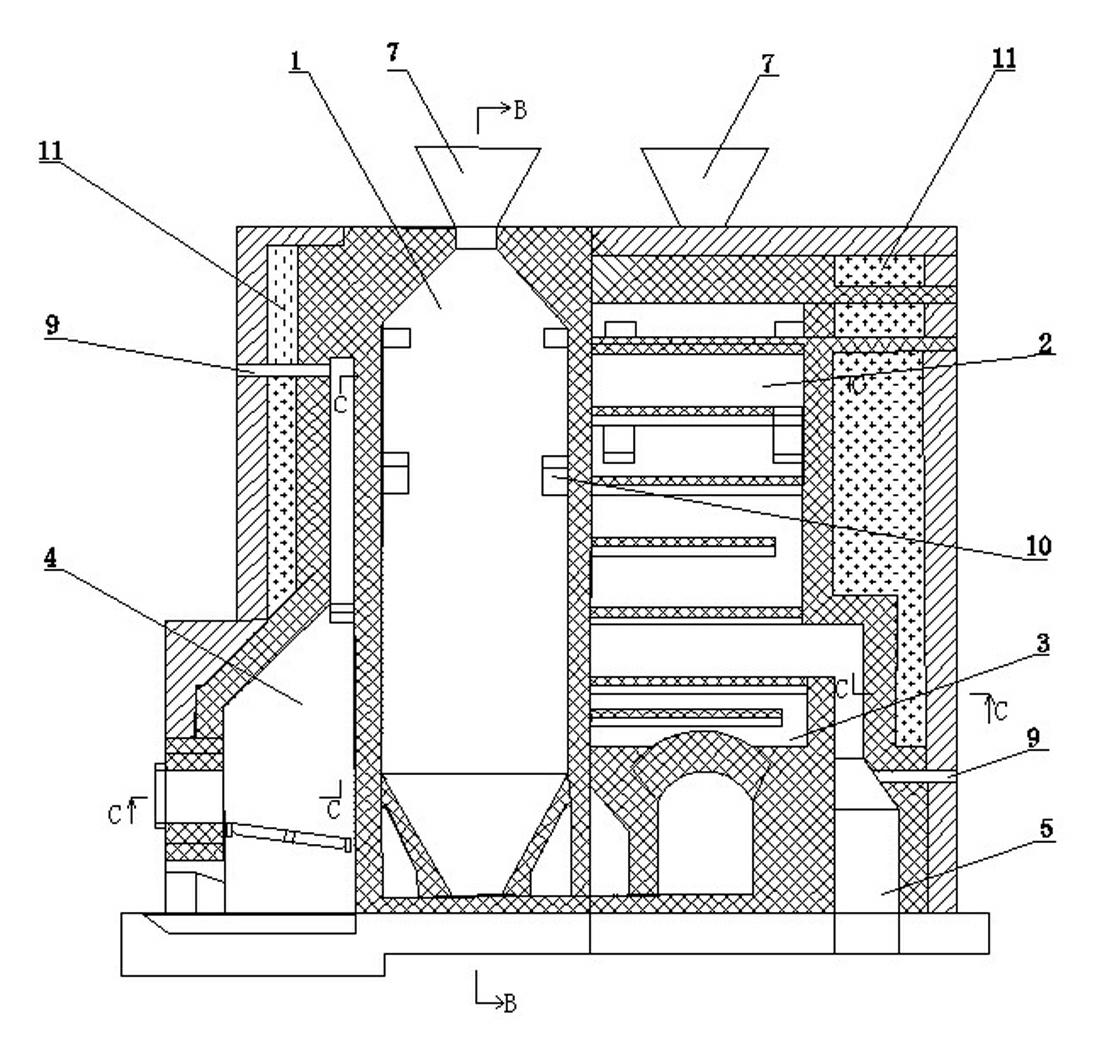

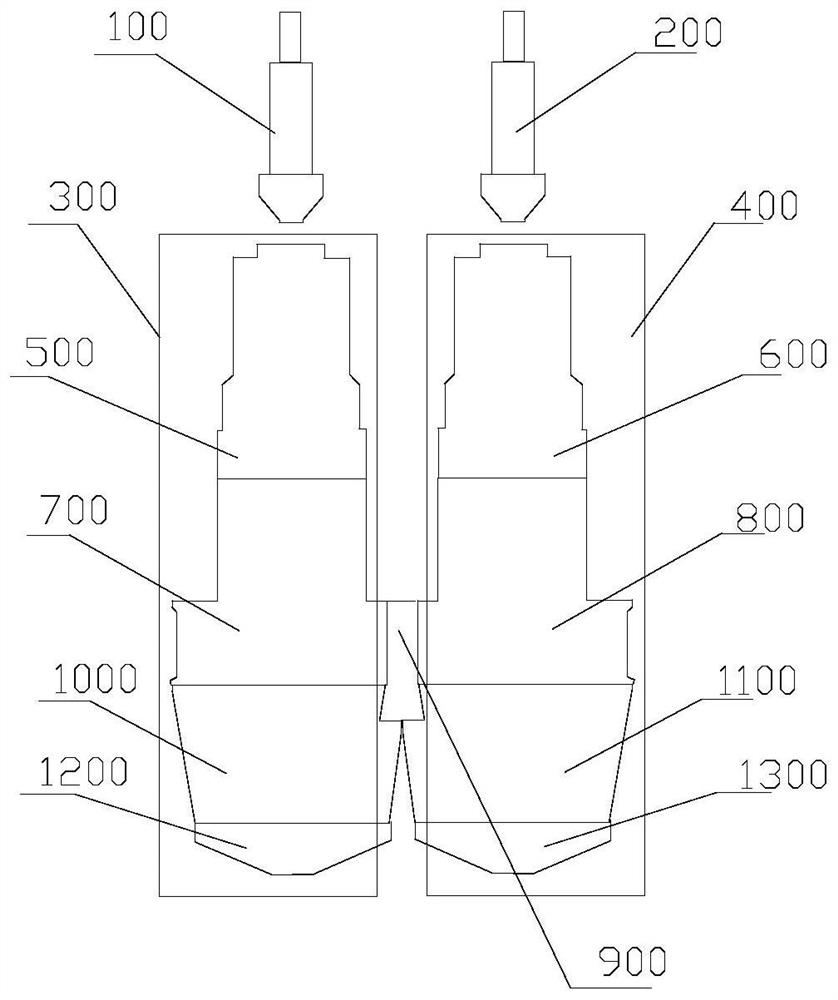

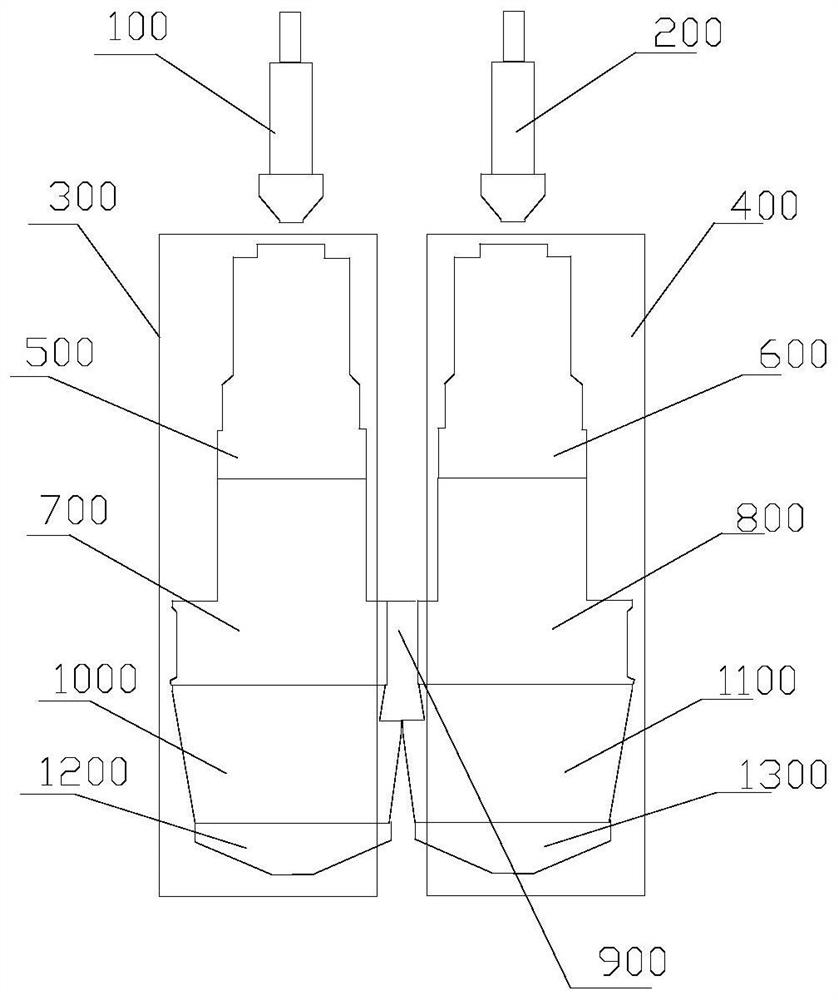

Novel double-hearth kiln for combustion of low-calorific-value fuel

ActiveCN111908811AOptimizing Calcination ResultsImprove calcination qualityPhysicsProcess engineering

The invention discloses a novel double-hearth kiln for combustion of low-calorific-value fuel, which comprises a feeding device, a first kiln body and a second kiln body, wherein the feeding device isrespectively connected with the first kiln body and the second kiln body; the first kiln body comprises a first preheating device, a first calcining device, a first cooling device and a first discharging device from top to bottom; the second kiln body comprises a second preheating device, a second calcining device, a second cooling device and a second discharging device from top to bottom; the first kiln body and the second kiln body are connected through a fixed connecting device. According to the novel double-hearth kiln for combustion of low-calorific-value fuel, the combustion temperatureof the low-calorific-value fuel can be increased through the branch pipes, the main pipe, the combustion chamber and the heat storage box, and the calcination effect is optimized; meanwhile, the cooling device can realize effective conversion and recovery of material heat, so that the energy consumption is further reduced; the double-hearth kiln can achieve mutual switching between the two kiln bodies, and continuous production of materials is completed; finally, the feeding device can enable the double-hearth kiln to discharge materials conveniently, so that the labor intensity of workers isreduced.

Owner:SHENYANG HONGSHAN TECH

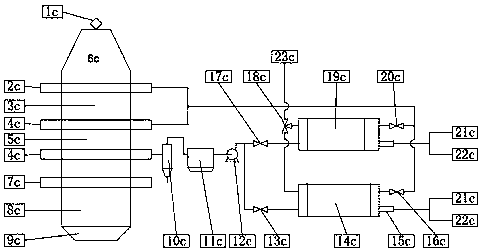

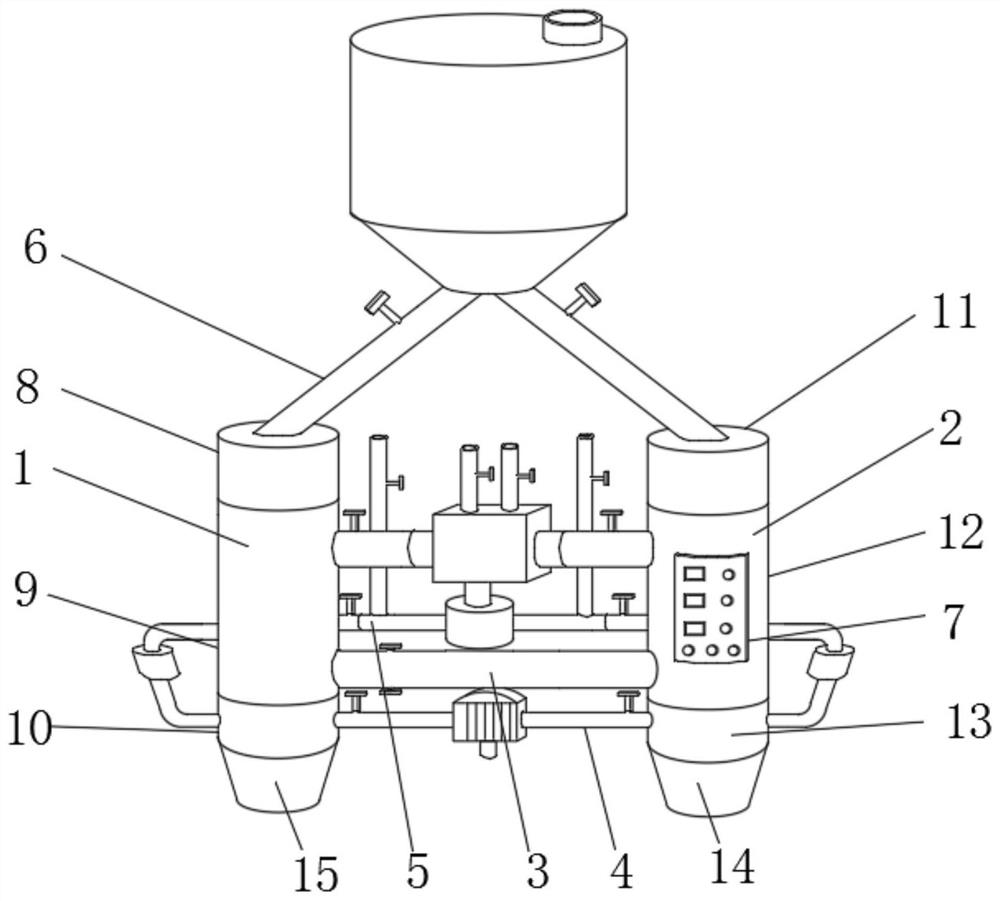

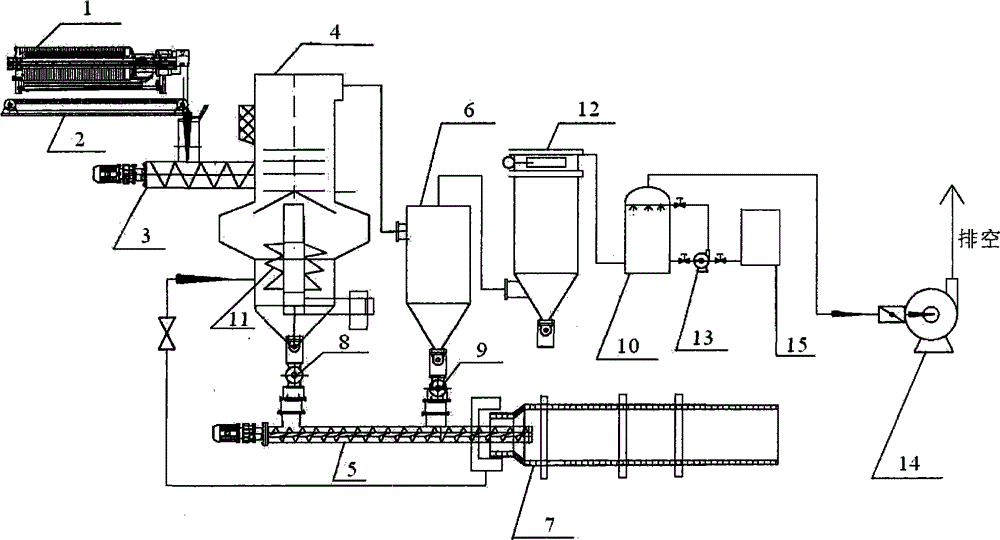

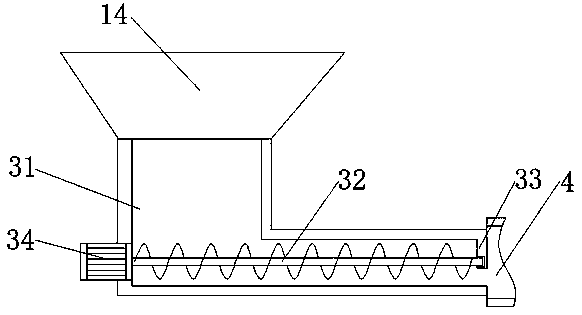

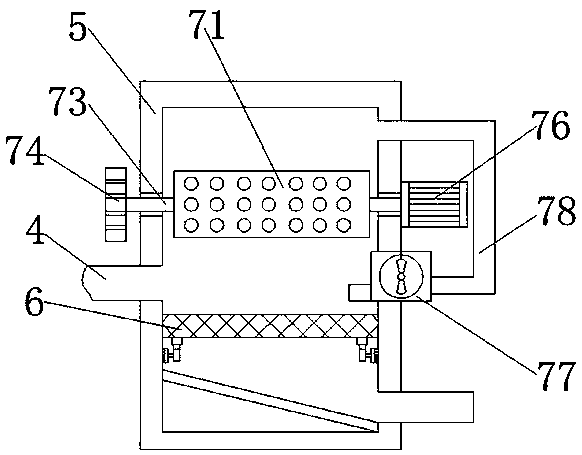

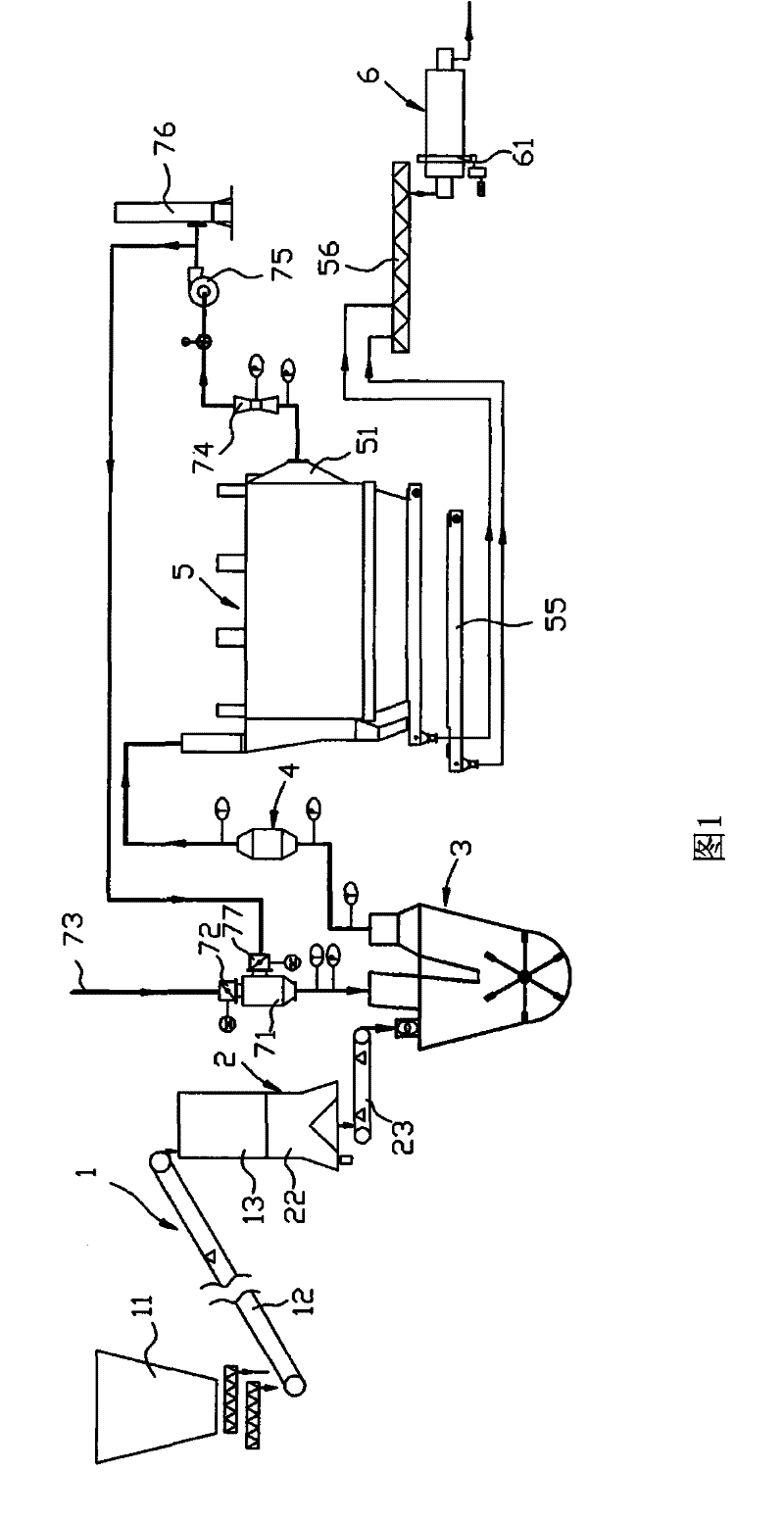

Feeding method and feeding equipment for titanium dioxide calcination rotary kiln

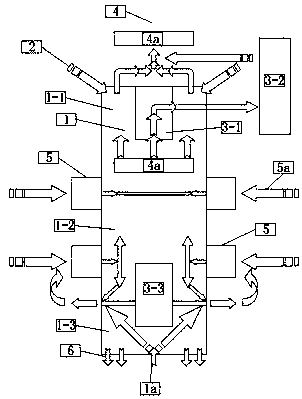

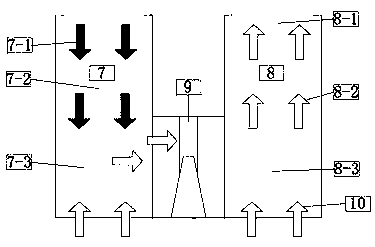

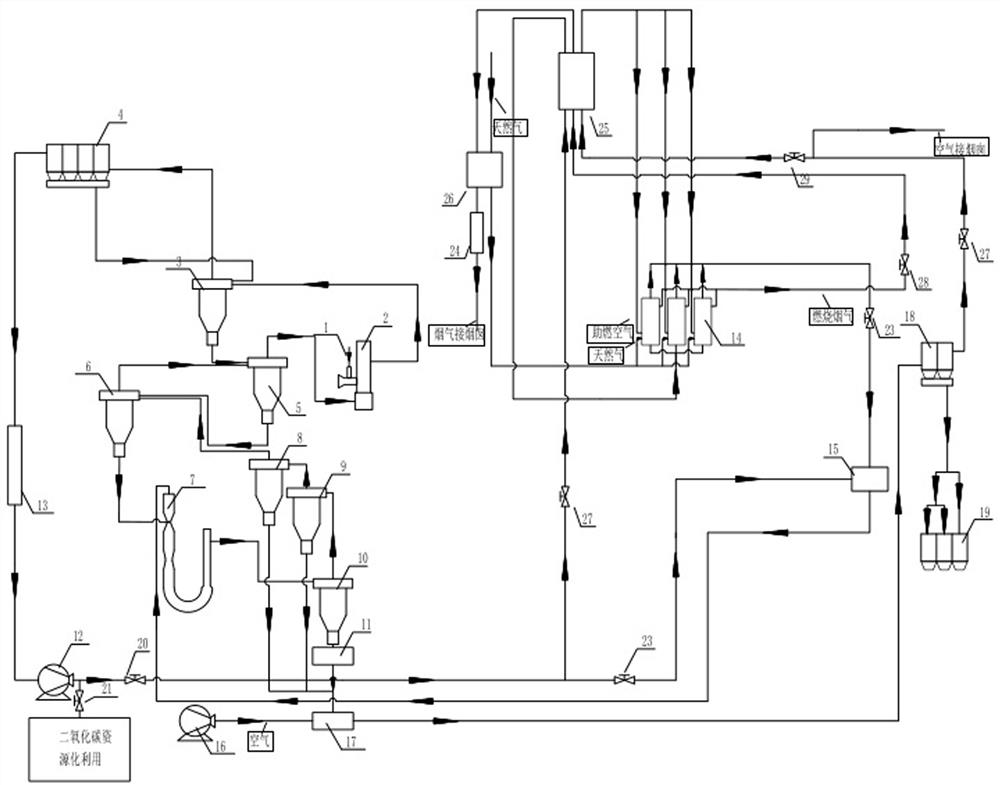

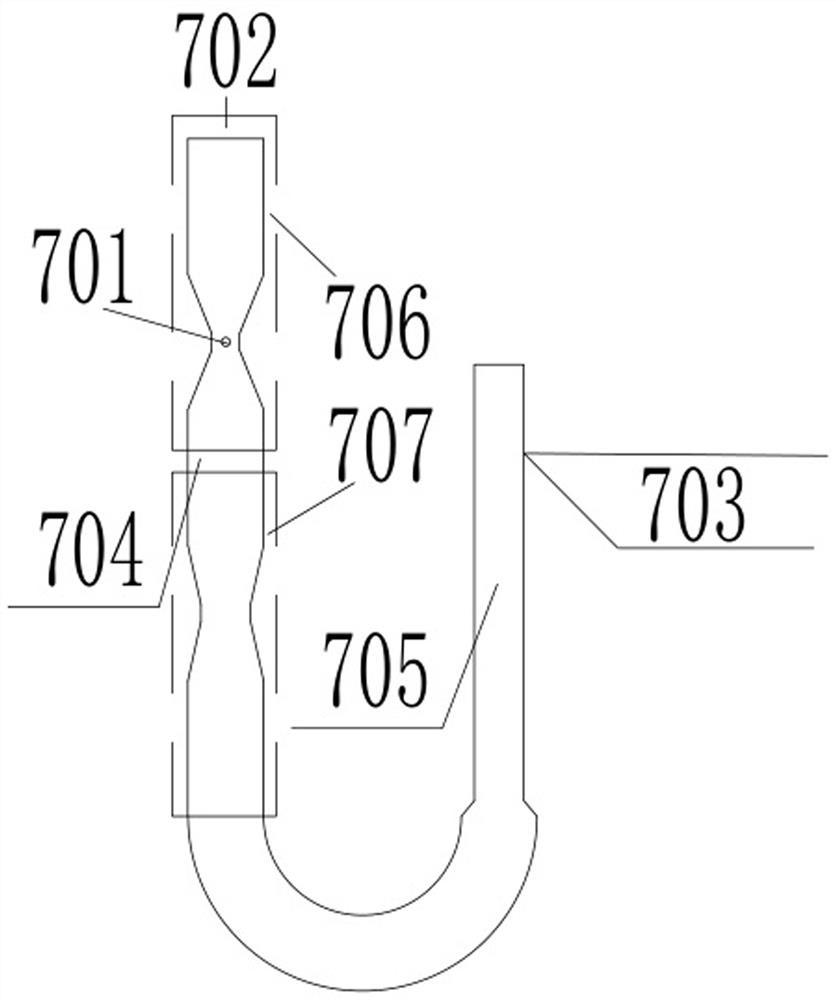

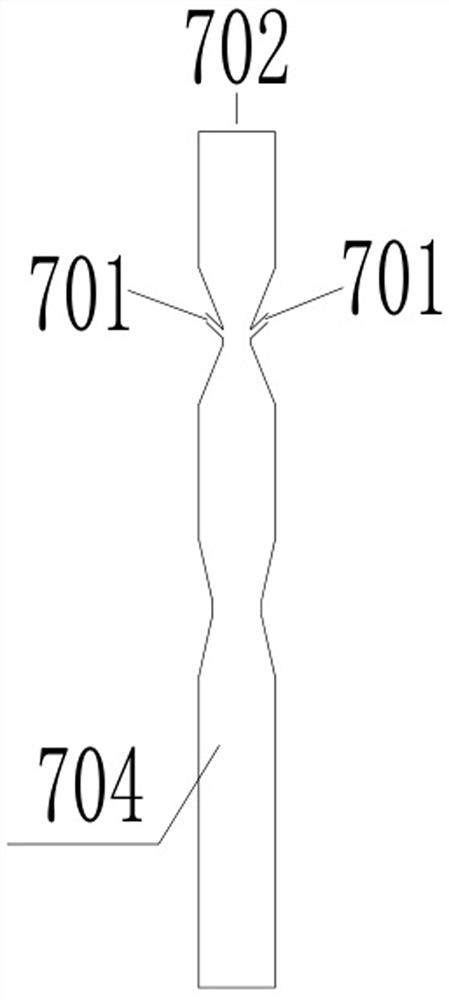

The invention relates to a feeding method and feeding equipment for a titanium dioxide calcination rotary kiln. The equipment comprises a membrane filter press (1), a belt conveyor (2), a first screw conveyor (3), a flash evaporation drying main machine (4), a second screw conveyor (5), a cyclone dust collector (6), the rotary kiln (7), a high pressure induced draft fan (14), an alkali liquor adsorption tower (10), an alkali liquor spraying pump (13), an alkali liquor storage tank (15) and a bag filter (12); a rotary blade (11) is arranged at the bottom of the flash evaporation drying main machine (4); and a first star-shaped discharge valve (8) and a second star-shaped discharge valve are respectively arranged at the bottoms of the flash evaporation drying main machine and the cyclone dust collector. The method adopting the feeding equipment comprises the steps of conveying, flash evaporation drying, recovery, collection and tail gas treatment. Metatitanic acid materials entering the flash evaporation drying main machine are in contact with high-temperature flue gas from the kiln tail of the rotary kiln; under the action of high speed rotation of the rotating blade at the bottom, the materials are crushed, dispersed and dried; and after flash evaporation drying, the materials with the moisture content of 10 to 15 percent enter the rotary kiln. Through the adoption of the feeding method and the feeding equipment disclosed by the invention, the productivity can be improved, energy consumption can be reduced and the calcination quality of products can also be improved.

Owner:GUANGXI JINMAO TITANIUM

Powder oscillation kiln

The invention provides a powder oscillation kiln; the technical scheme designs a brand new internal structure by matching with the powder calcining process characteristics; an upper cover and a base, buckled with each other, are used for forming a closed cavity; the cavity serves as heating space; and meanwhile, a refractory pipe for accommodating powder is arranged in the heating space. On the basis, the refractory pipe is slightly inclined, and is provided with a vibration motor at the bottom, so that the sling movement of the powder in the refractory pipe can be realized through a vibration effect; and the mode not only can realize progressive movement of the powder in the pipe, but also can accelerate the heated speed and the heating uniformity through a microscopic throwing effect. In addition, a feed pipe and a discharge pipe are respectively arranged at two ends of the refractory pipe, so that the continuous operation of powder calcining can be realized through continuous charging and unloading. The powder oscillation kiln realizes excellent technical effects by innovative technical improvement, and meanwhile, is lower in cost, liable to realize and excellent in popularization prospect.

Owner:王延兵

Production method of activated aluminum oxide micropowder

The invention discloses a production method of activated aluminum oxide micropowder and relates to the field of materials. In the production method, a tunnel kiln sintering method is adopted to produce alpha-aluminum oxide micropowder; a green brick is uniform in drying and small in deformation degree; in addition, green brick movement links are relatively small, the broken brick rate is low, andthe conditions are beneficial to keeping good working condition of a tunnel kiln and also ensuring good calcining quality; and the prepared activated aluminum oxide micropowder can be used for a lighttransmitting aluminum oxide sintered body, a carrier for a phosphor, a single crystal material, a high-grade porcelain, an artificial bone, a semiconductor, an integrated circuit substrate, an audiotape filler, a catalyst and a carrier thereof, an abrasive material, a laser material, a cutting tool and the like and particularly plays an important role in development of microelectronics and material industry. The production method has the advantages of simpleness in operation, obvious effect and the like and is suitable for large-scale popularization and application.

Owner:洛阳利尔功能材料有限公司

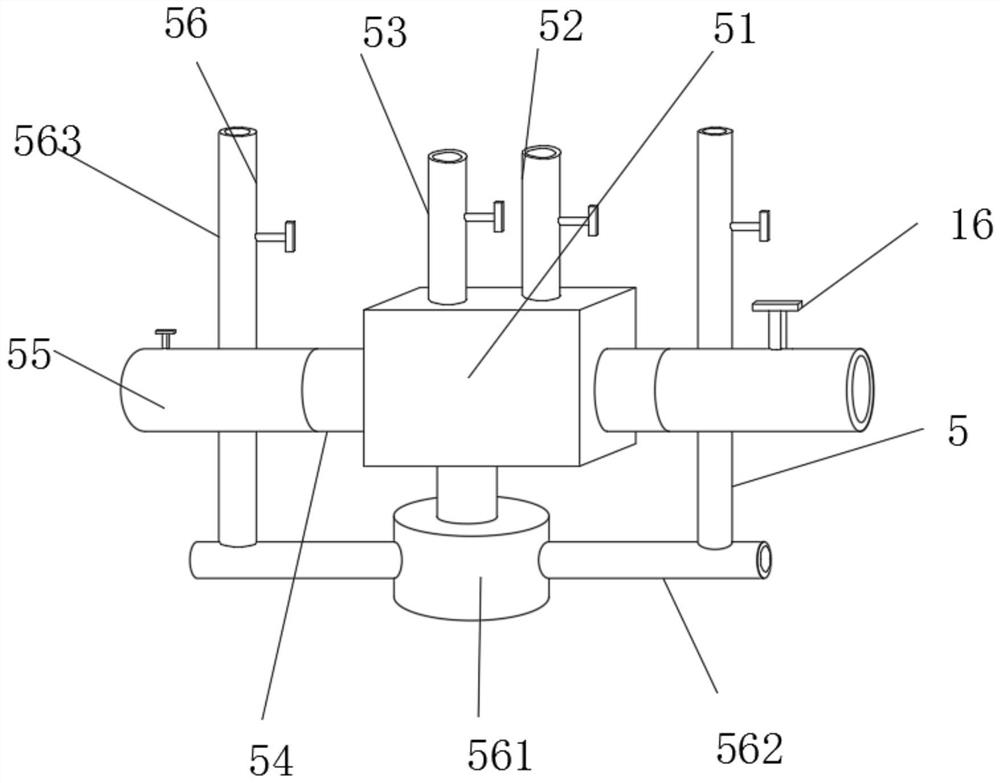

High-temperature calcining and grinding integrated machine for metal-acetylacetone complexes

PendingCN110142005ARealize circular crushingImprove production efficiencySievingScreeningEngineeringCalcination

The invention discloses a high-temperature calcining and grinding integrated machine for metal-acetylacetone complexes. The integrated machine comprises a calcinator main body, a feed pipe, a feed pretreatment assembly, a discharge pipe, a grinding tank, a filter plate, a cyclic grinding assembly, a vibratory filter assembly, an inclined plate, a discharge port, a first support, a second support,a bearing and a feed hopper, wherein the feed pipe is fixedly arranged on an outer wall of one side of the calcinator main body, and the feed pretreatment assembly is arranged at one end of the feed pipe. The high-temperature calcining and grinding integrated machine for metal-acetylacetone complexes is compact in structure and can achieve synchronous high-temperature calcining and grinding of metal-acetylacetone complexes; traditional division of the work is avoided, so that the production efficiency is improved; the feed pretreatment assembly is disposed in the machine to preliminarily grinda feedstock before calcination, thereby facilitating thorough calcination of the feedstock and improving the calcination quality; and with the cyclic grinding assembly, cyclic grinding of large-grained metal complexes is realized, guaranteeing later accepted and uniform grain size of a finished product.

Owner:HUNAN LILING HONGYU HONGCI CERAMICS

Gypsum calcining system

The invention discloses a system for calcinating plaster and a calcinating method thereof. The system includes a crusher for crushing the plaster material, a plaster drying device for drying the crushed plaster material, an oscillating sieve for sieving the dried plaster material, a calcinatory of a fluid bed for calcinating the sieved plaster material, a storage tower for storing the calcinated plaster as well as a hot air boiler for providing a thermal source for the plaster drying device and the calcinatory of the fluid bed. By adopting the device which first dries and then calcinates in the invention greatly promotes the efficiency and improves the quality of calcinating; besides, by adopting the single storage tower to carry out cooling, the efficiency of the whole system is greatly improved; the crushing and sieving of the plaster material guarantees that the calcinatory of the fluid bed sufficiently calcinates the plaster material, thus facilitating the production quality.

Owner:潍坊天洁环保科技有限公司

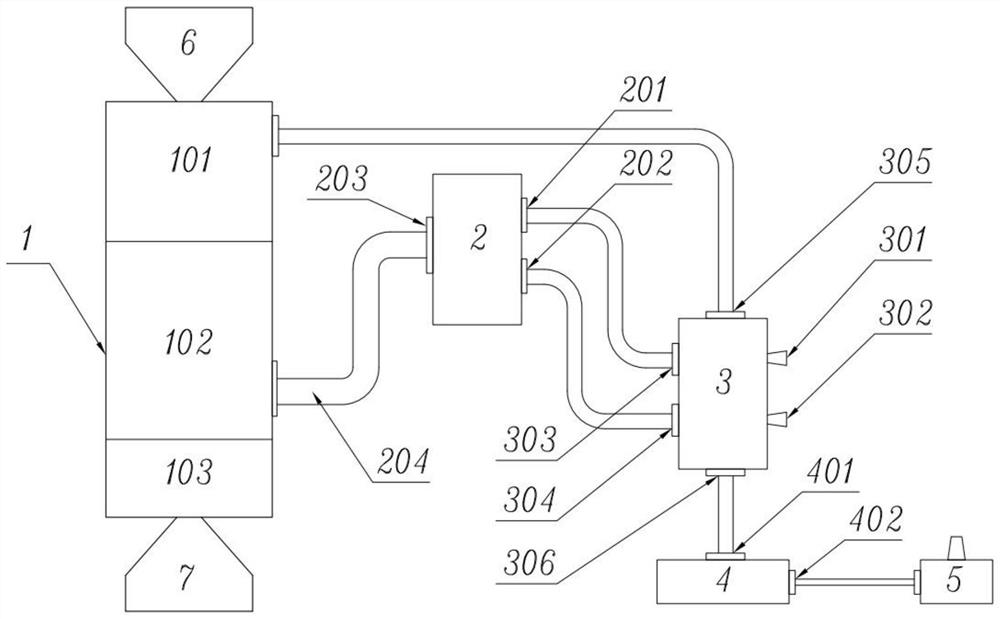

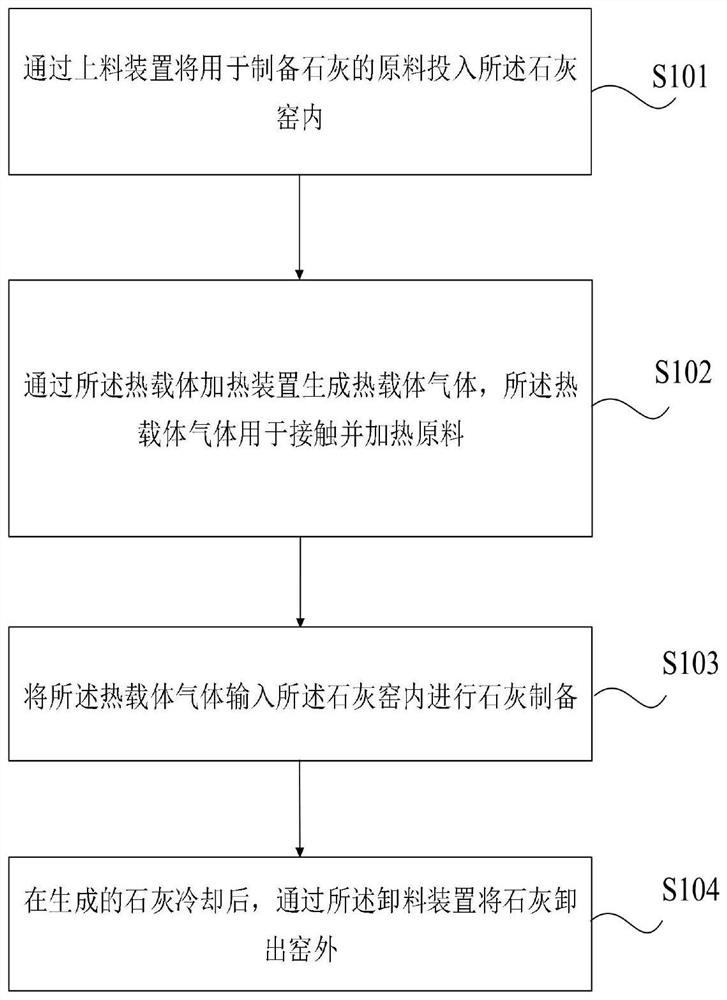

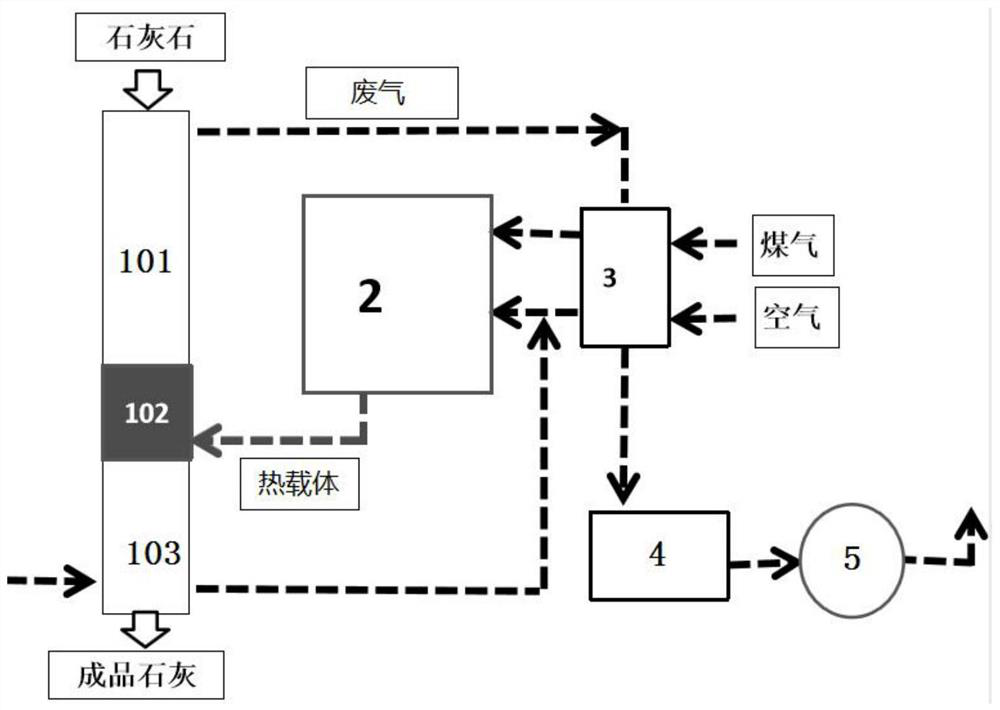

Lime kiln and lime preparation method

The embodiment of the invention provides a lime kiln and a lime preparation method. The lime kiln comprises a lime kiln body and one or more heat carrier heating devices arranged outside the kiln body; the heat carrier heating device comprises a fuel gas input port, an air input port and a heat carrier output port; the kiln body is connected with the heat carrier output port through a heat carrier conveying pipeline; and a high-temperature-resistant lining is laid on the inner wall of the heat carrier conveying pipeline. When the device is used for preparing lime, no combustion flame exists in the kiln, but the heat carrier heating device is used for providing hot flue gas for the lime kiln so as to heat raw materials in the kiln, so that the temperature and the pressure of heat carrier gas can be accurately controlled, the temperature and the pressure in the lime kiln are stable, and the calcining efficiency is improved.

Owner:明光瑞尔竞达科技股份有限公司

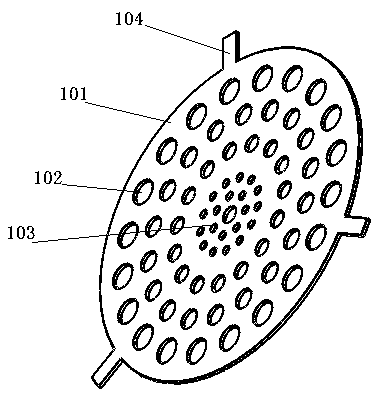

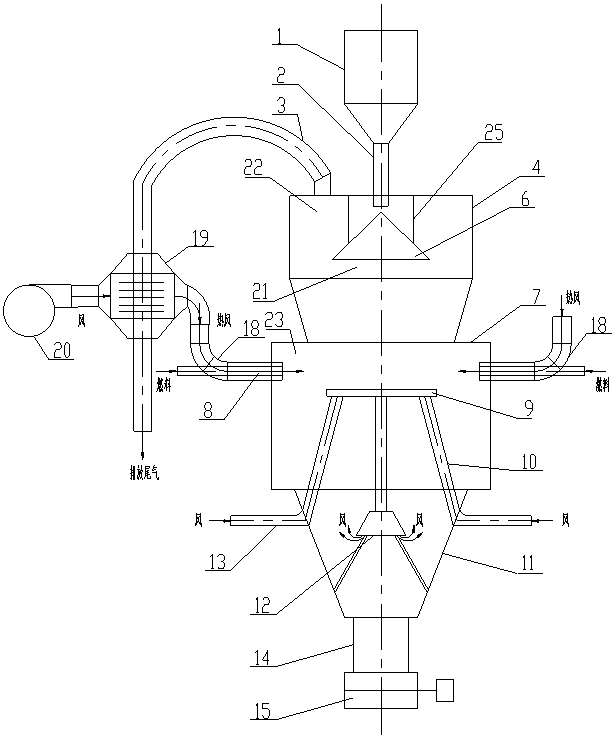

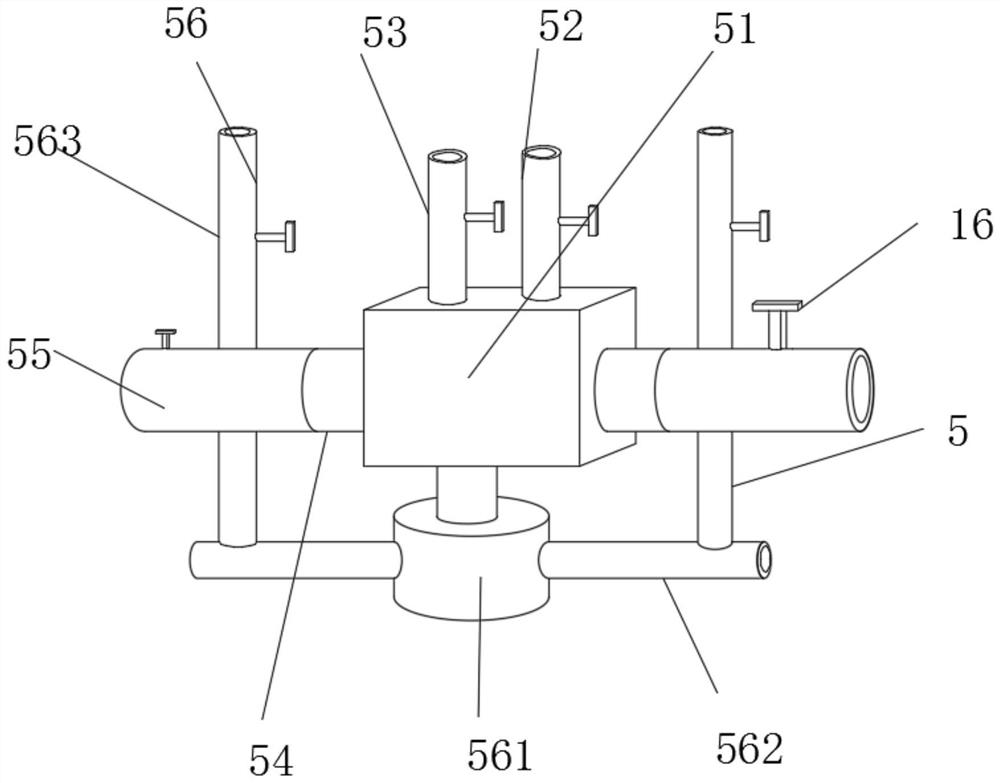

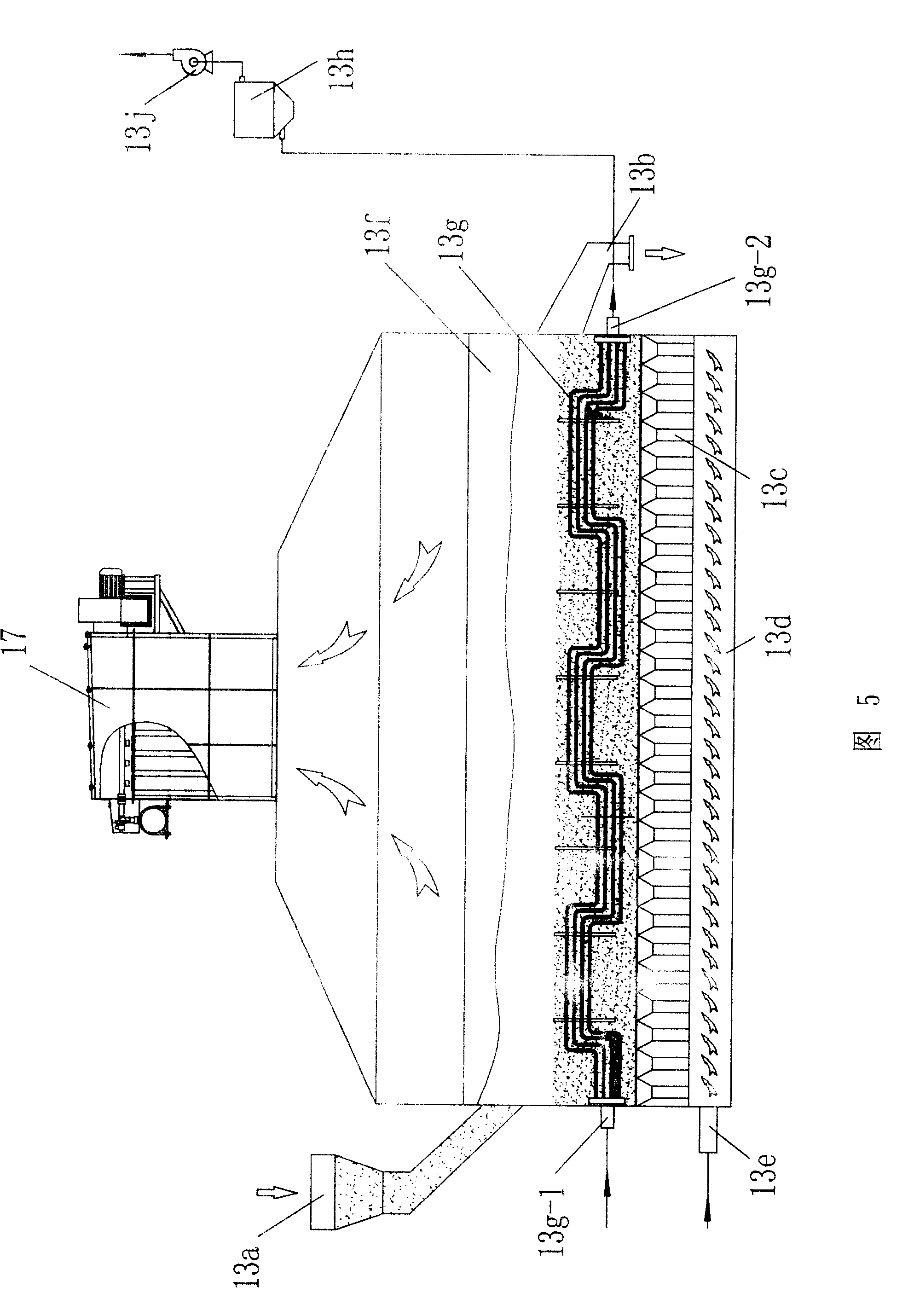

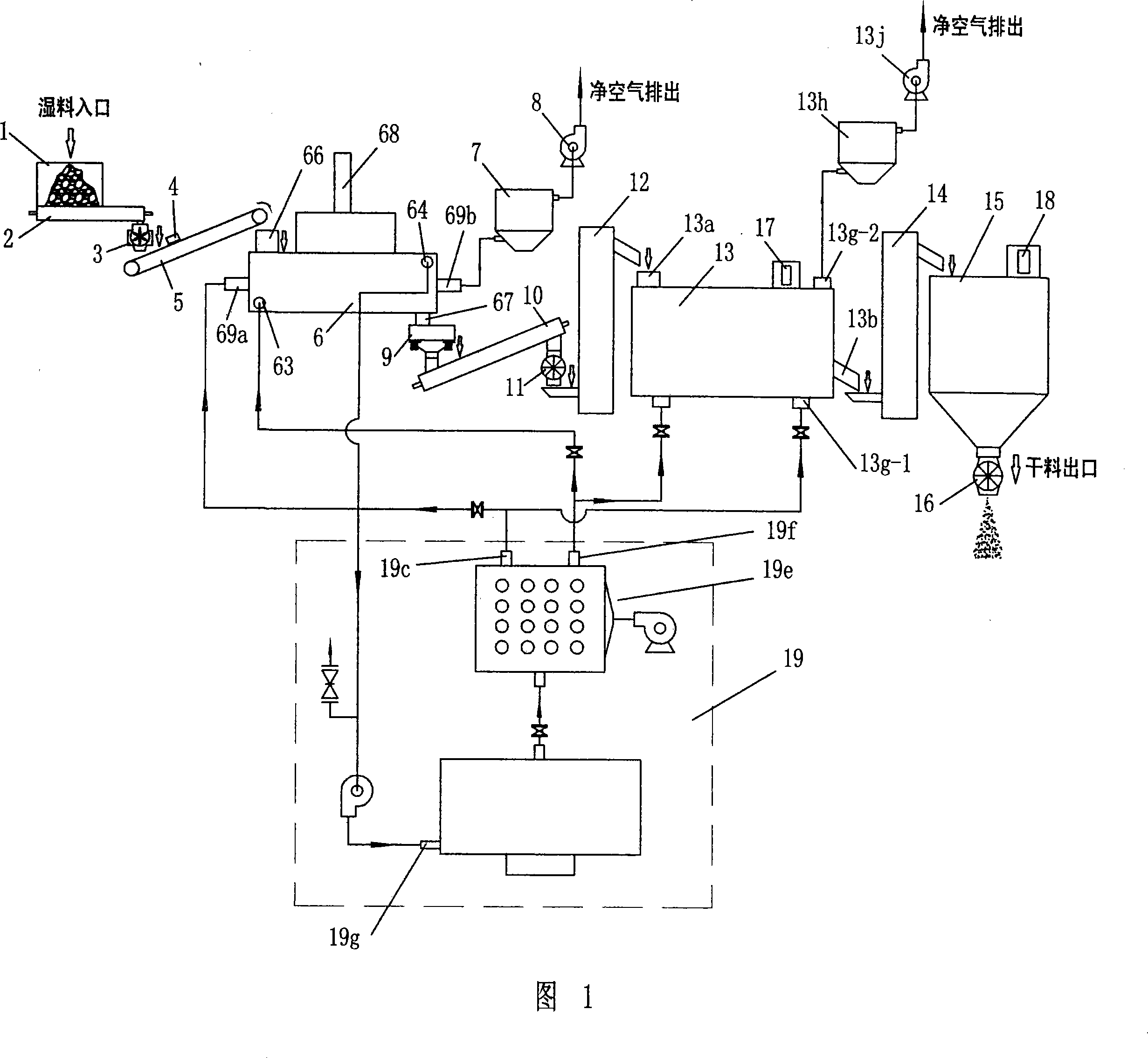

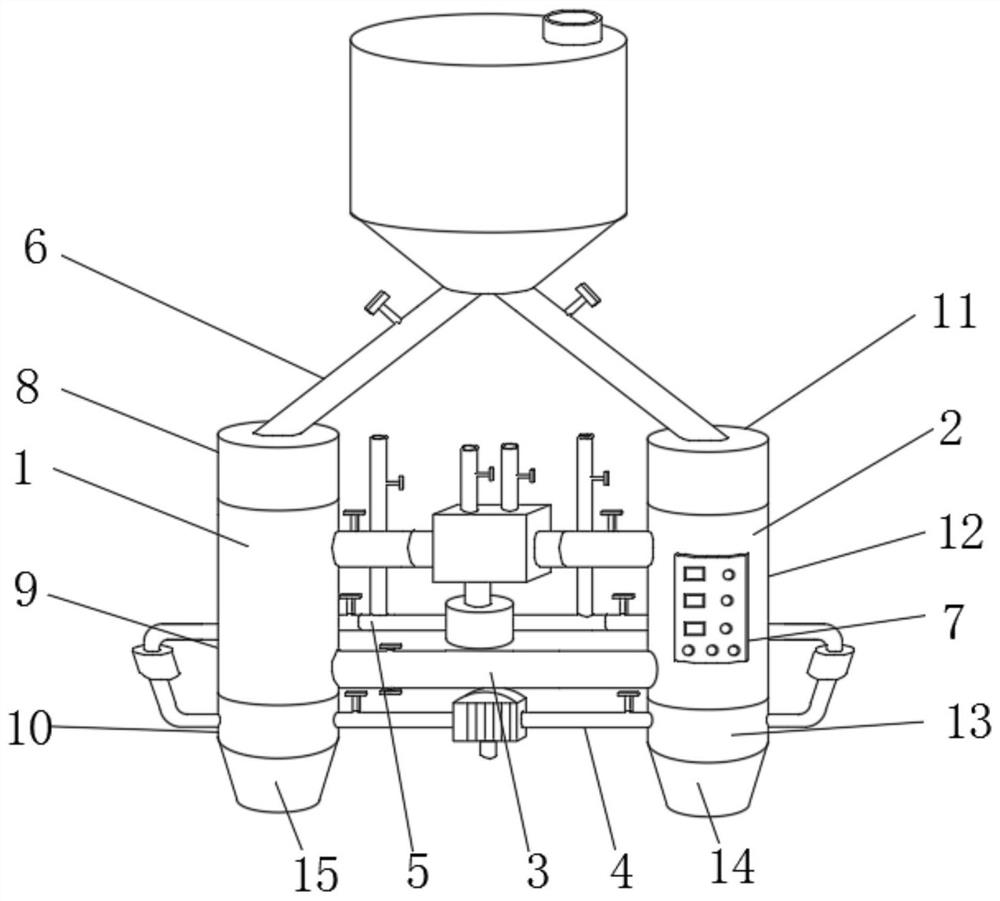

Device for preparing light calcined magnesia and collecting carbon dioxide

PendingCN111825350AEmission reductionReduce heat loadCombination devicesProductsHot air ovenCombustion

The invention relates to light calcined magnesia production, in particular to a device for preparing light calcined magnesia and collecting carbon dioxide. A feeding machine of the device is connectedwith a flash dryer, the flash dryer is respectively communicated with a multi-stage preheating cyclone device and a bag-type dust collector through pipelines, and the multi-stage preheating cyclone device is sequentially connected with a jet pulse type entrained-flow bed calcining furnace and a multi-stage recovery cyclone device; a gas circuit of the multi-stage recovery cyclone device is communicated with the multi-stage preheating cyclone device; a material path of the multi-stage recovery cyclone device is connected with the transition material bin, the transition material bin is connected with the gas-material mixing chamber, the bag-type dust collector is connected with the dehumidifying device, carbon dioxide gas enters the heat accumulating type hot blast stove through the three-fluid heat exchanger, and the three-fluid heat exchanger is communicated with the heat accumulating type hot blast stove and is connected with the jet flow pulse type entrained-flow bed calcining furnace through the temperature adjusting chamber. Waste heat of generated CO2 gas and combustion flue gas is utilized reasonably, heat is provided for a preheating and drying device, the CO2 gas and combustion air, and energy consumption is greatly reduced.

Owner:辽宁圣世资源环境科技有限公司

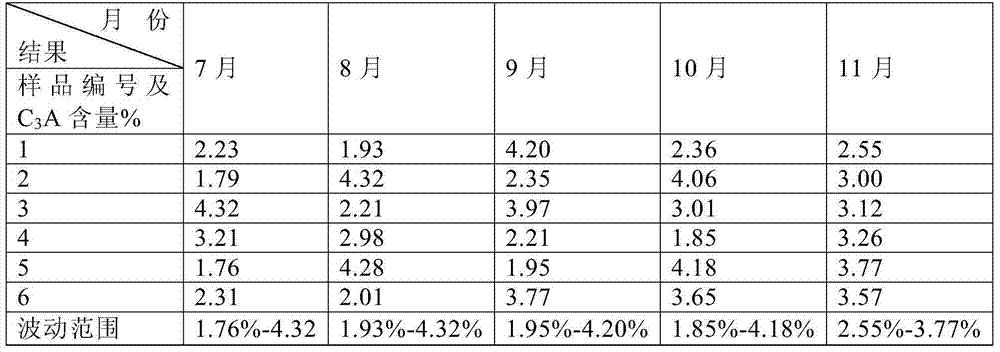

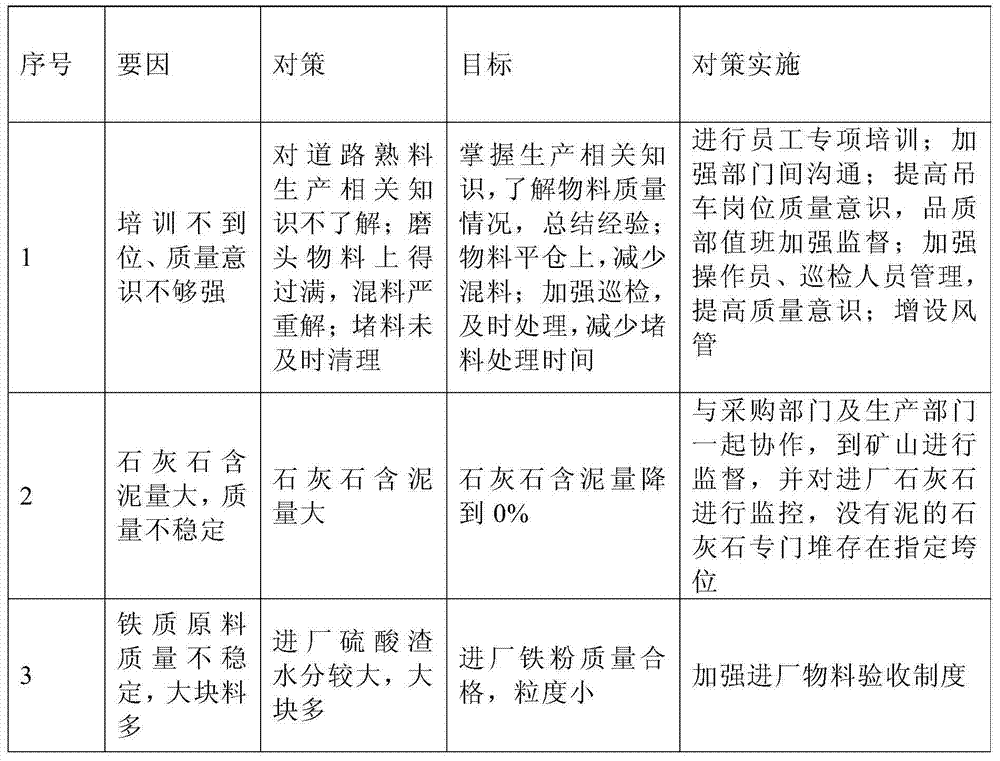

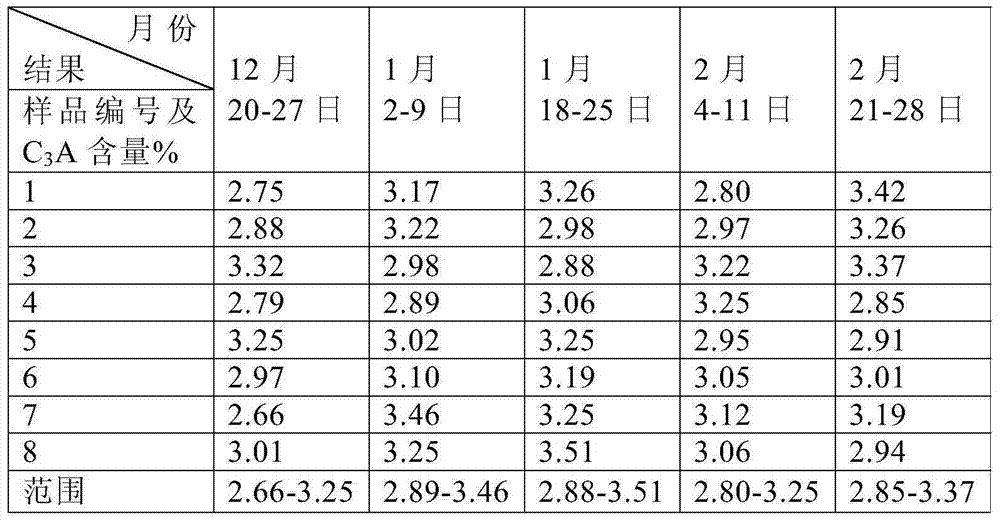

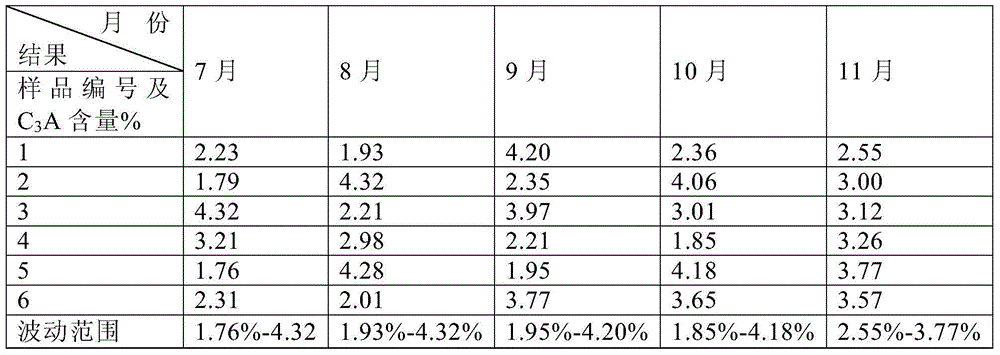

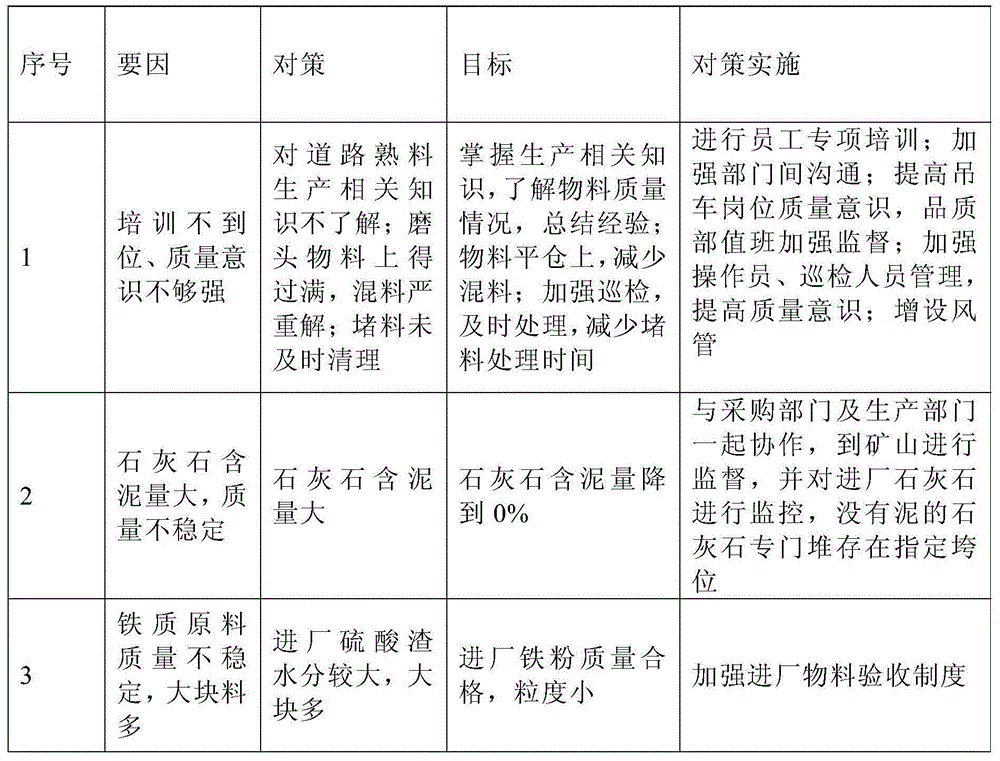

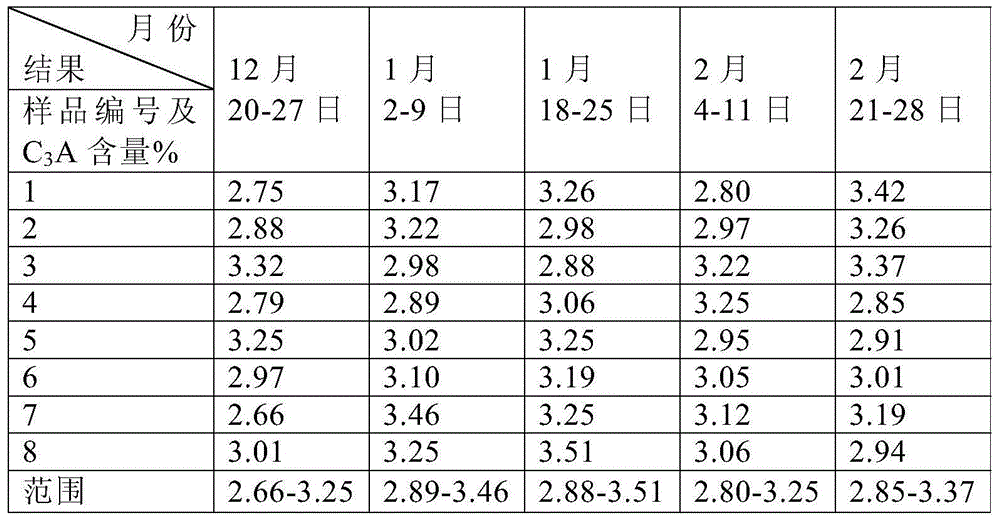

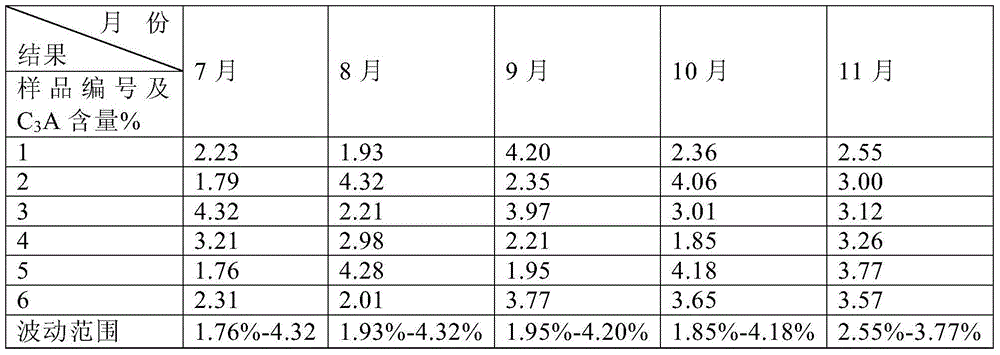

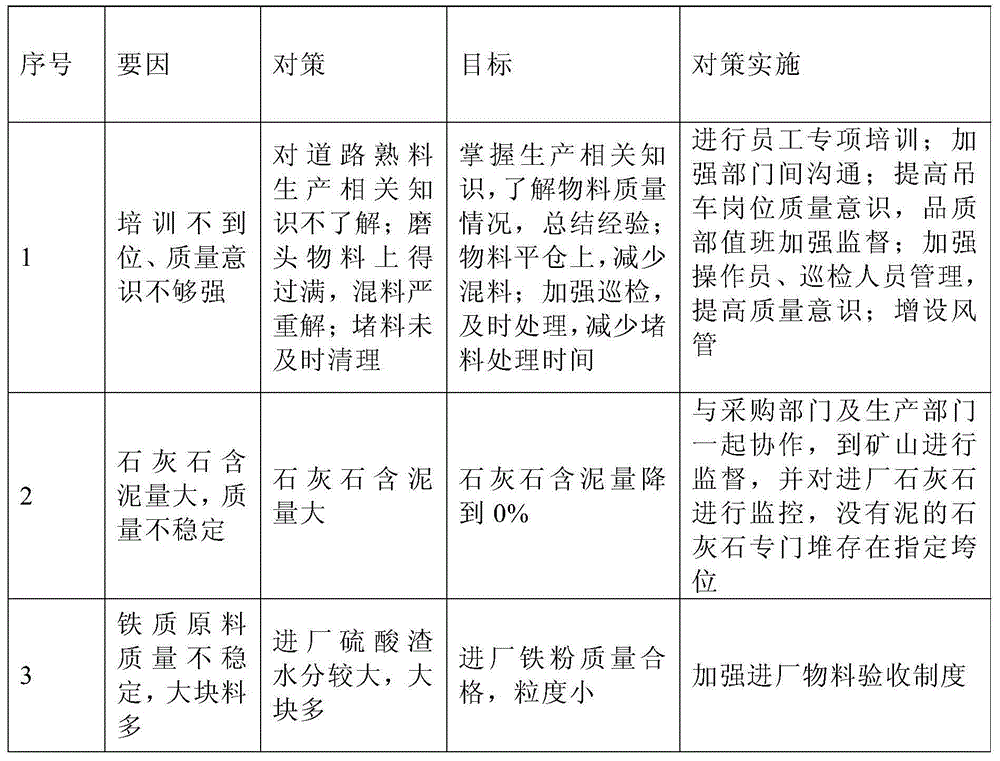

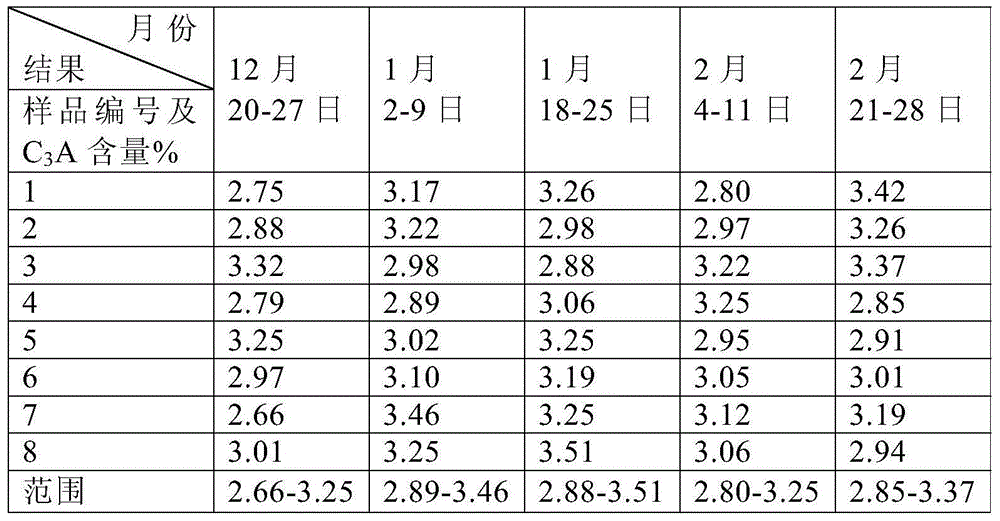

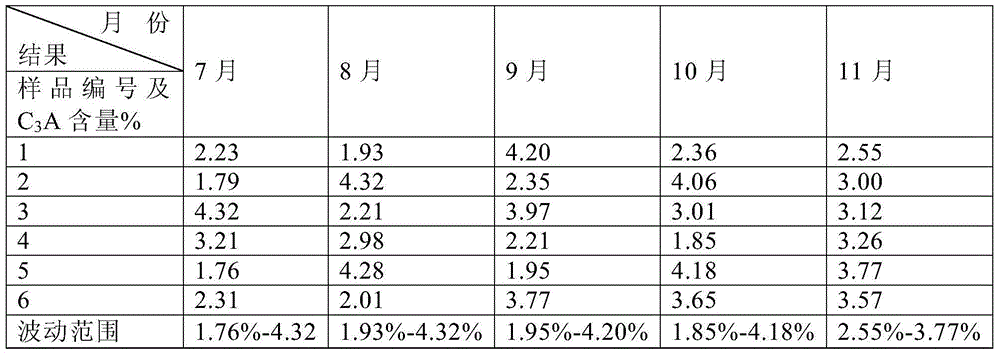

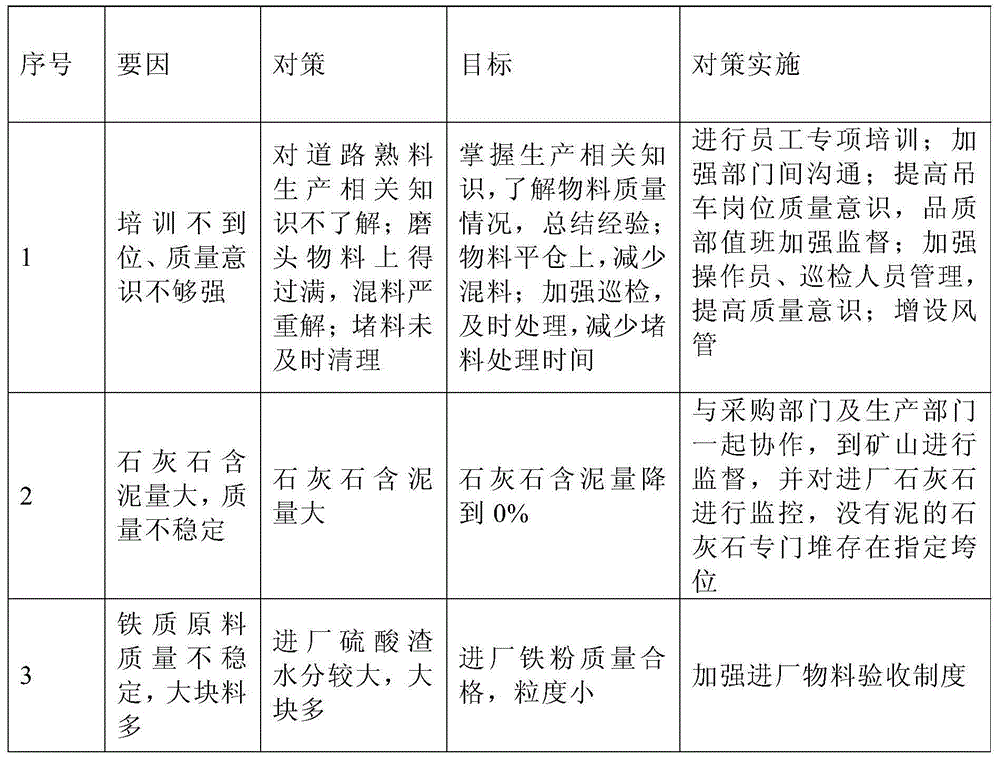

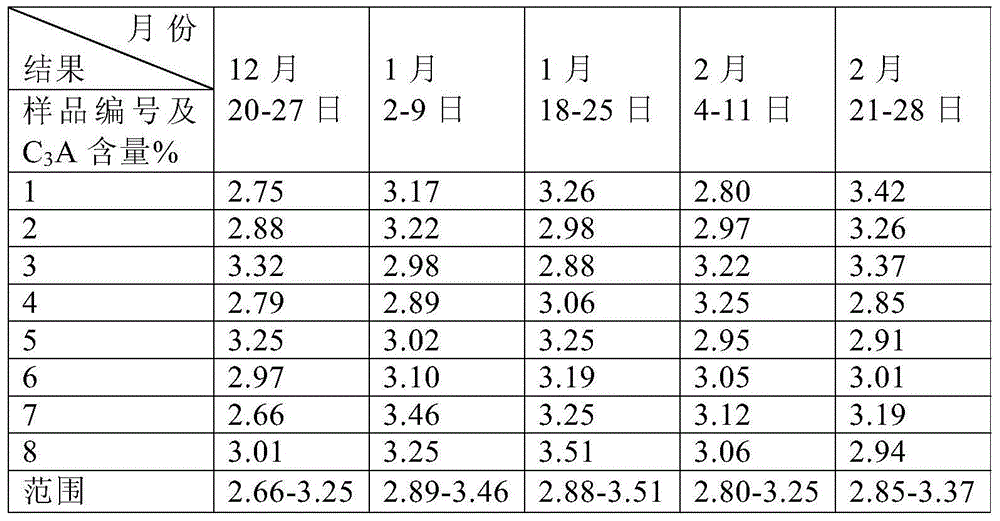

Method for stably controlling content of C3A in clinker in road getting out of kiln

The invention discloses a method for stably controlling the content of C3A in clinker in a road getting out of a kiln. The method comprises the following steps: reducing material mixing on a material flat bin; washing the clinker in the road, and drying after washing for reducing the mud content; additionally arranging a wind pipe on a material stirring site to ensure smooth discharging of materials and improve calcination quality; and adjusting the mixture ratio of the clinker in the road, wherein the clinker in the road comprises the following components in parts by weight: 2.5 parts of C3A, 50.20 parts of CaO, 1.27 parts of MgO, 13.1 parts of SiO2, 2.37 parts of Al2O3 and 3.35 parts of Fe2O3. According to the method for stably controlling the content of C3A in the clinker in the road getting out of the kiln, disclosed by the invention, the defects of large mud content, unstable quality, unreasonable mixture ratio and the like in the prior art can be overcome, and the advantages of large mud content, stable quality and reasonable mixture ratio are further realized.

Owner:GUANGXI YUFENG CEMENT

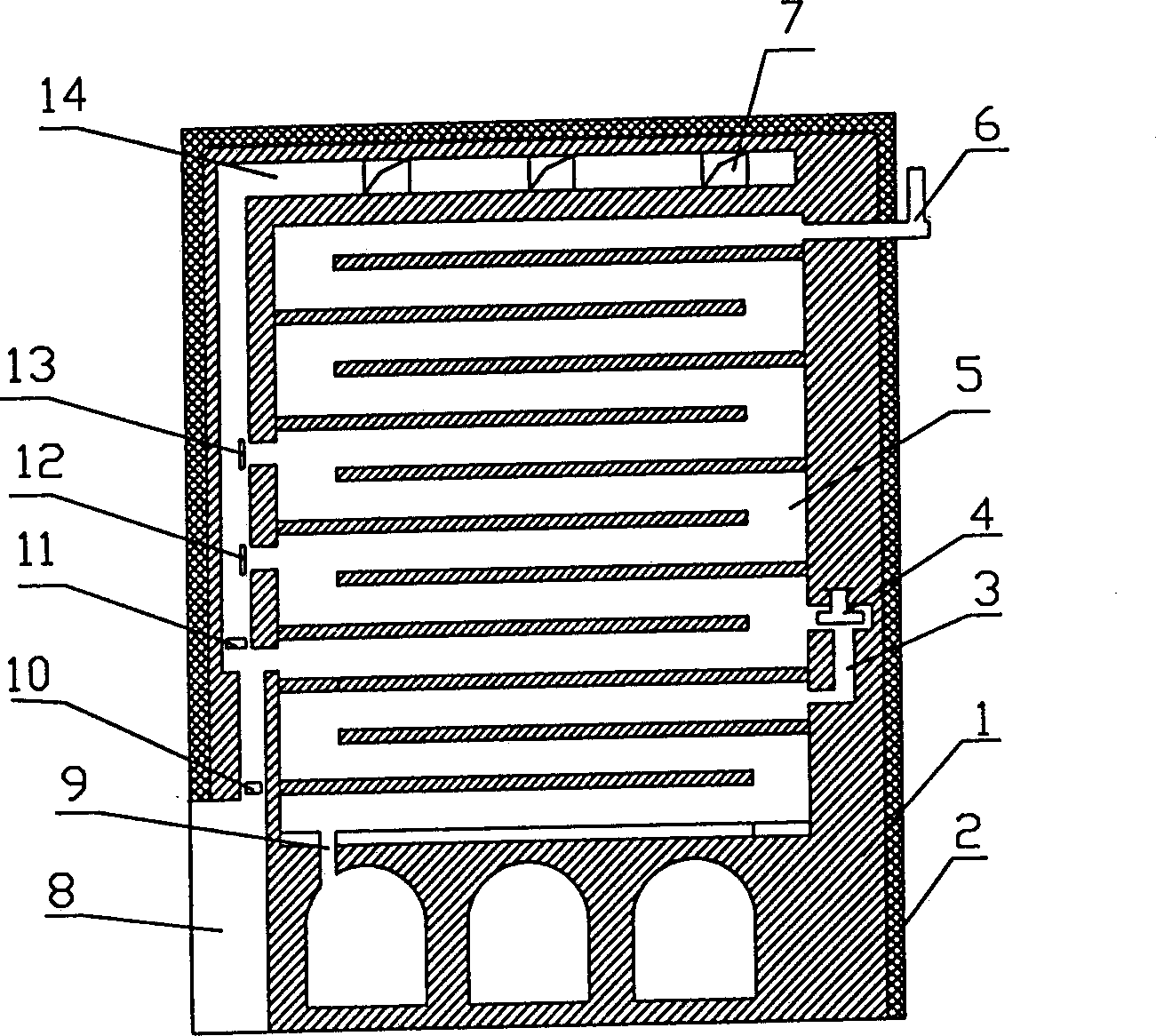

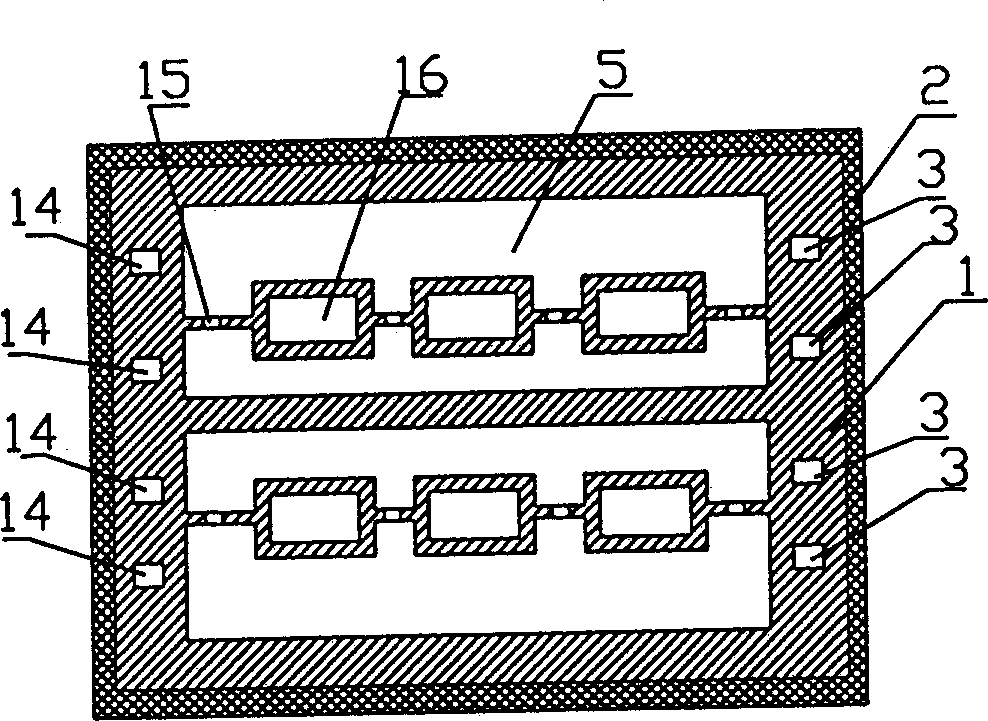

Carbon furnace

InactiveCN1142091CImprove calcination qualityCalcination process lengthenedEnergy inputCombustionEngineering

The carbon furnace has several alternately arranged combustion channels and calcination channels inside the furnace body; burner below the body with mouth communicated with the first layer of combustion channels via shutter; volatile component recovering channel inside the body connected to all the combustion channels; and air preheating channel communicated via air regulating board to the first layer of combustion channels. Normally, the carbon furnace may be closed to utilize the recovered volatile component as fuel for maintaining production. It has the advantags of homogeneous calcination temperature, saving in fuel, high yield and quality of product.

Owner:孙从群

Stability control process for C3A content of road clinker discharged from kiln

The invention discloses a stability control process for the C3A content of road clinker discharged from a kiln. The stability control process comprises the following steps: reducing mixing during material leveling; cleaning and drying the road clinker to reduce the mud content; additionally arranging an air pipe on a poking site to ensure material discharging smoothness and improve calcination quality; regulating the proportion of the road clinker, wherein the regulated road clinker comprises the following components in parts by weight: 3.2 parts of C3A, 50.22 parts of CaO, 1.28 parts of MgO, 12.8 parts of SiO2, 2.5 parts of Al2O3 and 3.7 parts of Fe2O3. According to the stability control process for the C3A content of the road clinker discharged from the kiln, the defects of high mud content, instable quality, unreasonable proportion and the like in the prior art can be overcome, and the advantages of low mud content, stable quality and reasonable proportion can be achieved.

Owner:GUANGXI YUFENG CEMENT

Process for stably controlling C3A content in road clinker taking out of kiln

The invention discloses a process for stably controlling C3A content in road clinker taking out of a kiln. The process comprises the following steps: when materials are spread, reducing material mixing; cleaning the road clinker, drying after cleaning, and reducing silt content; additionally arranging an air duct in the material poking field, ensuring that the materials are fed smoothly, and improving the calcining quality; adjusting the ratio of the road clinker, wherein the road clinker comprises the following constituents in parts by weight after adjustment: 2.8 parts of C3A, 50.18 parts of CaO, 1.15 parts of MgO, 13.3 parts of SiO2, 2.8 parts of Al2O3, and 3.4 parts of Fe2O3. The process for stably controlling the C3A content road clinker taking out of the kiln, disclosed by the invention, can overcome the defects of high silt content, unstable quality and unreasonable ratio in the prior art, so as to achieve the advantages of low silt content, stable quality and reasonable ratio.

Owner:GUANGXI YUFENG CEMENT

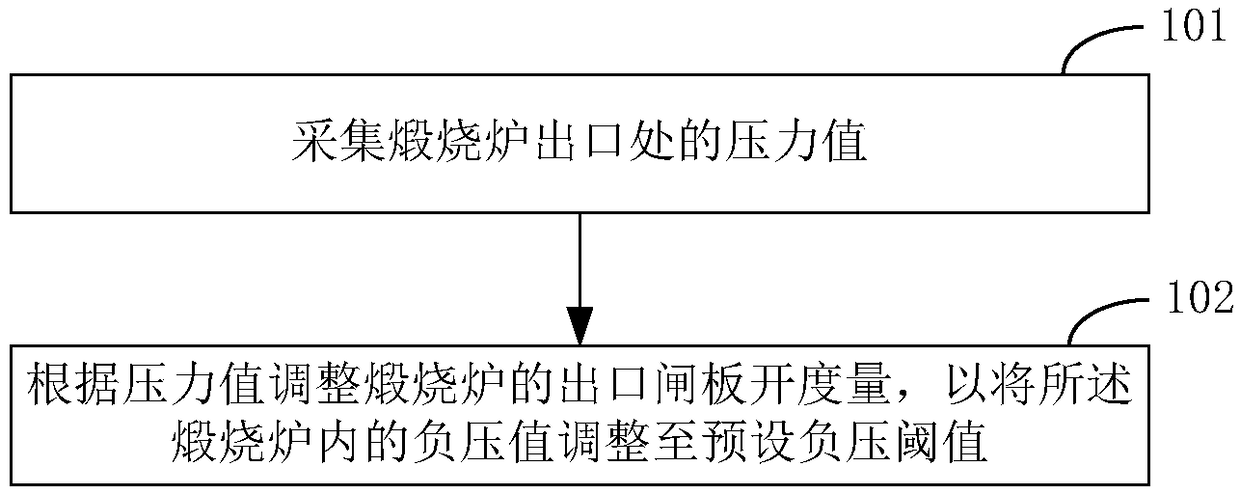

Method and device for controlling negative pressure in calcining furnace, and calcining furnace

InactiveCN109028991APrevent sprayingImprove calcination qualityControl devices for furnacesPressure thresholdMaterials science

The invention provides a method and device for controlling negative pressure in calcining furnace, and calcining furnace.The method comprises the steps that a pressure value at an outlet of the calcining furnace is collected; the opening degree of an outlet gate plate of the calcining furnace is adjusted according to the pressure value so as to adjust a negative pressure value in the calcining furnace to a preset negative pressure threshold. According to the method, the negative pressure in the calcining furnace can be adjusted to the suitable negative pressure threshold in real time, materialspraying is avoided, and meanwhile the calcination quality is improved.

Owner:太仓北新建材有限公司 +1

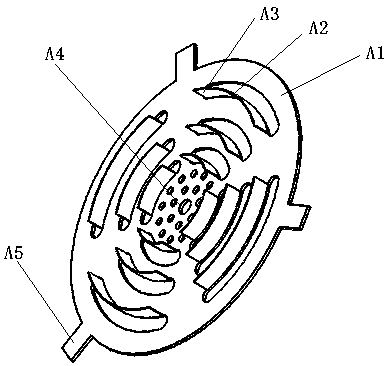

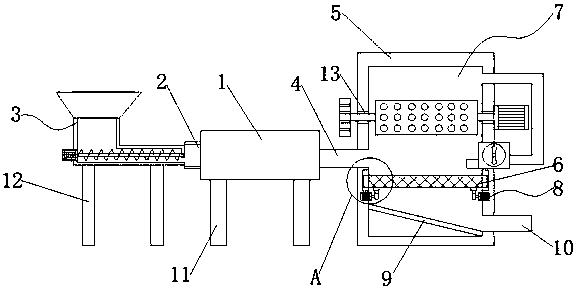

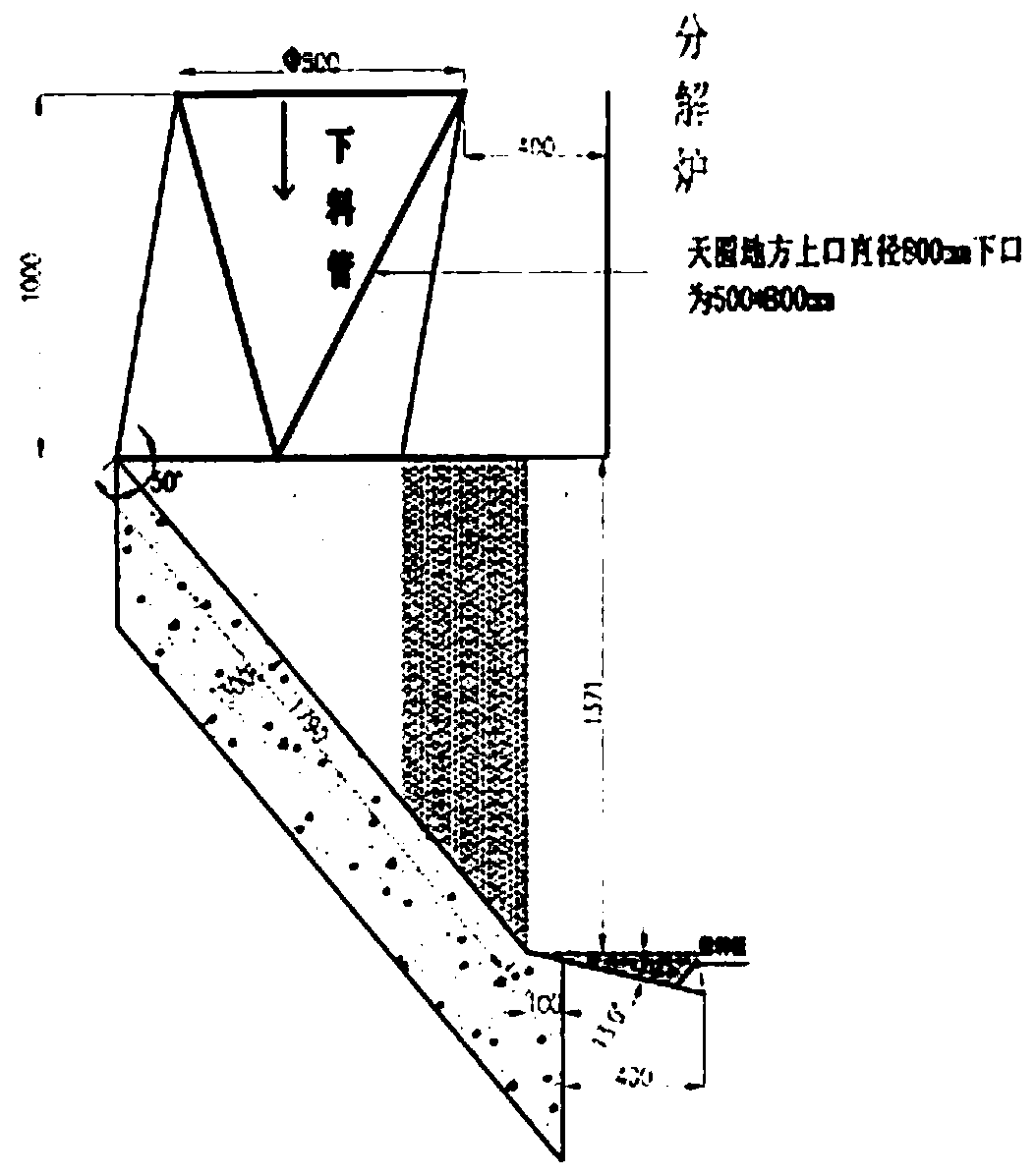

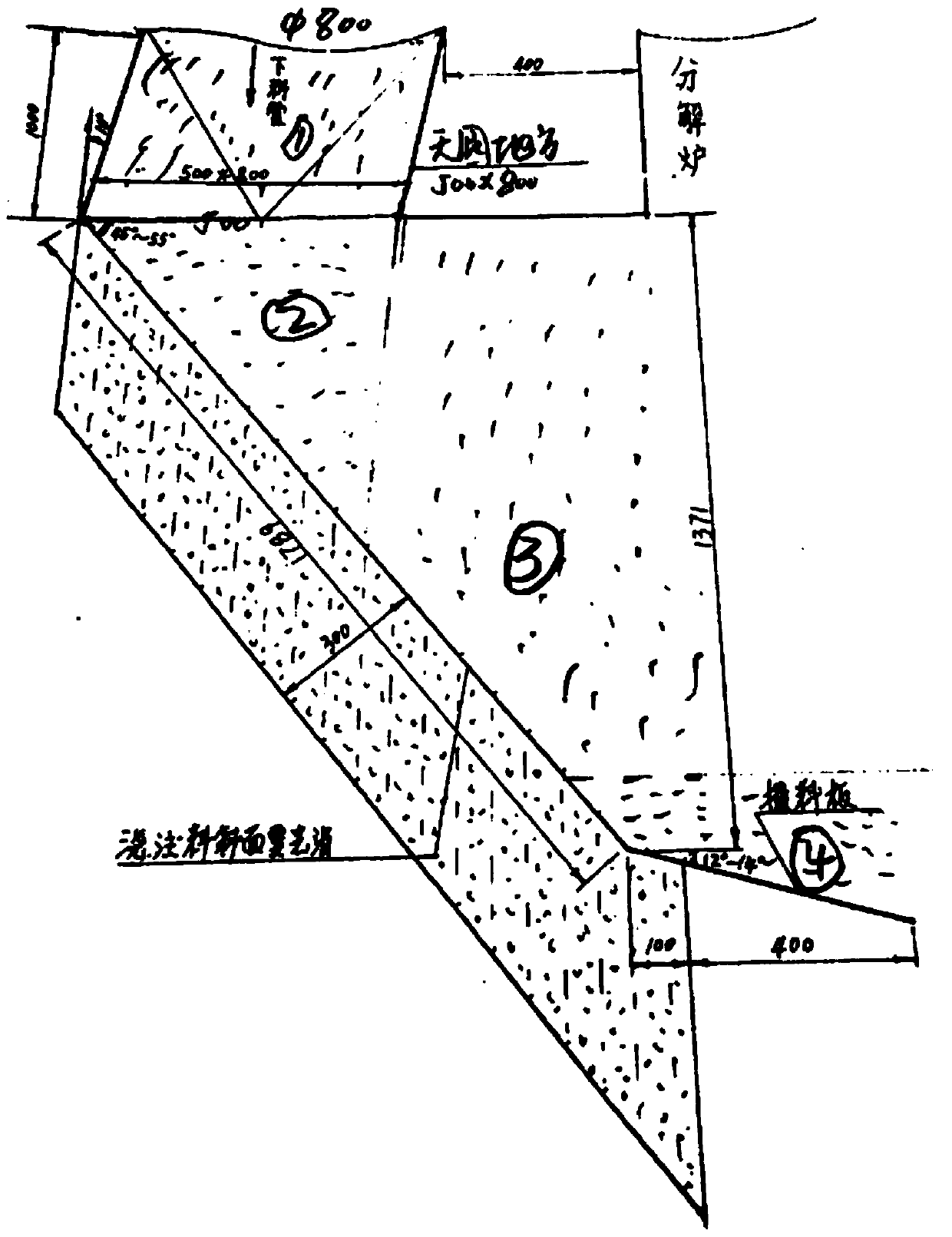

Novel feeding device for decomposing furnace for cement kiln

PendingCN110671940AConducive to calcining quality and energy-saving effectEfficient mixingCharge manipulationChemistryProcess engineering

The invention discloses a novel feeding device for a decomposing furnace for a cement kiln. The novel feeding device comprises an area I, an area II, an area III and an area IV, wherein the area I comprises a blanking pipe with the round top and the square bottom, and the blanking pipe is arranged obliquely; the area II is positioned below the feeding port of the area I, the area III is positionedunder the area II, and the area III and the area II are positioned on the oblique plane with the same gradient; and the area IV is connected to the bottom end of the area III and comprises a materialscattering plate which is tilted downwards. The novel feeding device for the decomposing furnace enhances the dispersion of materials to ensure the effective mixing of the materials with the rising high-temperature airflow in the decomposing furnace, so that all the materials are taken to a 5-stage preheater and deposited into the kiln. Thus, raw materials can be fully and uniformly decomposed, which is conducive to the calcination quality and an energy saving effect.

Owner:阿克苏天山多浪水泥有限责任公司

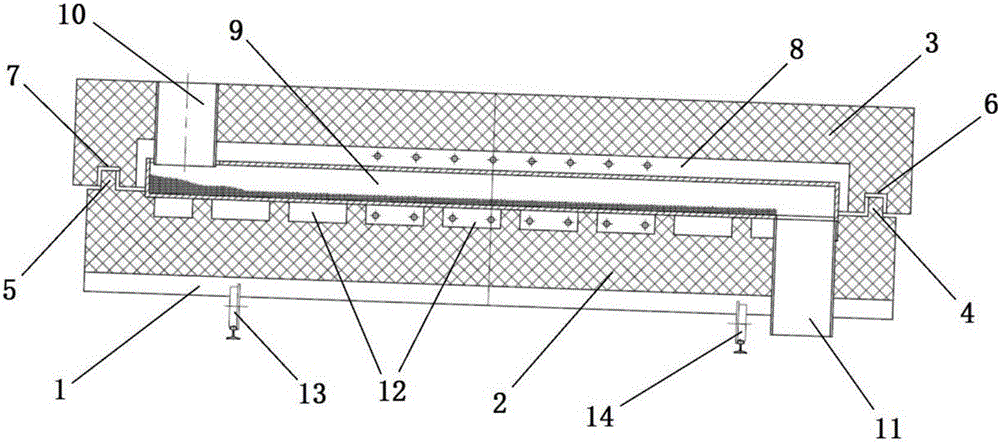

Lime preparation device and lime preparation method

The embodiment of the present invention provides a lime preparation device and a lime preparation method, including a heating device, a belt calciner and a cooling fan; The paving machine, and the screening and collecting mechanism arranged under the discharge end of the trolley; the trolley is divided into a preheating section, a calcination section and a cooling section in turn; the preheating section, the calcination section, and the cooling section There are gas hoods on the top and bellows on the bottom; pipe connections are provided on the top of each gas hood and the bottom of the bellows; the hot air outlet of the heating device is connected with the gas hood of the calcination section by pipelines; the cooling fan and the cooling The bellows are connected by pipes. The raw materials on the belt calciner are heated by the hot air with stable temperature and pressure supplied by the heating device, which shortens the lime calcination time, and because the belt calciner has a large amount of material, the production efficiency of the lime preparation process is greatly improved, which can be Significantly increase the stand-alone production capacity of lime preparation.

Owner:明光瑞尔竞达科技股份有限公司

A phosphogypsum calciner

Owner:ZHENGZHOU SUNDY BUILDING TECH

A double-chamber kiln burning fuel with low calorific value

ActiveCN111908811BRaise the combustion temperatureImprove calcination qualityCombustion chamberEngineering

The invention discloses a double-chamber kiln burning fuel with low calorific value, which includes a No. 1 kiln body and a No. 2 kiln body. The upper middle part of the No. 1 kiln body and the upper middle part of the No. 2 kiln body are jointly fixedly installed with a feeding device, and the upper right end of the No. 1 kiln body and the upper left end of the No. 1 kiln body are jointly fixedly connected with a preheating device. The lower part and the lower part of the left end of the No. 1 kiln body are jointly fixed with a cooling device. The double-chamber kiln for fuel with low calorific value described in the present invention can increase the combustion temperature of fuel with low calorific value through branch pipes, main pipes, combustion chambers and heat storage boxes, and optimize the calcination effect; and the cooling device can realize effective heat dissipation of materials Transformation and recycling further reduce energy consumption; the double-chamber kiln can realize the mutual switching between the two kiln bodies to complete the continuous production of materials; and the feeding device can make the double-chamber kiln unloading convenient and reduce the labor intensity of the staff.

Owner:SHENYANG HONGSHAN TECH

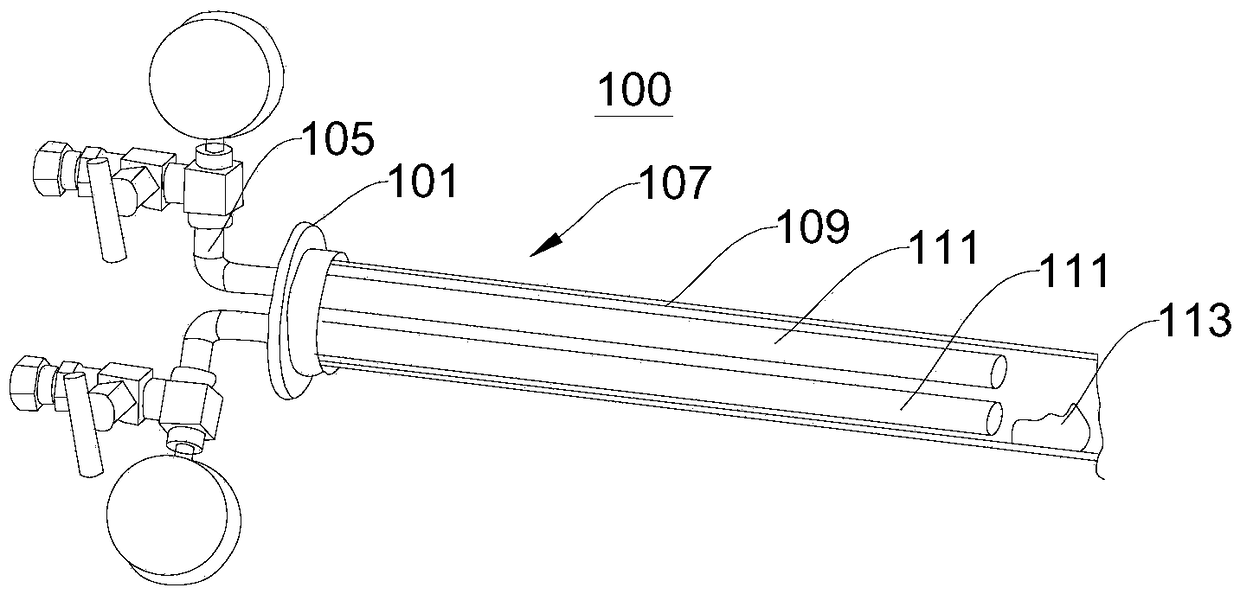

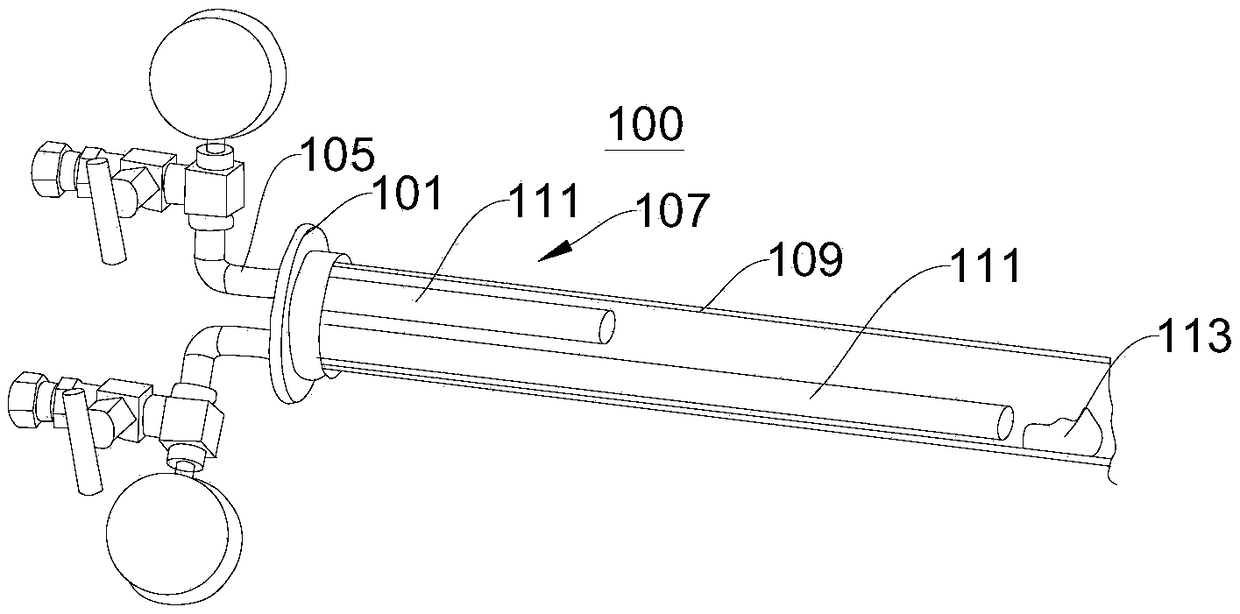

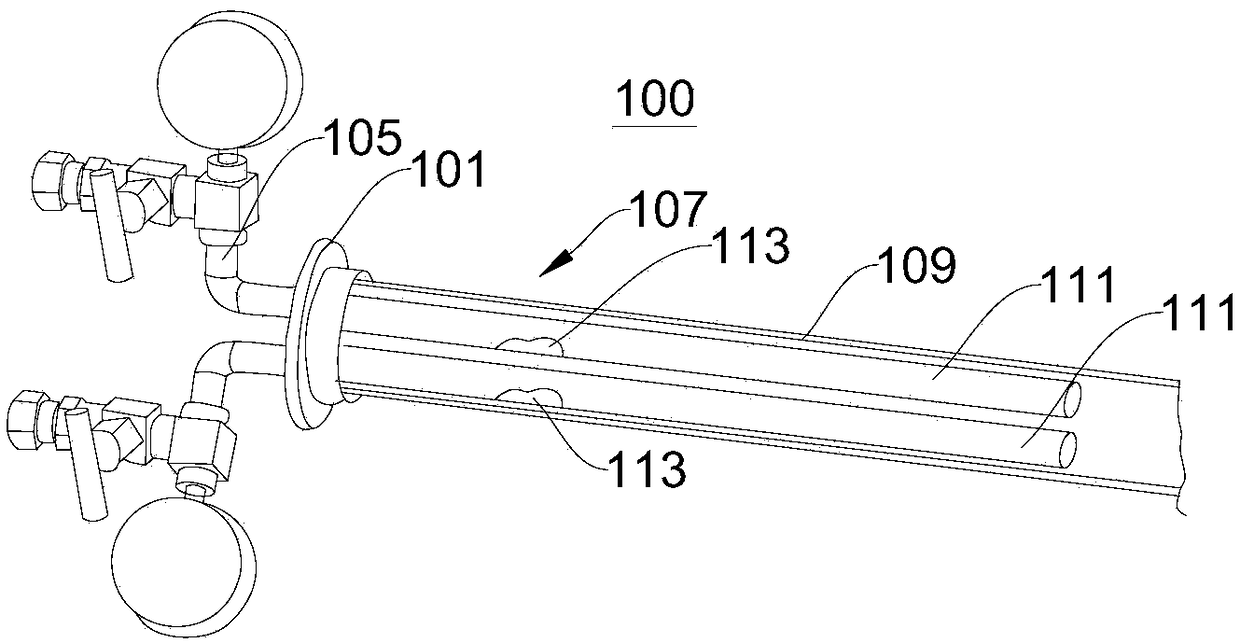

Calcination container and method

InactiveCN109269302AAvoid mixing with each otherImprove calcination efficiencyFurnace typesGas-gas reaction processesEngineeringCalcination

The invention discloses a calcination container and method, and relates to the technical field of calcination. The calcination container comprises a flange, at least two air inlet passages and a vessel body, wherein the flange is provided with at least two air inlets; the air inlet passages and the air inlets are connected in one-to-one correspondence for introducing gas; the container body is used for performing calcination and comprises a large quartz tube and at least two small quartz tubes, wherein the small quartz tubes are located in the large quartz tube, and the small quartz tubes arein one-to-one correspondence with the air inlets. The calcination container has the advantages that two samples can be separately placed in the small quartz glass tubes, so that the samples cannot bemixed with each other during experiments and operation; different atmospheres are introduced through the two air inlets of the flange respectively to meet different reaction conditions required for the experiments; the flow rate of the gas in different air inlets can be controlled respectively, and the ratio of the amount of two substances can be adjusted by adjusting the flow rate; the placementpositions of the samples and the temperature zone position of the reaction between the two samples can be controlled by designing the length of different small quartz tubes.

Owner:UNIV OF JINAN

Stable control method of C3A content in drawn road clinker

The invention discloses a stable control method of a C3A content in drawn road clinker. The stable control method comprises the steps of reducing a mixed material on a flat material warehouse, cleaning road clinker, then drying to reduce a silt content, additionally arranging an air pipe on a poking site to ensure smooth material blanking and improve roasting quality, and adjusting a matching ratio of ingredients of the road clinker to be as follows (in parts by weight): 2.6 parts of C3A, 50.26 parts of CaO, 1.24 parts of MgO, 12.21 parts of SiO2, 2.34 parts of Al2O3, and 3.23 parts of Fe2O3. The stable control method of the C3A content in the drawn road clinker can overcome defects such as a high silt content, unstable quality and the unreasonable matching ratio in the prior art to achieve the advantages of low silt content, stable quality and reasonable matching ratio.

Owner:GUANGXI YUFENG CEMENT

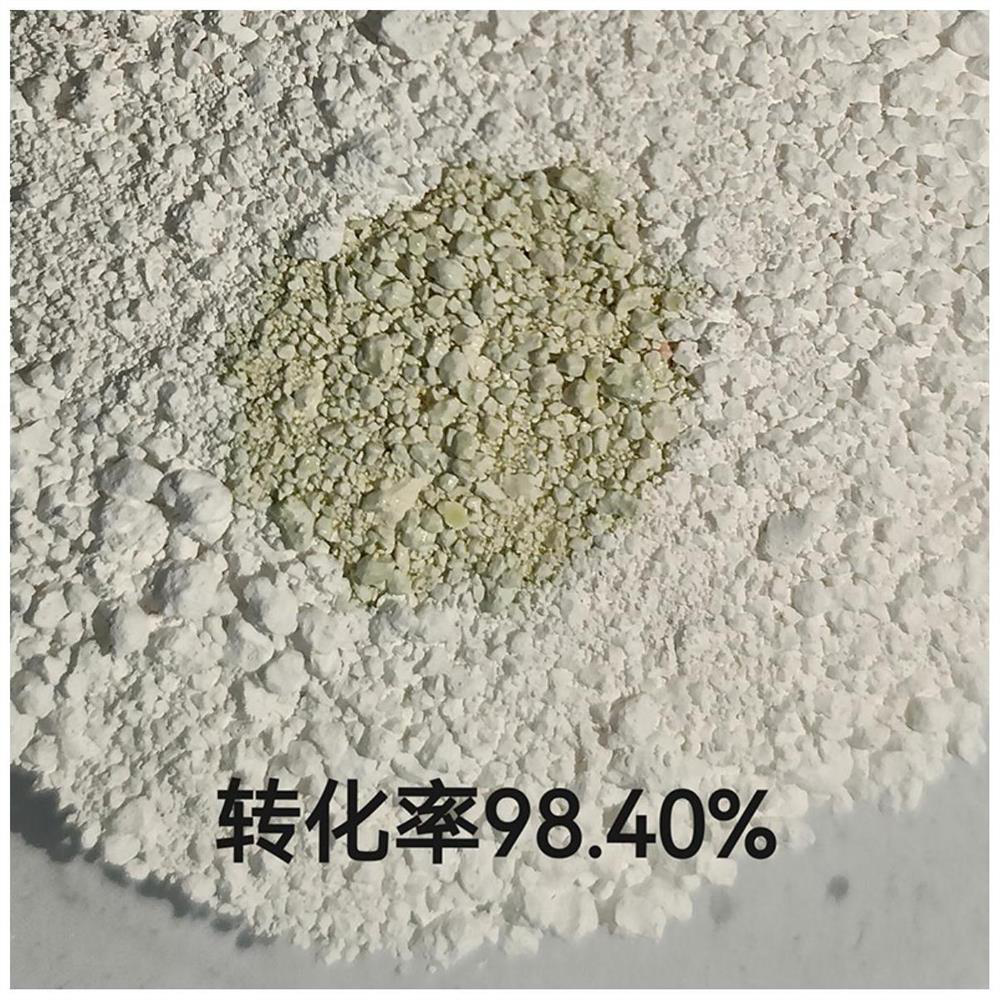

Method for rapidly determining conversion rate of titanium dioxide falling into kiln by sulfuric acid method

PendingCN114705707AImprove calcination qualityQuick checkMaterial analysis using wave/particle radiationMaterial analysis by observing effect on chemical indicatorProcess engineeringUniversal indicator

The invention provides a method for rapidly determining the conversion rate of a titanium dioxide kiln falling product by a sulfuric acid method, which at least comprises the following steps: S1, taking a titanium dioxide kiln falling product sample, and adding a universal indicator to enable the kiln falling product sample to develop color; s2, the color development result shown in the step S1 is substituted into a corresponding relation table of titanium dioxide kiln falling product color development and conversion rate shown in a table 1, and the kiln falling product sample conversion rate is determined; compared with the prior art, the indicator method is adopted for rapidly and accurately detecting the conversion rate of the falling kiln product, the qualified condition of the conversion rate of the falling kiln product can be rapidly known in time, production personnel can know the conversion rate index in the first time, judge the production process condition and take corresponding countermeasures, process control can be rapidly and effectively adjusted in time, and the production efficiency is improved. And meanwhile, energy conservation and consumption reduction are facilitated.

Owner:LOMON BILLIONS GRP CO LTD

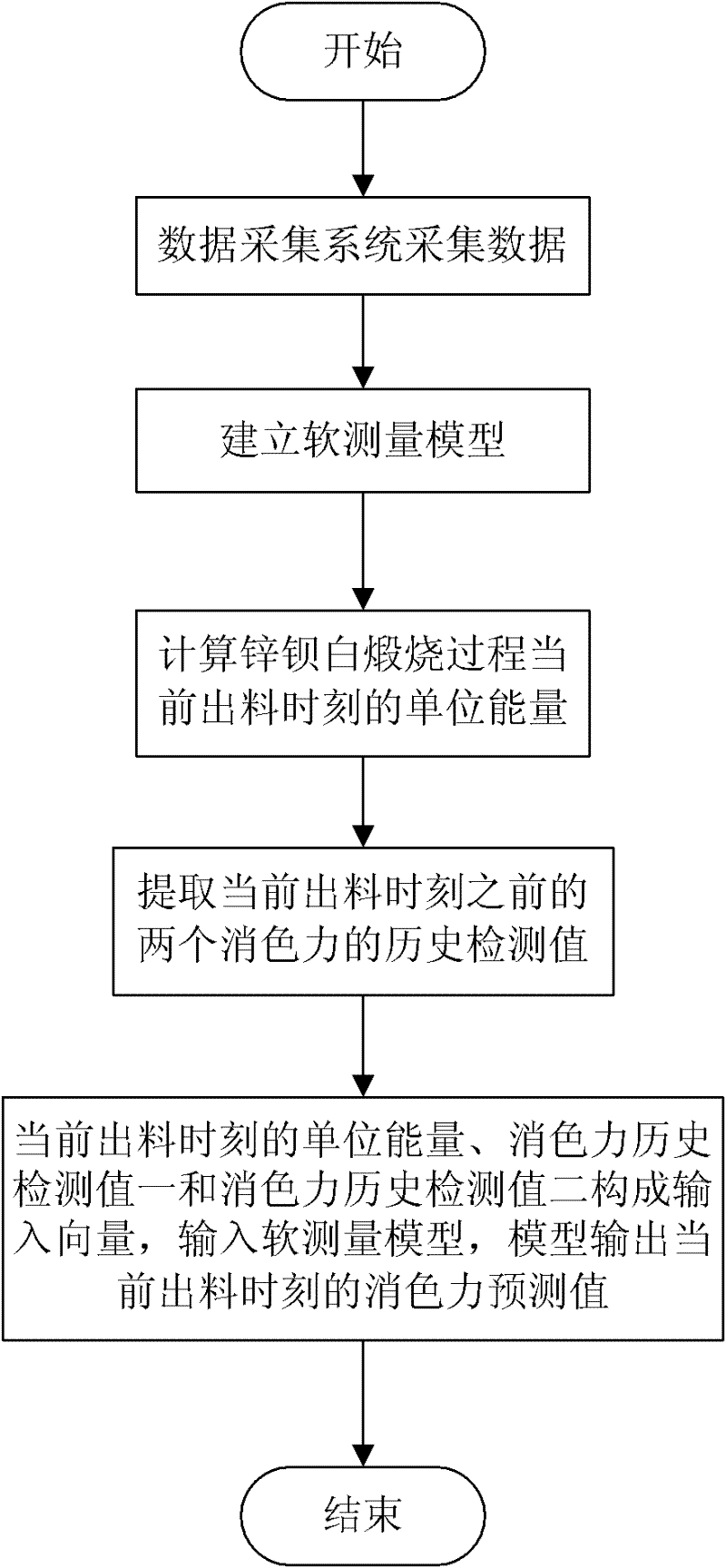

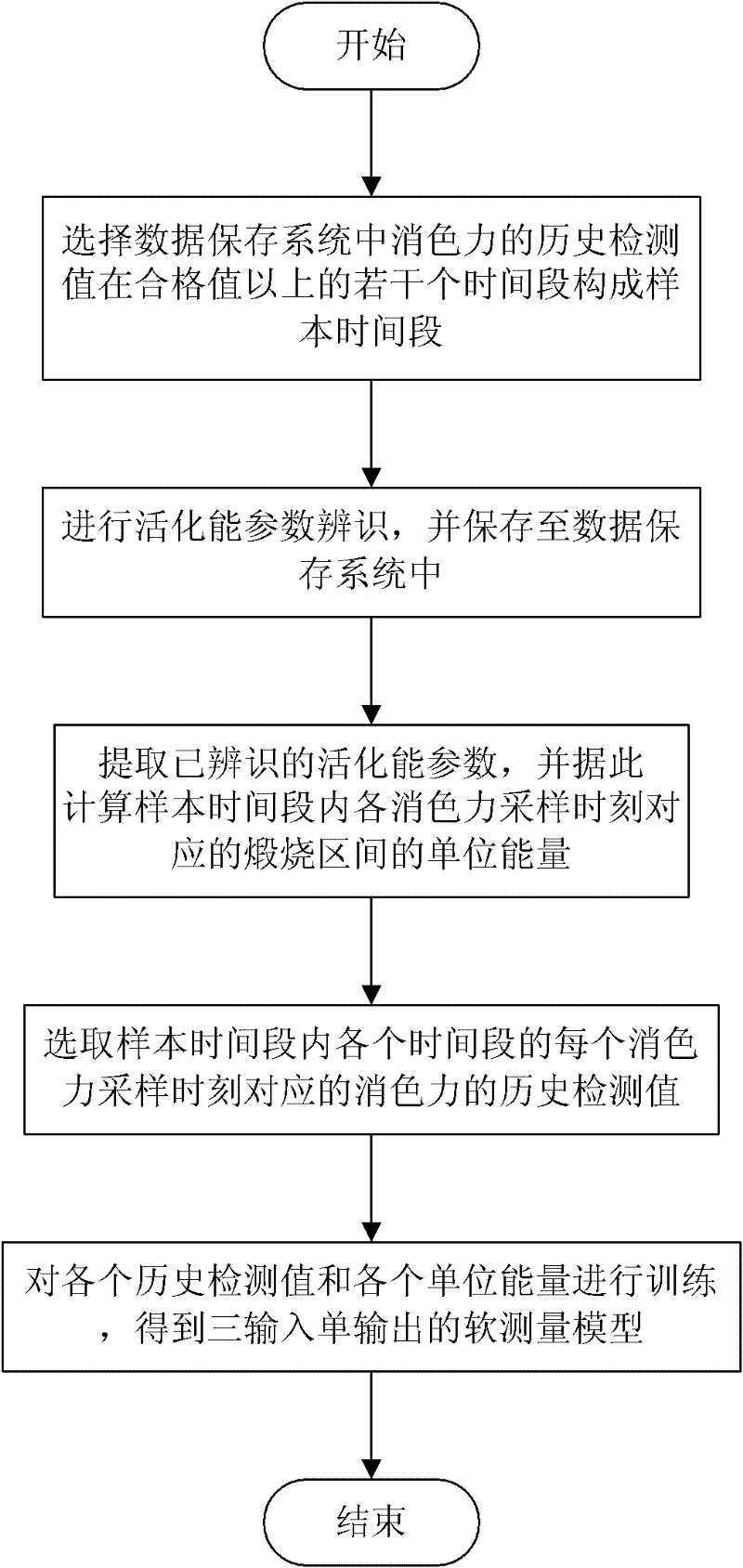

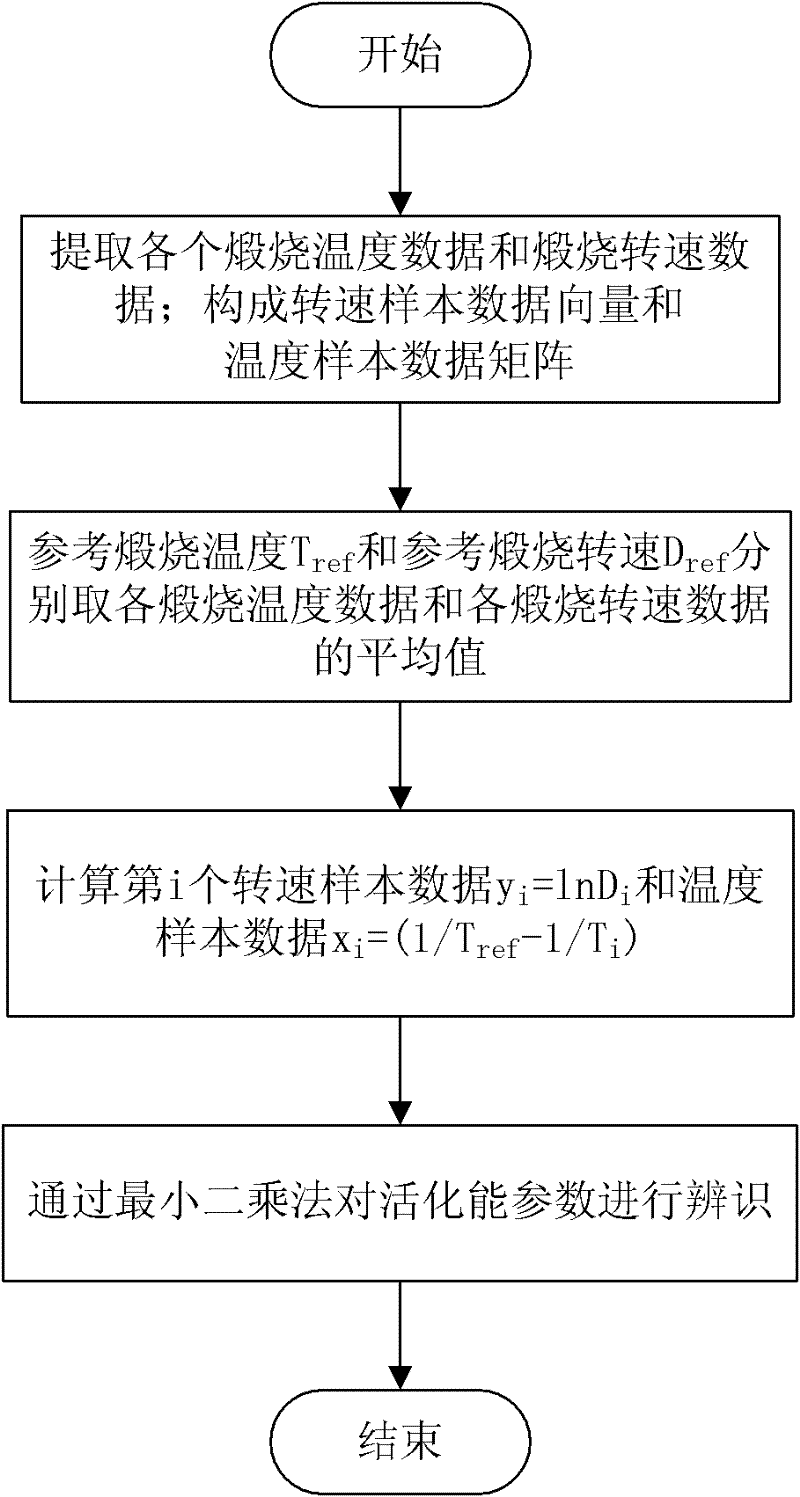

Soft measurement method of reducing power quality index in process of calcinating lithopone

InactiveCN101986144BReduce online predictionRealize online predictionMaterial heat developmentSpecial data processing applicationsPower qualityReduced model

The invention provides a soft measurement method of a reducing power quality index in the process of calcinating lithopone, comprising the following steps: (1) acquiring the historical detection values of calcination temperature data, calcination speed data and reducing power; (2) establishing a soft measurement module; (3) calculating the unit energy of the lithopone at the discharging moment inthe current lithopone calcination process; (4) extracting two historical detection values of the reducing power at two reducing power sampling moments before the discharging moment in the current lithopone calcination process from a data storage system in step (1) to respectively serve as a first historical detection value and a second historical detection value; and (5) constituting the unit energy obtained in step (3) and the first historical detection value and the second historical detection value which are obtained in step (4) into input vectors, and inputting the input vectors into the soft measurement module in step (2) to obtain a predicated value of the reducing power at the discharging moment in the current calcination process to complete soft measurement. The method has the advantages that the module structure is simplified and the like.

Owner:SOUTH CHINA UNIV OF TECH

Airflow desulphurization gypsum calcination system

The invention discloses an airflow desulphurization gypsum calcination system, which comprises a feeding storage system, a quantitative reclaiming system, a scattering machine, a post-calcination device, an electric dust collector, a modifying machine and a heat source stabilizing system, wherein the feeding storage system is used for delivering and temporarily storing the desulphurization gypsumraw materials; the quantitative reclaiming system is used for quantitatively measuring the desulphurization gypsum raw material which is conveyed by the feeding storage system and for sending the measured desulphurization gypsum raw material to the scattering machine; the scattering machine is used for scattering the desulphurization gypsum raw material of a given quantity which is sent by the quantitative reclaiming system to be dried and calcined in the high-temperature smoke; the electric dust collector is used for separating the desulphurization gypsum which is adequately burned from the smoke; the modifying machine is used for modifying the desulphurization gypsum after the calcinations which is separated from the electric dust collector and make the desulphurization gypsum into the building gypsum - a raw material which is suitable for the production of the gypsum board; and the heat source stabilizing system is used for supplying a stable heat source and for adequately utilizing the surplus heat of the system.

Owner:镇江北新建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com