Carbon furnace

A carbon furnace and furnace body technology, applied in the field of carbon sintering equipment, can solve the problems of uneven temperature, large specific resistance, low output, etc., and achieve the effect of improving calcination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

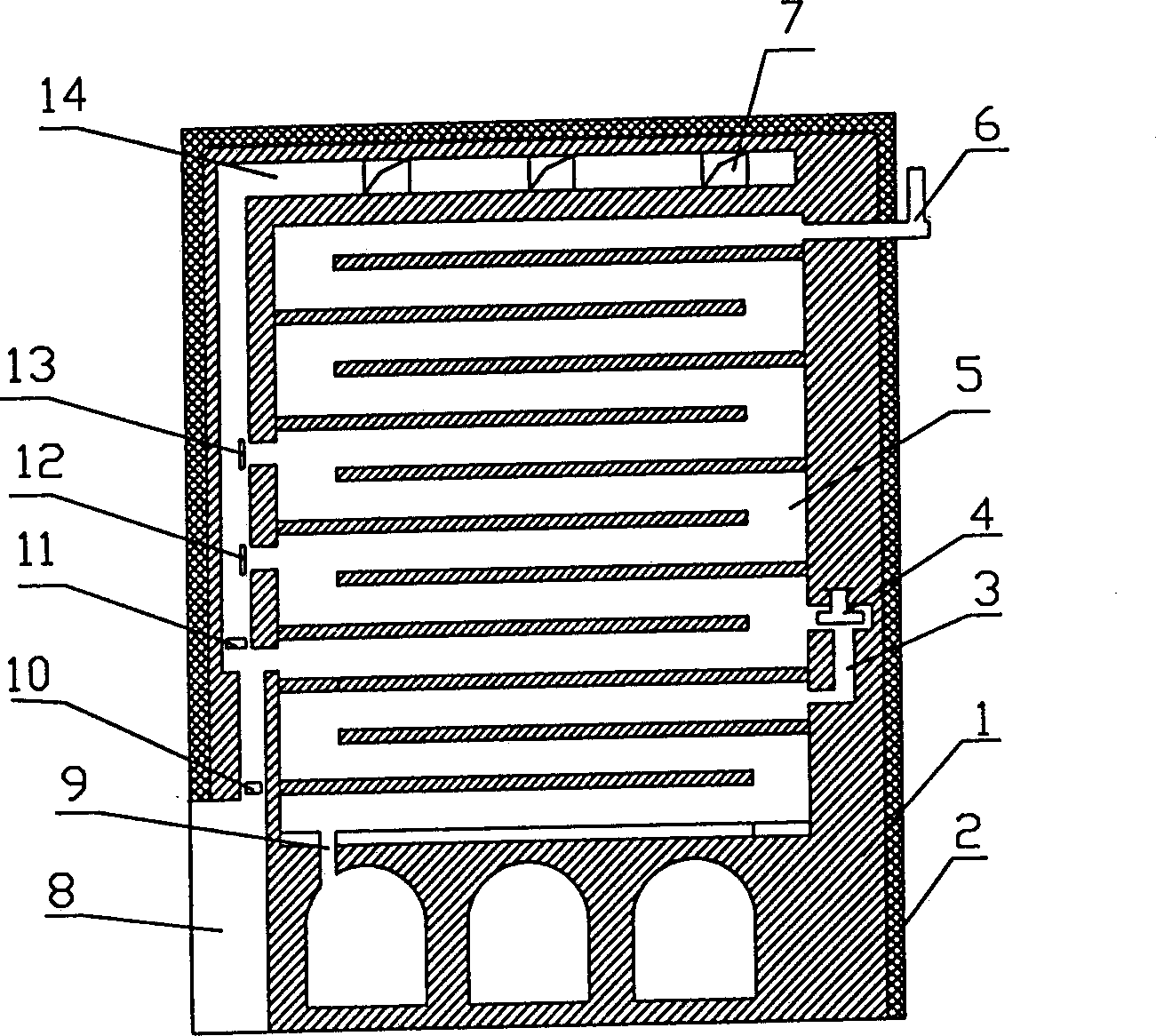

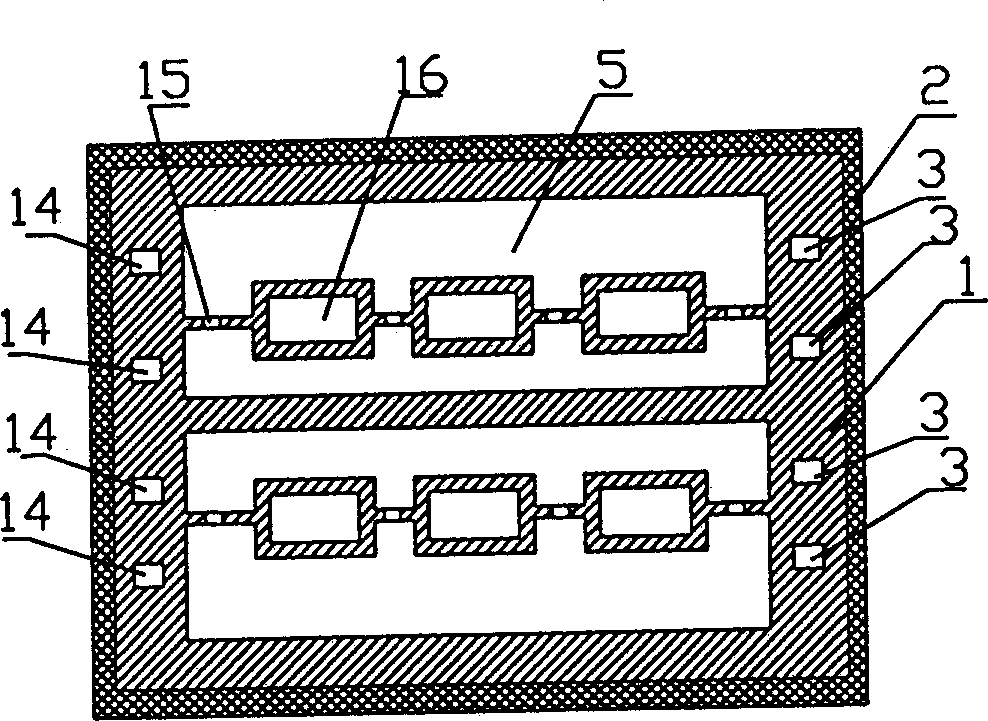

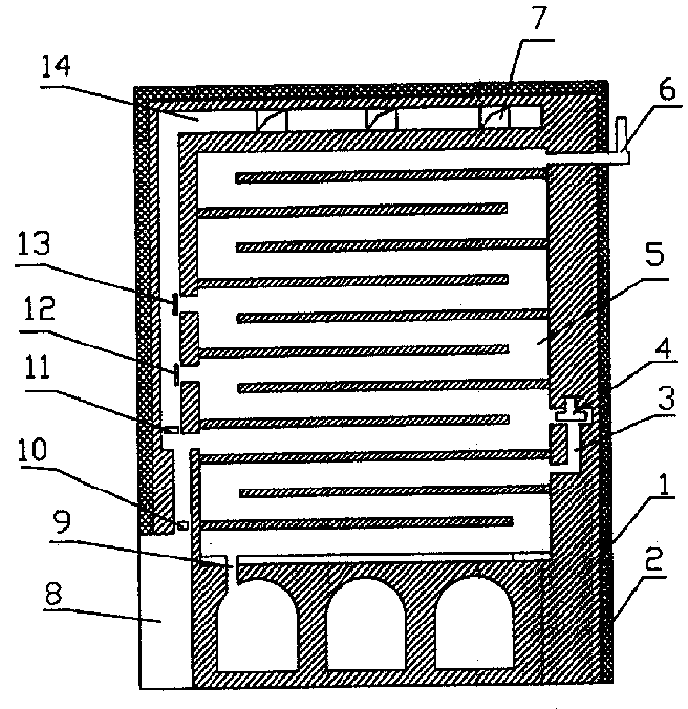

[0014] The carbon furnace described in this embodiment comprises a cuboid body of furnace 1, which is provided with an insulating layer 2 outside, and two furnaces 8 are arranged under the side of the body of furnace 1, and each furnace 8 passes through the gate 10 to two The combustion channel 5 formed by the fire wall of the nine-layer curved back and forth structure supplies heat, and its top is a smoke exhaust port; in this embodiment, there are four combustion channels arranged side by side, and there are three parallel calcined coal channels standing side by side between each two. 16. The coal block used for calcining carbon is put into the upper end of the coal calcination channel—that is, the coal inlet for calcination (no open flame), and finally the finished product is discharged from the lower end—that is, the carbon outlet, and then transported away by the conveying mechanism. In this embodiment, there are two groups of six calcined coal passages 16 . The top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com