Airflow desulphurization gypsum calcination system

A desulfurization gypsum and calcination technology, which is applied in the field of gypsum calcination system, can solve the problems of high resistance of cyclone dust collector and bag dust collection system, no stable heat source supply device, unstable and poor calcination quality, etc., and achieve full use of exhaust heat , Improve the effect of high bleeding and good calcination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

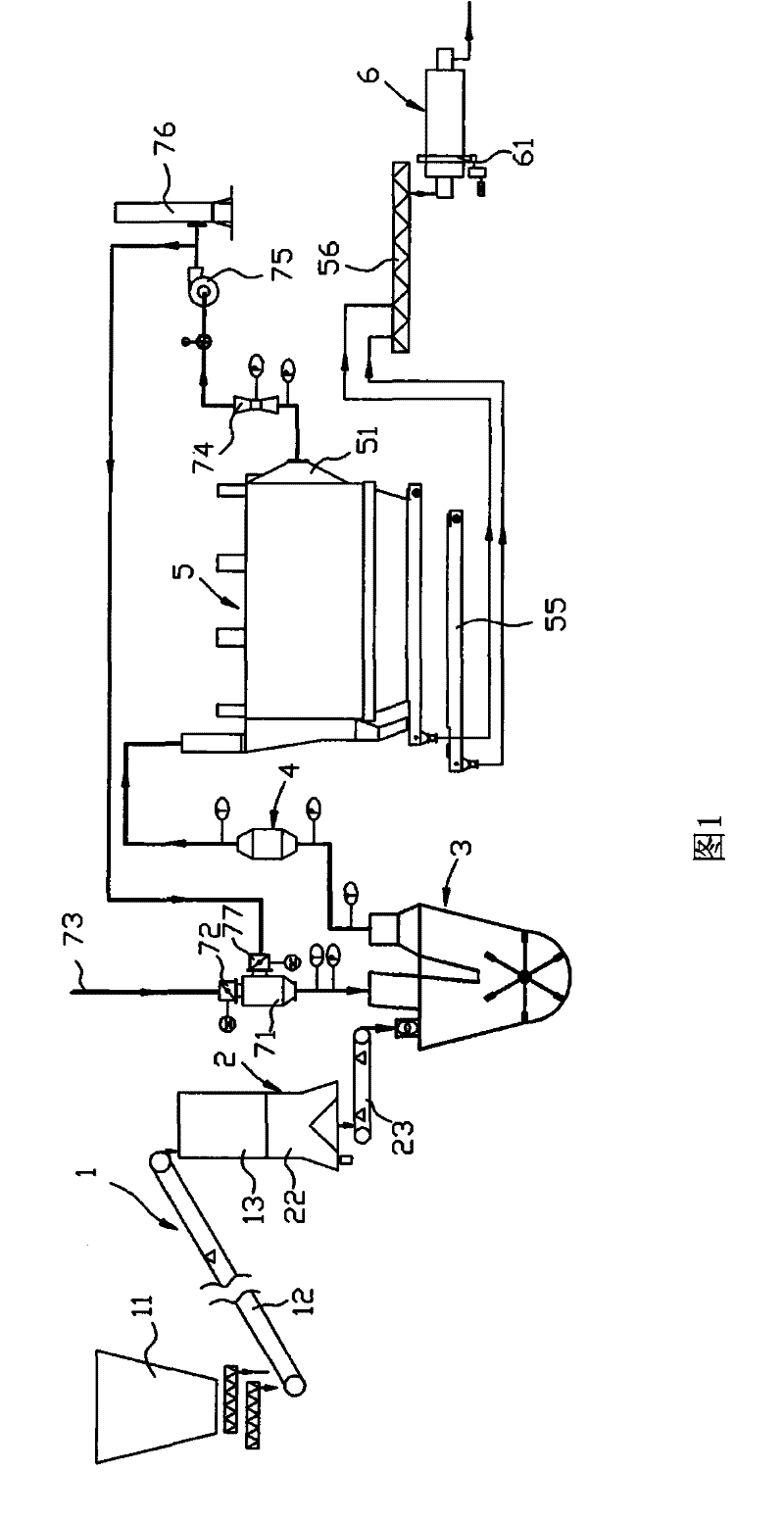

[0025] Such as figure 1 As shown, the present invention includes: a feeding storage system 1, a quantitative reclaiming system 2, a breaker 3, a post-calcination device 4, an electrostatic precipitator 5, a reformer 6, and a feeding storage system 1 arranged in sequence for conveying desulfurization Gypsum and temporary storage; the quantitative reclaiming system 2 is used to quantitatively weigh the desulfurized gypsum raw materials delivered by the feeding storage system 1, and send them to the breaker 3; the breaker 3 is used to transfer the quantitative reclaiming system A certain amount of desulfurized gypsum raw material is dispersed into the high-temperature flue gas for drying and calcination; the post-calcination device 4 is used to exchange heat with the hot air again for the desulfurized gypsum that has passed through the disintegrator 3 and undergoes sufficient calcination reaction; The dust collector 5 is used to separate the fully calcined desulfurized gypsum fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com