Built-out powder concentrator type vertical mill combined grinding system adopting non-metal grinding medium

A technology of grinding media and powder classifier, which is applied in the field of external vertical mill combined with grinding system of powder classifier, can solve the problems of reduced grinding efficiency, decreased output, increased power consumption, etc., and achieves improved grinding efficiency, reduced adsorption, Effect of Noise Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

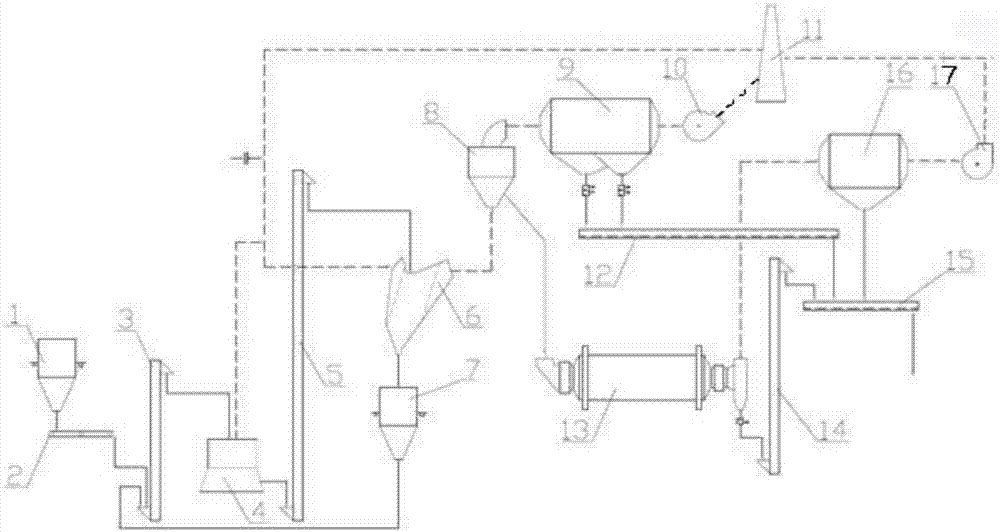

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0014] see figure 1 , a powder separator external vertical mill combined grinding system using non-metallic grinding media, characterized in that it includes a batching bin 1, a weighing scale 2, a feeding elevator 3, a vertical mill 4, and a V-shaped powder separator feeding Material elevator 5, V-shaped powder separator 6, buffer bin 7, high-efficiency powder separator 8, system dust collector 9, system fan 10, chimney 11, first finished product conveying chute 12, ball mill 13, grinding tail elevator 14. The second finished product conveying chute 15, the tail dust collector 16, the dust collector fan 17, and the chimney 18; a weighing scale 2 is installed below the batching bin 1 corresponding to the outlet of the batching bin, and the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com