Method for rapidly determining conversion rate of titanium dioxide falling into kiln by sulfuric acid method

A rapid determination of titanium dioxide technology, applied in the direction of material analysis by observing the influence of chemical indicators, measuring devices, analysis by making materials undergo chemical reactions, etc., can solve the problems of high instrument cost, long time-consuming detection, discomfort Rapid detection of problems in the production process to achieve the effect of improving the quality of calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

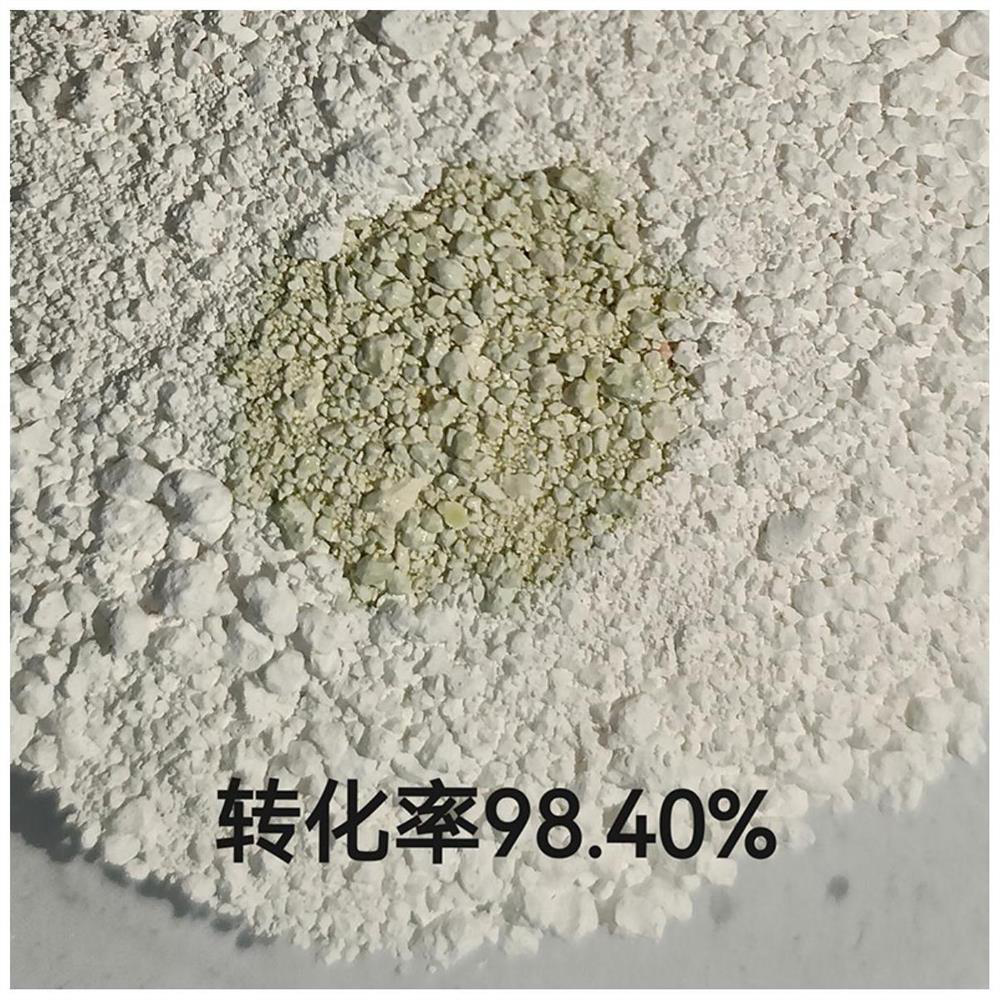

[0044] Take titanium dioxide kiln products with different base materials and different conversion rate gradients, and measure the conversion rate by the following methods:

[0045]1) Take zinc salt-treated and aluminum-salt-treated products from the kiln, respectively, for use;

[0046] 2) Take 6g sample of the kiln product in the vessel, add 4 drops of universal indicator to make the kiln product color develop, according to the corresponding relationship between the color development and conversion rate of the kiln product with different treatments in Table 1, determine the value of the sample of the dropped kiln product. Conversion rate;

[0047] The transformation ratios of all samples in the embodiment 1 are all titrated by the above-mentioned method, and the above-mentioned samples are carried out transformation ratio measurement using X-ray diffraction spectrometer simultaneously, and the transformation ratio results of measuring transformation ratio and titration are li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com