A double-chamber kiln burning fuel with low calorific value

A low calorific value, double-chamber kiln technology, applied in the field of industrial kilns, can solve the problems of lower production efficiency, inconvenient blanking, and increased production costs, so as to reduce energy consumption and production costs, reduce labor intensity of blanking, and improve calcination quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

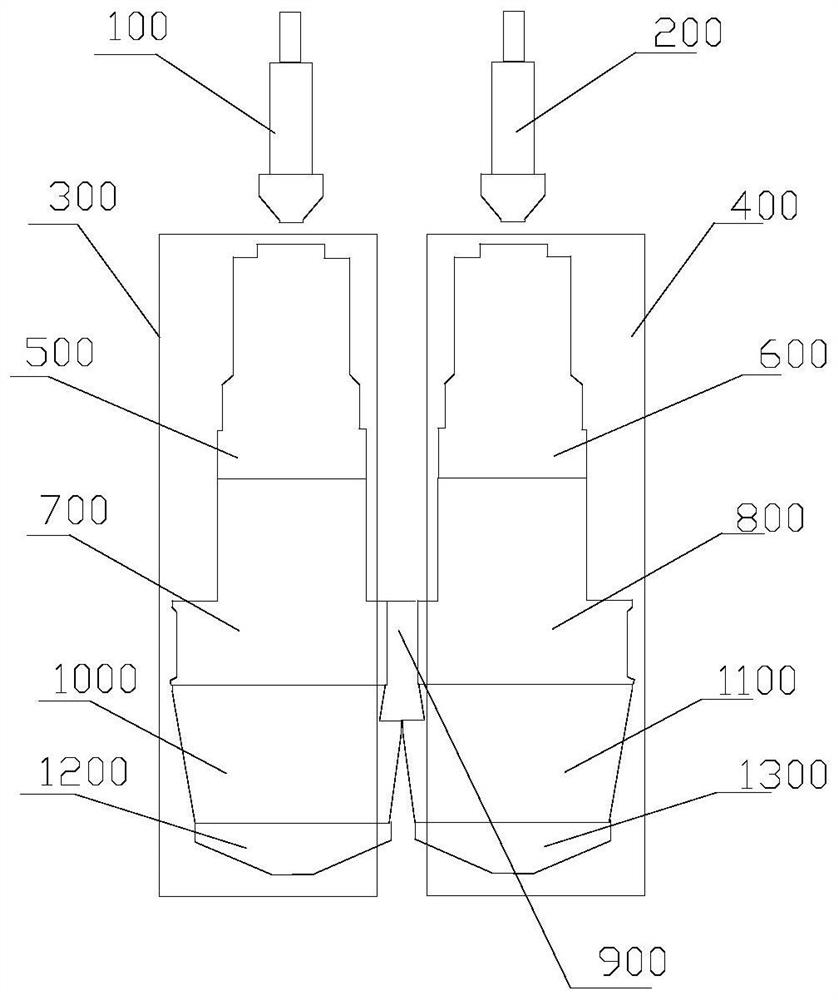

[0035] like figure 1As shown, a new double-chamber kiln burning fuel with low calorific value includes a feeding device and a No. 1 kiln body and a No. 2 kiln body, and the No. 1 kiln body and No. The kiln body includes No. 1 preheating device, No. 1 calcination device, No. 1 cooling device and No. 1 discharge device from top to bottom; the No. 2 kiln body includes No. 2 preheating device and No. 2 calcination device from top to bottom. , No. 2 cooling device and No. 2 discharge device; the No. 1 kiln body and the No. 2 kiln body are connected by a fixed connecting device; wherein, the charging device is a mobile charging device, including the No. 1 mobile charging device device and the No. 2 mobile feeding device, the No. 1 mobile feeding device is connected to the No. 1 kiln body, and the No. 2 mobile feeding device is connected to the No. 2 kiln body.

Embodiment 2

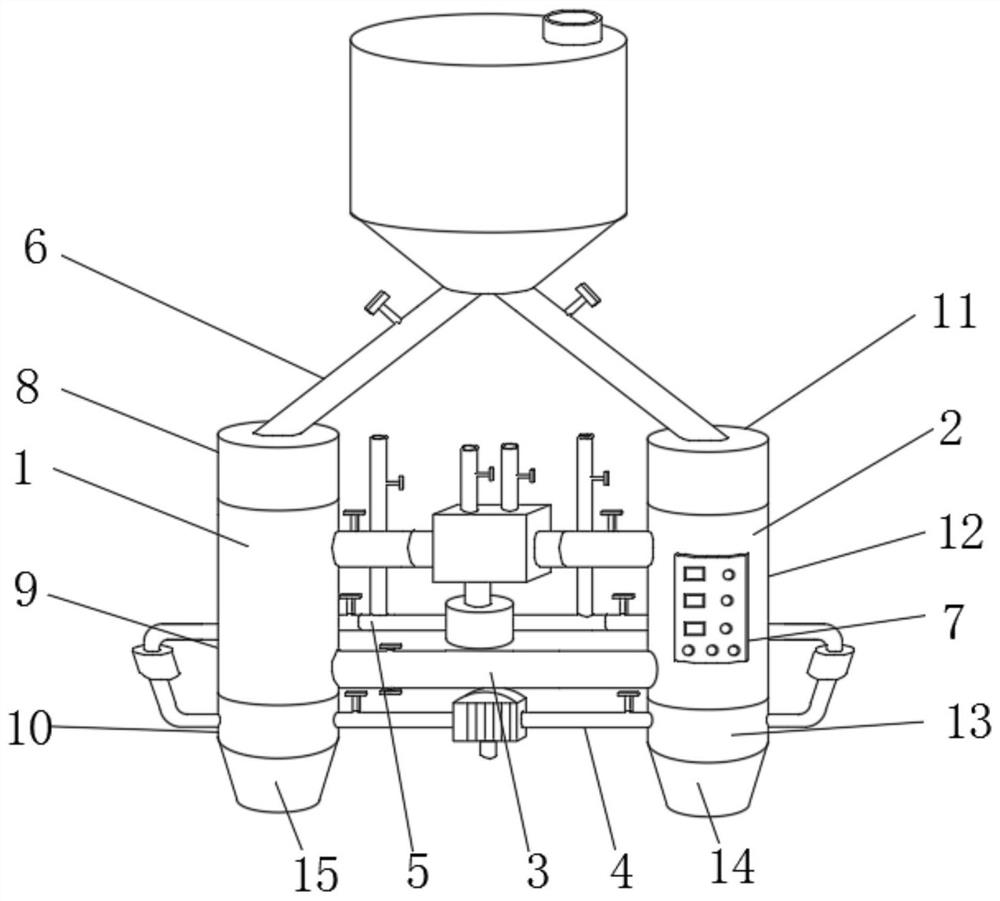

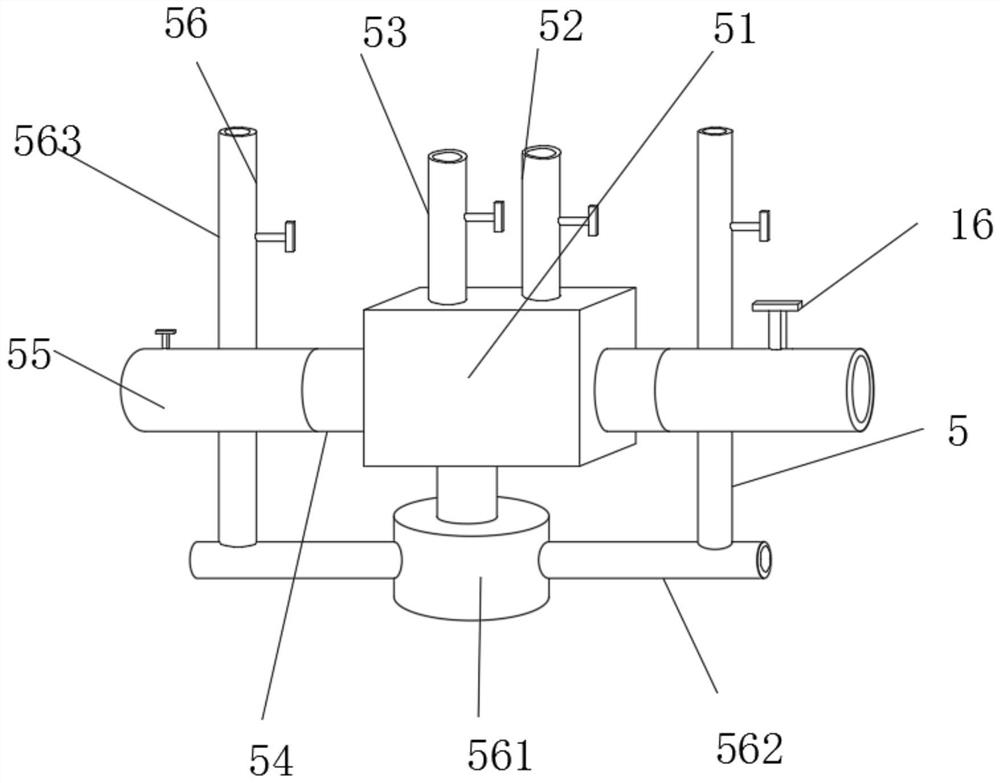

[0037] Such as Figure 2-7 As shown, a new double-chamber kiln burning fuel with low calorific value includes a No. 1 kiln body 1 and a No. 2 kiln body 2. The No. 1 kiln body 1 is located on the left side of the No. 2 kiln body 2, and the lower right end of the No. 1 kiln body 1 is connected to the The lower part of the left end of the No. 2 kiln body 2 is jointly fixedly connected with a connecting device 3 , the upper middle part of the No. 1 kiln body 1 and the upper middle part of the No. 2 kiln body 2 are jointly fixedly installed with a feeding device 6 , and the No. 1 kiln body 1 includes a No. 1 preheating element 8 , No. 1 calcined part 9, No. 1 cooling part 10 and No. 2 discharge part 15, No. 1 preheating part 8 is located at the upper end of No. 1 calcined part 9, No. 1 calcined part 9 is located at the upper end of No. 1 cooling part 10, and No. 1 The cooling part 10 is located at the upper end of the No. 2 discharge part 15. The No. 1 kiln body 1 includes the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com