Patents

Literature

117results about How to "Improve calcination effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali development type photocurable composition and calcined pattern obtained by use of the same

InactiveUS20020096666A1Improve calcination effectStable fastnessElectric discharge tubesConductive materialElectrical conductorPhotolithography

An alkali development type photocurable composition comprises (A) an alkali-soluble macromolecular binder having a weight-average molecular weight in the range of 5,000 to 100,000 and an acid value in the range of 50 to 150 mg KOH / g and obtained by causing (d) a compound possessing one glycidyl group in its molecule to react with a carboxyl group of (A-1) a copolymer of (a) an ethylenically unsaturated bond-containing compound possessing one carboxyl group in its molecule with (b) an ethylenically unsaturated bond-containing compound possessing neither hydroxyl group nor acidic group in its molecule, or a carboxyl group of (A-2) a copolymer of the compounds (a) and (b) mentioned above and (c) an ethylenically unsaturated bond-containing compound possessing a hydroxyl group and then causing (e) a polybasic acid anhydride to react with a hydroxyl group caused by the above reaction, (B) an inorganic powder, (C) a photopolymerizable monomer, (D) a photopolymerization initiator, and (E) an organic solvent. By using this composition, such calcined patterns as a conductor pattern and a dielectric pattern of high fineness may be formed by the photolithographic technique.

Owner:TAIYO INK MFG

Preparation method for titanium dioxide serving as catalyst carrier

InactiveCN102583522AImprove performanceEasy to processCatalyst carriersTitanium dioxidePtru catalystMaterials science

The invention discloses a preparation method for titanium dioxide serving as a catalyst carrier. The preparation method comprises the following steps of: dispersing metatitanic acid serving as a raw material by pulping, and adjusting until the concentration of the slurry is 12 to 26 mass percent based on titanium dioxide (TiO2); adding ammonia water into the slurry, and adjusting the pH value to be between 6.0 and 9.0; filtering and dehydrating to obtain a blocky filter cake; mechanically crushing the blocky filter cake; drying and calcining the crushed filter cake at 200 to 560 DEG C for 6 hours; and grinding the calcined material in a kiln to obtain a titanium dioxide product which serves as a denitration catalyst carrier. By the preparation method, the manufacturing cost is low, the process is simple, the prepared product has the advantages of large specific area, high surface chemical activity and high processability, and the prepared final product is high in catalytic efficiency.

Owner:四川华铁钒钛科技股份有限公司

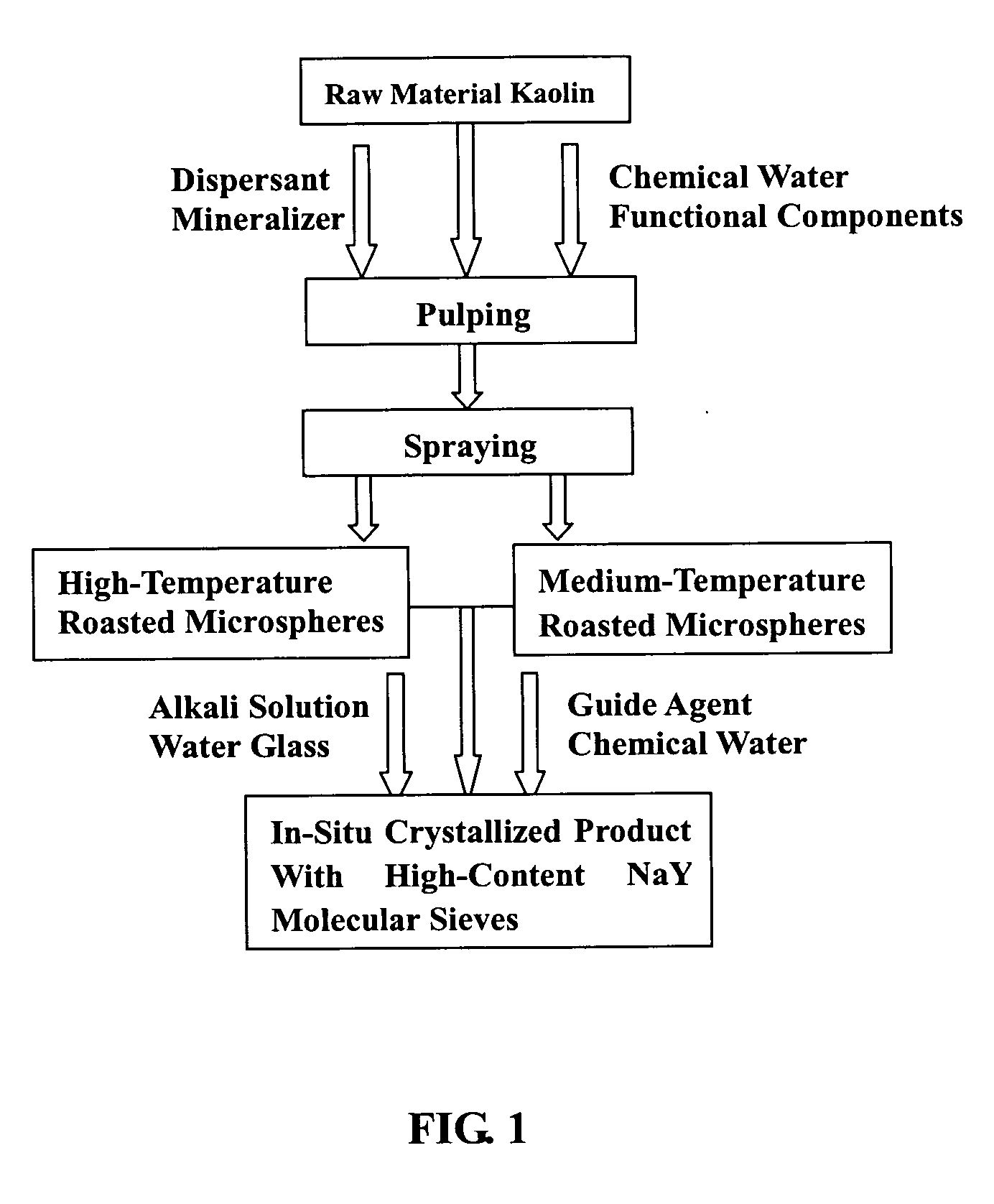

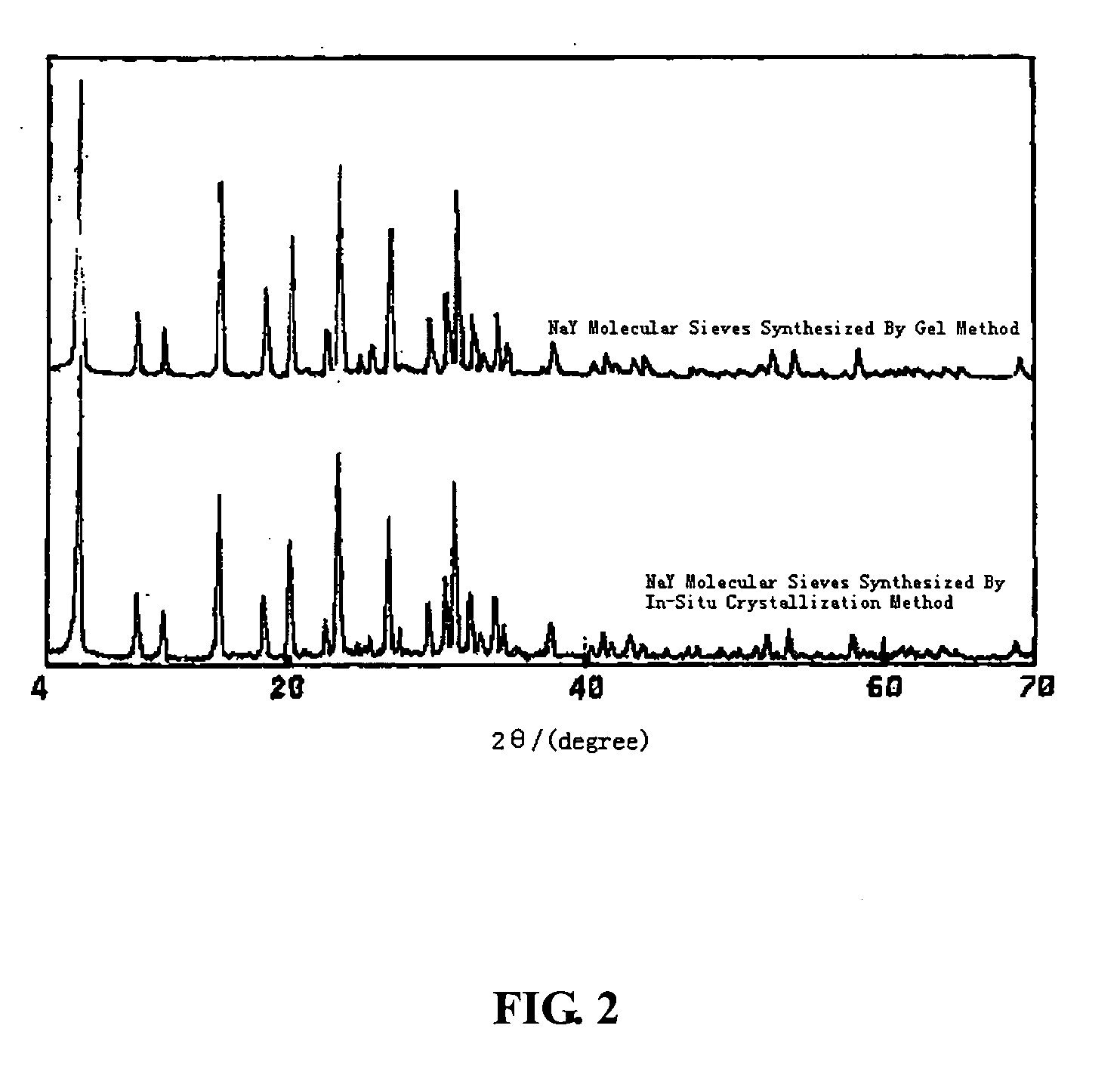

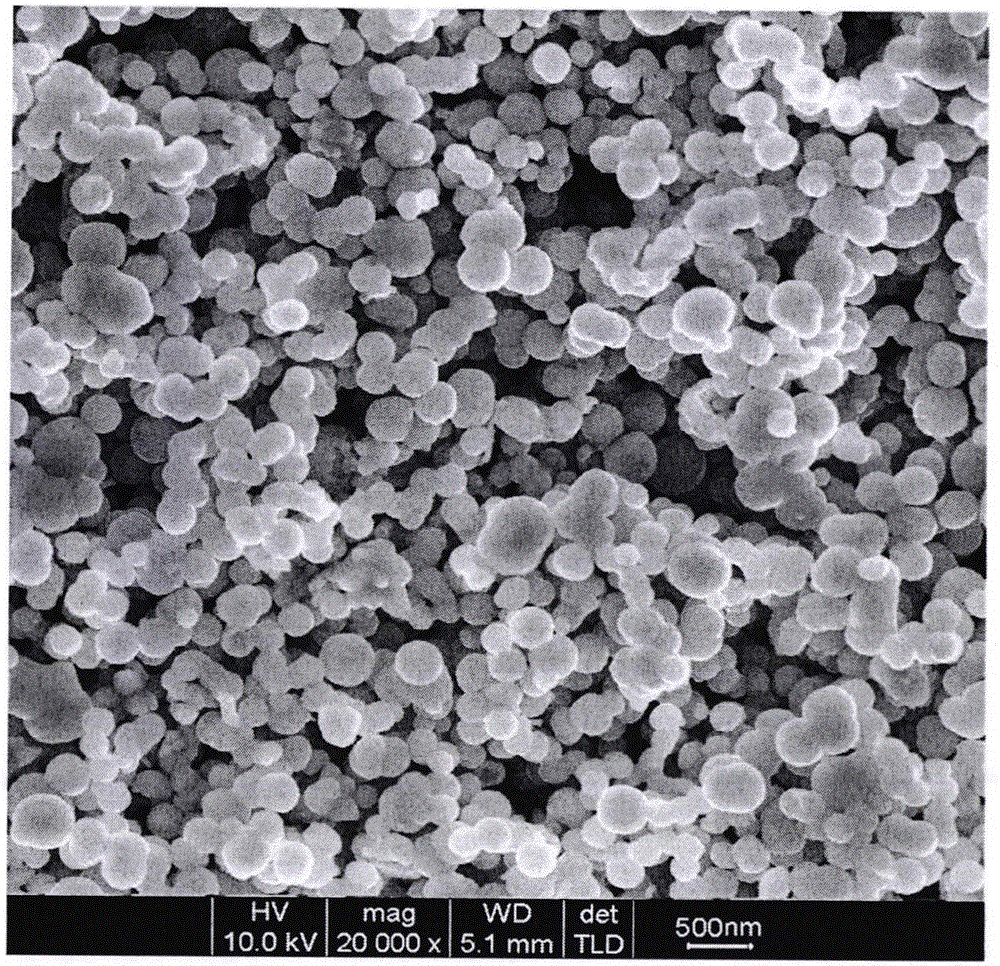

Method for the preparation of high-content NaY molecular sieves synthesized from kaolin sprayed microspheres

ActiveUS20060116277A1Improve pore structurePromotion is limitedMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMicrosphere

A method for synthesizing high-content NaY molecular sieves with kaolin sprayed microspheres is provided, comprising that functional components and deionized water are added into the kaolin so as to be pulped mixed slurry, and the slurry is sprayed into microspheres, the sprayed microspheres are calcined at a temperature between 700 and 1,000° C. and the obtained is mixed up with directing agent for crystallization, the resultant solid is filtrated from mother liquid and washed by water. The functional components include structural agents, and the addition of the agents is about 2˜10 percent by mass of the kaolin; the structural agents are one or more of starch, graphite powder, and carboxymenthyl cellulose. Alternatively according to the present invention, one part of the sprayed microspheres with particle sizes of 20˜110 μm is calcined at high temperature to get high-temperature calcined kaolin microspheres, while the other part is calcined at a low temperature to get meta kaolin microspheres. The two parts are mixed up for crystallization reaction in hydrothermal conditions to get a crystallized product containing 40 to 60 weight percent of NaY molecular sieves, and the ratio of silicon to aluminum therein is 3.5˜5.5.

Owner:PETROCHINA CO LTD

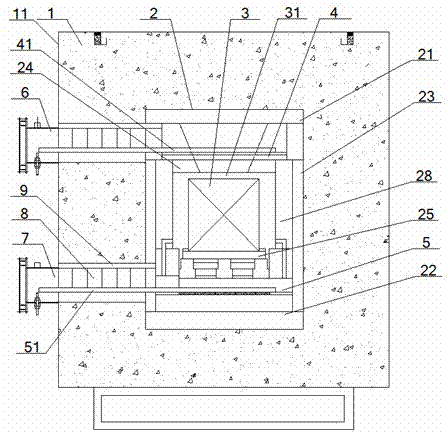

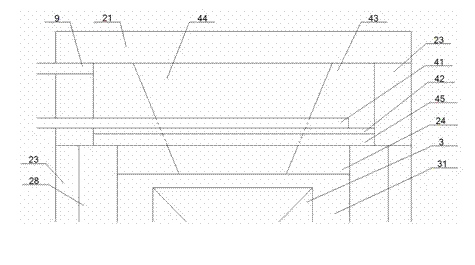

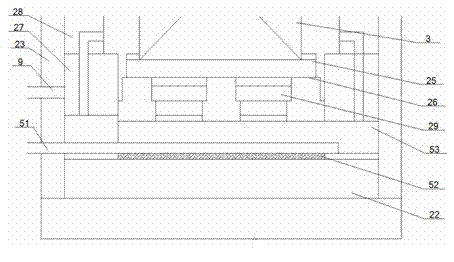

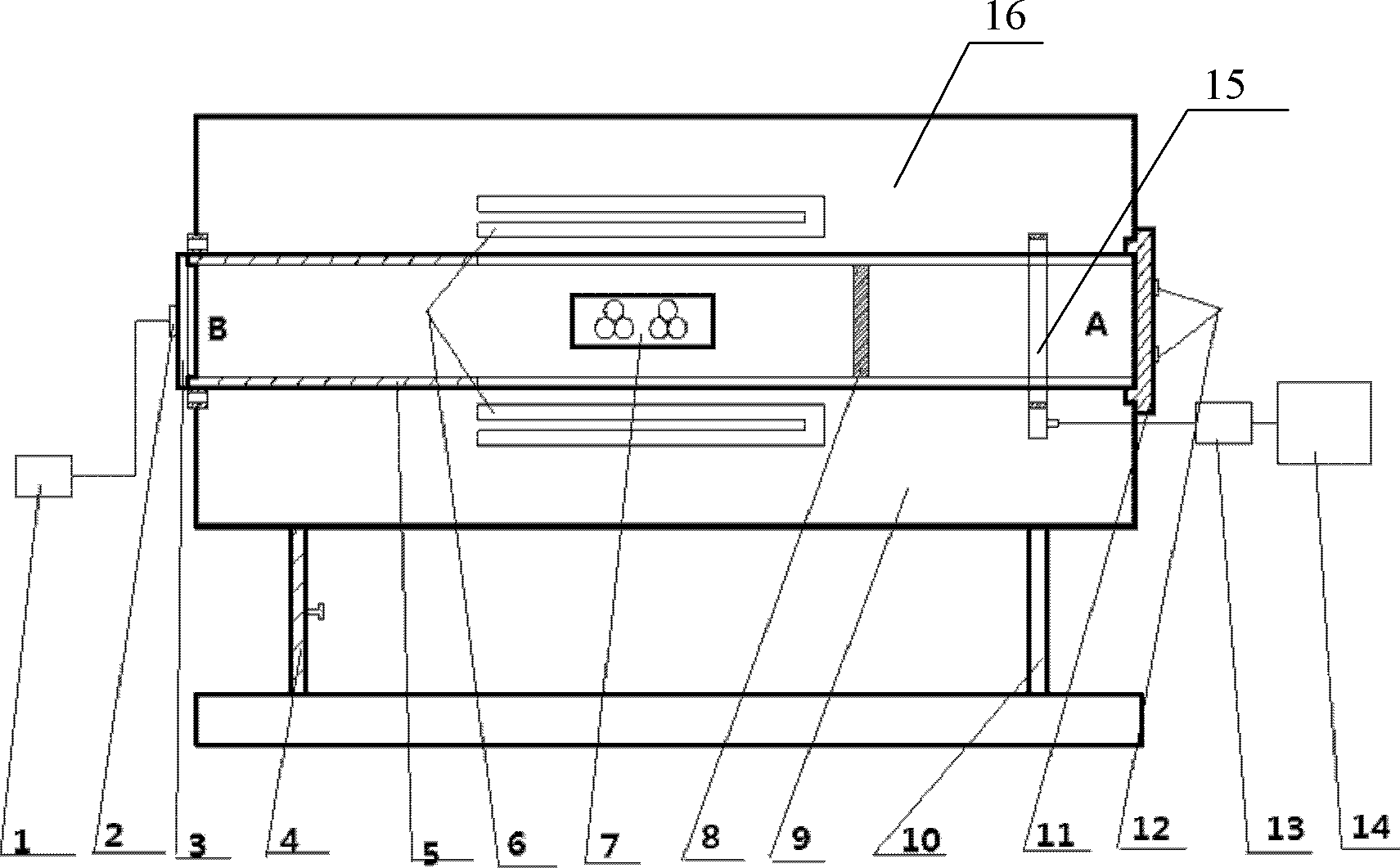

Energy-saving and environmentally-friendly kiln body and vanadium-nitrogen alloy high-temperature sintering kiln adopting energy-saving and environmentally-friendly kiln body

ActiveCN102853670ASave powerImprove distributionFurnace componentsFurnace typesFiberThermal insulation

An energy-saving and environmentally-friendly kiln body comprises a thermal insulation fire-proof layer, a calcining chamber, a graphite crucible, horizontal heating chambers and a sealing box, wherein the graphite crucible and the thermal insulation fire-proof layer are respectively arranged inside and outside the calcining chamber; the upper horizontal heating chamber and the lower horizontal heating chamber are respectively arranged above and under the graphite crucible; an upper horizontal heating body and a lower horizontal heating body that correspond to each other are horizontally arranged in the upper horizontal heating chamber and the lower horizontal heating chamber; one end of each horizontal heating body is arranged in each heating chamber, and the other end of the horizontal heating body passes through a side wall, the thermal insulation fire-proof layer and a furnace shell in sequence and then extends into the sealing box; high-temperature fibers are filled in gaps between the heating bodies and plug bricks; and a gas inlet port and a copper electrode are arranged on the sealing box. In a vanadium-nitrogen alloy high-temperature sintering kiln adopting the energy-saving and environmentally-friendly kiln body, a low-temperature segment, a transition segment and a high-temperature segment adopt different manufacturing materials and different heating bodies so as to adapt to calcining processes. According to the design, the unit energy consumption is lower, and the operation conditions are better; in addition, the process atmosphere and the calcining effect in the kiln are better, and the service life of the kiln is longer.

Owner:湖北晶洋科技有限公司

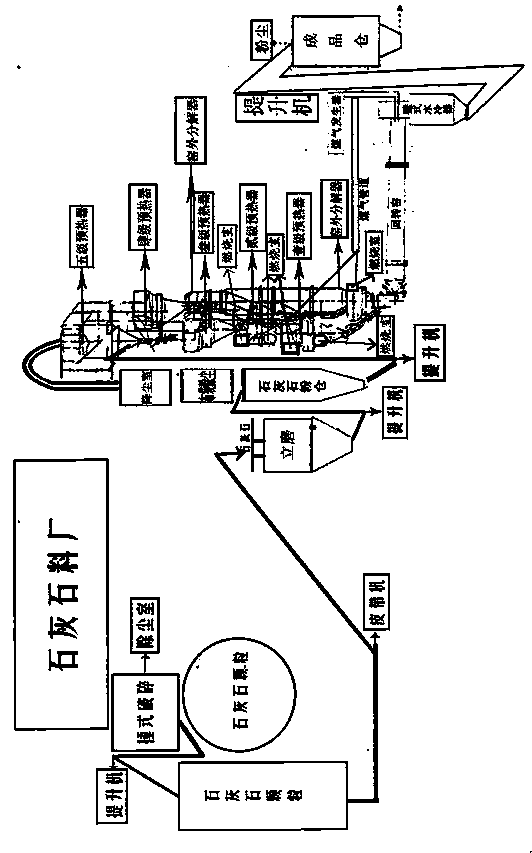

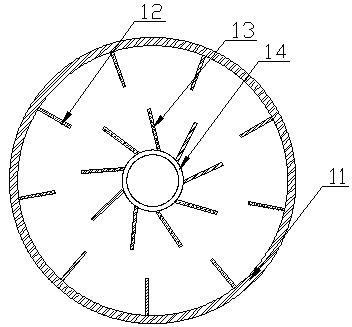

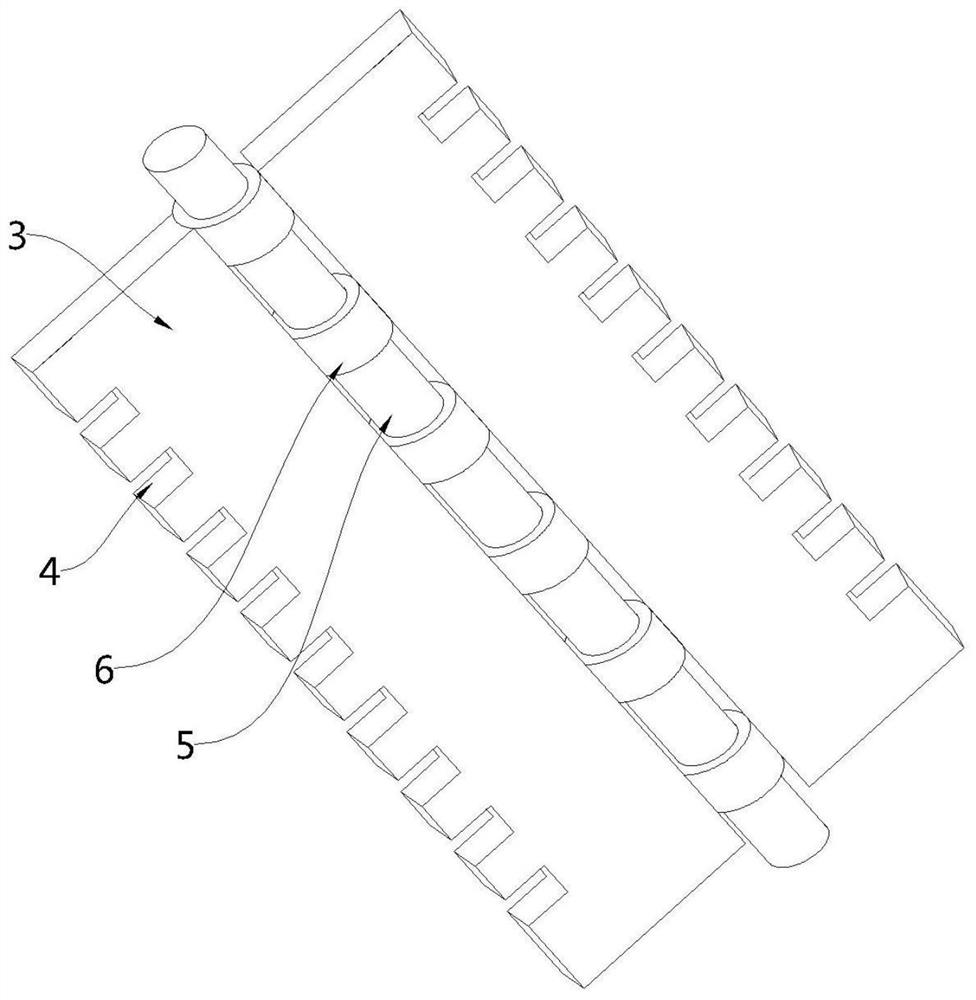

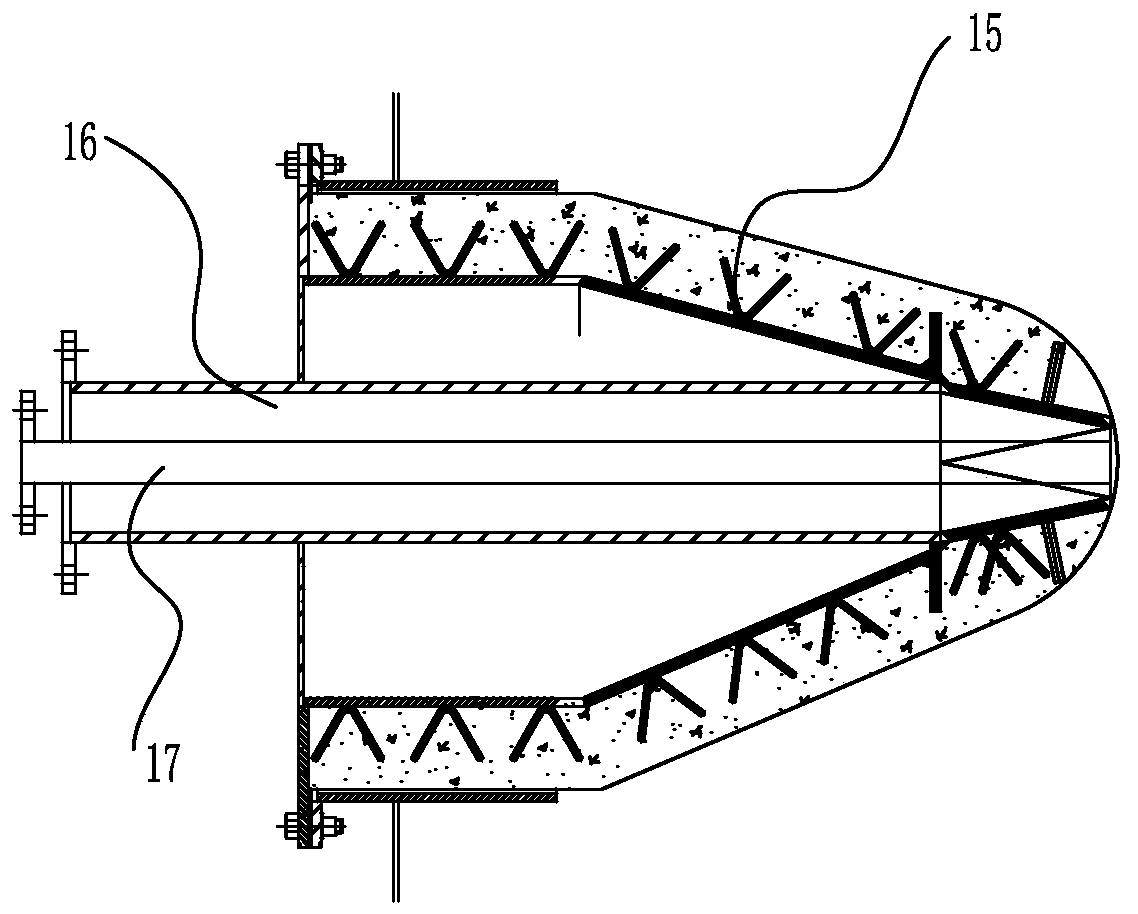

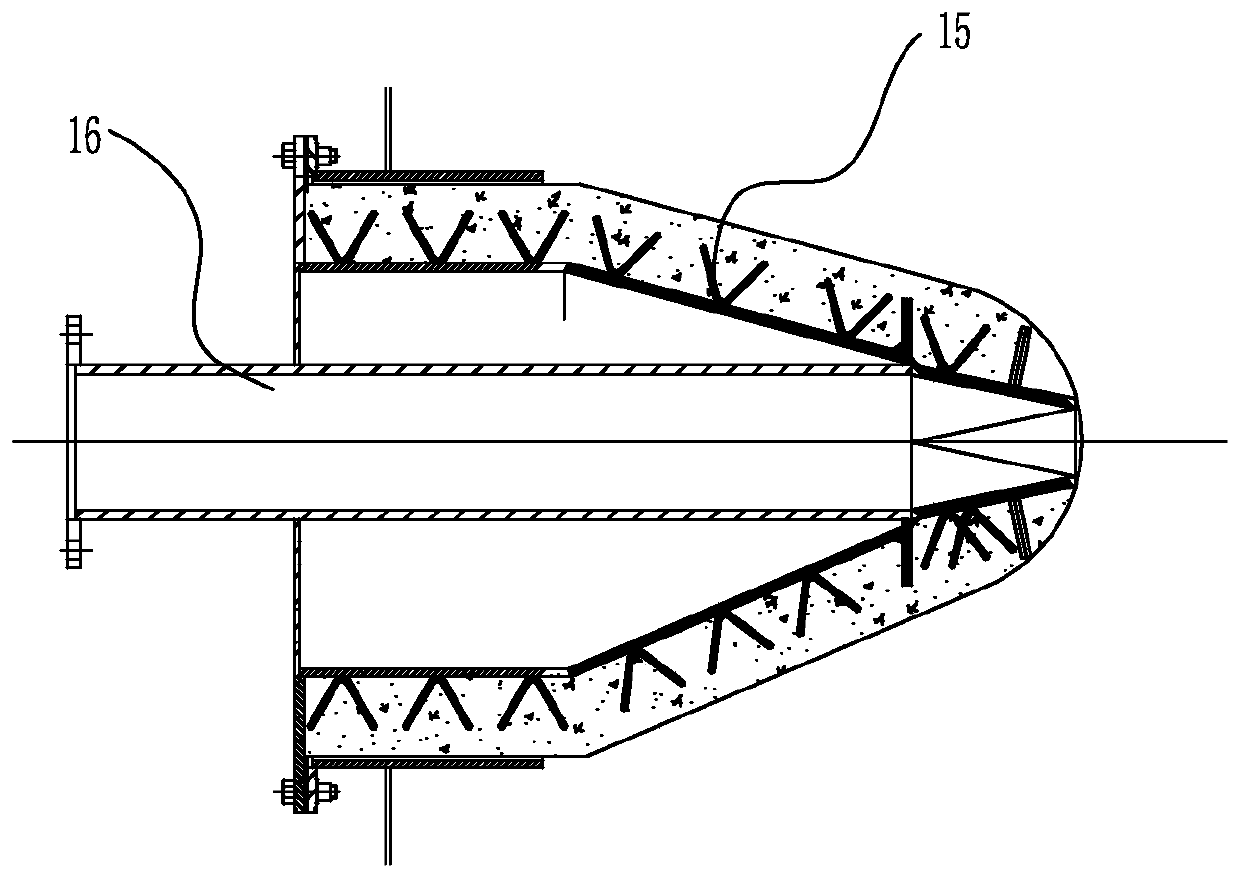

Technique method for producing active lime

The invention relates to a technique method for producing active lime. The technique method comprises the following steps: firstly pulverizing raw material limestone, so as to enable the raw material not to enter a preheater in a blocky manner. In the follow-up primary calcination and curing calcinations stages, the traditional equipment and production technique are incomparable with the completely curing results generated by the continuous calcination procedures through the preheater, an external kiln splitter and a rotary kiln; furthermore, through an insulating layer structure and a protruding structure on the surface of an inner cavity of the rotary kiln, the insulating property of the rotary kiln is superior to the conventional technology, powder can be sufficiently stirred evenly through protrusions on the inner cavity of the rotary kiln in the production process of the rotary kiln, so that the optimization of the calcination effects can be improved.

Owner:米长山

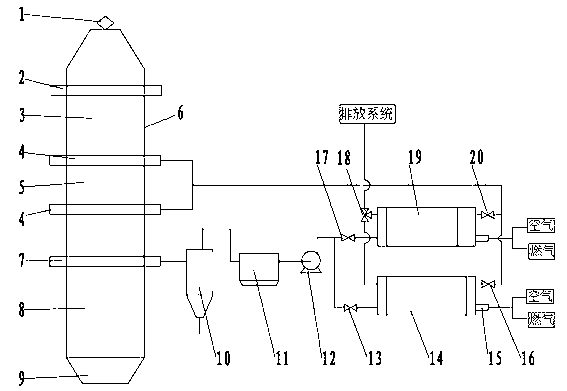

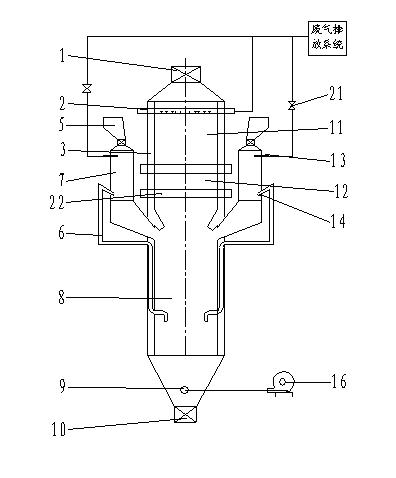

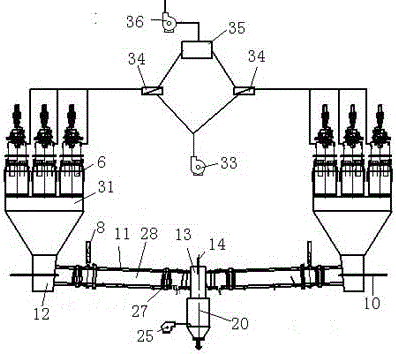

Beam type heat storage lime kiln

The invention relates to a beam type heat storage lime kiln. The beam type heat storage lime kiln comprises a kiln body, a feeding system, an air supply system, a discharging system, a cyclone dust collector, a bag-type dust collector, a draught fan, two heat accumulators with burners, a waste gas discharging system and a control system, wherein an outlet of a lower suction beam is connected into an inlet of the draught fan through the cyclone dust collector and the bag-type dust collector; an outlet of the draught fan is divided into two paths which are respectively connected into a combustion air inlet of a combustion beam through valves and the heat accumulators; a gas pipeline and an air pipeline are connected to the burners of the heat accumulators; and waste gas outlets of the heat accumulators are respectively connected to the waste gas discharging system through three-way valves; and the two heat accumulators are used for alternatively accumulating heat and preheating gases, and the reversing operation is realized through the opening and closing of each valve. The beam type heat storage lime kiln has the advantages that the high-temperature gases pumped out by the lower suction beam are dedusted, purified and preheated by the cyclone dust collector, the bag-type dust collector and the heat accumulators to serve as the combustion air, the burning temperature of a low-heat value fuel is increased, the full utilization of the low-heat value fuel is facilitated, and the quality of calcined products is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

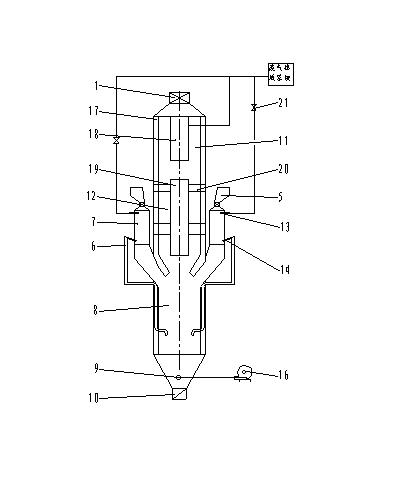

Compound lime kiln

ActiveCN102627418AEfficient use ofImprove calcination effectLime productionControl systemExhaust gas emissions

The invention relates to a compound lime kiln, comprising a kiln body, a charging equipment, a discharging equipment, a control system and an exhaust system.A preheating zone, a\calcining zone and a cooling zone are in the kiln body. A smoke outlet or a fume extractor is arranged in the preheating zone, and the smoke outlet or the fume extractor is connected with the exhaust system. A cooling tuyere is arranged in the cooling zone, and a cooling air inlet is connected with a cooling fan. Two to four granule kiln bins are arranged in the device. Granule hoppers, granule charging locks and cooling air outlets are arranged in the granule kiln bins. The underpart of the granule kiln bins are connected with the cooling zone. The cooling air outlet is connected with the exhaust system. Granule kiln bins are arranged in the device in the invention, exhaust gas after lime cooling is utilized to preheat granule limestone materials, and simultaneously large particle and granule materials are calcined, so that the preheating fully utilizes resources of limestones, effectively utilizes energy, reduces consumption and improves productivity. The cooling air does not enter the calcining zone, which is beneficial to an improving of calcining effects of the calcining zone, a reducing of a pressure load of the kiln body and an improving of qualities of the lime products.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

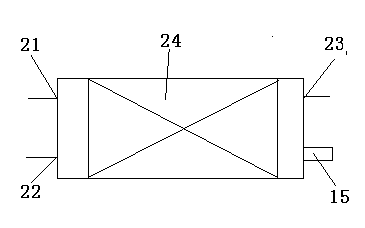

Method and equipment for calculating materials

ActiveCN101817649AImprove product qualityIncrease profitLime productionCombustionNuclear engineering

The invention provides a method and equipment for calculating materials. A preheating chamber, a calculating chamber and a cooling chamber of the equipment are in split structures; and the calculated materials are delivered by a bucket-type hoister among feeding equipment, the preheating chamber, the calculating chamber and the cooling chamber. The calculated materials are preheated, calculated and cooled in the split preheating chamber, calculating chamber and cooling chamber to obtain calculating products. High-temperature gas generated during cooling products in the cooling chamber is delivered to the preheating chamber by a gas pipeline for preheating the calculated materials and enters the calculating chamber to be used as combustion-supporting air after being preheated by a heat accumulator. The invention fully utilizes heat energy, reduces the consumption of fresh air and the emission of room temperature gas and is beneficial to environmental protection. Various units of the equipment are independent assemblies, can be separately produced and assembled on site and are beneficial to serially producing and calculating the equipment. The materials are delivered among various chambers by using the bucket-type hoister, so that the invention realizes split operations and improves the flexibility of operations.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

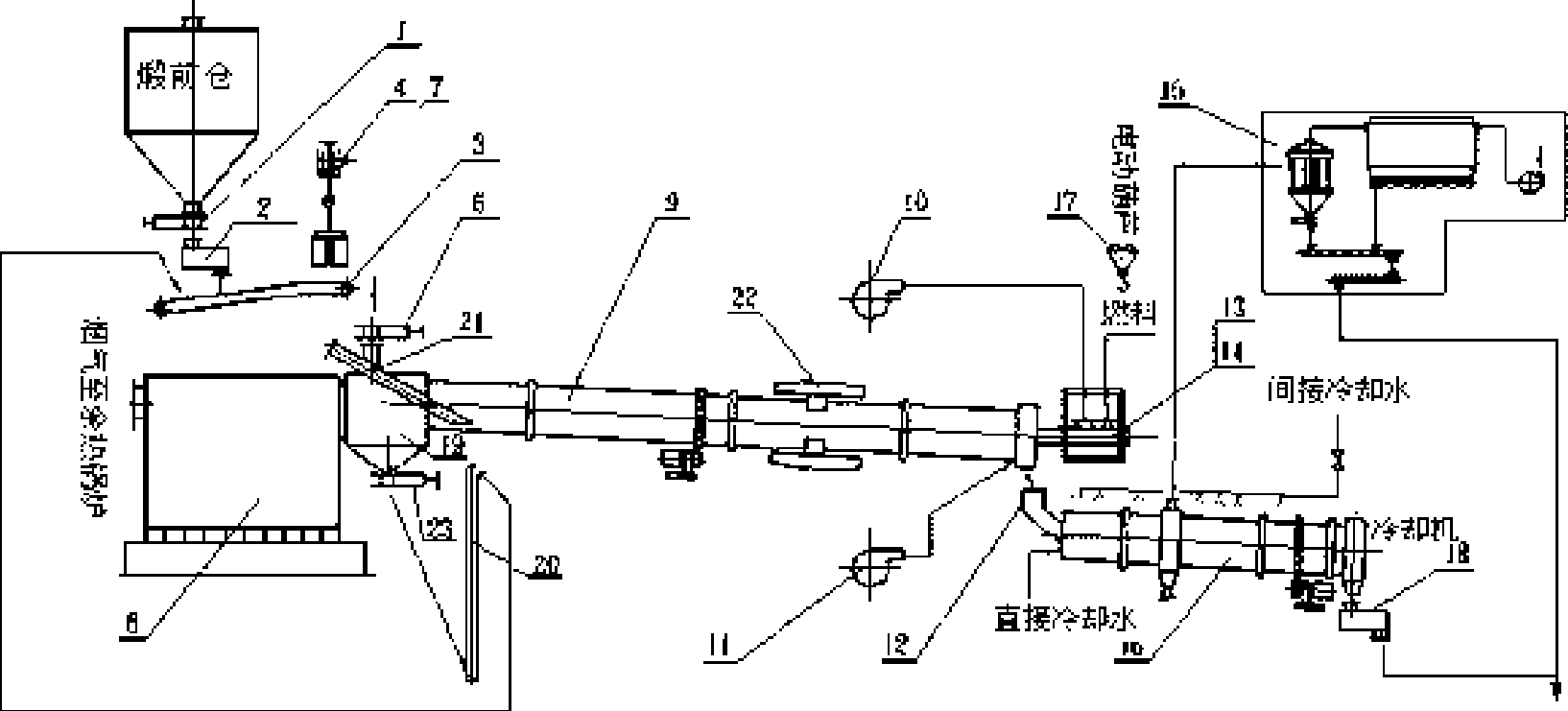

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

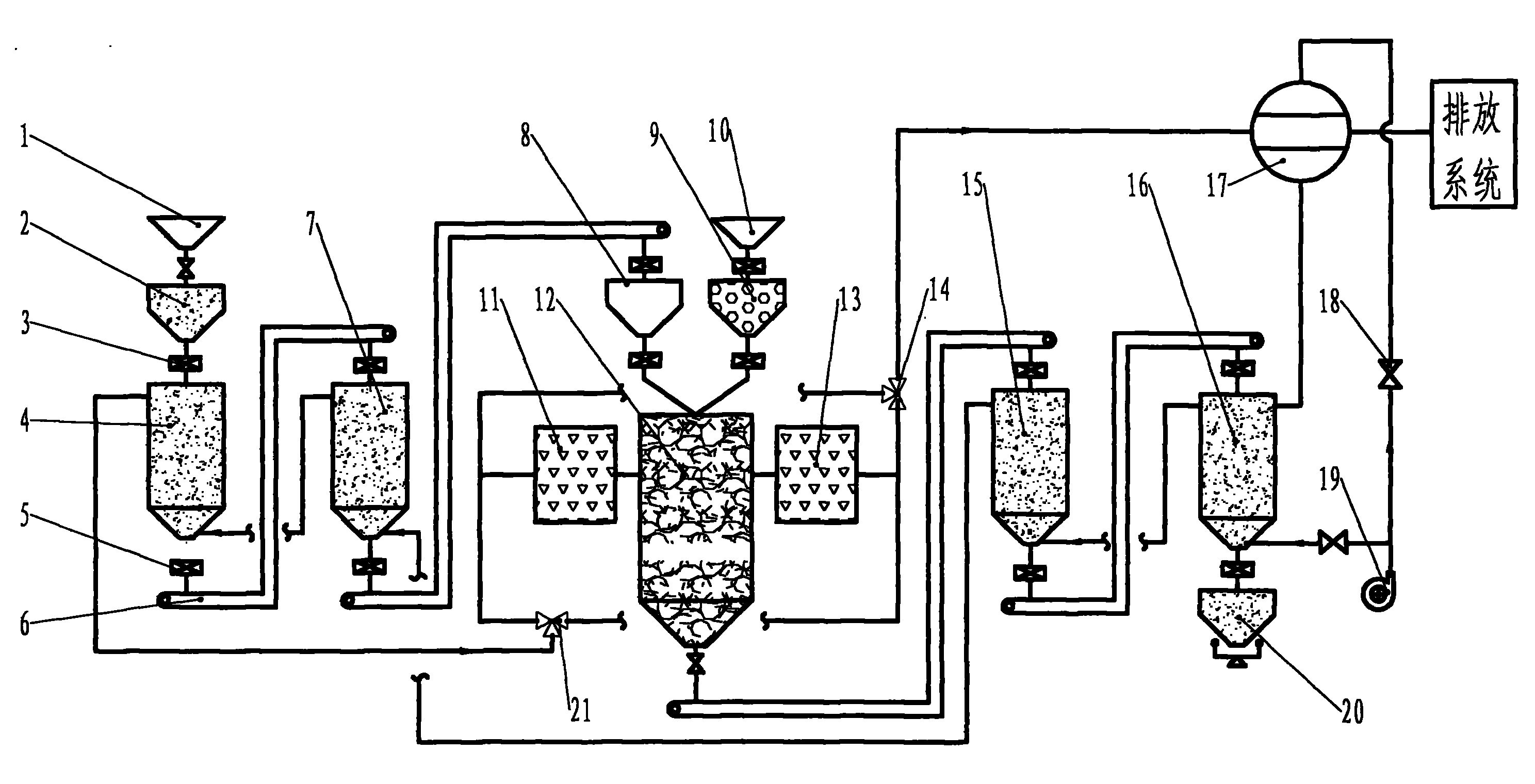

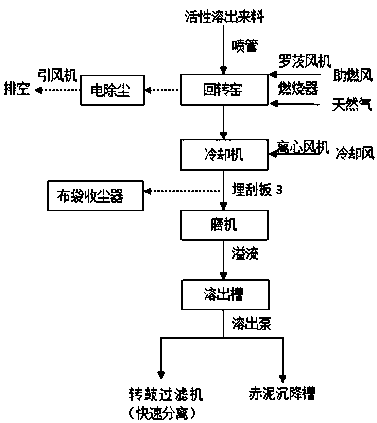

Method for treating inert aluminum ash in aluminum ash treatment technology

InactiveCN108640137AWon't pile upSafe and efficient handlingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasSlurry

The invention discloses a method for treating inert aluminum ash in an aluminum ash treatment technology. A mixture of aluminum ash and raw slurry is fired through a rotary kiln, is cooled through a cooling machine and is finally subjected to clinker leaching in a ball grinding mill in sequence. A device provided by the invention can be used for safely and efficiently treating the inert aluminum ash in the aluminum ash; lime milk is prepared and reacts with F<-> to generate CaF2, so that harmful elements and harms caused by the fact that the F<-> enter flue gas are eliminated; meanwhile, organic matters accumulated by a Bayer process can be treated. The rotary kiln is arranged and materials with different grain diameters can be uniformly mixed; the calcination efficiency and effect are improved.

Owner:YUNNAN WENSHAN ALUMINUM

Processing purification technology for high-purity quartz sand tailings

The invention discloses a processing purification technology for high-purity quartz sand tailings. The processing purification technology takes tailings in a process of producing high-purity quartz sand as raw materials and comprises the steps of roughing, cleaning, drying, calcining, water quenching, acid pickling, cleaning and drying, wherein sodium oxide is uniformly blended into the quartz sand tailings before calcining, and reacts with SiO2 at high temperature to generate soluble sodium silicate replacing hydrofluoric acid to open inclosure of quartz, so that contact reaction between metal impurities and acid is realized, and the usage amount of acid is greatly reduced. The processing purification technology is simple and environment-friendly, purification effect is good, deep processing on the quartz sand tailings is effectively realized, the purity of the quartz sand tailings treated by adopting the technology can reach up to 99.90% or above, and the standard of high-purity quartz sand is met.

Owner:江苏凯达石英股份有限公司

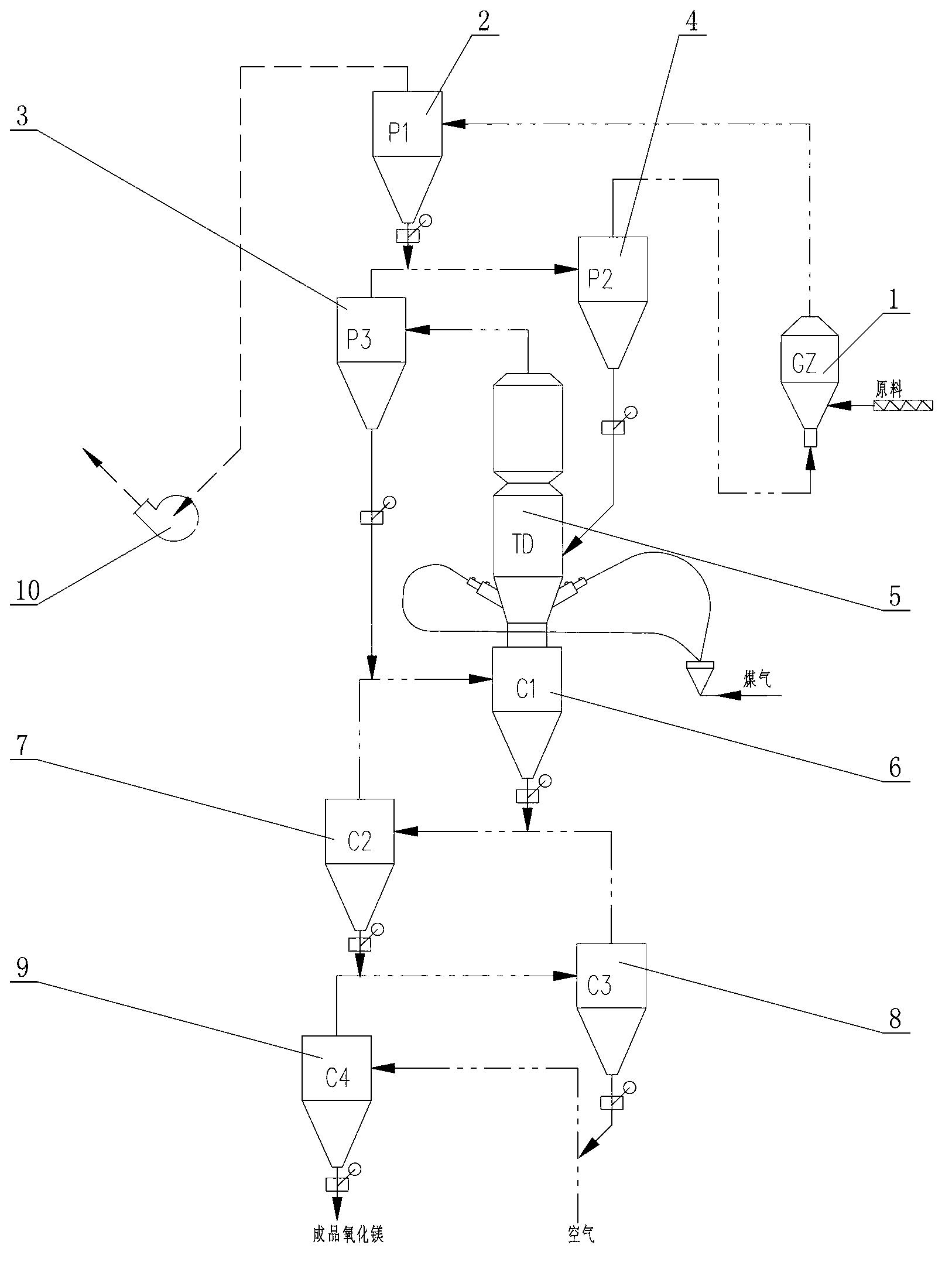

Temperature-controlled suspension roaster

ActiveCN103193400AImprove decomposition efficiencyImprove cooling effectLime productionCycloneDecomposition

The invention relates to a temperature-controlled suspension roaster. The temperature-controlled suspension roaster comprises a cyclone separator, a preheating cyclone drum, a temperature-controlled roaster, a drier and a multistage cyclone cooler, wherein the cyclone separator is a two-stage cyclone separator which comprises a first-stage cyclone separator and a secondary cyclone separator, and the multistage cyclone cooler sequentially comprises a first-stage cooler, a middle-stage cooler and a final-stage cooler from the upstream to the upstream of the running path of material. The temperature-controlled suspension roaster has the advantages that the process arrangement is simple, the occupied land is small, and the operation and maintenance expenses are low; the roasting effect is good, the decomposition efficiency of magnesium carbonate is high, and magnesium oxide products with different purities can be obtained by changing calcination temperature; magnesite powder is dried and preheated by using discharged waste gas, the heat of high-temperature waste flue gas is fully recycled, and the heat efficiency of the roaster is improved; and the four-stage cyclone cooler has a good cooling effect and can be used for cooling a finished product magnesium oxide to be below 100 DEG C so that caloric content of magnesium oxide can be fully recovered for disintegrating magnesite and the energy consumption of the roaster can be reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Production method of active metallurgical lime

The invention relates to a production method of lime, especially relates to a production method of active metallurgical lime, and aims to solve the problem that the active metallurgical lime produced by the existing technology is high in content of sulfur and carbon impurities, easily absorbs moisture and goes bad, and is high in production cost. The production method of active metallurgical lime comprises the following steps of: (1) purifying and crashing the lime stone raw material; (2) mixing the lime stone raw material with the combustion improver to prepare the mixture of the lime stone powder and the combustion improver; (3) preheating the mixture of the lime stone powder and the combustion improver; (4) with the coke oven gas as fuel, roasting the mixture of the lime stone powder and the combustion improver in a boiling kiln; (5) separating by a cyclone separator, and cooling to get the active metallurgical lime product. With the production method of active metallurgical lime provided by the invention, the produced active metallurgical lime is low in content of sulfur and carbon impurities, not easy to absorb moisture and go bad, and low in production cost.

Owner:ZHEJIANG JIANDE HONGXING CALCIUM

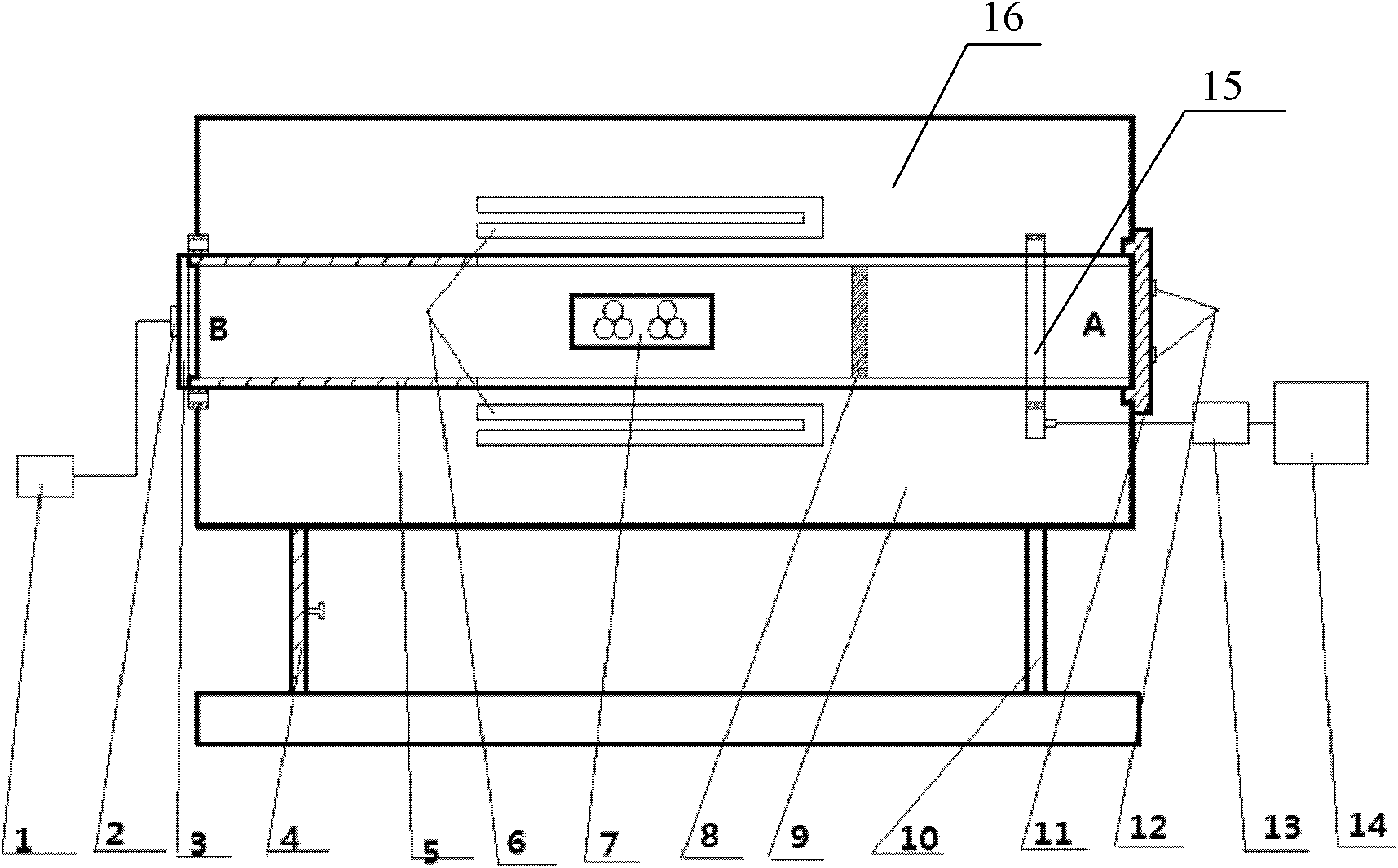

Regenerative multistage heating rotary kiln device

ActiveCN105698524AReduce energy consumptionLow investment costRotary drum furnacesLime productionEngineeringMechanical engineering

The invention relates to a regenerative multistage heating rotary kiln device. The regenerative multistage heating rotary kiln device comprises rotary kilns and raw material pre-heaters. Each rotary kiln comprises a kiln body, a kiln chamber, a kiln head cover, a kiln tail cover and a cooler. Each kiln tail cover is provided with a burner. Each kiln head cover is provided with an ejecting burner body. The raw material pre-heaters are connected with the kiln chambers through the kiln tail covers. The kiln chambers are connected with the coolers through the kiln head covers. The rotary kiln device is provided with 1-50 sets of rotary kilns and the raw material pre-heaters, each set comprises one rotary kiln and 1-50 raw material pre-heaters, and the raw material pre-heaters are combination pre-heaters, Maerz pre-heaters, brettis vertical kiln type pre-heaters or regenerators. According to the regenerative multistage heating rotary kiln device, by combining the rotary kilns with the raw material pre-heaters, the calcination effect and the product quality are improved, energy consumption of lime production is reduced, the production capacity of the device is improved, and occupied areas are decreased advantageously.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

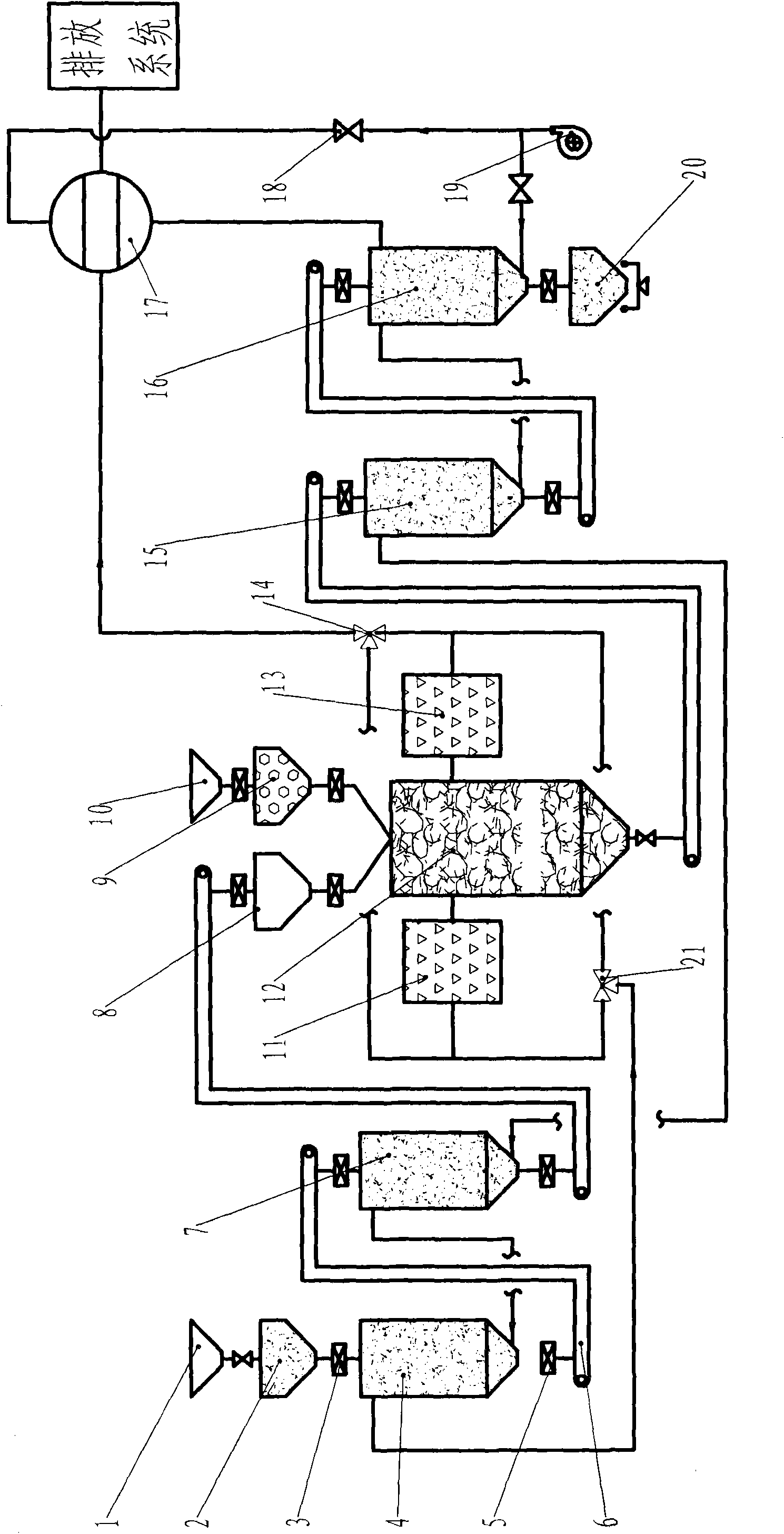

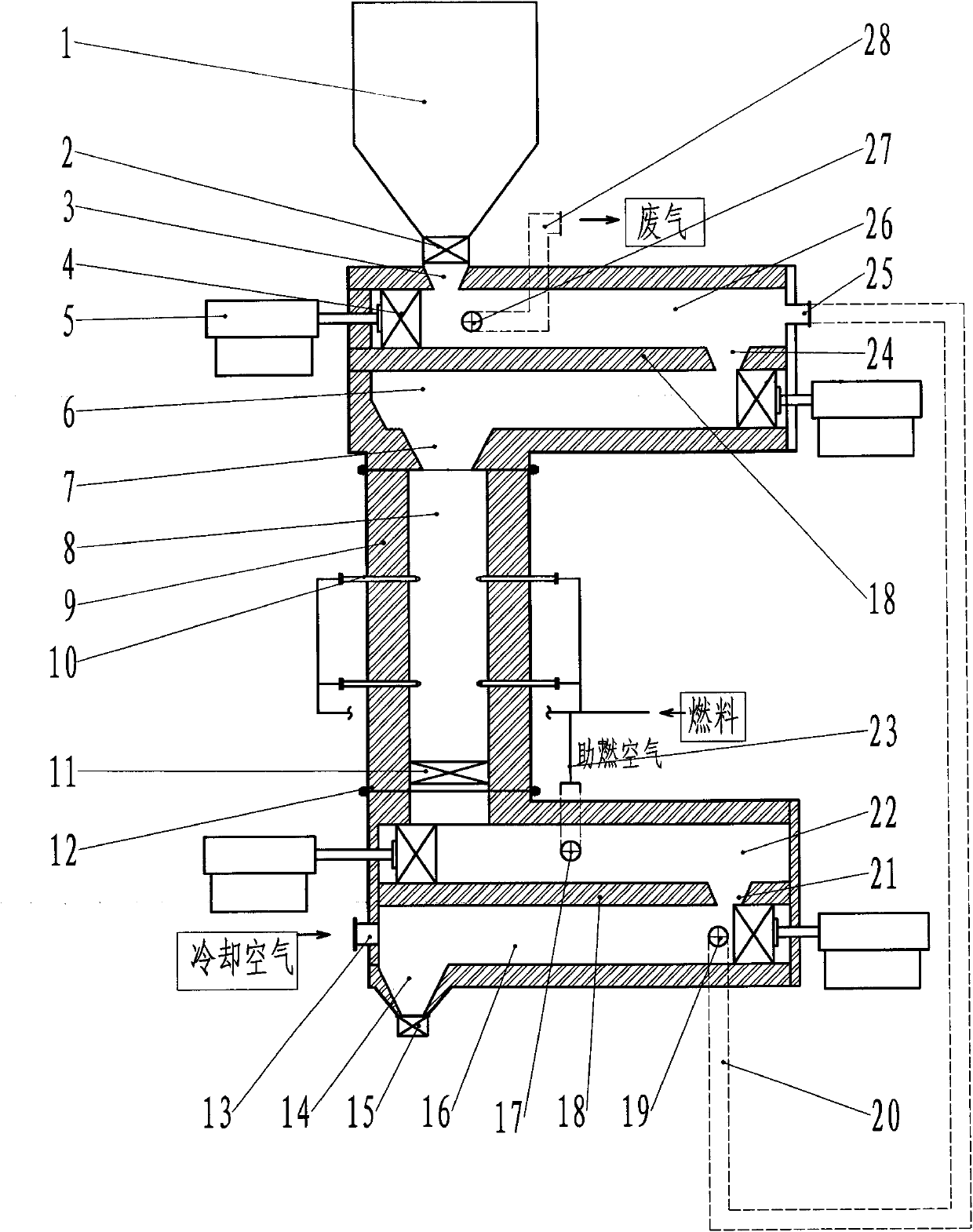

Method and machine for calcining materials

ActiveCN101792273AReduce heat exchange equipmentReduce equipment investment and operating costsEngineeringCombustion

The invention provides a method and a machine for calcining materials, comprising feeding equipment, a preheating chamber, a calcining chamber, a cooling chamber, discharging equipment and an exhaust emission system, wherein the calcining chamber is provided with 1-10 rows of peripheral burners, and the preheating chamber and the cooling chamber are transversely arranged. The preheating chamber and the cooling chamber are respectively divided into a high-temperature preheating chamber and a low-temperature preheating chamber as well as a high-temperature cooling chamber and a low-temperature cooling chamber by partition walls. The materials of the preheating chamber and the cooling chamber transversely move under the push of a pusher; higher-temperature air after the high-temperature cooling chamber cools products is used as combustion air; higher-temperature air after the low-temperature cooling chamber cools the products is used for preheating limestone materials in the preheating chamber. In the invention, heat energy is well utilized to save heat-exchange equipment and reduce equipment investments and operating costs, which reduces the discharge of greenhouse gases and is beneficial to environmental protection. The machinery is a detachable assembly, and all component equipment is manufactured separately and is assembled on site, thereby facilitating transportation, installation, overhauling and replacement and being beneficial to serialized production of calcining machinery.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for preparing magnesium

The invention discloses a method for preparing magnesium. The method comprises the following steps: calcining dolomite in a rotary kiln to obtain calcined dolomite and tail gas; mixing the calcined dolomite with ferrosilicon and fluorite to obtain a mixture; performing ball-milling on the mixture to obtain a granular mixture; briquetting the granular mixture to obtain pelletized materials; arranging the pelletized materials into a feeding region in a rotary hearth furnace, gradually heating the pelletized materials in the feeding region in a preheating region and a heating region, and performing reduction reaction on the pelletized materials in a high-temperature region to obtain magnesium steam, flue gas and furnace slag; condensing the magnesium steam to obtain magnesium. The method disclosed by the embodiment of the invention is simple in process and low in energy consumption; the reduction reaction is carried out by adopting the rotary hearth furnace, so that magnesium can be continuously produced, the yield is increased, and efficient production of magnesium can be carried out.

Owner:SHENWU TECH GRP CO LTD

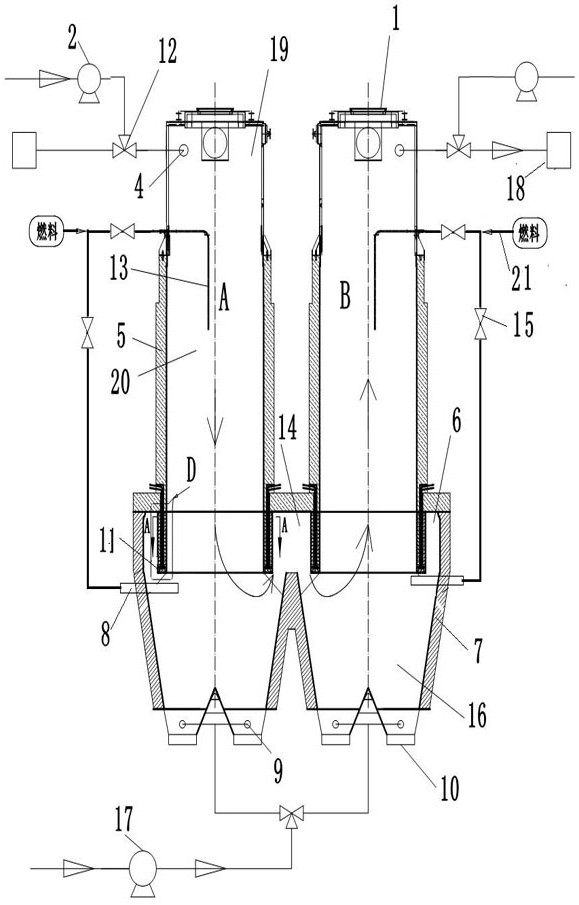

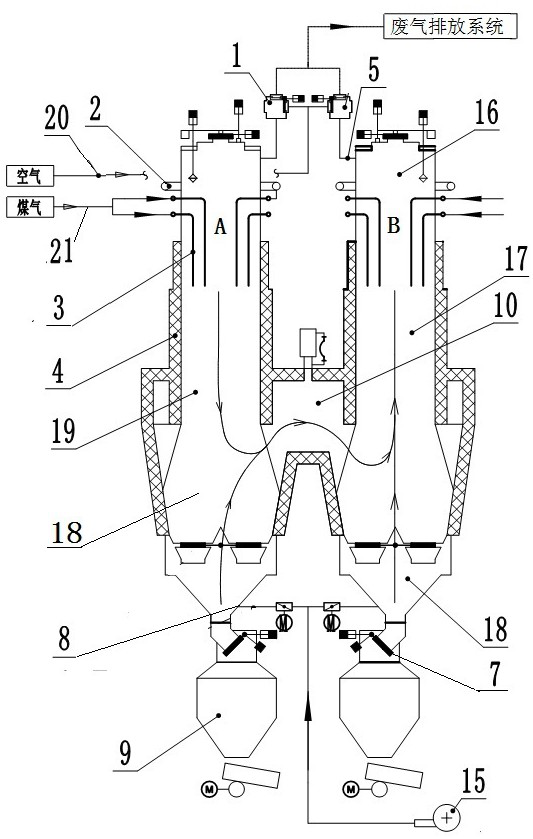

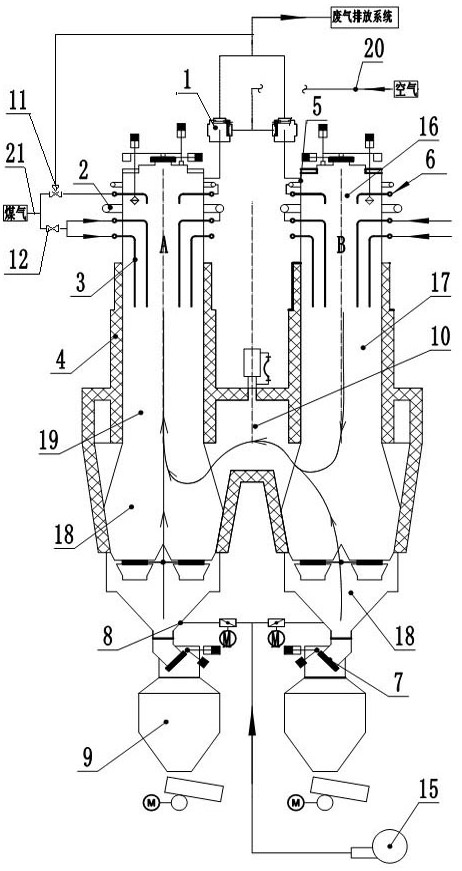

Double-hearth kiln for calcining lime by using low-calorific-value fuel and calcining method

The invention relates to a double-hearth kiln for calcining lime by using low-calorific-value fuel and a calcining method. The double-hearth kiln comprises a double-hearth kiln body, a fuel pipeline and an exhaust emission system. The double-hearth kiln body comprises a kiln hearth A and a kiln hearth B, a calcining zone is provided with an inserted burner, the lower part of the kiln hearth is provided with a fuel nozzle, and a fuel pipeline is respectively connected to the inserted burner and the fuel nozzle. The calcining method comprises the steps that the plug-in combustor sprays out fuel, combustion-supporting air enters the kiln hearth through the air inlet and outlet for combustion-supporting combustion, and limestone materials are calcined. The fuel and flue gas sprayed out of the fuel nozzles enter the kiln chamber on the other side through the flue gas channel and combust in a combustion-supporting mode on the lower portion of the calcining zone together with air obtained after lime is cooled in the cooling zone, and the limestone is further calcined. By arranging the fuel nozzles, secondary combustion is carried out on the lower portion of the kiln chamber on the other side, undecomposed limestone is continuously calcined, the fuel supply mode and the limestone calcining method are optimized, the calcining effect is improved, low-calorific-value fuel is fully utilized, and the quality of calcined products is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

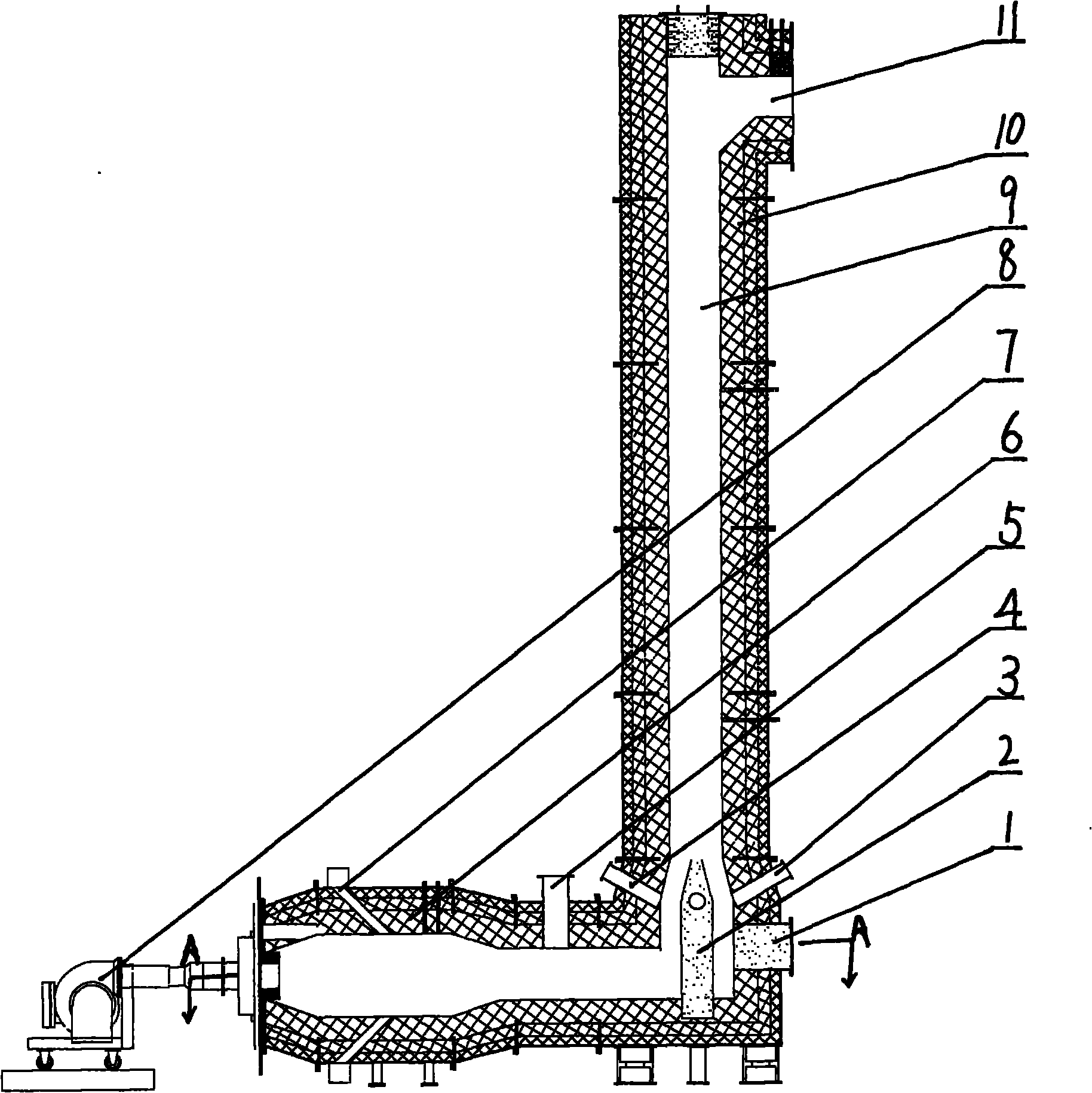

Built-in chimney flue type energy-saving environment protective smelting lime calcining kiln

InactiveCN101062844AIncrease profitImprove pressure resistanceLime productionCombustion chamberFlue gas

The invention discloses a energy-saving environmental protection metallurgy lime calcining kiln with built-in flue, which comprises the following steps: arranging a build-in chimney (15) in cave of kiln body (2); equipping a ring-shaped flue (10) with several flue gas reclaiming mouths at the lower of entering fire hole (6); communicating the flue gas reclaiming mouth with burning room (8); setting the built-in chimney (15) as hollow structure; opening circulating flue (4) at the upper; connecting the lower end to the ring-shaped flue (10) through flue gas pipe (12) and lower exhauster (11). This invention can be cycling utilized, which can decrease environmental pollution degree.

Owner:刘永智

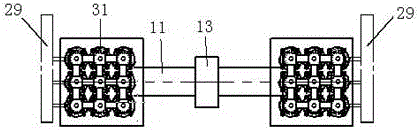

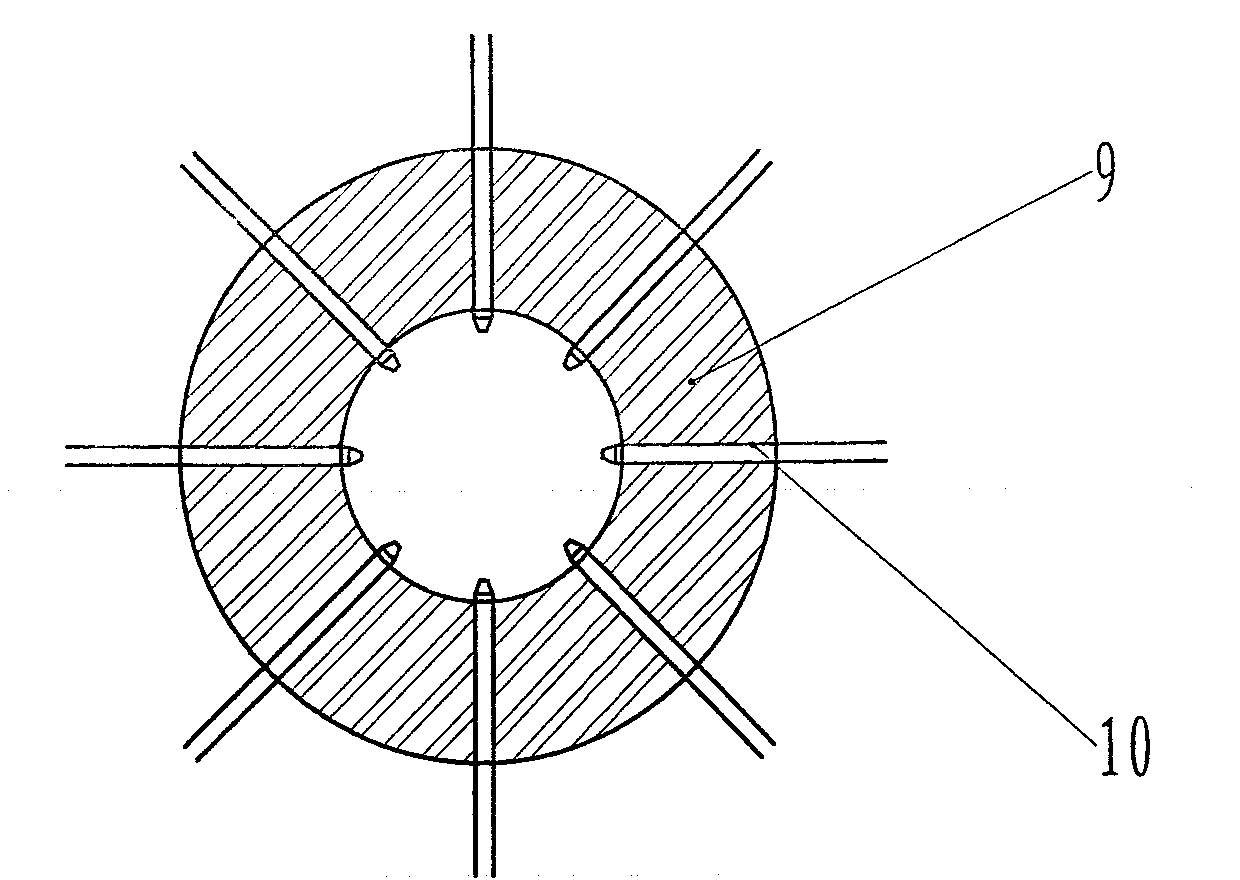

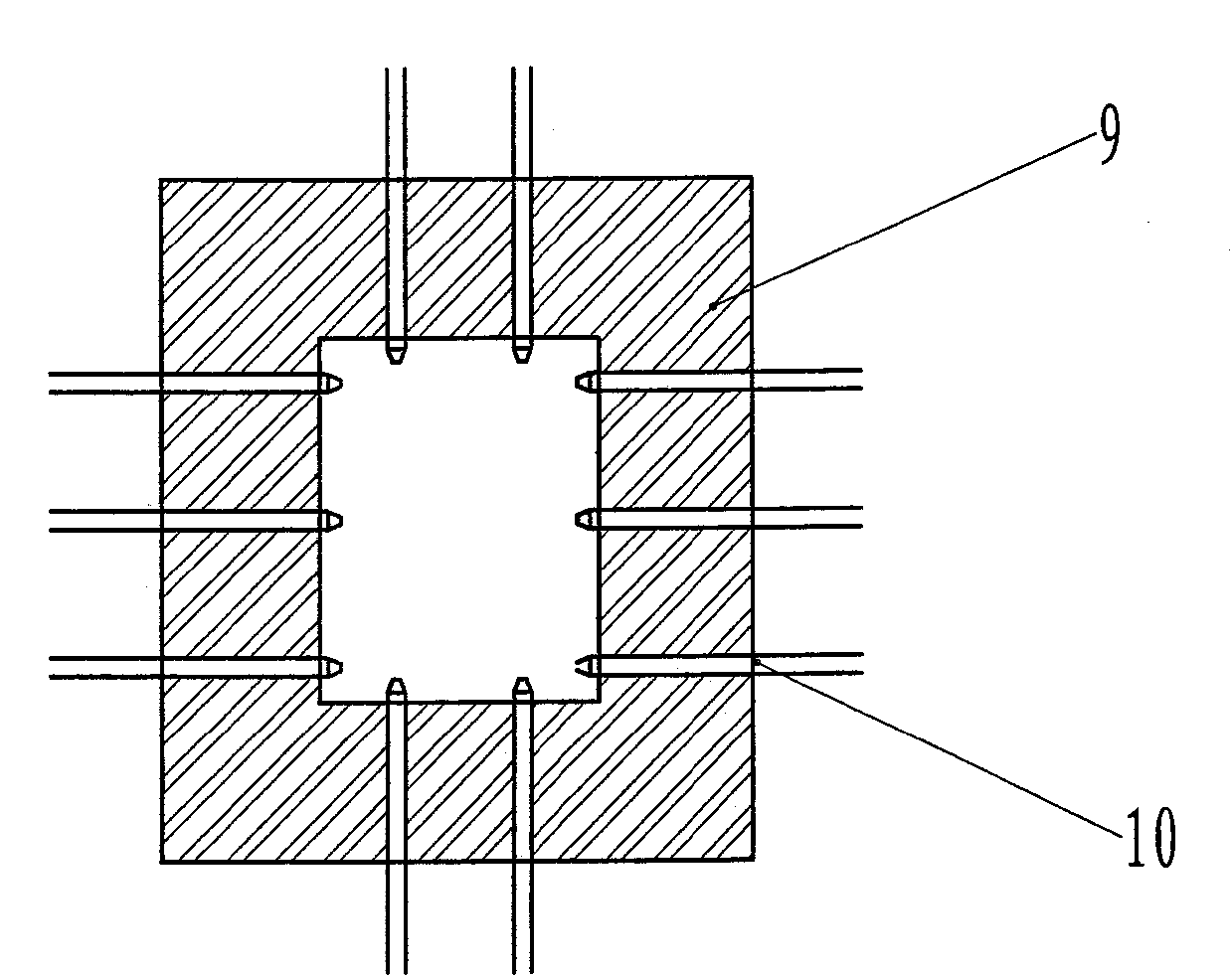

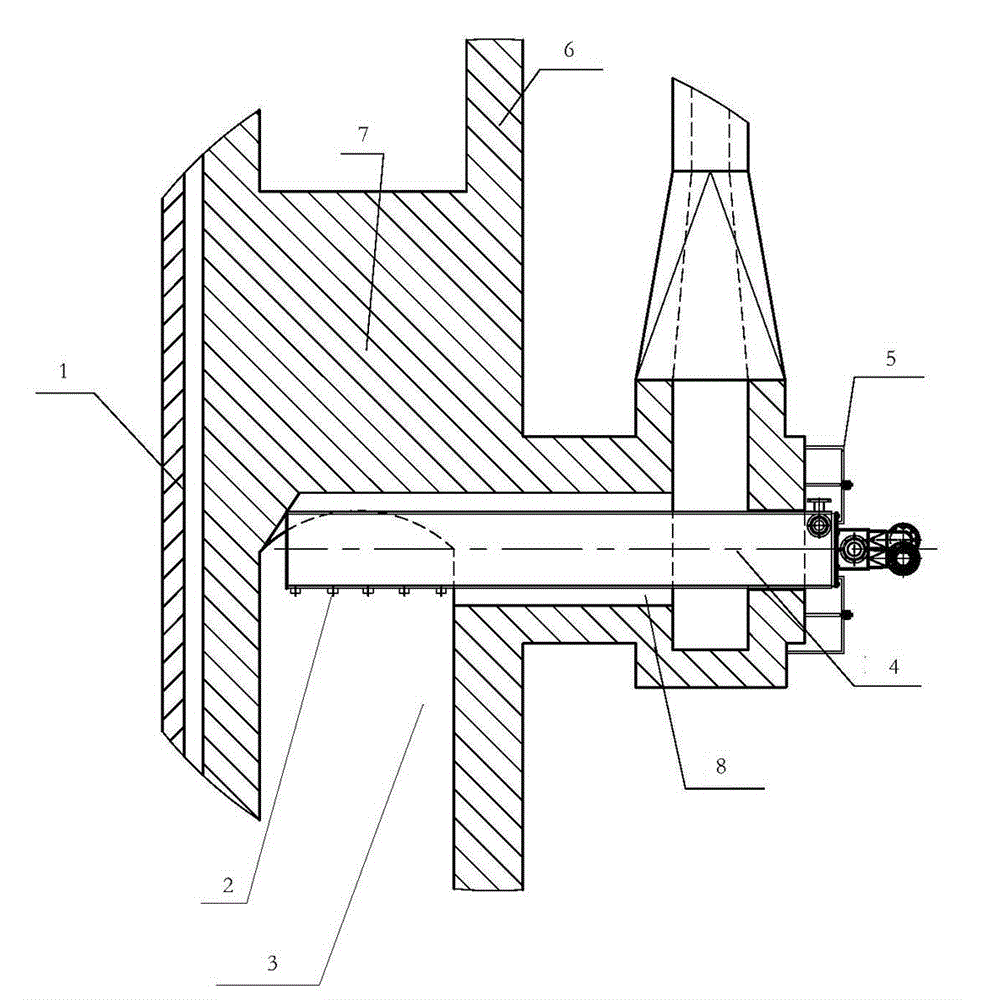

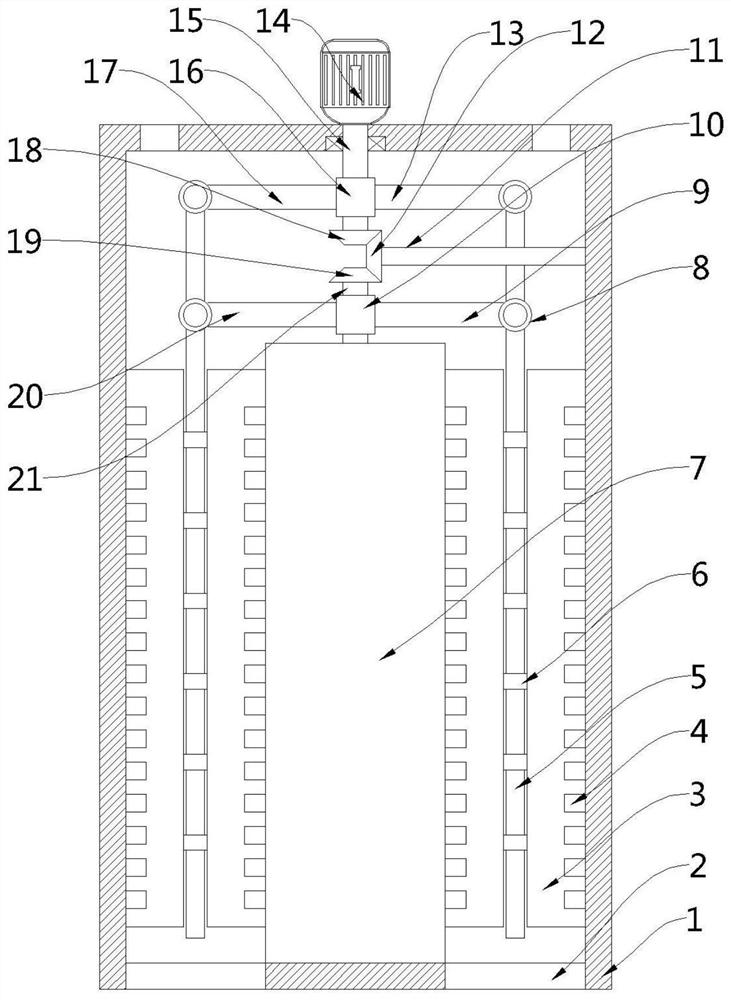

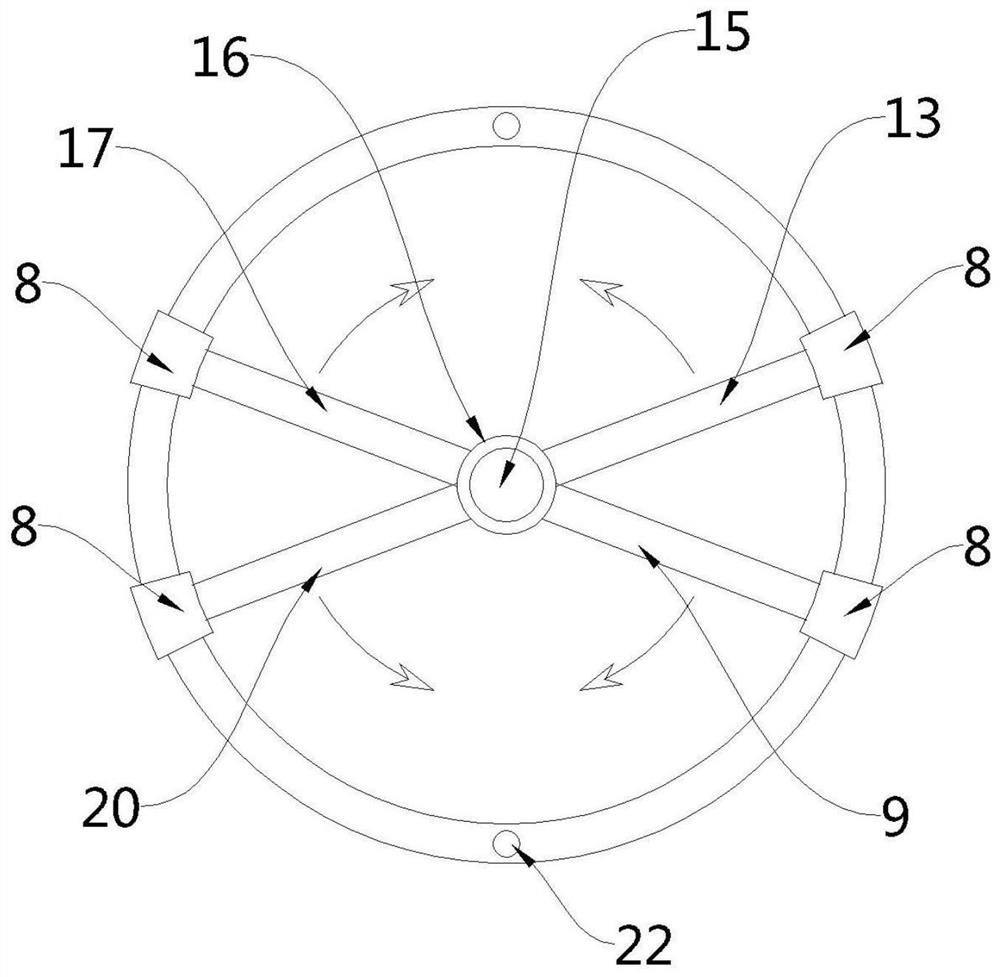

Atmosphere-controllable high-speed rotary kiln

InactiveCN102519246APrecisely control the temperature rangeReduce experimental errorRotary drum furnacesTemperature controlEngineering

The invention discloses an atmosphere-controllable high-speed rotary kiln, which comprises a horizontal rotary furnace placed in a transverse case. A transmission capable of driving the furnace to rotate is disposed outside the rotary furnace, adjustable struts are respectively arranged under two ends of the case, or an adjustable strut is arranged under one end of the case while a fixed strut is arranged under the other end of the case, so that one end of the rotary furnace can be high while the other end of the rotary furnace is low after the rotary furnace is adjusted according to needs. The adjustable struts are adopted, so that free angle change of a kiln body can be realized, an included angle between the kiln body and the horizontal plane can range from minus 5 degrees to 5 degree, raw materials are reacted sufficiently, simultaneously, the atmosphere-controllable high-speed rotary kiln is provided with a temperature control system capable of fast increasing and reducing the temperature in the furnace, and is further provided with a vacuumizing system, the atmosphere in the furnace is controllable, the rotation speed of the rotary kiln is high, so that a material calcination effect is fine, and effects of energy conservation, high efficiency and environmental protection are achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

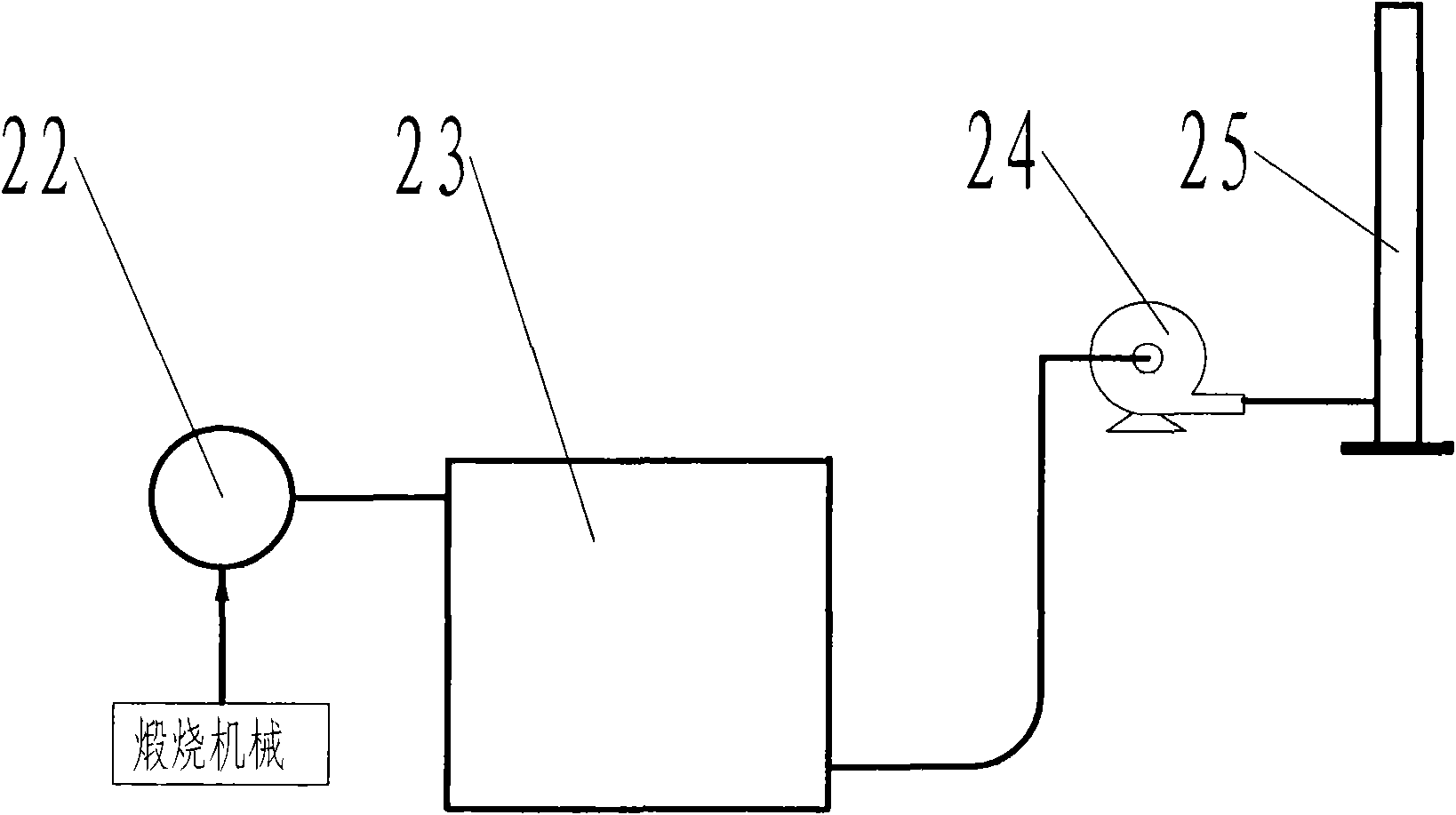

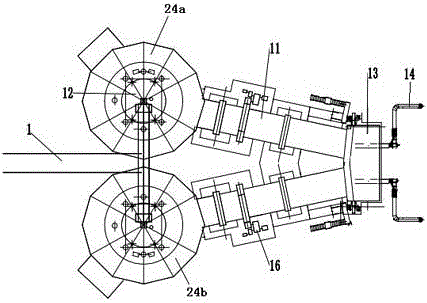

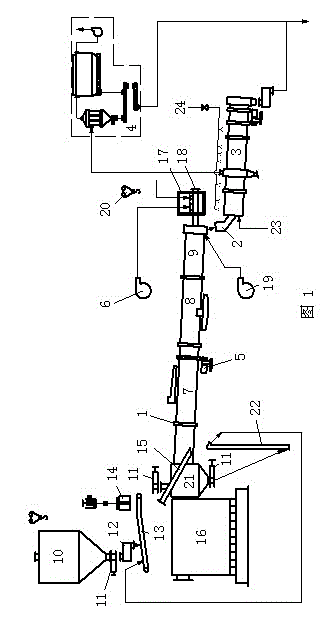

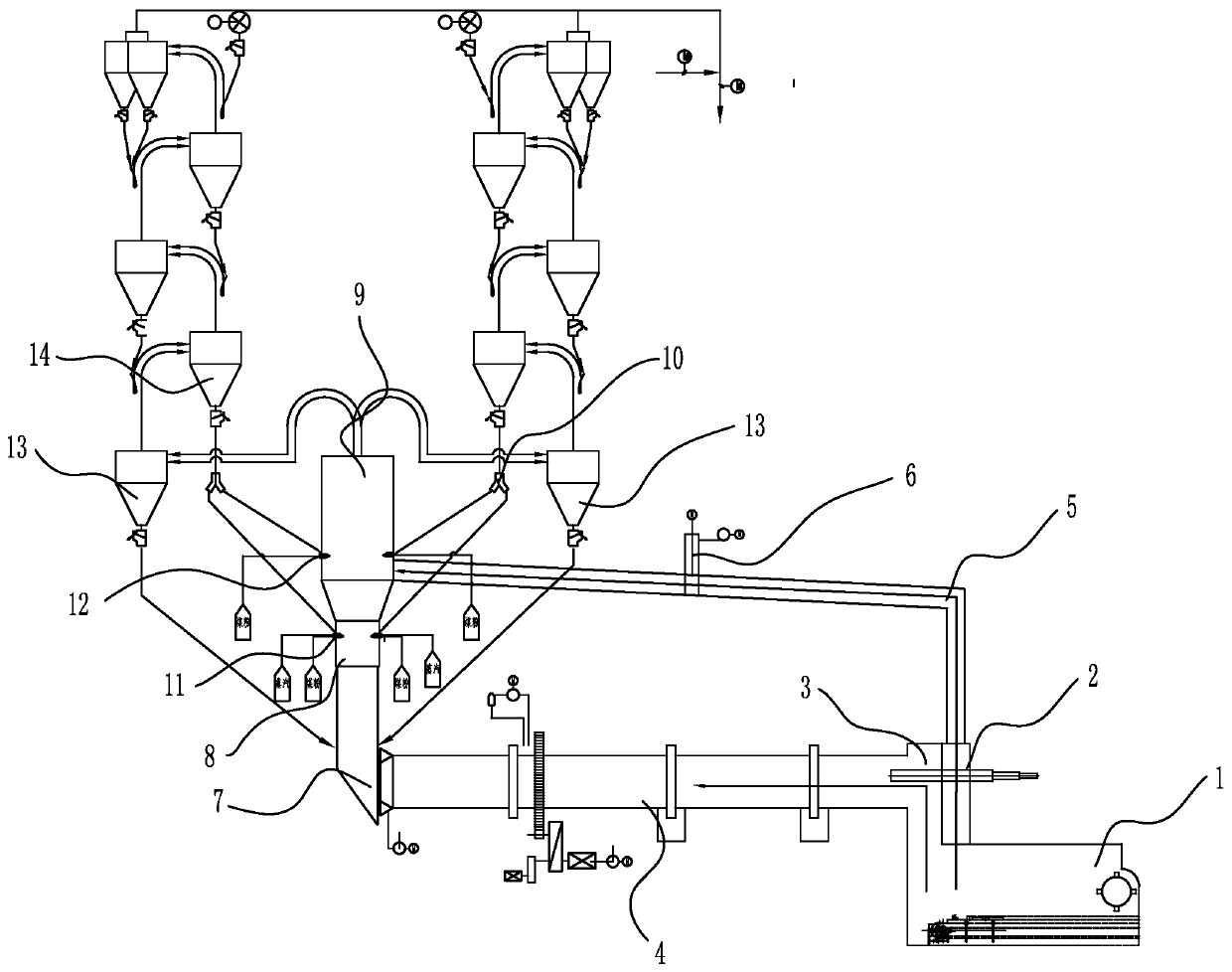

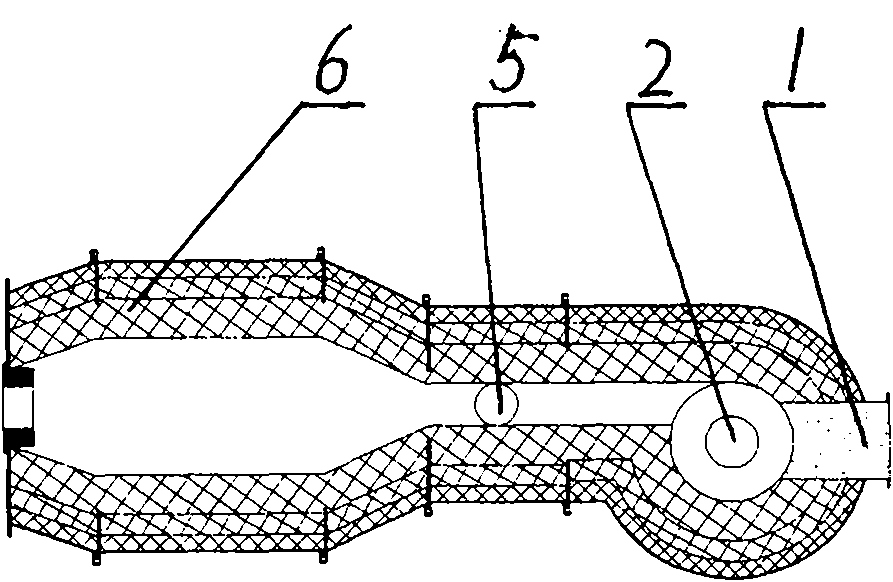

Method and device for calcinating needle coke with rotary kiln

InactiveCN102745664AReduce brittlenessAvoid severe thermal shockChemical industryCarbon preparation/purificationThermodynamicsElectric machine

The invention discloses a method and device for calcinating needle coke with a rotary kiln. The method makes use of a rotary kiln to calcinate needle coke, so that a violent thermal shock generated during green coke's entrance into existing rotary hearth calciners can be avoided, and the calcinated coke has greatly reduced brittleness, thus enhancing the content of coarse particles in modern large-specification electrode production. The device comprises a rotary kiln (1), the feed inlet of which is provided with a feeding device and an ash settling chamber. The discharge port of the rotary kiln is in connection with the feed inlet of a cooling machine (3) adopting dual cooling through an electric elephant trunk (2). The cooling machine is connected to a waste gas treatment system (4). The rotary kiln is driven to rotate by a variable frequency motor (5). The discharge port of the rotary kiln is provided with a double-frequency conversion blower (6). By employing the method and the device of the invention, the quality of calcinated coke can be improved, the investment can be reduced, the running rate can be high, automatic control is easy to realize, and the labor intensity of workers can be lowered.

Owner:GUIYANG AL-MG DESIGN & RES INST

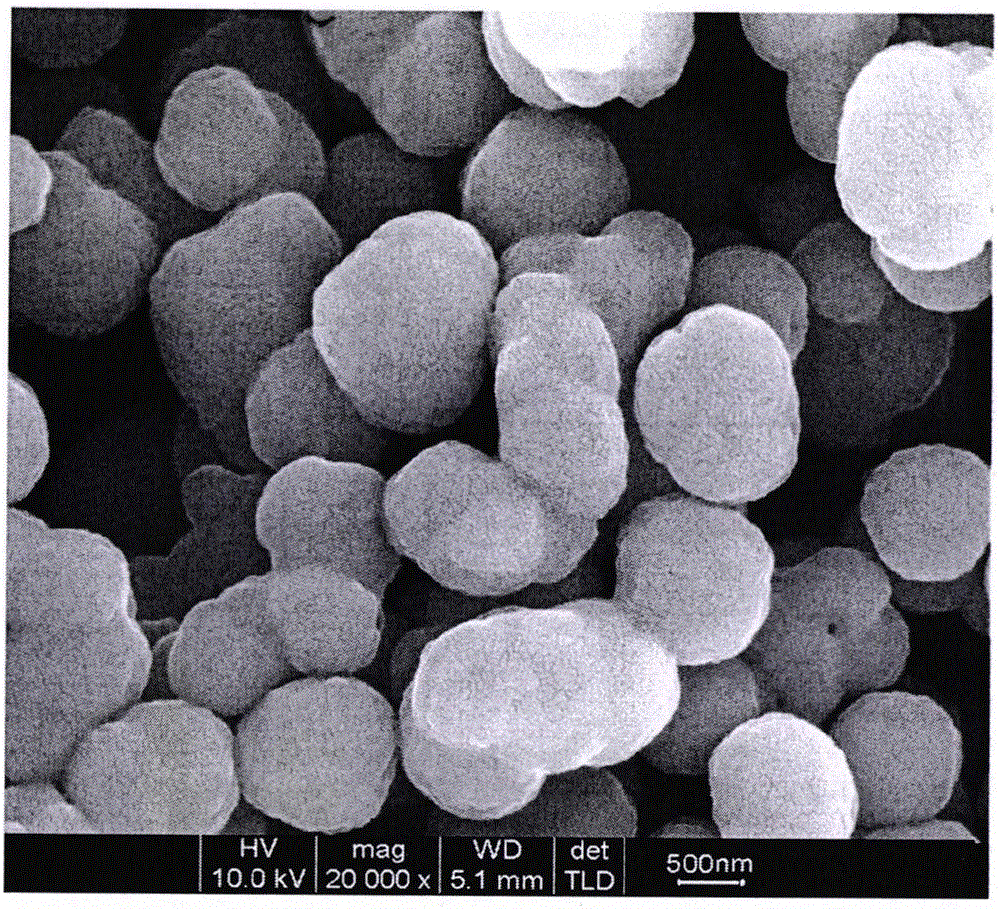

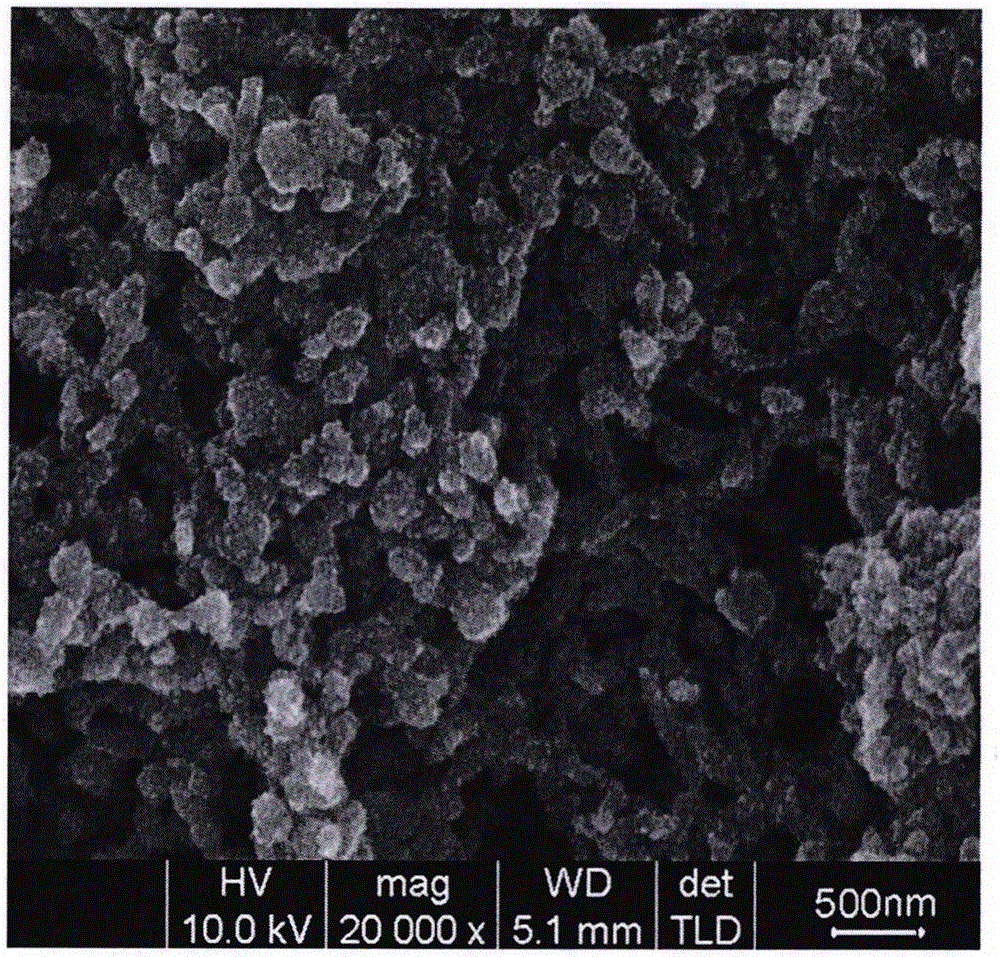

Wet-method preparation and activation method of nanometer calcium carbonate

InactiveCN109319814ASmall particle sizeUniform particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbon dioxideCalcium carbonate

The invention discloses a wet-method preparation and activation method of nanometer calcium carbonate. Limestone is calcined and crushed, wherein a crusher is adopted for crushing, the crushed particle size is 1-2 cm, then limestone particles are put into a calcinator for calcining, calcining time is 120-360 min, temperature is 900 DEG C, in a calcining process, a fluidized bed is arranged in thecalcinator, and the limestone particles are subjected to fluidized calcining in the fluidized bed; quicklime is obtained, water is added, stirring is conducted to obtain slaked lime, and stirring is conducted for 30-60 min; the slaked lime is put into an activation reaction kettle, water adding is continued, meanwhile, heating is conducted for stirring, heating temperature is 45-65 DEG C, in an activation device, carbon dioxide is introduced for bubbling, and an activator is added while stirring to accelerate activation; wet calcium carbonate is obtained; after sedimentation and filtering areconducted, a filter press is used for filter pressing; the wet calcium carbonate subjected to press filtering is dried. The activation method has the advantages that the calcining speed is higher thanthat in the prior art, a calcining effect is good, and energy consumption is saved; the activation rate is improved.

Owner:NANJING AIFENG TECH CO LTD

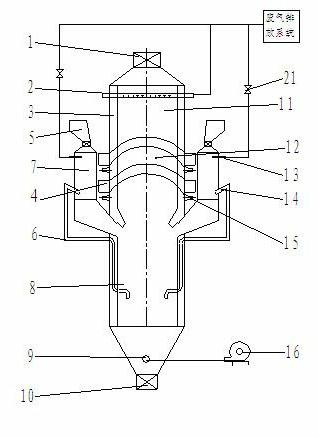

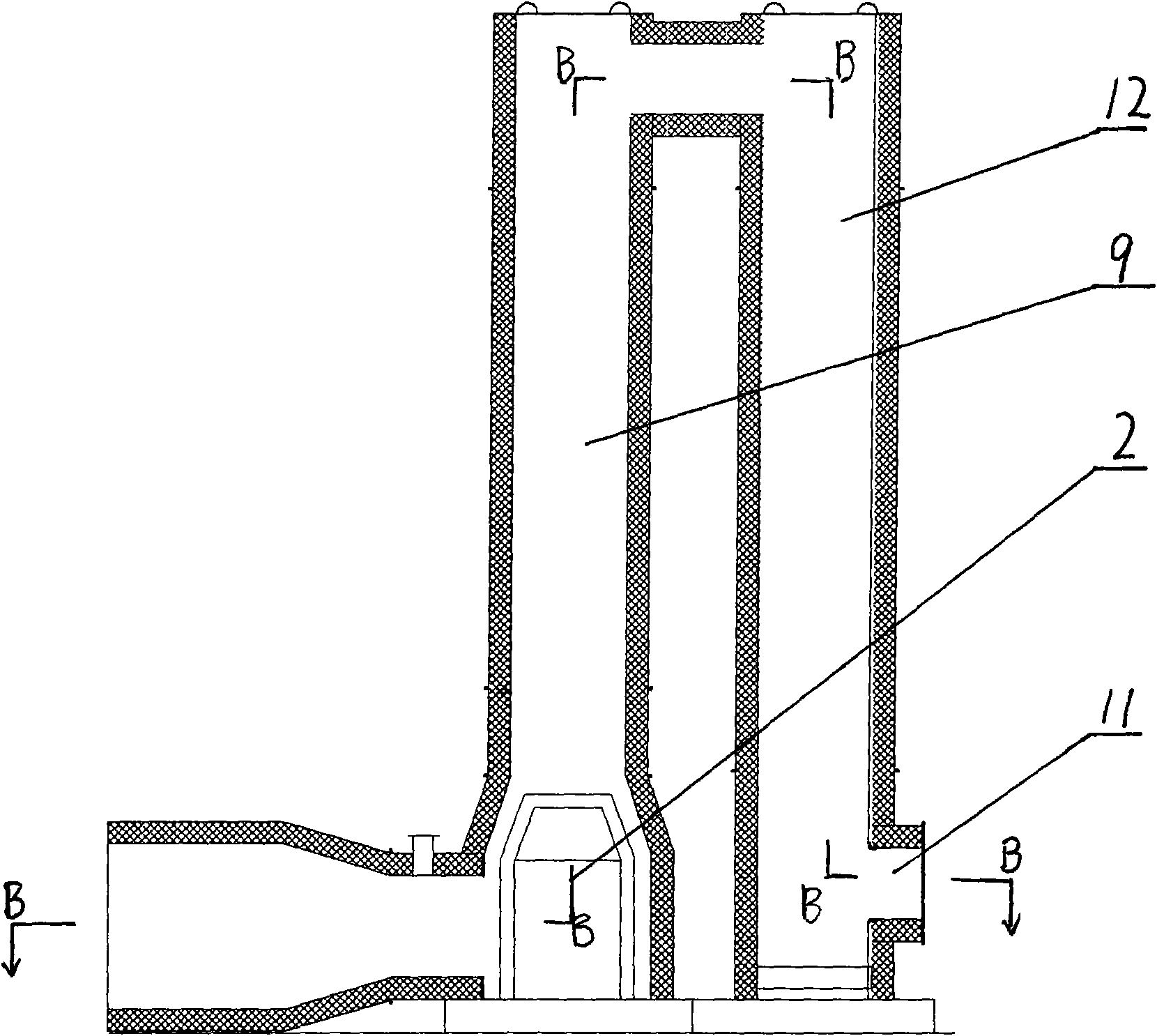

Novel multi-fuel sleeve type lime kiln

InactiveCN102910843AEliminate calcination dead angleImprove the uniformity of calcinationCombustion chamberEngineering

The invention discloses a novel multi-fuel sleeve type lime kiln which is composed of a kiln shell and upper and lower inner sleeves, wherein the upper and lower inner sleeves are arranged in the kiln shell; a calcining circular passage is formed between the kiln shell and the upper and lower inner sleeves; burning chambers which are distributed into two rows with one above the other are arranged in the circular passage at intervals; burning beams are arranged in the burning chambers; each burning beam extends into the circular passage from the wall of the kiln shell; and the beam body part of each burning beam extending into the circular passage is provided with a nozzle. By adopting the sleeve type lime kiln, good calcining effect can be still obtained under the condition that the distance between the kiln shell and the upper and lower inner sleeves is increased, thus, the capacity of limestone can be greatly improved through greatly enlarging the width of the circular passage, and the daily yield of a calcining kiln is improved further. With the adoption of the multi-fuel sleeve type lime kiln, the daily yield of the calcining kiln can reach 800 tons, the limitation that the highest daily yield of the existing kiln type is 600 tons is broken through thoroughly, and economic benefits are extremely outstanding.

Owner:BO GUANG THERMAL ENERGY

Process for preparing purely-natural nano supermicro calcium powder

InactiveCN106395876ADecompose fullyCalcination temperature is lowCalcium/strontium/barium oxides/hydroxidesHigh pressure waterEnergy consumption

The present invention discloses a process for preparing purely-natural nano supermicro calcium powder, and the process comprises selecting raw materials, washing, crushing, grinding, calcining, grinding again, hydrolyzing, superfinely grinding and drying; the washing includes water washing, ultrasonic acid pickling and high-pressure water washing, the ultrasonic acid pickling is as follows: ultrasonic acid pickling the raw materials in a dilute HCl solution with the concentration of 0.01-0.05mol / L for 30-60min, wherein the ultrasonic frequency is 20-60KHz; the calcining is as follows: using a temperature programming manner for heating and calcining the ground raw materials, the temperature programming comprises the following steps: (a) initially heating to 500-800 DEG C at the heating rate of 20-30 DEG C / min and holding for 2-4H, and (b) continuing heating to 1000-1200 DEG C at the heating rate of 5-10 DEG C / min and holding for 3-5H. The process for preparing the purely-natural nano supermicro calcium powder is low in temperature, calcining energy consumption is low, energy is saved, and the purity of the nano supermicro calcium powder is improved.

Owner:QINGDAO SHIAN BIOLOGICAL ENG

Method for calcining limestone by using low-calorific-value fuel in double-hearth kiln

The invention relates to a method for calcining limestone by using low-calorific-value fuel in a double-hearth kiln, which is characterized in that incomplete combustion calcination is performed in a kiln body on one side, and complete combustion calcination is performed in a second calcination area of a kiln body on the other side. The specific process is as follows: in the state (1), fuel and air are sprayed into a kiln chamber A for complete combustion, and flue gas enters a kiln chamber B for preheating materials; in the state (2), fuel and 3-30 (v)% of the required amount of air injected into the kiln chamber A are incompletely combusted, and burning is conducted in a second calcining area of the kiln chamber B, and the material is continuously calcined; in the state (3), fuel and air are sprayed into the kiln chamber B to be completely combusted, and flue gas enters the kiln chamber A to preheat the materials; and in the state (4), fuel and 3-30 (v)% of air are injected into the kiln chamber B for incomplete combustion, combustion is conducted in the second calcining area of the kiln chamber A, and the material is continuously calcined. By means of the second calcining area and time-controlled segmented calcining, the limestone calcining process of the double-hearth kiln is optimized, the calcining effect is improved, low-calorific-value fuel is fully utilized, high-quality fuel is saved, and the quality of calcined products is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

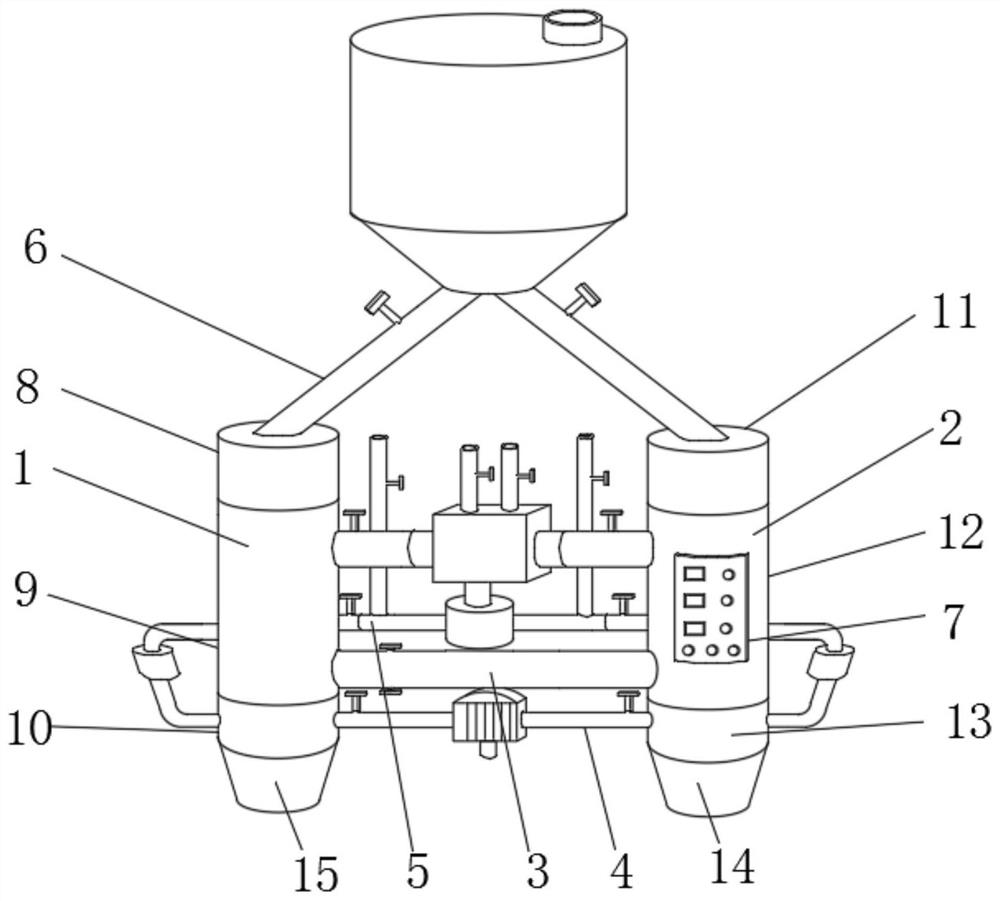

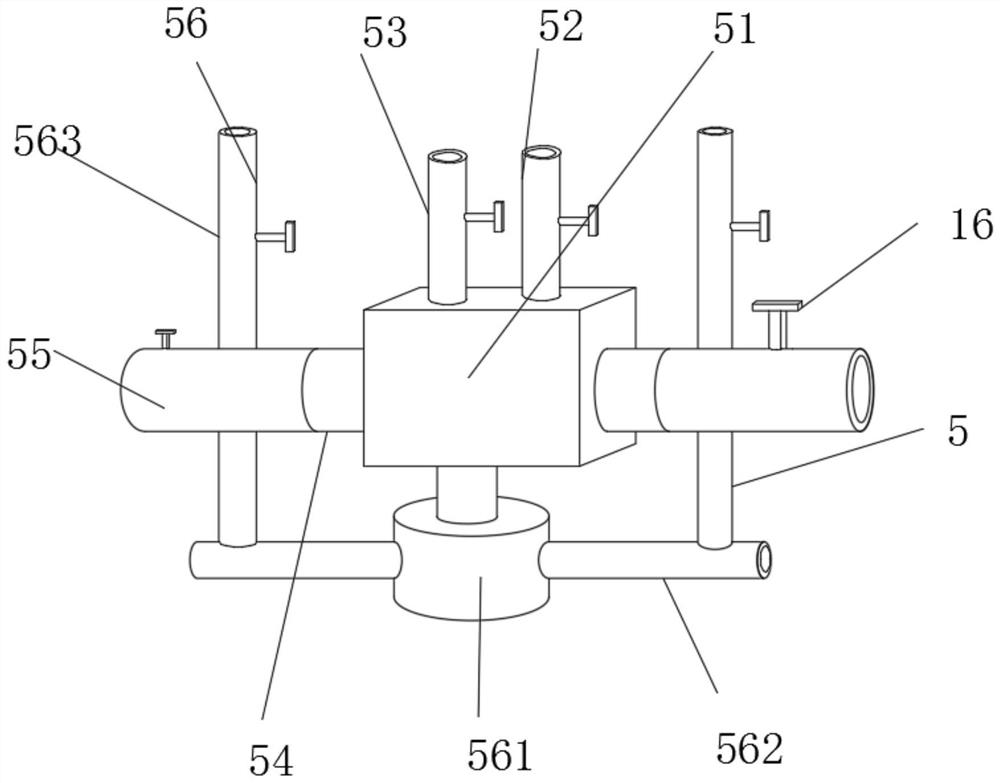

Petroleum coke calcining device for prebaked anode

ActiveCN111678334AIncrease contactImprove calcination effectRotary drum furnacesCarbon preparation/purificationThermodynamicsPhysical chemistry

The invention provides a petroleum coke calcining device for a prebaked anode, and belongs to the technical field of petroleum coke calcining. The device comprises a calcining cylinder and a central column arranged inside the calcining cylinder, an annular calcining channel is formed between the calcining cylinder and the central column, a plurality of feed inlets are formed in the upper portion of the calcining cylinder, a plurality of discharge outlets are formed in the bottom of the calcining cylinder, and heating plates are arranged on the inner wall of the calcining cylinder and the outerwall of the central column correspondingly; and four groups of stirring assemblies are arranged inside the annular calcining channel. According to the device, the four groups of stirring assemblies are arranged in the annular calcining channel, two opposite groups of stirring assemblies are driven to be close to each other by a first driving assembly, and material poking plates corresponding to the two groups of stirring assemblies form a V-shaped structure with a certain included angle under the action of petroleum coke raw materials, so that the petroleum coke raw materials are poked to theinner wall of the calcining cylinder and the outer wall of the central column, the petroleum coke raw materials can be in better contact with the heating plates, and the device has the advantage of good calcination effect.

Owner:百色皓海碳素有限公司

System and method for achieving green denitration by means of dry process production process

PendingCN110170239ASave coalLess investmentNitrous oxide captureDispersed particle separationCycloneProcess equipment

The invention discloses a system and a method for achieving green denitration by means of a dry process production process. The system comprises a multi-stage cyclone barrel, a decomposing furnace, afeed-end chamber, a rotary kiln and a grate cooler, wherein a denitration chamber is arranged on the lower part of the decomposing furnace, a spraying and scattering integrated machine is arranged inthe decomposing furnace, a spraying and scattering denitrator which sprays and scatters steam and pulverized coal simultaneously is arranged in the denitration chamber, the feed-end chamber is arranged below the denitration chamber and is communicated with the rotary kiln, the grate cooler at the head of the rotary kiln is provided with a secondary air taking hood and a tertiary air taking hood, the tertiary air taking hood is connected to the grate cooler and a tertiary air hose, and the air outlet of the tertiary air hose is communicated with the decomposing furnace. By combining characteristics of a cement production process, the system optimizes the process design and the process equipment, and reduces generation of NOX fundamentally by means of process measures based on efficient highquality production, so that green denitration is achieved.

Owner:山东泰溥节能环保科技有限公司

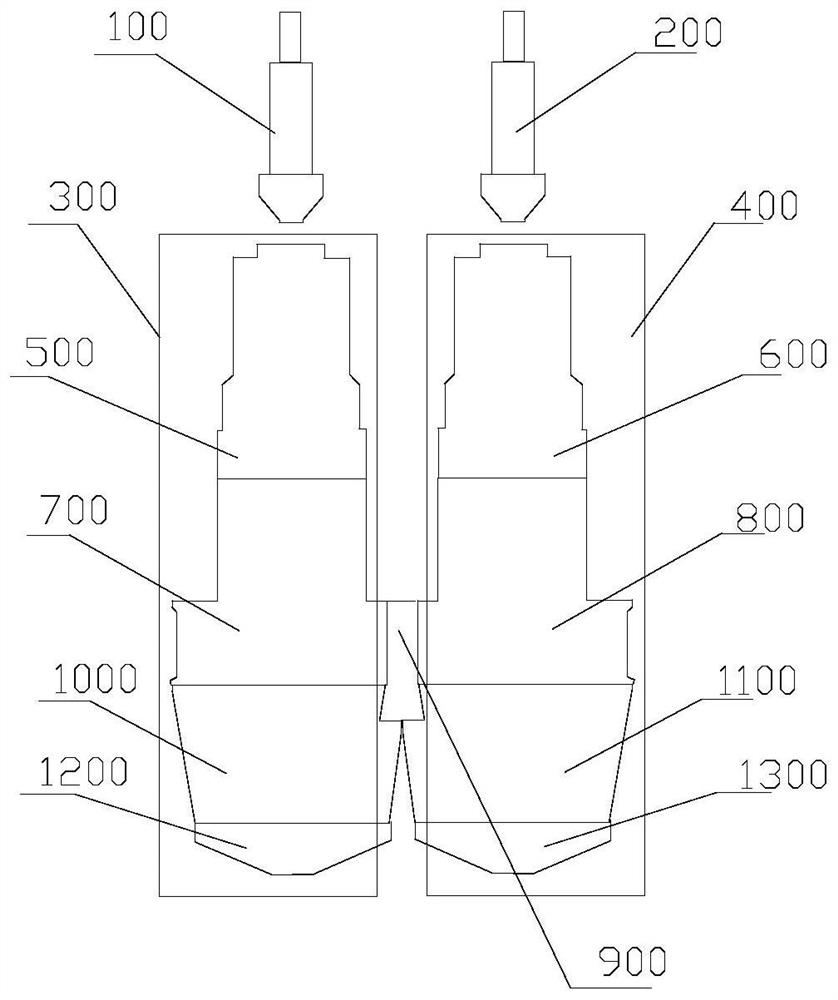

Novel double-hearth kiln for combustion of low-calorific-value fuel

ActiveCN111908811AOptimizing Calcination ResultsImprove calcination qualityPhysicsProcess engineering

The invention discloses a novel double-hearth kiln for combustion of low-calorific-value fuel, which comprises a feeding device, a first kiln body and a second kiln body, wherein the feeding device isrespectively connected with the first kiln body and the second kiln body; the first kiln body comprises a first preheating device, a first calcining device, a first cooling device and a first discharging device from top to bottom; the second kiln body comprises a second preheating device, a second calcining device, a second cooling device and a second discharging device from top to bottom; the first kiln body and the second kiln body are connected through a fixed connecting device. According to the novel double-hearth kiln for combustion of low-calorific-value fuel, the combustion temperatureof the low-calorific-value fuel can be increased through the branch pipes, the main pipe, the combustion chamber and the heat storage box, and the calcination effect is optimized; meanwhile, the cooling device can realize effective conversion and recovery of material heat, so that the energy consumption is further reduced; the double-hearth kiln can achieve mutual switching between the two kiln bodies, and continuous production of materials is completed; finally, the feeding device can enable the double-hearth kiln to discharge materials conveniently, so that the labor intensity of workers isreduced.

Owner:SHENYANG HONGSHAN TECH

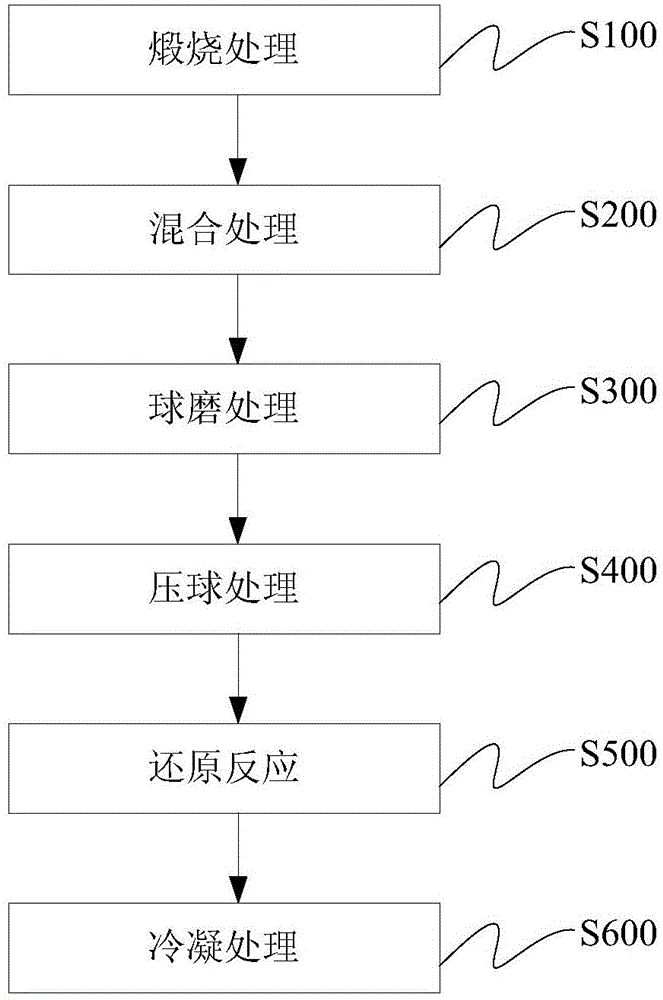

Preparation process of low-oxygen vanadium-nitrogen alloy

The invention discloses a preparation process of a low-oxygen vanadium-nitrogen alloy, and relates to the technical field of alloy materials. When the low-oxygen vanadium-nitrogen alloy is prepared, firstly, vanadium pentoxide is subjected to wet grinding, melamine is added before grinding, small vanadium pentoxide particles are prepared, the ground small vanadium pentoxide particles are placed in a calcining furnace to be subjected to multi-temperature-section calcining, nitrogen-vanadium molten slurry is prepared, finally, the nitrogen-vanadium molten slurry is sprayed, and the low-oxygen vanadium-nitrogen alloy is obtained. And the low-oxygen vanadium-nitrogen alloy is prepared by carrying out spray cooling molding and nitriding on the hedging vanadium molten slurry by using mixed gas of low-temperature carbon dioxide and nitrogen. The low-oxygen vanadium-nitrogen alloy prepared through the method is low in oxygen content, and industrial production is easy.

Owner:江西林力高新材料有限公司

Fluidizing calciner

InactiveCN101995158ABurn fullyObserve the combustionFluidised-bed furnacesCombustorCombustion chamber

The invention discloses a fluidizing calciner, which relates to the improvement on the structure of the calciner. The invention provides a fluidizing calciner which allows for easy observation and has excellent calcining effect. The fluidizing calciner comprises a calciner consisting of a combustion chamber and a flue which has a discharge opening and is arranged beside the combustion chamber; the combustion chamber is connected with a combustor; and the bottom of the flue is provided with a backflow column, and a backflow opening is formed beside the backflow column. The structural key points of the fluidizing calciner lie in that: correspondingly, an observation hole and a feeding hole are formed on the flue wall above the backflow column respectively; and the tail part of the combustion chamber is provided with a high-temperature feeding pipe.

Owner:李竟川 +1

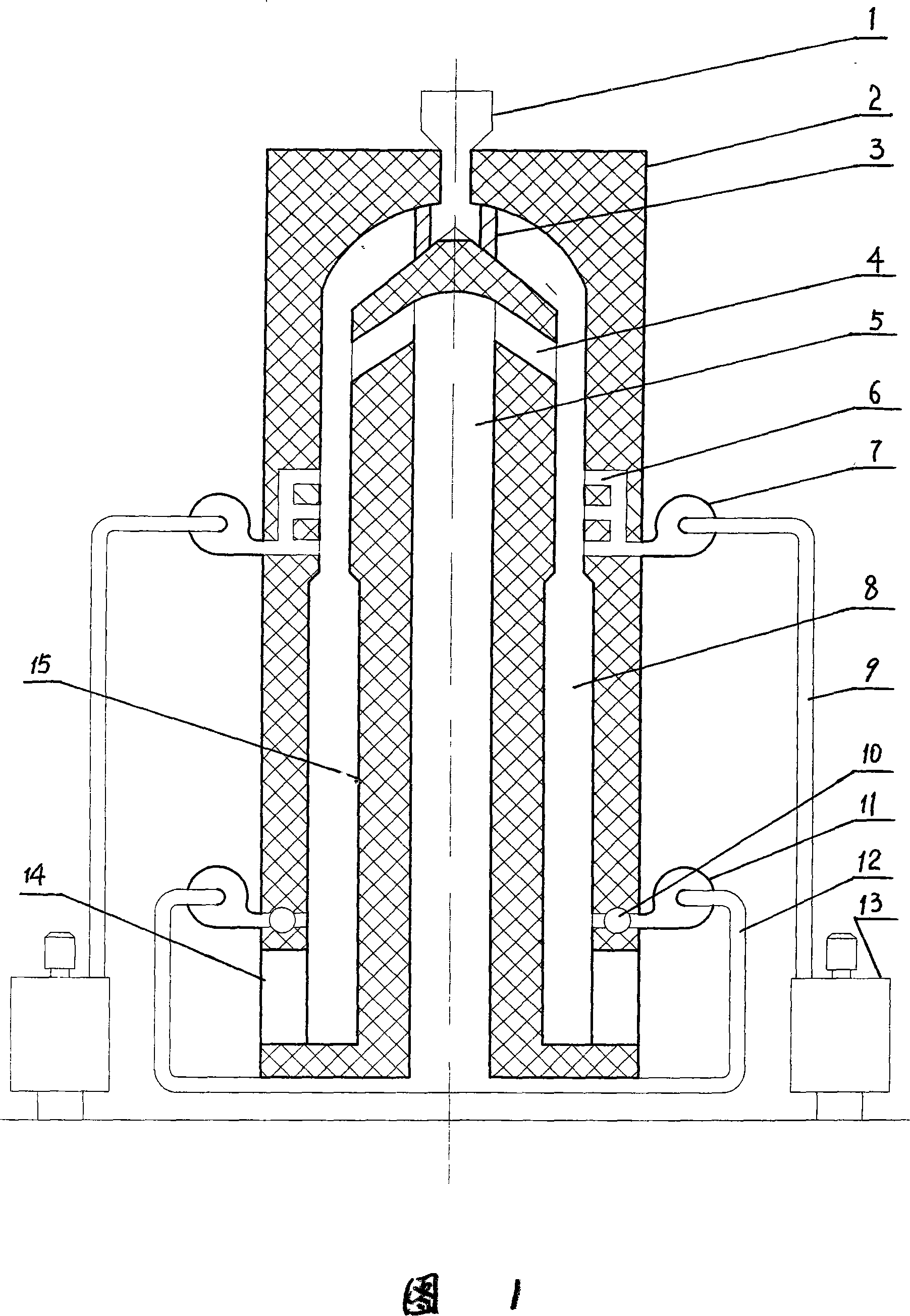

Calcining processing method and device thereof of single crystal growth thermal system

InactiveCN101914807AShorten the calcination cycleReduce energy consumptionBy pulling from meltInterior spaceSingle crystal growth

The invention relates to a technology in the field of a crystal growth furnace for processing a solar silicon battery. A calcining processing method of a crystal growth furnace thermal system is characterized in that a special calcining container is provided with an openable and closed container door, the size of the internal space of the calcining container is more than that of the appearance size of the single crystal furnace thermal system comprising a graphite element and an insulating layer; the peripheral wall of the inner part of the special calcining container is electrically heated at a temperature of 1600-2000 DEG C, the container is in a vacuum state during the calcining, and the cold vacuum degree is not more than 1Pa; and the single crystal furnace thermal system is integrally or detachably placed in the special calcining container for calcining. The invention correspondingly provides a device for calcining the single crystal thermal system. Therefore, the invention firstly changes the treatment method only for heating and calcining the single crystal furnace thermal system in a single crystal furnace; in addition, the invention also provides the device specially for calcining the single crystal furnace thermal system; and the calcining parts are more flexible, therefore, the calcining effect and the calcining efficiency are improved, and the energy resources are saved.

Owner:上海卡姆丹克太阳能科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com