Calcining processing method and device thereof of single crystal growth thermal system

A calcination treatment and thermal system technology, applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of low efficiency, high cost, poor heating and calcination effect, etc., and achieve energy saving, huge economic benefits and Social benefits, the effect of shortening the calcination cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

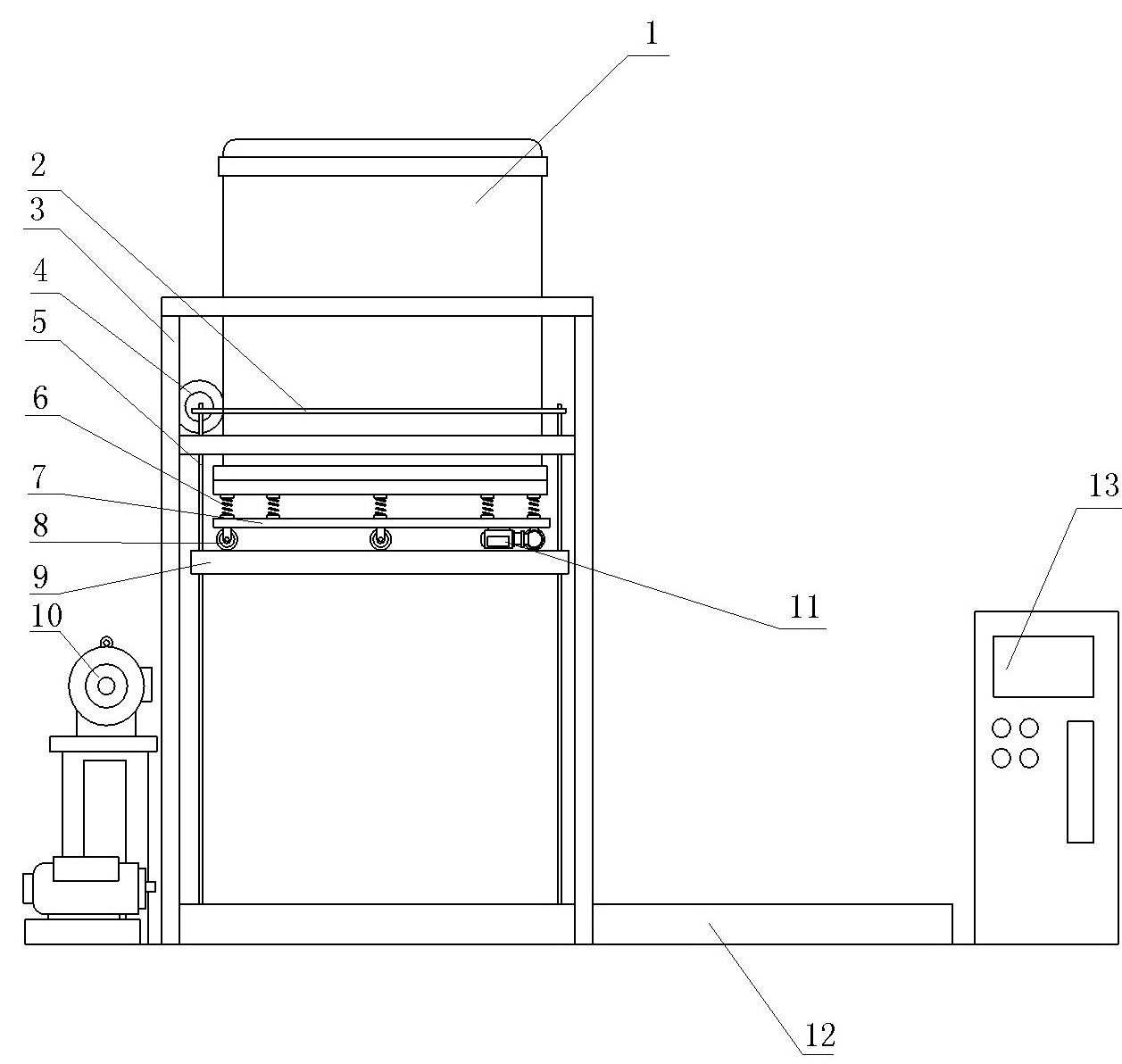

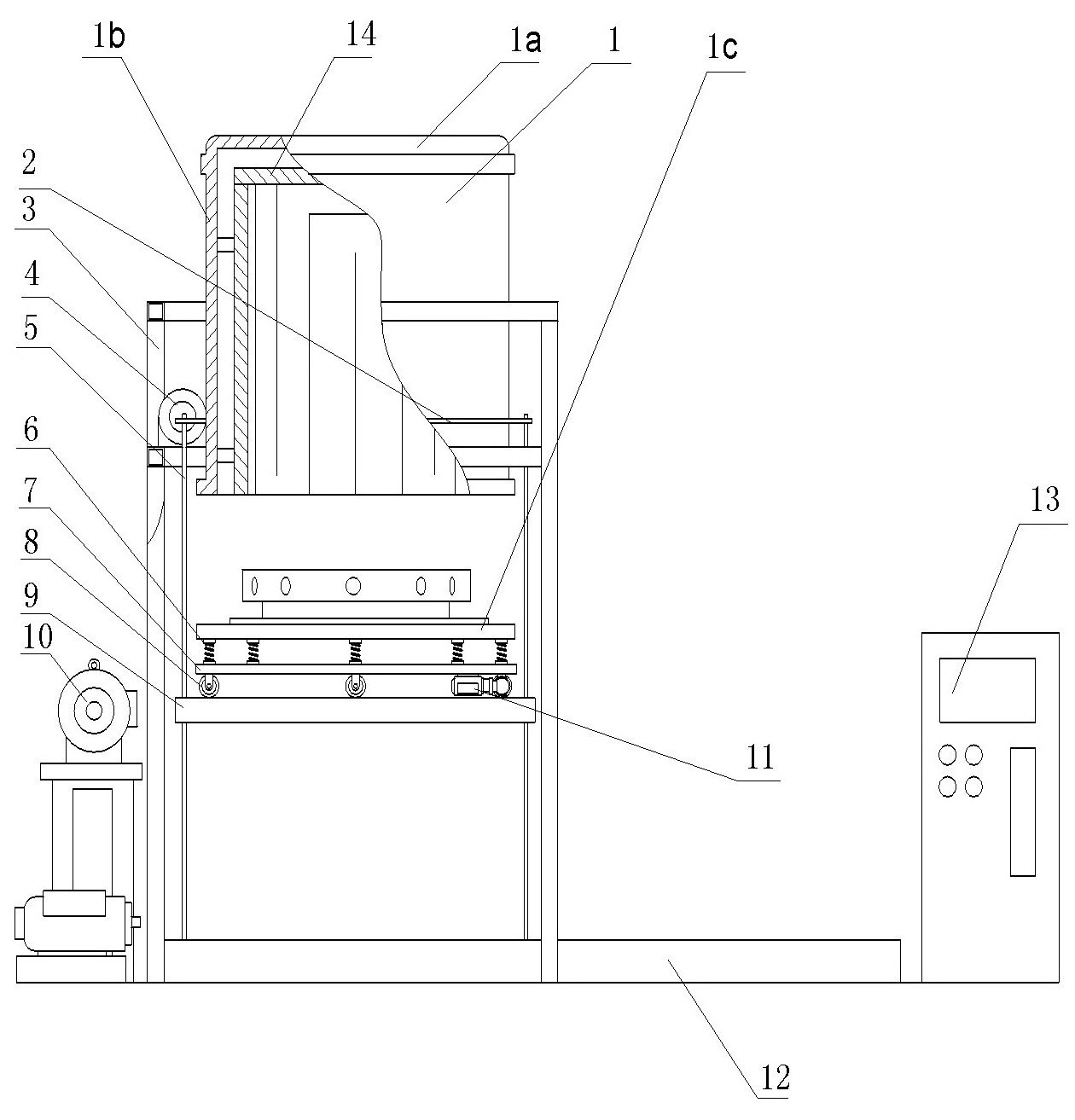

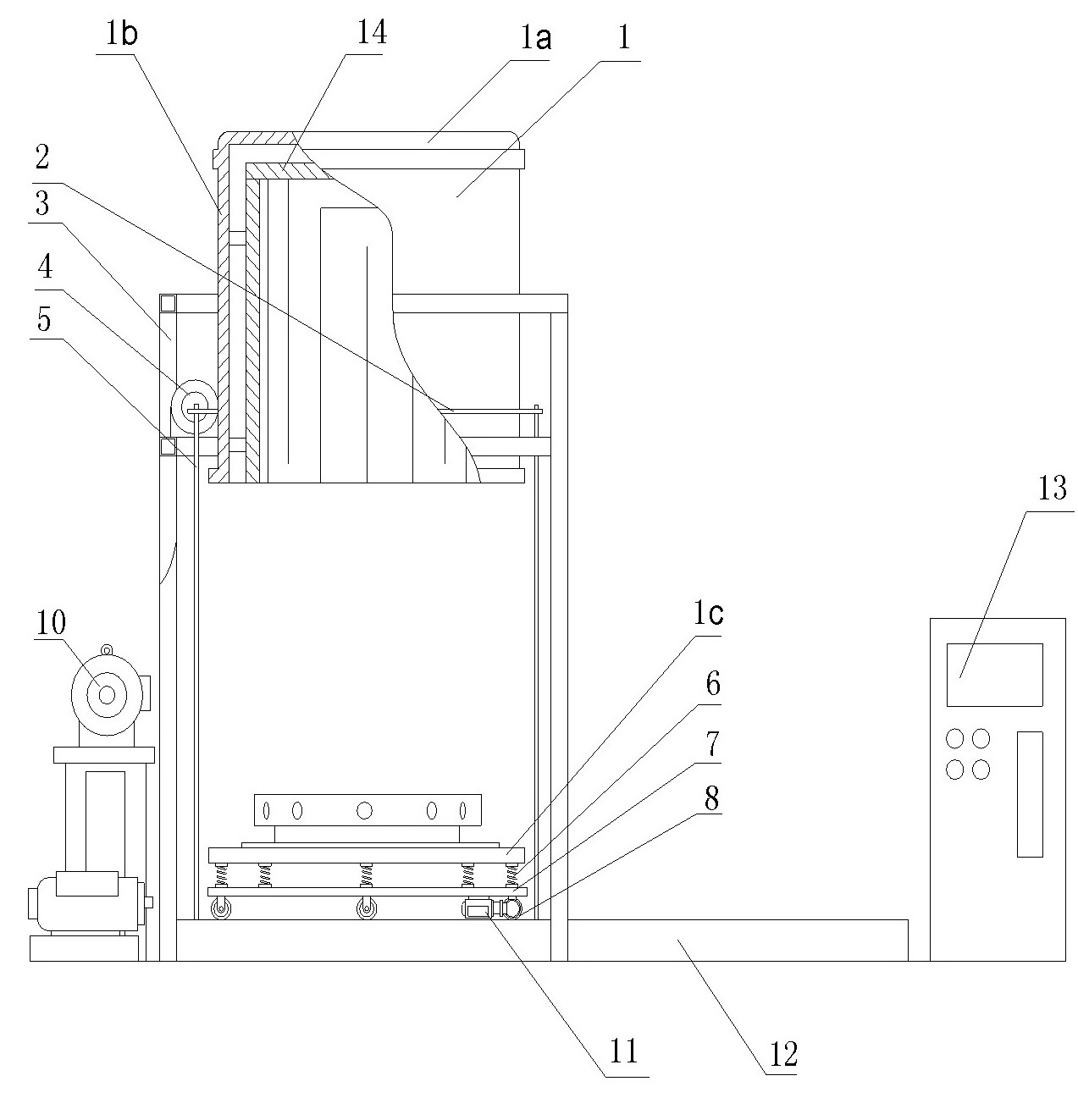

[0027] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] A special calcination furnace for calcination treatment of a single crystal growth heat system is composed of a furnace body, a frame 3, a vacuum pump 10, a controller 13, an electric heater 14 and a lifting mechanism.

[0029] The internal space size of the calcination container is larger than the thermal system of the single crystal furnace including the graphite device and the insulation layer;

[0030] The special calcining container adopts the electric heating method. By lowering and removing the lower furnace cover 1a, the calcined graphite device can be put in and taken out very conveniently. The temperature can reach 2000°C during heating, and it is in a vacuum state, and the vacuum degree in the cold state is less than Equal to 1Pa;

[0031] Adopt technical scheme, first furnace bottom 1c is moved down to the bottom of frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com